- Article

Experimental and Numerical Characterization of the Stable Operating Range of a Highly Loaded Axial Compressor Stage

- Riccardo Toracchio,

- Koen Hillewaert and

- Fabrizio Fontaneto

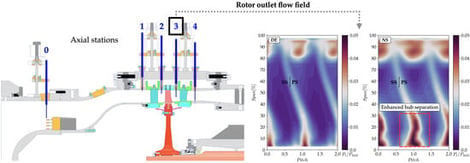

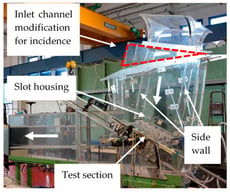

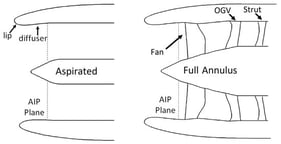

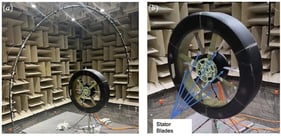

High-bypass ratio engines are currently among the most investigated solutions to achieve efficiency benefits and noise reduction in gas turbine engines. When equipped with a gearbox, these engines enable an optimized operation of the fan and of the low-pressure core, resulting in reduced weight and fuel consumption. The higher spool speed allows higher pressure ratios per stage, and consequently a reduced stage count. However, all this contributes to an enhanced sensitivity of the engine components to the development of secondary flow structures and separations, with a consequent impact on the aerodynamic performance and stability. In this context, an experimental campaign was conducted at the von Karman Institute for Fluid Dynamics on a highly loaded axial compressor representative of the first stage of a modern booster. The aim was to identify the flow features responsible of the performance loss at the operating points and speeds considered more critical in terms of rotor inlet incidence. To this end, time-averaged instrumentation was employed to characterize the performance and to retrieve the distribution of flow quantities at different axial positions within the stage, while fast-response probes allowed for the detailed characterization of the rotor outlet flow field. Unsteady 3D simulations complemented the experimental results and supported this interpretation, especially in regions with limited instrumentation access. The experimental and numerical results emphasized the role of the secondary flow structures developing near the hub wall as the main drivers for aerodynamic stall, due to the enhanced loading in this blade region.

3 February 2026