-

Condition-Dependent Rate Capability of Laser-Structured Hard Carbon Anodes in Sodium-Based Batteries

Condition-Dependent Rate Capability of Laser-Structured Hard Carbon Anodes in Sodium-Based Batteries -

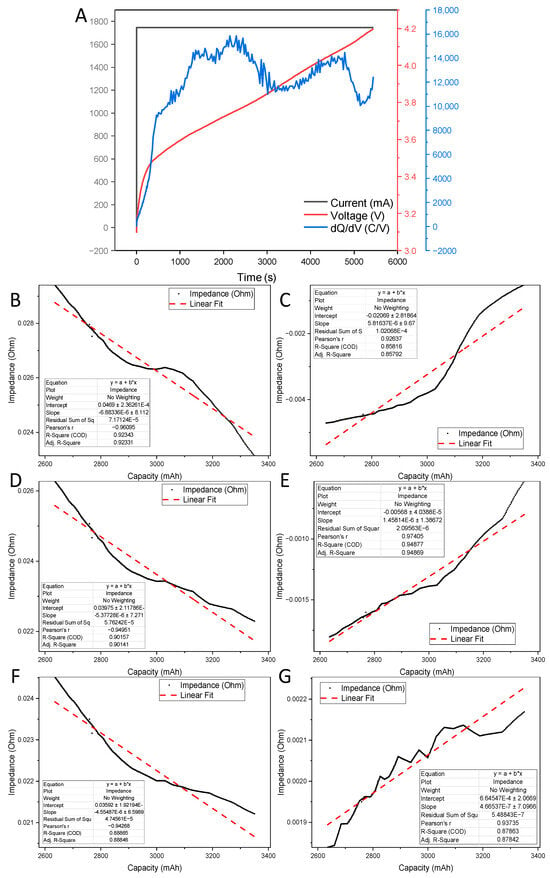

SOC-Dependent Compression of Lithium-Ion Battery Electrodes

SOC-Dependent Compression of Lithium-Ion Battery Electrodes -

Electrochemical and Post-Mortem Study of Pyrrolinium-Based Ionic Liquid on a Single-Layer Pouch Cell

Electrochemical and Post-Mortem Study of Pyrrolinium-Based Ionic Liquid on a Single-Layer Pouch Cell -

Thermal System Simulation of Heating Strategies for 21700 Lithium-Ion Battery Modules Under Cold-Start Conditions

Thermal System Simulation of Heating Strategies for 21700 Lithium-Ion Battery Modules Under Cold-Start Conditions -

Precisely Engineering Interfaces of Lithium Batteries

Precisely Engineering Interfaces of Lithium Batteries

Journal Description

Batteries

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), Inspec, Ei Compendex, CAPlus / SciFinder, and other databases.

- Journal Rank: JCR - Q2 (Electrochemistry) / CiteScore - Q1 (Electrical and Electronic Engineering)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 19.2 days after submission; acceptance to publication is undertaken in 2.8 days (median values for papers published in this journal in the second half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Sections: published in 7 topical sections.

- Journal Cluster of Energy and Fuels: Energies, Batteries, Hydrogen, Biomass, Electricity, Wind, Fuels, Gases, Solar, ESA and Methane.

Latest Articles

E-Mail Alert

News

Topics

Deadline: 10 March 2026

Deadline: 31 March 2026

Deadline: 30 April 2026

Deadline: 31 May 2026

Conferences

Special Issues

Deadline: 16 March 2026

Deadline: 16 March 2026

Deadline: 17 March 2026

Deadline: 20 March 2026