A Review of Production Scheduling with Artificial Intelligence and Digital Twins

Abstract

1. Introduction

2. Methodology

3. Artificial Intelligence and Digital Twins for Production Scheduling

3.1. Introduction to DT-AI-Based Production Scheduling

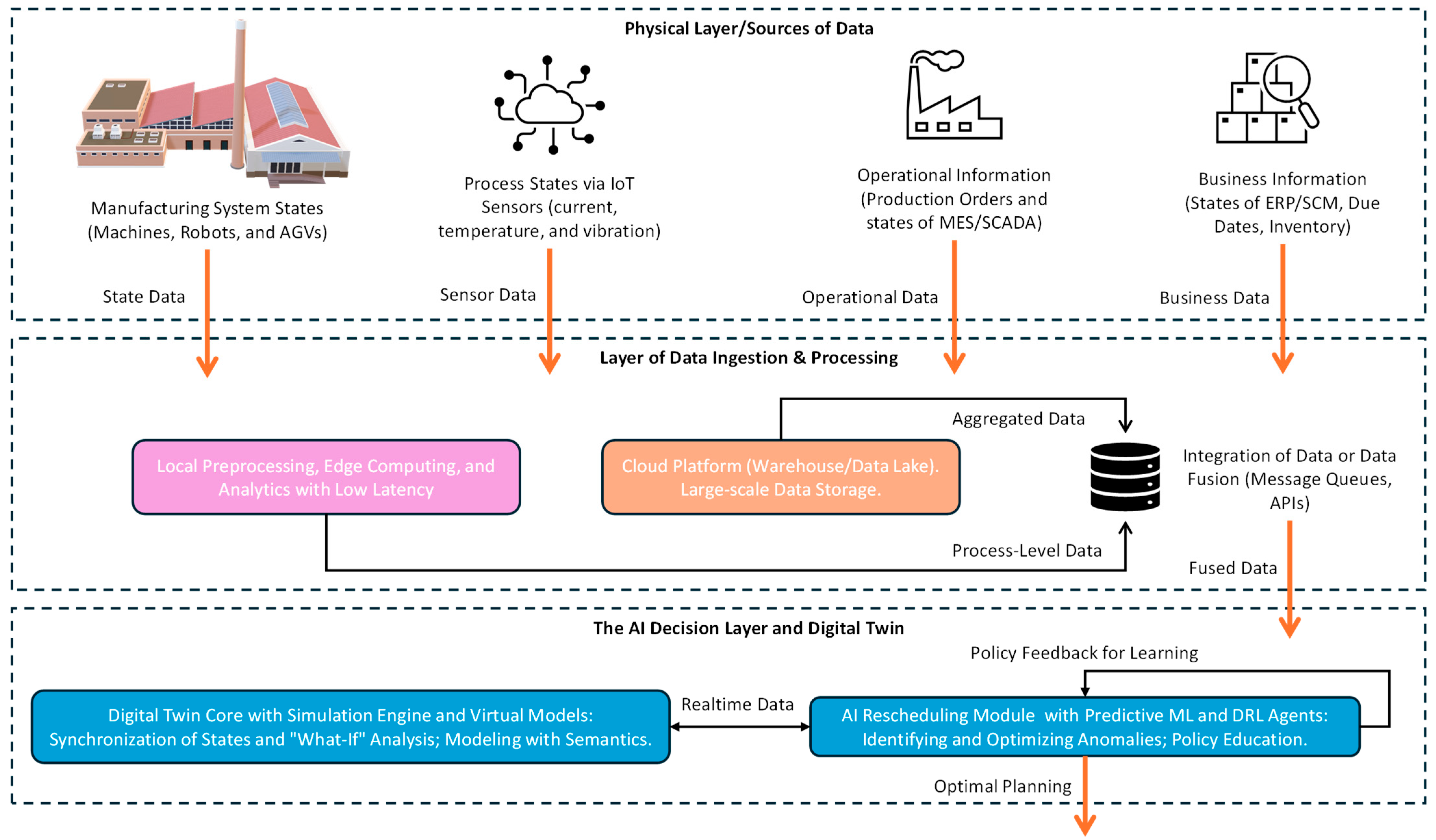

- Physical-Virtual Synchronization Layer: Sensors and data logging provide real-time data for shopfloor control, MES, ERP, Supply Chain Management (SCM), and data clouds. Data clouds store curated info in a data lake, while edge nodes filter and preprocess.

- DT Core Layer: High-fidelity models facilitate the creation of “what-if” scenarios, maintain semantic context (e.g., asset administration shells), and synchronize with the physical system. For each asset class (machine, process, or flow), fidelity can be adjusted.

- AI Decision Layer: Hybrid planners include metaheuristics for local optimization, supervised ML for estimated-time-of-arrival prediction or anomaly detection, and DRL for dispatching policies. Under resource limitations, including setup times, transportation delays, and personnel availability, policies are updated online.

- Integration and Orchestration Layer: Protocol compatibility is guaranteed via middleware like OPC UA. Plug-and-play modules are made possible by common data models and standardized Application Program Interfaces (APIs). Transparency is enforced by explainable AI gateways.

- Human-in-the-Loop Governance Layer: Humans are involved at some point in the AI workflow to ensure accuracy, safety, accountability, and ethical decision-making during each rescheduling cycle.

3.2. Industrial Applications of DT-AI-Based Production Scheduling

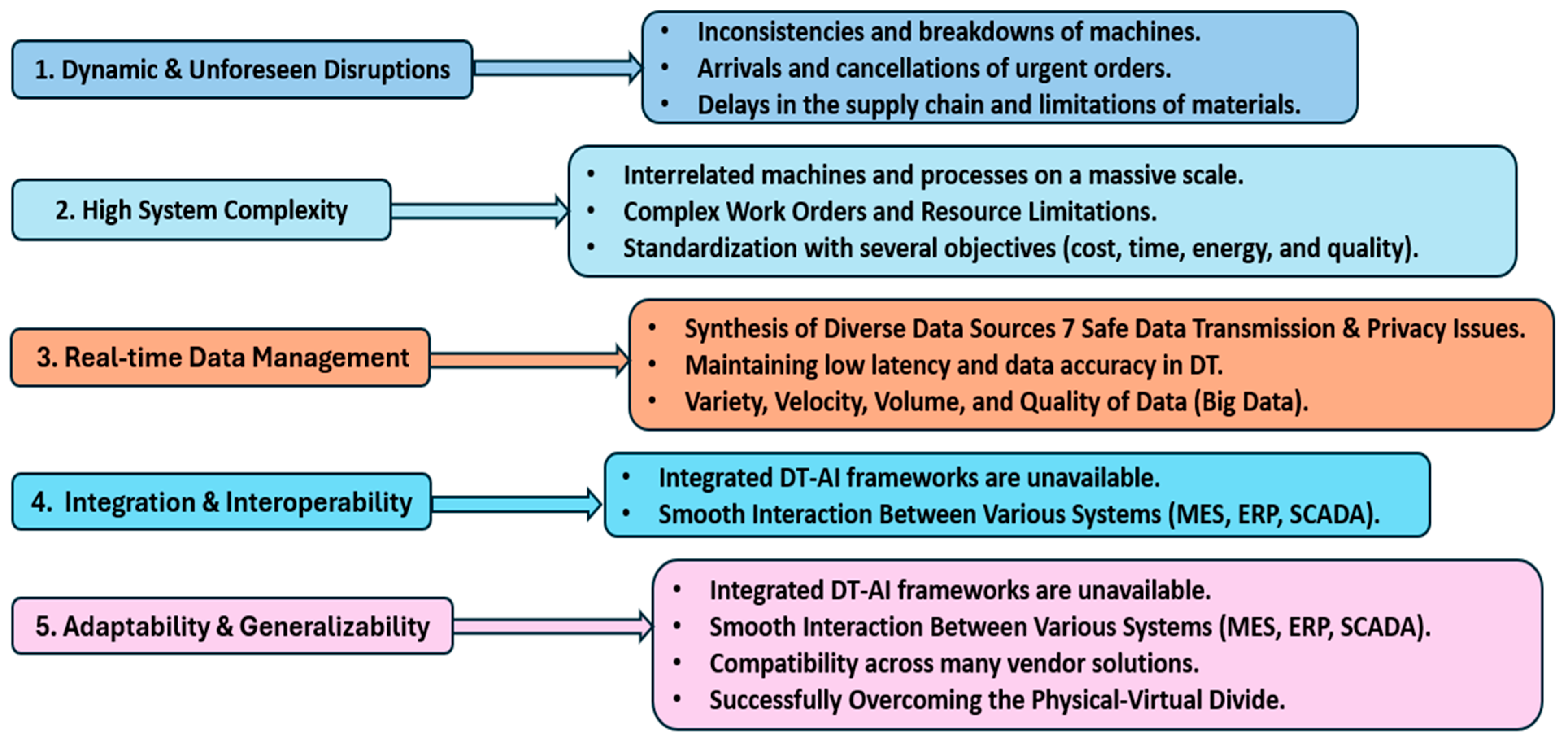

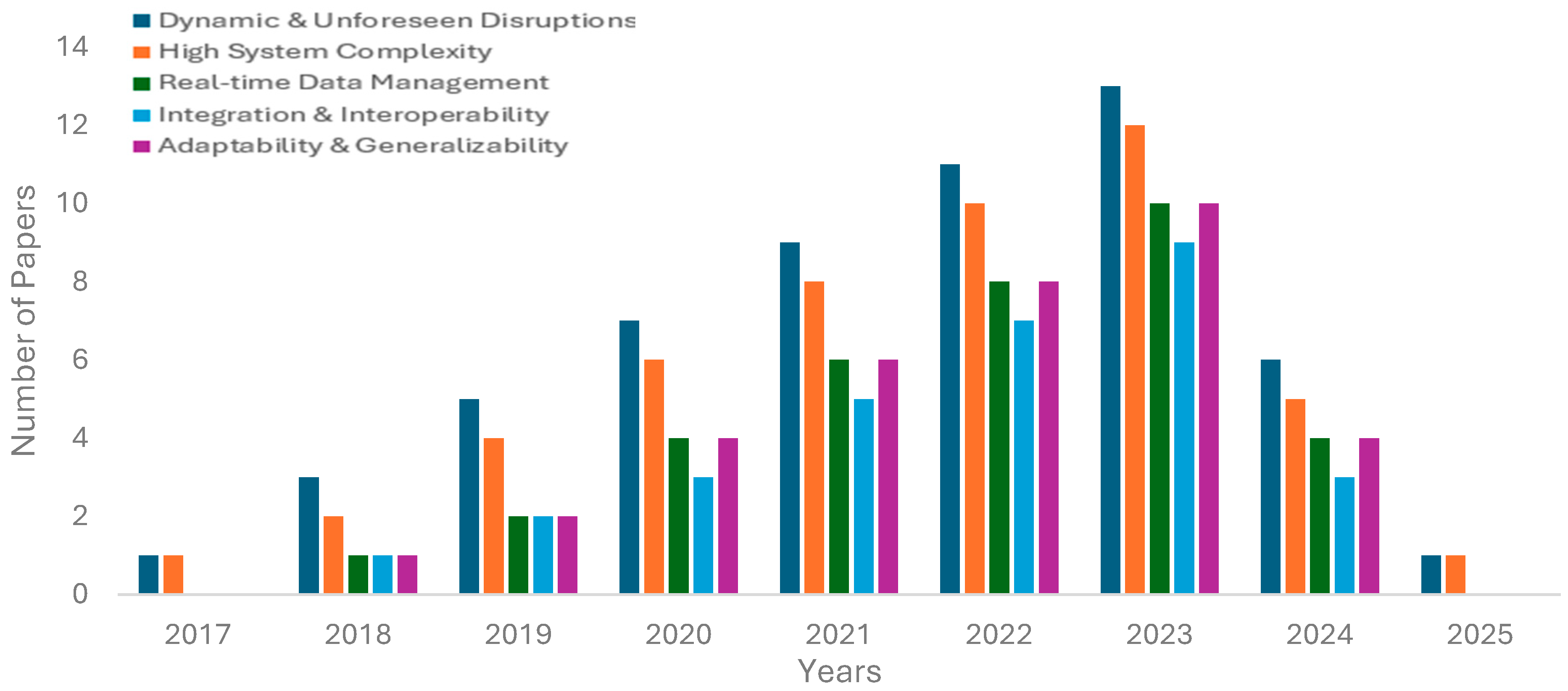

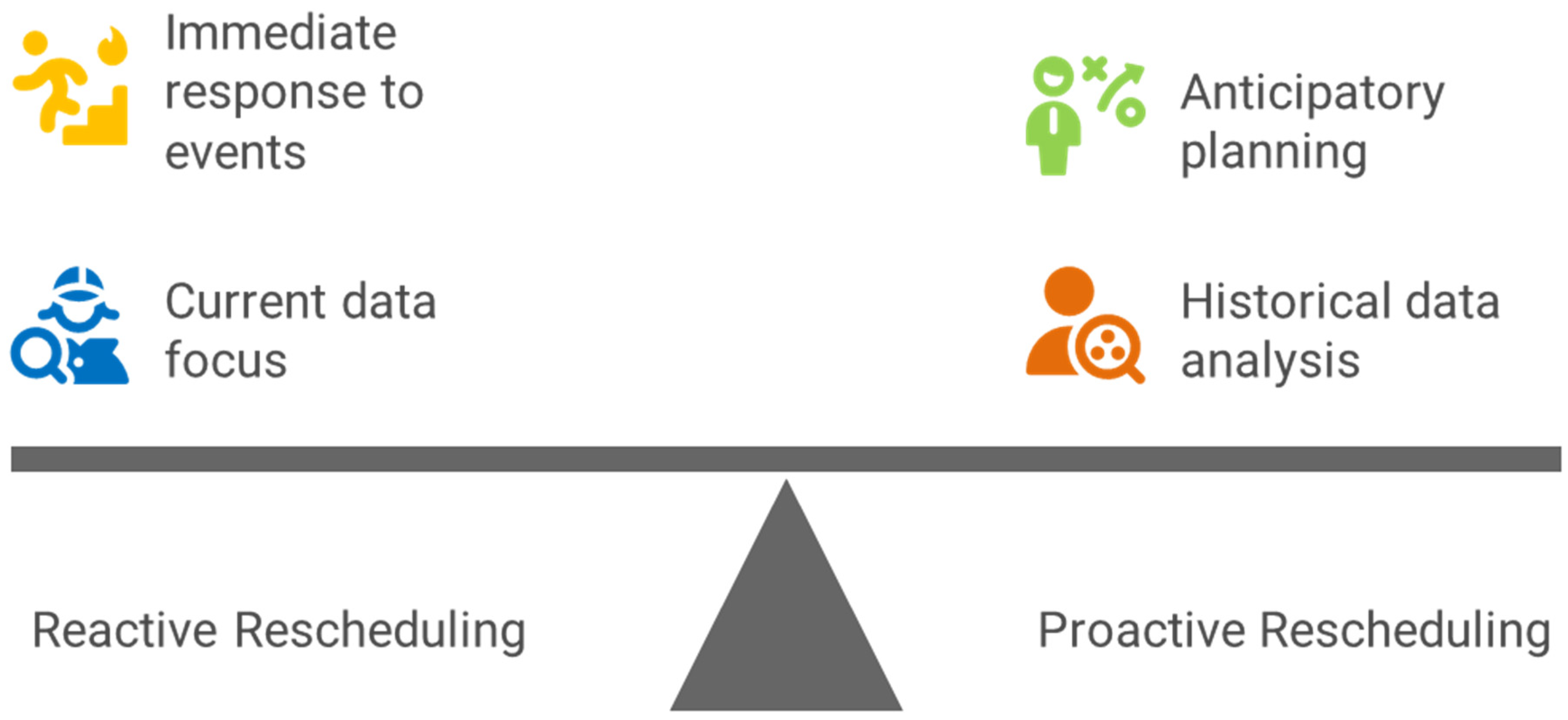

4. Dynamic and Unforeseen Disruptions

4.1. Advancements

4.2. Opportunities

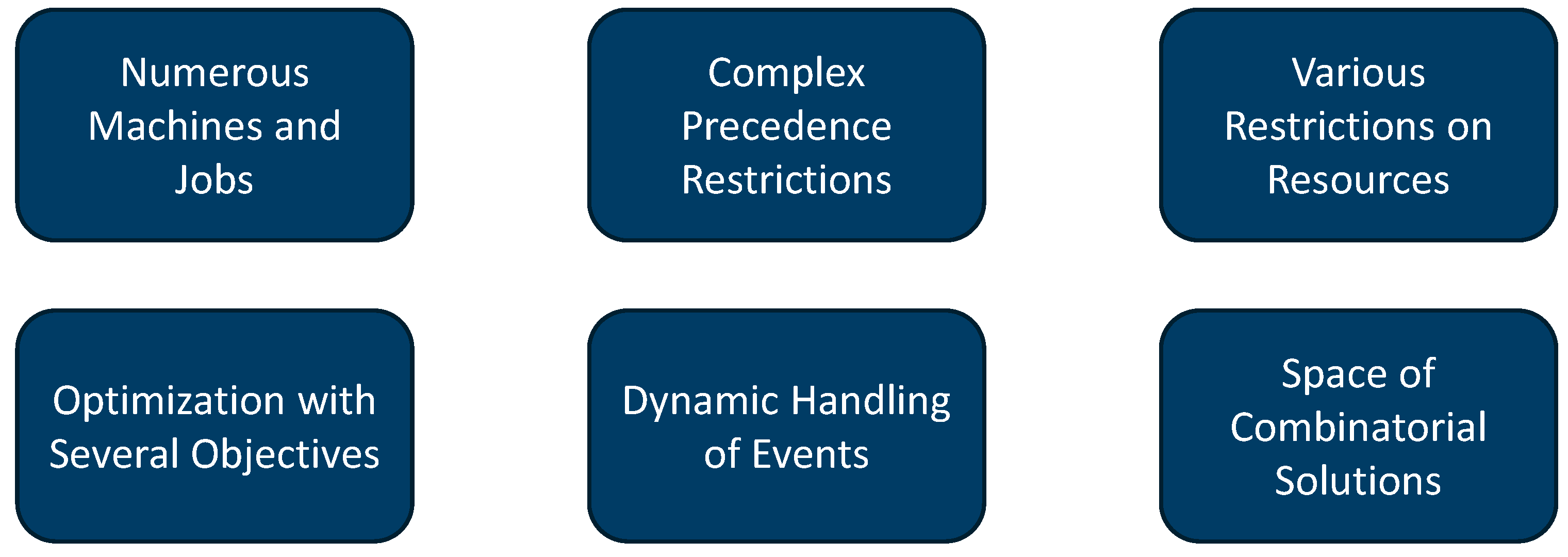

5. High System Complexity

5.1. Advancements

5.2. Opportunities

6. Real-Time Data Management

6.1. Advancement

6.2. Opportunities

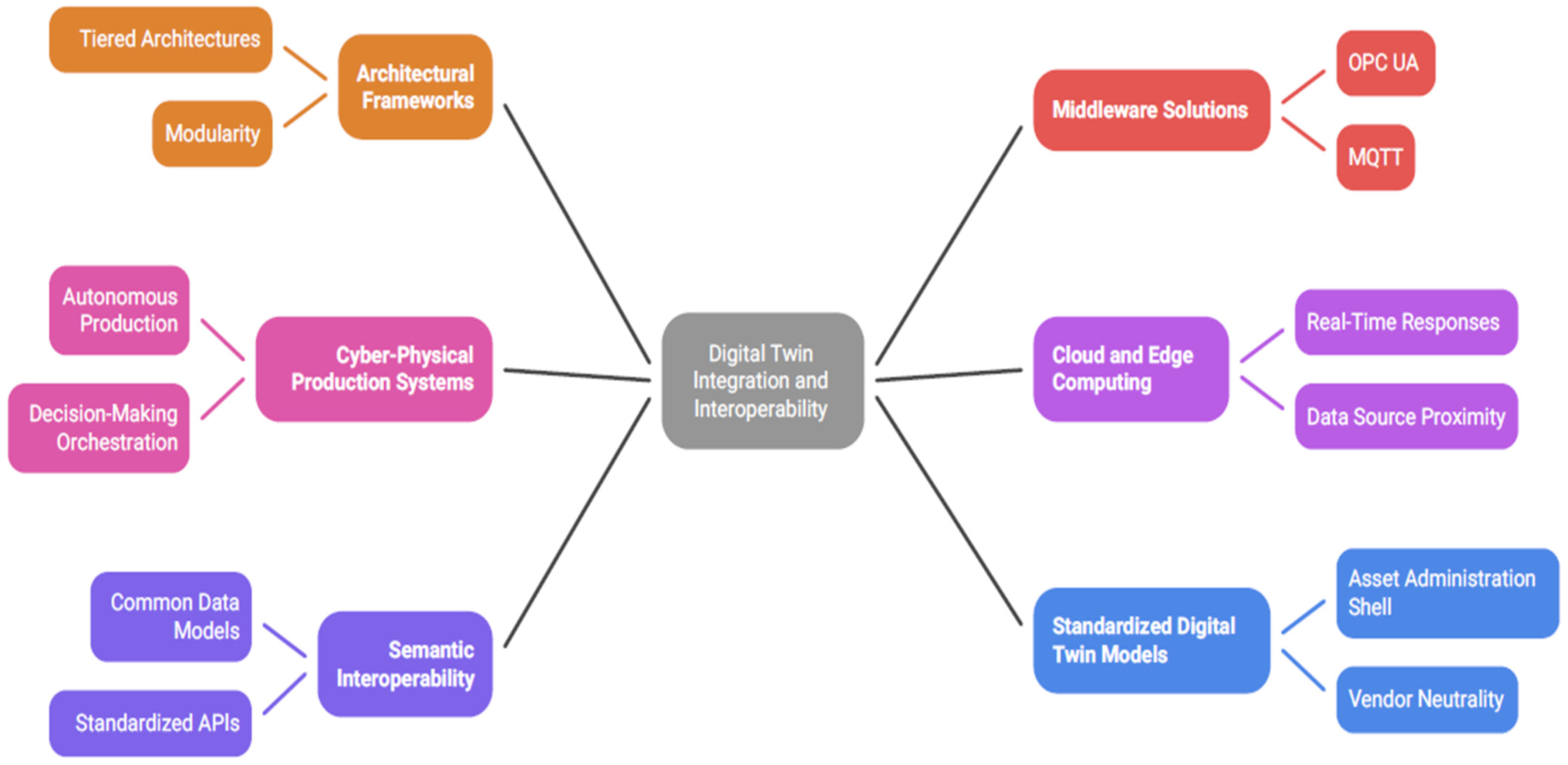

7. Integration and Interoperability

7.1. Advancements

7.2. Opportunities

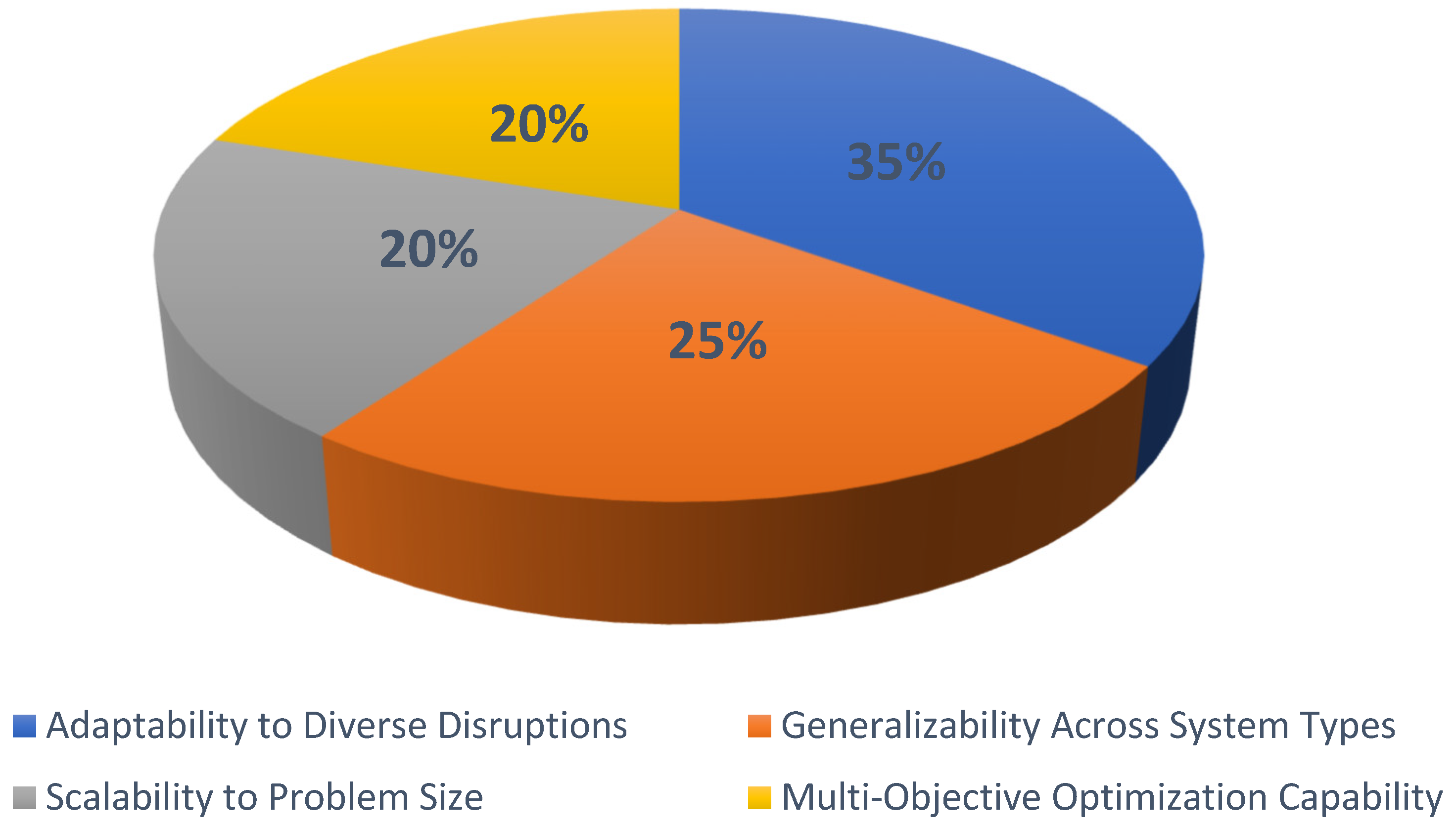

8. Adaptability and Generalizability

8.1. Advancements

8.2. Opportunities

9. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| DT | Digital Twin |

| BDA | Big Data Analytics |

| CPS | Cyber-Physical Systems |

| DRL | Deep Reinforcement Learning |

| KPI | Key Performance Indicator |

| IoT | Internet of Things |

| ERP | Enterprise Resource Planning |

| MES | Manufacturing Execution System |

| SCADA | Supervisory Control and Data Acquisition |

| ML | Machine Learning |

| CNN | Convolution Neural Network |

| GNN | Graph Neural Network |

| DL | Deep Learning |

| RL | Reinforcement Learning |

| FJSSP | Flexible Job Shop Scheduling Problem |

| BOM | Bill of Materials |

| OPC UA | Open Platform Communication Unified Architecture |

References

- Pinedo, M.; Hadavi, K. Scheduling: Theory, Algorithms and Systems Development. In Operations Research Proceedings 1991; Springer: Berlin/Heidelberg, Germany, 1992; pp. 35–42. [Google Scholar]

- Priore, P.; Fuente, D.; Gomez, A.; Puente, J. A review of machine learning in dynamic scheduling of flexible manufacturing systems. AI EDAM 2001, 15, 251–263. [Google Scholar] [CrossRef]

- Ouelhadj, D.; Petrovic, S. A survey of dynamic scheduling in manufacturing systems. J. Sched. 2009, 12, 417–431. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, P.; Jinsong, B. Digital Twin-based manufacturing system: A survey based on a novel reference model. J. Intell. Manuf. 2023, 35, 2517–2546. [Google Scholar] [CrossRef]

- Besigomwe, K. Closed-Loop Manufacturing with AI-Enabled Digital Twin Systems. Cogniz. J. Multidiscip. Studies 2025, 5, 18–38. [Google Scholar] [CrossRef]

- Alfaro-Viquez, D.; Zamora-Hernandez, M.; Fernandez-Vega, M.; Garcia-Rodriguez, J.; Azorin-Lopez, J. A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions. Electronics 2025, 14, 646. [Google Scholar] [CrossRef]

- Fang, Y.; Peng, C.; Lou, P.; Zhou, Z.; Hu, J.; Yan, J. Digital-Twin-Based Job Shop Scheduling Toward Smart Manufacturing. IEEE Trans. Ind. Inform. 2019, 15, 6425–6435. [Google Scholar] [CrossRef]

- Liu, L.; Guo, K.; Gao, Z.; Li, J.; Sun, J. Digital Twin-Driven Adaptive Scheduling for Flexible Job Shops. Sustainability 2022, 14, 5340. [Google Scholar] [CrossRef]

- Gomaa, A.H. Digital Twins for Improving Proactive Maintenance Management. Eng. Sci. 2024, 9, 60–70. [Google Scholar] [CrossRef]

- Ma, S.; Flanigan, K.A.; Bergés, M. State-of-the-art review: The use of digital twins to support artificial intelligence-guided predictive maintenance. arXiv 2024, arXiv:2406.13117. [Google Scholar]

- Holguin Jimenez, S.; Trabelsi, W.; Sauvey, C. Multi-Objective Production Rescheduling: A Systematic Literature Review. Mathematics 2024, 12, 3176. [Google Scholar] [CrossRef]

- Li, Y.; Carabelli, S.; Fadda, E.; Manerba, D.; Tadei, R.; Terzo, O. Machine learning and optimization for production rescheduling in Industry 4.0. Int. J. Adv. Manuf. Technol. 2020, 110, 2445–2463. [Google Scholar] [CrossRef]

- Kalra, M.; Singh, S. A review of metaheuristic scheduling techniques in cloud computing. Egypt. Inform. J. 2015, 16, 275–295. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Nee, A.Y.C. Digital Twin Driven Smart Manufacturing; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Monostori, L. Cyber-physical Production Systems: Roots, Expectations and R&D Challenges. Procedia CIRP 2014, 17, 9–13. [Google Scholar] [CrossRef]

- Ding, K.; Chan, F.; Zhang, X.; Zhou, G.; Zhang, F. Defining a Digital Twin-based Cyber-Physical Production System for Autonomous Manufacturing in Smart Shop Floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Li, M.; Liu, X.; Zhong, R.Y.; Pan, W.; Huang, G.Q. Digital twin-enabled real-time synchronization for planning, scheduling, and execution in precast on-site assembly. Autom. Constr. 2022, 141, 104397. [Google Scholar] [CrossRef]

- Adadi, A.; Berrada, M. Peeking Inside the Black-Box: A Survey on Explainable Artificial Intelligence (XAI). IEEE Access 2018, 6, 52138–52160. [Google Scholar] [CrossRef]

- Park, J.; Bakhtiyar, S.; Park, J. Schedulenet: Learn to solve multi-agent scheduling problems with reinforcement learning. arXiv 2021, arXiv:2106.03051. [Google Scholar]

- Zemskov, A.D.; Fu, Y.; Li, R.; Wang, X.; Karkaria, V.; Tsai, Y.-K.; Chen, W.; Zhang, J.; Gao, R.; Cao, J. Security and privacy of digital twins for advanced manufacturing: A survey. arXiv 2024, arXiv:2412.13939. [Google Scholar] [CrossRef]

- Lee, I.; Mangalaraj, G. Big Data Analytics in Supply Chain Management: A Systematic Literature Review and Research Directions. Big Data Cogn. Comput. 2022, 6, 17. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, L.; Zhou, M.; Yu, X.; Zhu, Y.; Song, W.; Lu, Z.; Li, J. Deep Reinforcement Learning Based Dynamic Scheduling of Random Arrival Tasks in Cloud Manufacturing. In Proceedings of the 2022 6th International Conference on Universal Village (UV), Boston, MA, USA, 21–23 October 2022; pp. 1–6. [Google Scholar]

- Liu, Z.; Zhang, Y.; Zhang, C.; Yan, J.; Guo, S. Real-time workshop digital twin scheduling platform for discrete manufacturing. J. Phys. Conf. Ser. 2021, 1884, 012006. [Google Scholar]

- Yan, B.; Liu, X.; Lu, S.; Hu, C.; Wang, X.; Zhou, Z. Deep reinforcement learning approach for a dynamic flexible job shop problem with sequence dependent setup times. Comput. Ind. Eng. 2025, 207, 16. [Google Scholar] [CrossRef]

- Lohtander, M.; Garcia, E.; Lanz, M.; Volotinen, J.; Ratava, J.; Kaakkunen, J. Micro Manufacturing Unit—Creating Digital Twin Objects with Common Engineering Software. Procedia Manuf. 2018, 17, 468–475. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Nee, A. Digital twin-driven product design framework. Int. J. Prod. Res. 2018, 57, 3935–3953. [Google Scholar] [CrossRef]

- Kasie, F.; Bright, G.; Walker, A. Integrating Artificial Intelligence and Simulation for Controlling Steady Flow of Fixtures. In Lecture Notes in Mechanical Engineering, CAD/CAM, Robotics and Factories of the Future; Springer: New Delhi, India, 2016. [Google Scholar]

- Zhang, L.; Zhou, L.; Ren, L.; Laili, Y. Modeling and simulation in intelligent manufacturing. Comput. Ind. 2019, 112, 103123. [Google Scholar] [CrossRef]

- Cimino, A.; Gnoni, M.; Longo, F.; La Rosa, A. Digital Twin (DT) based methodology to support effective design of industrial production lines. Procedia Comput. Sci. 2023, 217, 1896–1907. [Google Scholar] [CrossRef]

- Yan, D.; Sha, W.; Wang, D.; Yang, J.; Zhang, S. Digital twin-driven variant design of a 3C electronic product assembly line. Sci. Rep. 2022, 12, 3846. [Google Scholar] [CrossRef]

- Tang, J.; Haddad, Y.; Salonitis, K. Reconfigurable manufacturing system scheduling: A deep reinforcement learning approach. Procedia CIRP 2022, 107, 1198–1203. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D. Digital twin-enabled reconfigurable modeling for smart manufacturing systems. Int. J. Comput. Integr. Manuf. 2019, 34, 709–733. [Google Scholar] [CrossRef]

- Fera, M.; Greco, A.; Caterino, M.; Gerbino, S.; Caputo, F.; Macchiaroli, R.; D’Amato, E. Towards Digital Twin Implementation for Assessing Production Line Performance and Balancing. Sensors 2020, 20, 97. [Google Scholar] [CrossRef]

- Zhao, R.; Zou, G.; Su, Q.; Zou, S.; Deng, W.; Yu, A.; Zhang, H. Digital Twins-Based Production Line Design and Simulation Optimization of Large-Scale Mobile Phone Assembly Workshop. Machines 2022, 10, 367. [Google Scholar] [CrossRef]

- Chang, J.; Yu, D.; Hu, Y.; He, W.; Yu, H. Deep Reinforcement Learning for Dynamic Flexible Job Shop Scheduling with Random Job Arrival. Processes 2022, 10, 760. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, J.; Li, H.; Zhuang, C.; Liu, Z. Digital twin-driven dynamic scheduling for the assembly workshop of complex products with workers allocation. Robot. Comput.-Integr. Manuf. 2024, 89, 102786. [Google Scholar] [CrossRef]

- Macchi, M.; Ragazzini, L.; Negri, E. A conceptual framework for Digital Twins in production scheduling and control. IFAC-PapersOnLine 2023, 56, 5661–5666. [Google Scholar] [CrossRef]

- Ma, G.; da Silva, E.R.; Møller, C. Digital Twin-based Demand-Driven Production Planning and Scheduling System: A New Conceptual Framework. Procedia CIRP 2024, 130, 705–710. [Google Scholar] [CrossRef]

- Lee, H.; Yang, H. Cognitive Digital Twin for Multiobjective Production Scheduling. J. Manuf. Sci. Eng. 2025, 147, 091004. [Google Scholar] [CrossRef]

- Luo, S. Dynamic scheduling for flexible job shop with new job insertions by deep reinforcement learning. Appl. Soft Comput. 2020, 91, 106208. [Google Scholar] [CrossRef]

- Song, W.; Chen, X.; Li, Q.; Cao, Z. Flexible job-shop scheduling via graph neural network and deep reinforcement learning. IEEE Trans. Ind. Inform. 2022, 19, 1600–1610. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, J.; Zhang, P.; Cui, L.; Zhang, G. Independent double DQN-based multi-agent reinforcement learning approach for online two-stage hybrid flow shop scheduling with batch machines. J. Manuf. Syst. 2022, 65, 694–708. [Google Scholar] [CrossRef]

- Li, Y.; Tao, Z.; Wang, L.; Du, B.; Guo, J.; Pang, S. Digital twin-based job shop anomaly detection and dynamic scheduling. Robot. Comput.-Integr. Manuf. 2023, 79, 17. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Shi, D.; Fan, W.; Xiao, Y.; Lin, T.; Xing, C. Intelligent scheduling of discrete automated production line via deep reinforcement learning. Int. J. Prod. Res. 2020, 58, 3362–3380. [Google Scholar] [CrossRef]

- Lin, W.; Deng, Q.; Han, W.; Gong, G.; Li, K. An effective algorithm for flexible assembly job-shop scheduling with tight job constraints. Int. Trans. Oper. Res. 2020, 29, 496–525. [Google Scholar] [CrossRef]

- Johnson, D.; Chen, G.; Lu, Y. Multi-Agent Reinforcement Learning for Real-Time Dynamic Production Scheduling in a Robot Assembly Cell. IEEE Robot. Autom. Lett. 2022, 7, 7684–7691. [Google Scholar] [CrossRef]

- Park, J.; Chun, J.; Kim, S.H.; Kim, Y.; Park, J. Learning to schedule job-shop problems: Representation and policy learning using graph neural network and reinforcement learning. Int. J. Prod. Res. 2021, 59, 3360–3377. [Google Scholar] [CrossRef]

- Han, B.; Yang, J.-J. A Deep Reinforcement Learning Based Solution for Flexible Job Shop Scheduling Problem. Int. J. Simul. Model. 2021, 20, 375–386. [Google Scholar] [CrossRef]

- Fadda, E.; Fedorov, S.; Perboli, G.; Barbosa, I. Mixing machine learning and optimization for the tactical capacity planning in last-mile delivery. In Proceedings of the 2021 IEEE 45th Annual Computers, Software, and Applications Conference (COMPSAC), Virtually, 12–16 July 2021; pp. 1291–1296. [Google Scholar]

- Maruyama, T.; Ueshiba, T.; Tada, M.; Toda, H.; Endo, Y.; Domae, Y.; Nakabo, Y.; Mori, T.; Suita, K. Digital Twin-Driven Human Robot Collaboration Using a Digital Human. Sensors 2021, 21, 8266. [Google Scholar] [CrossRef]

- Ramasubramanian, A.K.; Mathew, R.; Kelly, M.; Hargaden, V.; Papakostas, N. Digital Twin for Human–Robot Collaboration in Manufacturing: Review and Outlook. Appl. Sci. 2022, 12, 4811. [Google Scholar] [CrossRef]

- Luo, S.; Zhang, L.; Fan, Y. Real-Time Scheduling for Dynamic Partial-No-Wait Multiobjective Flexible Job Shop by Deep Reinforcement Learning. IEEE Trans. Autom. Sci. Eng. 2021, 19, 3020–3038. [Google Scholar] [CrossRef]

- Li, X.; Guo, A.; Yin, X.; Tang, H.; Wu, R.; Zhao, Q.; Li, Y.; Wang, X. A Q-learning improved differential evolution algorithm for human-centric dynamic distributed flexible job shop scheduling problem. J. Manuf. Syst. 2025, 80, 794–823. [Google Scholar] [CrossRef]

- Lei, K.; Guo, P.; Zhao, W.; Wang, Y.; Qian, L.; Meng, X.; Tang, L. A multi-action deep reinforcement learning framework for flexible Job-shop scheduling problem. Expert Syst. Appl. 2022, 205, 117796. [Google Scholar] [CrossRef]

- Xiong, H.; Fan, H.; Jiang, G.; Li, G. A simulation-based study of dispatching rules in a dynamic job shop scheduling problem with batch release and extended technical precedence constraints. Eur. J. Oper. Res. 2017, 257, 13–24. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhou, X. Flexible job-shop scheduling problem with job precedence constraints and interval grey processing time. Comput. Ind. Eng. 2020, 149, 106781. [Google Scholar] [CrossRef]

- Zhang, S.; Li, X.; Zhang, B.; Wang, S. Multi-objective optimisation in flexible assembly job shop scheduling using a distributed ant colony system. Eur. J. Oper. Res. 2020, 283, 441–460. [Google Scholar] [CrossRef]

- Du, Y.; Li, J.; Li, C.; Duan, P. A Reinforcement Learning Approach for Flexible Job Shop Scheduling Problem With Crane Transportation and Setup Times. IEEE Trans. Neural Netw. Learn. Syst. 2022, 35, 5695–5709. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Gao, L. An effective hybrid genetic algorithm and tabu search for flexible job shop scheduling problem. Int. J. Prod. Econ. 2016, 174, 93–110. [Google Scholar] [CrossRef]

- Xie, J.; Li, X.; Gao, L.; Lin, G. A hybrid genetic tabu search algorithm for distributed flexible job shop scheduling problems. J. Manuf. Syst. 2023, 71, 82–94. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, M.; Yang, M.; Wang, D. Hybrid quantum particle swarm optimization and variable neighborhood search for flexible job-shop scheduling problem. J. Manuf. Syst. 2024, 73, 334–348. [Google Scholar] [CrossRef]

- Li, H.; Cai, R.; Liu, N.; Lin, X.; Wang, Y. Deep reinforcement learning: Algorithm, applications, and ultra-low-power implementation. Nano Commun. Netw. 2018, 16, 81–90. [Google Scholar] [CrossRef]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2019, 13, 534–556. [Google Scholar] [CrossRef]

- Yildiz, E.; Møller, C.; Bilberg, A.; Rask, J. Virtual Prototyping: Evaluating the Digital Twin Based Virtual Factory for New Product Introduction. Complex Syst. Inform. Model. Q. 2021, 29, 1–16. [Google Scholar] [CrossRef]

- Yildiz, B. Reinforcement learning using fully connected, attention, and transformer models in knapsack problem solving. Concurr. Comput. Pract. Exp. 2021, 34, e6509. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Hussain, M.S. A Multi-agent Based Dynamic Scheduling of Flexible Manufacturing Systems. Glob. J. Flex. Syst. Manag. 2019, 20, 267–290. [Google Scholar] [CrossRef]

- David, I.; Shao, G.; Gomes, C.; Tilbury, D.; Zarkout, B. Interoperability of Digital Twins: Challenges, Success Factors, and Future Research Directions. In Proceedings of the Leveraging Applications of Formal Methods, Verification and Validation. Application Areas; Margaria, T., Steffen, B., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 27–46. [Google Scholar]

- Lee, J.-H.; Zhao, C.; Li, J.; Papadopoulos, C. Analysis, design, and control of Bernoulli production lines with waiting time constraints. J. Manuf. Syst. 2018, 46, 208–220. [Google Scholar] [CrossRef]

- He, N.; Sahnoun, M.h.; Zhang, D.; Bettayeb, B. A hybrid approach using ant colony optimisation for integrated scheduling of production and transportation tasks within flexible manufacturing systems. Comput. Oper. Res. 2025, 180, 107059. [Google Scholar] [CrossRef]

- Huang, X.; Yang, L. A hybrid genetic algorithm for multi-objective flexible job shop scheduling problem considering transportation time. Int. J. Intell. Comput. Cybern. 2019, 12, 154–174. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Q. A Hybrid Genetic Algorithm for Flexible Job Shop Scheduling Problem With Sequence-Dependent Setup Times and Job Lag Times. IEEE Access 2021, 9, 104864–104873. [Google Scholar] [CrossRef]

- Xu, S.; Li, Y.; Li, Q. A Deep Reinforcement Learning Method Based on a Transformer Model for the Flexible Job Shop Scheduling Problem. Electronics 2024, 13, 3696. [Google Scholar] [CrossRef]

- Wang, R.; Wang, G.; Sun, J.; Deng, F.; Chen, J. Flexible job shop scheduling via dual attention network-based reinforcement learning. IEEE Trans. Neural Netw. Learn. Syst. 2023, 35, 3091–3102. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Cybulski, J.; Kozielski, M. Personalization of AI-Based Digital Twins to Optimize Adaptation in Industrial Design and Manufacturing. Appl. Sci. 2025, 15, 8525. [Google Scholar] [CrossRef]

- Sajadieh, S.M.M.; Noh, S.D. From Simulation to Autonomy: Reviews of the Integration of Artificial Intelligence and Digital Twins. Int. J. Precis. Eng. Manuf.-Green Technol. 2025, 12, 1597–1628. [Google Scholar] [CrossRef]

- Kusiak, A. Federated explainable artificial intelligence (fXAI): A digital manufacturing perspective. Int. J. Prod. Res. 2024, 62, 171–182. [Google Scholar] [CrossRef]

- Ababio, I.B.; Bieniek, J.; Rahouti, M.; Hayajneh, T.; Aledhari, M.; Verma, D.C.; Chehri, A. A Blockchain-Assisted federated learning framework for secure and Self-Optimizing digital twins in industrial IoT. Future Internet 2025, 17, 13. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, K.; Niyato, D.; Chen, W.; Karagiannidis, G.K. Digital Twin-Assisted Federated Learning with Blockchain in Multi-tier Computing Systems. arXiv 2024, arXiv:2411.02323. [Google Scholar] [CrossRef]

| Exclusion Category | Applied Criterion | Notes |

|---|---|---|

| Maintenance-only DT without scheduling | DT-based methods pertain to predictive or preventative maintenance without scheduling | Excluded as they focus on maintenance, not production scheduling |

| Non-manufacturing domain | Methodologies pertain to non-manufacturing or service sectors | Excluded unless they specifically cover production scheduling |

| AI scheduling without DT integration | AI-based scheduling methods without any DT modeling or synchronization. | Excluded unless they discuss DT integration |

| DT idea, in general, without scheduling | DT is used for life cycle modeling, design, and monitoring without regard to scheduling | Relevant background references are maintained but excluded from synthesis |

| Non-peer-reviewed or preprints | Preprints or workshop papers are not subject to peer review unless they are foundational. | Kept only if they are specifically required by relevant references |

| Duplicates between databases | Same record fetched from several databases | Deduplicated before analysis |

| Fidelity Levels | Model Granularity | Synchronization Rates | Semantic Completeness | Scheduling Performance Implications |

|---|---|---|---|---|

| Low | Coarse discrete event models | ≥5–10 min | Restricted semantics | Suitable for long-term planning; Poor reaction to interruptions |

| Medium | Mixed discrete events with simplified physics | 30–120 s | Partially standardized semantics | Balances timeliness and computational cost; Has moderate accuracy in rescheduling |

| High | Detailed physics-based constrained models | ≤5–10 s | Fully standardized semantics, e.g., industrial communication standards like OPC UA | Enables near real-time rescheduling; Has maximum accuracy and adaptability under disruptions |

| Metrics | Thresholds or Targets | Scheduling Performance Implications |

|---|---|---|

| End-to-end latency from sensing to decision | ≤1–2 s for shopfloor events; ≤100–200 ms for critical machine failure signals | Enables prompt rescheduling decisions and minimize downtime |

| Synchronization skew across Manufacturing Execution System (MES)/ERP/Supervisory Control and Data Acquisition (SCADA) | ≤100 ms | Prevents a mismatch between virtual and physical states |

| Error tolerance in sensor measurements | ≤1–2% steady state error with transient spikes filtered | Keeps job-state and throughput forecasts accurate |

| Freshness of data for job-state updates | ≤5 s under normal load; ≤1 s during disruption | Makes sure that the schedule accurately represents the states of the shopfloor |

| Packet loss tolerance | ≤0.1–0.5% with redundancy | Maintains continuous data stream dependability |

| Studies | Manufacturing Context | DT Fidelity | DT-AI-Based Method | Objectives |

|---|---|---|---|---|

| Chen et al. [23] | Cloud Manufacturing | Medium | Deep Reinforcement Learning (DRL) | Makespan minimization |

| Fang et al. [7] | Discrete Job Shop | Medium | DT and rule-based scheduling | Makespan minimization |

| Liu et al. [8] | Flexible Job | Medium-High | DT and DRL | Makespan and tardiness minimization |

| Chang et al. [36] | Flexible Job | Medium | DRL for random arrivals | Makespan minimization |

| Luo [41] | Flexible Job | Medium | DRL for new job insertion | Multi-objective optimization without wait |

| Yan et al. [25] | Flexible Job | Medium | DRL for sequence-dependent setups | Makespan minimization |

| Gao et al. [37] | Assembly Workshop | Medium | DT and dynamic scheduling | Makespan minimization and allocation optimization |

| Song et al. [42] | Flexible Job | Medium | Graph Neural Networks and Deep Reinforcement Learning (GNN and DRL) | Makespan minimization |

| Wang et al. [43] | Hybrid Flow Shop | Medium | Multi-Agent RL, e.g., double Deep Q-Network (DQN) | Throughput maximization and tardiness minimization |

| Li et al. [44] | Job Shop | Medium-High | DT-anomaly detection and dynamic scheduling | Robustness maximization and delay minimization |

| Tao et al. [45] | Architecture | N Medium-High | Reference Models | Literature review |

| Potential Technologies | Gaps | Logical Connection |

|---|---|---|

| Explainable AI (XAI) | Adaptive scheduling often lacks transparency (Section 8: Adaptability and Generalizability) | Provides interpretable policies and rationale for rescheduling decisions |

| Federated Learning | Inadequate generalization exists across diverse shopfloors (Section 5: High System Complexity) | Enables cross-site learning without centralizing sensitive data |

| Blockchain | Data exchange is fragmented or insecure (Section 6: Real-Time Data Management; Section 7: Integration and Interoperability) | Ensures secure, traceable, and interoperable data flows |

| Quantum Computing | Large-scale dynamic scheduling exhibits computational bottlenecks (Section 5: High System Complexity) | Provides scalable computation for challenging scheduling problems |

| Human DT | Insufficient human monitoring and trust may exist in DT-AI-based production scheduling (Section 8: Adaptability and Generalizability) | Incorporates operator feedback and knowledge into DT-AI-based production scheduling loops |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Singh, P.; Krishnan, K.; Boldsaikhan, E. A Review of Production Scheduling with Artificial Intelligence and Digital Twins. J. Manuf. Mater. Process. 2026, 10, 6. https://doi.org/10.3390/jmmp10010006

Singh P, Krishnan K, Boldsaikhan E. A Review of Production Scheduling with Artificial Intelligence and Digital Twins. Journal of Manufacturing and Materials Processing. 2026; 10(1):6. https://doi.org/10.3390/jmmp10010006

Chicago/Turabian StyleSingh, Punit, Krishna Krishnan, and Enkhsaikhan Boldsaikhan. 2026. "A Review of Production Scheduling with Artificial Intelligence and Digital Twins" Journal of Manufacturing and Materials Processing 10, no. 1: 6. https://doi.org/10.3390/jmmp10010006

APA StyleSingh, P., Krishnan, K., & Boldsaikhan, E. (2026). A Review of Production Scheduling with Artificial Intelligence and Digital Twins. Journal of Manufacturing and Materials Processing, 10(1), 6. https://doi.org/10.3390/jmmp10010006