- Article

A Novel Multi-Point Depletion Model for Molten Salt Reactors

- Mohamed H. Elhareef and

- Zeyun Wu

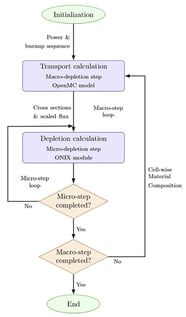

Molten Salt Reactors (MSRs) offer significant advantages over conventional reactors but introduce unique modeling challenges due to their circulating liquid fuel and strong coupling among nuclear, chemical, and fluid transport processes. These challenges are amplified in depletion calculations, where MSR specific phenomena such as online refueling, off-gas removal, material redistribution, and other flow driven processes must be accurately represented. This work presents a novel multi-point depletion model that efficiently and accurately predicts isotopic evolution in MSRs by explicitly accounting for these characteristics. The mathematical formulation is derived from first principles and is computationally implemented in the open-source depletion code ONIX using neutronics solutions from open-source transport code OpenMC. The new model represents the entire primary loop by dividing it into interconnected depletion zones and tracks nuclide transport, irradiation, and removal mechanisms through a system of coupled ordinary differential equations. This approach enables parallel computation and improves performance over traditional sequential depletion methods. Validation of the developed model against Molten Salt Reactor Experiment data shows good agreement for salt-seeking isotopes and those without noble gas precursors, while discrepancies for other nuclides suggest underestimation of the corresponding removal rates. The depletion model was further applied to a reference Molten Salt Fast Reactor design to assess a new reprocessing scheme intended to expedite the achievement of equilibrium operation.

18 February 2026

![Five unit self-organizing neural network classifier of two-phase flow. Reprinted with permission from Ref. [28]. Copyright 2025, Elsevier.](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/jne/jne-07-00015/article_deploy/html/images/jne-07-00015-g001-550.jpg)