Multi-Objective Optimization of Processes

Share This Topical Collection

Editors

Prof. Dr. Gade Pandu Rangaiah

Prof. Dr. Gade Pandu Rangaiah

Prof. Dr. Gade Pandu Rangaiah

Prof. Dr. Gade Pandu Rangaiah

E-Mail

Website

Collection Editor

Department of Chemical and Biomolecular Engineering, National University of Singapore, Block E5, #02-25, 4 Engineering Drive 4, Singapore 117585, Singapore

Interests: multi-criteria decision making (MCDM) and multi-objective optimization (MCDM); process design; process intensification; process retrofitting and revamping; waste heat recovery; process control

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

Optimization has been playing a significant role for designing and controlling improved processes for many decades. However, over recent years, the view of an optimized process has changed from considering just the economic return to include other objectives including environmental impacts, social impacts, process safety, on-stream time, reliability, maintainability, and recyclability, to name just some of the possibilities. When a process designer needs to consider more than one criterion, this is known as multi-criteria decision analysis/making (MCDA/M). Multi-objective optimization (MOO) or optimization for multiple objectives has been a fast developing field of research, because of its ability to identify conflicts between objectives using Pareto-generating techniques that can provide many Pareto-optimal solutions at the same time.

This Special Issue on “Multi-Objective Optimization of Processes” focuses on new developments and applications of MOO to processes and systems of interest to chemical engineers. Topics include but not limited to the following:

- New techniques for multi-objective optimization;

- Developments in the selection of Pareto-optimal solutions;

- Applications to design and control of new processes and systems;

- Applications to retrofitting/revamping of existing processes and systems;

- Applications in product design, energy systems, food processing, mineral processing, and drug delivery;

- Optimization for diverse objectives related to economics, environmental impact, safety, controllability, and/or flexibility.

Prof. Dr. Gade Pandu Rangaiah

Prof. Dr. Andrew Hoadley

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Processes is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- Optimization of processes for multiple objectives

- Multi-criteria optimization

- Multi-criteria decision analysis

- Process design

- Process control

- Process retrofitting

- Process revamping

- Industrial processes

- Energy systems

Published Papers (12 papers)

Open AccessFeature PaperArticle

Multi-Objective Optimizations of Non-Isothermal Simulated Moving Bed Reactor: Parametric Analyses

by

Jian Wang, Wenwei Chen, Yan Li, Jin Xu, Weifang Yu and Ajay K. Ray

Cited by 4 | Viewed by 3271

Abstract

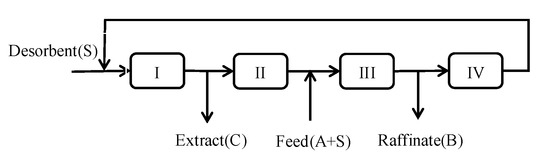

Simulated moving bed reactor (SMBR), a multicolumn multifunctional integrated reactor system, which can be exploited with on-site adsorptive separation to enhance conversion of equilibrium-limited reversible chemical reaction. In this article, for generality, a dimensionless SMBR model was developed and effects of five representative

[...] Read more.

Simulated moving bed reactor (SMBR), a multicolumn multifunctional integrated reactor system, which can be exploited with on-site adsorptive separation to enhance conversion of equilibrium-limited reversible chemical reaction. In this article, for generality, a dimensionless SMBR model was developed and effects of five representative temperature distributions among different zones on the performance of an SMBR for reversible reaction in the general form of a reactant decomposed to two products were evaluated based on simultaneous maximization of unit throughput and product purity. Multipliers were applied to adjust some of the model parameters such that different operation modes can be compared under various conditions in the parametric space. The multiobjective optimization problems were solved using the non-dominated sorting genetic algorithm. All simulations were carried out using FORTRAN codes. The results showed that both kinetics and adsorptive separation play important roles in SMBR. When kinetics is fast or adsorptive potency of the reactant is higher than the desired product (B) but lower than byproduct (C), non-isothermal operation can significantly improve unit throughput. On the contrary, feed concentration and reaction enthalpy have minor effects on the optimal solutions. Decision variables based on flow rate ratios and internal concentration profiles were used to explain the trends of Pareto optimal solution.

Full article

►▼

Show Figures

Open AccessFeature PaperArticle

Methodology to Solve the Multi-Objective Optimization of Acrylic Acid Production Using Neural Networks as Meta-Models

by

Geraldine Cáceres Sepulveda, Silvia Ochoa and Jules Thibault

Cited by 7 | Viewed by 4380

Abstract

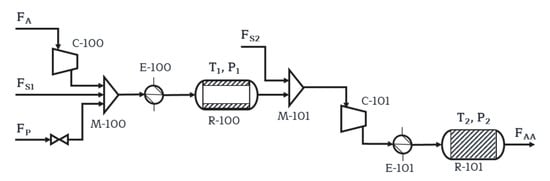

It is paramount to optimize the performance of a chemical process in order to maximize its yield and productivity and to minimize the production cost and the environmental impact. The various objectives in optimization are often in conflict, and one must determine the

[...] Read more.

It is paramount to optimize the performance of a chemical process in order to maximize its yield and productivity and to minimize the production cost and the environmental impact. The various objectives in optimization are often in conflict, and one must determine the best compromise solution usually using a representative model of the process. However, solving first-principle models can be a computationally intensive problem, thus making model-based multi-objective optimization (MOO) a time-consuming task. In this work, a methodology to perform the multi-objective optimization for a two-reactor system for the production of acrylic acid, using artificial neural networks (ANNs) as meta-models, is proposed in an effort to reduce the computational time required to circumscribe the Pareto domain. The performance of the meta-model confirmed good agreement between the experimental data and the model-predicted values of the existent relationships between the eight decision variables and the nine performance criteria of the process. Once the meta-model was built, the Pareto domain was circumscribed based on a genetic algorithm (GA) and ranked with the net flow method (NFM). Using the ANN surrogate model, the optimization time decreased by a factor of 15.5.

Full article

►▼

Show Figures

Open AccessArticle

Comprehensive Improvement of Mixed-Flow Pump Impeller Based on Multi-Objective Optimization

by

Mengcheng Wang, Yanjun Li, Jianpin Yuan, Fan Meng, Desmond Appiah and Jiaqi Chen

Cited by 23 | Viewed by 5639

Abstract

The spanwise distribution of impeller exit circulation (SDIEC) has a significant effect on the impeller performance, therefore, there is a need for its consideration in the optimization design of mixed-flow pumps. In this study, a combination optimization system, including a 3D inverse design

[...] Read more.

The spanwise distribution of impeller exit circulation (SDIEC) has a significant effect on the impeller performance, therefore, there is a need for its consideration in the optimization design of mixed-flow pumps. In this study, a combination optimization system, including a 3D inverse design method (IDM), computational fluid dynamics (CFD), Latin hypercube sampling (LHS) method, response surface model (RSM), and non-dominated sorting genetic algorithm (NSGA-Ⅱ) was used to improve the performance of the mixed-flow pump after considering the effect of SDIEC on the performance of the impeller. The CFD results confirm the accuracy and credibility of the optimization results because of the good agreement the CFD results established with the experimental measurements. Compared with the original impeller, the pump efficiency of the preferred impeller at 0.8

Qdes, 1.0

Qdes, and 1.2

Qdes improved by 0.63%, 3.39%, and 3.77% respectively. The low-pressure region on the blade surface reduced by 96.92% while the pump head difference was less than 1.84% at the design point. In addition, a comparison of the flow field of the preferred impeller and the original impeller revealed the effect of SDIEC on mixed-flow pump performance improvement and flow mechanism.

Full article

►▼

Show Figures

Open AccessArticle

Integrated Biorefinery of Empty Fruit Bunch from Palm Oil Industries to Produce Valuable Biochemicals

by

Rendra Hakim Hafyan, Lupete K. Bhullar, Shuhaimi Mahadzir, Muhammad Roil Bilad, Nik Abdul Hadi Nordin, Mohd Dzul Hakim Wirzal, Zulfan Adi Putra, Gade Pandu Rangaiah and Bawadi Abdullah

Cited by 24 | Viewed by 10915

Abstract

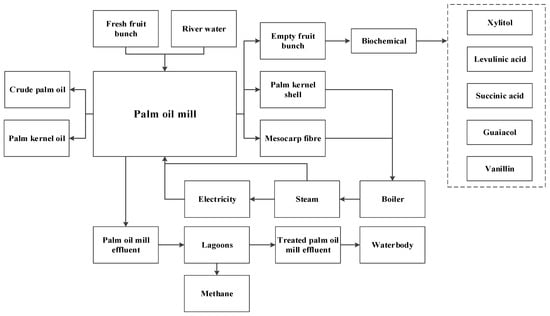

Empty fruit bunch (EFB) utilization to produce valuable bio-chemicals is seen as an economical and sustainable alternative to waste management in palm oil industries. This work proposed an integrated biorefinery configuration of EFB valorization considering sustainability pillars—namely, economic, environmental, and safety criteria. Techno-economic

[...] Read more.

Empty fruit bunch (EFB) utilization to produce valuable bio-chemicals is seen as an economical and sustainable alternative to waste management in palm oil industries. This work proposed an integrated biorefinery configuration of EFB valorization considering sustainability pillars—namely, economic, environmental, and safety criteria. Techno-economic analysis, life cycle assessment, and hazard identification ranking methods were used to estimate annual profit, global warming potential (GWP), fire explosion damage index (FEDI), and toxicity damage index (TDI) of the proposed integrated biorefinery. A multi-objective optimization problem was then formulated and solved for simultaneous maximization of profit and minimization of GWP, FEDI and TDI. The resulting Pareto-optimal solutions convey the trade-off among the economic, environmental, and safety performances. To choose one of these optimal solutions for implementation, a combined approach of fuzzy analytical hierarchy process and a technique for order preference by similarity to ideal solution was applied. For this selection, the economic criterion was more preferred, followed by the safety and environmental criterion; thus, the optimal solution selected for integrated biorefinery configuration had the highest annual profit, which was at the maximum capacity of 100 ton/h of EFB. It can fulfill the global demand of xylitol (by 55%), levulinic acid (by 98%), succinic acid (by 25%), guaiacol (by 90%), and vanillin (by 12%), and has annual profit, GWP, FEDI, and TDI of 932 M USD/year, 284 tonCO

2-eq, 595, and 957, respectively.

Full article

►▼

Show Figures

Open AccessArticle

An Improved Artificial Electric Field Algorithm for Multi-Objective Optimization

by

Hemant Petwal and Rinkle Rani

Cited by 17 | Viewed by 4037

Abstract

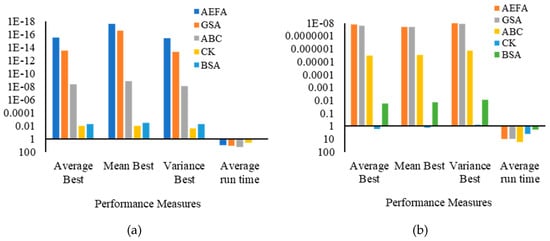

Real-world problems such as scientific, engineering, mechanical, etc., are multi-objective optimization problems. In order to achieve an optimum solution to such problems, multi-objective optimization algorithms are used. A solution to a multi-objective problem is to explore a set of candidate solutions, each of

[...] Read more.

Real-world problems such as scientific, engineering, mechanical, etc., are multi-objective optimization problems. In order to achieve an optimum solution to such problems, multi-objective optimization algorithms are used. A solution to a multi-objective problem is to explore a set of candidate solutions, each of which satisfies the required objective without any other solution dominating it. In this paper, a population-based metaheuristic algorithm called an artificial electric field algorithm (AEFA) is proposed to deal with multi-objective optimization problems. The proposed algorithm utilizes the concepts of strength Pareto for fitness assignment and the fine-grained elitism selection mechanism to maintain population diversity. Furthermore, the proposed algorithm utilizes the shift-based density estimation approach integrated with strength Pareto for density estimation, and it implements bounded exponential crossover (BEX) and polynomial mutation operator (PMO) to avoid solutions trapping in local optima and enhance convergence. The proposed algorithm is validated using several standard benchmark functions. The proposed algorithm’s performance is compared with existing multi-objective algorithms. The experimental results obtained in this study reveal that the proposed algorithm is highly competitive and maintains the desired balance between exploration and exploitation to speed up convergence towards the Pareto optimal front.

Full article

►▼

Show Figures

Open AccessFeature PaperReview

Multi-Objective Optimization Applications in Chemical Process Engineering: Tutorial and Review

by

Gade Pandu Rangaiah, Zemin Feng and Andrew F. Hoadley

Cited by 123 | Viewed by 18330

Abstract

This tutorial and review of multi-objective optimization (MOO) gives a detailed explanation of the 5 steps to create, solve, and then select the optimum result. Unlike single-objective optimization, the fifth step of selection or ranking of solutions is often overlooked by the authors

[...] Read more.

This tutorial and review of multi-objective optimization (MOO) gives a detailed explanation of the 5 steps to create, solve, and then select the optimum result. Unlike single-objective optimization, the fifth step of selection or ranking of solutions is often overlooked by the authors of papers dealing with MOO applications. It is necessary to undertake a multi-criteria analysis to choose the best solution. A review of the recent publications using MOO for chemical process engineering problems shows a doubling of publications between 2016 and 2019. MOO applications in the energy area have seen a steady increase of over 20% annually over the last 10 years. The three key methods for solving MOO problems are presented in detail, and an emerging area of surrogate-assisted MOO is also described. The objectives used in MOO trade off conflicting requirements of a chemical engineering problem; these include fundamental criteria such as reaction yield or selectivity; economics; energy requirements; environmental performance; and process control. Typical objective functions in these categories are described, selection/ranking techniques are outlined, and available software for MOO are listed. It is concluded that MOO is gaining popularity as an important tool and is having an increasing use and impact in chemical process engineering.

Full article

►▼

Show Figures

Open AccessArticle

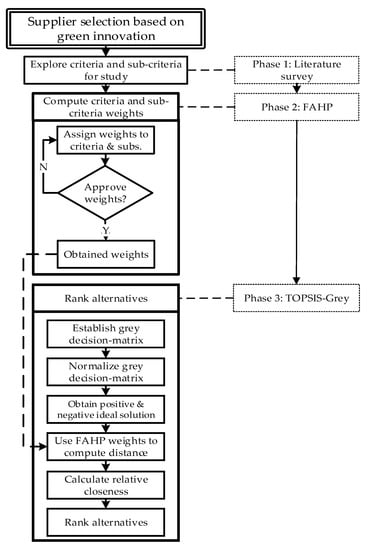

An Integrated Multi-Criteria Decision Support Framework for the Selection of Suppliers in Small and Medium Enterprises based on Green Innovation Ability

by

Almalki Sultan Musaad O, Zhang Zhuo, Zafar Ali Siyal, Ghulam Muhammad Shaikh, Syed Ahsan Ali Shah, Yasir Ahmed Solangi and Almalki Otaibi Musaad O

Cited by 51 | Viewed by 5876

Abstract

Globally, organizations are under enormous pressure to implement green supply chain processes due to growing environmental concerns. Subsequently, organizations and firms have become more conscious of their suppliers’ green innovation ability. However, the selection of the most optimum supplier concerning green innovation ability

[...] Read more.

Globally, organizations are under enormous pressure to implement green supply chain processes due to growing environmental concerns. Subsequently, organizations and firms have become more conscious of their suppliers’ green innovation ability. However, the selection of the most optimum supplier concerning green innovation ability remains a challenging task that needs to be analyzed. Thus, this study develops an integrated fuzzy and grey-based methodology to analyze and prioritize suppliers for small and medium enterprises (SMEs) in the context of Saudi Arabia. Initially, the study identifies 4 criteria and 20 sub-criteria through extensive literature review with respect to suppliers’ green innovation ability. Later, the Fuzzy Analytical Hierarchy Process (AHP) computes weights of criteria and sub-criteria. Finally, the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS)-Grey was employed to rank the suppliers. The process of assigning weights to criteria and sub-criteria involved twelve experts from academics and industry. The results of Fuzzy AHP indicated that the “Green Innovation Initiatives” is the most significant criterion for the supplier selection. The results of TOPSIS-Grey revealed that the “Supplier-3” is the most optimum supplier having the highest potential of adopting green practices among other suppliers. The overall results provide adequate feedback for organizations and firms to maximize their ability to curb environmental impacts from their upstream activities.

Full article

►▼

Show Figures

Open AccessArticle

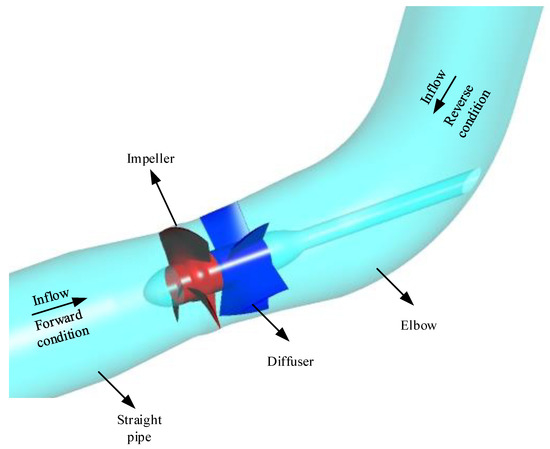

Multiobjective Combination Optimization of an Impeller and Diffuser in a Reversible Axial-Flow Pump Based on a Two-Layer Artificial Neural Network

by

Fan Meng, Yanjun Li, Shouqi Yuan, Wenjie Wang, Yunhao Zheng and Majeed Koranteng Osman

Cited by 17 | Viewed by 5321

Abstract

This study proposed a kind of optimization design for a reversible axial-flow pump based on an ordinary one-way pump. Three-dimensional (3D) Reynolds-averaged Navier–Stokes (RANS) equations was used to predict the pump performance, and the optimized design was validated by an external characteristic test.

[...] Read more.

This study proposed a kind of optimization design for a reversible axial-flow pump based on an ordinary one-way pump. Three-dimensional (3D) Reynolds-averaged Navier–Stokes (RANS) equations was used to predict the pump performance, and the optimized design was validated by an external characteristic test. Six main geometry parameters of an impeller and diffuser based on an orthogonal experiment were set as design variables. The efficiency and head under forward and reverse design conditions were set as the optimization objective. Based on 120 groups of sample designs obtained from Latin hypercube sampling (LHS), a two-layer artificial neural network (ANN) was used to build a non-linear function with high accuracy between the design variables and optimization objective. The optimized design was obtained from 300 groups of Pareto-optimal solutions using the non-dominated based genetic algorithm (NSGA) for multiobjective optimization. After optimization, there was a slight decrease in the forward pump efficiency and head. The reverse pump efficiency and head on the other hand was largely improved and the high efficiency range was also widened.

Full article

►▼

Show Figures

Open AccessArticle

Multi-Criteria Decision Making (MCDM) Model for Supplier Evaluation and Selection for Oil Production Projects in Vietnam

by

Chia-Nan Wang, Hsiung-Tien Tsai, Thanh-Phong Ho, Van-Thanh Nguyen and Ying-Fang Huang

Cited by 65 | Viewed by 16582

Abstract

The following research utilizes Multi-Criteria Decision Making (MCDM) in order to build a business strategy to reduce product costs, improve competitiveness, focus on production planning based on actual operating capacity and flexible adjustment according to the market, maximize the labor productivity of technology

[...] Read more.

The following research utilizes Multi-Criteria Decision Making (MCDM) in order to build a business strategy to reduce product costs, improve competitiveness, focus on production planning based on actual operating capacity and flexible adjustment according to the market, maximize the labor productivity of technology workshops, reduce costs and inventory, and focus on producing many petrochemical products and products of high economic value. Selecting the right materials supplier is of paramount importance to the success of the organization as a whole. Supplier evaluation and the selection of a suitable supplier is a complex problem in which the decision maker must consider both qualitative and quantitative factors. Multi-Criteria Decision Making Models are an effective tool used to solve complex selection issues including multiple criteria and options, especially for qualitative variables. Thus, the author proposes an MCDM model including the Supply Chain Operation Reference (SCOR) model, analytic hierarchy process (AHP) and the Data Envelopment Analysis (DEA) method to evaluate and select the optimal supplier in the oil industry. The criteria used to evaluate potential suppliers are determined through the SCOR model, the weight of all criteria are defined by the AHP model through an expert’s opinion, and DEA is used to rank providers at the final stage. After the model implementation and the results, decision-making unit DMU_01, DMU_04 and DMU_10 are shown to be the best suppliers. This research provides a Multi-Criteria Decision Making model for supplier evaluation and selection in oil production projects. This research also presents useful guidelines for supplier selection processes in other industries.

Full article

►▼

Show Figures

Open AccessArticle

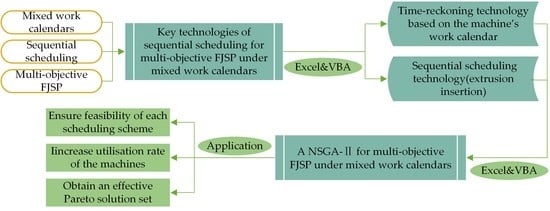

Sequential Scheduling Method for FJSP with Multi-Objective under Mixed Work Calendars

by

Qiang Zeng, Menghua Wang, Ling Shen and Hongna Song

Cited by 5 | Viewed by 3750

Abstract

A sequential scheduling method for multi-objective, flexible job-shop scheduling problem (FJSP) work calendars is proposed. Firstly, the sequential scheduling problem for the multi-objective FJSP under mixed work calendars was described. Secondly, two key technologies to solve such a problem were proposed: one was

[...] Read more.

A sequential scheduling method for multi-objective, flexible job-shop scheduling problem (FJSP) work calendars is proposed. Firstly, the sequential scheduling problem for the multi-objective FJSP under mixed work calendars was described. Secondly, two key technologies to solve such a problem were proposed: one was a time-reckoning technology based on the machine’s work calendar, the other was a sequential scheduling technology. Then, a non-dominated sorting genetic algorithm with an elite strategy (NSGA-II) was designed to solve the problem. In the algorithm, a two-segment encoding method was used to encode the chromosome. A two-segment crossover and mutation operator were used with an improved strategy of genetic operators therein to ensure feasibility of the chromosomes. Time-reckoning technology was used to calculate start and end time of each process. The sequential scheduling technology was used to implement sequential scheduling. The case study shows that the proposed method can obtain an effective Pareto set of the sequential scheduling problem for multi-objective FJSP under mixed work calendars within an acceptable time.

Full article

►▼

Show Figures

Open AccessArticle

Multi-Attribute Decision-Making: Applying a Modified Brown–Gibson Model and RETScreen Software to the Optimal Location Process of Utility-Scale Photovoltaic Plants

by

Nasser Yimen and Mustafa Dagbasi

Cited by 30 | Viewed by 9969

Abstract

Due to environmental and economic drawbacks of fossil fuels, global renewable energy (RE) capacity has increased significantly over the last decade. Solar photovoltaic (PV) is one of the fastest-growing RE technologies. Selecting an appropriate site is one of the most critical steps in

[...] Read more.

Due to environmental and economic drawbacks of fossil fuels, global renewable energy (RE) capacity has increased significantly over the last decade. Solar photovoltaic (PV) is one of the fastest-growing RE technologies. Selecting an appropriate site is one of the most critical steps in utility-scale solar PV planning. This paper aims at proposing a rational multi-criteria decision-making (MCDM) approach based on the Brown–Gibson model for optimal site selection for utility-scale solar PV projects. The proposed model considers the project’s net present value (NPV) along with seven suitability factors and six critical (constraint) factors. The RETScreen software was applied in calculating the NPV, the simple payback period and the carbon emission savings of the project at each alternative site. The weights of the suitability factors were determined using the analytical hierarchy process. Applied to the case study of finding the best location for a 5 MW solar PV project in northern Cameroon, the optimization results showed that Mokolo was the optimal location. The sensitivity analysis results revealed that the rankings of alternative sites based on the project’s NPV and the proposed model are not consistent. Compared to the traditional MCDM approaches, the proposed model provides decision-makers with a more practical thinking method in the optimal location process of utility-scale solar projects.

Full article

►▼

Show Figures

Open AccessArticle

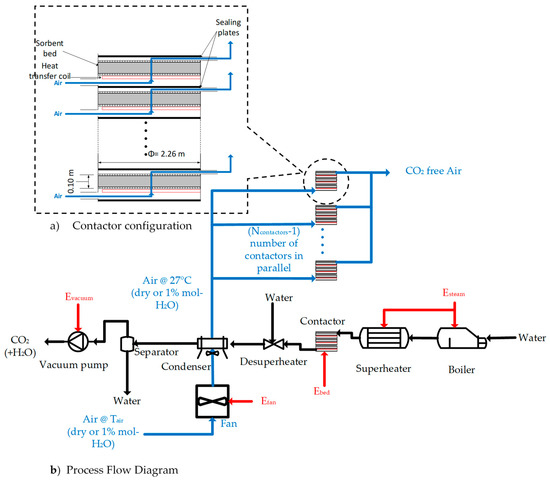

Technoeconomic Evaluation of a Process Capturing CO2 Directly from Air

by

Romesh Pramodya Wijesiri, Gregory Paul Knowles, Hasina Yeasmin, Andrew Forbes Alexander Hoadley and Alan Loyd Chaffee

Cited by 25 | Viewed by 7692

Abstract

Capturing CO

2 directly from air is one of the options for mitigating the effects global climate change, and therefore determining its cost is of great interest. A process model was proposed and validated using laboratory results for adsorption/desorption of CO

2,

[...] Read more.

Capturing CO

2 directly from air is one of the options for mitigating the effects global climate change, and therefore determining its cost is of great interest. A process model was proposed and validated using laboratory results for adsorption/desorption of CO

2, with a branched polyethyleneimine (PEI) loaded mesocellular foam (MCF) silica sorbent. The model was subjected to a Multi-Objective Optimization (MOO) to evaluate the technoeconomic feasibility of the process and to identify the operating conditions which yielded the lowest cost. The objectives of the MOO were to minimize the cost of CO

2 capture based on a discounted cash flow analysis, while simultaneously maximizing the quantity of CO

2 captured. This optimization identified the minimum cost of capture as 612 USD tonne

−1 for dry air entering the process at 25 °C, and 657 USD tonne

−1 for air at 22 °C and 39% relative humidity. The latter represents more realistic conditions which can be expected for subtropical climates. The cost of direct air capture could be reduced by ~42% if waste heat was utilized for the process, and by ~27% if the kinetics of the sorbent could be improved by a factor of two. A combination of both would allow cost reductions of ~54%.

Full article

►▼

Show Figures