1. Introduction

The use of secondary raw materials in industry through economic circularization is a key approach to limit resource depletion and waste generation. New ways to utilize by-product streams instead of virgin resources are necessary to mitigate the effects of economic growth on the environment [

1]. In the last decade, significant advancements have been made in developing a circular approach to utilize processed bauxite (PB), a byproduct from alumina production, as a substitute for clinker in cement [

2,

3,

4]. This is of significant economic and environmental relevance due to the high impact of the cement industry: the sector accounted for around 8% of the total anthropogenic carbon dioxide emissions and is responsible for 7% of the global industrial energy use [

5,

6].

All naturally occurring substances exhibit some degree of radioactivity originating from naturally occurring radioactive materials (NORMs). Treatments such as the Bayer process for converting bauxite to alumina can concentrate natural radionuclides in specific product streams, such as the undissolved portion of bauxite (i.e., PB). As such, it is critical to monitor the level of radioactivity in products made from secondary raw materials of concern. Our work focuses on investigating the radiological risk posed by building materials developed from processed bauxite (in co-calcined, vitrified, or smelted form; collectively, modified PB). The product chain is investigated in detail to determine the main sources of radioactivity.

An accurate assessment of radiological risks is important for informed decision-making. The health risk associated with exposure to NORM is most directly affected by the activity of the source, the proximity of the person to the source, and the duration of exposure. Accordingly, we focused on the gamma radiation exposure from construction products containing modified processed bauxite in residential buildings. The International Atomic Energy Agency (IAEA) has developed the Activity Concentration Index (ACI) as a screening value to determine whether a given material needs further dose assessment to declare it safe for use in construction from a radiological perspective. The ACI is related to the external gamma radiation dose limit of 1 mSv y

−1, estimated in a model room with specified dimensions. The ACI value was used as a criterion for suitability in the present work [

7].

This study aims to demonstrate and validate a generalized mixing-based approach to the calculation of the ACI value of a building material. To achieve this, data on the activity concentrations of various radionuclides in mortars and their upstream input materials were determined as a specific case. The goal of this case-specific investigation was to assess whether these building materials based on modified PB are suitable for use in the construction of residential buildings. Additionally, the factors affecting the final ACI value of the mortars were discussed.

2. Materials and Methods

Processed bauxite (PB) is a byproduct of the Bayer process for alumina production from bauxite. In this work, bauxite and PB samples were collected and analyzed from 7 leading alumina refineries cooperating in the Horizon 2020 ReActiv project.

PB undergoes additional treatment to enhance its suitability as a supplementary cementitious material (SCM), primarily by increasing its cementitious activity through thermal processes [

8]. Three distinct processing technologies—co-calcination, vitrification, and smelting—were developed in related work from the ReActiv project. These technologies were assessed here for their impact on PB radioactivity. For all technologies, all of the available raw materials, additives, and products (intermediate and final), including differing sources of PB, were sampled and measured through gamma spectrometry.

All samples examined from operational alumina plants were below the 1 Bq/g per radionuclide limit, classifying them as exempt waste (non-radioactive) [

9,

10].

All three processing technologies involve thermal processing, indicating that mass is lost to gases that evolve during the treatment. As a result, the mass of non-radioactive components (water, carbon dioxide, etc.) decreases, and accordingly, the activity concentration of a thermally treated substance has the potential to be higher than the weighted average of the constituent input materials in ways that are unavoidably difficult to predict.

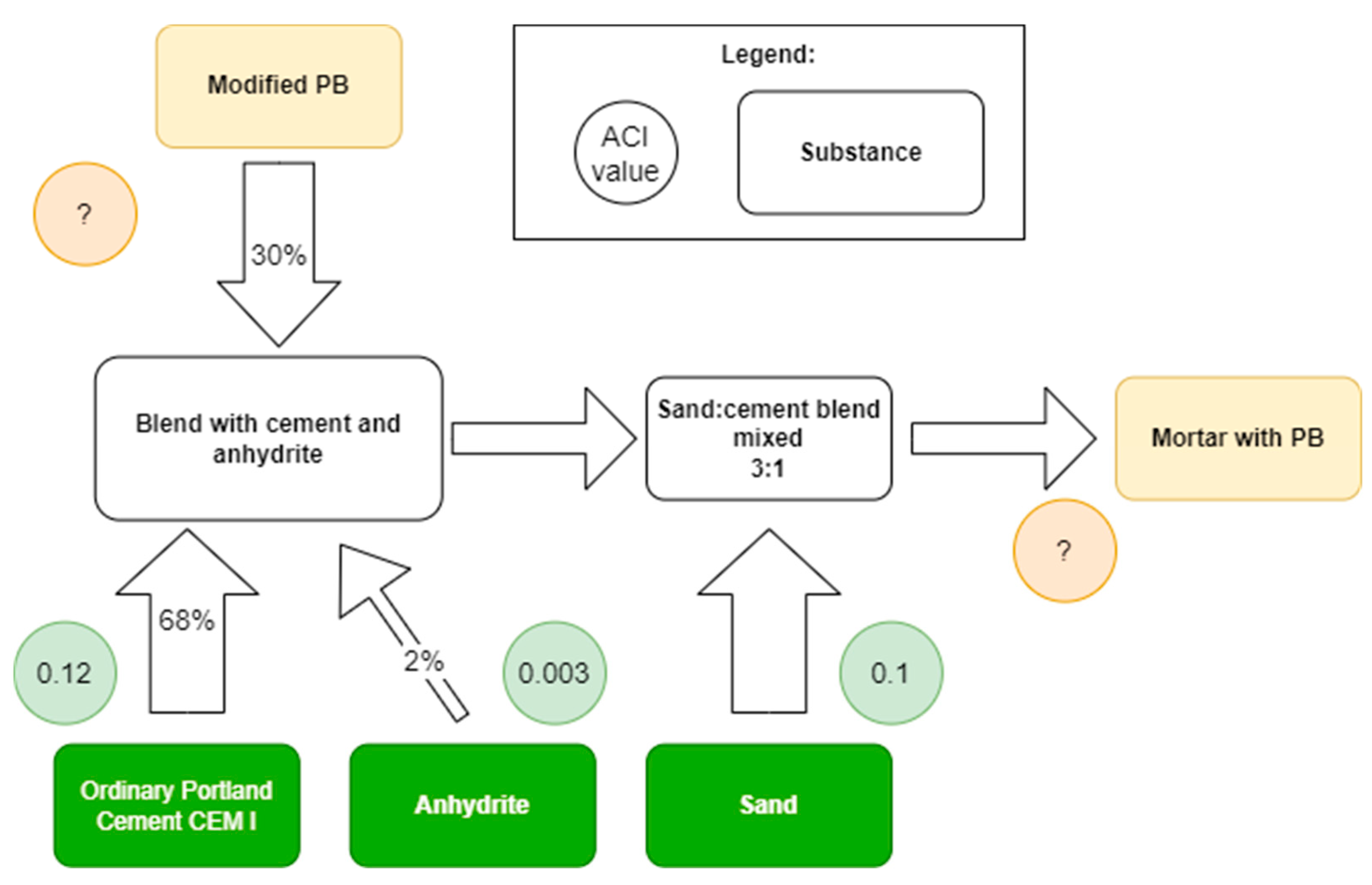

In all cases, the SCM obtained from the modification of PB was mixed in the ratio of 30 wt.% modified PB, 68 wt.% ordinary Portland cement (OPC), and 2 wt.% gypsum to create a cement blend that could subsequently be used to prepare mortars according to the EN-196 standard [

11]. The main cement-containing construction products are concrete and mortar. The latter was selected for radiological risk assessment due to its higher cement content and corresponding radionuclide activity concentration.

2.1. Processed Bauxite (PB)

PB is a byproduct from alumina production, sometimes called “red mud” or “bauxite residue”. For this work, bauxite and PB samples were obtained from seven refineries worldwide, one of which is no longer operating. These have been anonymized, with a capital letter from A–G referencing the same refinery throughout the present work.

For all PB sources, up to three raw bauxite sources and their respective mixing ratios during PB production were identified. These were consolidated into a single average raw bauxite for each refinery during data analysis as the inclusion-rate-weighted average of the different sources.

These results are presented in

Table 1 and elaborated upon in the subsequent sections.

2.2. Co-Calcination

The process of heating the PB along with kaolinitic clay is known as co-calcination and has been explained thoroughly in the literature [

12]. The PB inclusion rate in the mix to produce co-calcined PB (CB) was 70 wt.% or 50 wt.%, with the samples with 50 wt.% PB having more attractive properties. The process temperature was 750 °C.

CB SCMs were prepared with the PB from refineries A, B, C, and G, cement blends from refineries C and E, and mortars from refineries C and G.

2.3. Vitrification

PB can be transformed into a glassy material through vitrification, with a detailed description of the process available in the work of Giels et al. [

13], resulting in vitrified PB (VB). The PB inclusion rate in the SCM prepared through vitrification was approximately 65–85 wt.%, varying between PB sources. The process temperature was 1200–1300 °C.

VB SCMs were prepared with the PB from refineries A, C, D, E, and G, and mortars from refineries A, C, D, and F.

2.4. Smelting

The smelting of PB with ilmenite and aluminum powder can be exploited to create smelted PB (SB), a material similar to ground granulated blast furnace slag or calcium aluminate cement, depending on the reaction conditions. This approach has been investigated, and the samples have been provided by Sparis et al. [

14]. The inclusion rate of PB in the preparation of an SCM through smelting was 50–70 wt.%. The process temperature is difficult to estimate precisely due to the exothermic reactions that occur during the processing, which increase the temperature of the reagents even further. For calculations, a temperature of 1650 °C was assumed in the work cited above.

SB SCMs were prepared with the PB from refinery E.

2.5. Gamma Spectroscopy

All samples were received in a powdered form and dried at 40 °C for 48 h. Samples were mixed, sieved through a 2 mm mesh, and stored in radon-tight containers for at least 30 days before measurement. The subsample mass of the dry specimens was generally between 100 and 200 g.

Measurements were conducted using Canberra-Packard spectrometers, with acquisition times ranging from 24 to 72 h. The acquired spectra were analyzed using the Gamma 2k software version 3.4, supported by nuclear data from the literature to provide decay energies and emission probabilities [

15,

16,

17,

18].

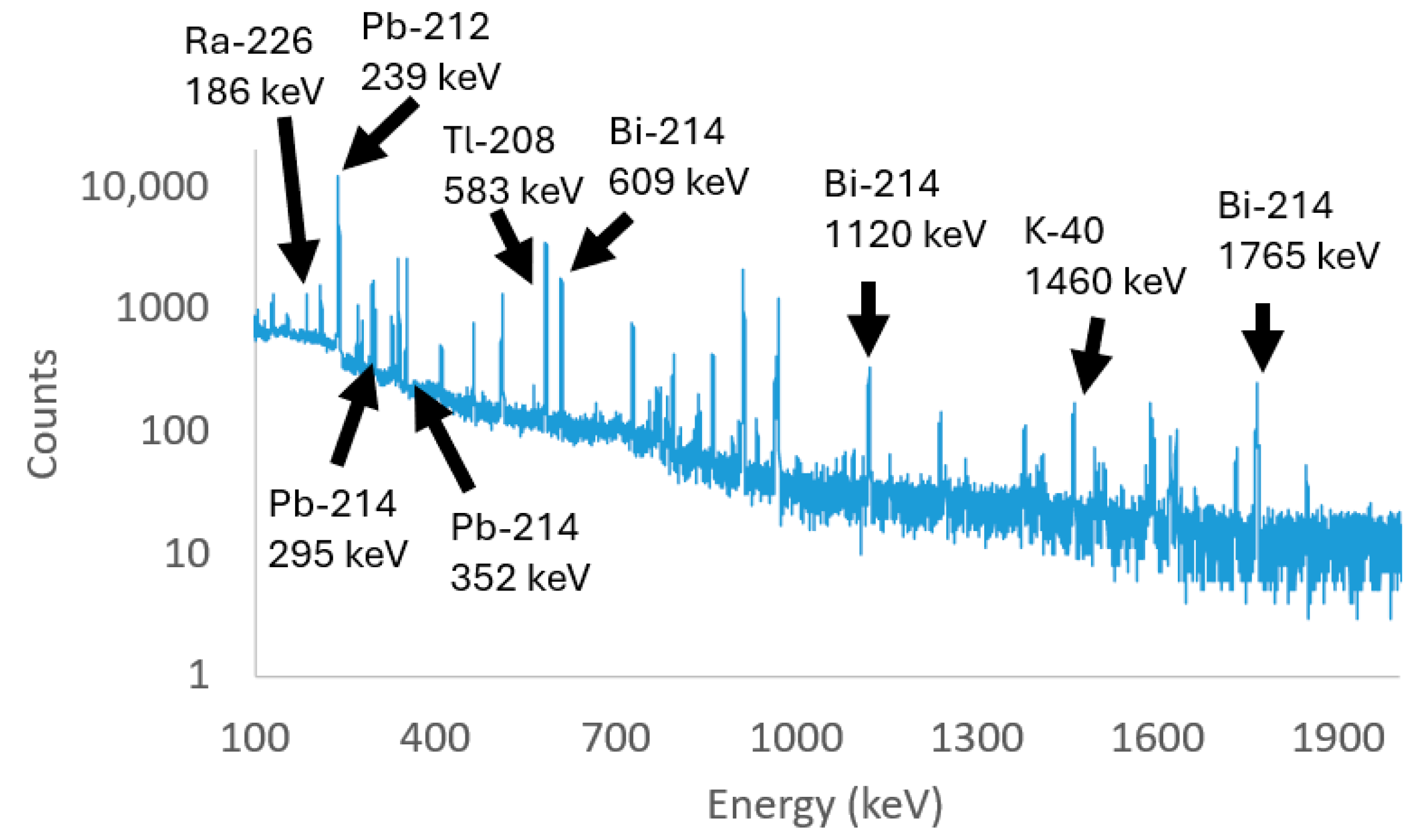

For the analysis, the following gamma-ray spectral lines, shown in

Figure 1, were used:

226Ra was determined directly (186 keV) and indirectly via short-lived radon progeny 214Bi (609, 1120, 1765 keV) and 214Pb (295, 352 keV) gamma lines.

232Th was determined via 212Pb (239 keV) and 208Tl (583 keV) gamma lines, including the correction related to branching of the decay chain.

40K was determined directly (1461 keV gamma line).

For plural gamma lines, weighted averages were calculated using the gamma emission probability. The uncertainty of the activity concentration and the detection limit, expressed as MDC (minimal detectable concentration), were determined for each sample.

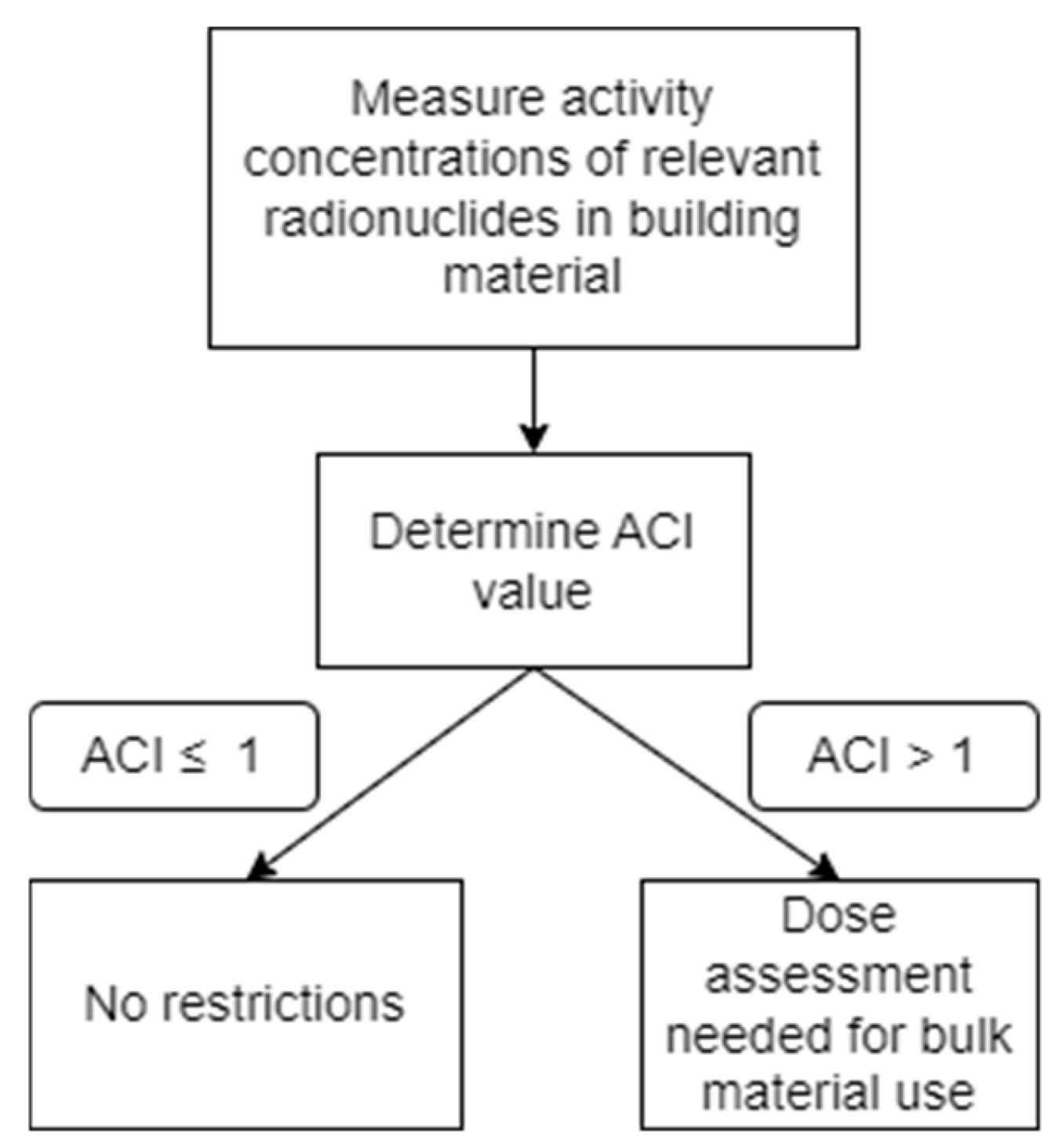

The unitless activity concentration index (ACI) was calculated using the equation from the European Commission’s Directive on basic safety standards (Equation (1)), referencing a dose criterion of 1 mSv a

−1 [

19]:

where

denotes the activity concentration of the radionuclide

in Bq/kg. ACI values are used to assess whether a material requires further dose evaluation before its application in construction. The threshold values and corresponding decisions are illustrated in

Figure 2.

The approach to calculating the error bars in the figures is as follows. ACI uncertainty was calculated based on the inaccuracies in the sample mass

, detection efficiency

, gamma emission probability

, live acquisition time

, and net event count

as shown in Equation (2). Here,

represents the measured activity concentration. Across most samples, the relative uncertainty of the ACI was below 10%, only exceeding this value for very low-radioactivity samples with an ACI value near 0.1, such as sand. In modeling, all mixing ratios were taken to be exact.

Building materials are deemed most suitable when no further dose assessments are required for their intended application. Therefore, the ACI of the mortar will serve as the primary metric when assessing its radiological risk and potential for use.

3. Results

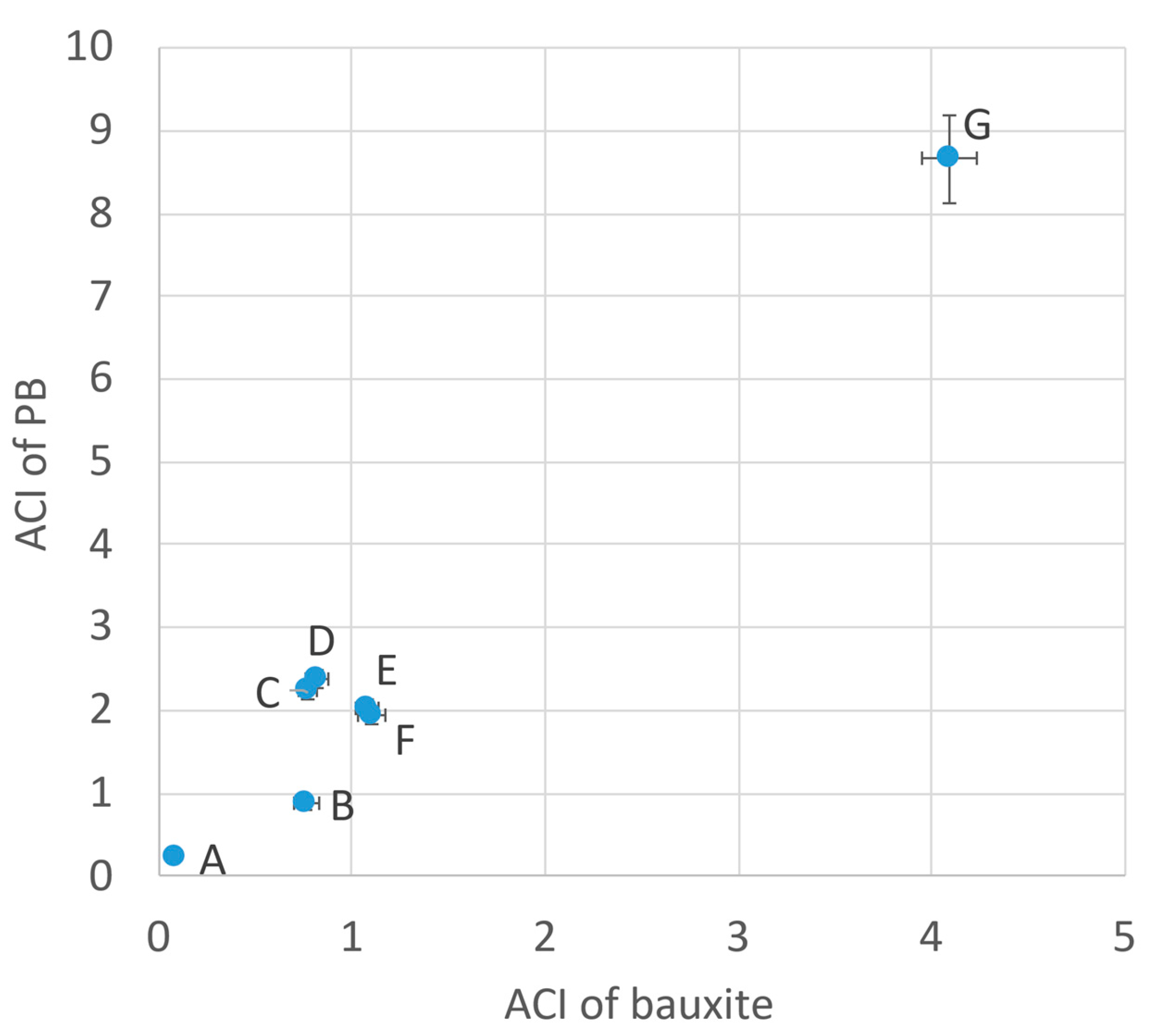

Despite the differing processing implementations in the various refineries, the degree to which the activity concentration of the investigated radionuclides was concentrated was relatively similar, as can be seen in

Figure 3. This correlation indicates that bauxite is the main source of radioactivity in the processed bauxite, rather than any refinery-specific parameters.

For simplified data presentation, the ACI value was also used in relation to the constituent parts of a building material. Notably, bauxite, PB, and modified PB exhibit ACI values for theoretical building products composed entirely (100 wt.%) of these materials. In practice, it would not be feasible to use these materials in pure form in final products. Here, ACI serves as an indicative weighted sum for intermediate products, comparing activity concentrations to interpret the intrinsic properties of materials involving PB. Conversely, ACI values of mortars, as potential end products, reflect exposure risk.

With the assumption of no mass loss during a mixing process, the activity concentration of each radionuclide in the mixture is the weighted sum of the activity concentrations of the mixed substances. This can be expressed mathematically as seen in Equation (3).

where

is the weight fraction of the constituent

in the mixture and

is its ACI. Notably, the process of the preparation of mortar from the co-calcined, smelted, or vitrified PB (collectively, modified PB) along with cement, gypsum, sand, and water can be suitably thought of as a sequence of such mixing processes. With the only varying parameter being the activity concentration of the modified PB, an estimation of the activity concentration can be made according to the mixing weight fractions and activity concentrations measured in this work (

Figure 4). The mixing fractions are taken to be exact.

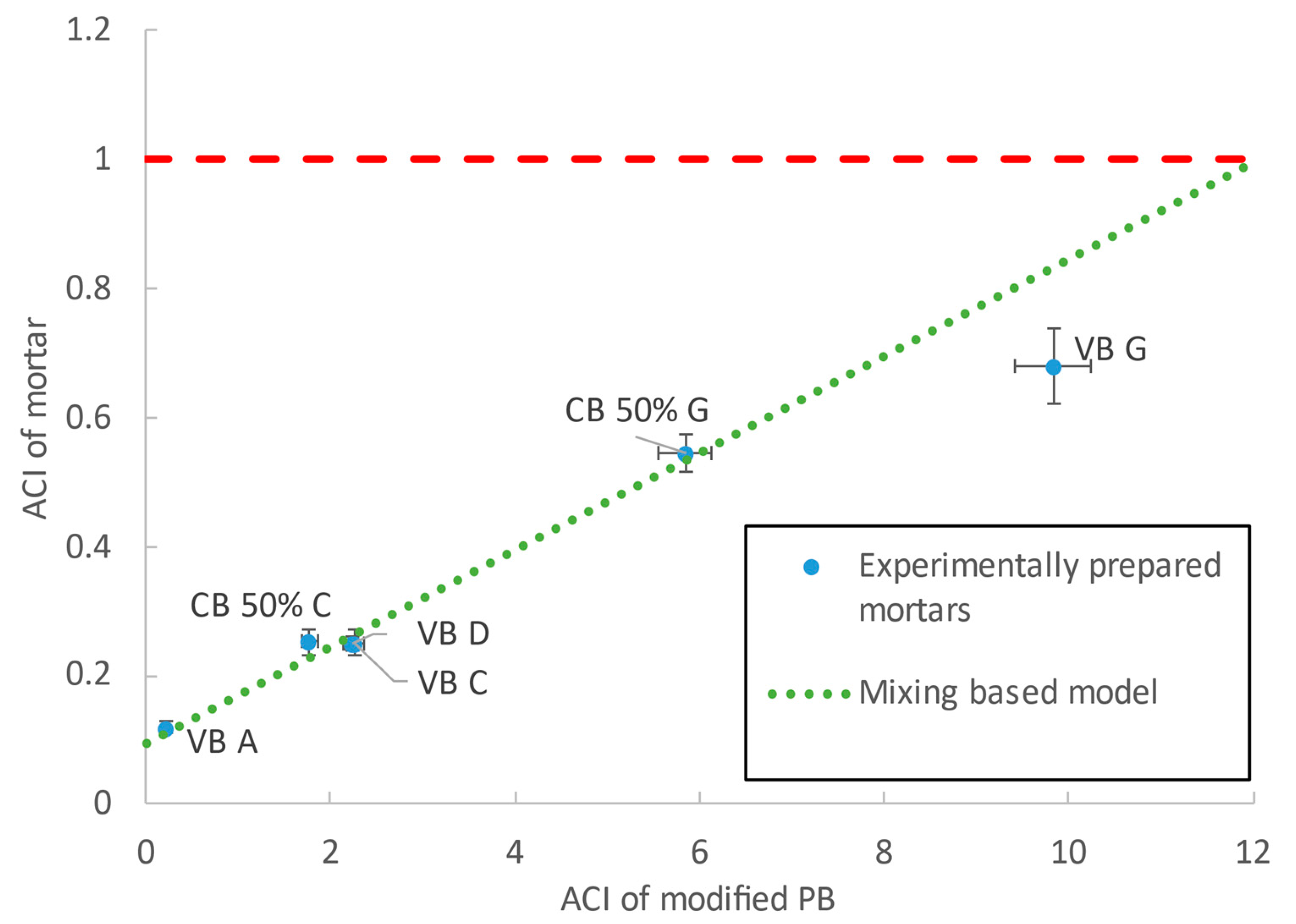

The calculated mixing-based estimation behaves well compared to the available data for the prepared mortars and the used modified PB (

Figure 5). Notably, the mixing-based model overestimates the data for higher PB activities. This conservative behavior is desirable from a radiological safety perspective. The data presented in

Figure 5, along with the ACI values of the associated input materials, are shown in

Table 2 to clarify the variation of ACI values along the product chain.

Based on these results, all experimentally prepared mortars would be fit for use as a building material from the perspective of gamma radiation. This is expected to apply for any combination of the three processing technologies and alumina refineries, as the PB from refinery G had the highest ACI of the investigated samples, and vitrification had the highest PB inclusion rate of the three technologies. This ensures that the worst-case combination has been assessed and accounted for. All mortars lie on or above the line representing the mixing model, indicating that the model is a satisfactory estimator.

It must be noted that estimating mortar activity requires only two inputs: mixing ratios and activity concentrations (ACI values) of constituents such as sand, anhydrite, ordinary Portland cement, and the SCM of choice. This means that the process can easily be adapted to different scenarios, for example, varying the source of sand used or the SCM under investigation. The assumption of no mass loss during mixing must be kept in mind.

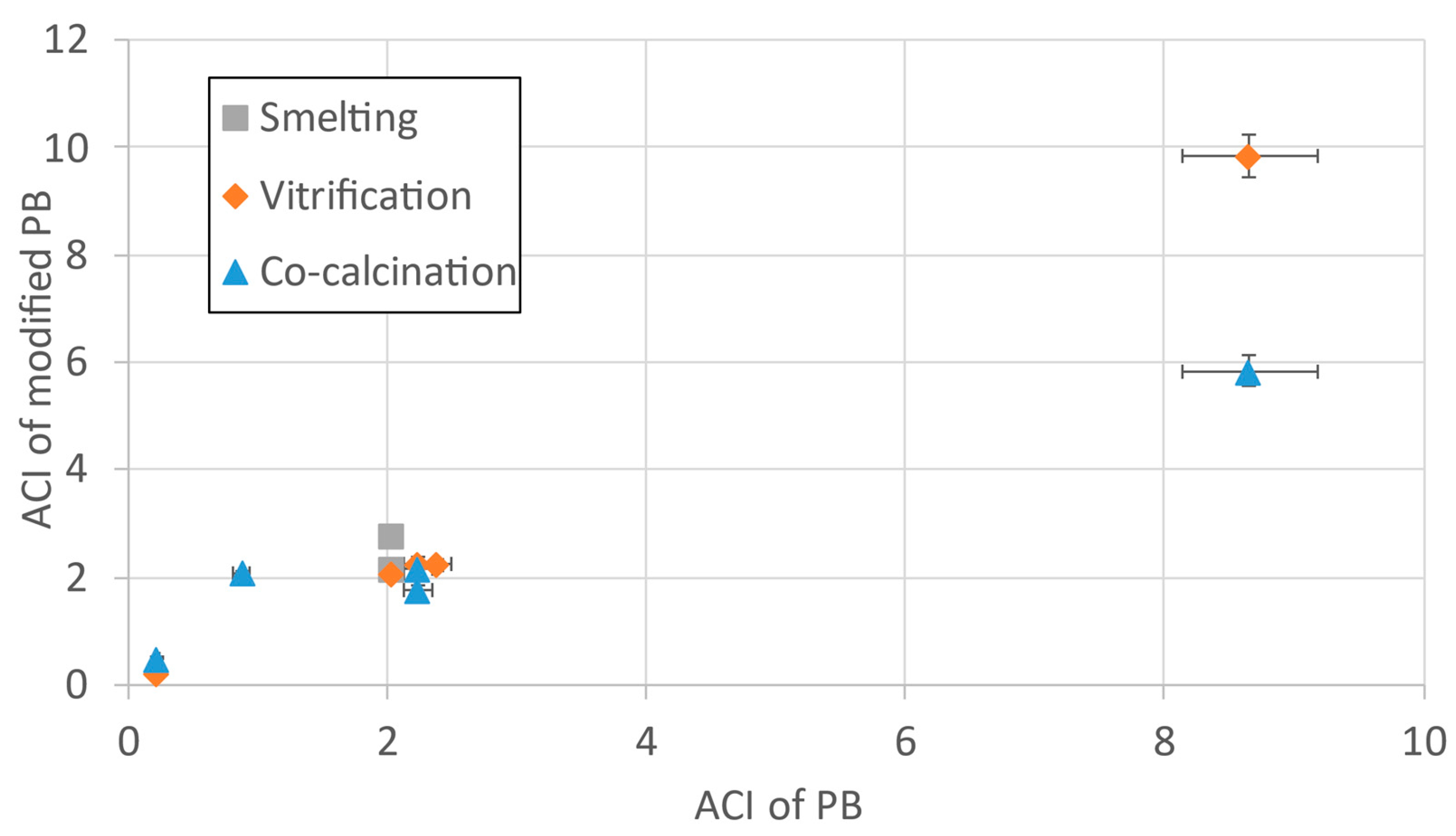

The relationship shown in

Figure 6 further reinforces the observation that the main contributor to the activity concentration and ACI of the final building material is the ACI of the PB used (and, by extension, that of the initial bauxite). This stems from higher PB ACI values clearly correlating with higher ACI values in the modified PB. A secondary factor is the processing technology used. Variations in PB inclusion rates result in co-calcination having a lower ACI value, even though its additive—kaolinite—has a slightly higher ACI value compared to additives in other technologies.

A detailed breakdown of the upstream source of the ACI of mortar products was conducted for three indicative examples, as shown in

Figure 7. Smelting received less detailed investigation as no experimental mortar was prepared. This analysis involved estimating each constituent’s contribution to the final ACI of mortar, based on their mixing ratios and ACI values.

The main contributors are modified PB, due to its higher ACI value, and sand, due to its substantial mass fraction in the final mortar. The difference in the magnitude of the contribution from additives when comparing co-calcined and vitrified mortars stems from the nature of the additives: the kaolinite used for co-calcination has an ACI value of 0.51 and a comparatively higher inclusion rate, while the additives for vitrification have an ACI value of 0.1 or less.

4. Discussion

Based on the results of the radiological measurements conducted in the present work, all of the treatment technologies and bauxite sources within the scope of the research are suitable for creating supplementary cementitious materials that can be used to create building materials with ACI < 1. The findings suggest that these building materials can be used in construction without additional gamma radiation dose assessment, provided modified PB constitutes up to 30 wt.% of the blended cements.

Given that mortar contains a higher cement content than concrete and other cementitious materials, this result can be viewed as conservative. If mortar using modified PB is radiologically safe, concrete made with the same modified PB is likely to be even safer. Although case-by-case assessment is necessary to assess radiological safety in detail, the presented method could serve as a valuable screening tool for radiological assessment.

Analysis of the PB product chain identified modified PB as the primary contributor to radionuclide concentrations in final building materials, with its ACI closely linked to that of the original bauxite. The most important secondary contributor was the sand used as an aggregate. These findings offer valuable insights into the impact of geographic variation in raw material sourcing.

A mixing-based calculation based solely on the mixing ratios and ACI values of the constituents of the building material was shown to provide results that agree very well with experimentally measured values. This generality indicates that the same approach could be used in other cases as well, for example, when investigating other SCMs, other sources of aggregate, or a different building material (e.g., concrete) entirely. Avoiding the preparation of final building materials makes this approach ideal for cases with limited data availability.

It must be noted that building materials can also emanate radon and simultaneously influence the degree to which radon migrates from the soil to ground- or basement-level floors of a building. Recent European Radon Action Plans (RAPs) present differing viewpoints on the link between ACI and radon risk. In the RAP of Belgium, it is recognized that a material with ACI ≤ 1 has minimal radon risk, while in Estonia, the RAP states that additional research is needed to verify this aspect [

20,

21].

Consequently, the applicability of the ACI to radon risk is uncertain at this time, as seen in recent Radon Action Plans. Further research to elucidate the possibility of using the same or similar index value to judge radon risk would be invaluable for a more complete view of radiation risk due to building materials. Nevertheless, as in Belgium’s RAP, it may be expected that building materials do not directly contribute much to the indoor radon concentration—implying that only gamma radiation should be accounted for when assessing the radiological risk due to building materials. This is supported by there not being any legal provisions limiting the direct contribution by building materials to the indoor radon concentration [

22].

The PB samples used in the ReActiv project were selected to be representative of the material normally generated from each alumina refinery. Most alumina refineries use a consistent bauxite feed, and it is therefore expected that the concentrations of radioactive species in the PB will not significantly vary. Consequently, based on the uncertainty assessment and industrial experience, the results for the modified PBs are expected to fall within the error bars reported in the results. Future studies could seek a more quantitative assessment of variability in the activity concentrations of the different components, based on samples from the same alumina refinery, taken across multiple months or varying conditions.

Our work confirms the acceptability from a gamma radiation perspective of using processed bauxite in an SCM, paving the way for its broader adoption and supporting a circular economy through efficient by-product utilization. The modern approaches to the activation of PB for enhanced use as an SCM were compared, with co-calcination demonstrating a slightly lower ACI value of the modified PB compared to the other technologies’ modified versions of the same PB. This is believed to be a consequence of the smaller inclusion rate of PB in the co-calcination mix.

Such a method is well-suited for advisory purposes as well as in product development in order to foresee and/or estimate potential radiological issues before manufacturing the final product. This approach supports a safe and informed transition to broader adoption of environmentally friendly SCMs. Such a shift reduces reliance on virgin resources, minimizing waste and emission generation.