- 3.7Impact Factor

- 5.8CiteScore

- 16 daysTime to First Decision

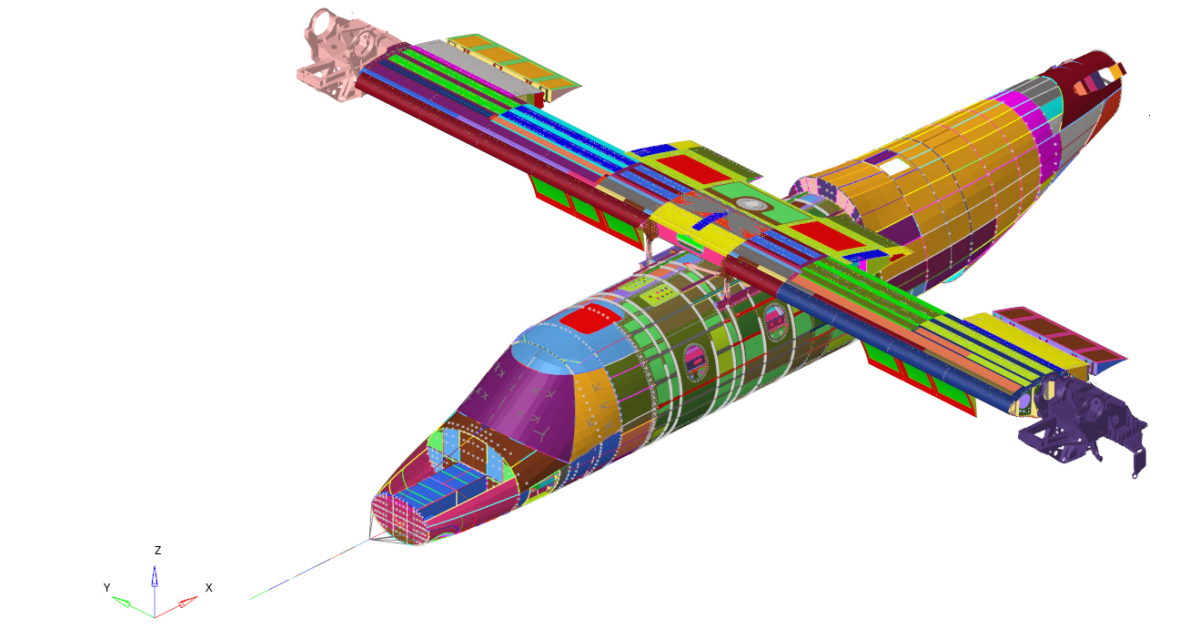

Modeling and Simulation in Aerospace Composites

This special issue belongs to the section “Composites Modelling and Characterization“.

Special Issue Information

Dear Colleagues,

Today, the use of composite materials and structures is a common practice in aerospace, especially in aeronautics. Modeling and simulation (M&S) have been widely used and increasingly improved over the years with the aims of supporting a more reliable design practice and to aid the products’ final qualification with respect to the authorities’ rules and guidelines. Scientists and engineers are constantly looking for a more digital qualification and certification exploring M&S advancements and high-fidelity approaches in several disciplines (structure strength, aeroelasticity clearance, internal noise, thermal effects, EMC, crashworthiness, etc.). Advanced M&S methods have demonstrated the ability to simulate highly complex composite systems’ behaviors, reducing the amount of physical testing. Such an approach requires the development of a credibility assurance framework (CAF) to support risk-informed applications of advanced M&S. This is a crucial research and innovation stream to make viable the M&S advanced methods for practical applications in aerospace composite. In addition, the current aerospace innovation topics are devoted to the development of greener aircraft and new systems for space exploration; thus, the M&S methods are required to take into account technical issues never considered before such as onboard cryogenic H2 tanks for greener aircraft and new type of ceramic composite for the thermal protections of spacecraft.

We are pleased to invite you to contribute to this Special Issue your original and beyond state-of-the-art studies, methods, techniques, results and V&V experiences in aeronautical and space composite to improve the M&S methods for theoretical, numerical and practical point of views, with the aim of supporting the worldwide aerospace communities in making the whole development pathway of composite aircraft and spacecraft more reliable and affordable.

This Special Issue aims to collect original and state-of-the-art studies, methods, techniques, and results including V&V experiences in aeronautical and space composite.

In this Special Issue, original research articles and reviews are welcome. Research areas may include (but are not limited to) the following:

- Structures strength and buckling;

- Aeronautical virtual certification;

- Credibility assurance framework;

- Aeroelasticity and dynamics;

- Crashworthiness;

- Numerical formulations;

- Noise detection and reduction;

- Impact loads (e.g., bird strike and space debris);

- Hot structures and protection systems for re-entry spacecraft;

- Multi-disciplinary optimization;

- Electromagnetic compatibility;

- Lighting protection;

- Stealth capabilities;

- Low-weight structures.

We look forward to receiving your contributions.

Dr. Luigi Di Palma

Dr. Marika Belardo

Dr. Alessandro De Luca

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Journal of Composites Science is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 1800 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- composites

- structure

- aeronautics

- spacecraft

- virtual certification

- credibility assurance framework

- aeroelasticity

- dynamics

- crashworthiness

- FEM

- BEM

- FVM

- noise

- impact loads

- bird strike

- debris impact

- hot structures

- re-entry spacecraft

- multi-disciplinary optimization

- electromagnetic compatibility

- lighting protection

- stealth capabilities

- low-weight structures

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.