- 3.2Impact Factor

- 6.4CiteScore

- 16 daysTime to First Decision

Additive Manufacturing of Composites, Volume II

This special issue belongs to the section “Advanced Composites“.

Special Issue Information

Dear Colleagues,

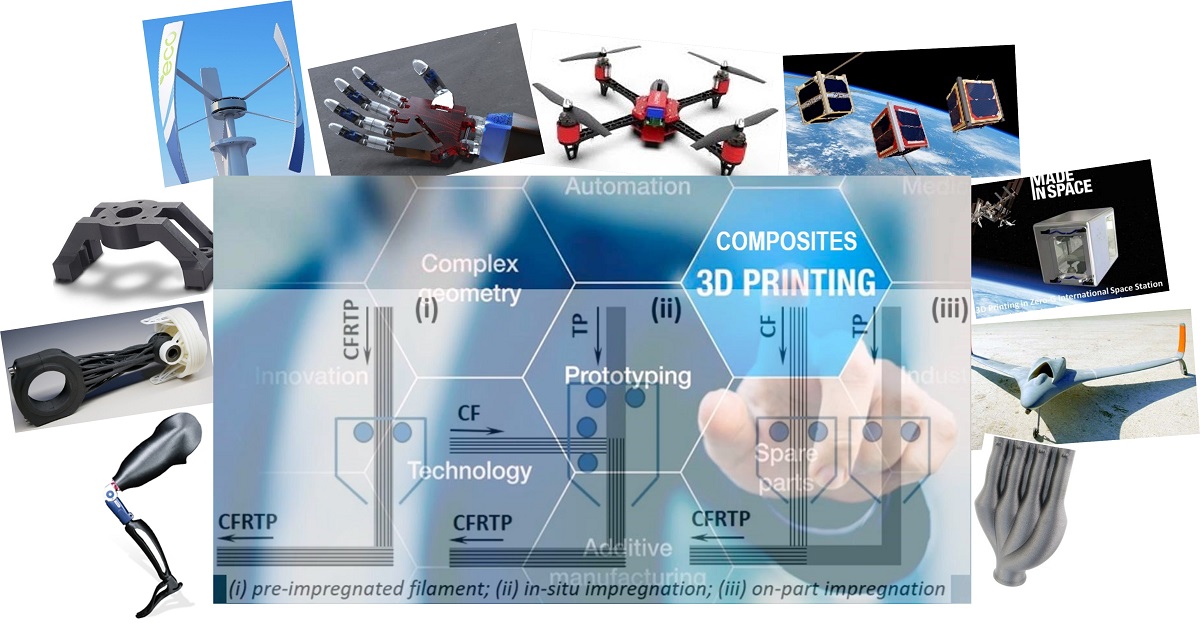

Currently, there is an increasing demand for high performance/fiber-reinforced composite/materials for structural applications in key industry sectors (e.g., aerospace, military, automotive and motorsport, robotics, medical). The common feature of these applications is the lightweight design strategy which provides reduced structural weight while preserving high mechanical performance, less fuel consumption directly related to less carbon emission, and increased design flexibility compared to traditional isotropic materials. The concept especially applies to fiber reinforced polymer, ceramic, and metallic matrices for structural application under severe loading conditions.

At the same time, digital additive manufacturing (AM, commonly referred to as 3D printing) has emerged as a relatively new and booming concept, a manufacturing method of extreme interest for further development and innovation due to its potential to bring complete modification of the production chain: no need for complex tooling and reduced need for auxiliary manufacturing systems which translates into fewer associated costs, more efficient use of resources and positive environment impact, adaption to low production rates at competitive costs, possibility to produce parts of high geometrical complexity and complex assemblies with fewer parts and fewer joining elements, flexibility to rapidly apply design changes thus meeting the needs of a more and more dynamic market, almost zero manufacturing waste, and advanced human–machine interaction in a compact and predominantly computer controlled environment for integrated design and manufacturing.

The scope of this Special Issue is to present the latest developments in the field of 3D printing of fiber reinforced composites. Topics addressed include new additive manufacturing technologies covering various families of material extrusion, material lamination, binder jetting, selective curing/sintering, etc., especially designed for the processing of fiber-reinforced composites. New composite systems based on polymeric (both thermoplastic and thermoset), ceramic (oxide and non-oxide) or metallic matrices, containing either short or continuous fiber reinforcement, are also covered.

Dr. Adi Adumitroaie

Prof. Dr. Paolo Colombo

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- additive manufacturing

- 3D printing

- fiber-reinforced composite

- polymer matrix composite

- ceramic matrix composite

- metal matrix composite

- non-fiber reinforced composites

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.

Related Special Issues

- Additive Manufacturing of Fiber CompositesinMaterials (9 articles)