Review: Pipeline Layout Effect on the Wall Thinning of Mihama Nuclear Power Plants

Abstract

1. Introduction

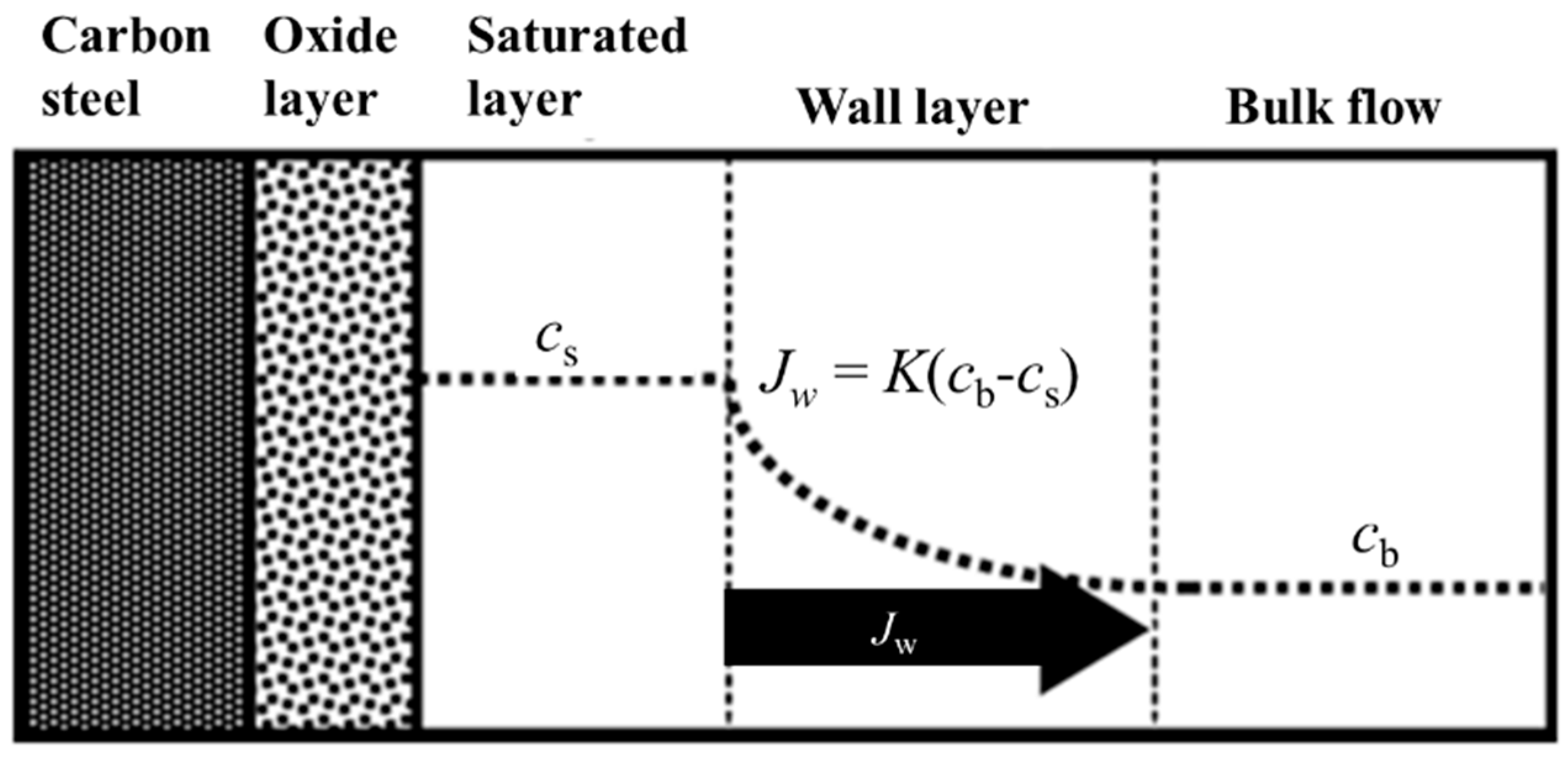

2. Basics of Flow-Accelerated Corrosion

3. Experimental and Numerical Approach to Mihama Pipeline Model

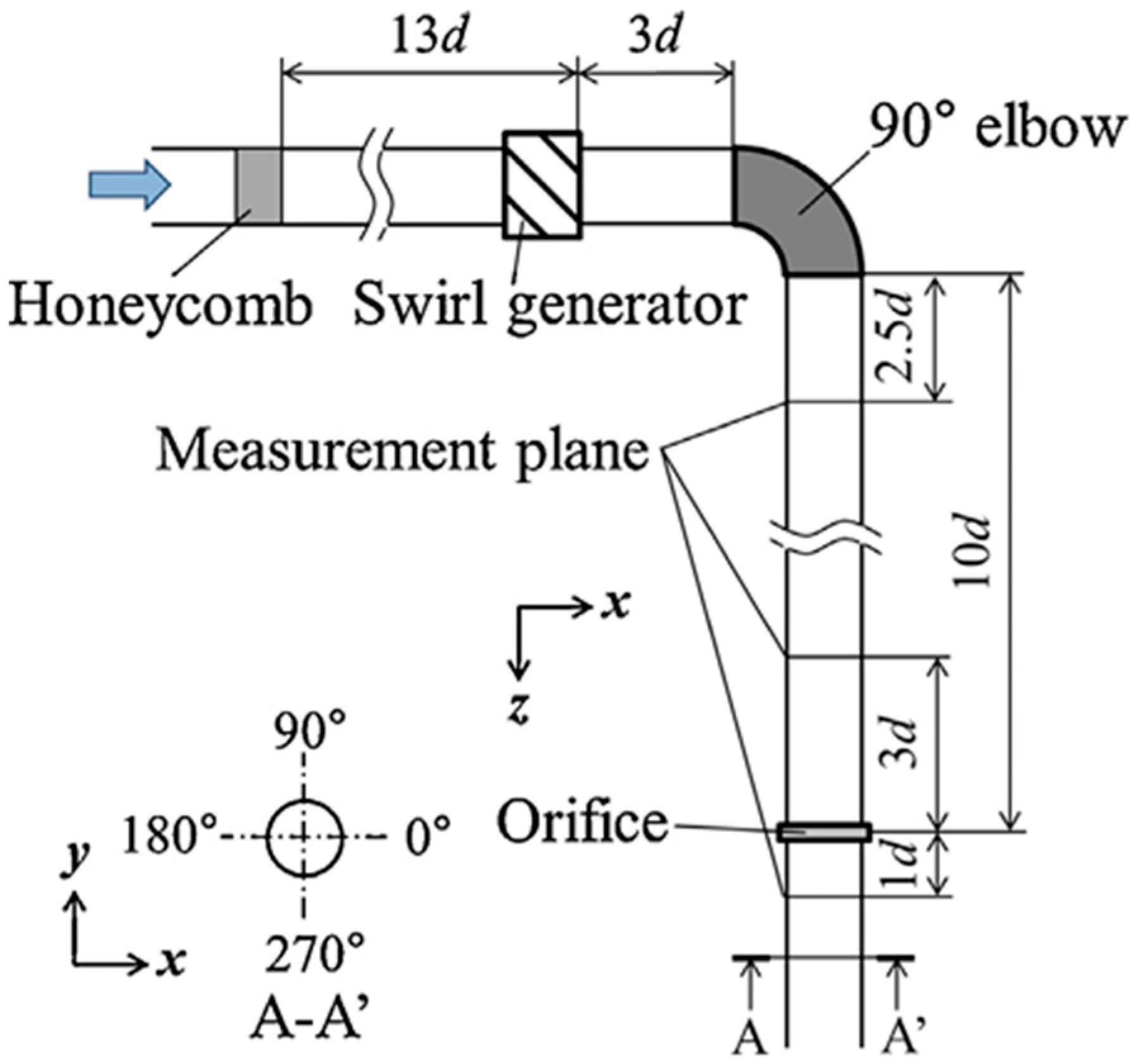

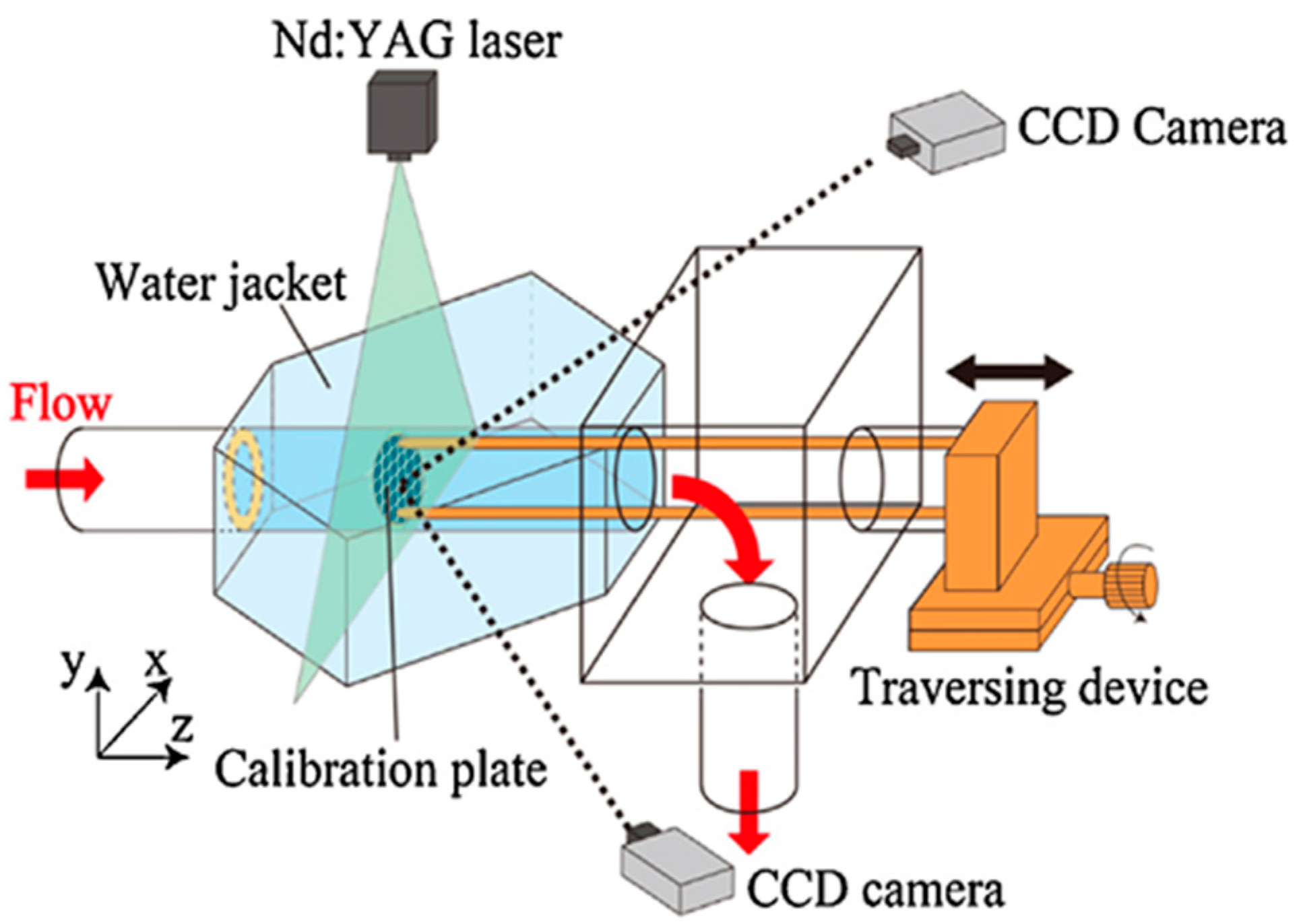

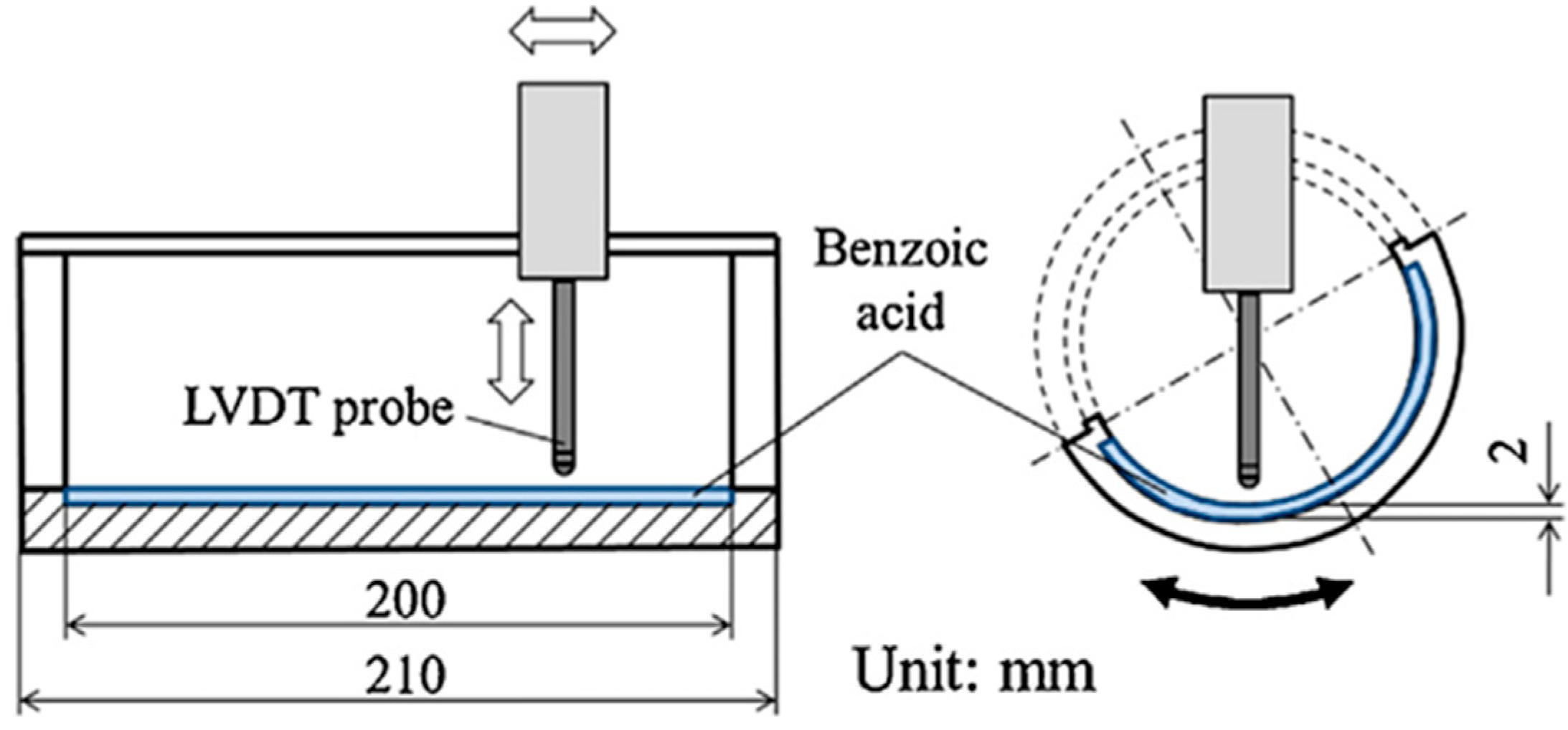

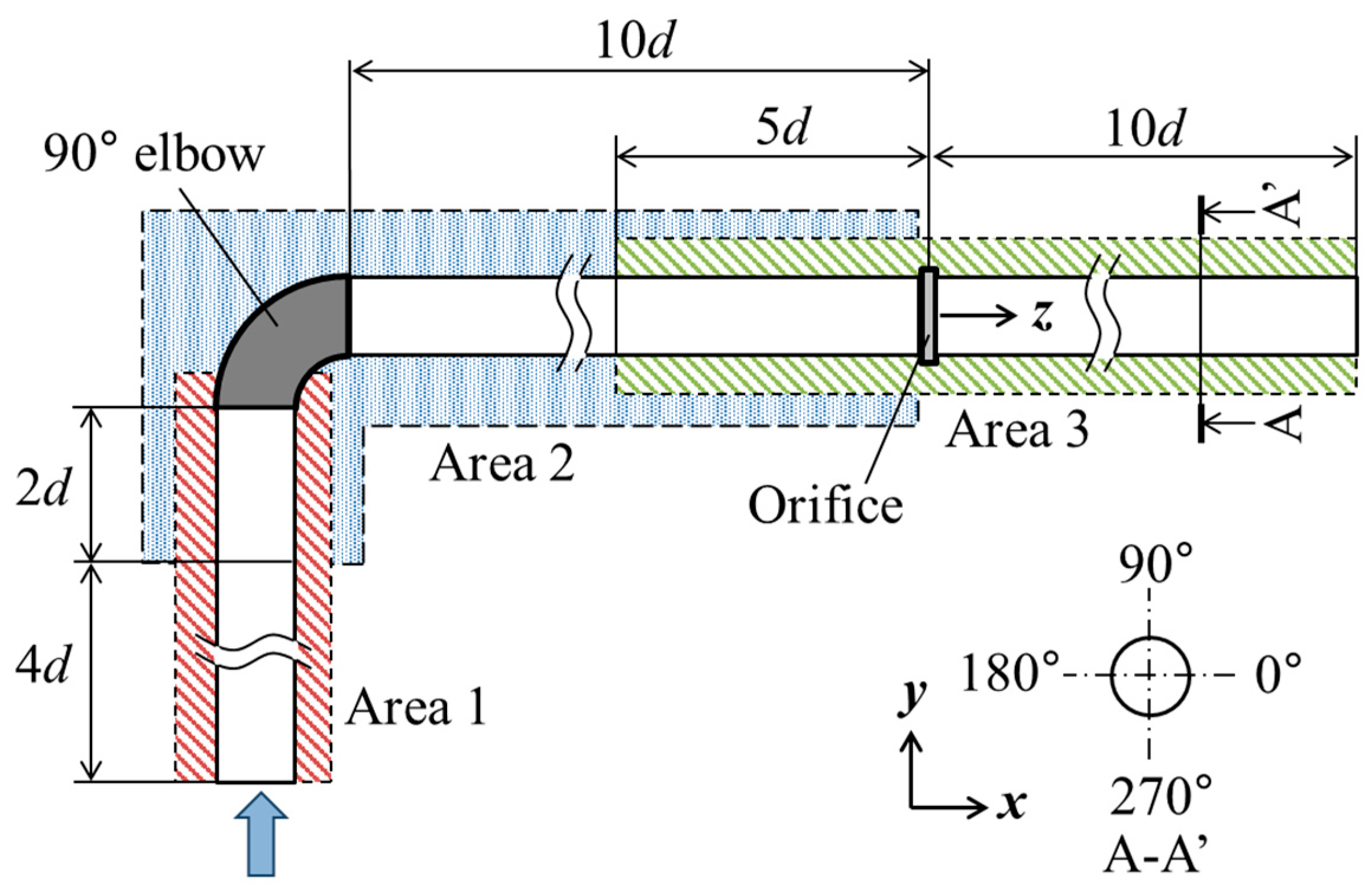

3.1. Experimental Model of Mihama Pipeline and Method

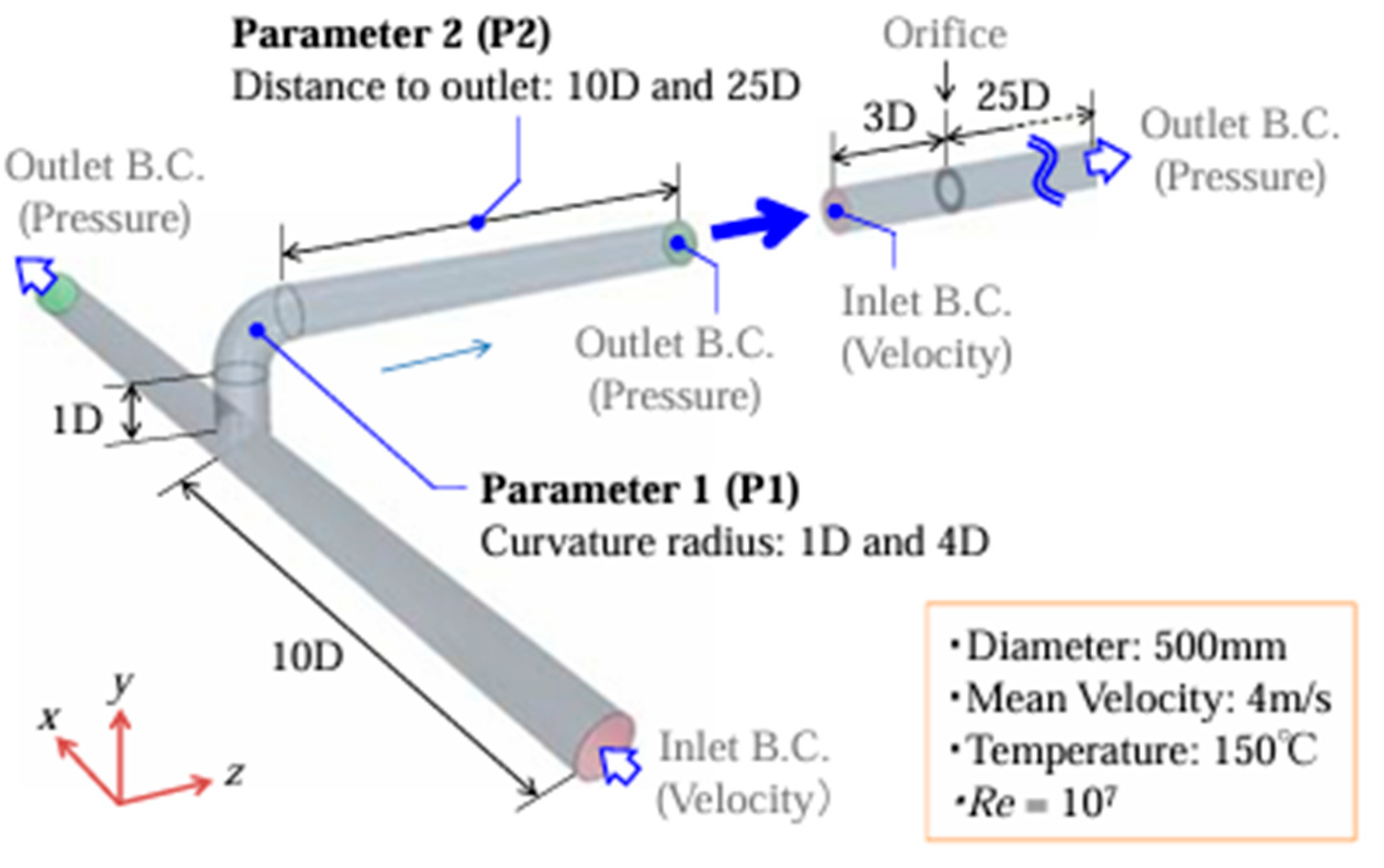

3.2. Numerical Prediction of Wall Thinning in Mihama Pipeline Model

4. Experimental and Numerical Results for Mihama Pipeline Model

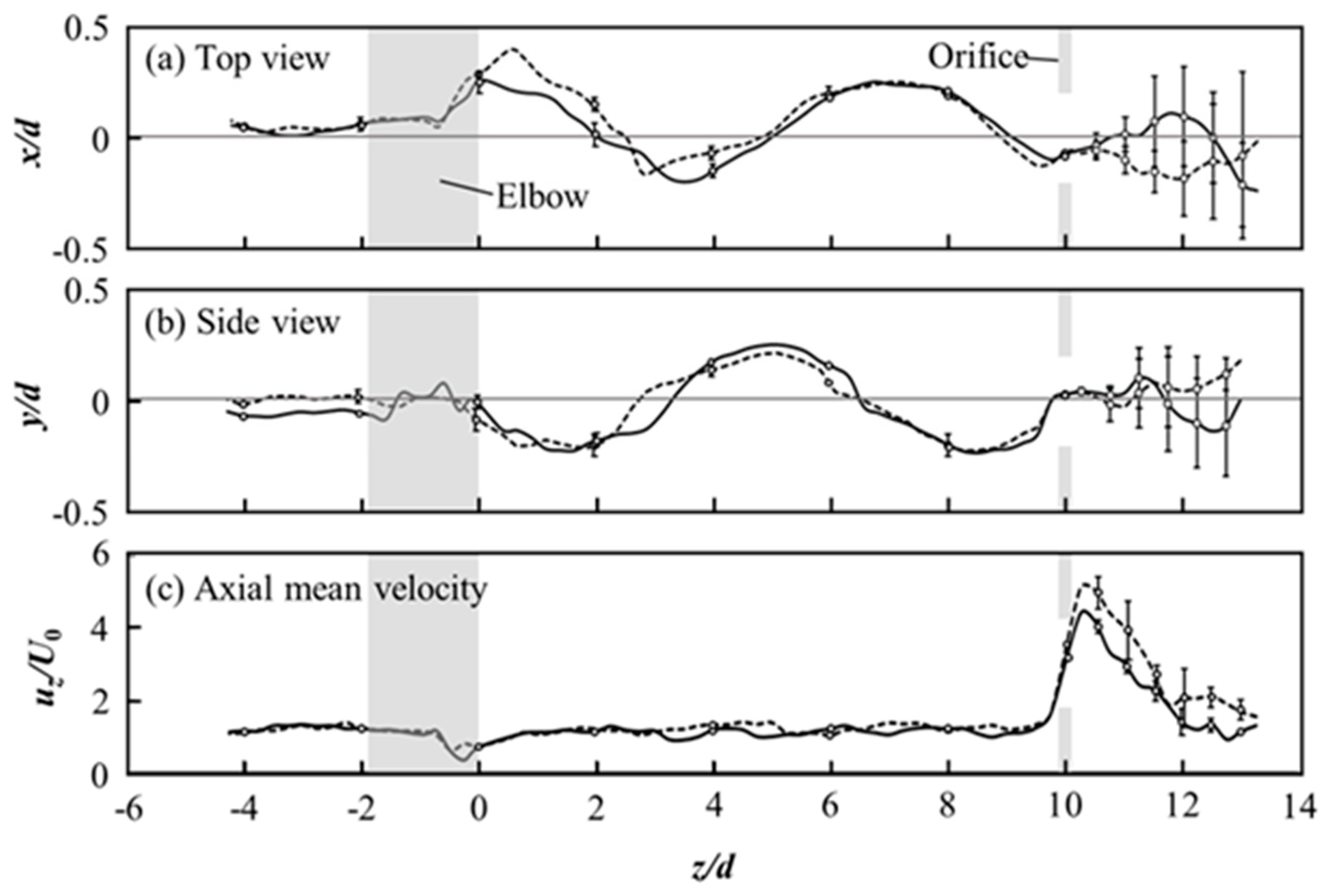

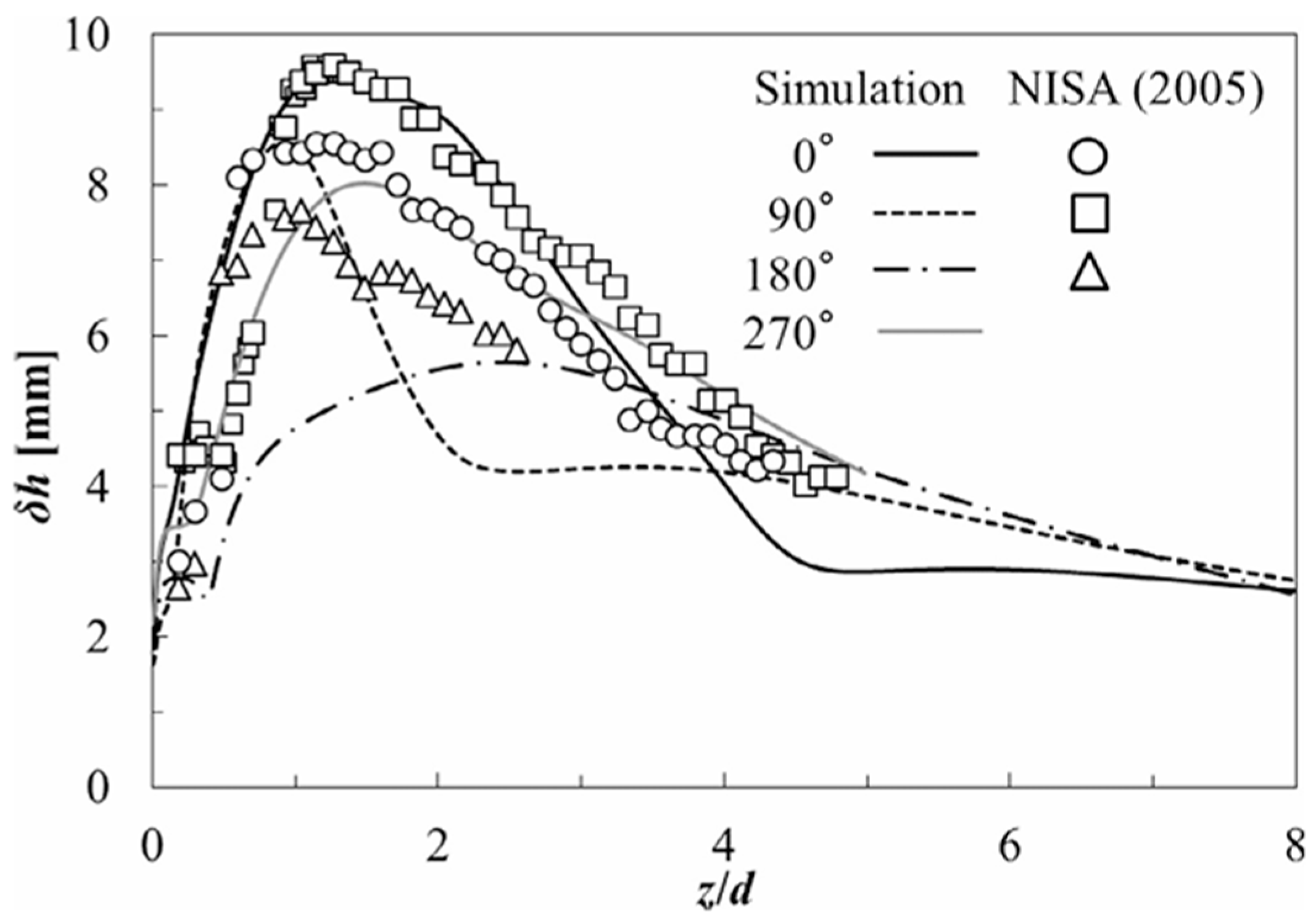

4.1. Flow Field Measurements and Numerical Simulations

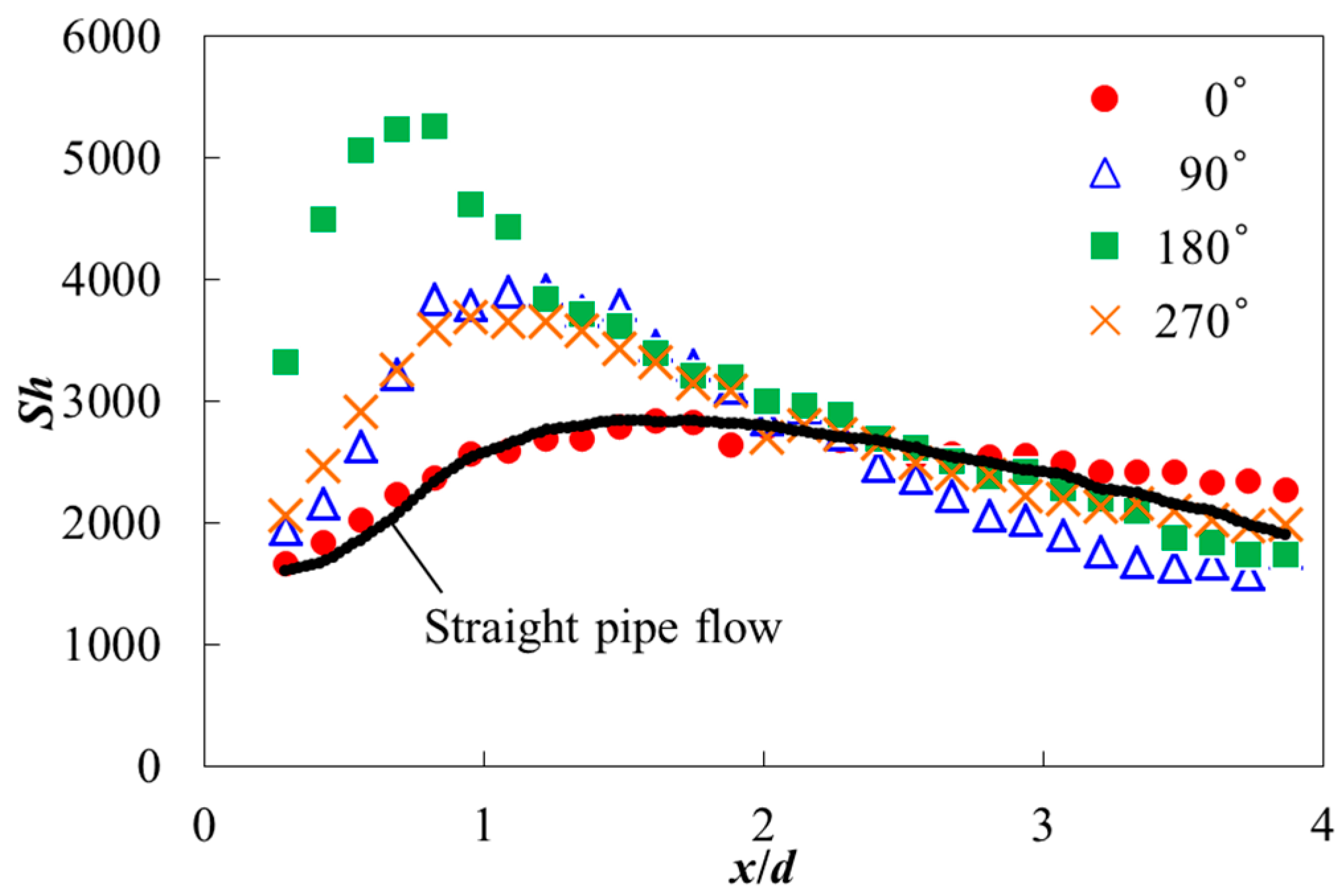

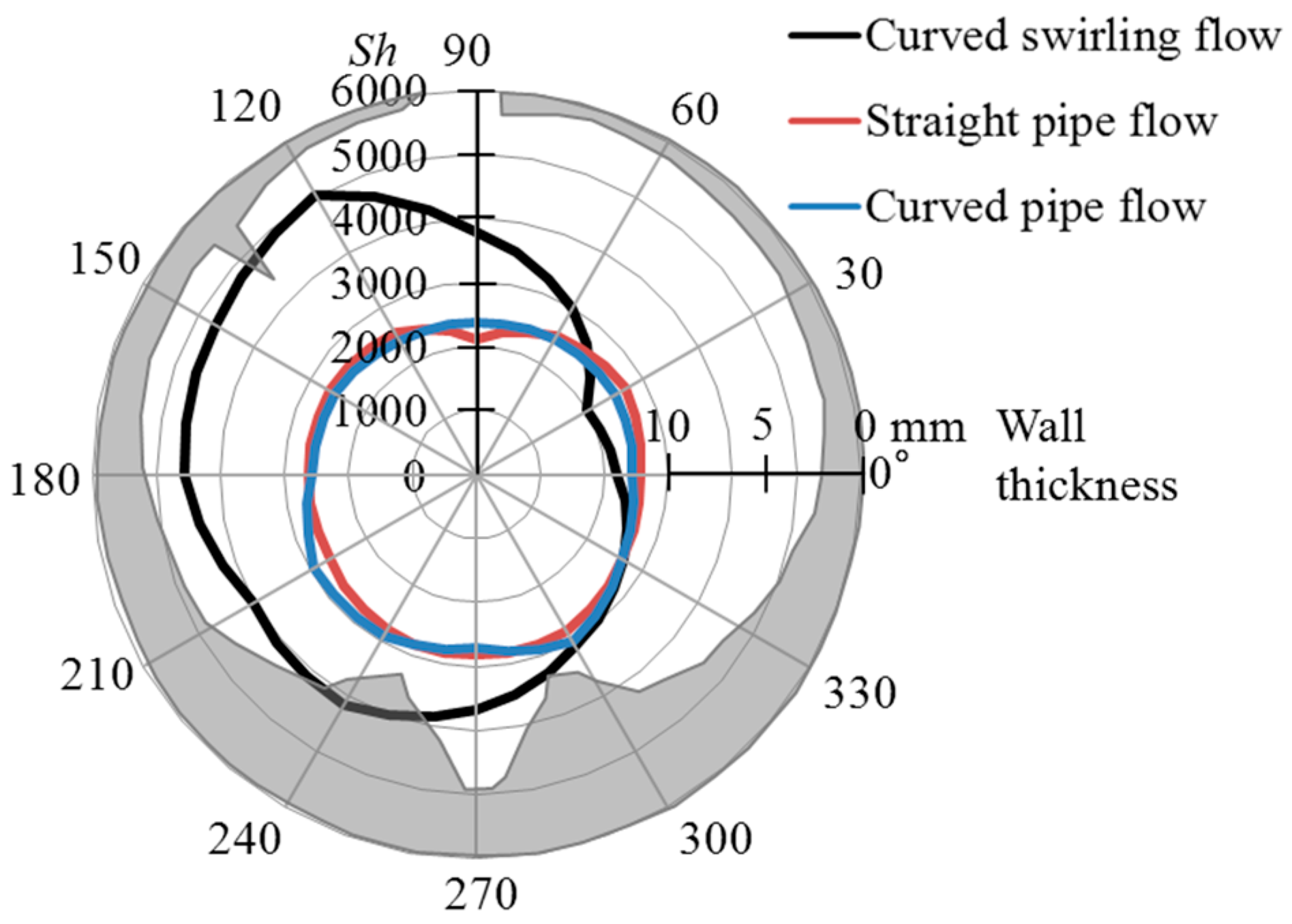

4.2. Mass Transfer and Wall-Thinning Distributions Downstream in Mihama Pipeline Model

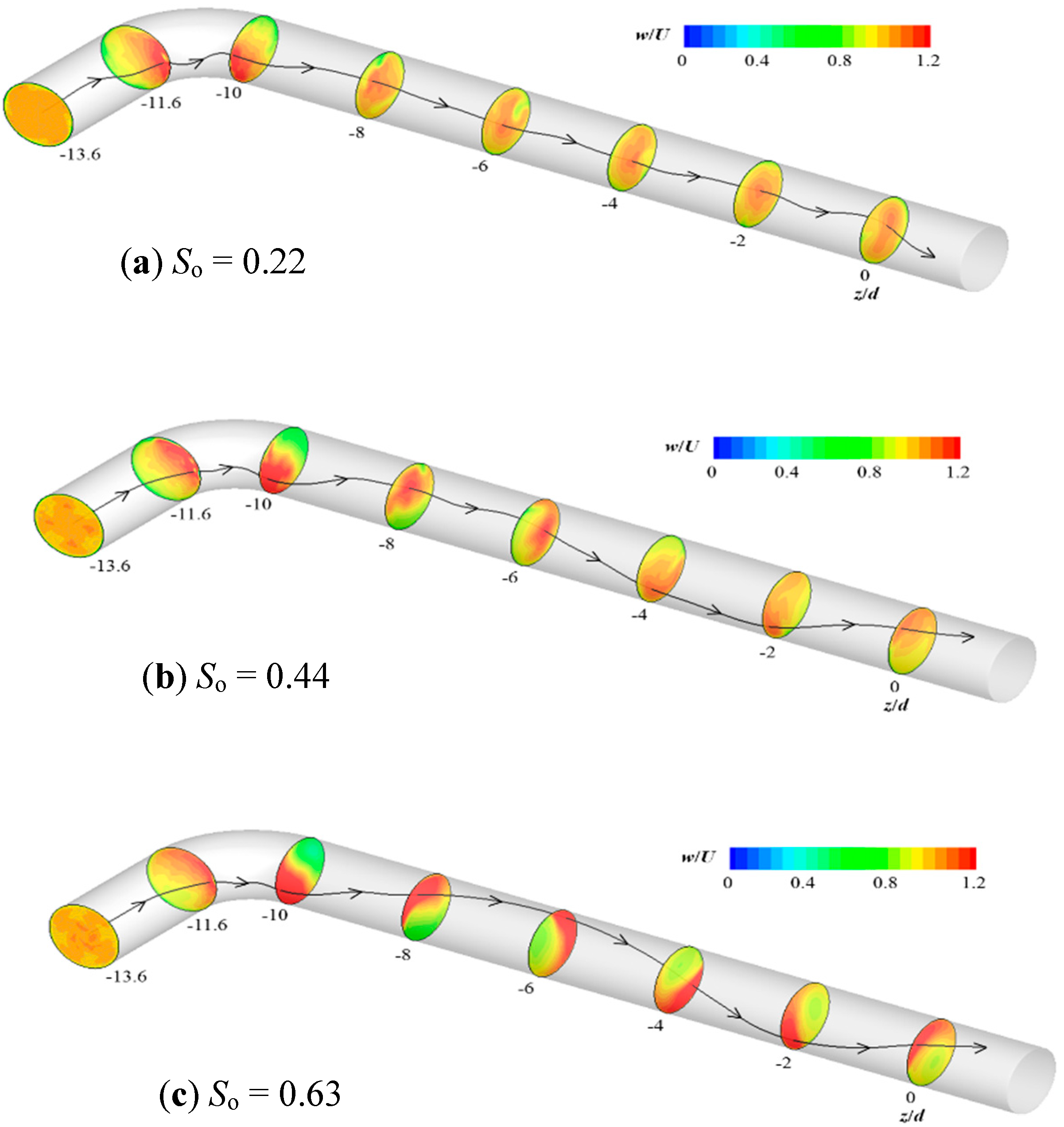

4.3. Numerical Studies on the Generation of Swirl Flow in Coupled T-Junction and Elbow

5. Recent Advances in Flow and Mass Transfer Studies on Curved Pipes and Elbows

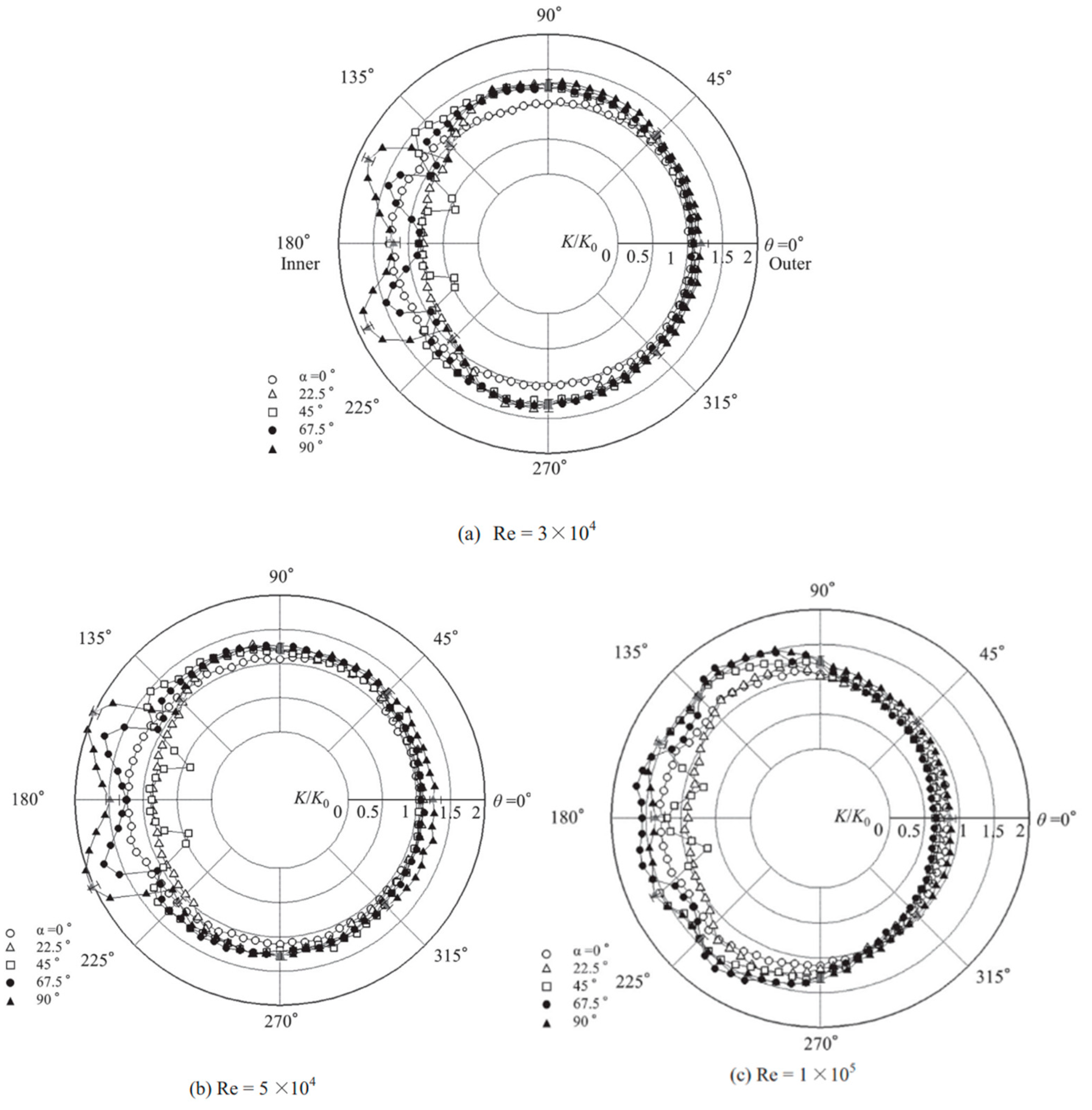

5.1. Flow Field Studies on Curved Pipes and Elbows

5.2. Mass Transfer Studies on Curved Pipes and Elbows

5.3. Influence of Wall Roughness and Formation of Scallop Pattern

6. Conclusions

- (1)

- The rupture of the Mihama pipeline was caused by asymmetric wall thinning down-stream of the orifice owing to the FAC. This was caused by the pipeline layout effect of the mutual interaction of flows through the elbow, orifice, and other pipeline elements in a swirl flow. The orifice flow responded highly to the spiral flow generated by the elbow in the swirl flow, which was the major cause of asymmetric pipe wall thinning downstream of the orifice in the Mihama pipeline model.

- (2)

- The interaction of the flow through the elbow and orifice in the Mihama pipeline model exhibited an increased mass transfer coefficient downstream of the orifice when the swirl intensity exceeded 0.3. This might have been a cause of the pipe rupture in the Mihama pipeline downstream of the orifice. The position of the pipe rupture might depend on the distance between the elbow and orifice because the spiral flow behavior is closely related to the asymmetric wall thinning downstream of the elbow.

- (3)

- A numerical simulation revealed the generation of a swirl flow downstream of the elbow when the T-junction flow entered the elbow in an out-of-plane configuration. An increased mass transfer coefficient was observed downstream of the elbow, caused by the interaction of the flow through the T-junction and elbow. This suggests the possible generation of swirl flow at the entry of the Mihama pipeline model. When the elbow curvature and the distance between the T-junction and elbow decreases, the swirl intensity increases beyond 0.3 of an increased mass transfer coefficient condition.

- (4)

- The flow downstream of the curved pipes and coupled elbows is a critical issue at the high Reynolds number of the actual pipeline. This is because the flow downstream of the short elbow is affected by the secondary flow and flow separation, resulting in low-frequency flow oscillations downstream of the elbow. This flow oscillation could be the cause of the increased mass transfer coefficient in the piping system. When the dual and triple elbows were placed in an out-of-plane configuration, a swirl flow was generated downstream of the elbow. This results in an asymmetric mass transfer coefficient and increased wall thinning downstream of the elbow.

- (5)

- The mass transfer coefficients in the short elbow exhibited an increase in the first half of the inner wall, whereas it decreased in the second half of the inner wall at high Reynolds numbers. An increased mass transfer coefficient was observed in coupled short elbows when they were located in an out-of-plane configuration. Furthermore, the influence of surface roughness and scalloping on the mass transfer coefficient helped increase the mass transfer coefficient in the pipeline. However, these topics, including the influence of the Reynolds number, are not clearly understood at present and require further study.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| c | concentration |

| cb | concentration in bulk flow |

| cs | saturated concentration |

| D | diffusion coefficient |

| d | pipe diameter |

| Jw | wall mass flux |

| K | mass transfer coefficient |

| k | turbulent energy |

| p | pressure |

| R | pipe radius |

| r | radial distance |

| Re | Reynolds number |

| S | swirl intensity at −3d upstream of orifice |

| So | swirl intensity at −3d upstream of elbow |

| Sc | Schmidt number |

| Sh | Sherwood number |

| t | time |

| U | streamwise mean velocity |

| u | velocity |

| w | axial velocity component |

| x, y, z | coordinates (See Figure 4) |

| δh/δt | wall thinning rate |

| ε | dissipation rate |

| θ | angle |

| μ | viscosity |

| ν | kinematic viscosity |

| ρ | density |

References

- Dooley, R.B.; Chexal, V.K. Flow-accelerated corrosion of pressure vessels in fossil plants. Int. J. Pres. Ves. Pip. 2000, 77, 85–90. [Google Scholar] [CrossRef]

- Dooley, R.B. Flow-accelerated corrosion in fossil and combined cycle/HRSG plants. Power Plant Chem. 2008, 10, 68–89. [Google Scholar]

- Fujiwara, K.; Domae, M.; Yoneda, K.; Inada, F.; Ohira, T.; Hisamune, K. Correlation of flow accelerated corrosion rate with iron solubility. Nucl. Eng. Des. 2011, 241, 4482–4486. [Google Scholar] [CrossRef]

- Kain, V.; Roychowdhury, S.; Ahmedabadi, P.; Barua, D.K. Flow accelerated corrosion: Experience from examination of components from nuclear power plants. Eng. Fail. Anal. 2011, 18, 2028–2041. [Google Scholar] [CrossRef]

- Dooley, B.; Lister, D. Flow-accelerated corrosion in steam generating plants. Power Plant Chem. 2018, 20, 194–244. [Google Scholar]

- Khunphakdee, P.; Chalermsinsuwan, B. Review of flow accelerated corrosion mechanism, numerical analysis, and control measures. Chem. Eng. Res. Des. 2023, 199, 519–535. [Google Scholar] [CrossRef]

- Keller, H. Erosionskorrosion an nassdampfturbien. VGB-Kraftwerkstechnik 1974, 54, 292–295. [Google Scholar]

- Sanchez-Caldera, L.E. The Mechanism of Corrosion Erosion in Steam Extraction Lines of Power Station. Ph.D. Thesis, MIT Department of Mechanical Engineering, Cambridge, MA, USA, 1984. [Google Scholar]

- Uchida, S. Latest experience with water chemistry in nuclear power plants in Japan. Power Plants Chem. 2006, 8, 282–292. [Google Scholar]

- Yoneda, K.; Morita, R. Investigation of flow characteristics affecting on pipe wall thinning (part 1): Turbulent properties at orifice downstream in single phase flow. CRIEPI Res. Rep. 2006, L05007. (In Japanese) [Google Scholar]

- Yoneda, K.; Morita, R.; Satake, M.; Inada, F. Quantitative evaluation of effective factors on flow accelerated corrosion (part 2): Modelling of mass transfer coefficient with hydraulic features at wall. CRIEPI Res. Rep. 2008, L07015. (In Japanese) [Google Scholar]

- Uchida, S.; Okada, H.; Naitoh, M.; Uehara, Y.; Koshizuka, S.; Lister, D.H.; Svoboda, R. Effects of water chemistry on flow accelerated corrosion and liquid droplet impingement accelerated corrosion. Power Plant Chem. 2009, 11, 704–717. [Google Scholar]

- Hwang, K.M.; Jin, T.E.; Kim, K.H. Identification of relationship between local velocity components and local wall thinning inside carbon steel piping. J. Nucl. Sci. Technol. 2009, 46, 469–478. [Google Scholar] [CrossRef]

- Ahmed, W.H. Evaluation of the proximity effect on flow-accelerated corrosion. Ann. Nucl. Ene. 2010, 37, 598–605. [Google Scholar] [CrossRef]

- Kim, K.H.; Park, S.H.; Hwang, K.M. Verification of the interrelation between local wall thinning and velocity components observed in the deflected turbulent flow inside orifice of carbon steel piping. Microsyst. Technol. 2010, 16, 1945–1950. [Google Scholar] [CrossRef]

- Uchida, S.; Naitoh, M.; Okada, H.; Uehara, Y.; Koshizuka, S. Evaluation of flow accelerated corrosion by coupled analysis of corrosion and flow dynamics: Relationship of oxide film thickness, hematite/magnetite ratio, ECP and wall thinning rate. Nucl. Eng. Des. 2011, 241, 4585–4593. [Google Scholar] [CrossRef]

- Pietralik, J.M.; Schefski, C.S. Flow and mass transfer in bends under flow-accelerated corrosion wall thinning conditions. J. Eng. Gas Turbines Power 2011, 133, 012902. [Google Scholar] [CrossRef]

- Pietralik, J.M. The role of flow in flow-accelerated corrosion under nuclear power plant conditions. E-J. Adv. Maint. 2012, 4, 63–78. [Google Scholar]

- Utanohara, Y.; Nagaya, Y.; Nakamura, A.; Murase, M. Influence of local flow field on flow accelerated corrosion downstream from an orifice. J. Power Ene. Syst. 2012, 6, 18–33. [Google Scholar] [CrossRef]

- Kain, V. Flow accelerated corrosion: Forms, mechanisms and case studies. Procedia Eng. 2014, 86, 576–588. [Google Scholar] [CrossRef]

- Abe, H.; Watanabe, Y.; Nakashima, M.; Tatsuki, T. Characterization of the corroded surface morphology of a carbon steel piping elbow affected by flow-accelerated corrosion. E.-J. Adv. Mainte. 2017, 9, 26–32. [Google Scholar]

- Utanohara, Y.; Murase, M. Influence of flow velocity and temperature on flow accelerated corrosion rate at an elbow pipe. Nucl. Eng. Des. 2019, 342, 20–28. [Google Scholar] [CrossRef]

- Madasamy, P.; Chandramohan, P.; Mukunthan, M.; Mohan, T.K.; Rangarajan, S.; Uttam, N.; Nair, J.P. Flow accelerated corrosion rate on carbon steel pipe bend by thin layer activation technique and computational modeling: Under PHWR operating conditions. Eng. Fail. Anal. 2021, 121, 105125. [Google Scholar] [CrossRef]

- Bao, G.; Qin, W.; Pan, D.; Si, X. Empirical model of flow-accelerated corrosion at elbow of carbon steel pipeline based on dimensional analysis. Ann. Nucl. Ene. 2024, 201, 110462. [Google Scholar] [CrossRef]

- Moon, S.; Lee, J.Y.; Kim, K.M.; Han, S.W.; Lee, G.G.; Maeng, W.Y.; Kim, D.J. Assessment of flow-accelerated corrosion-induced wall thinning in SA106 pipes with elbow sections. Nucl. Eng. Technol. 2024, 56, 1244–1249. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, R.; Si, X. Effects of fluid dynamics parameters on flow-accelerated corrosion at elbow of carbon steel pipeline. Mat. Res. Express 2024, 11, 056520. [Google Scholar] [CrossRef]

- Sydberger, T.; Lotz, U. Relation between mass transfer and corrosion in a turbulent pipe flow. J. Electrochem. Soc. 1982, 129, 276–283. [Google Scholar] [CrossRef]

- Nakamura, A.; Murase, M.; Utanohara, Y.; Nagaya, Y. The effect of local flow field on flow accelerated corrosion: The background of the research and measurements of corrosion rate after an orifice. INSS J. 2008, 15, 78–87. (In Japanese) [Google Scholar]

- Ahmed, W.H.; Bello, M.M.; Nakla, M.E.; Sarkhi, A.A. Flow and mass transfer downstream of an orifice under flow accelerated corrosion conditions. Nucl. Eng. Des. 2012, 252, 52–67. [Google Scholar] [CrossRef]

- El-Gammal, M.; Ahmed, W.H.; Ching, C.Y. Investigation of wall mass transfer characteristics downstream of an orifice. Nucl. Eng. Des. 2012, 242, 353–360. [Google Scholar] [CrossRef]

- Ahmed, W.H.; Bello, M.M.; El Nakla, M.; Al Sarkhi, A.; Badr, H.M. Experimental investigation of flow accelerated corrosion under two-phase flow conditions. Nucl. Eng. Des. 2014, 267, 34–43. [Google Scholar] [CrossRef]

- Fujisawa, N.; Yamagata, Y.; Kanno, S.; Ito, A.; Takano, T. The mechanism of asymmetric pipe-wall thinning behind an orifice by combined effect of swirling flow and orifice bias. Nucl. Eng. Des. 2012, 252, 19–26. [Google Scholar] [CrossRef]

- Takano, T.; Yamagata, T.; Ito, A.; Fujisawa, N. Mass transfer measurements behind an orifice in a circular pipe flow for various combinations of swirl intensity and orifice bias. J. Power Energy Syst. 2012, 6, 402–411. [Google Scholar] [CrossRef][Green Version]

- Shan, F.; Fujishiro, A.; Tsuneyoshi, T.; Tsuji, Y. Particle image velocimetry measurements of flow field behind a circular square-edged orifice in a round pipe. Exp. Fluids 2013, 54, 1–18. [Google Scholar] [CrossRef]

- Shan, F.; Fujishiro, A.; Tsuneyoshi, T.; Tsuji, Y. Effects of flow field on the wall mass transfer rate behind a circular orifice in a round pipe. Int. J. Heat Mass Transf. 2014, 73, 542–550. [Google Scholar] [CrossRef]

- Fujisawa, N.; Kanatani, N.; Yamagata, T.; Takano, T. Mechanism of non-axisymmetric pipe-wall thinning in pipeline with elbow and orifice under influence of swirling flow. Nucl. Eng. Des. 2015, 285, 126–133. [Google Scholar] [CrossRef]

- NISA Secondary Piping Rupture Accident at Mihama Power Station, Unit 3, of the Kansai Electric Power Co. Inc. Final Report. 2005. Available online: https://www.aec.go.jp/kaigi/teirei/2005/siryo13/1-1_haifu.pdf (accessed on 12 June 2025). (In Japanese).

- Aloui, F.; Souhar, M. Experimental study on turbulent asymmetric flow in a flat duct symmetric sudden expansion. ASME J. Fluid Eng. 2000, 122, 174–177. [Google Scholar] [CrossRef]

- Fujisawa, N.; Yamamoto, H. Occurrence of asymmetric flow pattern behind a double orifice in a square pipe. J. Vis. 2009, 12, 93–94. [Google Scholar] [CrossRef]

- Ohkubo, M.; Kanno, S.; Yamagata, T.; Takano, T.; Fujisawa, N. Occurrence of asymmetrical flow pattern behind an orifice in a circular pipe. J. Vis. 2011, 14, 15–17. [Google Scholar] [CrossRef]

- Rani, H.P.; Divya, T.; Sahaya, R.R.; Kain, V.; Barua, D.K. Numerical investigation of energy and Reynolds stress distribution for a turbulent flow in an orifice. Eng. Fail. Anal. 2013, 34, 451–463. [Google Scholar] [CrossRef]

- Takano, T.; Yamagata, T.; Sato, Y.; Fujisawa, N. Non-axisymmetric mass transfer phenomenon behind an orifice in a curved swirling flow. J. Flow Contr. Meas. Vis. 2013, 1, 1–5. [Google Scholar] [CrossRef]

- Takano, T.; Ikarashi, Y.; Uchiyama, K.; Yamagata, T.; Fujisawa, N. Influence of swirling flow on mass and momentum transfer downstream of a pipe with elbow and orifice. Int. J. Heat Mass Transf. 2016, 91, 394–402. [Google Scholar] [CrossRef]

- Yamagata, T.; Ishizuka, A.; Fujisawa, N. Numerical investigation on non-axisymmetric pipe wall thinning downstream of elbow-orifice pipeline with swirling flow. Ann. Nucl. Ene. 2017, 101, 196–202. [Google Scholar] [CrossRef]

- Escudier, M. Vortex breakdown: Observations and explanations. Prog. Aero. Sci. 1988, 25, 189–229. [Google Scholar] [CrossRef]

- Anwar, M.; So, R.M.C. Swirling turbulent flow through a curved pipe (part 1): Effect of swirl and bend curvature. Exp. Fluids 1993, 14, 85–96. [Google Scholar] [CrossRef]

- Fujisawa, N.; Yamagata, T.; Abe, A.; Maxey, M. Characterization of swirling-flow behavior in complex pipeline using bubble trajectory method with stereo particle tracking/image velocimetry. Flow Meas. Instrum. 2022, 85, 102159. [Google Scholar] [CrossRef]

- Watanabe, S.; Yoneda, K.; Nakamura, T.; Matsushita, M. Effect of swirl flow on wall thinning phenomenon by flow accelerated corrosion. Proc. Natl. Symp. Power Energy Syst. 2015, 20, 209–210. (In Japanese) [Google Scholar] [CrossRef]

- JSME Codes for Nuclear Power Generation Facilities: Rules on Pipe Wall Thinning Management for PWR Power Plants, JSME S NG1. 2022. (In Japanese)

- JSME Codes for Nuclear Power Generation Facilities: Rules on Pipe Wall Thinning Management for BWR Power Plants, JSME S NH1. 2022. (In Japanese)

- Tamura, A. A review, Recent advances in pipe-wall thinning inspection technologies in nuclear power plants. J. Flow Energy 2024, 2, 118–135. [Google Scholar]

- Cragnolino, G.; Czajkowski, C.; Shack, W.J. Review of Erosion-Corrosion in Single-Phase Flows; No. NUREG/CR-5156; ANL-88-25; Nuclear Regulatory Commission: Washington, DC, USA; Argonne National Lab.: Lemont, IL, USA, 1988.

- Yamagata, T.; Ito, A.; Sato, A.; Fujisawa, N. Experimental and numerical studies on mass transfer characteristics behind an orifice in a circular pipe for application to pipe-wall thinning. Exp. Therm. Fluid Sci. 2014, 52, 239–247. [Google Scholar] [CrossRef]

- Funatani, S.; Fujisawa, N. Simultaneous measurement of temperature and three velocity components in planar cross-section by liquid crystal thermometry combined with stereoscopic particle image velocimetry. Meas. Sci. Technol. 2002, 13, 1197–1205. [Google Scholar] [CrossRef]

- Raffel, M.; Willert, C.E.; Werely, S.T.; Kompenhans, J. Particle Image Velocimetry: A Practical Guide, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 211–225. [Google Scholar]

- Issa, R.I. Solution of implicitly discretized fluid flow equations by operator-splitting. J. Comput. Phys. 1986, 62, 40–65. [Google Scholar] [CrossRef]

- Xiong, J.; Koshizuka, S.; Sakai, M. Turbulence modelling for mass transfer enhancement by separation and reattachment with two-equation eddy viscosity models. Nucl. Eng. Des. 2011, 241, 3190–3200. [Google Scholar] [CrossRef]

- Lin, C.H.; Ferng, Y.M. Predictions of hydrodynamic characteristics and corrosion rates using CFD in the piping systems of pressurized-water reactor power plant. Ann. Nucl. Ene. 2014, 65, 214–222. [Google Scholar] [CrossRef]

- Kader, B.A. Temperature and concentration profiles in fully turbulent boundary layers. Int. J. Heat Mass Transf. 1981, 24, 1541–1544. [Google Scholar] [CrossRef]

- Suzuki, S.; Nakamura, T. Evaluation of mass transfer coefficient under swirl flow generated by the combination of pipe elements. In Proceedings of the ASME 2012 Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012; ASME: New York, NY, USA, 2012. [Google Scholar]

- Yamamoto, K.; Suzuki, S.; Nakamura, T. Evaluation of mass transfer coefficient under swirl flow generated by the combination of pipe elements (part 2). In Proceedings of the ASME 2013 Pressure Vessels and Piping Conference, Paris, France, 14–18 July 2013. [Google Scholar]

- Matsushita, M.; Yamamoto, K.; Nakamura, N. Evaluation of mass transfer coefficient under swirl flow generated by the combination of pipe elements (part 3): Analysis of geometry factor under swirl flow on pipe element. In Proceedings of the ASME 2014 Pressure Vessels and Piping Conference, Anaheim, CA, USA, 20–24 July 2014; ASME: New York, NY, USA, 2014. [Google Scholar]

- Watanabe, S.; Yoneda, K.; Morita, R. Evaluation of swirl flow effect on pipe wall thinning phenomenon by flow-accelerated corrosion. CRIEPI Res. Rep. 2016, L15002. (In Japanese) [Google Scholar]

- Spedding, P.L.; Benard, E.; McNally, G.M. Fluid flow through 90 degree bends. Dev. Chem. Eng. Mineral Process. 2004, 12, 107–128. [Google Scholar] [CrossRef]

- Rütten, F.; Schröder, W.; Meinke, M. Large-eddy simulation of low frequency oscillations of the Dean vortices in turbulent pipe bend flows. Phys. Fluids 2005, 17, 035107. [Google Scholar] [CrossRef]

- Ono, A.; Kimura, N.; Kamide, H.; Tobita, A. Influence of elbow curvature on flow structure at elbow outlet under high Reynolds number condition. Nucl. Eng. Des. 2011, 241, 4409–4419. [Google Scholar] [CrossRef]

- Yamano, H.; Tanaka, M.; Murakami, T.; Iwamoto, Y.; Yuki, K.; Sago, H.; Hayakawa, S. Unsteady elbow pipe flow to develop a flow-induced vibration evaluation methodology for Japan sodium-cooled fast reactor. J. Nucl. Sci. Technol. 2011, 48, 677–687. [Google Scholar] [CrossRef][Green Version]

- Tanaka, M.; Ohshima, H. Numerical investigation on large scale eddy structure in unsteady pipe elbow flow at high Reynolds number conditions with large eddy simulation approach. J. Power Energy Syst. 2012, 6, 210–228. [Google Scholar] [CrossRef][Green Version]

- Iwamoto, Y.; Kondo, M.; Minamiura, H.; Tanaka, M.; Yamano, H. Unsteady flow characteristics in a 90 degree elbow affected by developed, undeveloped and swirling inflow conditions. J. Fluid Sci. Technol. 2012, 7, 12–0244. [Google Scholar] [CrossRef][Green Version]

- Sakakibara, J.; Machida, N. Measurement of turbulent flow upstream and downstream of a circular pipe bend. Phys. Fluids 2012, 24, 041702. [Google Scholar] [CrossRef]

- Takamura, H.; Ebara, S.; Hashizume, H.; Aizawa, K.; Yamano, H. Flow visualization and frequency characteristics of velocity fluctuations of complex turbulent flow in a short elbow piping under high Reynolds number condition. ASME J. Fluids Eng. 2012, 134, 101201. [Google Scholar] [CrossRef]

- Iwamoto, Y.; Yamano, H. Unsteady wall pressure characteristics of a 90 degree elbow in high Reynolds numbers. J. Fluid Sci. Technol. 2014, 9, 14–00047. [Google Scholar] [CrossRef][Green Version]

- Ono, A.; Tanaka, M.; Kobayashi, J.; Kamide, H. Influence of inlet velocity condition on unsteady flow characteristics in piping with a short elbow under a high-Reynolds-number condition. Mech. Eng. J. 2017, 4, 16–00217. [Google Scholar] [CrossRef][Green Version]

- Guala, M.; Hommema, S.E.; Adrian, R.J. Large-scale and very-large-scale motions in turbulent pipe flow. J. Fluid Mech. 2006, 554, 521–542. [Google Scholar] [CrossRef]

- Hellström, L.H.; Zlatinov, M.B.; Cao, G.; Smits, A.J. Turbulent pipe flow downstream of a a 90° bend. J. Fluid Mech. 2013, 735, R7. [Google Scholar] [CrossRef]

- Kalpakli, A.; Örlü, R. Turbulent pipe flow downstream a 90° pipe bend with and without superimposed swirl. Int. J. Heat Fluid Flow 2013, 41, 103–111. [Google Scholar] [CrossRef]

- Kalpakli, A.; Örlü, R.; Alfredsson, P.H. Turbulent flows in curved pipes: Recent advances in experiments and simulations. Appl. Mech. Rev. 2016, 68, 050802. [Google Scholar] [CrossRef]

- Hufnagel, L.; Canton, J.; Örlü, R.; Marin, E.; Merzari, O.; Schlatter, P. The three-dimensional structure of swirl-switching in bent pipe flow. J. Fluid Mech. 2018, 835, 86–101. [Google Scholar] [CrossRef]

- Wang, Z.; Örlü, R.; Schlatter, P.; Chung, Y.M. Direct numerical simulation of a turbulent 90° bend pipe flow. Int. J. Heat Fluid Flow 2018, 73, 199–208. [Google Scholar] [CrossRef]

- Discetti, S.; Bellani, G.; Örlü, R.; Serpieri, J.; Vila, C.S.; Raiola, M.; Zheng, X.; Tallamelli, A.; Ianiro, A. Characterization of very-large-scale motions in high-Re pipe flows. Exp. Therm. Fluid Sci. 2019, 104, 1–8. [Google Scholar] [CrossRef]

- Ikarashi, Y.; Yamagata, T.; Yamagishi, F.; Fujisawa, N. Unsteady turbulence structure in and downstream of a short elbow at post-critical Reynolds numbers. Nucl. Eng. Des. 2020, 364, 110649. [Google Scholar] [CrossRef]

- Yuki, K.; Hasegawa, S.; Sato, T.; Hashizume, H.; Aizawa, K.; Yamano, H. Matched refractive-index PIV visualization of complex flow structure in a three-dimensionally connected dual elbow. Nucl. Eng. Des. 2011, 241, 4544–4550. [Google Scholar]

- Ebara, S.; Takamura, H.; Hashizume, H.; Yamano, H. Characteristics of flow field and pressure fluctuation in complex turbulent flow in the third elbow of a triple elbow piping with small curvature radius in three-dimensional layout. Int. J. Hydrog. Ene. 2016, 41, 7139–7145. [Google Scholar] [CrossRef]

- Mazhar, H.; Ewing, D.; Cotton, J.S.; Ching, C.Y. Measurement of the flow field characteristics in single and dual S-shape 90° bends using matched refractive index PIV. Exp. Therm. Fluid Sci. 2016, 79, 65–73. [Google Scholar] [CrossRef]

- Takahashi, H.; Shwin, S.; Hamdani, A.; Fujisawa, N.; Kikura, H. Experimental and numerical investigation of swirling flow on triple elbow pipe layout. J. Flow Contr., Meas. Visual. 2020, 8, 45. [Google Scholar] [CrossRef]

- Yoneda, K.; Uchiyama, Y.; Morita, R.; Fujiwara, K. Prediction of flow-accelerated corrosion in single/dual elbow in pipelines considering geometric parameters and layout effect. Mech. Eng. J. 2023, 10, 22–00344. [Google Scholar] [CrossRef]

- Achenbach, E. Mass transfer from bends of circular cross section to air. In Future Energy Production Systems; Academic Press: New York, NY, USA, 1976; pp. 327–337. [Google Scholar]

- Goldstein, R.J.; Cho, H.H. A review of mass transfer measurements using naphthalene sublimation. Exp. Therm. Fluid Sci. 1995, 10, 416–434. [Google Scholar] [CrossRef]

- Mazhar, H.; Ewing, D.; Cotton, J.S.; Ching, C.Y. Experimental investigation of mass transfer in 90° pipe bends using a dissolvable wall technique. Int. J. Heat Mass Transf. 2013, 65, 280–288. [Google Scholar] [CrossRef]

- Ikarashi, Y.; Taguchi, S.; Yamagata, T.; Fujisawa, N. Mass and momentum transfer characteristics in and downstream of 90° elbow. Int. J. Heat Mass Transf. 2017, 107, 1085–1093. [Google Scholar] [CrossRef]

- Ikarashi, Y.; Uno, T.; Yamagata, T.; Fujisawa, N. Influence of elbow curvature on flow and turbulence structure through a 90° elbow. Nucl. Eng. Des. 2018, 339, 181–193. [Google Scholar] [CrossRef]

- Taguchi, S.; Ikarashi, Y.; Yamagata, T.; Fujisawa, N.; Inada, F. Mass and momentum transfer characteristics in 90° elbow under high Reynolds number. Int. Comm. Heat Mass Transf. 2018, 90, 103–110. [Google Scholar] [CrossRef]

- Ikarashi, Y.; Fujisawa, N. Mass transfer measurements and flow separation behavior in a 90° short elbow. Int. J. Heat Mass Transf. 2019, 136, 1106–1114. [Google Scholar] [CrossRef]

- Fujisawa, N.; Takizawa, T.; Yamagata, T. Comparative study of mass transfer distributions and oil-flow visualizations with image analysis on long and short 90° elbows. Exp. Therm. Fluid Sci. 2021, 123, 110332. [Google Scholar] [CrossRef]

- Mazhar, H.; Ewing, D.; Cotton, J.S.; Ching, C.Y. Mass transfer in dual pipe bends arranged in an S-configuration. Int. J. Heat Mass Transf. 2014, 71, 747–757. [Google Scholar] [CrossRef]

- Dawson, D.A.; Trass, O. Mass transfer at rough surfaces. Int. J. Heat Mass Transf. 1972, 15, 1317–1336. [Google Scholar] [CrossRef]

- Poulson, B. Mass transfer from rough surfaces. Corros. Sci. 1990, 30, 743–746. [Google Scholar] [CrossRef]

- Zhao, W.; Trass, O. Electrochemical mass transfer measurements in rough surface pipe flow: Geometrically similar V-shaped grooves. Int. J. Heat Mass Transf. 1997, 40, 2785–2797. [Google Scholar] [CrossRef]

- Lolja, S.A. Momentum and mass transfer on sandpaper-roughened surfaces in pipe flow. Int. J. Heat Mass Transf. 2005, 48, 2209–2218. [Google Scholar] [CrossRef]

- Wang, D.; Ewing, D.; Ching, C.Y. Time evolution of surface roughness in pipes due to mass transfer under different Reynolds numbers. Int. J. Heat Mass Transf. 2016, 103, 661–671. [Google Scholar] [CrossRef]

- Wang, D.; Ewing, D.; Ching, C.Y. The effect of naturally developing roughness on the mass transfer in pipes under different Reynolds numbers. J. Heat Transf. 2017, 139, 102005. [Google Scholar] [CrossRef]

- Fujisawa, N.; Uchiyama, K.; Yamagata, T. Mass transfer measurements on periodic roughness in a circular pipe and downstream of orifice. Int. J. Heat Mass Transf. 2017, 105, 316–325. [Google Scholar] [CrossRef]

- Fujisawa, N.; Yamagata, T.; Nagasaki, T. Mass transfer behaviors on sinusoidal wavy walls at different Reynolds numbers. Int. Commun. Heat Mass Transf. 2020, 110, 104383. [Google Scholar] [CrossRef]

- Yamagata, T.; Fujisawa, N. Experimental and numerical studies of flow field and mass transfer phenomena on sinusoidal wavy walls. Hear. Mass Transf. 2021, 57, 715–722. [Google Scholar] [CrossRef]

- Curl, R.L. Scallops and flutes. Trans. Cave Res. Group Great Br. 1966, 7, 121–160. [Google Scholar]

- Blumberg, P.N.; Curl, R.L. Experimental and theoretical studies of dissolution roughness. J. Fluid Mech. 1974, 65, 735–751. [Google Scholar] [CrossRef]

- Thomas, R.M. Size of scallops and ripples formed by flowing water. Nature 1979, 277, 281–283. [Google Scholar] [CrossRef]

- Hanratty, T.J. Stability of surfaces that are dissolving or being formed by convective diffusion. Annu. Rev. Fluid Mech. 1981, 13, 231–252. [Google Scholar] [CrossRef]

- Poulson, B. Complexities in predicting erosion corrosion. Wear 1999, 233, 497–504. [Google Scholar] [CrossRef]

- Villien, B.; Zheng, Y.; Lister, D. Surface dissolution and the development of scallops. Chem. Eng. Comm. 2005, 192, 125–136. [Google Scholar] [CrossRef]

- Meakin, P.; Jamtveit, B. Geological pattern formation by growth and dissolution in aqueous systems. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 659–694. [Google Scholar] [CrossRef]

- Hammer, O.; Lauritzen, S.E.; Jamtveit, B. Stability of dissolution flutes under turbulent flow. J. Cave Karst Stud. 2011, 73, 181–186. [Google Scholar] [CrossRef]

- Poulson, B. Predicting and preventing flow accelerated corrosion in nuclear power plant. Int. J. Nucl. Energy 2014, 2014, 423295. [Google Scholar] [CrossRef]

- Abe, H.; Yano, T.; Watanabe, Y.; Nakashima, M. Characteristics of scalloped surface and its relation to FAC rate of carbon steel piping elbow. Trans. JSME 2017, 83, 16–00453. (In Japanese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fujisawa, N. Review: Pipeline Layout Effect on the Wall Thinning of Mihama Nuclear Power Plants. J. Nucl. Eng. 2025, 6, 19. https://doi.org/10.3390/jne6020019

Fujisawa N. Review: Pipeline Layout Effect on the Wall Thinning of Mihama Nuclear Power Plants. Journal of Nuclear Engineering. 2025; 6(2):19. https://doi.org/10.3390/jne6020019

Chicago/Turabian StyleFujisawa, Nobuyuki. 2025. "Review: Pipeline Layout Effect on the Wall Thinning of Mihama Nuclear Power Plants" Journal of Nuclear Engineering 6, no. 2: 19. https://doi.org/10.3390/jne6020019

APA StyleFujisawa, N. (2025). Review: Pipeline Layout Effect on the Wall Thinning of Mihama Nuclear Power Plants. Journal of Nuclear Engineering, 6(2), 19. https://doi.org/10.3390/jne6020019