Abstract

The conversion of rough marble blocks into building products is environmentally intensive in terms of energy and water consumption and the generation of solid fragments and marble sludge (MS). This LCA study evaluates the environmental impact of two marble processing plants (for sawing and cutting) with respect to alternative scenarios of MS management including its (a) land disposal (baseline scenario—BS), (b) land disposal after filter pressing (current scenario—CS) and (c) partial valorization in cement mortars associated with the application of solar energy (eco-friendly scenario—ES). In this context, a “gate-to-gate” methodology is applied, while three main steps are considered: the sawing and cutting of marble blocks (main process) and the MS disposal and reuse. The LCA results indicate that terrestrial acidification (TAP), freshwater eutrophication (FEP), climate change and ozone depletion decreased by 10.8 to 37.1% by the adaptation of the BS and by 18 to 38.2% by the adaptation of the ES. At the same time, cumulative energy demand increases by 25.3% and 28.9%, respectively. The contribution analysis showed that the main process has the dominant effect on the examined categories. The contribution of the disposal step on TAP and FEP decreased by 61.6% and 47.9% via the application of the valorization technique.

1. Introduction

Marble is a metamorphic rock primarily composed of calcium carbonate, formed through the high-pressure recrystallization of limestone. Due to its excellent physicochemical properties—including durability, hardness, high compressive strength, and aesthetic appeal—it is one of the most widely used building and decorative stones []. Its processing typically involves the following: (a) the homogenization and cutting of irregular blocks, usually near the quarry site, (b) the cutting of these homogenized blocks into slabs and (c) the refinement processes including resin stabilization and polishing in a separate plant. The entire marble processing sequence is characterized by high electricity and water consumption as well as the generation of large volumes of waste. Producing a marble tile measuring 0.4 × 0.4 × 0.02 m requires between 3.6 and 4.3 MJ of energy [,,]. According to an alternative estimation basis, the processing of 1 m3 of rough block into thick slabs (0.4 m thick) and thin slabs (0.02 m thick) consumes approximately 300 MJ and 800 MJ of energy, respectively [,]. Sawing/cutting and polishing/refining are the most energy-intensive steps, accounting for 50–70% and up to 35% of the total energy consumed [,]. Electricity and diesel oil account for approximately 75–80% and 20–25% of the total energy mix [,]. The consumption of water for cooling and cleaning the diamond wire saw in a medium-capacity quarry plant is approximately 10 m3 per m3 of cut rough marble block []. Although the water recycling rate is generally high, it is often not specified in detail. The water footprint of producing one tonne of finished marble tile has been estimated at 3.6 m3 []. Climate change (CC), abiotic depletion (AD) and acidification (AP) have been identified as the most significant impact categories throughout the entire marble processing sequence. CC was estimated at the range of 310–390 kg CO2-eq./m3 [,] or 3.7–4 kg CO2 eq/m2 [] of processed tiles. Nevertheless, CC, AP, and human toxicity (HT) values are up to 50% lower in comparison to the respective values in the case of ceramic tile production [].

The processing of a 1 m3 raw marble block results in the formation of 540–756 kg of marble waste (MW) including sludge and solid fragments at a mass ratio of about 1:1 []. Marble sludge (MS), despite the absence of toxic trace elements [,], is hazardous due to the following: (a) the presence of styrene-based polymers that originated by various resins applied for raw marble stabilization, (b) the presence of Al2(SO4)3 and FeCl3 used as flocculant agents at the thickening process, (c) the high levels of chemical oxygen demand (COD) and (d) the small particle size (d90 < 50 μm) [,]. Landfill disposal remains the predominant global method for managing marble waste, including sludge and solid fragments []. Consequently, marble mining and processing sites are often heavily impacted, as MS is frequently accumulated in nearby unmonitored or illegal landfills.

Over the last two decades, numerous Life Cycle Assessment (LCA) studies have supported the valorization of marble waste (MW) in construction and building materials as a sustainable alternative to landfill disposal. The substitution of limestone with MW has been shown to reduce global warming potential (GWP) by 53%, while eutrophication potential (EP), smog formation potential (S), and acidification potential (AP) are decreased by 61–71% []. An alternative valorization approach involves the use of MW as a substitute for aggregates and/or cement in cementitious materials. However, relative studies have reported contradictory technical results regarding the effects of MW addition on compressive strength (f′c), workability, and resistance to chlorides [,,,,]. In general, limited substitution (up to 20%) of conventional aggregates and cement by MW does not negatively affect or slightly improve the mechanical and chemical properties of the end-products [,]. The replacement of limestone with MS in the clinkering process, combined with the additional incorporation of MS into CEM-II cement, reduces greenhouse gas emissions (GHG) by 34% and water consumption by 60% []. A 15% replacement of ordinary Portland cement (OPC) with MW in concrete showed negligible or slightly positive effects on several impact categories, including climate change, human toxicity, stratospheric ozone depletion, and particulate matter formation []. The substitution of 50 wt.% of ordinary aggregates by MS in concrete reduces the impacts related to carcinogens and organic pollutants, ozone layer depletion, ionizing radiation, and mineral scarcity by 15–35% []. Partial substitution of ordinary OPC by a mixture of MW (up to 20%) and silica fume (up to 10%) in Type II cement can reduce GWP, AP, and fossil fuel depletion potential (FFDP) by up to 70% []. The dehydration of marble-containing sludges—through methods such as air drying, spray drying, flash drying, and rotary drying—is the most environmentally intensive step in their valorization process [,].

Apart from its valorization in cementitious materials, the utilization of MW and MS has been explored in a wide range of other applications. MW has been successfully employed as an additive in the production of eco-fired bricks, yielding satisfactory compressive strength and thermal conductivity properties []. In contrast, less favorable performance was observed via MS addition into the clay matrix of ceramic tile bodies, as this led to increased water absorption and, consequently, to decreased bending strength []. MW has been found to enhance the physical and mechanical properties of alkali-activated materials []. Moreover, MW has been investigated as an additive for reinforced polymer composites. Its addition in mass fractions of up to 10 wt.% improves both the wear resistance and tensile strength of polylactic acid (PLA) and polyethylene terephthalate (PET) polymers, with a maximum tensile strength of 57.94 MPa reported for PET composites []. Respective results were observed in polypropylene (PP) composites []. Finally, submicron MS has demonstrated potential as an adsorbent for wastewater decontamination, exhibiting an adsorption capacity of approximately 21 mg·g−1 for Cu2+ ions []. Based on the above data, it can be concluded that MS can be valorized in a wide range of applications. However, its use as an additive in more complex materials could be further investigated in the future, such as MS-containing clinker for soft clay stabilization [,].

Despite the results obtained by a number of LCA studies demonstrating the environmental benefit of MS valorization at lab/pilot scale, the direct environmental effect of valorization on marble processing remains unclear at plant/industrial scale. To address this gap, the present gate-to-gate LCA study compares the environmental impact of marble processing at two plants located near Athens, Greece. Plant A handles the homogenization and sawing of rough blocks, while Plant B carries out downstream processing through the refinement and cutting of blocks into slabs. Three waste management scenarios are considered: (a) disposal of hydrated, as-generated MS (baseline scenario—BS), (b) disposal of dehydrated (filter-pressed) MS (current scenario—CS), and (c) partial valorization of MS in cement mortars along with the use of solar energy instead of grid electricity throughout the process (eco-friendly scenario—ES). To the best of our knowledge, this is the first study in the literature to simultaneously consider the application of a filter press for MS dehydration followed by its valorization in a cementitious material, as well as the integration of renewable (solar) energy into marble processing through an eco-friendly proposed scenario (scenario c). The environmental benefit of the optimum scenario is quantified across a number of impact categories and compared to scenarios (a) and (b). This study will contribute to evaluating the environmental implications of MS valorization at an industrial scale and provide useful outcomes for more sustainable marble production practices in terms of environmental performance.

2. Materials and Methods

The LCA study was conducted in accordance with the ISO 14040 and 14044 standards [,]. In line with these standards, the four key phases of an LCA were followed: (i) Goal and Scope Definition, which provides the objectives and system boundaries; (ii) life cycle inventory (LCI) analysis, which involves gathering data on material and energy inputs and emissions; (iii) life cycle impact assessment (LCIA), which evaluates potential environmental impacts; and (iv) interpretation, where outcomes are analyzed to inform decision making and strategies for reducing GHG emissions and enhancing environmental performance.

2.1. Goal and Scope

The goal of the LCA study is to comparatively quantify the environmental impact of rough marble processing under different waste management scenarios. Raw marble (irregular block) was processed successively in (a) Plant A, where the sawing of the irregular marble blocks takes place, and (b) Plant B, where the subsequent refinement and cutting of homogenized marble blocks into semifinished slabs were performed.

2.2. Marble Processing Route—System Boundaries

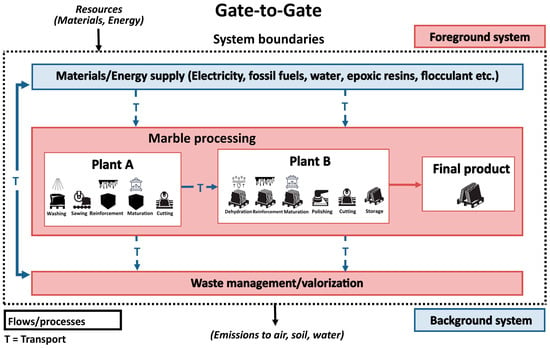

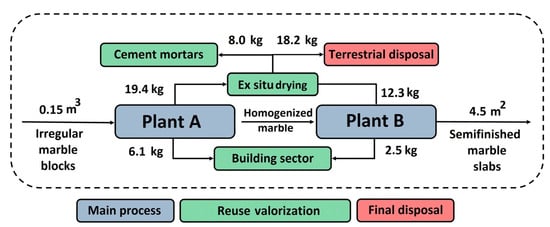

A semifinished marble slab with a surface area of 4.5 m2 and a thickness of 0.02 m [3 (W) × 1.5 (H) × 0.02 (T) m] was selected as the functional unit. These specific dimensions correspond to the actual sizes in which marble is processed at Plant B. It consists of the main intermediate material for the fabrication of various types of domestic floor tiles, wall cladding panels and benches at various standardized dimensions. The localities of both marble quarrying and processing are situated in Greece, a major worldwide marble producer country with an annual production of approximately 1 million m3 []. Plants A and B are located in Attika administrative region near the capital city of Athens, while marble blocks were quarried in Northern Greece. A gate-to-gate approach was adopted with the import of irregular marble blocks into Plant A defined as the entry gate and the export of semifinished marble slabs from Plant B defined as the exit gate (Figure 1).

Figure 1.

Gate-to-gate system boundaries adopted in the present LCA study.

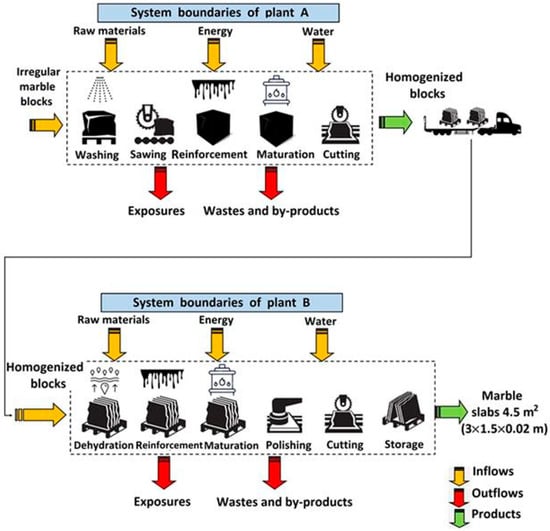

The analytical system boundaries shown in Figure 2 cover a wide range of various processing stages and material/energy flows associated with the production of marble slabs. These boundaries include on-site processes such as washing, block cutting, polishing, water use and recycling, energy consumption, flocculant use and others. Downstream flows, such as waste generation (dust, slurry, wastewater), by-product handling, and resource recovery, were also considered.

Figure 2.

Analytical system boundaries describing the processing of irregular marble blocks in Plants A and B.

Irregular dolomitic marble blocks with an approximate volume of 6 m3 were supplied to Plant A from open-pit quarries in Eastern Macedonia and Thrace administrative region, Northern Greece. At this stage, superficial inhomogeneities on the blocks were sawn in order to obtain a rectangular cubic structure, while, subsequently, defects and cracks were filled with fiberglass resin. Mechanically stabilized blocks were cut into slabs (with thickness of 2 or 3 cm) in Plant B. The cutting process duration is about 10 h per block, while the plant disposes 5 cutting machines operating in parallel. Secondarily revealed marble defects were treated through resining in vacuum after the dehydration of the slabs in furnace at 40 °C.

The last stage includes their geometric configuration and polishing. MS and solid marble waste (fragments) were generated via the cutting process in both Plants A and B. MS was separated from the water phase in precipitation tanks using flocculant agents such as aluminum sulfate or iron chloride. MS dehydration was performed in a filter press. The process includes the pumping of the sludge in the filter press system, the capture of the marble cake on the surface of cloths and the evacuation of the wastewater through a drainage system into a tank. Filtration pressure increases progressively with the increase in marble particle retention degree. Wastewater produced through precipitation and filter pressing was recycled into the plant. Electrical energy for the operation of various systems (i.e., cutting machines, furnaces, vacuum chambers and filter presses) was provided by the public electricity grid mix network.

2.3. Data Collection

The life cycle inventory data for the present study were collected from various sources, including the following:

- i.

- Primary data regarding technical and production annual data, provided by the private company operating marble processing Plants A and B through targeted questionnaires and on-site visits.

- ii.

- Secondary literature data mainly concerning the use of MS as a substitute for the synthesis of cementitious products [].

- iii.

- Data based on assumptions in combination with technical specifications provided by the personnel of Plants A and B.

This data retrieval approach proved successful in the environmental and energy assessment of industrial and agricultural products through improved accuracy and reduced data uncertainty [,,].

2.4. Scenario Analysis

Scenario analysis was used to identify differences in key parameters and production stages and to provide a comprehensive assessment of how various assumptions or input changes may affect the LCA results []. In this context, three different waste management scenarios were considered, focusing on rough marble processing, the handling and reuse of the generated MS, and the management of energy sources. More specifically, the following scenarios were examined: (a) land disposal of untreated (non-dehydrated) MS, representing the baseline scenario (BS), (b) disposal of MS after press filtration, along with recycling of the collected wastewater representing the current production and normal operation in both Plants A and B, representing the current scenario (CS), and (c) disposal of dehydrated MS followed by its partial valorization in cement mortar and the use of renewable solar energy, representing an eco-friendly scenario (ES). BS served as the baseline for quantifying the environmental impact reductions achieved through the two additional CS and ES.

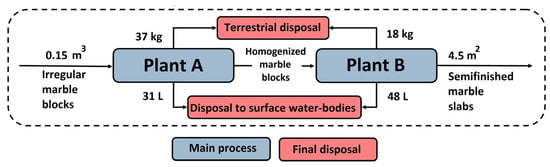

2.4.1. Baseline Scenario (BS): Land Disposal of Untreated MS

The disposal of non-dehydrated MS was selected as the worst-case environmental scenario, since this practice is still applied in lower-income countries worldwide [,,], and significant amounts of hydrated residue have accumulated over past decades, even within EU countries [], while it was the common practice in Greece during the previous decades. MS that formed at the bottom of the thickening tanks in both Plants A and B was transferred to adjacent evaporation tanks for a few days until moisture decreased to 25%. Subsequently, the sludge was deposited in landfills without any prior treatment, while the wastewater collected during the thickening process was discharged untreated into surface water bodies (Figure 3).

Figure 3.

Flowsheet and mass balance of the Baseline Scenario (BS): land disposal of untreated MS.

2.4.2. Current Scenario (CS): MS Press Filtering and Wastewater Recycling (Current Production)

This scenario corresponds to the existing operational conditions, processing practices, and waste management approaches of the Plants A and B. It involves the total recycling and reusing of the water consumed as a coolant for the cutting and polishing machines through the continuous chemical flocculation and filter press systems. The thickened hydrated sludge was sent to a filter press, where the largest amount of water was removed to achieve a maximum 10–15% moisture content. The sludge was further treated via ex situ drying and subsequently sent to an approved solid waste disposal site. Plants A and B generated solid marble cuttings of inhomogeneous sizes, which were collected and managed as follows: approximately 80% of the solid marble waste mass was composed of small fragments that cannot be directly recycled and were sent to an approved solid waste disposal site. The remaining 20% of solid marble waste was reused in construction works (Figure 4). Marble fragments, almost totally composed of calcium carbonate, were deposited as non-hazardous aggregate material in accordance with the latest legislation, including the EU Waste Framework Directive (Directive 2008/98/EC) and applicable national waste management regulations.

Figure 4.

Flowsheet and mass balance of current scenario (CS): MS press filtering and wastewater recycling.

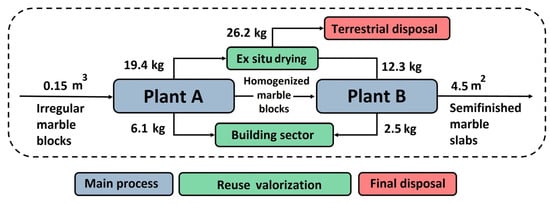

2.4.3. Eco-Friendly Scenario (ES): MS Valorization into Cement Mortar and Use of Renewable Energy Sources

This scenario involves the partial valorization of MS by the combination of solar energy use. The 20% of the generated MS (597 tonnes/year), after its dehydration, is valorized for the production of cement-based mortars (Figure 5). The chemical composition (wt.%) of MS generated in Plant B is CaO: 53.40, SiO2: 2.31, Al2O3: 0.85, Fe2O3: 0.30, MgO: 0.24, K2O: 0.13 and LOI: 42.35, while its particle size distribution is d90 < 30 μm and d50 < 5.5 μmm. A previous technical study indicated that the residue can be successfully used as an OPC replacement. The compressive strength of the mortar originated by the mixing of OPC-MS at a mass ratio of 5:1 was reduced by only 4%, reaching 54.4 MPa after 90 days of curing compared to the reference conventional OPC mortar. Therefore, MS consists of a promising OPC replacement in specific CEM I applications [].

Figure 5.

Flowsheet and mass balance of the eco-friendly scenario (ES): MS press filtering and partial valorization into cement mortar.

The application of renewable solar energy within the main marble processing facilities (Plants A and B) covers 40% of the total energy demand (675 MWh/year). For this purpose, a typical photovoltaic (PV) panel installation with a total capacity of 500 kWp, corresponding to a typical solar yield of about 1350 kWh·kWp−1·year−1 for central Greece, should be installed near Plants A and B or alternatively on a sloped surface such as the roofs of their main facilities. The annual energy production from the PV system is expected to reach 675 MWh, which fully offsets the required partial replacement of existing conventional electricity supplied by the public grid mix.

2.5. Life Cycle Inventory

The life cycle inventory of marble processing for Plants A and B under current production conditions is presented in Table 1. The mass and energy balances were estimated on a functional unit basis and cross-checked with technical reports obtained from the company to ensure data consistency and representativeness.

Table 1.

Life cycle inventory of marble processing for Plants A and B under current operational conditions (CS) for the production of a semifinished marble slab with a surface area of 4.5 m2 and a thickness of 0.02 m.

Primary data refer to the normal mode of operations carried out during the year 2020 and include water consumption, the use of chemicals (i.e., epoxy resins and flocculant agents), as well as transportation between Plants A and B. Background data for the inventory list related to process equipment and machinery, energy flows (electricity and fossil fuels), transportation, and materials/chemical reagents used during the marble slab production phase were sourced from the Ecoinvent v3.6 database.

2.6. Determination of LCA Impact Categories

The LCA study was conducted using the OpenLCA. V1.10.3 software, which permits the introduction and the editing of various databases. The assessment of the environmental impact was performed via the calculation of four midpoint impact categories (Table 2) according to the ReCiPe 2016 assessment methodology []. The cumulative energy demand (CED) was estimated as an indicator of energy flow in the studied system [].

Table 2.

The impact categories calculated in the LCA study according to the ReCiPe 2016 assessment methodology.

The ReCiPe 2016 characterization method was selected as it is more recent, comprehensive, realistic, and up-to-date compared to previous methods (e.g., IMPACT 2002+, Eco-indicator 99, ILCD 2011). Within this context, ReCiPe 2016 is considered a modern method that can more accurately and reliably characterize the range of environmental impacts associated with an environmental system or product, both in the short and long term [].

2.7. Key Considerations—Assumptions

A limited number of assumptions along with key considerations were made in the current study aiming to simplify the analysis and manage the inherent complexity associated with the estimation of the environmental impact generated by the management of the MS. More specifically,

- -

- The average mass of the functional unit (marble slab with dimensions A: 4.5 m2, d = 2 cm) is 235 kg. An irregular marble block with a volume of 0.15 m3 (405 kg) is considered the raw marble input in Plant A. MS (particle size < 2 mm) amount generated by the sawing and cutting processes corresponds to 27% of the initial mass of the block.

- -

- The marble recovery rate, referring to the main input-to-output conversion efficiency, is estimated at 69% in Plant A and 84% in Plant B.

- -

- The total installed power of Plant A is 1136 kW, of which 1019 kW corresponds to drive power and 117 kW to environmental protection equipment, while the total power of Plant B is 860 kW, including 794 kW of drive power and 66 kW dedicated to environmental protection systems.

- -

- The average road transport distance of the squared marble blocks from Plant A to Plant B is 12.7 km and is carried out using a EURO 4 heavy-duty truck with a maximum load capacity of 60 tons.

- -

- The end-products of the Plant B are distributed in the market on wooden pallets (wood mass by functional unit: 3.4 kg).

- -

- The waste management scenario involving land disposal accounts for both MS and solid marble fragments produced during the processing stage.

3. Results and Discussion

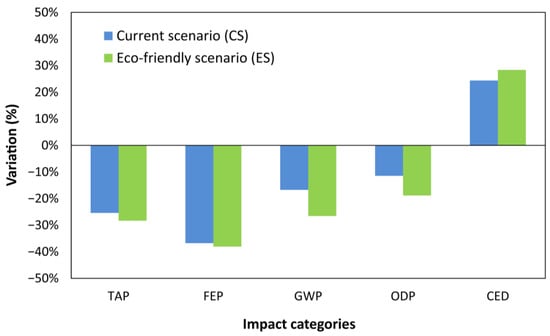

The life cycle assessment results following three different waste management scenarios for the production of marble slabs are presented in Table 3. As can be observed, all the studied impact categories are reduced between 12% and 38% via the implementation of the scenarios that involve the MS processing either through filter pressing dehydration (CS) or dehydration and partial valorization in cement mortars (ES). On the contrary, the cumulative energy demand increases up to 28% through the adoption of MS processing and valorization techniques.

Table 3.

Calculated values of the impact categories with respect to the three scenarios for the management of the MS.

The introduction of the filter press dehydration process in the CS results in a significant reduction in the environmental impact categories. More specifically, terrestrial acidification potential (TAP), freshwater eutrophication potential (FEP), climate change (CC) and ozone depletion potential (ODP) values are decreased by 25.4%, 36.8%, 16.7% and 11.4%, respectively. Further treatment of the MS through its valorization in cement mortars, according to the ES, results in a slight additional decrease in TAP and FEP, along with more intense reduction in CC and ODP by 26.6% and 18.8%, respectively. Conversely, the cumulative energy demand (CED) increases by 25.3% and 28.9% in the CS and ES, respectively, compared to the baseline scenario of untreated MS disposal. This increase is attributed to the higher energy requirements of processes such as MS filter pressing, cement mortar blending, and associated impacts (Figure 6).

Figure 6.

Variation in impact categories adopting the CS and ES (treatment and valorization of MS) in comparison to BS (disposal of untreated MS).

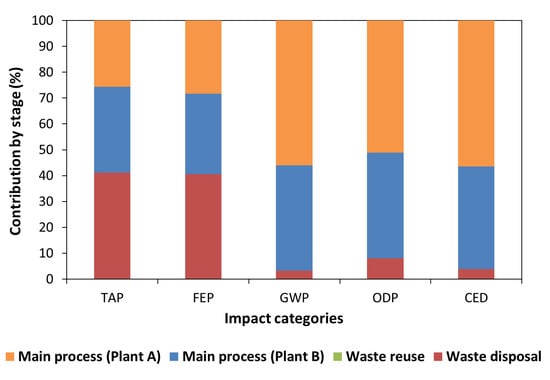

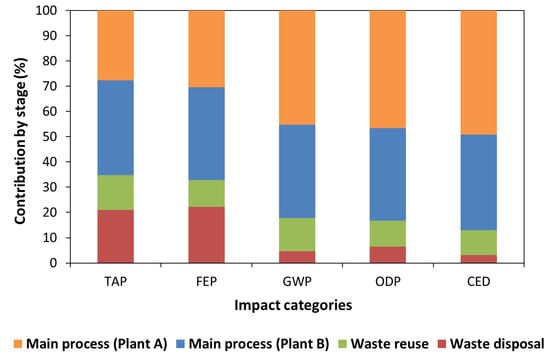

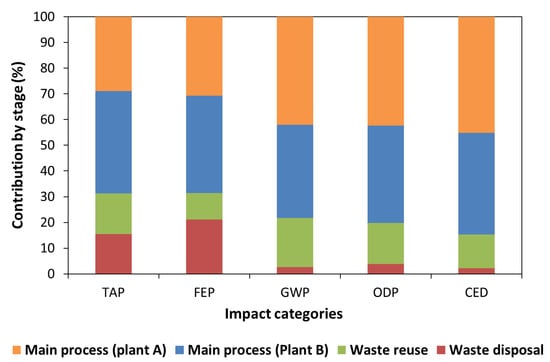

The contribution of each processing step to the impact categories is illustrated in Figure 7, Figure 8 and Figure 9. The sawing of irregular blocks in Plant A and their further cutting into slabs in Plant B are defined as the “main process” The “waste disposal” step refers to the following: (i) the land disposal of untreated marble MS, solid marble fragments, and wastewater in the BS; (ii) the land disposal of dehydrated MS and solid marble fragments (80% of the total mass amount) at an approved waste disposal site in the CS; and (iii) the land disposal of dehydrated MS (80% of the total mass amount) and solid marble fragments (80% of the total mass amount) in the ES. “Waste reuse” in the CS involves the recycling of wastewater and the partial reuse (20%) of solid marble fragments in the building sector. Additionally, in the case of the ES, MS is partially reused (20%) for the production of cement mortar.

Figure 7.

Contribution analysis of different processes to the impact categories in the case of disposal of untreated MS (BS).

Figure 8.

Contribution analysis of different processes to the impact categories in the case of MS dehydration (CS).

Figure 9.

Contribution analysis of different processes to the impact categories in the case of MS valorization (ES).

The contribution analysis results show that the “main process” in Plants A and B is the dominant contributor to the CC and ODP categories in BS, accounting for 96.7% and 92% of the impacts, respectively. The “main process” step contributes to a lower extent to TAP and FEP, where its share does not exceed 60%. The TAP and FEP values are significantly configured by the waste disposal process, which involves the land disposal of the non-dehydrated MS and the wastewater. CED value is primarily driven by the main process in Plant A (56%) and Plant B (41%), while the contribution of the “waste disposal” step is minimal (4%), exclusively attributed to the transportation of MS to the disposal site by the heavy-duty truck (Figure 7).

CS includes an additional step of wastewater recycling and partial reuse of marble fragments. Despite these modifications, the main process remains the dominant contributor to all evaluated environmental impact categories, ranging from 65.2% to 87.1%, and contributes 87.1% to CED. The sawing of irregular marble blocks in Plant A, as in the case of BS, seems to be more energy-intensive (contribution to CED by 49.2%) in comparison to the production of marble slabs in Plant B (contribution to CED by 38%) (Figure 8). The waste reuse step contributes between 10.3% and 13.7% across the environmental categories. Its contribution to cumulative energy (9.8%) is mainly due to the ex situ drying of the filter-pressed MS. The filter pressing process results in the limitation of the environmental impact of the “waste disposal” step as it is evidenced by the reduction in TAP and FEP values by 49% and 45%, respectively. However, a residual impact on terrestrial (TAP: 21%) and freshwater environments (FEP: 22%) persists, which is attributed to the continuation of dehydrated MS accumulation in the disposal site (Figure 8).

ES, in addition to the valorization of dehydrated MS into cement mortar, involves the use of solar energy to meet 40% of the energy demand for sawing, cutting, and MS filter pressing in both Plants A and B. The main process contributes from 68.6% to 80.2% to the examined environmental indicators and 84.7% to cumulative energy (Figure 9).

As it can be observed, the integration of renewable energy does not significantly differentiate the contribution of the main process (in Plants A and B) to the examined impact categories and CED. More specifically, the effect of the main processes on GWP, ODP and CED is decreased by 4.9%, 3.6% and 2.6%, respectively, in comparison to CS, while, at the same time, their effect on TAP and FEP increases by approximately 5% and 2%, respectively. The impact of the “waste disposal” step on TAP is further reduced by 26.2% in the ES compared to the CS. Meanwhile, the contribution of the “waste reuse” step increases across all impact categories as a result of the implementation of the dehydrated MS valorization into cement mortars. This increase is particularly significant in the categories of ODP, CC and CED, with contributions rising by 35.6%, 30.5%, and 25.2%, respectively.

4. Conclusions

The present life cycle assessment (LCA) study investigated the potential reduction in the environmental impact of the marble industry through the adoption of alternative marble sludge (MS) management techniques and the integration of renewable energy sources. The examined scenarios comparatively addressed the following: (a) the land disposal of the untreated as-generated MS—representing the worst, baseline scenario; (b) the disposal of the dehydrated MS after its filter pressing and ex situ air drying—consisting the currently applied scenario (CS); and (c) the partial valorization of the dried MS by its incorporation into cement mortar in combination to the application of renewable solar energy—representing the proposed optimal eco-friendly scenario (ES). The supply of rough marble blocks to processing Plant A, where the sawing is performed, was defined as the system’s entry gate, while the export of semi-finished marble slabs from Plant B, where the preparation of semi-finished products is taking place, was defined as the exit gate. The environmental impact assessment considered the following categories: terrestrial acidification potential (TAP), freshwater eutrophication potential (FEP), ozone depletion potential (ODP), climate change (CC) and cumulative energy demand (CED). The results indicated that the ES presents the lowest overall environmental impact. Compared to the worst-case scenario (BS), TAP, FEP, ODP and CC indicators are reduced by 10.8% to 37.1% in the CS and by 18% to 38.2% in the ES. More specifically, CC impact is significantly reduced in the CS and ES (reduction by 16.7% and 26.6%, respectively) compared to the BS. On the other hand, CED increases by 25.3% and 28.9% with the implementation of the CS and ES due to the introduction of the filter pressing and filter pressing/valorization steps. The overall marble treatment sequence was divided into the following: (a) the main process in Plants A and B, (b) the waste reuse and (c) the waste disposal. The contribution of each of these steps on the impact categories was assessed. The contribution analysis revealed that the main process in Plants A and B is the main impact contributor in the examined scenario. The main process accounts for 96.8%, 82.2% and 78.3% of the CC impact in the BS, CS and ES, respectively. The integration of solar energy in the ES had a limited positive effect on the reduction in the environmental impact of the main process. However, the combination of solar energy use and MS valorization notably decreases all the examined impact categories at the “waste disposal” step. The contribution of waste disposal to TAP and FEP was reduced by 61.6% and 47.9%, respectively. The overall LCA results, obtained by considering an industrial-scale case, are consistent with the literature data, indicating that the primary processes of marble sawing and cutting are the main contributors to several environmental impact categories and CED. The contribution of these main processes was not significantly reduced by the integration of renewable (solar) energy into the marble processing route. On the contrary, the MS filter-pressing in association with its partial valorization in cement mortar leads to a significant reduction in the environmental impact of the waste disposal step. As future work, aiming at the further reduction in the environmental impact of the marble processing sector, a performance life cycle assessment involving the valorization of MW in innovative materials (i.e., eco-friendly bricks, geopolymers, and adsorbents for water decontamination) is proposed.

Author Contributions

Conceptualization, A.C. and G.B.; methodology, A.C. and G.B.; software, A.C. and G.B.; formal analysis, G.B.; investigation, A.C. and G.B.; resources, G.B.; data curation, M.S. and G.B.; writing—original draft preparation, A.C. and M.S.; writing—review and editing, G.B.; visualization, A.C. and M.S.; supervision, G.B.; project administration, G.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors confirm that all data supporting the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yardley, B.; Warren, C. An Introduction to Metamorphic Petrology, 2nd ed.; Cambridge University Press: Cambridge, UK, 2020; pp. 4–31. [Google Scholar]

- Nicoletti, G.M.; Notarnicola, B.; Tassielli, G. Comparative Life Cycle Assessment of flooring materials: Ceramic versus marble tiles. J. Clean. Prod. 2002, 10, 283–296. [Google Scholar] [CrossRef]

- Traverso, M.; Rizzo, G.; Finkbeiner, M. Environmental performance of building materials: Life cycle assessment of a typical Sicilian marble. Int. J. Life Cycle Assess. 2010, 15, 104–114. [Google Scholar] [CrossRef]

- Gazi, A.; Skevis, G.; Founti, M.A. Energy efficiency and environmental assessment of a typical marble quarry and processing plant. J. Clean. Prod. 2012, 32, 10–21. [Google Scholar] [CrossRef]

- Prajwal, B.; Mali, H.S.; Nagar, R. Life cycle energy assessment of a typical marble processing plant. Int. J. Soc. Ecol. Sustain. Dev. 2019, 10, 31–45. [Google Scholar] [CrossRef]

- Liguori, V.; Rizzo, G.; Traverso, M. Marble quarrying: An energy and waste intensive activity in the production of building materials. In Proceedings of the WIT Congress, Cadiz, Spain, 26–28 May 2008. [Google Scholar]

- Ahmad, T.; Hussain, M.; Iqbal, M.; Ali, A.; Manzoor, W.; Bibi, H.; Ali, S.; Rehman, F.; Rashedi, A.; Amin, M.; et al. Environmental, Energy, and Water Footprints of Marble Tile Production Chain in a Life Cycle Perspective. Sustainability 2022, 14, 8325. [Google Scholar] [CrossRef]

- Günkaya, Z.; Karakasulu, L.; Evliyaoglu, G.; Ciftci, M. Life cycle assessment of marble plate production. J. Nat. Appl. Sci. 2018, 22, 521–527. [Google Scholar] [CrossRef]

- Yurdakul, M. Natural stone waste generation from the perspective of natural stone processing plants: An industrial-scale case study in the province of Bilecik, Turkey. J. Clean. Prod. 2020, 276, 123339. [Google Scholar] [CrossRef]

- Khan, A.; Patidar, R.; Pappu, A. Marble waste characterization and reinforcement in low density polyethylene composites via injection moulding: Towards improved mechanical strength and thermal conductivity. Constr. Build. Mater. 2020, 269, 121229. [Google Scholar] [CrossRef]

- Scioti, A.; Bernardo, G.; Mecca, I.; Fatiguso, F. Characterization of stone waste sludge and preliminary investigation on green materials based on traditional lime putty for sustainable construction. Sustainability 2024, 16, 9173. [Google Scholar] [CrossRef]

- Arslan, E.I.; Aslan, S.; Ipek, U.; Altun, S.; Yazicioğlu, S. Physico-chemical treatment of marble processing wastewater and the recycling of its sludge. Waste Manag. Res. 2005, 23, 550–559. [Google Scholar] [CrossRef]

- Rizzo, G.; D’Agostino, F.; Ercoli, L. Problems of soil and groundwater pollution in the disposal of “marble” slurries in NW Sicily. Environ. Geol. 2007, 55, 929–935. [Google Scholar] [CrossRef]

- Tazzini, A.; Gambino, F.; Casale, M.; Dino, G.A. Managing marble quarry waste: Opportunities and challenges for circular economy implementation. Sustainability 2024, 16, 3056. [Google Scholar] [CrossRef]

- Vieira, L.B.; Francioso, V.; Mariani, B.B.; Moro, C.; Barbosa, J.D.V.; Cardoso, L.S.P.; Dias, C.M.R.; Velay-Lizancos, M. Valorization of marble waste powder as a replacement for limestone in clinker production: Technical, environmental and economic evaluation. Sustainability 2023, 15, 13902. [Google Scholar] [CrossRef]

- Agarwal, S.K.; Gulati, D. Utilization of industrial wastes and unprocessed micro-fillers for making cost effective mortars. Constr. Build. Mater. 2006, 20, 999–1004. [Google Scholar] [CrossRef]

- Rodrigues, R.; de Brito, J.; Sardinha, M. Mechanical properties of structural concrete containing very fine aggregates from marble cutting sludge. Constr. Build. Mater. 2015, 77, 349–356. [Google Scholar] [CrossRef]

- Rana, A.; Kalla, P.; Csetenyi, L.J. Sustainable use of marble slurry in concrete. J. Clean. Prod. 2015, 94, 304–311. [Google Scholar] [CrossRef]

- Mashaly, A.O.; El-Kaliouby, B.A.; Shalaby, B.N.; El-Gohary, A.M.; Rashwan, M.A. Effects of marble sludge incorporation on the properties of cement composites and concrete paving blocks. J. Clean. Prod. 2016, 112, 731–741. [Google Scholar] [CrossRef]

- Vardhan, K.; Siddique, R.; Goyal, S. Strength, permeation and micro-structural characteristics of concrete incorporating waste marble. Constr. Build. Mater. 2019, 203, 45–55. [Google Scholar] [CrossRef]

- Alyamaç, K.E.; Aydin, A. Concrete properties containing fine aggregate marble powder. KSCE J. Civ. Eng. 2015, 19, 2208–2216. [Google Scholar] [CrossRef]

- Sánchez, A.R.; Ramos, V.C.; Polo, M.S.; Ramón, M.V.L.; Utrilla, J.R. Life cycle assessment of cement production with marble waste sludges. Int. J. Environ. Res. Public Health 2021, 18, 10968. [Google Scholar] [CrossRef]

- Singh, M.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Bhunia, D. A study on environmental and economic impacts of using waste marble powder in concrete. J. Build. Eng. 2017, 13, 87–95. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life cycle assessment (LCA) of different kinds of concrete containing waste for sustainable construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef]

- Khodabakhshian, A.; de Brito, J.; Ghalehnovi, M.; Asadi Shamsabadi, E. Mechanical, environmental and economic performance of structural concrete containing silica fume and marble industry waste powder. Constr. Build. Mater. 2018, 169, 237–251. [Google Scholar] [CrossRef]

- Rebello, T.A.; Zulcão, R.; Calmon, J.L.; Gonçalves, R.F. Comparative life cycle assessment of ornamental stone processing waste recycling, sand, clay and limestone filler. Wast. Manag. Res. 2019, 37, 186–195. [Google Scholar] [CrossRef]

- Zulcão, R.; Calmon, J.L.; Rebello, T.A.; Vieira, D.R. Life cycle assessment of the ornamental stone processing waste use in cement-based building materials. Constr. Build. Mater. 2020, 257, 119523. [Google Scholar] [CrossRef]

- Bayoussef, A.; Moukannaa, S.; Loutou, L.; Taha, Y.; Benzaazoua, M.; Hakkou, R. Eco-Fired Bricks from Phosphate Mine Waste Rocks: The effects of marble waste powder on the physical and microstructural properties. Ceramics 2025, 8, 48. [Google Scholar] [CrossRef]

- Montero, M.A.; Jordán, M.M.; Hernández-Crespo, M.S.; Sanfeliu, T. The use of sewage sludge and marble residues in the manufacture of ceramic tile bodies. Appl. Clay Sci. 2009, 46, 404–408. [Google Scholar] [CrossRef]

- Komnitsas, K.; Soultana, A.; Bartzas, G. Marble waste valorization through alkali activation. Minerals 2021, 11, 46. [Google Scholar] [CrossRef]

- Singh, T.; Pattnaik, P.; Shekhawat, D.; Ranakoti, L.; Lendvai, L. Waste marble dust-filled sustainable polymer composite selection using a multi-criteria decision-making technique. Arab. J. Chem. 2023, 16, 104695. [Google Scholar] [CrossRef]

- Bakshi, P.; Pappu, A.; Patidar, R.; Gupta, M.K.; Thakur, V.K. Transforming marble waste into high-performance, water-resistant, and thermally insulative hybrid polymer composites for environmental sustainability. Polymers 2020, 12, 1781. [Google Scholar] [CrossRef]

- Ramos, V.C.; Utrilla, J.R.; Sánchez, A.R.; Ramón, M.V.L.; Polo, M.S. Marble waste sludges as Effective nanomaterials for Cu (II) adsorption in aqueous media. Nanomaterials 2021, 11, 2305. [Google Scholar] [CrossRef]

- Wu, J.; Deng, Y.; Zhang, G.; Zhou, A.; Tan, Y.; Xiao, H.; Zheng, Q. A generic framework of unifying industrial by-products for soil stabilization. J. Clean. Prod. 2021, 321, 128920. [Google Scholar] [CrossRef]

- Wu, J.; Liu, L.; Deng, Y.; Zhang, G.; Zhou, A.; Xiao, H. Use of recycled gypsum in the cement-based stabilization of very softclays and its micro-mechanism. J. Rock. Mech. Geotech. Eng. 2022, 14, 909–921. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Laskaridis, K.; Arapakou, A.; Patronis, M.; Kouseris, I. Physical Mechanical Properties and Producing Areas of Greek Dimension Stones. Mater. Proc. 2001, 5, 64. [Google Scholar]

- Kechagia, P.; Koutroumpi, D.; Bartzas, G.; Peppas, A.; Samouhos, M.; Deligiannis, S.; Tsakiridis, P.E. Waste marble dust and recycled glass valorization in the production of ternary blended cements. Sci. Total Environ. 2021, 761, 143224. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Life cycle assessment of ferronickel production in Greece. Resour. Conserv. Recycl. 2015, 105, 113–122. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Life cycle analysis of pistachio production in Greece. Sci. Total Environ. 2017, 595, 13–24. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Cradle to gate life-cycle assessment of battery grade nickel sulphate production through high-pressure acid leaching. Sci. Total Environ. 2024, 952, 175902. [Google Scholar] [CrossRef]

- El-Sayed, H.A.; Farag, A.B.; Kandeel, A.M.; Younes, A.A.; Yousef, M.M. Characteristics of the marble processing powder waste at Shaq El-Thoaban industrial area, Egypt, and its suitability for cement manufacture. HBRC J. 2018, 14, 171–179. [Google Scholar] [CrossRef]

- Ural, N.; Yakşe, G. Utilization of marble piece wastes as base materials. Open Geosci. 2020, 12, 1247–1262. [Google Scholar] [CrossRef]

- Singh, R.; Fitzgerald, S.; Dada, R.; Frank, A.L. Marble waste dump yard in Rajasthan, India revealed as a potential asbestos exposure hazard. Int. J. Environ. Res. Public Health 2025, 22, 215. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Knöpfel, S.B.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y. Evaluating the potential health and economic effects of nitrogen fertilizer application in grain production systems of China. J. Clean. Prod. 2020, 264, 121635. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).