Goals and Strategies for Open Fan Design †

Abstract

1. Introduction

2. Design Methods

2.1. Flow Solver

2.2. Mesh Sensitivity

2.3. Design Strategy

2.4. Performance Metrics

2.4.1. Transfer Efficiency

2.4.2. Propulsive Efficiency

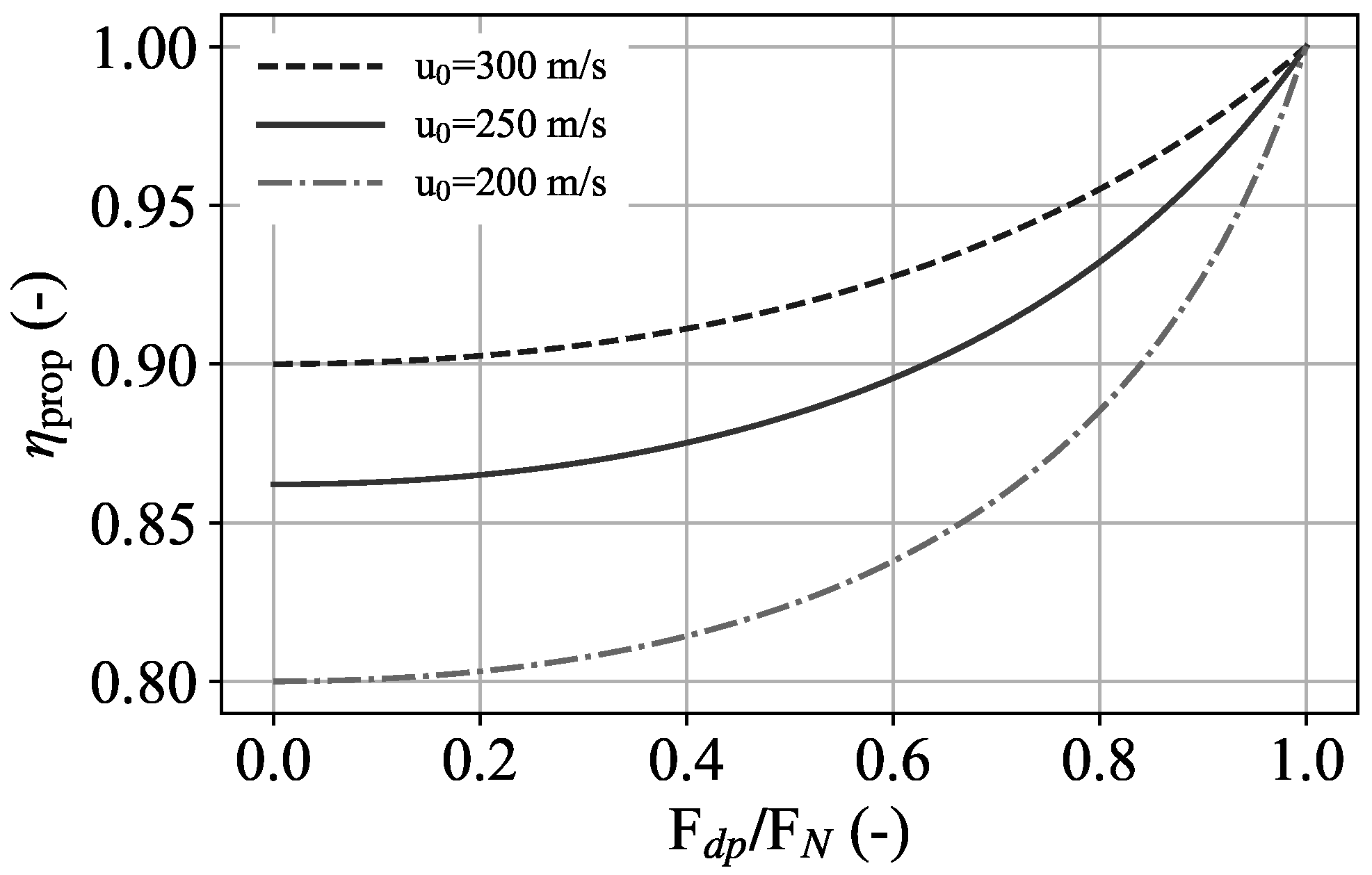

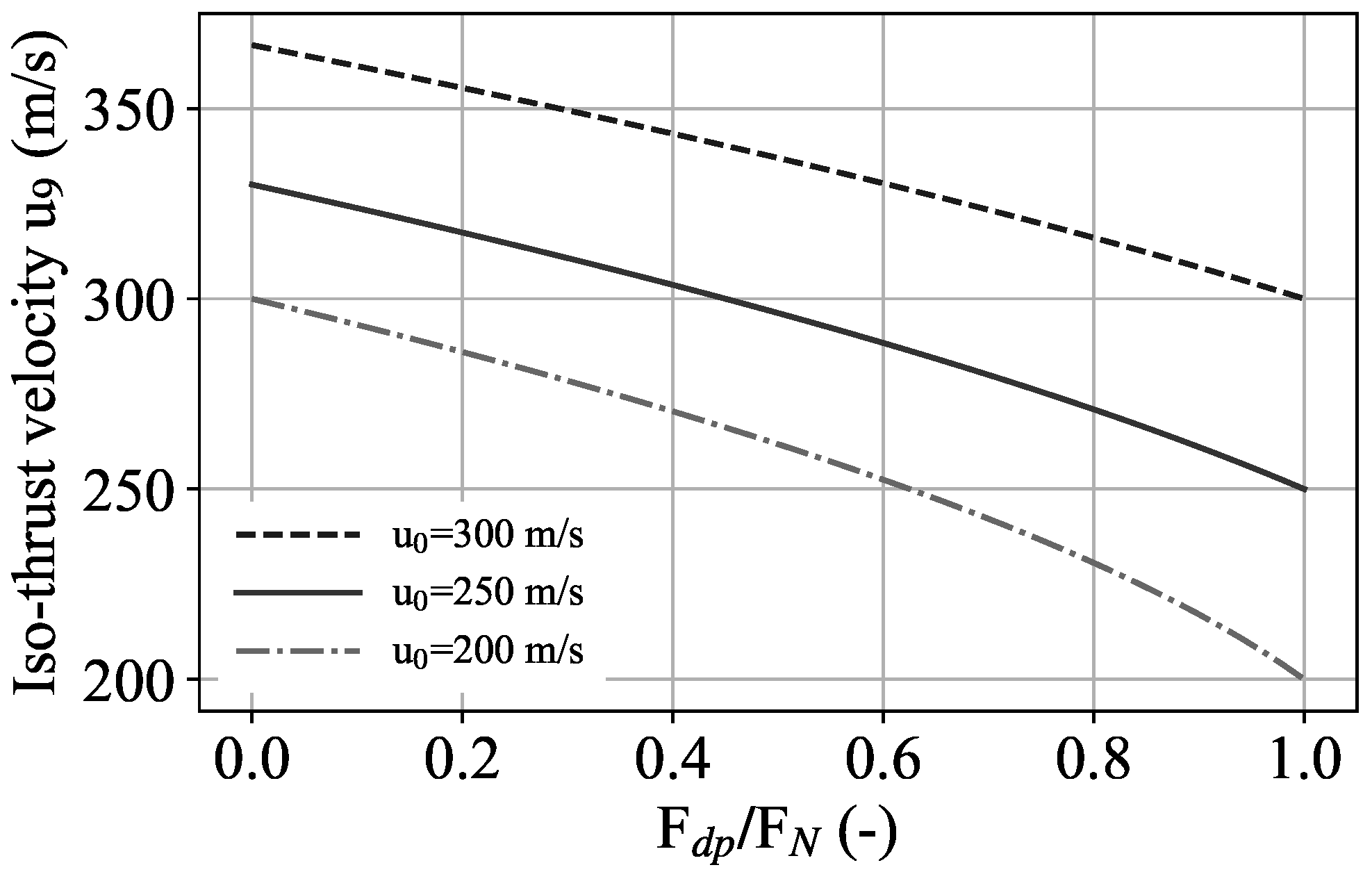

2.4.3. Ideal Propulsive Efficiency

2.4.4. Overall Efficiency

2.4.5. Pseudo and Effective Efficiency

3. Results and Discussion

3.1. Conceptual Design

3.1.1. Design Rationale

3.1.2. Sensitivity Studies

Blades-On/Blades-Off Simulations and Force Contribution Breakdown

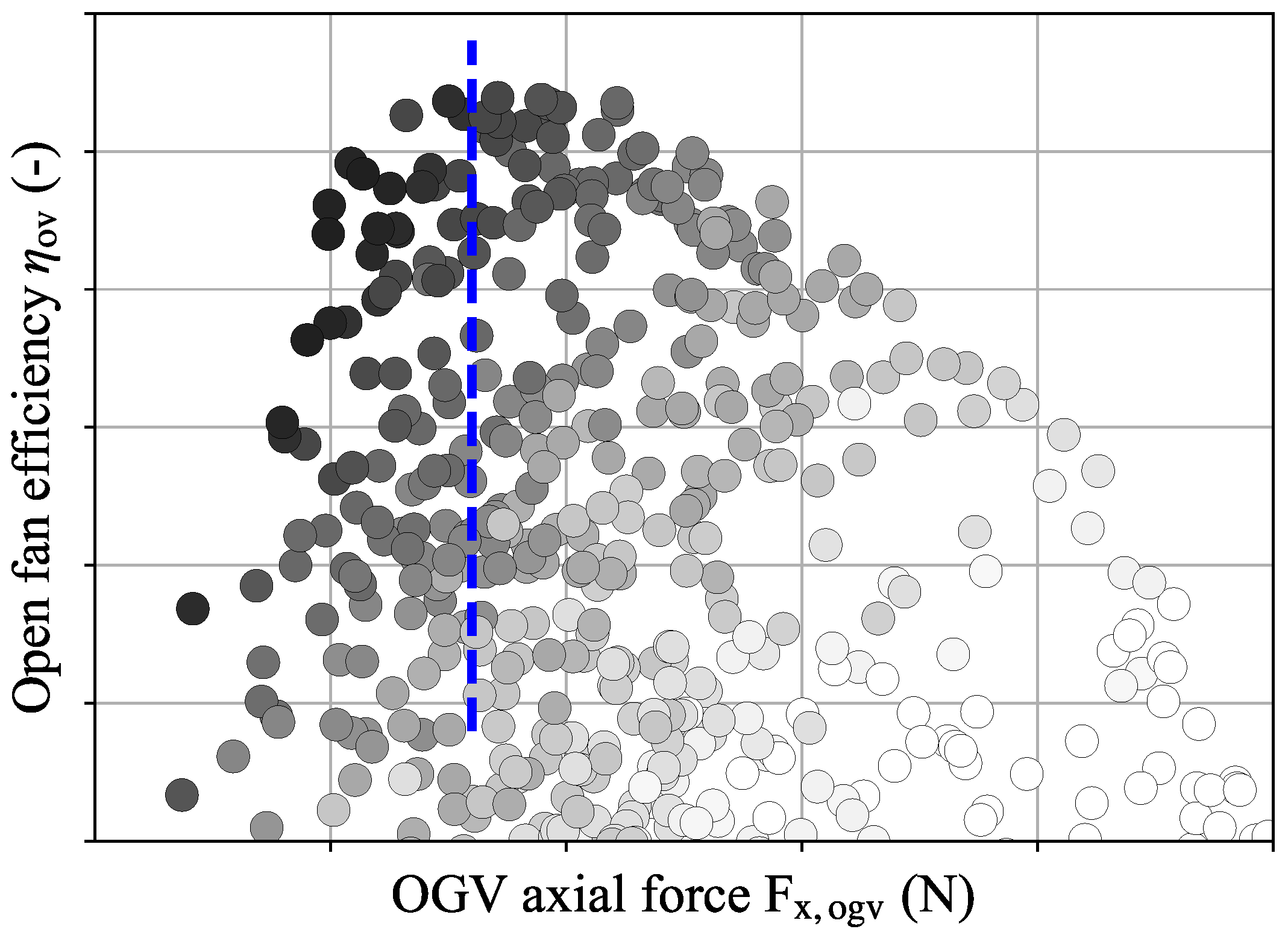

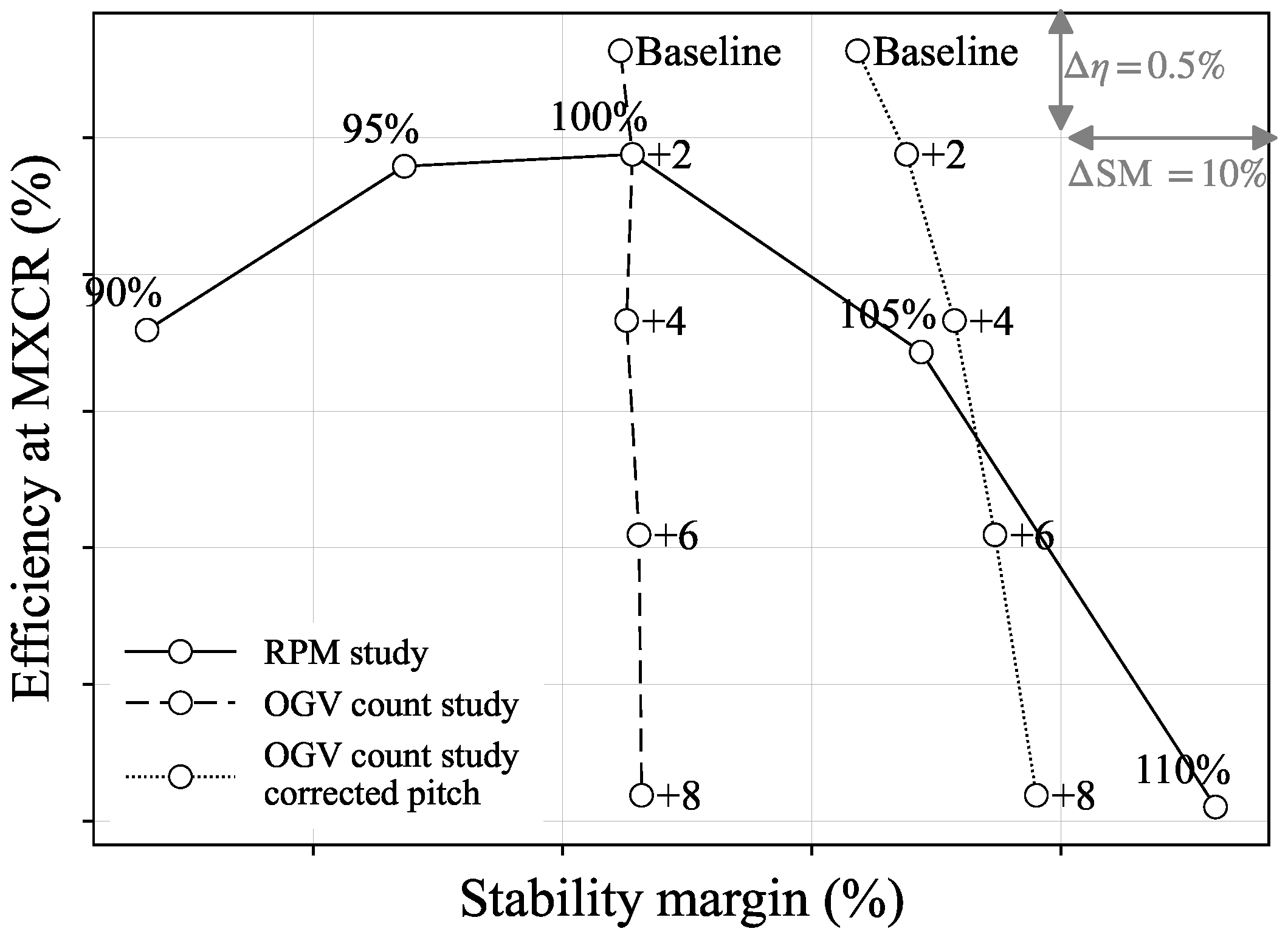

Stability–Efficiency Trade-Off

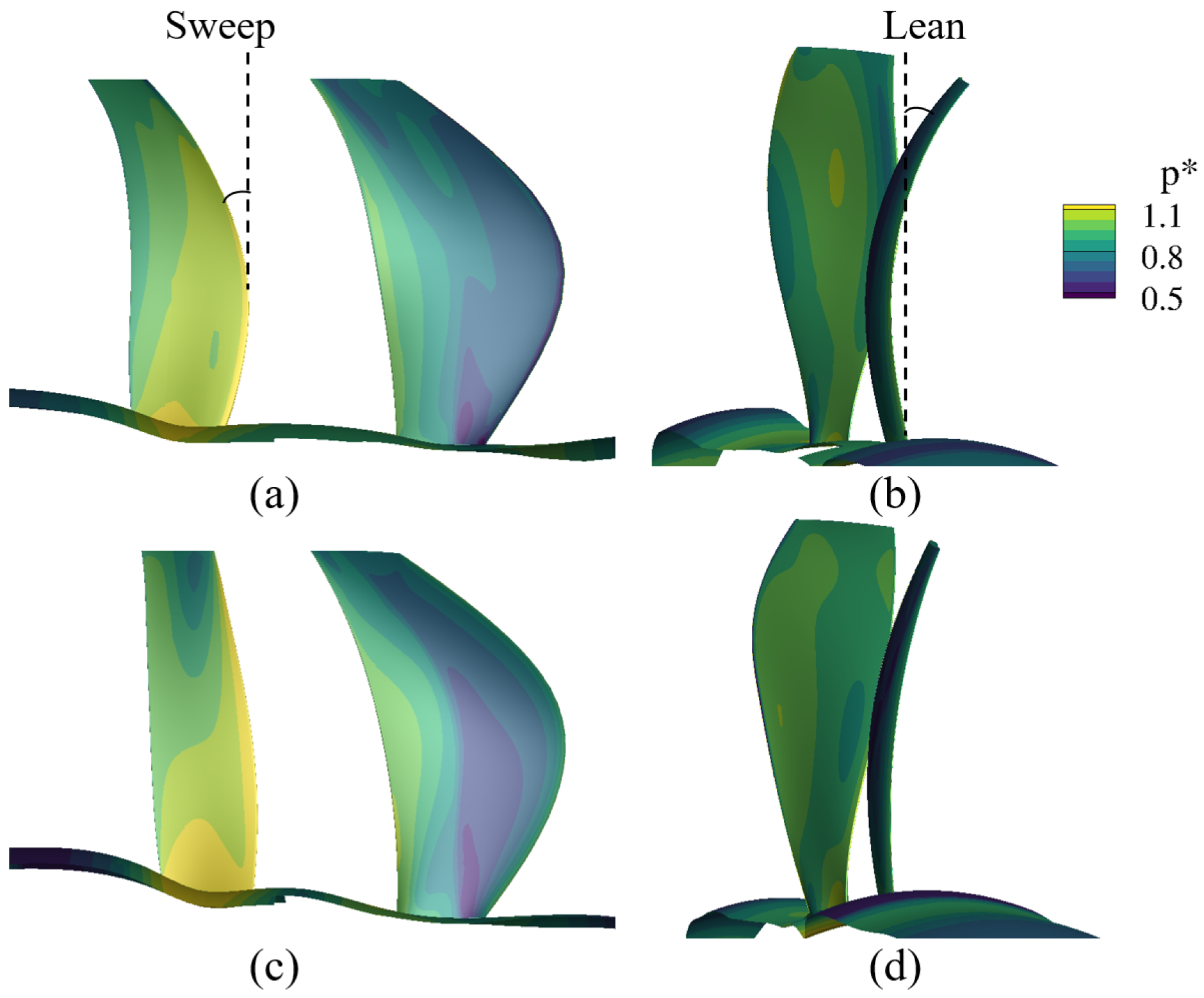

Lean, Sweep, and Chord Variation

3.2. Performance Characterisation and Operability

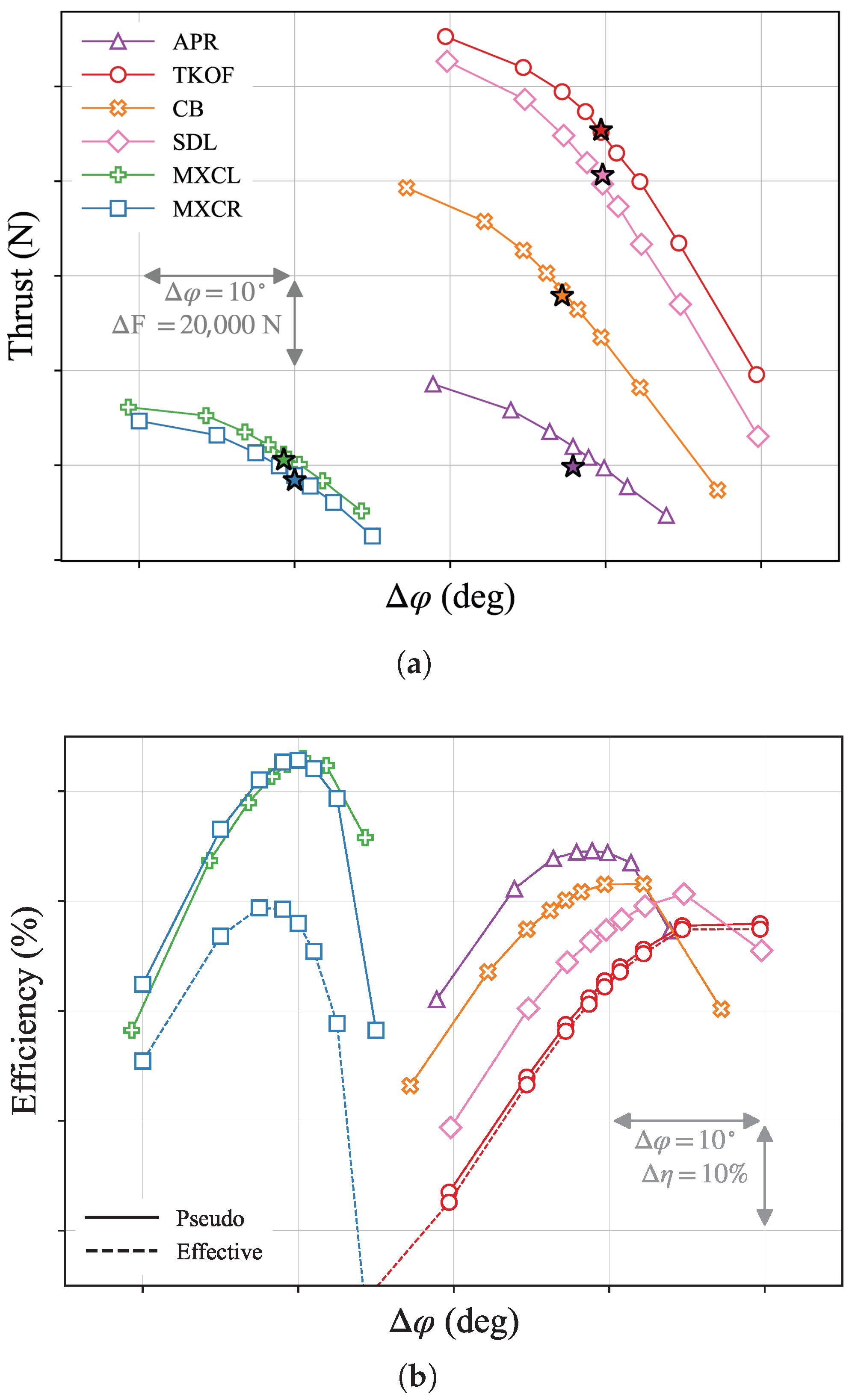

3.2.1. Performance Characteristics

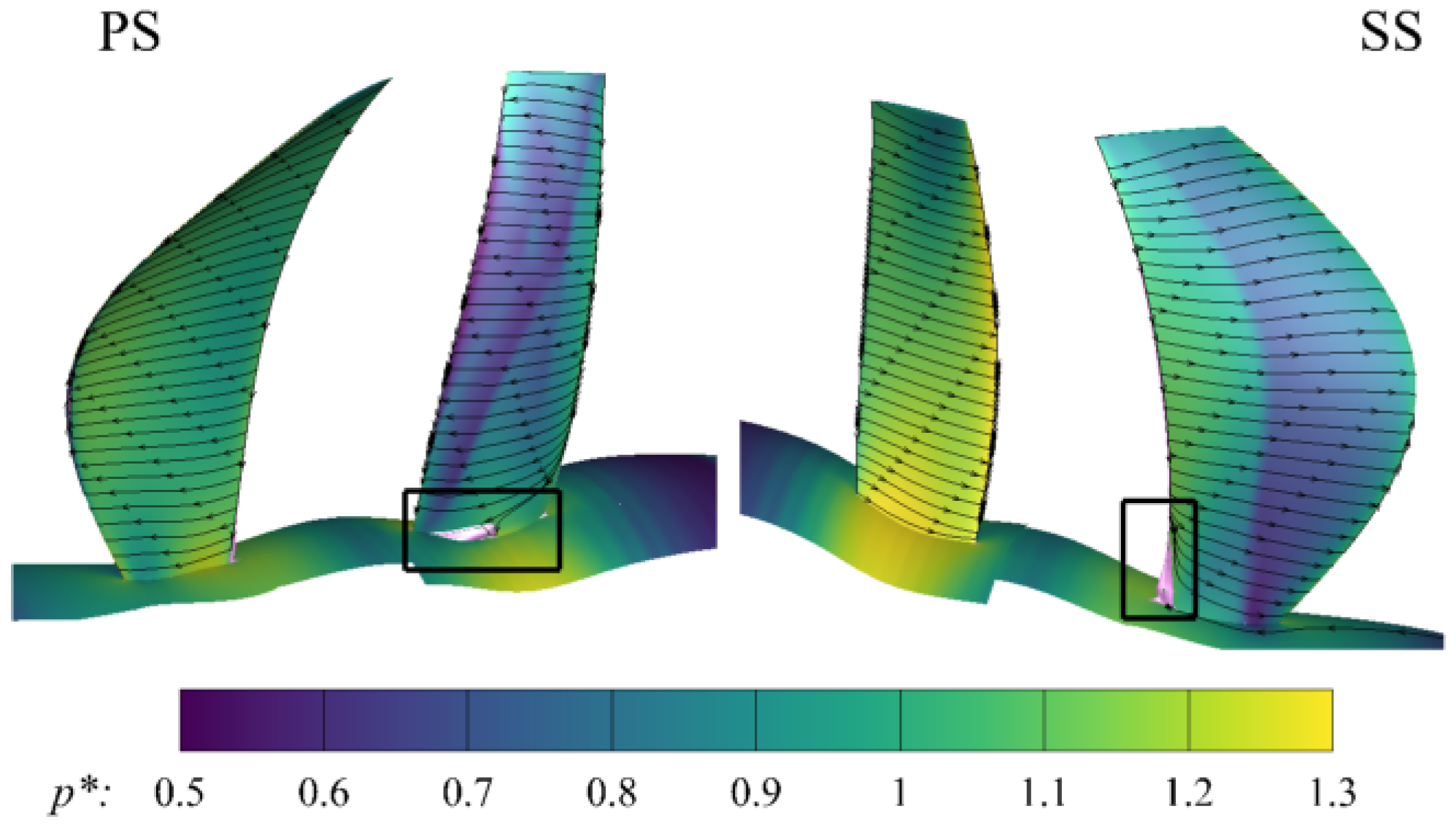

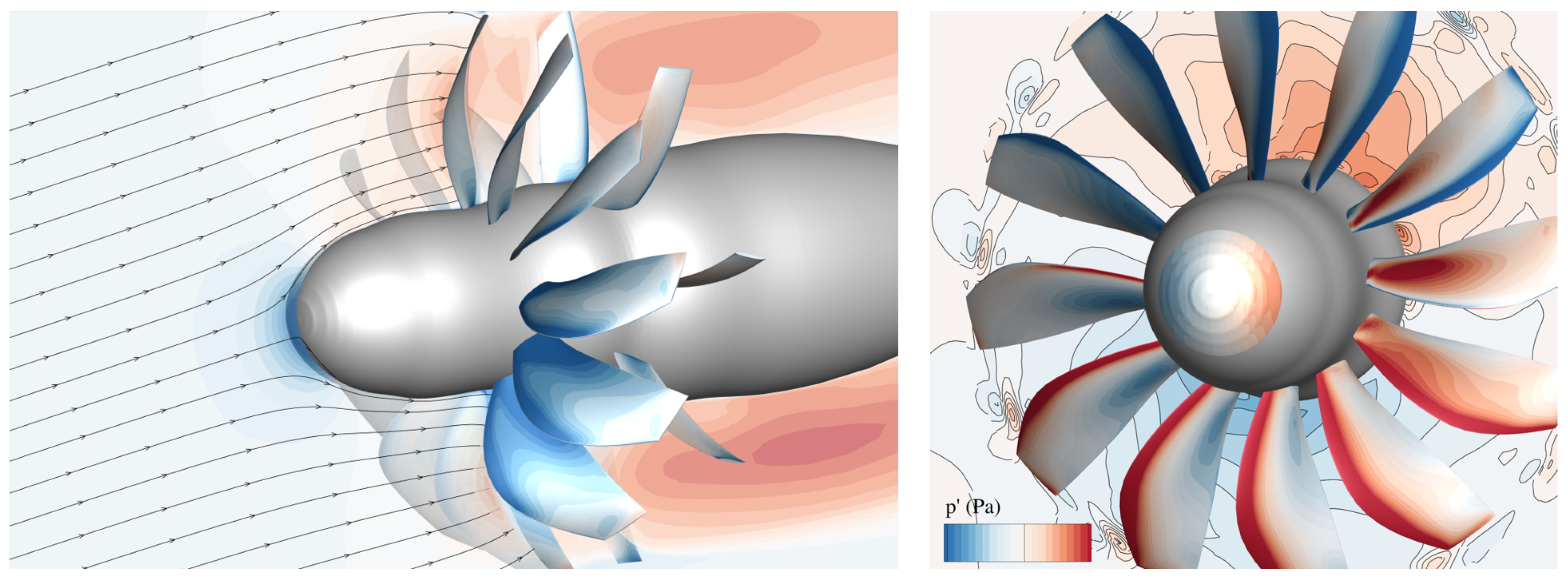

3.2.2. Flow Field

3.3. Unsteady Effects

3.3.1. Harmonic Balance

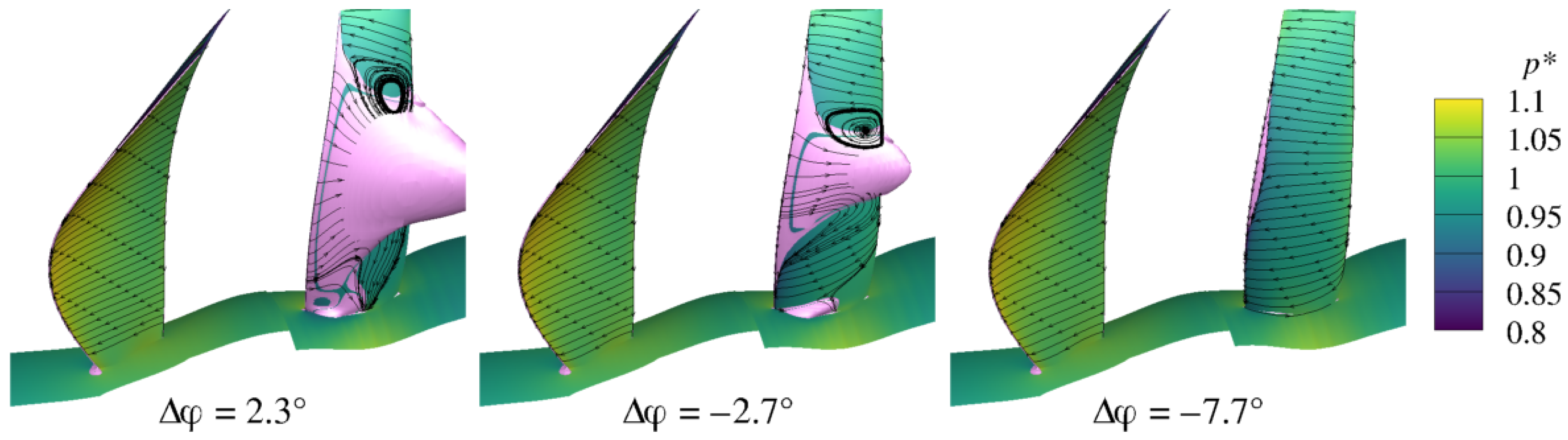

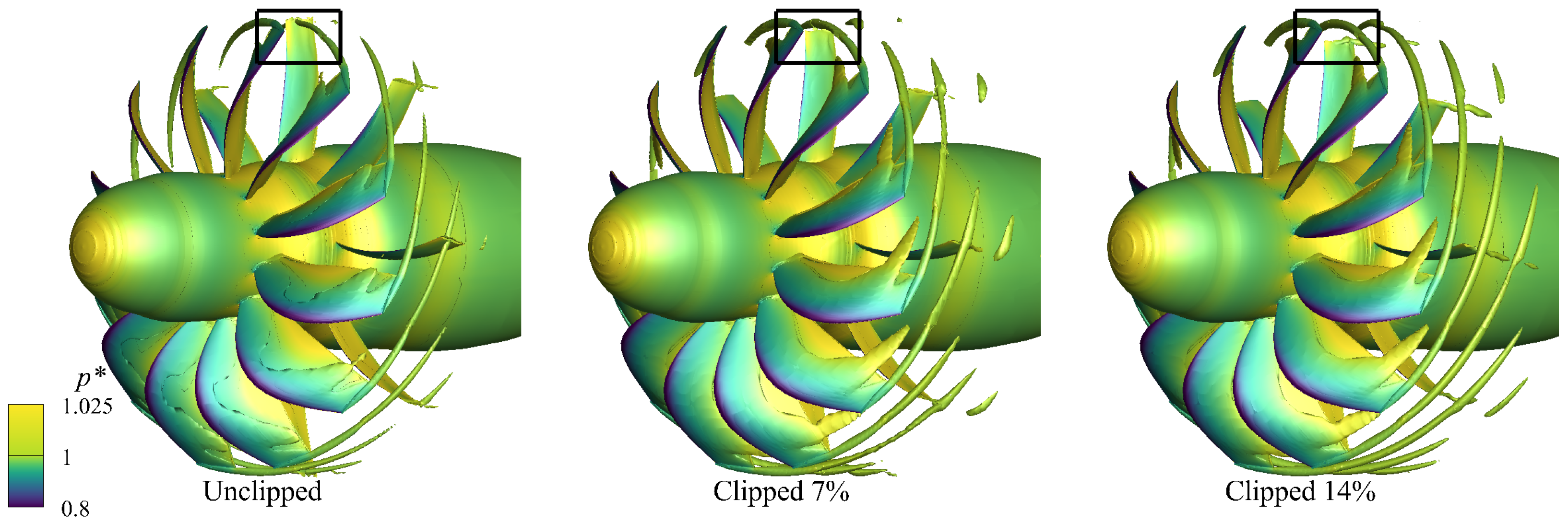

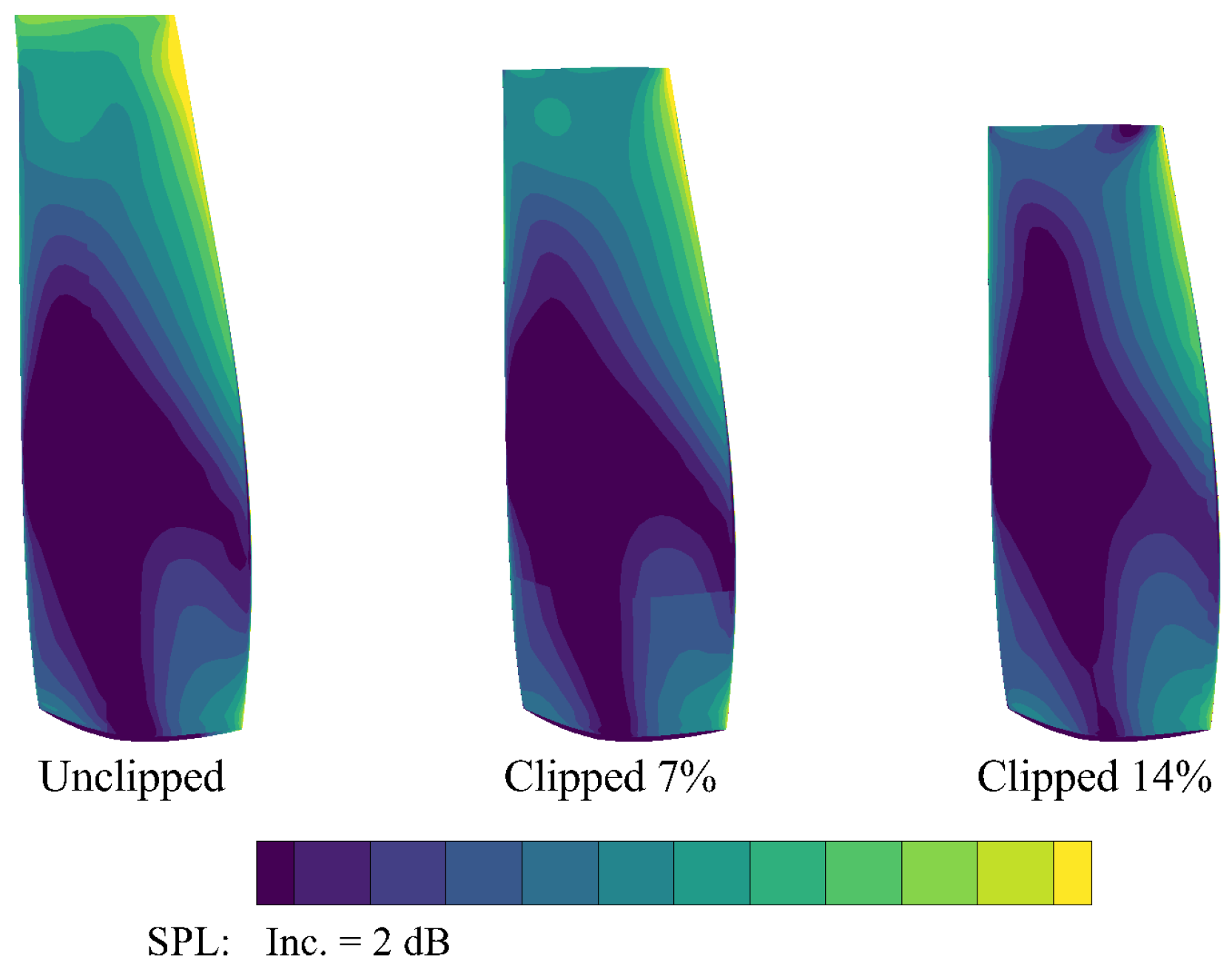

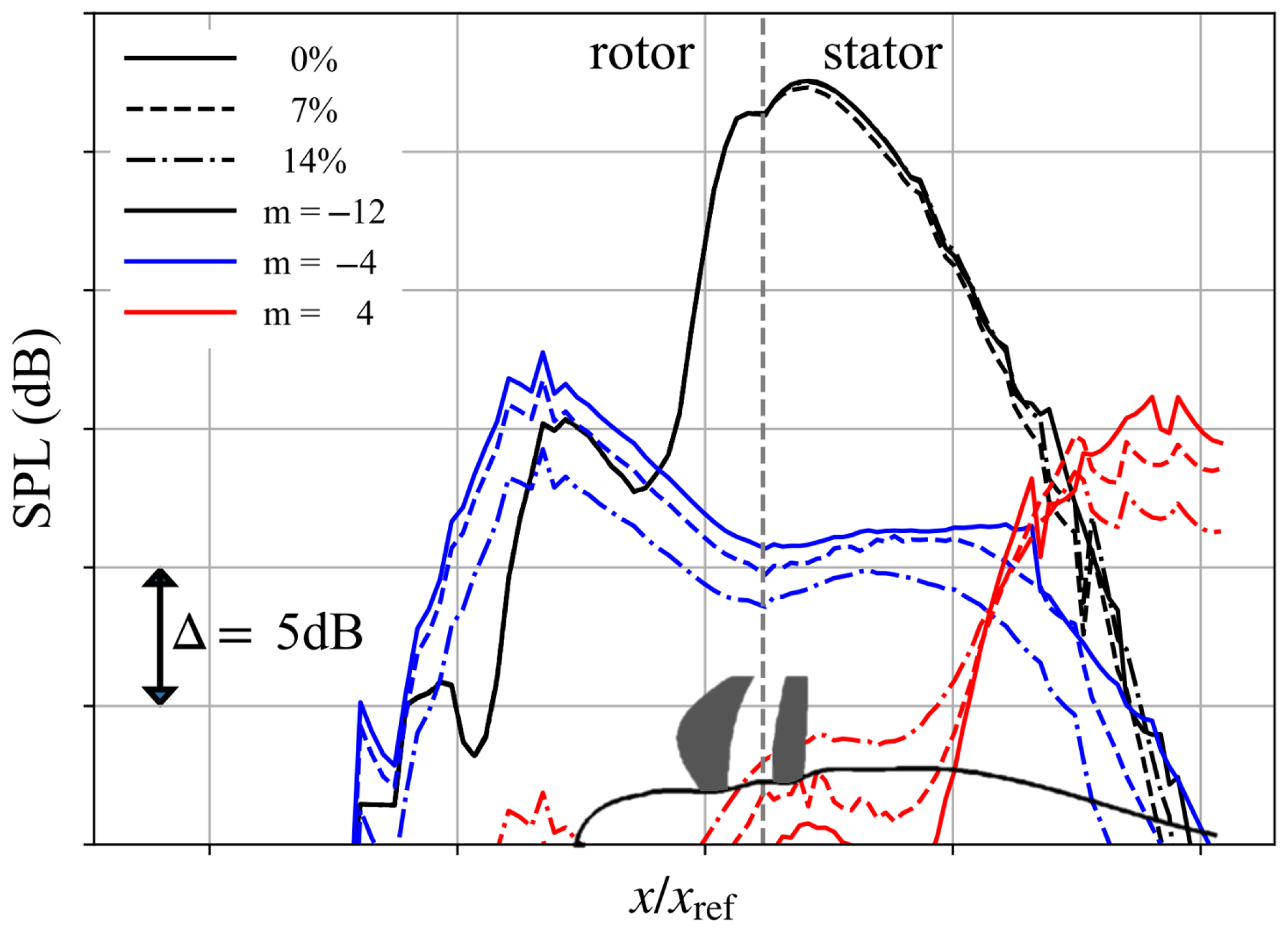

3.3.2. Acoustic Characterisation and Clipping Effects

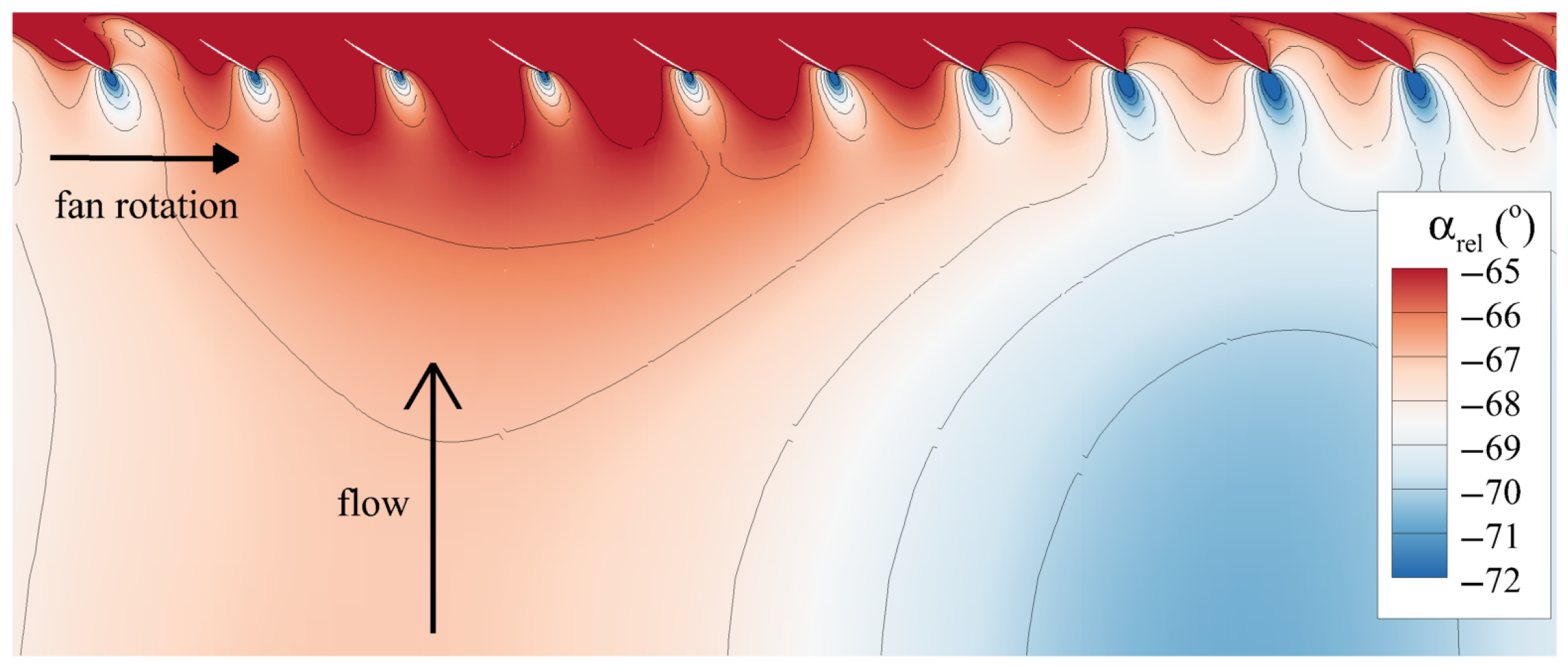

3.3.3. Angle-of-Attack

4. Conclusions

- The propeller efficiency over characteristics from original Wald’s theory [20], although being derived with a number of simplifications and for incompressible flows, has been reproduced by a series of RANS-based design optimisations, and hence can be useful in the given high-transonic and compressible flight regime to support the conceptual design of the open fan.

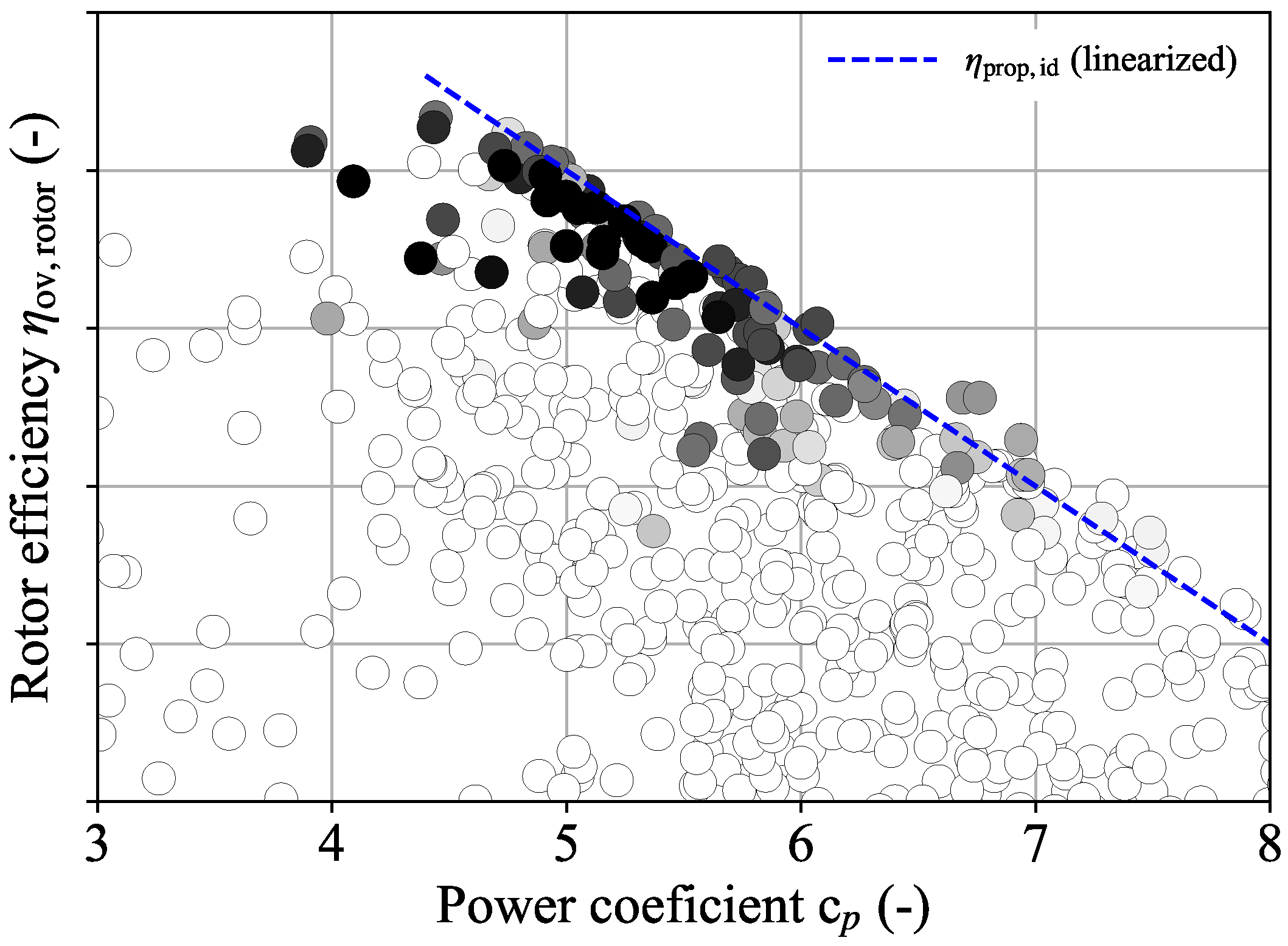

- The effectiveness of the guide vane grows with increasing rotor power coefficient due to the higher amount of swirl that can be recovered. This can be quantified by the divergence of the swirl-free propulsive efficiency and classical rotor propeller efficiency. However, the latter decreases more rapidly with increasing rotor power coefficient; hence, the overall efficiency of the open fan drops towards higher values of . Therefore, low values of rotor are favourable, reducing the effectiveness of the vane and limited by the loss levels in the vanes, rendering the guide vane less effective. This requires for a very careful selection of rotor and an accurate quantification of guide vane loss levels.

- The different sensitivity studies allowed the analysis of the impact of different design parameters key to the aerodynamics performance such as hub effects; stability margin; and geometrical variables, like sweep and lean angle. A positive outcome was obtained by adding together the results of the separate studies into the design, leading to a viable open rotor configuration.

- The generated drag due to the hub contributes approximately 10% to the total thrust, similarly to the thrust contribution of the stator. Therefore, the hub forces need to be included in the efficiency computation to have consistent performance and steer the design correctly. Additionally, the blades have an impact on the hub line forces generated, resulting in the production of 2.5% less drag in its overall contribution to the total thrust compared to the blades-off simulation.

- It is possible to gain an approximately 10% stability margin with an increment of 5% of the RPM, sacrificing less than 1% in efficiency for the MXCR condition for the range of stability margin between 10 and 25%. The increment of OGV count does not impact as significantly to the stability margin as the increment in RPM.

- A 14% clipping of the OGV represents a loss of 0.75% in efficiency, whereas with a 7%, the loss is around 0.25% and it already avoids the rotor vortices interaction. However, when looking further from the blades, the 14% clipping presents the best decrease in acoustic impact, whereas the mid-value clipping does not show a significant reduction.

- The use of the harmonic balance solver with a coarse mesh gives results good enough to see the tendencies of the rotor-stator interaction and also dynamic forcing under angle-of-attack conditions. For the iterative design process, it is a viable option; however, a finer grid is necessary to validate the final design, and therefore further studies on acoustics are needed to fully determine the acoustic impact.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Latin symbols | |||

| power coefficient | thrust coefficient | ||

| T | thrust or axial force | P | shaft power |

| p | static pressure | u | axial velocity |

| Greek symbols | |||

| angle-of-attack | relative inflow angle | ||

| efficiency | fluid density | ||

| pitch | |||

| Subscripts | |||

| ∞ | free stream values | 9 | exit |

| ax, x | axial | dp | pressure force |

| h | hub | id | ideal |

| ov | overall | prop | propulsive |

| ref | reference value | trans | transfer |

| Superscripts | |||

| ’ | perturbation | * | normalised quantity |

| Acronyms | |||

| APR | approach | CB | cutback |

| CFD | computational fluid dynamics | FPR | fan pressure ratio |

| LE | leading edge | MXCL | maximum climb |

| MXCR | maximum cruise | OGV | outlet guided vane |

| PS | pressure side | SDL | sideline |

| SS | suction side | TE | trailing edge |

| TKOF | take-off |

References

- Degeorge, C.L. Large-Scale Advanced Prop-Fan (LAP) Technology Assessment Report; Tech Rep. NASA-CR-1882142; NASA: Cleveland, OH, USA, 1988. [Google Scholar]

- Mitchell, G.; Mikkelson, D. Summary and recent results from the NASA advanced high-speed propeller research program. In Proceedings of the 18th Joint Propulsion Conference, Cleveland, OH, USA, 21–23 June 1982. [Google Scholar]

- Groeneweg, J.F.; Bober, L.J. NASA Advanced Propeller Research; Tech Rep.; NASA: Cleveland, OH, USA, 1988; p. 101361. [Google Scholar]

- Baum, J.A.; Dumais, P.J.; Mayo, M.G.; Metzger, F.B.; Shenkman, A.M.; Walker, G.G. Prop-Fan Data Support Study; Tech Rep. NASA-CR-152141; NASA: Mountain View, CA, USA, 1978. [Google Scholar]

- Daydé-Thomas, V.; Polacsek, C.; Gloerfelt, X.; Sugiyama, M.; Mardjono, J. Tone noise prediction of an open-fan engine using a source-mode integral formulation. In Proceedings of the Forum Acousticum, Turin, Italy, 11–15 September 2023. [Google Scholar]

- Dittmar, J.H.; Hall, D.G. Cruise Noise of an Advanced Propeller with Swirl Recovery Vanes. J. Aircr. 1993, 30, 221–226. [Google Scholar] [CrossRef]

- Stokkermans, T.; van Arnhem, N.; Veldhuis, L. Mitigation of propeller kinetic energy losses with boundary layer ingestion and swirl recovery vanes. In Proceedings of the Applied Aerodynamics Research Conference, London, UK, 13–17 July 2016. [Google Scholar]

- Van Zante, D.E. Progress in Open Rotor Research: A U.S. Perspective. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition. Volume 1: Aircraft Engine; Fans and Blowers; Marine, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Khalid, S.A.; Lurie, D.; Breeze-Stringfellow, A.; Wood, T.; Ramakrishnan, K.; Paliath, U.; Wojno, J.; Janardan, B.; Goerig, T.; Opalski, A.; et al. Open Rotor Engine Aeroacoustic Techology Final Report; Tech Rep. DOT/FAA/AEE/2014-04; General Electric Company: Lincoln, NE, USA, 2013. [Google Scholar]

- Schnell, R.; Yin, J.; Voss, C.; Nicke, E. Assessment and Optimization of the Aerodynamic and Acoustic Characteristics of a Counter Rotating Open Rotor. J. Turbomach. 2012, 134, 061016. [Google Scholar] [CrossRef]

- Tantot, N.; Giannakakis, P.; Yesilcimen, H.; Binder, A. A performance modelling approach to open fan propeller module. In Proceedings of the Aerospace Europe Conference 2023—10th EUCASS—9th CEAS, Lausanne, Switzerland, 9–13 July 2023. [Google Scholar]

- Rovira Sala, C.; Dygutsch, T.; Frey, C.; Schnell, R.; Martinez Luque, R. Goals and Strategies for Open Fan Design. In Proceedings of the 16th European Turbomachinery Conference (ETC), paper n. ETC2025-123, Hannover, Germany, 24–28 March 2025. [Google Scholar]

- Becker, K.; Heitkamp, K.; Kügeler, E. Recent Progress In A Hybrid-Grid CFD Solver For Turbomachinery Flows. In Proceedings of the Fifth European Conference on Computational Fluid Dynamics(ECCOMAS CFD), Lisbon, Portugal, 14–17 June 2010. [Google Scholar]

- Wilcox, D.C. Reassessment of the scale-determining equation for advanced turbulence models. AIAA J. 1988, 26, 1299–1310. [Google Scholar] [CrossRef]

- Spalding, D.B. A Single Formula for the “Law of the Wall”. J. Appl. Mech. 1961, 28, 455–458. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Voß, C.; Aulich, M.; Kaplan, B.; Nicke, E. Automated Multiobjective Optimisation in Axial Compressor Blade Design. In Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air. Volume 6: Turbomachinery, Parts A and B, Barcelona, Spain, 8–11 May 2006. [Google Scholar]

- Schnell, R.; Mennicken, M. Unified Assessment of Open and Ducted Propulsors. Aerospace 2024, 11, 1002. [Google Scholar] [CrossRef]

- Drela, M. Power Balance in Aerodynamic Flows. AIAA J. 2009, 47, 1761–1771. [Google Scholar] [CrossRef]

- Wald, Q.R. The aerodynamics of propellers. Prog. Aerosp. Sci. 2006, 42, 85–128. [Google Scholar] [CrossRef]

- Giannakakis, P.; Goulos, I.; Laskaridis, P.; Pilidis, P.; Kalfas, A.I. Novel Propeller Map Scaling Method. J. Propuls. Power 2016, 32, 1325–1332. [Google Scholar] [CrossRef]

- Schnoes, M.; Voß, C.; Nicke, E. Design optimization of a multi-stage axial compressor using throughflow and a database of optimal airfoils. J. Glob. Power Propuls. Soc. 2018, 2, 516–528. [Google Scholar] [CrossRef]

- Hall, K.C.; Thomas, J.P.; Clark, W.S. Computation of Unsteady Nonlinear Flows in Cascades Using a Harmonic Balance Technique. AIAA J. 2002, 40, 879–886. [Google Scholar] [CrossRef]

- Frey, C.; Ashcroft, G.; Kersken, H.; Voigt, C. A Harmonic Balance Technique for Multistage Turbomachinery Applications. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. Volume 2B: Turbomachinery, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Junge, L.; Frey, C.; Ashcroft, G.; Kügeler, E. A New Harmonic Balance Approach Using Multidimensional Time. J. Eng. Gas Turbines Power 2021, 143, 081007. [Google Scholar] [CrossRef]

- Junge, L.; Frey, C.; Ashcroft, G.; Kügeler, E. Simulation of Indexing and Clocking with a New Multidimensional Time Harmonic Balance Approach. Int. J. Turbomach. Propuls. Power 2024, 9, 17. [Google Scholar] [CrossRef]

- Jang, J.S.; Choi, S.; Kwon, H.I.; Im, D.K.; Lee, D.J.; Kwon, J.H. A Preliminary Study of Open Rotor Design Using a Harmonic Balance Method. In Proceedings of the 50th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Nashvielle, TN, USA, 9–12 January 2012. [Google Scholar]

- Kwon, H.I.; Yi, S.G.; Choi, S.; Lee, D.J.; Kwon, J.H.; Im, D.K. Design of a Low-Noise Open Rotor Using an Implicit Harmonic Balance Method. In Proceedings of the 51th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the EUROTURBO. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Rovira Sala, C.; Dygutsch, T.; Frey, C.; Schnell, R.; Martinez Luque, R. Goals and Strategies for Open Fan Design. Int. J. Turbomach. Propuls. Power 2025, 10, 28. https://doi.org/10.3390/ijtpp10030028

Rovira Sala C, Dygutsch T, Frey C, Schnell R, Martinez Luque R. Goals and Strategies for Open Fan Design. International Journal of Turbomachinery, Propulsion and Power. 2025; 10(3):28. https://doi.org/10.3390/ijtpp10030028

Chicago/Turabian StyleRovira Sala, Carola, Thomas Dygutsch, Christian Frey, Rainer Schnell, and Raul Martinez Luque. 2025. "Goals and Strategies for Open Fan Design" International Journal of Turbomachinery, Propulsion and Power 10, no. 3: 28. https://doi.org/10.3390/ijtpp10030028

APA StyleRovira Sala, C., Dygutsch, T., Frey, C., Schnell, R., & Martinez Luque, R. (2025). Goals and Strategies for Open Fan Design. International Journal of Turbomachinery, Propulsion and Power, 10(3), 28. https://doi.org/10.3390/ijtpp10030028