- 3.2Impact Factor

- 6.4CiteScore

- 16 daysTime to First Decision

Piezoelectrics and Ferroelectrics for End Users

This special issue belongs to the section “Electronic Materials“.

Special Issue Information

Dear Colleagues,

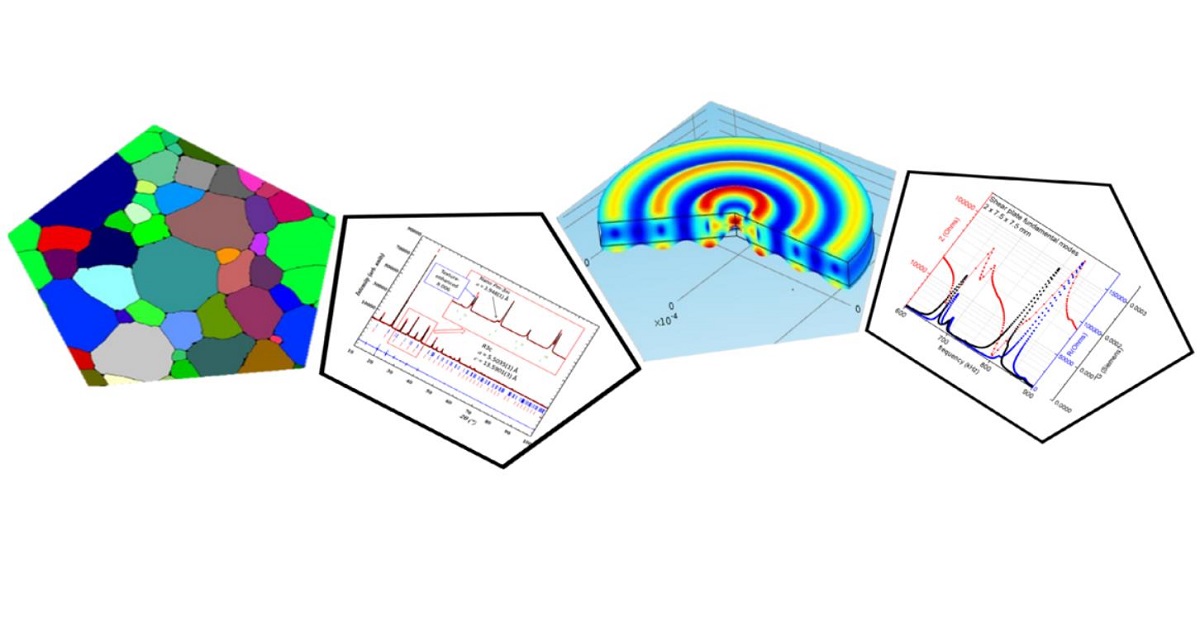

The study of ferroelectric and piezoelectric materials based on these constitutes a consolidated, but still challenging, field of research activities. Their multifunctionality has resulted in numerous applications as sensors, actuators and transducers, covering a well-known range of human activities (communications, transport, health, manufacture and quality control). Emerging applications in energy (energy storage, piezoelectric harvesting, photovoltaic, thermoelectricity...) are receiving increasing interest nowadays. Increasing effort has been devoted to obtaining high sensitivity and lead-free composition materials since the turn of the century. This was driven by the toxicity of lead oxide, the main component of commercial ceramics, and now by directives for environmental protection, demanding the elimination of lead from piezoelectric components in devices. This demand must be accompanied by the development of green methods of processing. While being a key topic for the performance and life time of these materials, the mechanical properties of ferro-piezoelectric ceramics are difficult to control, and this opens a so far poorly explored field of activities.

Manuscripts and review papers on the topics of “Piezoelectrics and Ferroelectrics for End Users” are welcomed. S. Cochran is the Chairman and L. Stoica and S. Garroni are Co-Chairs of the Conference “ELECTROCERAMICS FOR END USERS XII—PIEZO2023 WITH FERROELECTRICS UK”, 5–8 November 2023, Glasgow University, Glasgow, UK. L. Pardo and S. Garroni are members of the Organization of the European Institute of Piezoelectric Materials and Devices that co-organizes the Conference. Attendees are encouraged to publish the work presented at the event in this Special Issue (Email: ECEUXII@glasgow.ac.uk).

Prof. Dr. Lorena Pardo

Dr. Sebastiano Garroni

Prof. Dr. Sandy Cochran

Guest Editors

Dr. Laura Stoica

Guest Editor Assistant

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- piezoelectrics, pyroelectrics, ferroelectrics, relaxors, tuneable materials

- ceramics, single crystals, thick and thin films, polymers and composites

- lead-free materials

- materials processing including low-temperature sintering techniques and chemical routes avoiding toxic precursors

- raw materials avoiding environmentally aggressive conditions

- advanced and innovative characterization of structural, electrical, mechanical, thermal and optical properties of piezoelectrics and ferroelectrics

- materials and devices for sensors, acoustic transducers and medical imaging

- materials and devices for energy conversion, energy harvesting, cooling and energy storage

- piezoelectrics for actuators

- multiferroics, electrocalorics, magnetoelectrics, photovoltaics, thermoelectrics and photo-ferroelectrics

- theory and modelling of piezoelectrics and ferroelectrics

- thermoelectrics and photovoltaics

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- Reprint: MDPI Books provides the opportunity to republish successful Special Issues in book format, both online and in print.