Validation of an Eddy-Viscosity-Based Roughness Model Using High-Fidelity Simulations †

Abstract

1. Introduction

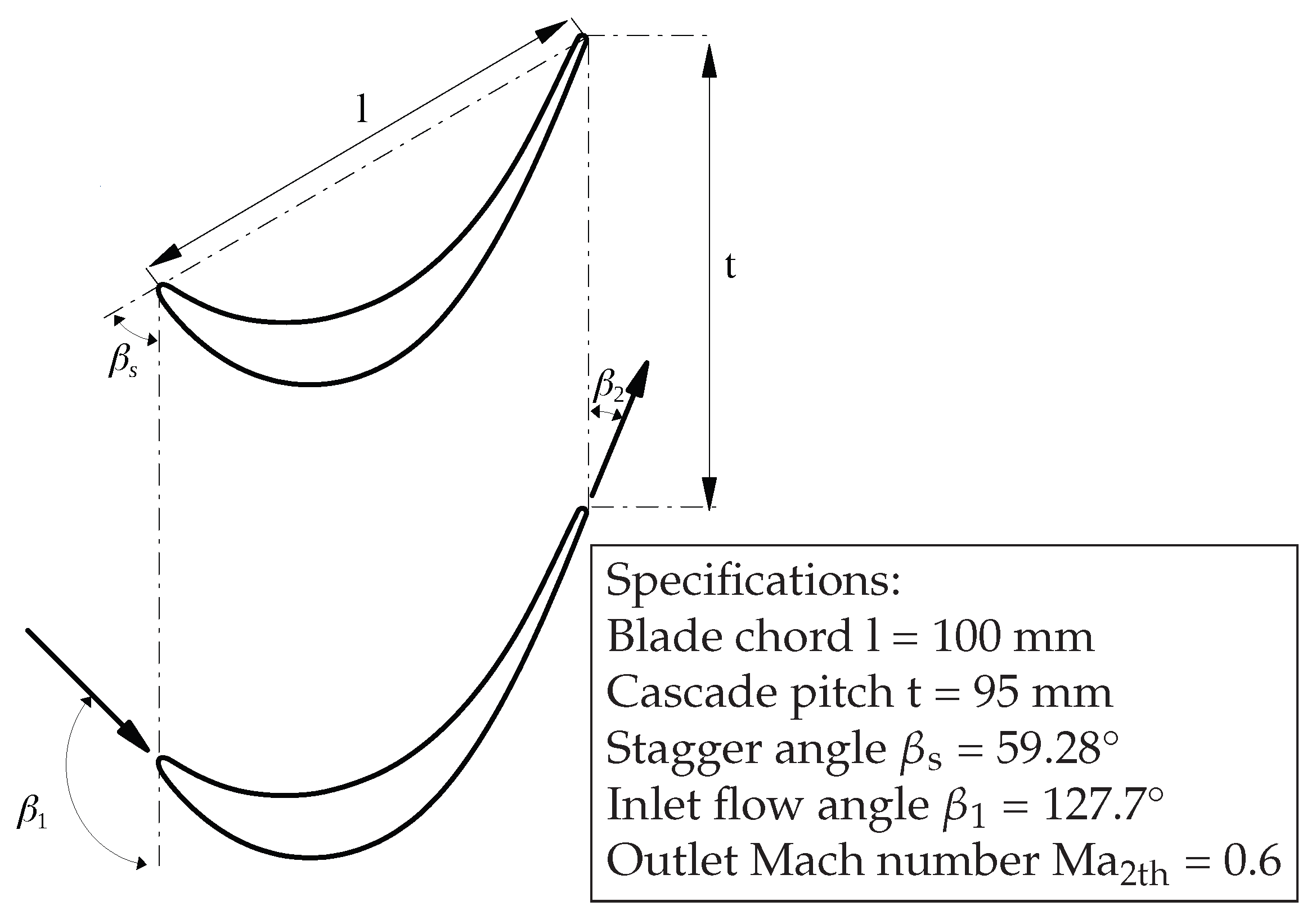

2. Test Case

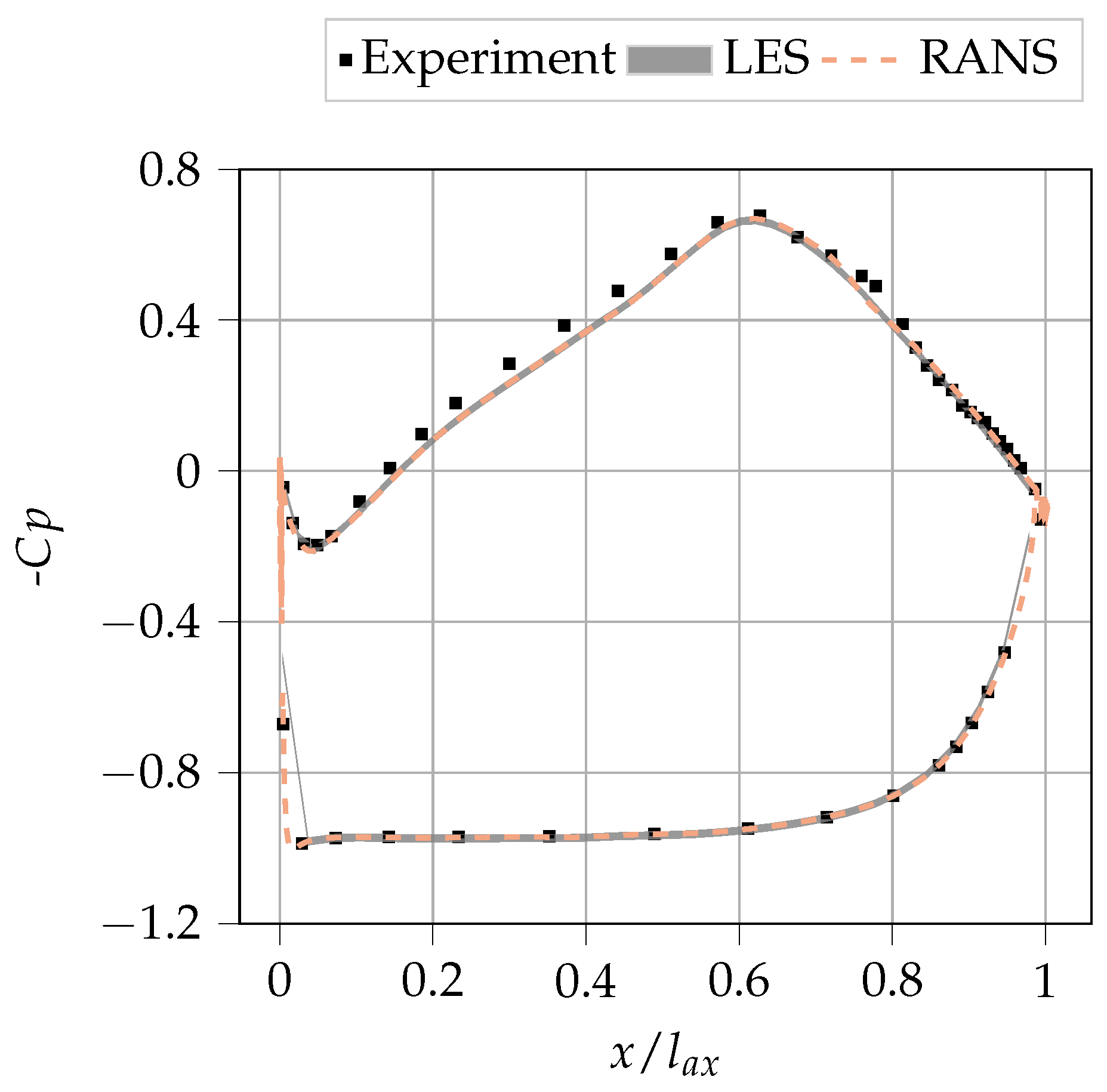

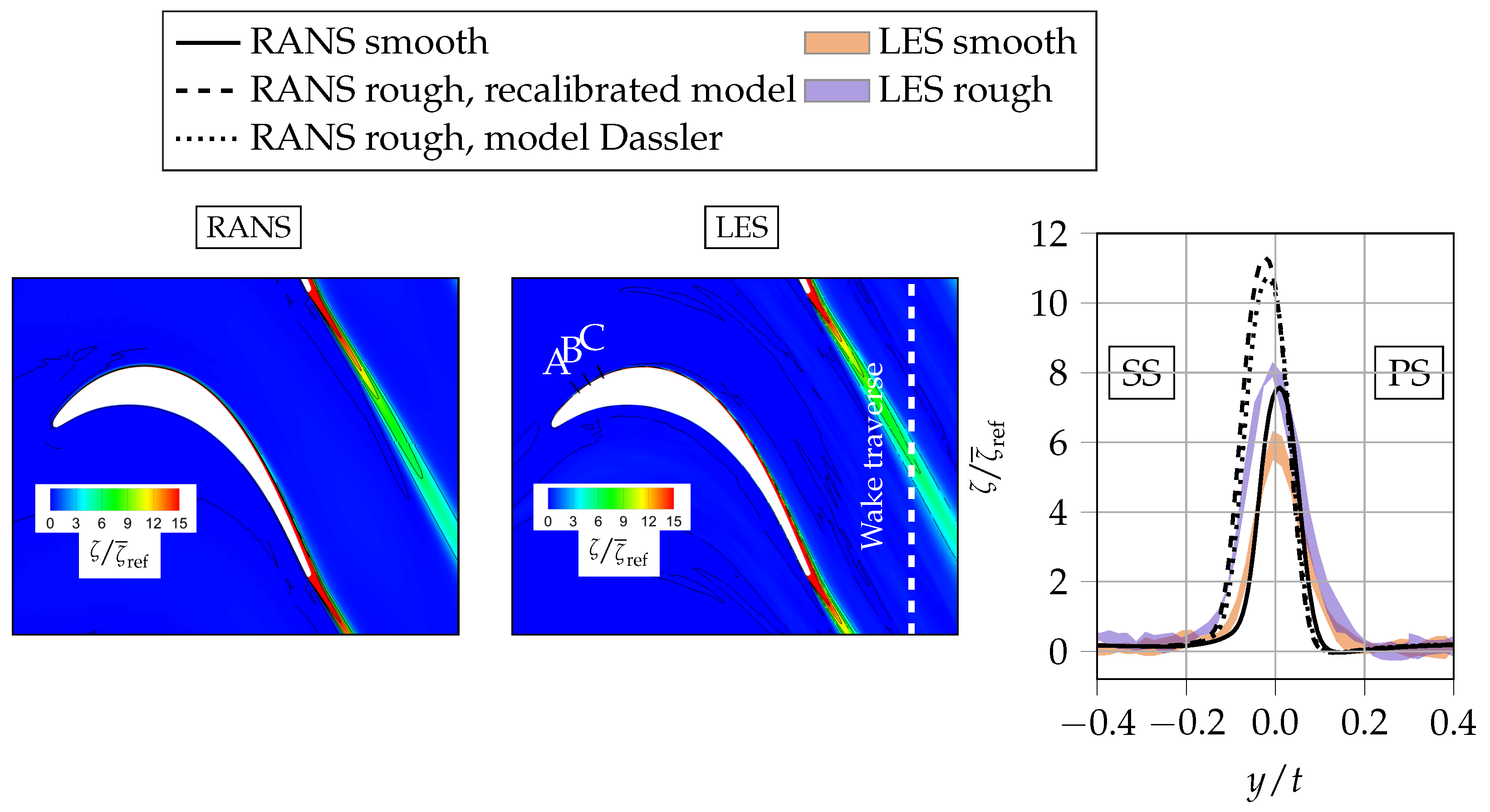

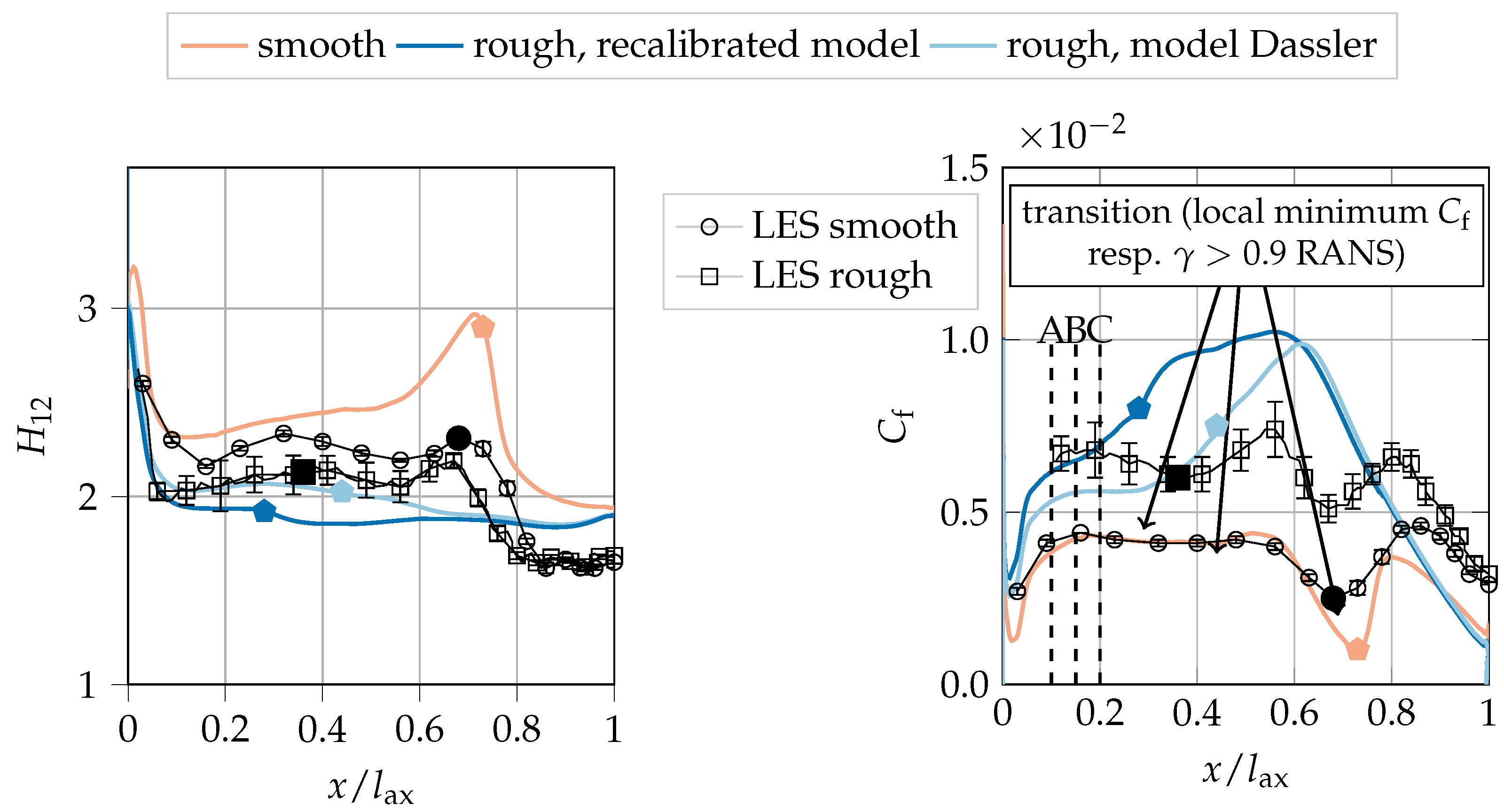

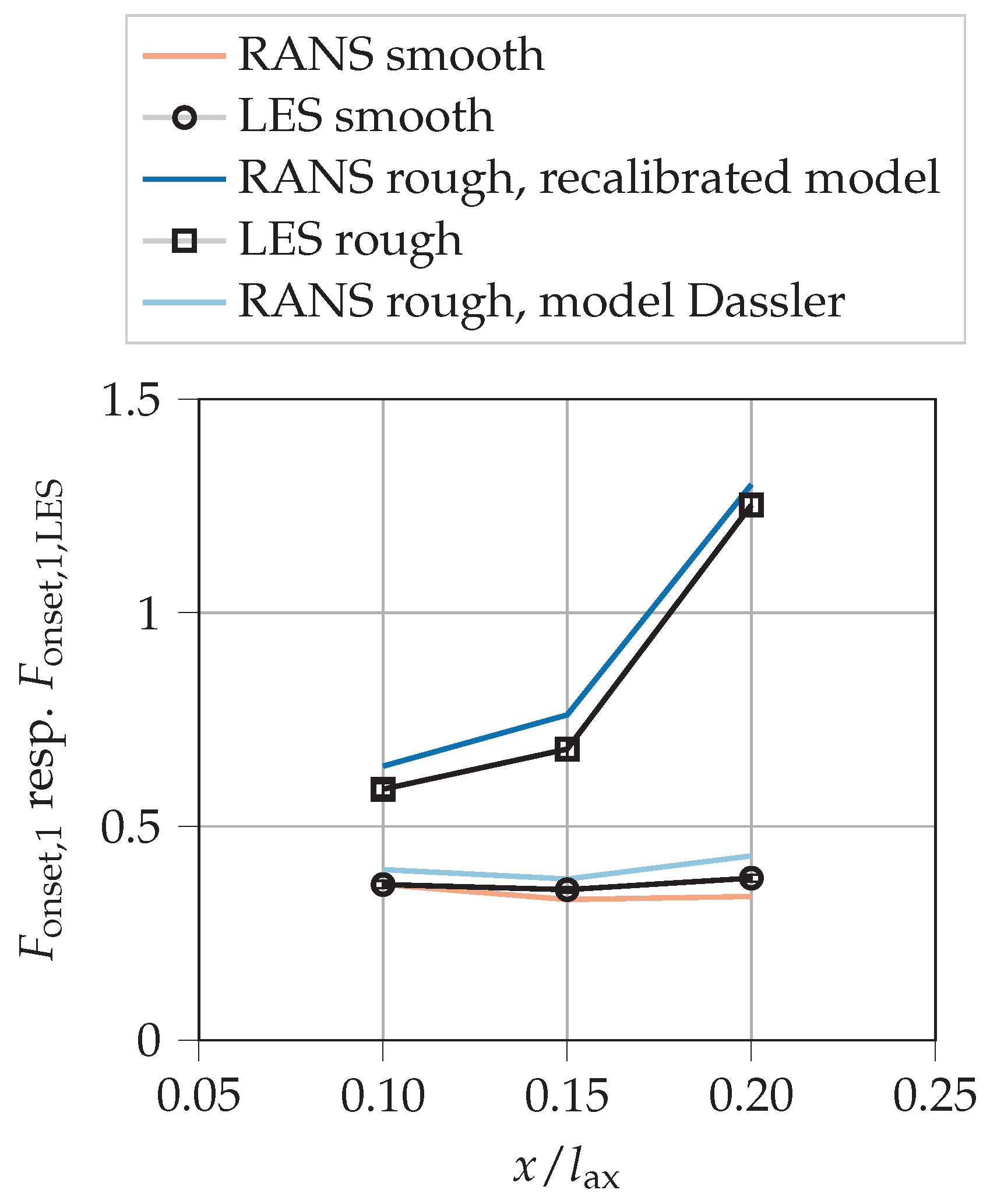

3. Methodology

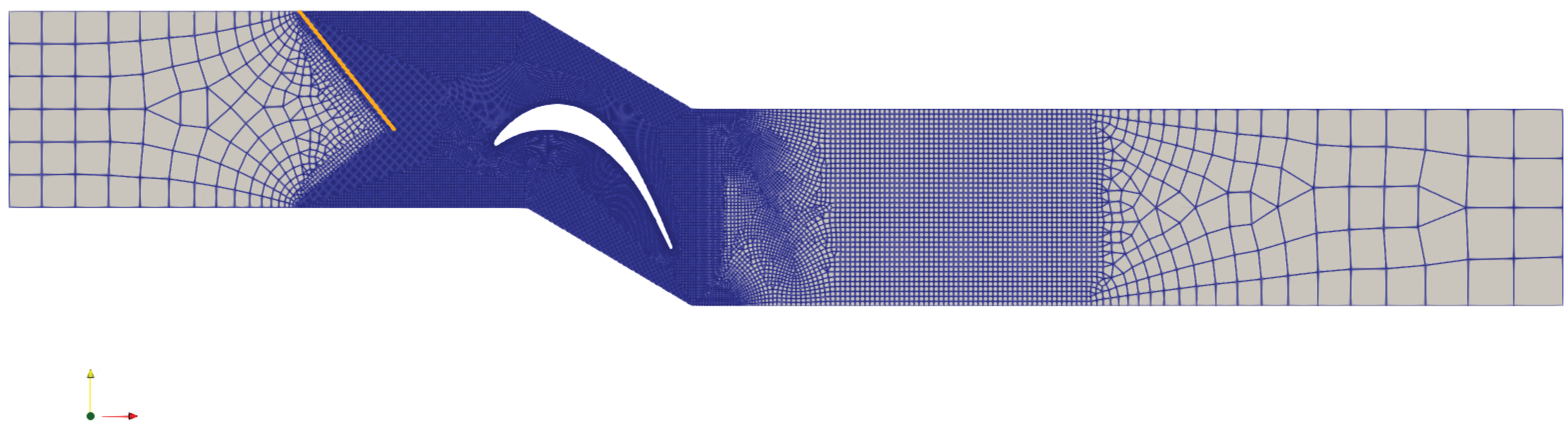

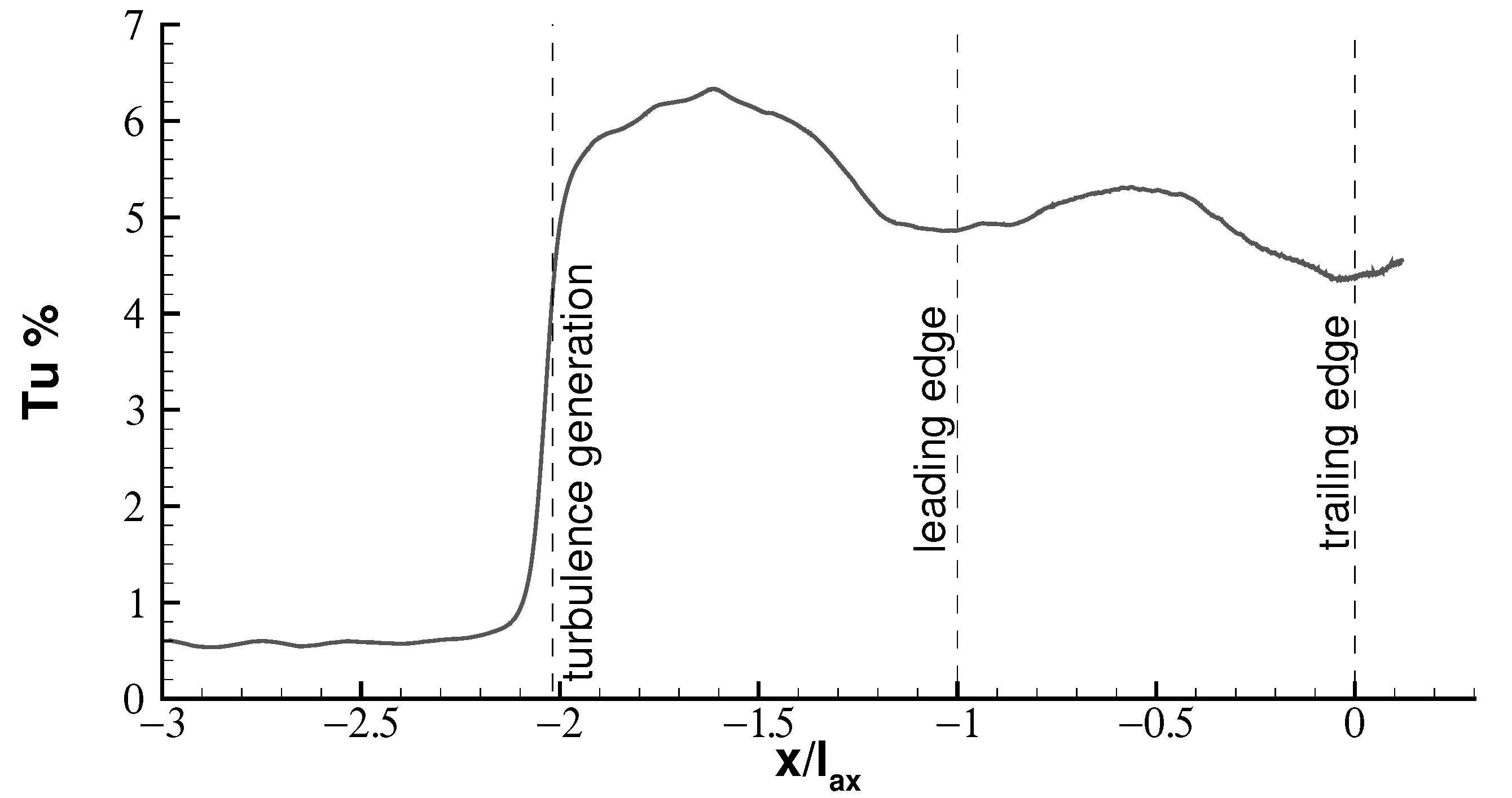

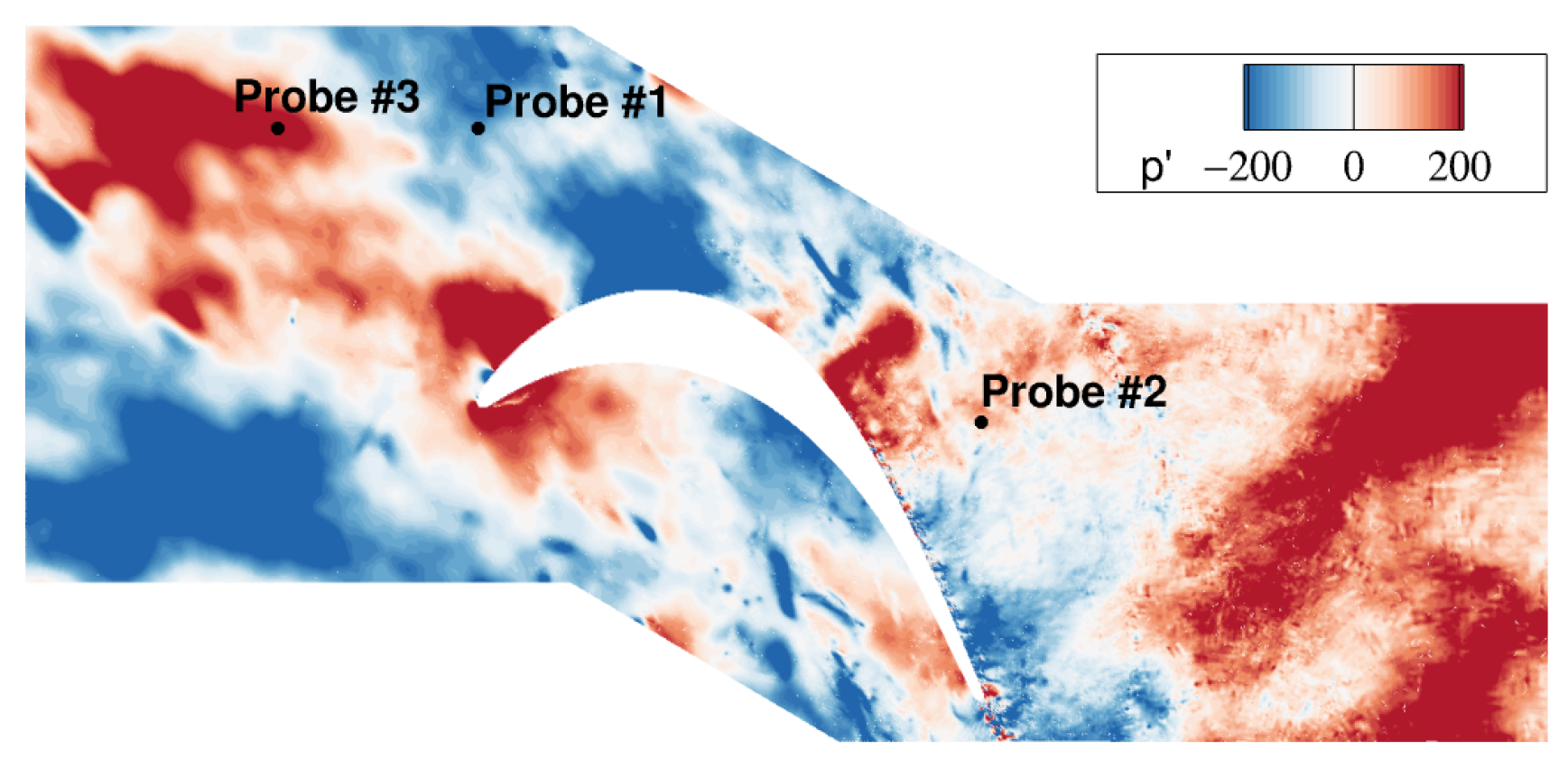

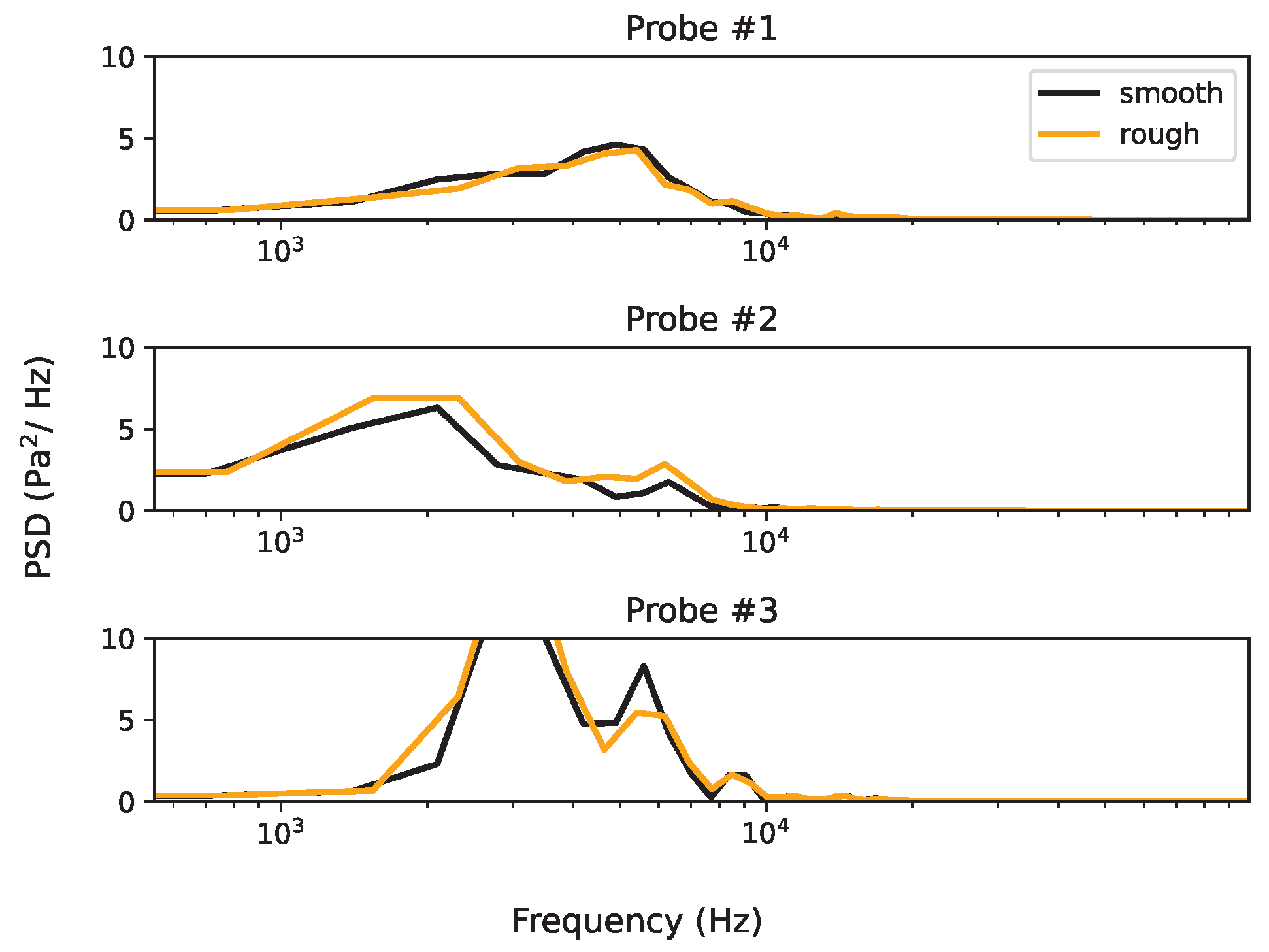

3.1. LES

3.2. RANS

3.3. Proposed Recalibration of the Roughness Model

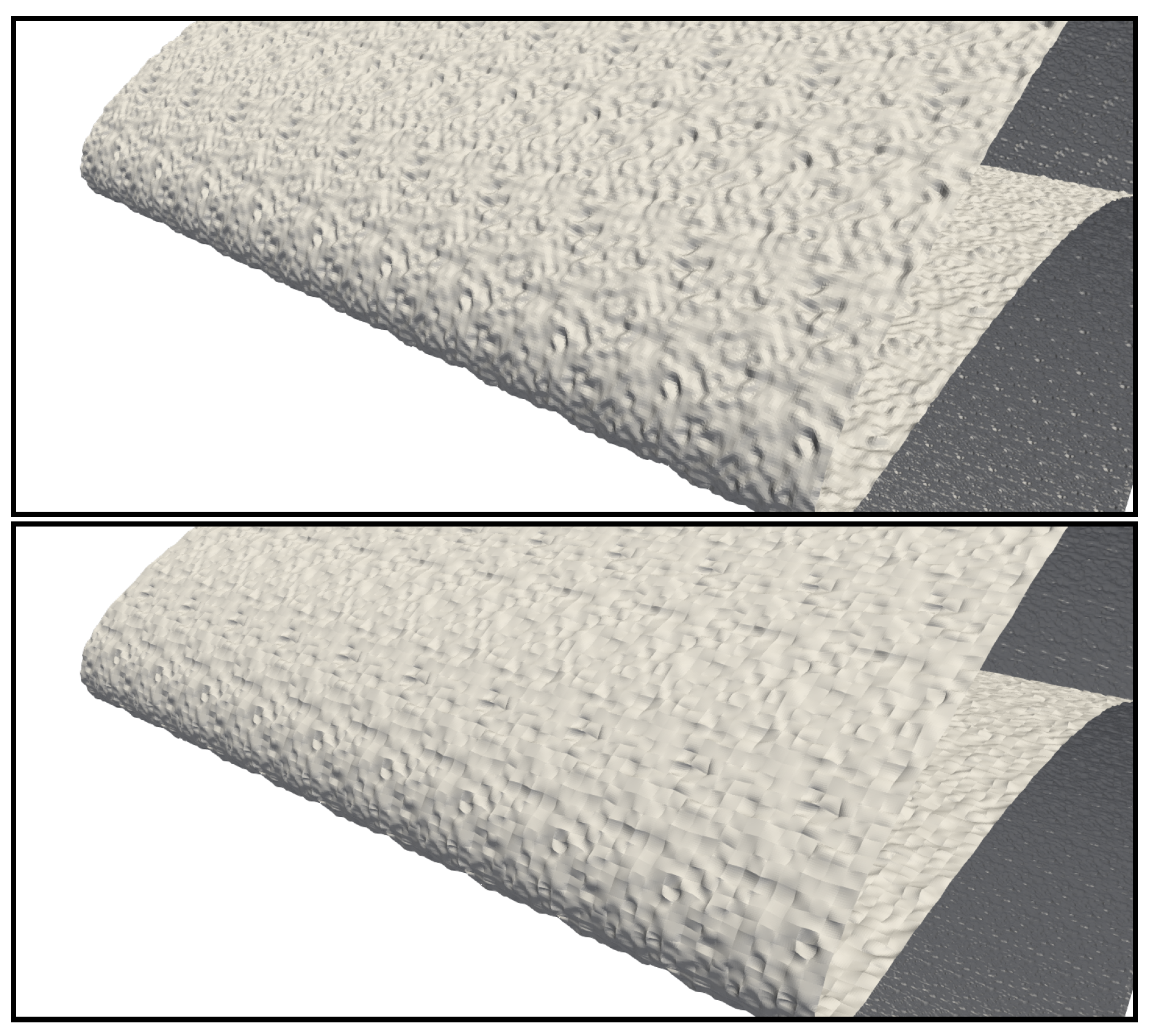

3.4. Surface Roughness

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Amplification roughness | |

| Pressure coefficient, | |

| k | Characteristic roughness height |

| Equivalent sand-grain roughness | |

| Non-dimensional sand-grain roughness, | |

| l | Chord length |

| Ma | Mach number |

| p | Pressure |

| Re | Reynolds number |

| Momentum thickness Re transported scalar | |

| S | Strain rate |

| Area mean roughness height, ( in line measurement) | |

| Area root mean square roughness height, | |

| Skewness of height values, | |

| Area maximum roughness height, ( in line measurement) | |

| Tu | Turbulent intensity |

| t | Cascade pitch |

| Shear velocity, | |

| Non-dimensional wall distance, | |

| Greek symbols | |

| Intermittency | |

| Boundary-layer thickness | |

| Total pressure loss coefficient, | |

| Momentum thickness | |

| Scaling factor roughness correlation, | |

| Shape and density parameter, | |

| Dynamic viscosity | |

| Density | |

| Wall shear stress | |

| Specific dissipation rate | |

| Subscripts | |

| Axial | |

| ref | Reference test conditions |

| SD | Shape and density |

| SDS | Shape, density, and skewness |

| tot | Stagnation flow conditions |

| 1 | Inlet conditions |

| 2 | Downstream flow conditions in the traversing plane |

| 2th | Isentropic expansion to tank pressure |

| Mean area peak-to-valley height of the surface divided into 5 × 5 sections with equal size | |

| Acronyms | |

| CFD | Computational Fluid Dynamics |

| DLR | German Aerospace Center |

| GCI | Grid Convergence Index |

| LES | Large-Eddy Simulation |

| ORTM | Original Roughness Transition Model |

| RANS | Reynolds-Averaged Navier-Stokes |

| RRTM | Recalibrated Roughness Transition Model |

| SST | Shear Stress Transport |

References

- Hummel, F.; Lötzerich, M.; Cardamone, P.; Fottner, L. Surface Roughness Effects on Turbine Blade Aerodynamics. J. Turbomach. 2005, 127, 453–461. [Google Scholar] [CrossRef]

- Kurz, R.; Meher-Homji, C.; Brun, K.; Moore, J.J.; Gonzalez, F. Gas Turbine Performance and Maintenance. In Proceedings of the Forty-Second Turbomachinery Symposium, Houston, TX, USA, 1–3 October 2013; Texas A&M University. Turbomachinery Laboratories: College Station, TX, USA, 2013. [Google Scholar] [CrossRef]

- Boyle, R.J.; Senyitko, R.G. Measurements and Predictions of Surface Roughness Effects on the Turbine Vane Aerodynamics. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, 2003, Atlanta, GA, USA, 16–19 June 2003; Turbo Expo 2003, Parts A and B. Volume 6, pp. 291–303. [Google Scholar] [CrossRef]

- Stripf, M.; Schulz, A.; Bauer, H. Modeling of Rough-Wall Boundary Layer Transition and Heat Transfer on Turbine Airfoils. ASME J. Turbomach. 2008, 130, 021003. [Google Scholar] [CrossRef]

- Mayle, R.E. The 1991 IGTI Scholar Lecture: The Role of Laminar-Turbulent Transition in Gas Turbine Engines. ASME J. Turbomach. 1991, 113, 509–536. [Google Scholar] [CrossRef]

- Suzen, Y.B.; Xiong, G.; Huang, P.G. Predictions of Transitional Flows in Low-Pressure Turbines Using Intermittency Transport Equation. AIAA J. 2002, 40, 254–266. [Google Scholar] [CrossRef]

- Menter, F.R.; Langtry, R.B.; Likki, S.R.; Suzen, Y.B.; Huang, P.G.; Völker, S. A Correlation-Based Transition Model Using Local Variables—Part I: Model Formulation. J. Turbomach. 2006, 128, 413. [Google Scholar] [CrossRef]

- Kožulović, D. Modellierung des Grenzschichtumschlags bei Turbomaschinenstroemungen unter Beruecksichtigung Mehrerer Umschlagsarten. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2007. [Google Scholar]

- Langtry, R.B.; Menter, F.R. Correlation-Based Transition Modeling for Unstructured Parallelized Computational Fluid Dynamics Codes. AIAA J. 2009, 47, 2894–2906. [Google Scholar] [CrossRef]

- Menter, F.; Smirnov, P.; Liu, T.; Avancha, R. A One-Equation Local Correlation-Based Transition Model. Flow Turbul. Combust. 2015, 95, 1–37. [Google Scholar] [CrossRef]

- Abu-Ghannam, B.; Shaw, R. Natural Transition of Boundary Layers—The Effects of Turbulence, Pressure Gradient, and Flow History. J. Mech. Eng. Sci. 1980, 22, 213–228. [Google Scholar] [CrossRef]

- Tolksdorf, V.; Gokhale, A.; Kessler, D.; Benjamin, L.; Bode, C.; Friedrichs, J. Influence of Roughness on the Transition Modeling in Compressor Flows. In Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference and Exposition, Volume 2C: Turbomachinery—Design Methods and CFD Modeling for Turbomachinery; Ducts, Noise, and Component Interactions, Virtual, Online, 7–11 June 2021; p. V02CT34A039. [Google Scholar] [CrossRef]

- Stripf, M.; Schulz, A.; Bauer, H.J.; Wittig, S. Extended Models for Transitional Rough Wall Boundary Layers with Heat Transfer—Part I: Model Formulations. J. Turbomach. 2009, 131, 031016. [Google Scholar] [CrossRef]

- Dassler, P. Modellierung der Grenzschichttransition auf rauen Oberflächen in Turbinen. Ph.D. Thesis, Technische Universität Braunschweig, Braunschweig, Germany, 2013. [Google Scholar]

- Gilge, P.; Kellersmann, A.; Friedrichs, J.; Seume, J.R. Surface roughness of real operationally used compressor blade and blisk. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 5321–5330. [Google Scholar] [CrossRef]

- Seehausen, H.; Gilge, P.; Kellersmann, A.; Friedrichs, J.; Herbst, F. Numerical Study of Stage Roughness Variations in a High Pressure Compressor. Int. J. Gas Turbine 2020, 11, 16–25. [Google Scholar] [CrossRef]

- Thakkar, M.; Busse, A.; Sandham, N. Surface correlations of hydrodynamic drag for transitionally rough engineering surfaces. J. Turbul. 2017, 18, 138–169. [Google Scholar] [CrossRef]

- Kurth, S.; Cengiz, K.; Möller, D.; Wein, L.; Seume, J.R. Systematic roughness variation to model the influence of skewness on wall bounded flows. J. Glob. Power Propuls. Soc. (GPPS) 2023, 7, 177–187. [Google Scholar] [CrossRef]

- Ahrens, J.D.; Kurth, S.; Cengiz, K.; Wein, L.; Seume, J.R. Investigation of turbulence production and dissipation due to isotropic and anisotropic roughness components on real surfaces. J. Glob. Power Propuls. Soc. 2022, 6, 227–237. [Google Scholar] [CrossRef] [PubMed]

- Garai, A.; Diosady, L.T.; Murman, S.M.; Madavan, N.K. Scale-Resolving Simulations of Low-Pressure Turbine Cascades with Wall Roughness Using a Spectral-Element Method. In Proceedings of the Turbomachinery Technical Conference and Exposition, Oslo, ON, USA, 11–15 June 2018; Turbo Expo: Power for Land, Sea, and Air, Volume 2C: Turbomachinery. p. V02CT42A026. [Google Scholar] [CrossRef]

- Cengiz, K.; Kurth, S.; Wein, L.; Seume, J.R. Use of High-Order Curved Elements for Direct and Large Eddy Simulation of Flow over Rough Surfaces. Tech. Mech.-Eur. J. Eng. Mech. 2023, 43, 38–48. [Google Scholar] [CrossRef]

- Seehausen, H.; Cengiz, K.; Wein, L. Validation of an Eddy-Viscosity-Based Roughness Model Using High-Fidelity Simulations. In Proceedings of the 16th European Turbomachinery Conference, Hannover, Germany, 24–28 March 2025; paper n. ETC2025-144. Available online: https://www.euroturbo.eu/publications/conference-proceedings-repository/ (accessed on 14 May 2025).

- Montis, M.; Niehuis, R.; Fiala, A. Effect of Surface Roughness on Loss Behaviour, Aerodynamic Loading and Boundary Layer Development of a Low-Pressure Gas Turbine Airfoil. In Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010; Turbo Expo: Power for Land, Sea, and Air; Volume 7: Turbomachinery, Parts A, B, and C;. pp. 1535–1547. [Google Scholar] [CrossRef]

- Kožulović, D.; Juchmann, N.; Führing, A.; Bode, C. Transition Model Extension for Roughness Effects. In Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, The Netherlands, 13–17 June 2022; Turbo Expo: Power for Land, Sea, and Air; Volume 10C: Turbomachinery—Design Methods and CFD Modeling for Turbomachinery; Ducts, Noise, and Component Interactions. p. V10CT32A042. [Google Scholar] [CrossRef]

- Witherden, F.; Farrington, A.; Vincent, P. PyFR: An open source framework for solving advection—Diffusion type problems on streaming architectures using the flux reconstruction approach. Comput. Phys. Commun. 2014, 185, 3028–3040. [Google Scholar] [CrossRef]

- Giangaspero, G.; Witherden, F.; Vincent, P. Synthetic Turbulence Generation for High-Order Scale-Resolving Simulations on Unstructured Grids. AIAA J. 2022, 60, 1032–1051. [Google Scholar] [CrossRef]

- Bergmann, M.; Morsbach, C.; Ashcroft, G.; Kügeler, E. Statistical Error Estimation Methods for Engineering-Relevant Quantities From Scale-Resolving Simulations. J. Turbomach. 2021, 144, 031005. [Google Scholar] [CrossRef]

- Geiser, G.; Wellner, J.; Kügeler, E.; Weber, A.; Moors, A. On the Simulation and Spectral Analysis of Unsteady Turbulence and Transition Effects in a Multistage Low Pressure Turbine. J. Turbomach. 2019, 141, 051012. [Google Scholar] [CrossRef]

- Menter, F.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. In Proceedings of the 4th Internal Symposium on Turbulence, Heat and Mass Transfer, Antalya, Turkey, 2003; pp. 625–632, ISBN 1567001963. [Google Scholar]

- Roache, P.J. Perspective: A Method for Uniform Reporting of Grid Refinement Studies. J. Fluids Eng. 1994, 116, 405–413. [Google Scholar] [CrossRef]

- Wilcox, D.C. Reassessment of the scale-determining equation for advanced turbulence models. AIAA J. 1988, 26, 1299–1310. [Google Scholar] [CrossRef]

- Alldieck, R.; Seehausen, H.; Herbst, F.; Seume, J.R. The Effect of Rough-Wall Boundary Condition on RANS-Based Transition Prediction. In Proceedings of the GPPS. GPPS-CH-2020-053, Chania, Greece, 7–9 September 2020. [Google Scholar]

- Hellsten, A.; Laine, S. Extension of the k-omega-SST turbulence model for flows over rough surfaces. In Proceedings of the 22nd Atmospheric Flight Mechanics Conference, New Orleans, LA, USA, 11–13 August 1997. [Google Scholar] [CrossRef]

- Feindt, E.G. Untersuchungen über die Abhängigkeit des Umschlages Laminar-Turbulent von der Oberflächenrauhigkeit und der Druckverteilung. Ph.D. Thesis, Dt. Forschungsanstalt f. Luft- u. Raumfahrt e.V, Braunschweig, Germany, 1956. [Google Scholar]

- Schlichting, H. Experimentelle Untersuchungen zum Rauhigkeitsproblem. Ingenieur-Archiv 1936, 7, 1–34. [Google Scholar] [CrossRef]

- Nikuradse, J. Law of Flows in Rough Pipes. In NACA Technical Memorandum 1292; NACA: Washington, DC, USA, 1933. [Google Scholar]

- Bons, J.P. A Review of Surface Roughness Effects in Gas Turbines. J. Turbomach. 2010, 132, 021004. [Google Scholar] [CrossRef]

- Sigal, A.; Danberg, J.E. New correlation of roughness density effect on the turbulent boundary layer. AIAA J. 1990, 28, 554–556. [Google Scholar] [CrossRef]

- Bons, J.P. A Critical Assessment of Reynolds Analogy for Turbine Flows. J. Heat Transf. 2005, 127, 472–485. [Google Scholar] [CrossRef]

- Flack, K.A.; Schultz, M.P.; Volino, R.J. The effect of a systematic change in surface roughness skewness on turbulence and drag. Int. J. Heat Fluid Flow 2020, 85, 108669. [Google Scholar] [CrossRef]

- Thakkar, M.; Busse, A.; Sandham, N.D. Direct numerical simulation of turbulent channel flow over a surrogate for Nikuradse-type roughness. J. Fluid Mech. 2017, 837, R1. [Google Scholar] [CrossRef]

- Liu, C.; Gao, Y.S.; Dong, X.R.; Wang, Y.Q.; Liu, J.M.; Zhang, Y.N.; Cai, X.S.; Gui, N. Third generation of vortex identification methods: Omega and Liutex/Rortex based systems. J. Hydrodyn. 2019, 31, 205–223. [Google Scholar] [CrossRef]

- Van Driest, E.R.; Blumer, C.B. Boundary Layer Transition- Freestream Turbulence And Pressure Gradient Effects. AIAA J. 1963, 1, 1303–1306. [Google Scholar] [CrossRef]

- Doak, P. Momentum potential theory of energy flux carried by momentum fluctuations. J. Sound Vib. 1989, 131, 67–90. [Google Scholar] [CrossRef]

- Brooks, T.F.; Pope, D.S.; Marcolini, M.A. Airfoil Self-Noise and Prediction; NASA Reference Publication 1218; NASA: Hampton, VA, USA, 1989. [Google Scholar]

| Parameter Group | Values |

|---|---|

| Gas Constants | , , |

| Inlet Conditions | K, |

| Outlet Tank Conditions | , K |

| Incidence Angle | 38.7° (1° larger than the experiment) |

| Sutherland’s Law Constants | , , × |

| Montis et al. [23] | Thakkar et al. [41] | Equation (5) | |

|---|---|---|---|

| 187 µm | 127 µm | 101 µm | |

| 11.2 | 99 | 99 | |

| k | 96.6 µm | 147 µm | 147 µm |

| Experiment | LES | RANS Recalibrated Model | RANS Model Dassler [14] | |

|---|---|---|---|---|

| smooth | 0.9 (1.1%) | |||

| rough | 1.44 (2.8%) | 1.34 (−4.3%) | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the EUROTURBO. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Seehausen, H.; Cengiz, K.; Wein, L. Validation of an Eddy-Viscosity-Based Roughness Model Using High-Fidelity Simulations. Int. J. Turbomach. Propuls. Power 2025, 10, 34. https://doi.org/10.3390/ijtpp10040034

Seehausen H, Cengiz K, Wein L. Validation of an Eddy-Viscosity-Based Roughness Model Using High-Fidelity Simulations. International Journal of Turbomachinery, Propulsion and Power. 2025; 10(4):34. https://doi.org/10.3390/ijtpp10040034

Chicago/Turabian StyleSeehausen, Hendrik, Kenan Cengiz, and Lars Wein. 2025. "Validation of an Eddy-Viscosity-Based Roughness Model Using High-Fidelity Simulations" International Journal of Turbomachinery, Propulsion and Power 10, no. 4: 34. https://doi.org/10.3390/ijtpp10040034

APA StyleSeehausen, H., Cengiz, K., & Wein, L. (2025). Validation of an Eddy-Viscosity-Based Roughness Model Using High-Fidelity Simulations. International Journal of Turbomachinery, Propulsion and Power, 10(4), 34. https://doi.org/10.3390/ijtpp10040034