The Effect of Interrupted Loading on the Lüder Phenomena in AISI 1524 Steel Alloy

Abstract

1. Introduction

2. Materials and Methods

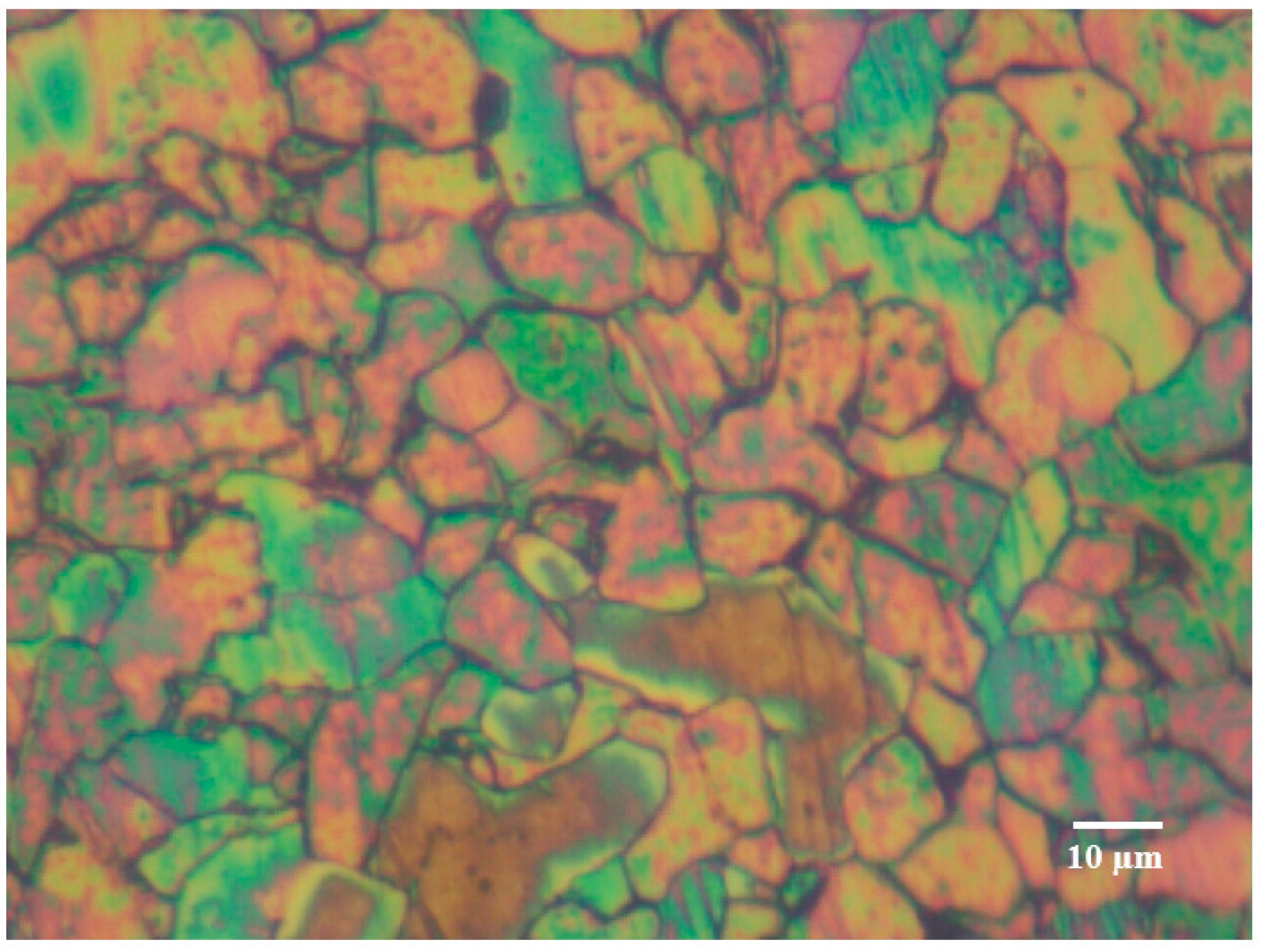

2.1. Specimen Material

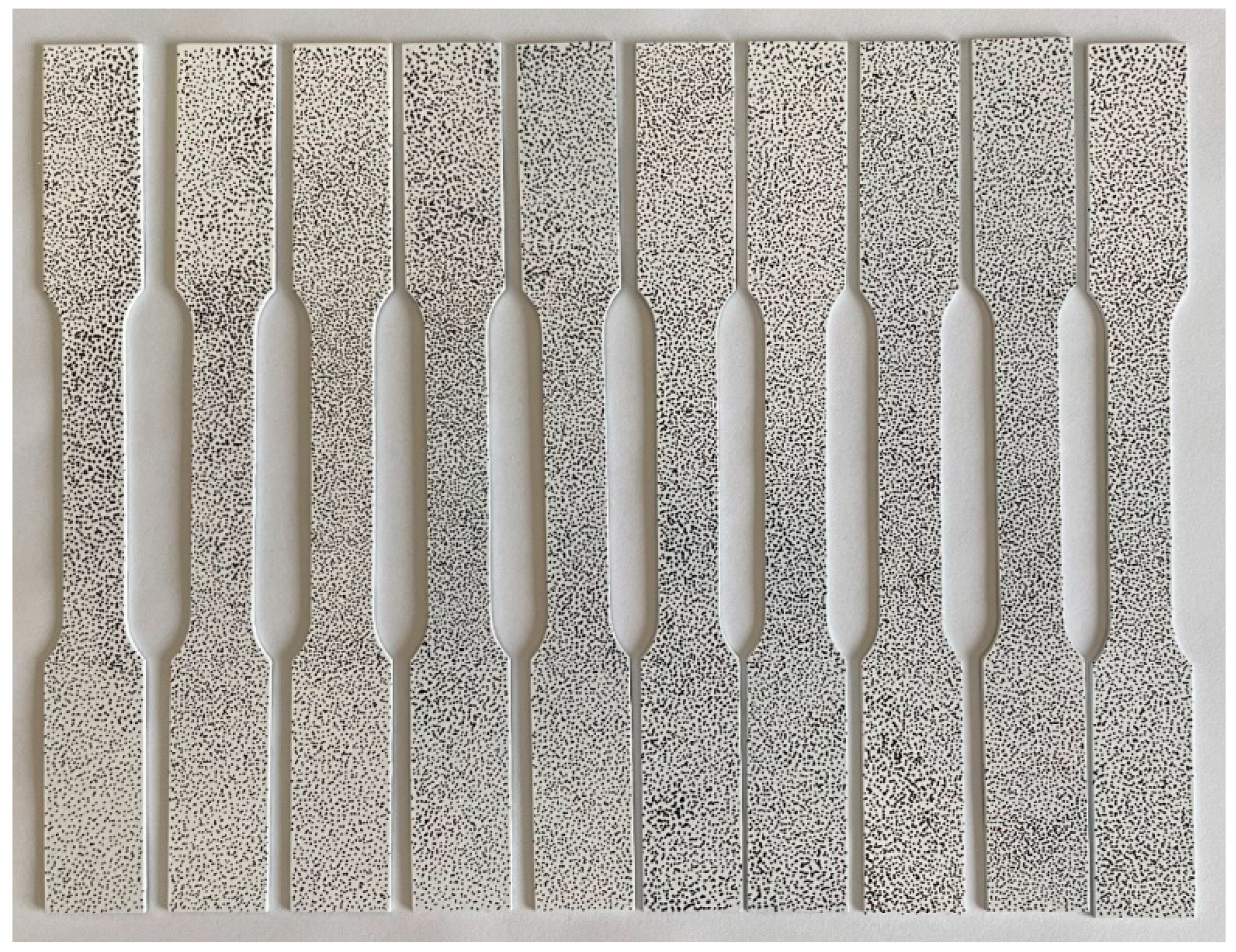

2.2. Specimen Geometry

2.3. Specimen Preparation

2.4. Test Equipment

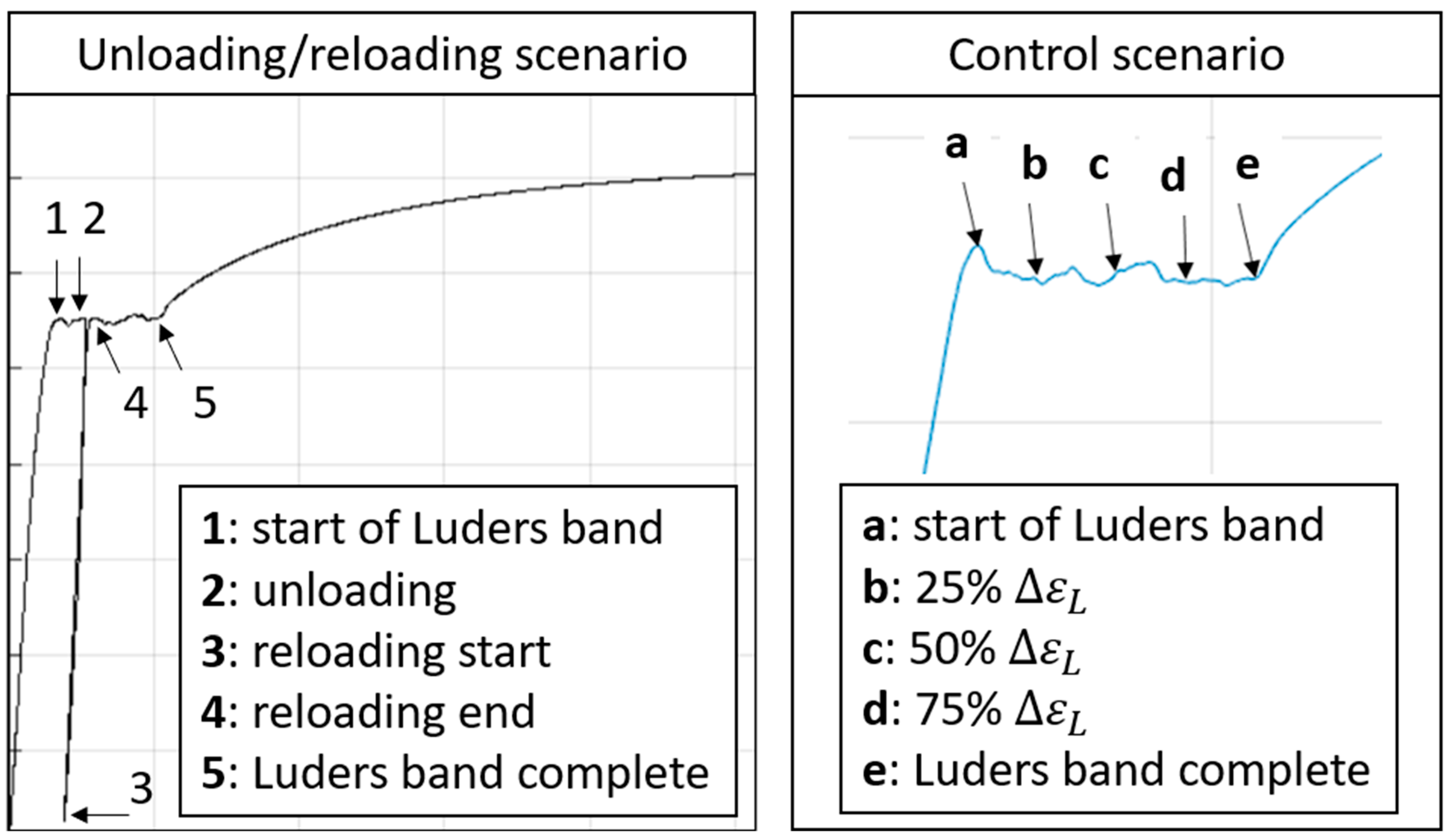

2.5. Test Program

3. Data Collection and Post-Processing

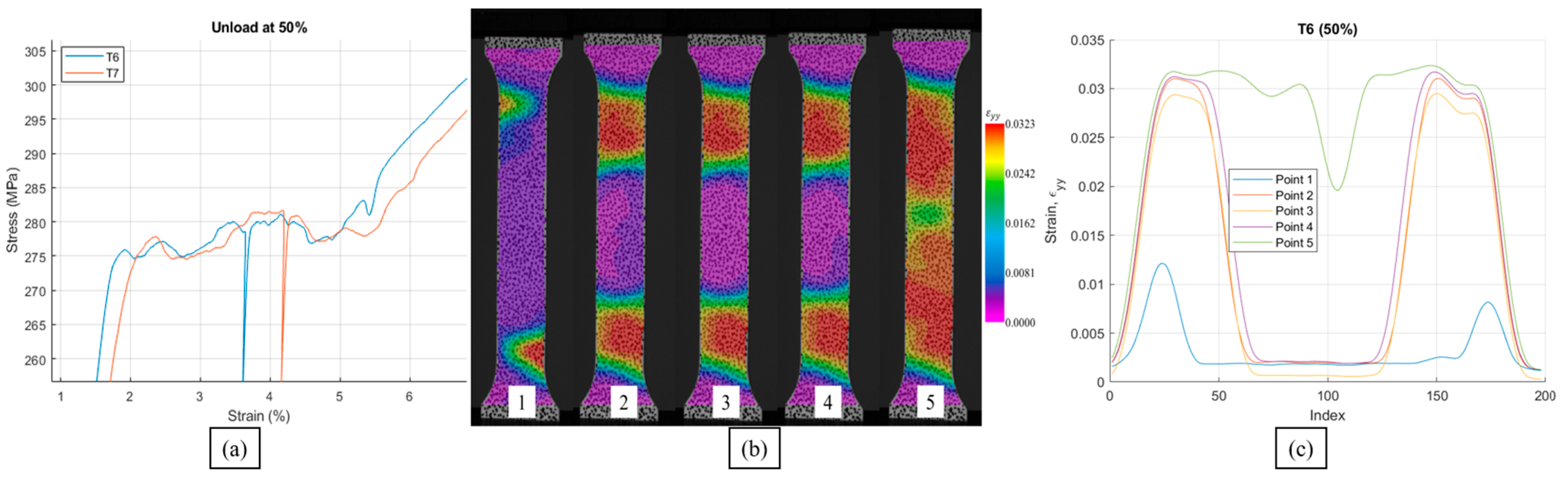

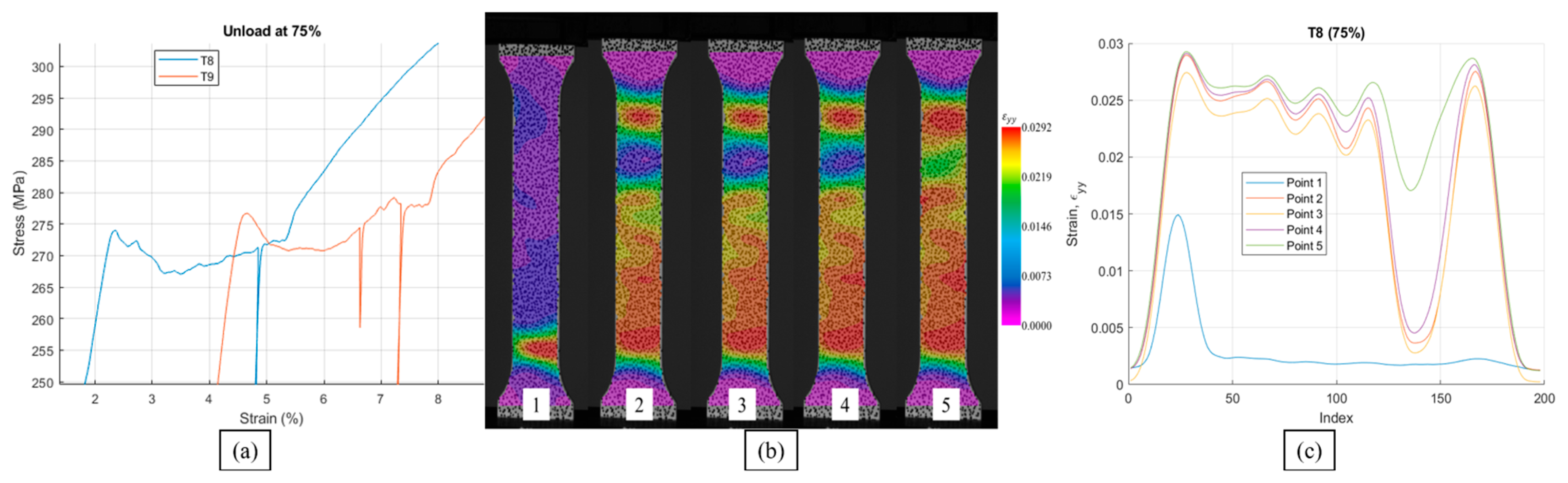

4. Results and Discussions

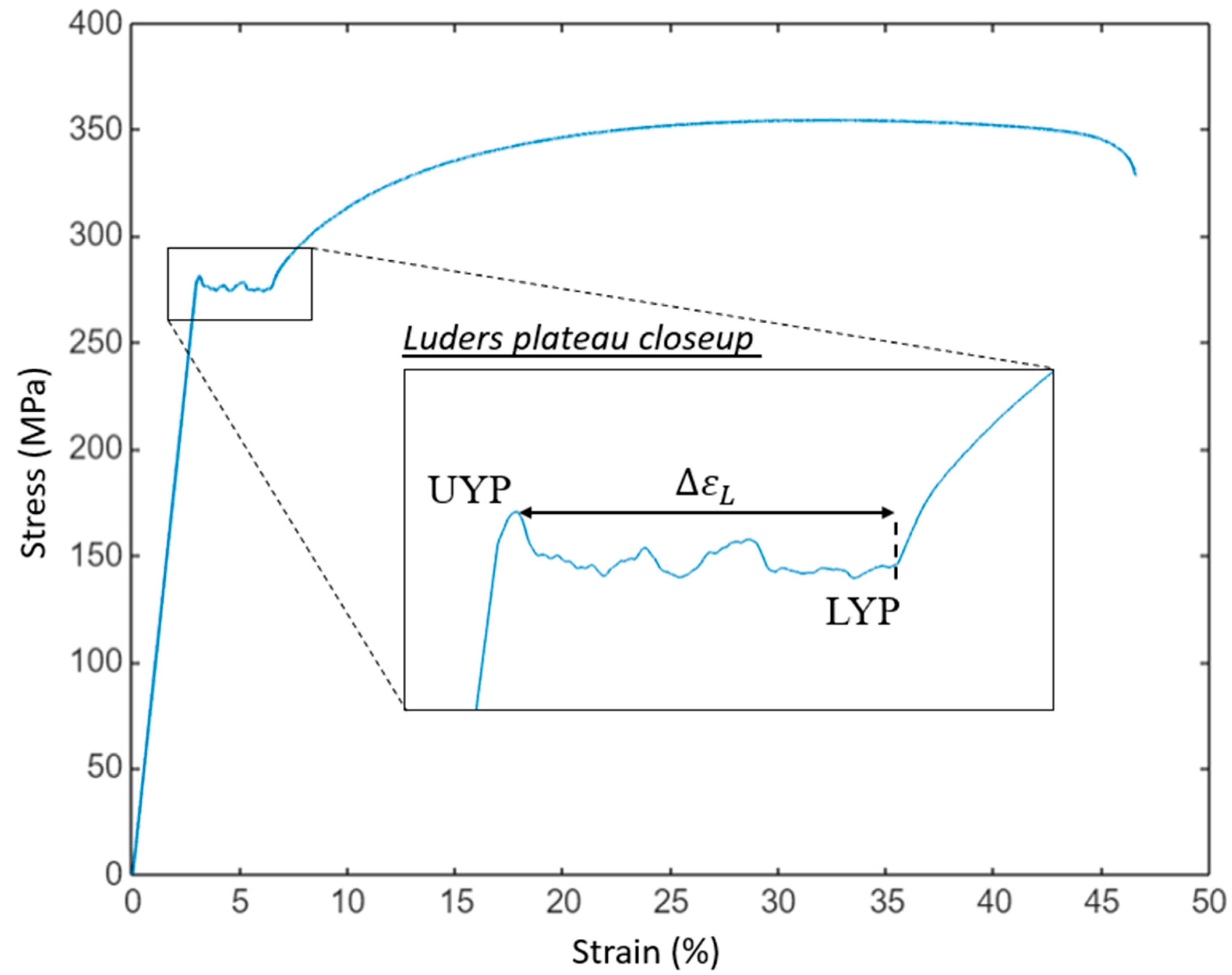

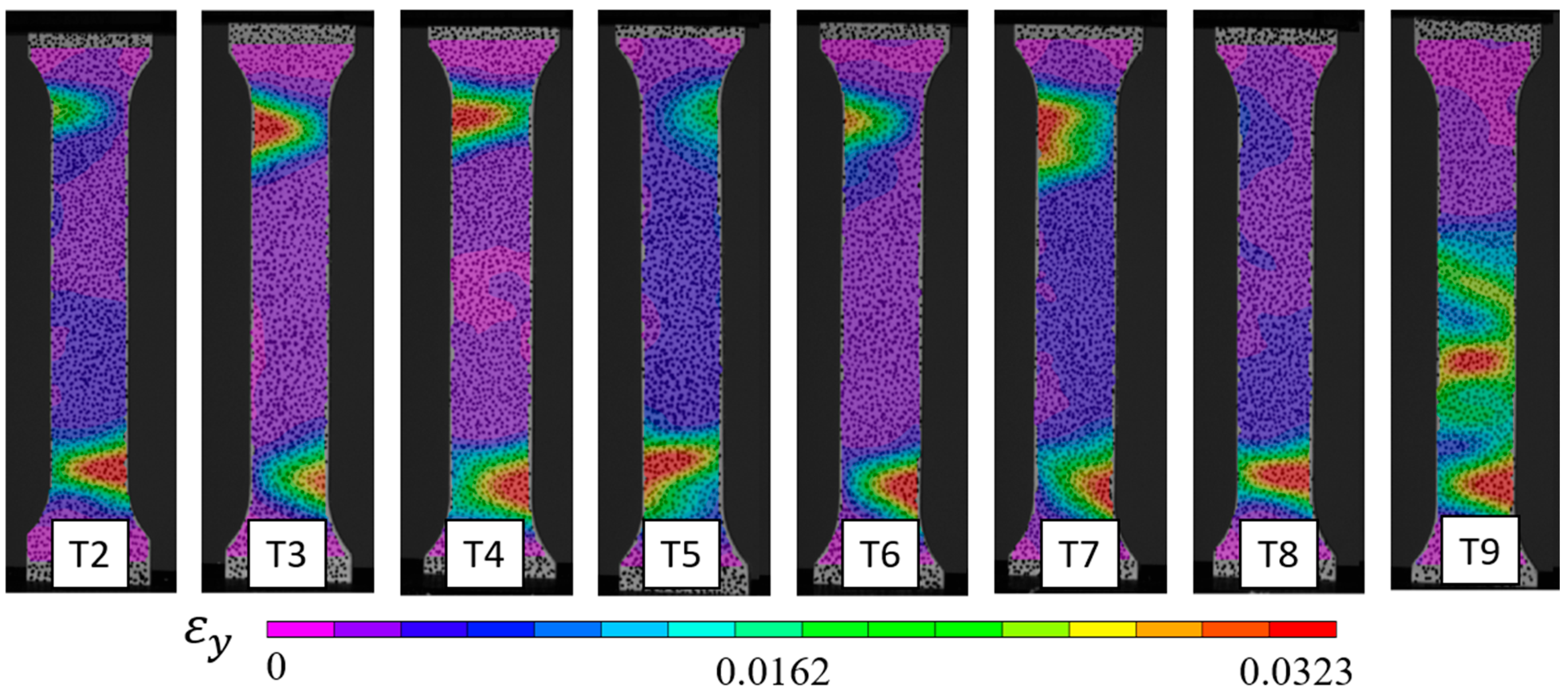

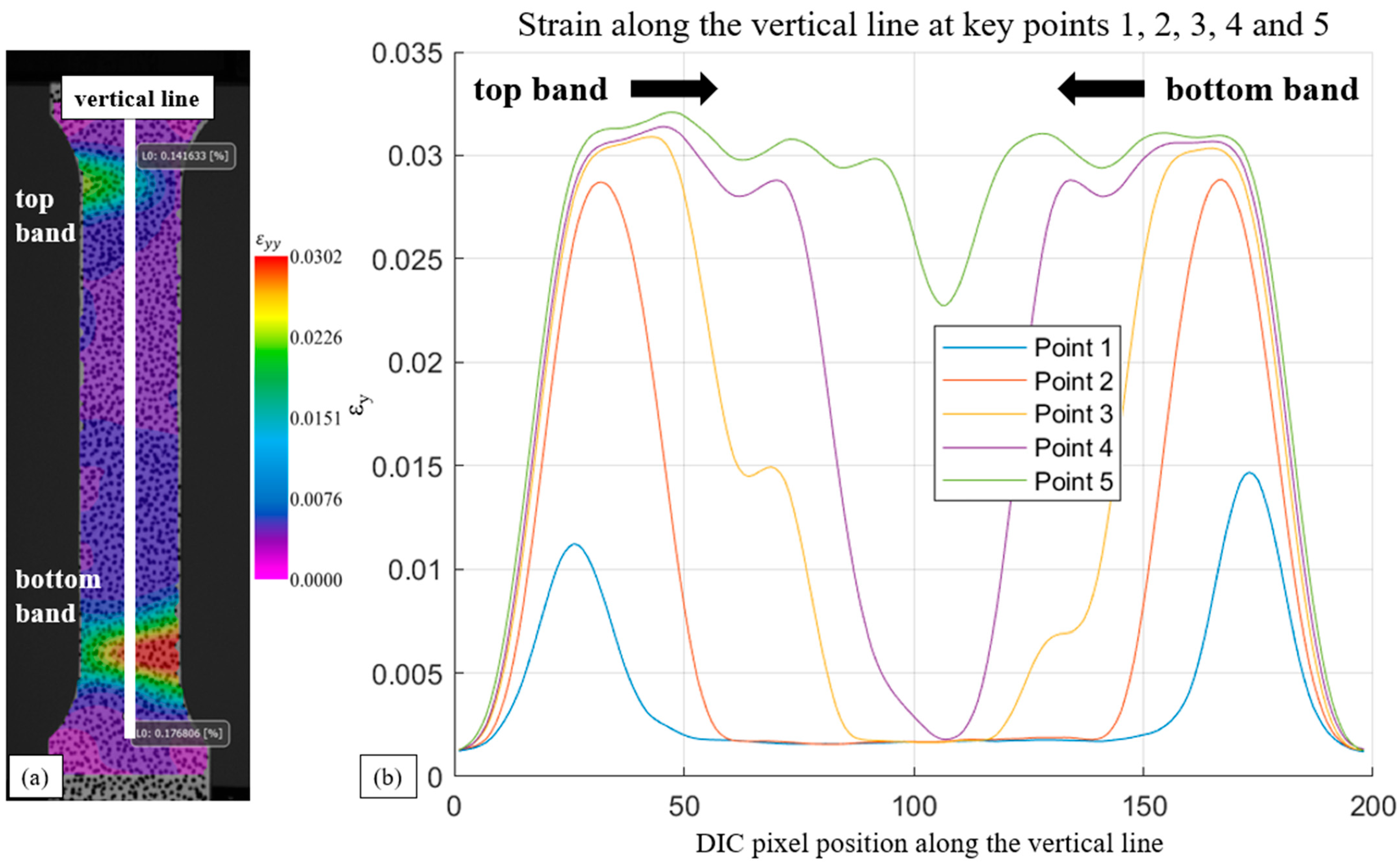

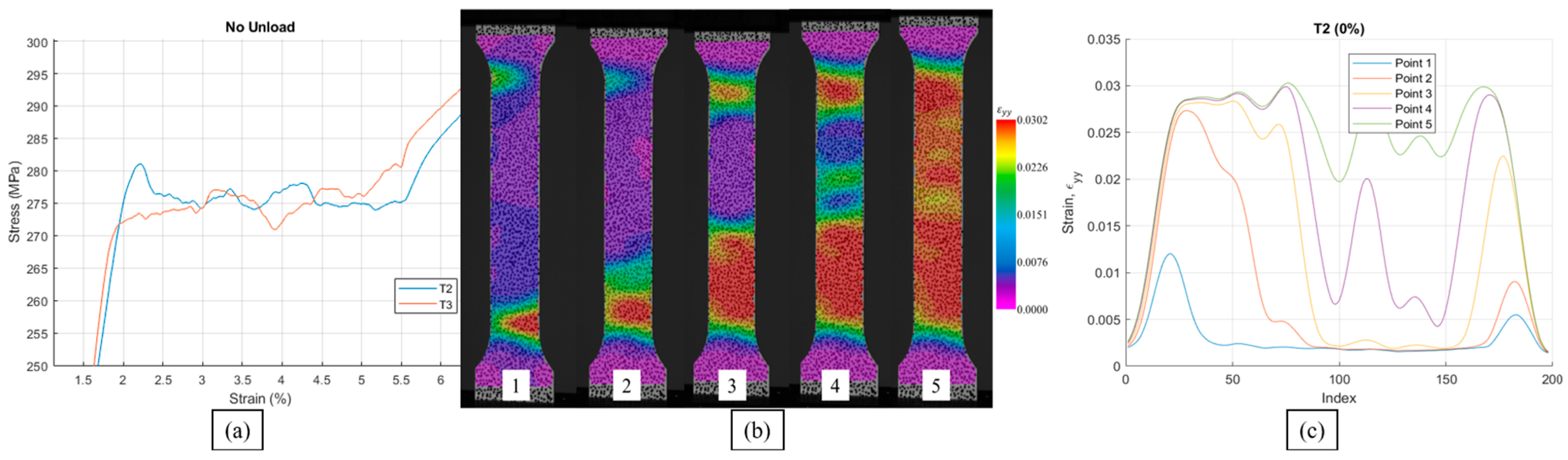

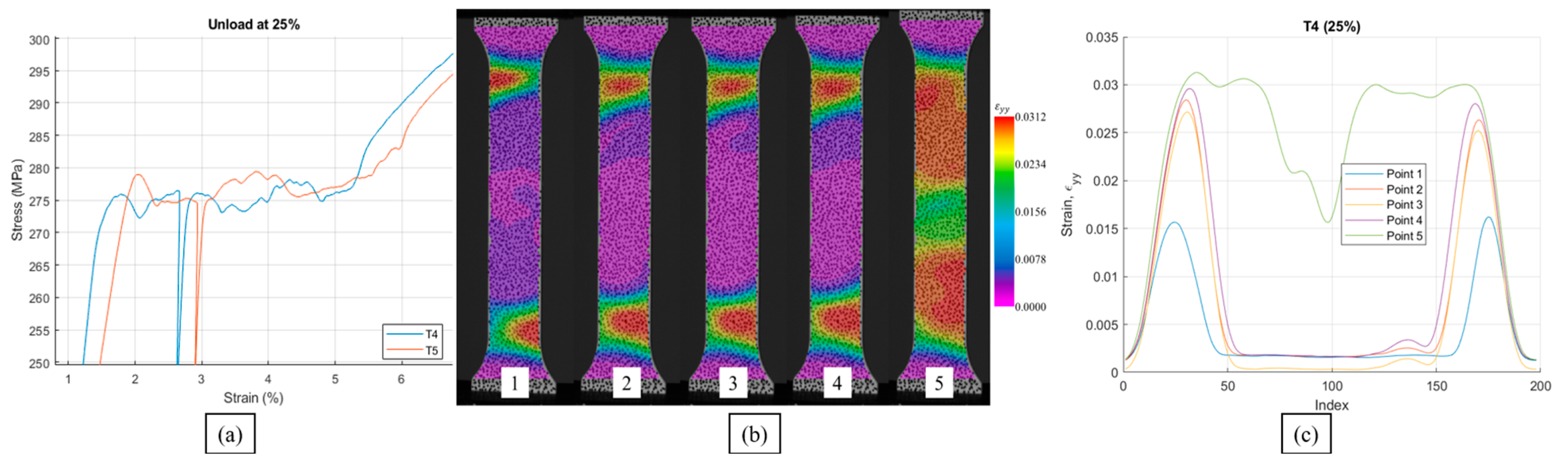

4.1. Lüders Band Formation

4.2. Lüders Strain

4.3. Lüders Band Evolution

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Ananthan, V.; Hall, E. Macroscopic aspects of Lüders band deformation in mild steel. Acta Metall. Mater. 1991, 39, 3153–3160. [Google Scholar] [CrossRef]

- Kyriakides, S.; Miller, J.E. On the Propagation of Luders Bands in Steel Strips. J. Appl. Mech. 2000, 67, 645–654. [Google Scholar] [CrossRef]

- Onodera, R.; Nonomura, M.; Aramak, M. Stress Drop, Luders Strain and Strain Rate during Serrated Flow. J. Jpn. Inst. Met. Mater. 2000, 64, 1162–1171. [Google Scholar] [CrossRef][Green Version]

- Nagarajan, S.; Narayanaswamy, R.; Balasubramaniam, V. An Insight into Lüders Deformation Using Advanced Imaging Techniques. J. Mater. Eng. Perform. 2013, 22, 3085–3092. [Google Scholar] [CrossRef]

- Liu, G.-L.; Li, Y.-R.; Huang, G.-Y.; Ke, L.-L.; Wang, Y.-Z. Characterization of Portevin–Le Chatelier effect in aluminum alloy AA5052 under strain-controlled tensile test via digital image correlation and acoustic emission. J. Mater. Sci. 2024, 59, 16341–16354. [Google Scholar] [CrossRef]

- Lisiecka-Graca, P.; Lisiecki, Ł.; Zyguła, K.; Wojtaszek, M. Evaluation of cracking risk of 80MnSi8-6 nanobainitic steel during hot forging in the range of lower temperature limits. Mater. Sci. Pol. 2024, 42, 171–185. [Google Scholar]

- Brlić, T.; Rešković, S.; Vodopivec, F.; Jandrlić, I. Lüders Bands at the Beginning of the Plastic Flow of Materials. Metalurgija 2018, 47, 357–359. [Google Scholar]

- Johnson, D.; Edwards, M.; Chard-Tuckey, P. Microstructural effects on the magnitude of Lüders strains in a low alloy steel. Mater. Sci. Eng. A 2015, 625, 36–45. [Google Scholar] [CrossRef]

- van der Heijde, J.; Samad, W.A. The Effect of Specimen Thickness on the Lüders Phenomena in AISI 1524 Steel Alloy: Experimental Observations Using DIC. Exp. Mech. 2023, 63, 885–896. [Google Scholar] [CrossRef]

- Cai, Y.-L.; Yang, S.-L.; Fu, S.-H.; Zhang, Q.-C. The Influence of Specimen Thickness on the Lüders Effect of a 5456 Al-Based Alloy: Experimental Observations. Metals 2016, 6, 120. [Google Scholar] [CrossRef]

- Sun, H.B.; Yoshida, F.; Ohmori, M.; Ma, X. Effect of strain rate on Lüders band propagating velocity and Lüders strain for annealed mild steel under uniaxial tension. Mater. Lett. 2003, 57, 4535–4539. [Google Scholar] [CrossRef]

- Brlić, T.; Rešković, S.; Jandrlić, I.; Skender, F. Influence of strain rate on stress changes during Lüders bands formation and propagation. IOP Conf. Ser. Mater. Sci. Eng. 2018, 461, 012007. [Google Scholar] [CrossRef]

- Rešković, S.; Jandrlić, I.; Vodopivec, F. Influence of Testing Rate on Lüders Band Propagation in Niobium Microalloyed Steel. Metalurgija 2016, 55, 157–160. [Google Scholar]

- Zhang, W.; Kyriakides, S. Evolution of Lüders banding under axial loading and reverse loading. Int. J. Solids Struct. 2022, 257, 111780. [Google Scholar] [CrossRef]

- ASTM E415-21; Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E112-24; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2021.

- Tsuchidaa, N.; Masuda, H.; Harada, Y.; Fukaura, K.; Tomato, Y.; Nagai, K. Effect of ferrite grain size on tensile deformation behavior of a ferrite-cementite low carbon steel. Mater. Sci. Eng. A 2008, 488, 446–452. [Google Scholar] [CrossRef]

- Adkins, I. Vic-3D 9 Testing Guide; Correlated Solutions, Inc.: Irmo, SC, USA, 2020. [Google Scholar]

- Tsuchida, N.; Tomato, Y.; Nagai, K.; Fukaura, K. A simple relationship between Lüders elongation and work-hardening rate at lower yield stress. Scr. Mater. 2006, 54, 57–60. [Google Scholar] [CrossRef]

- Qiu, H.; Inoue, T.; Ueji, R. Experimental measurement of the variables of Lüders deformation in hot-rolled steel via digital image correlation. Mater. Sci. Eng. A 2020, 790, 139756. [Google Scholar] [CrossRef]

- Qiu, H.; Inoue, T.; Ueji, R. In-Situ Observation of Lüders Band Formation in Hot-Rolled Steel via Digital Image Correlation. Metals 2020, 10, 530. [Google Scholar] [CrossRef]

- Shariat, B.S.; Li, Y.; Yang, H.; Wang, Y.; Liu, Y. On the Lüders band formation and propagation in NiTi shape memory alloys. J. Mater. Sci. Technol. 2022, 116, 22–29. [Google Scholar] [CrossRef]

- Wang, X.G.; He, B.B.; Liu, C.H.; Jiang, C.; Huang, M.X. Extraordinary Lüders-strain-rate in medium Mn steels. Materialia 2019, 6, 100288. [Google Scholar] [CrossRef]

| Element | Mn | C | Si | P | S | Fe |

|---|---|---|---|---|---|---|

| Content (wt. %) | 1.55 | 0.24 | 0.34 | 0.03 | 0.06 | Balance |

| Camera Resolution | 1920 × 1200 (2.3 MP) |

|---|---|

| Exposure Time | 19 μs–1 s |

| Field of View | Fixed: 150 × 200 mm |

| Displacement Resolution | In-plane: ±2 μm, Out-of-plane: ±4 μm |

| Strain Resolution | 50 με |

| Strain Range | 0.005% to >2000% |

| Test Number | Specimen ID | ) | Thickness (mm) | Crosshead Speed (mm/min) | DIC Frame Rate (Hz) | Temperature (°C) |

|---|---|---|---|---|---|---|

| 1 | T1 | 0% | 1 | 1 | 0.5 | 23 |

| 2 | T2 | 0% | 1 | 0.5 | 0.5 | 23 |

| 3 | T3 | 0% | 1 | 0.5 | 0.5 | 23 |

| 4 | T4 | 25% | 1 | 0.5 | 0.5 | 23 |

| 5 | T5 | 25% | 1 | 0.5 | 0.5 | 23 |

| 6 | T6 | 50% | 1 | 0.5 | 0.5 | 23 |

| 7 | T7 | 50% | 1 | 0.5 | 0.5 | 23 |

| 8 | T8 | 75% | 1 | 0.5 | 0.5 | 23 |

| 9 | T9 | 75% | 1 | 0.5 | 0.5 | 23 |

| Specimen ID | E (GPa) | UYS (MPa) | LYS (MPa) | TS (MPa) |

|---|---|---|---|---|

| T2 | 230 | 281 | 276 | 354 |

| T3 | 230 | 273 | 273 | 353 |

| T4 | 220 | 276 | 272 | 353 |

| T5 | 241 | 279 | 274 | 356 |

| T6 | 239 | 276 | 275 | 356 |

| T7 | 256 | 278 | 275 | 358 |

| T8 | 248 | 274 | 271 | 352 |

| T9 | 248 | 277 | 272 | 357 |

| Average | 239 | 277 | 274 | 355 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almatroushi, M.; Pervaiz, S.; Samad, W.A. The Effect of Interrupted Loading on the Lüder Phenomena in AISI 1524 Steel Alloy. Alloys 2025, 4, 19. https://doi.org/10.3390/alloys4030019

Almatroushi M, Pervaiz S, Samad WA. The Effect of Interrupted Loading on the Lüder Phenomena in AISI 1524 Steel Alloy. Alloys. 2025; 4(3):19. https://doi.org/10.3390/alloys4030019

Chicago/Turabian StyleAlmatroushi, Mohamed, Salman Pervaiz, and Wael A. Samad. 2025. "The Effect of Interrupted Loading on the Lüder Phenomena in AISI 1524 Steel Alloy" Alloys 4, no. 3: 19. https://doi.org/10.3390/alloys4030019

APA StyleAlmatroushi, M., Pervaiz, S., & Samad, W. A. (2025). The Effect of Interrupted Loading on the Lüder Phenomena in AISI 1524 Steel Alloy. Alloys, 4(3), 19. https://doi.org/10.3390/alloys4030019