- Article

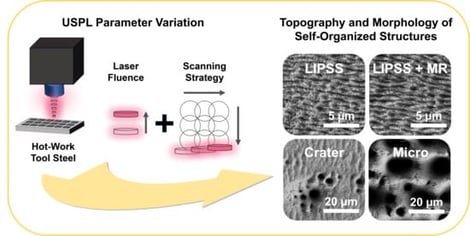

Effect of Laser Scanning Parameters on Topography and Morphology of Femtosecond Laser-Structured Hot-Work Tool Steel Surfaces

- Robert Thomas,

- Hermann Seitz and

- Georg Schnell

In mechanical engineering, interest in reliable and practicable technologies for nano- and microstructuring of tool surfaces is increasing. Femtosecond laser structuring offers a promising approach that combines high processing speeds with high precision. However, a knowledge gap remains regarding the optimal process parameters for achieving specific surface patterns on hot-work tool steel substrates. The current study aims to investigate the effects of laser scanning parameters on the formation of self-organized surface structures and the resulting topography and morphology. Therefore, samples were irradiated using a 300 fs laser with linearly polarized light (λ = 1030 nm). Scanning electron microscopy revealed four structure types: laser-induced periodic surface structures (LIPSSs), micrometric ripples, micro-crater structures, and pillared microstructures. The results for surface area and line roughness indicate that high laser pulse overlaps lower the strong ablation threshold more effectively than high scanning line overlaps, promoting the formation of pillared microstructures. For efficient ablation and increased surface roughness, higher pulse overlaps are therefore advantageous. In contrast, at low fluences, higher scanning line overlaps support a more homogeneous formation of nanostructures and reduce waviness.

7 February 2026

![An example of a holistic approach involving the creation of both a physical model and an in silico (computational) model of a human skull, as studied in [15,16]. (A) A number of replicas of the skull were impacted at the same point in a drop tower, suitable illumination and high speed cameras were used, full details in [15,16]; (B) crack patterns at the site of impact were emanating in 3 diverging crack routes, which were identical in all replicas of the skull used [15]; (C) other cracks at the base of the skull (red square) appeared reliably and repeatedly in certain areas and where FEA modelling predicted them to appear (enlarged views of the area in (D,E)), showing a synergy and agreement between these two powerful biomechanical testing methodologies (AM produced physical model and in silico computational model).](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/jmmp/jmmp-10-00056/article_deploy/html/images/jmmp-10-00056-g001-550.jpg)