- Review

High-Efficiency Continuous Microreactors for Controlled Synthesis of Nanosized Particles of Functional Materials: Review

- Rufat Sh. Abiev

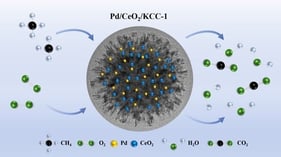

The current state and prospects of microreactor synthesis of functional materials in single- and two-phase flows with a liquid continuous phase are analyzed. Microreactors allow fine control over the size, composition, structure, and properties of synthesized particles in co-precipitation processes. The results obtained by various teams provide grounds to expect fairly extensive capabilities for controlling the processes of nucleation and particle growth in microreactors—by controlling the pH, reagent concentrations, micromixing quality, and residence time in each of the reactor zones—in the nucleation growth zones. The advantages of microreactor synthesis have been demonstrated with a high quality of micromixing in a volume of 0.2–0.5 mL, which ensures the production of nanoparticles without impurities, a stoichiometric ratio of atoms in the product, and limitation of agglomerate growth due to a short residence time (in the order of several milliseconds). The transition to an industrial scale is very easy due to the fairly high productivity of a single microreactor (up to 10 m3/day for suspension, up to 200–300 kg/day for solid phase). Intensive mixing in microreactors with a diameter of 2–4 mm or less, due to Taylor vortices, contributed to the use of two-phase microreactors for the synthesis of both organic and inorganic substances.

11 February 2026