Bioenergy Technologies

A topical collection in Clean Technologies (ISSN 2571-8797).

Viewed by 22264Editor

2. iBB – Institute for Bioengineering and Biosciences, Department of Bioengineering, Instituto Superior Técnico, Universidade de Lisboa, 1649-004 Lisboa, Portugal

Interests: biocatalysis; bioreactors; bioprocess engineering

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

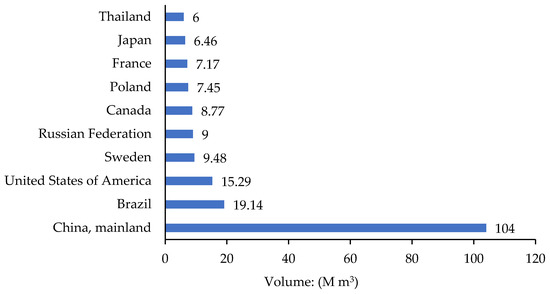

The significantly escalating global energy demand is caused by industrial activity in developed and developing countries, growing transportation fuel requirements and the population increase. The scarcity of conventional sources of energy, instability in gas and oil regions and concomitant fluctuations in gas/oil-based energy prices, alarming greenhouse gas emissions and soaring air pollution have prompted dedicated and widespread research efforts in developing bioenergy technologies to cope with such an energy demand. This trend has been substantially boosted recently and is foreseen as a sustainable, environmentally friendly approach for the intended goal that, moreover, fits within the concept of the circular economy concept, later largely fostered in several contexts such as the UN 2030 Agenda for Sustainable Development.

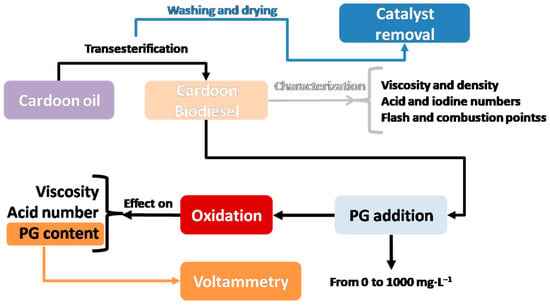

Bioenergy processes anchor on the translation of organic material (e.g., agro-forestry, industrial and municipal waste) into either an end-product (e.g., biodiesel, hydrogen and syngas) used to produce energy, or directly into electricity (e.g., microbial fuel cells). The implementation of bioenergy processes relies on either biochemical or thermochemical-based approaches, both having recently experienced major advances.

This Topical Collection looks for original contributions regarding technological developments focused on the production of energy from biomass or/and organic waste, and its assessment in a circular economy context. Topics include, but are not limited to, bio-based processes for the conversion of organic material, e.g., alcoholic fermentation, anaerobic digestion, microbial fuel cells, photobiologic hydrogen synthesis and transesterification; the thermo-chemical conversion of organic materials, e.g., direct combustion, gasification, liquefaction and pyrolysis; bioenergy production and the economic/environmental impacts.

Dr. Pedro Fernandes

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Clean Technologies is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 1600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- bioenergy

- biofuels

- bioelectricity

- circular bioeconomy

- life cycle assessment