- Review

The Evolution of Lithography: From Resolution Scaling to Manufacturing Constraints

- Heejoon Chae,

- Hyunje Park and

- Dae Joon Kang

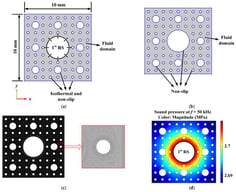

Lithographic patterning continues to evolve under the dual pressure of ever-finer features and manufacturable, cost-effective integration. Beyond headline resolution, industrial adoption is increasingly determined by a small set of coupled metrics: throughput, overlay (registration), defectivity, and cost, as well as by how these trade-offs shift with materials, substrate form factors, and integration flows. Here, we review lithographic techniques across three eras: traditional methods (pre-1990s), non-conventional innovations (1990s), and contemporary advancements (post-2000s), with an explicit goal that goes beyond compilation. Specifically, we provide a decision framework for interpreting each method using the same manufacturing-relevant criteria. For each class of technique, we summarize the operating principle and representative process routes, then map the dominant bottlenecks to the metric that ultimately limits scale-up. This cross-cutting lens clarifies why many emerging methods are compelling at the physics level yet remain constrained at the system level, where process windows, in-line control, and compatibility with existing fabrication ecosystems govern viability. By connecting mechanism-level innovation to manufacturing-level constraints, this review offers practical guidance for researchers and engineers seeking to position nanolithography options for applications ranging from high-volume semiconductor production to agile prototyping and materials- or substrate-limited devices.

18 February 2026

![Chronological evolution of lithographic techniques. Patterning methods are classified into traditional, non-conventional, and contemporary innovations. Adapting recent trends for AI technology or IoT devices, next-generation lithography will be highly demanded. Inset plots summarize key trade-offs. The serial-lithography map (resolution–throughput–cost) compares serial techniques, with cost encoded by the color scale (low → high). The parallel-lithography map (resolution–scalability–cost) compares parallel techniques, again with cost represented by color [11,31,32,60,65,66,67,68,69,70,71,72].](https://mdpi-res.com/cdn-cgi/image/w=470,h=317/https://mdpi-res.com/micromachines/micromachines-17-00261/article_deploy/html/images/micromachines-17-00261-g001-550.jpg)

![Schematic diagrams of BCF and MPF propulsion modes. (a) Schematic diagrams of BCF mode [14]. (b) Schematic diagrams of MPF mode [15].](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/micromachines/micromachines-17-00258/article_deploy/html/images/micromachines-17-00258-g001-550.jpg)