- Article

Effect of Crystal Orientation on Dislocation Loop Evolution Under Electron Radiation in Pure Aluminum

- Yupeng Yin,

- Qianfei Feng and

- Farong Wan

- + 6 authors

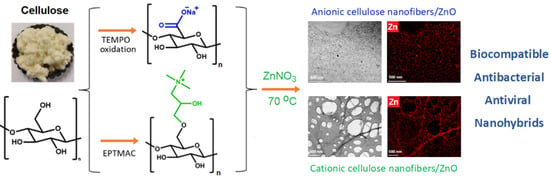

Aluminum, the primary structural material used in spacecraft, operates in low Earth orbit (LEO). It is subjected to high-energy electron irradiation with energies ranging from 0.1 to 10 MeV, which produces significant irradiation damage. Understanding the characteristics of irradiation defects with crystallographic orientations is crucial for analyzing the failure of spacecraft components and for developing aerospace materials with improved irradiation resistance. In this study, pure aluminum was irradiated in situ at room temperature using 200 kV transmission electron microscopy. The irradiation defects were comparatively analyzed for four crystallographic orientations, focusing on the size, density, and interstitial content of <111> and <110> dislocation loops. For all four irradiation directions, the interstitial atom density (IAD) within <111> loops is significantly higher than that in <110> loops. Notably, under [110]-direction irradiation, IAD in <111> loops is approximately 55 times that in <110> loops. This phenomenon is attributed to the one-dimensional migration of <110> loops. Among the four irradiation directions, the total IAD in the two types of loops decreases in the order: [110] > [111] > [310] > [100]. The threshold displacement energy (Ed) of aluminum at room temperature is inferred to follow the relationship: [110] < [111] < [310] < [100].

15 January 2026

![Selected-area electron diffraction (SAED) patterns and TEM bright-field images of the sample acquired along the [100], [310], [110], and [111] crystallographic orientations, obtained before and after 10 min of electron irradiation.](https://mdpi-res.com/materials/materials-19-00350/article_deploy/html/images/materials-19-00350-ag-550.jpg)

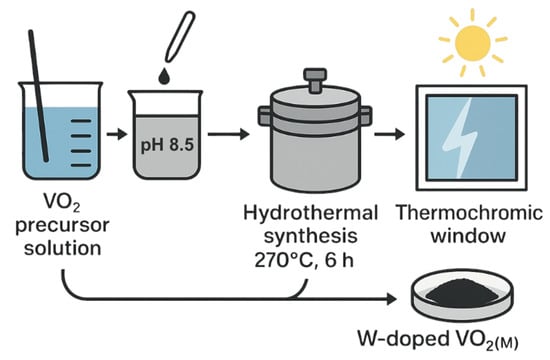

![(a) Schematics of the UHG system applied in this work. (b) Temperature profile of the ultrafast graphitization process. The continuous line represents the temperature simulated by finite element modeling (FEM) [15], while the data points were obtained by melting reference materials with well-defined melting points. For temperature calibration, three small wires/pieces were embedded at different positions on both the top and sides of the sample. The error bars indicate the time interval from partial to complete melting of each wire/piece located at the three probing positions. The reference samples UHG1 and UHG2 have discharge times of 180 s and 300 s at a maximum graphitization current of 95 A, respectively. (c) XRD patterns and (d) Raman spectra of the corresponding graphitized samples derived from UHG compared to commercial-grade graphite.](https://mdpi-res.com/materials/materials-19-00348/article_deploy/html/images/materials-19-00348-ag-550.jpg)