Abstract

Additive manufacturing offers new perspectives for creating complex geometries with improved design features at lower cost and with reduced manufacturing time. It may even become possible to print a micro-turbojet engine in one single print, but then unconventional geometrical constraints on compressor and turbine designs are inevitable. If a radial machine were printed through additive manufacturing as a standalone component, the most logical print direction would be from the radial outlet/inlet to the axial inlet/outlet to ease the process and limit the supports, with limited additional constraints compared to traditional manufacturing methods. If the rotor comprising a radial compressor and turbine needs to be printed in one single print, one of the components will be printed in a direction that is not favorable. In the present work, the radial turbine is considered to be printed in the unfavorable direction, namely, from the axial outlet to the radial inlet. These geometrical constraints orient the geometry towards a mixed-flow configuration with a trailing-edge cutback. Such design features reduce the available design space for improvement and will clearly have an unfavorable impact on performance. Therefore, a multi-disciplinary gradient-based adjoint optimization of the mixed-flow turbine is performed, striving to limit the adverse impact on total-to-total efficiency while respecting the mass flow rate and power matching with the upstream compressor. The structural constraint limits the p-Norm von Mises stress to a maximum threshold based on the material yield strength at the operating temperature. The results show that a satisfactory compromise can be found between manufacturability constraints, material limits and aerodynamic performance.

1. Introduction

Additive manufacturing (AM) is a technology that consists of selective addition/deposition of material, generating the desired geometry layer by layer. The technique originates from material stereolithography, developed by C. W. Hull in 1984 [1], and has since evolved to a mature production method with a wide range of materials and production techniques. Steady improvement in process management, control and post-treatments (surface finish, temperature history, support generation, post-treatments, …) [2,3,4,5] has allowed for the manufacture of complex parts to the specifications required by the aeronautical sector. At present, AM is used for the production of turbomachinery parts, offering in many cases large advantages over traditional subtractive methods, allowing faster production with less waste [6,7,8]. Additional benefits of AM include the realization of complex features, such as internal cooling channels to improve thermal performance [9], whereas traditional processes would require a much more complex technique.

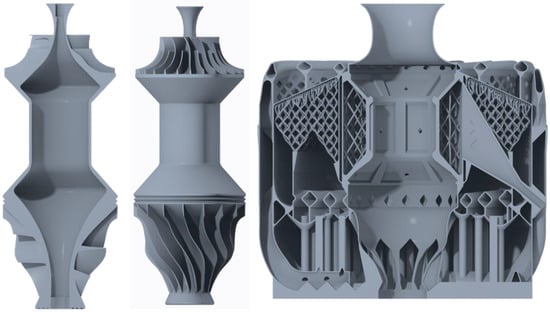

The production of a micro-turbojet engine typically relies on a supply chain for various external parts, which, when disrupted, leads to significant downtimes. These considerations have lead to the idea of producing a complete jet engine by additive manufacturing. The engine (see Figure 1) is conceptualized such that both rotating and stationary parts can be manufactured in a single, uninterrupted print using powder bed fusion with Inconel 718 powder [10]. This approach, while appealing for its production simplicity, leads to unconventional constraints on the design of the turbomachinery components with inevitable penalties on the aerodynamic performance.

Figure 1.

Illustration of the micro-turbojet engine design proposed by Ben Horing and Cukurel [11]. Beam-based lattices are used to optimize the design for printability. Several spots have been designed for localized powder evacuation.

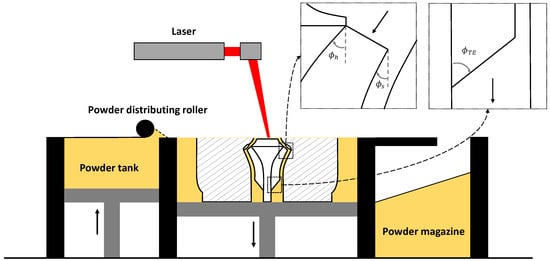

Due to the absence of support structures that can be later removed, each new layer of the print requires having solid material underneath, such that overhanging structures are limited to only. As a consequence, the turbine, which is printed progressively from the axial outlet to the radial inlet, is required to be of the mixed inlet flow type. Additionally, the trailing edge of the blades cannot be radial but needs to be shaped with a backward lean to fulfill the overhanging requirement. Both features are illustrated in Figure 2.

Figure 2.

Selective laser melting process applied to the engine and impacts on the turbine design.

Paradoxically, the potential performance improvement of gas turbines that one can imagine, as a result of the larger shape freedom offered by additive manufacturing, may not ultimately be achieved due to the additional unconventional constraints. Fewer restrictions are present on the radial compressor, although the leading-edge blade angle is restricted to be less than from the axial direction. The design of the radial compressor has already been performed and is discussed in [12]. Since then, a further iteration on the compressor design has been made, resulting in a new value for the mass flow rate.

The present work focuses on the design of a mixed-flow turbine where, with the help of a gradient-based optimization method, the performance loss as a result of the additive manufacturing constraints will be minimized as much as possible. The use of a gradient-based approach is essential in this work, as this allows for efficiently dealing with the large freedom provided by the manufacturing process. The objective consists of improving the efficiency at the design point while still matching the turbine to the compressor (single shaft configuration). Additionally, the mechanical stresses due to the centrifugal forces need to be sufficiently below the material yield strength. Finally, the geometric constraints resulting from the additive manufacturing process need to be satisfied. The paper is structured as follows: first the optimization setup is presented, and then structural and aerodynamic improvements are investigated.

2. Optimization Problem

Geometrical constraints related to AM should not be treated as optimization constraints, as this would require computing additional gradients, but more importantly, it would lead to tedious iterations of the optimizer to satisfy the constraints. By including them in the parametrization (selecting appropriate boundary values for the parameters), all geometries generated during the optimization process will automatically satisfy the geometrical constraints.

2.1. Parametrization

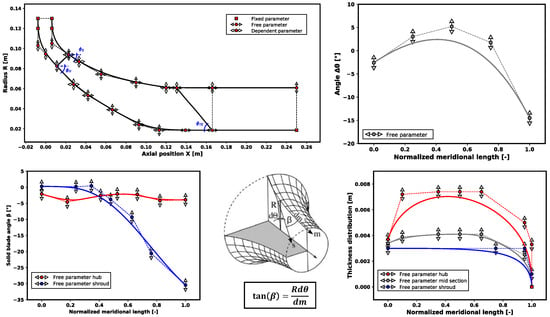

The geometry is parameterized using 63 parameters according to the general methodology presented in [13] for any turbomachinery component. These parameters concern the following:

- Meridional contours at hub and shroud: Thirty-one parameters dictate the position of the control points of the b−spline curves. Critical points at the inlet and outlet should respect AM manufacturing constraints, limiting the construction angles to below 55 degrees. Angle and distance with respect to the neighboring point are therefore used as parameters instead of the x-y coordinates.

- Blade angle distribution at hub and shroud: Fourteen parameters control the blade angles. The design space is selected within the acceptable range regarding the maximum absolute angle of .

- Azimuthal angle variations at mid-span: Five parameters control the deviation from the linear interpolation between hub and shroud azimuthal angles. They dictate the local bowing of the blade, deviating it from a ruled surface, as would be a limitation imposed by manufacturing through flank milling.

- Thickness distribution at hub, mid-span and shroud: Eighteen parameters control the thickness distribution. Rounded trailing edges are considered. However, as a rule of thumb, there should be at least three passes of the laser for the skin of the printed component, with an overall thickness not smaller than 0.8 mm. Therefore, a control point is located for each section close to the trailing edge, and its value is maintained above 1 mm.

Additional parameters are the rake angle and the hub fillet radius. The backplate, aside from the connection with the hub contour, remains fixed. It has been designed as such to avoid a large concentration of stress in the center of the rotor. The whole parametrization is presented in Figure 3.

Figure 3.

Parametrization of the centrifugal turbine: meridional contour (Upper Left), solid blade angle distribution (Upper Right), azimuthal angle variation (Lower Left) and thickness distribution (Lower Right).

2.2. Mesh and Solver Setup

The fluid domain contains a 3D multiblock structured mesh with approximately 1,300,000 cells. Fluid grid generation relies on stacking annular surface grids generated by a conformal mapping in 2D. The procedure is described extensively in [14]. The initial mesh respects all quality criteria. Mesh quality during the optimization process is maintained thanks to a structured mesh topology. On the other hand, the solid domain is discretized by an unstructured mesh with approximately 500,000 tetrahedra, using Delaunay triangulation. For the solid mesh, quality is maintained by using a mesh morphing approach, such that each new mesh is slightly modified compared to the previous one. The procedure is detailed in [15]. The flow is predicted using an in-house finite-volume implicit structured Computational Fluid Dynamics (CFD) solver with a Spalart–Allmaras turbulence model [16]. The turbine consists of 10 blades, but only a single channel is meshed, and periodic boundary conditions are used. Roughness is known to negatively affect the performance of turbulent flows by thickening the boundary layer and increasing the losses. Regarding selective laser melting of Inconel 718, typical roughness values are = 4–12 m [17]. Relative roughness and the Reynolds number have been computed based on the hydraulic diameter: and . It corresponds to a point in the Moody diagram for which the effect of roughness is limited. Therefore, performance computed by the CFD solver excludes the potential impact of roughness, as does the adjoint solver. The structural performance is assessed using the in-house Computational Structural Mechanics (CSM) solver described in [15]. The material is considered linear elastic, without pores, monophasic and isotropic. The latter hypotheses may seem unfounded regarding AM and powder bed fusion. Indeed, residual stresses (due to high cooling rates and non-homogeneous recrystallization), formation of dentritic sub-grains and undesirable phases (Laves phases), and the AM-inherently layered structure lead to material anisotropy [18]. However, recent extensive efforts on developing specific heat post-treatment demonstrated materials with near-isotropic behavior at both room and elevated temperatures [19,20].

2.3. Problem Definition

Inlet conditions are set by imposing the total temperature, total pressure and flow angle. Total temperature is prescribed from the combustion chamber’s designed outlet condition, while the total pressure is assumed to be equal to the compressor outlet’s total pressure subtracted by the total pressure loss in the combustion chamber (assumed to be 5% according to [21]). The inlet flow only has components in the radial and tangential directions. Outlet conditions are prescribed by imposing the static pressure at the hub with a radial equilibrium law. All boundary conditions are summarized in Table 1.

Table 1.

Imposed boundary conditions.

Moreover, the turbine should match the compressor mass flow rate and power. The latter criterion depends not only on the compressor but also on the power dissipated by the bearing. Using a hydrostatic bearing model, these losses have been estimated at 30 kW. Mass flow and power matching are translated into constraints for the optimization problem, and acceptable ranges are defined inside Table 2.

Table 2.

Matching conditions and ranges.

The objective of the optimization is to maximize the isentropic total-to-total efficiency. This choice is more relevant than its traditionally used total-to-static counterpart (for turbines) due to the presence of a downstream nozzle to recover the kinetic energy and transform it into thrust.

The last constraint concerns the material yield strength at the operating temperature (1000 K). It has been interpolated from the data provided in [22] and found to be equal to 830 MPa. The optimizer should therefore ensure that the maximum von Mises stress remains bounded by this threshold value with a safety factor of at least 1.1 and at best 1.2. However, the adjoint formulation that will be presented in the following section relies on global integrable quantities. An interesting alternative consists of using the volume-weighted p-Norm stress to approximate the local maximum von Mises stress according to Equation (1) [23].

The p-Norm has as advantage of weighing stress concentrations by their spread and will place more emphasis on larger zones with high stress than on small zones with high stress peaks, which are considered less dangerous. It will, however, underestimate the maximum von Mises stress, requiring a lower target value to be set to ensure that the maximum stress is below the imposed safety factor. Since estimating this offset is difficult, the authors have dedicated the first part of the optimization to minimizing the stresses while maintaining an efficiency of 85% or above. When the maximum von Mises stress reached a safety factor of 1.2, the objectives were switched to maximizing the efficiency while maintaining the p-Norm stress at the then-found value.

2.4. Optimization Algorithm

Gradient-based algorithms take advantage of the gradient value to derive a search direction and focus on a particular region of the design space, increasing the convergence towards the optimum. By adopting the adjoint formulation, the computational cost proved to be mainly scaling with the number of objective/constraint functions, allowing the performance of optimization cases with a large number of parameters [24,25,26]. While the unimodality of the objective function has not been investigated for this particular turbine geometry, no signs of multi-modality were detected for another radial turbine case in [27]. There is, however, no possible proof to claim a global optimum has been found by any optimization technique, so this subject is not touched in this paper, and focus is given to the analysis of the best design found through the optimization.

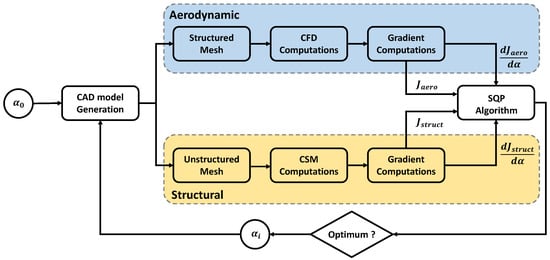

The overall multi-disciplinary optimization cycle is presented in Figure 4. The geometry is generated from the parametrization and meshed in the fluid and solid domains. Structural and aerodynamic performance are evaluated, and the corresponding cost functions, and , determined. Adjoint variables for both the fluid and solid domains are then computed according to Equation (2), and the gradients are eventually assembled. The adjoint gradient computation has been validated on another case by computing the gradients through a complex step method and verifying that both methods yield the same results.

Figure 4.

Schematic of the optimization cycle and methodology.

Finally, a Sequential Quadratic Programming (SQP) algorithm generates a quadratic approximation of the objective function based on the function itself J, its gradients and an approximate Hessian matrix (using a limited-memory Broyden–Fletcher–Goldfarb–Shanno quasi-Newton method), while constraints are approximated linearly. The determination of the appropriate step in the global design space is performed through a non-derivative line search and stops when a minor iteration highlights a better objective function. The SQP algorithm implementation is detailed in [28]. The complete numerical approach (CFD solver, adjoint solver and optimizer) has been described and validated in [29] by comparing the gradients computed with the adjoint method and those computed with an accurate second-order complex step method, verifying that both yield the same result.

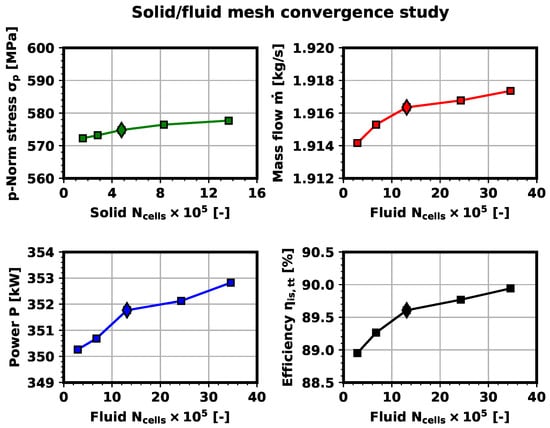

2.5. Mesh Independence Study

A mesh independence study was conducted to assess the impact of mesh refinement on the computed performance. The study was performed on both the fluid and solid grids, using key variables of interest: mass flow rate, total-to-total isentropic efficiency, power and p-Norm von Mises stress. Mesh refinement was performed uniformly across all blocks, in all directions, and on the first cell size near the wall. The results of this study are presented in Figure 5. The computed variables on grid 3 (diamond marker) can be considered grid-converged, as their variations compared to the finest grid are less than 0.5%.

Figure 5.

Mesh independence study for both the solid and fluid grids. The grid that has been used during the optimization is depicted by the diamond marker.

3. Results and Discussion

3.1. Optimization History and Optimal Geometry

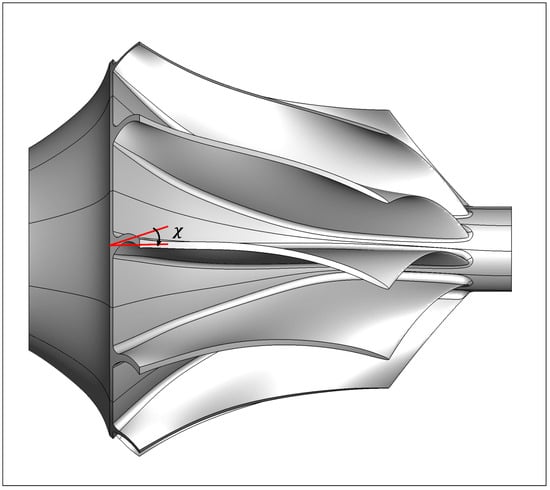

A preliminary, purely aerodynamic optimization has been performed on an initial geometry, increasing the efficiency by more than 11%, while ensuring both mass flow rate and power constraints are respected. Performance was improved through the reduction in the trailing-edge shock strength and its interaction with the tip vortex. Several modifications were brought to the preliminary optimization setup to expand the design space for the multi-disciplinary optimization outlined in the previous section. The primary change involves allowing a completely free blade inlet, initially without any sweep, whereas it was previously constrained to a purely radial configuration. These adjustments account for the remaining potential for efficiency improvements, despite the problem becoming more constrained. The baseline geometry is presented in Figure 6.

Figure 6.

Baseline geometry. The rake angle is indicated by .

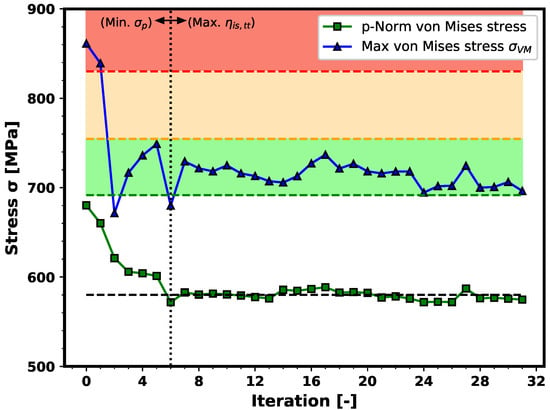

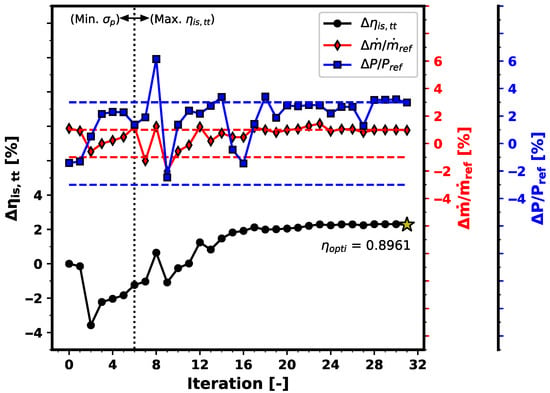

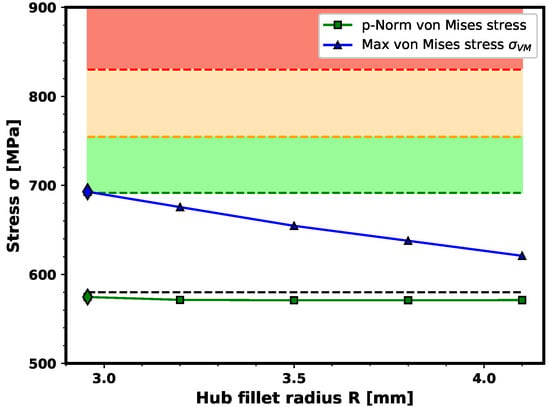

According to the methodology described previously for the determination of an appropriate p-Norm stress constraint, the optimization is first launched by striving for the minimum value of the p-Norm stress (Figure 7 and Figure 8). As already stated, the offset between the p-Norm and the maximum von Mises stress is not constant during those first iterations. The first six iterations are thus performed by minimizing the p-Norm of the stresses while maintaining an efficiency above 85%. This results in a geometry that satisfies the power constraint while having a mass flow just above the imposed constraints. From this iteration onwards, the objective is switched to the efficiency while keeping the p-Norm stress below the value found at iteration 6, which is 580 MPa. This strategy assumes that the offset between the p-Norm and maximum stress will remain constant during further iterations. Convergence is reached after 31 overall iterations. The optimized sample demonstrates an increase in performance compared to the baseline geometry, highlighting that the new parametrization setup (compared to the aerodynamic optimization) offers more freedom for performance improvement. Mass flow rate, power and p-Norm constraints are located at their respective upper bounds. The p-Norm constraint is associated with a maximum von Mises stress corresponding to a safety factor of 1.2, as initially targeted.

Figure 7.

Optimization history: stress evolution. Red, orange and green dotted lines indicate, respectively, the yield strength and safety factors of 1.1 and 1.2.

Figure 8.

Optimization history: evolution of the aerodynamic quantities.

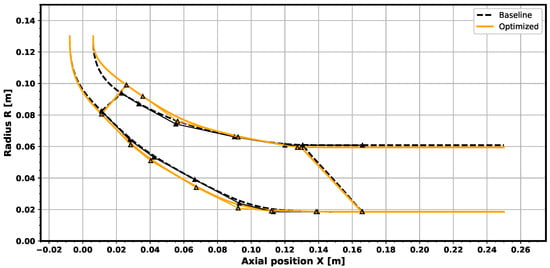

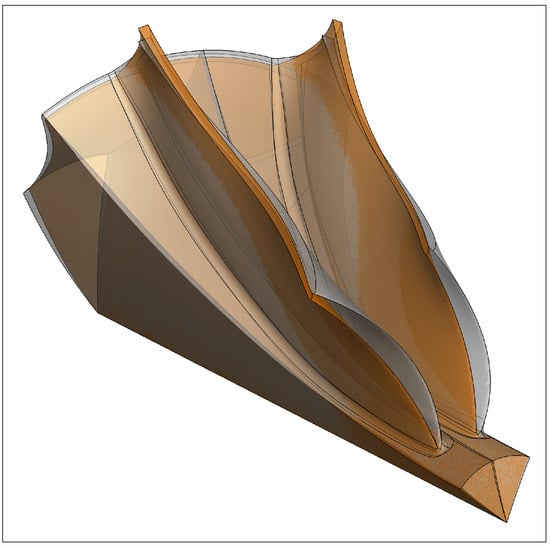

Structural and aerodynamic performance for both the baseline and optimized geometries are compared in Table 3, and a comparison in meridional contours and 3D geometry is given in, respectively, Figure 9 and Figure 10.

Table 3.

Structural and aerodynamic performance comparison between the baseline and optimized geometries.

Figure 9.

Meridional contours comparison between the baseline (gray) and optimized turbines (orange).

Figure 10.

A 3D geometry comparison between the baseline (gray) and optimized turbines (orange).

The main design feature modifications are listed below:

- 1.

- The inlet blade section has been increased by moving the first blade shroud control point upward without inducing any sweep.

- 2.

- The inlet rake angle and azimuthal angle variations are reduced, particularly near the trailing edge. This induces a blade with smaller bowing, leading to a more radially fibered design with less bending stress.

- 3.

- The hub fillet radius has increased from 2.8 mm to 2.97 mm.

- 4.

- The overall thickness at the shroud has been reduced. The thickness of the intermediate section at mid-span has been decreased, starting from the second half of the chord. This tapering reduces stresses, as less mass is positioned at a higher radius, whereas the cross-sectional area increases towards the hub, distributing the reduced centrifugal load over a larger area.

- 5.

- The solid blade angle at the inlet is now slightly negative.

Each of these modifications will be explained according to the structural and flow analyses in the following sections.

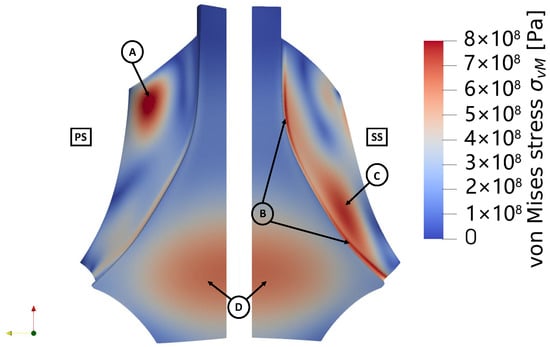

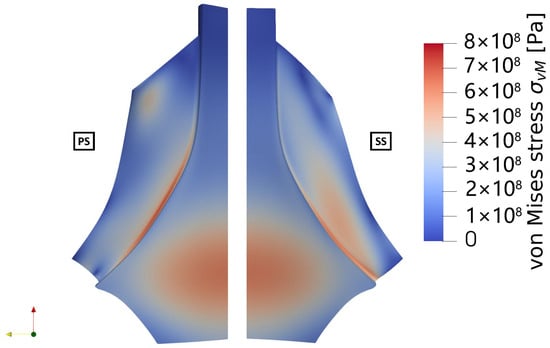

3.2. Structural Analysis

The results of the CSM computations for both baseline and optimized geometries are displayed, respectively, in Figure 11 and Figure 12. The initial turbine blade is characterized by high-stress-concentration regions:

Figure 11.

Von Mises stress contours for the baseline geometry on the pressure side (Left) and suction side (Right).

Figure 12.

Von Mises stress contours for the optimized geometry on the pressure side (Left) and suction side (Right).

- On the pressure side near the trailing edge (A). By reducing the blade bowing midway between leading and trailing edges, the geometry is closer to a radially fibered blade, known for its higher stress resistance. The reduced thickness at the shroud and intermediate sections also contributes to relieving the stress.

- On the suction side at the intersection with the hub (B). The stress is reduced mostly by increasing the hub fillet radius and hub thickness.

- On the suction side around (C). The stress is decreased by reducing the inlet rake angle and the blade bowing near the leading edge. Modifications of the hub’s solid angle distribution contribute favorably but to a lesser extent.

- In the rotor center, aligned with the inlet (D). Stresses in this region are generated by centrifugal force due to mass located at a large radius. The backplate has been designed to partially relieve the stress there. The presence of a center hole has not been considered in this study but is very likely to increase the circumferential stress in this region.

The maximum von Mises stress in the optimized case is located at the hub fillet on the suction side. Since this fillet is not considered in the fluid mesh, one should be careful that the expected drive for larger fillet radii by the structural requirements is not large enough to perturb the aerodynamic performance, so this should be included in the CFD model. A study on the effect of the fillet radius on the structural behavior has been performed and is summarized in Figure 13. As expected, the maximum stress decreases with increased fillet radius. While this reduction levels off, the fillet size becomes too large and violates geometric constraints (the fillet from the pressure side coincides with the one on the suction side near the trailing edge). The p-Norm stress, however, decreases but very quickly levels off. This is understood from the fact that the volume over which this stress concentration region spans is small. While the maximum stress decreases, its impact on the numerical integration used to compute the p-Norm value is limited. The use of the p-Norm is thus a safer choice to avoid too-large fillet radii and avoid modeling fillets in the CFD domain. Fillets, however, do have an impact on the aerodynamics: small fillets can increase efficiency compared to no fillets by suppressing corner flow separation; too-large fillets, on the other hand, will increase friction losses and decrease the cross-sectional flow, leading to more blockage and reduced choking mass flow [30,31]. Since, in the present study, the fillets remain small, their effect has not been modeled.

Figure 13.

The influence of the hub fillet radius on the maximum von Mises stress.

3.3. Flow Analysis

As stated previously, the remaining potential for efficiency improvement with respect to the initial purely aerodynamic optimization is mainly located at the inlet due to modifications in the setup. The inlet section of the blade has therefore been investigated first. In the initial case, going from larger to smaller radii at a constant meridional channel height implies that the meridional speed is accelerated through the induced convergent. On the other hand, by gradually increasing the meridional channel height, the section remains (more or less) fixed along the inlet channel, as does meridional velocity. Tangential velocity increases with decreasing radius according to the conservation of angular momentum. By varying the channel height, the velocity triangle is modified, and the flow near the blade leading edge becomes more tangential, increasing the potential to extract power. This is further improved by increasing the radius at the tip, since most of the mass flow rate passes near the shroud, where the aerodynamic loading is the highest.

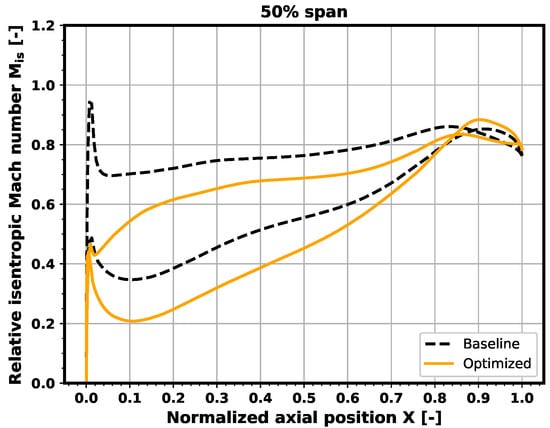

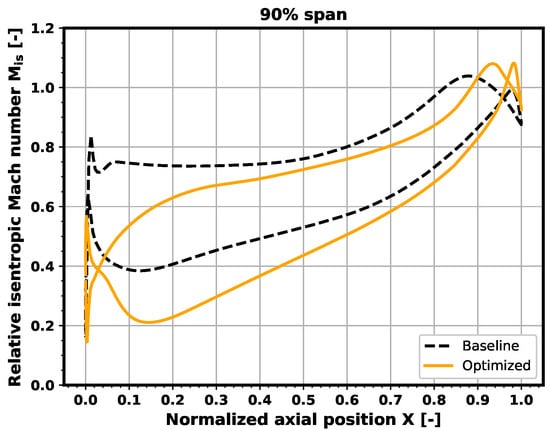

Another quantity of interest is the isentropic Mach number distribution on the blade surface. It has been computed at 50% and 90% span (respectively, Figure 14 and Figure 15). The average velocity is indeed smaller in the optimized case, as previously stated due to the increased meridional channel height near the inlet. The load has been redistributed on the blade in the first half of the chord. Near the shroud, the shock onset near the trailing edge is shifted from to , but its strength has increased, with a peak isentropic Mach number going from to . All these elements indicate that the shock has adopted a more normal configuration near the trailing edge. The suction side highlights continuous acceleration from the leading edge up to the shock, while the baseline geometry suffered from a velocity peak at the leading edge due to slightly positive incidence, followed by a plateau. Consequently, the optimized boundary layer on the suction side is less prone to separation. On the other hand, the presence of a velocity peak on the pressure side, due to negative incidence, generates a small negative load in the first 2.5% of the blade. At mid-span, the incidence has been reduced, and so has the induced flow acceleration over the leading edge. In the optimized case, the loading is more negative towards the trailing edge.

Figure 14.

Isentropic Mach number distribution on the blade surface for the baseline and optimized geometries at 50% span.

Figure 15.

Isentropic Mach number distribution on the blade surface for the baseline and optimized geometries at 90% span.

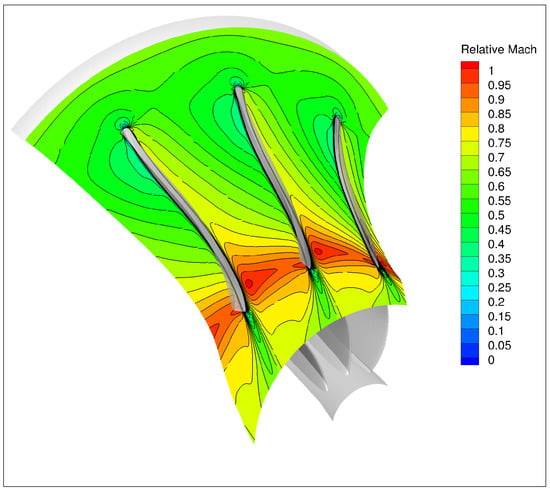

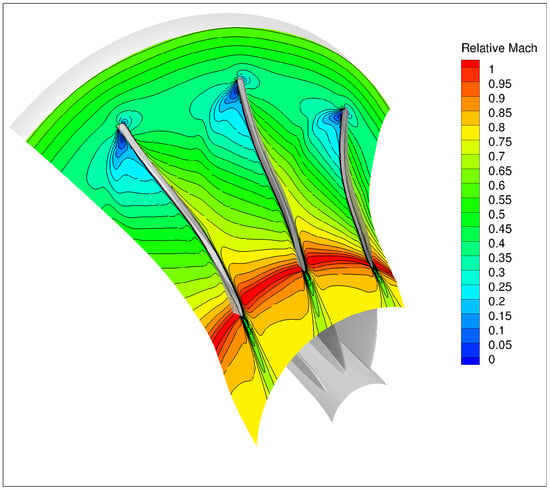

The relative Mach number contours at 90% span are compared for both baseline and optimized geometries in Figure 16 and Figure 17, respectively. The shock configuration at the trailing edge did switch from an oblique to a normal shock. However, the shock only spans over a region near the shroud and its strength remains limited. A separation occurs on the blade leading edge on the pressure side due to the negative incidence. This separation region is rapidly convected to the following blade and disappears as the flow is accelerated.

Figure 16.

Contour of the relative Mach number at 90% span for the baseline geometry.

Figure 17.

Contour of the relative Mach number at 90% span for the optimized geometry.

The gradients have been investigated to understand why the inlet blade angle has not been adapted according to the modified (more tangential) inlet flow. It turned out that all four gradients (efficiency, power, mass flow rate and p-Norm von Mises stress) are positive. As expected, the aerodynamic gradient indicates that a larger (closer to 0) would be beneficial for efficiency by improving the adaptation to the flow. The mass flow rate would also increase as the available section is larger, thereby not respecting the corresponding constraint. Moreover, it would lead to a larger flow deviation, increasing the blade loading. The latter two effects would positively impact the turbine power, which would increase beyond its upper bound. Finally, as a higher loading is located at a large radius, it would also increase the stresses. Since all three constraints reached their respective upper bounds, the blade angle cannot be reduced anymore and acts as a compromise for efficiency between the reduced averaged velocity and the negative-incidence-induced separation. Such a compromise illustrates the need for a multi-disciplinary optimization. Another improvement is the more uniform flow in the blade channel, maximizing the mass flow that can go through in choked conditions.

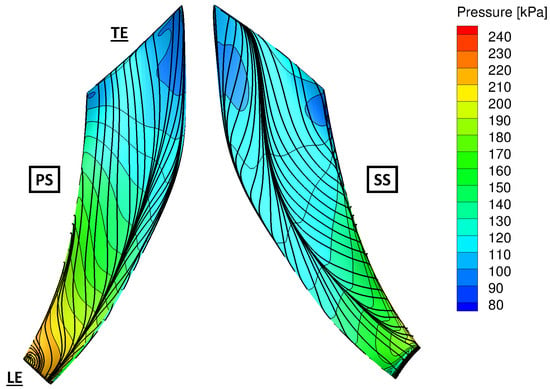

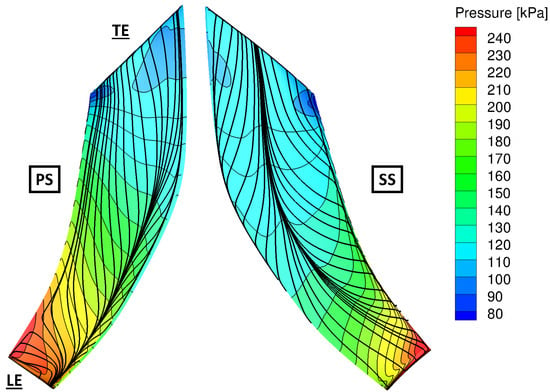

Pressure contours and near-blade streamlines have been plotted in Figure 18 and Figure 19, respectively, for the baseline and optimized geometries. At the pressure-side inlet near the shroud, the previously discussed flow separation region is observed as streamlines move in the reverse flow direction. Secondary flows on the pressure and suction sides are spotted through their influence on the pressure contours, inducing a local pressure drop in the region where they are located. The two passage vortices are highlighted through their impact on the near-blade streamlines. The imbalance between the pressure gradient and the centrifugal forces leads to a flow that, at the center of the passage, tends to move towards the pressure side and thus takes away the flow on the center part of the suction side. This leads to a movement of the flow on the suction side, where streamlines concentrate towards the center, and on the pressure side, where the streamlines escape from the center. The center, in this case, is not located precisely in the middle of the channel, mostly due to the influence of other forces. Another equilibrium occurs between the centrifugal force induced by the channel curvature, the one due to rotation, and the hub-to-shroud pressure gradient. Passage vortices and their low momentum break this equilibrium and are convected downward by the pressure gradient. These plots alone are, however, insufficient to demonstrate that the passage vortex strength has been reduced in the optimized case. On the other hand, what can already be observed is that the pressure decrease along the blade is more uniform.

Figure 18.

Pressure contours and near-blade streamlines on the pressure (Left) and suction (Right) sides for the baseline geometry.

Figure 19.

Pressure contours and near-blade streamlines on the pressure (Left) and suction (Right) sides for the optimized geometry.

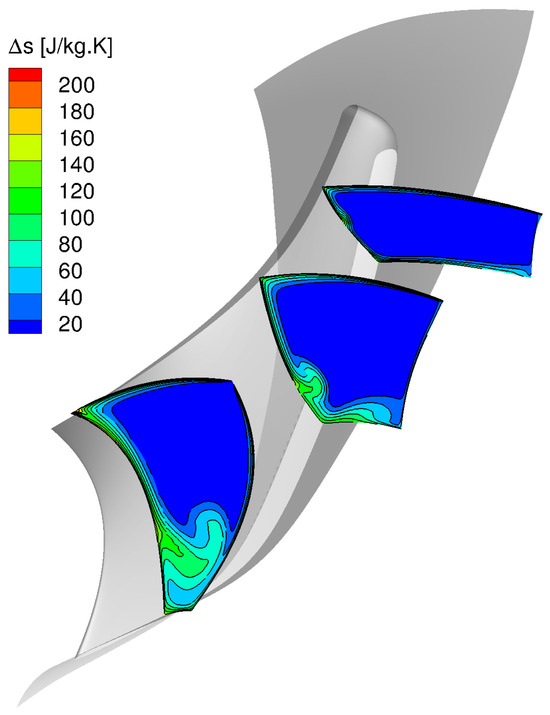

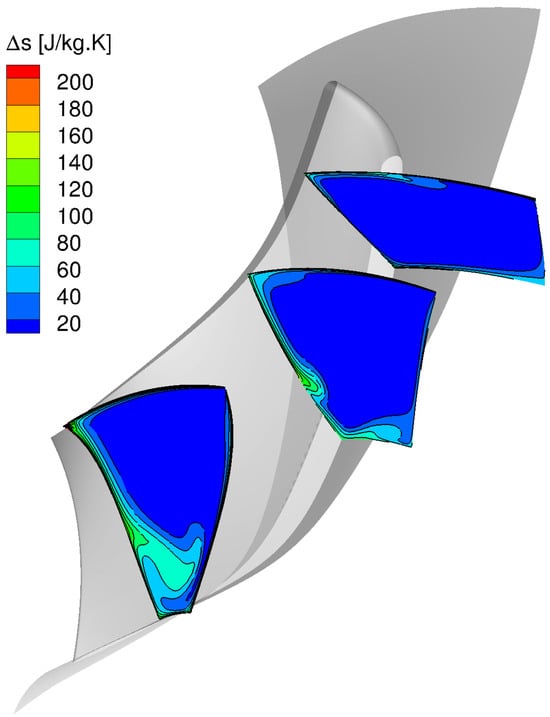

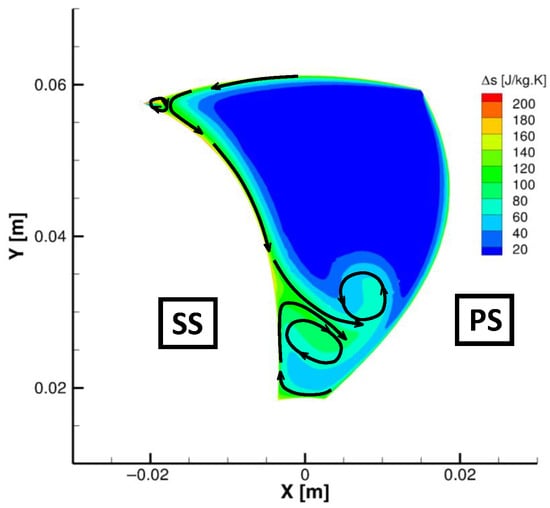

The last post-processing investigates the specific entropy contours at different slices along the blade channel at = 0.2–0.5–0.9 (Figure 20 and Figure 21). The aforementioned passage vortices induce spots of high-entropy generation in the contours. In the optimized case, their strength has decreased, as demonstrated by the lower levels of entropy. The separation flow in the optimized case is only visible at the first section and then vanishes. In both cases, the tip vortex remains very small, mostly due to small loading and clearance-to-height ratios (a clearance of 0.6mm has been designed regarding the manufacturing process capability).

Figure 20.

Specific entropy contours at = 0.2–0.5–0.9 for the baseline geometry.

Figure 21.

Specific entropy contours at = 0.2–0.5–0.9 for the optimized geometry.

To better illustrate the formation of the passage vortex, a schematic is proposed in Figure 22 for a slice at . The fluid is flowing from the pressure side to the suction side along the end-walls. On the one hand, it follows the shroud casing and comes down along the suction side. On the other hand, it follows the hub casing and rises on the suction side. Both flows interact and are pushed towards the pressure side, generating high shear and losses.

Figure 22.

Specific entropy contours at for the baseline geometry and schematized secondary flow streamlines.

4. Conclusions

The development of a fully printable micro-jet turbine requires considering specific constraints in relation to additive manufacturing. Regarding the design of the centrifugal turbine, these constraints oriented the geometry towards a mixed-flow configuration with a trailing-edge cutback to ensure self-supported structures [32]. A multi-disciplinary discrete adjoint optimization has been performed, striving for maximum isentropic total-to-total efficiency while ensuring appropriate matching with the upstream compressor and limiting the stresses to values under the material yield strength. The process has converged towards an optimized geometry for which stresses have been drastically reduced, mainly thanks to the reduced blade bowing and rake angle, as well as an increased hub fillet radius. From the aerodynamic point of view, the efficiency has increased while ensuring that power and mass flow constraints are respected. The main mechanisms involved in this improvement are the reduced averaged velocity and friction and the weaker passage vortices. Despite the unconventional constraints arising from the manufacturing process, the adjoint-based multi-disciplinary optimization allowed the full potential of such a configuration to be reached while satisfying all imposed constraints.

Author Contributions

Conceptualization, V.L.; methodology, V.L. and T.V.; software, V.L. and T.V.; validation, V.L.; formal analysis, V.L. and T.V.; investigation, V.L. and T.V.; resources, V.L.; data curation, V.L.; writing—original draft preparation, V.L., T.V. and B.H.S.; writing—review and editing, V.L, T.V. and B.H.S.; visualization, V.L.; supervision, T.V. and B.H.S.; project administration, B.H.S.; funding acquisition, T.V. and B.H.S. All authors have read and agreed to the published version of the manuscript.

Funding

The project was funded by the NATO Science for Peace and Security Programme (Grant No. G5939).

Data Availability Statement

Data are contained within the article.

Acknowledgments

This paper has been written in collaboration with the Israel Institute of Technology (Technion) and the Izmir Katip Çelebi University (IKCU).

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AM | Additive Manufacturing |

| CFD | Computational Fluid Dynamics |

| CSM | Computational Structural Mechanics |

| SQP | Sequential Quadratic Programming |

| Nomenclature | |

| p | Static pressure [Pa] |

| P | Power [W] |

| J | Objective function |

| Equivalent sand grain size [m] | |

| Hydraulic diameter [m] | |

| Reynolds number [-] | |

| Hub | |

| Shroud | |

| Inlet | |

| Outlet | |

| Von Mises | |

| p-Norm value | |

| Design parameter | |

| Solid blade angle [-] | |

| Efficiency [-] | |

| Adjoint variable | |

| Stress [Pa] | |

| Rotor angular velocity [s−1] | |

| Azimuthal angle [-] | |

| Meridional contour angle [-] | |

| Rake angle [-] | |

References

- Bartolo, P. Stereolithographic Processes. In Stereolitography: Materials, Processes and Applications; Bartolo, P., Ed.; Springer: Boston, MA, USA, 2011; pp. 1–36. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.; Shin, Y.; Zhang, S.; Zavattieri, P. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Mercado, F.; Rojas, A.A. Additive Manufacturing Methods: Techniques, Materials, and Closed-loop Control Applications. J. Adv. Manuf. Technol. 2020, 109, 17–31. [Google Scholar] [CrossRef]

- Dinita, A.; Neacsa, A.; Portoaca, A.I.; Tanase, M.; Ilinca, C.N.; Ramadan, I.N. Additive Manufacturing Post-Processing Treatments, a Review with Emphasis on Mechanical Characteristics. Materials 2023, 16, 4610. [Google Scholar] [CrossRef] [PubMed]

- Bello, K.A.; Kanakan-Katumba, M.G.; Maladzhi, R.W. A Review of Additive Manufacturing Post-Treatment Techniques for Surface Quality Enhancement. Proc. CIRP 2023, 120, 404–409. [Google Scholar] [CrossRef]

- Prakash, P.; Jothilakshmi, P. Additive Manufacturing in Turbomachineries. Int. J. Eng. Tech. Mgmt. Res. 2019, 9, 31–47. [Google Scholar]

- Magerramova, L.; Volkow, M.; Svinareva, M.; Siversky, A. The Use of Additive Technologies to Create Lightweight Parts for Gas Turbine Engine Compressors. In Proceedings of the Name of the AMSE Turbo Expo, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- 3D Systems. Available online: https://www.3dsystems.com/turbomachinery (accessed on 18 August 2024).

- Pietropaoli, M.; Ahlfeld, R.; Montomoli, F.; Ciani, A.; d’Ercole, M. Design for Additive Manufacturing: Internal Channel Optimization. J. Eng. Gas Turbines Power 2017, 139, 102101. [Google Scholar] [CrossRef]

- Palman, M.; Abraham, Y.; Agapovichev, A.; Yildrim, A.; Acarer, S.; Verstraete, T.; Saracoglu, B.H.; Cukurel, B. Conceptualizing a Pre-Assembled Additively Manufactured Gas Turbine Engine: Technological Feasibility. In Proceedings of the AIAA SCITECH 2024, Orlando, FL, USA, 8–12 January 2024. [Google Scholar]

- Additively Manufactured Pre-Assembled Engine (APE). Available online: https://bcukurel.net.technion.ac.il/ape/ (accessed on 29 July 2024).

- Ergin, C.; Verstraete, T.; Saracoglu, B.H. The Design and Optimization of Additively Manufactured Radial Compressor of a Miniature Gas Turbine Engine. J. Fluids Eng. 2024, 146, 071108. [Google Scholar] [CrossRef]

- Agromayor, R.; Anand, N.; Muller, J.D.; Pini, M.; Nord, L.O. A Unified Geometry Parametrization Method for Turbomachinery Blades. Comput. Aided Des. 2021, 133, 102987. [Google Scholar] [CrossRef]

- Chatel, A.; Verstraete, T. Aerodynamic Optimization of the SRV2 Radial Compressor Using an Adjoint-Based Optimization Method. In Proceedings of the ASME Turbo Expo 2022, Rotterdam, The Netherlands, 13–17 June 2022. [Google Scholar]

- Verstraete, T.; Muller, L.; Mueller, J.D. CAD-Based Adjoint Optimization of the Stresses in a Radial Turbine. In Proceedings of the ASME Turbo Expo 2017, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Spalart, P.R.; Allmaras, S.R. A One-Equation Turbulence Model for Aerodynamic Flows. La Rech. Aerosp. 1994, 1, 5–21. [Google Scholar]

- Balbaa, M.; Mekhiel, S.; Elbestawi, M.; McIsaac, J. On Selective Laser melting of Inconel 718: Densification, Surface Roughness, and Residual Stresses. Mater. Des. 2020, 193, 108818. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective Laser Melting Additive Manufacturing of Inconel 718 Superalloy Parts: Densification, Microstructure and Properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Sharma, S.; Panaiappan, K.; Mishra, V.D.; Vedantam, S.; Murthy, H.; Rao, B.C. Mechanical Characterization of Near-Isotropic Inconel 718 Fabricated by Laser Powder-Bed Fusion. Metall. Mater. Trans. A 2023, 54, 270–285. [Google Scholar] [CrossRef]

- Gruber, K.; Stopyra, W.; Kobiela, K.; Madejski, B.; Malicki, M.; Kurzynowski, T. Mechanical Properties of Inconel 718 Additively Manufactured by Laser Powder Bed Fusion after Industrial High-Temperature Heat Treatment. J. Manuf. Process. 2022, 73, 642–659. [Google Scholar] [CrossRef]

- Muduli, S.K.; Mishra, R.K.; Satapathy, R.K.; Chandel, S. Effect of Operating Variables on the Performance of a Highly Loaded Annular Combustor. Int. J. Turbo Jet Engines 2014, 32, 85–95. [Google Scholar] [CrossRef]

- High Temp Metals. Available online: https://www.hightempmetals.com/techdata/hitempInconel718data.php/ (accessed on 5 August 2024).

- Kambampati, S.; Gray, J.S.; Kim, H.A. Level Set Topology Optimization of Structures under Stress and Temperature Constraints. Comput. Struct. 2020, 235, 106265. [Google Scholar] [CrossRef]

- Xu, S.; Radford, D.; Meyer, M.; Mueller, J.D. Stabilisation of Discrete Steady Adjoint Solvers. J. Comput. Phys. 2015, 299, 175–195. [Google Scholar] [CrossRef]

- Nielsen, E.J.; Lu, J.; Park, M.A.; Darmofal, D.L. An Implicit, Exact Dual Adjoint Solution Method for Turbulent Flows on Unstructured Grids. Comput. Fluids 2004, 33, 1131–1155. [Google Scholar] [CrossRef]

- Dwight, R.P.; Brezillon, J. Efficient and Robust Algorithms for Solution of the Adjoint Compressible Navier-Stokes Equations with Applications. Int. J. Numer. Methods Fluids 2009, 60, 365–389. [Google Scholar] [CrossRef]

- Muller, L.; Verstraete, T. Adjoint-based Multi-Point and Multi-Objective Optimization of a Turbocharger Radial Turbine. Int. J. Turbomach. Propuls. Power 2019, 4, 10. [Google Scholar] [CrossRef]

- Hottois, R.; Chatel, A.; Coussement, G.; Debruyn, T.; Verstraete, T. Comparing Gradient-Free and Gradient-Based Multi-Objective Optimization Methodologies on the VKI-LS89 Turbine Vane Test Case. J. Turbomach. Propuls. Power 2022, 145, 1–30. [Google Scholar]

- Muller, L.; Verstraete, T. CAD Integrated Multipoint Adjoint-Based Optimization of a Turbocharger Radial Turbine. J. Turbomach. Propuls. Power 2017, 2, 14. [Google Scholar] [CrossRef]

- Meng, F.; Zheng, Q.; Zhang, J. Effects of Blade Fillet Structures on Flow Field and Surface Heat Transfer in a Large Meridional Expansion Turbine. Energies 2019, 12, 3035. [Google Scholar] [CrossRef]

- Kienzle, N.; Hoang, D.H.N.; Waesker, M.; Buelten, B.; di Mare, F.; Doetsch, C. Influence of Fillet Radius on the Flow and Strength Behaviour of a Shrouded Centrifugal Compressor Impeller. In Proceedings of the 14th European Conference on Turbomachinery Fluid Dynamics & Thermodynamics, Gdansk, Poland, 12–16 April 2021. [Google Scholar]

- Loir, V.; Saracoglu, B.H.; Verstraete, T. Mixed-flow turbine multi-disciplinary optimization for additive manufacturing. In Proceedings of the 16th European Turbomachinery Conference, Hannover, Germany, 24–28 March 2025. paper n. ETC2025-183. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the EUROTURBO. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).