Abstract

This research investigates the effects of the addition of the rare-earth element La on the microstructure, phase transformation, and mechanical properties of Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2) alloys. The results show that a primary matrix composed of Ni-Ti-Hf and featuring La-rich second phases formed. The temperature at which the martensitic phase transformation starts decreases with an increase in La content. As the amount of La increases, hardness decreases slightly, while the elastic modulus increases.

1. Introduction

Ni-Ti-based shape memory alloys exhibit elasticity, with a crystalline structure that exhibits a cubic lattice (austenite) at high temperatures and transforms into a monoclinic lattice (martensite) at low temperatures [1]. These materials possess unique properties, such as the ability to remember and recover their original shape after deformation due to mechanical force or temperature changes and excellent corrosion resistance. Such properties make them widely applicable in various scientific and technological fields, especially in engineering, smart technologies [2], and medicine [3].

Composition, precipitates, and heat treatment significantly affect the properties of Ni-Ti based alloys. To enhance these properties, researchers have investigated how changing impurity levels, adding tertiary and quaternary transition metals, and modifying heat treatment temperatures influence these alloys’ crystal structure, microstructure, phase transformation temperatures, and mechanical properties. When added to these materials, most metals decrease the transformation temperature, although the addition of some transition metals, such as Zr [4], Hf [5], Au [6], and Pd [7], increase it. Therefore, Ni-Ti-Au, Ni-Ti-Zr, Ni-Ti-Pd, and Ni-Ti-Hf alloys are preferred for high-temperature applications like robotics and the development of automotive and aerospace technologies. However, the high cost of Au and Pd limits the use of NiTiAu and NiTiPd alloys. In contrast, Ni-Ti-Hf alloys are more economical and thus widely used in high-temperature applications [8]. However, their shape memory effect (SME) is relatively poor (~3%) due to their low matrix strength [9]—which is significantly less than that of commercial Ti-Ni binary alloys—limiting their broader application.

To improve mechanical and shape memory properties, quaternary elements are added. Research has also explored the addition of rare-earth elements such as Y [10] and Nd [11] to Ni-Ti-Hf alloys. These studies indicate that the addition of these elements slightly decreases the phase transformation temperature and also leads to a decrease in hardness. The addition of rare-earth elements to the alloy tends to form rare-earth-rich second phases, which reduce the structural density of the matrix and consequently lead to a decrease in overall hardness. A slight decrease in hardness has the advantage of increasing the elastic modulus in shape memory alloys. However, the effect of La addition on the microstructures, phase transformation, and mechanical properties of Ni-Ti-Hf alloys remains unclear.

Therefore, we aimed to investigate how the addition of the rare-earth element La influences the microstructure, phase transformation behavior, and mechanical properties of Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2) shape memory alloys. We sought to determine the extent to which La doping can be used to tune transformation temperatures and mechanical performance, providing insight into the alloy design of next-generation high-temperature shape memory materials.

2. Experiment

Ni50Ti30Hf 20−x Lax (x = 0, 0.5, 1, 2) alloys were prepared using the following purities for the constituent elements: Ni, 99.9%; Ti, 99.9%; Hf, 99.9%; and La, 99.95%. The materials were melted in a vacuum consumable arc melting furnace by using a water-cooled copper crucible. The melting–cooling cycle was repeated four times to ensure a uniform microstructure was generated [11]. The samples were then heat-treated at 850 °C for 1 h and mechanically polished. Microstructure and chemical composition were analyzed using a Jeol-6000Plus scanning electron microscope (SEM) (Jeol, Akishima, Japan) in conjunction with an Oxford EDS system. The SEM was operated at 15 kV with a 5 mm working distance. Hardness was measured using an HBE-3000A Brinell Hardness Tester with a 10 mm ball and 3000 N load; the average of 10 measurements was taken. The elastic modulus was evaluated using an Agilent Nano Indenter G200. Phase transformation characteristics were determined using a DSC Q2000 Differential Scanning Calorimeter, with heating and cooling rates of 10 °C/min in the 0–500 °C temperature range.

3. Results and Discussion

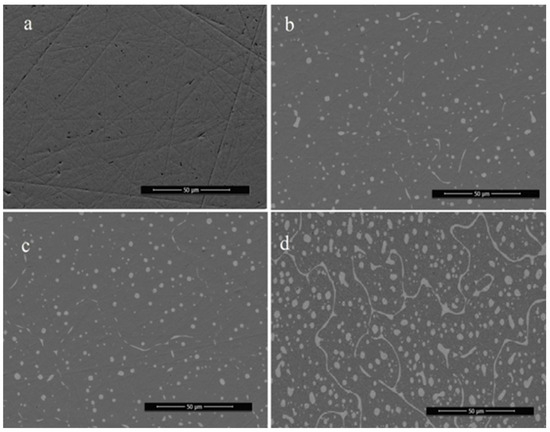

The backscattering SEM images of the Ni50Ti30Hf 20−x Lax (x = 0, 0.5, 1, 2) alloys are shown in Figure 1. The Ni50Ti30Hf20 sample exhibited a homogeneous matrix phase (gray). In contrast, the La-containing samples showed the second phase (white), and its size increased with an increase in La content. The average diameters of these phases were 6 μm (La0.5), 7 μm (La1), and 9 μm (La2).

Figure 1.

SEM images Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2 at%). (a) Ni50Ti30Hf20; (b) Ni50Ti30Hf19.5La0.5; (c) Ni50Ti30Hf19La1; (d) Ni50Ti30Hf18La2.

EDS analysis (Table 1) indicated that La was not present in the matrix because of its large atomic radius, preventing dissolution [10]. However, the La concentration in the second phases increased upon La addition. Table 1 presents the atomic percentages of each element in both the matrix and second phases across different compositions. The data confirm that La preferentially segregates into precipitate regions, while the matrix composition remains largely constant. This compositional partitioning supports the observation that an La-rich second phase forms independently of the Ni-Ti-Hf matrix structure. The observed microstructure resembles those of Ni-Ti-Hf-Y [10] and Ni-Ti-Hf-Nd [11] alloys.

Table 1.

Compositions of Ni-Ti-Hf-La alloys.

The Ni/Ti/Hf ratio in the matrix phase is nearly identical across all alloys, with an approximate composition of 50:30:20. This suggests that the addition of La has a negligible impact on the chemical composition of the matrix. The Ni/Ti/Hf/La ratio in the second phase of the alloys is approximately 12:4:2:82, suggesting that these phases can be considered La-rich.

These La-rich second phases likely alter the chemical uniformity and local stress fields in the alloy, potentially affecting its phase transformation behavior. Specifically, the formation of these phases may reduce the driving force or hinder the lattice reconfiguration needed for martensitic transformation, thus lowering the transformation temperature.

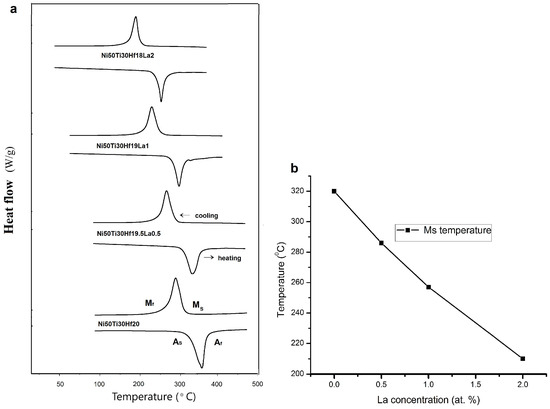

Figure 2a shows the DSC results for the Ni50Ti30Hf20-xLax (x = 0, 0.5, 1, 2) alloy. As the measurement results show, there was one peak in the process when all the alloy samples were heated and cooled, indicating that the temperature-dependent crystal structure transition is a one-step B2↔B19’ or direct transition. The nature of this phase transformation corresponds to the phase transitions of Ni-Ti-Hf-Y [10], Ni-Ti-Hf-Nd [11], and Ni-Ti-Hf-Ta [12] alloys. The martensitic phase transformation start temperature (Ms), the martensitic phase transformation finishing temperature (Mf), the austenite phase transformation start temperature (As), and the austenite phase transformation finishing temperature (Af) determined from the differential scanning calorimeter (DSC) curves and the results of some articles are shown in Table 2.

Figure 2.

Differential scanning calorimeter curves of Ni-Ti-Hf-La alloys: (a) DSC curves and (b) martensitic transformation start temperature on La concentration.

Figure 2b shows the variation in the Ms at which the transition to the martensite phase transformation starts depending on the amount of La. For the Ni-Ti-Hf alloy, the temperature at which the transition to the martensite phase transformation starts is Ms = 320 °C. As the amount of La increases, the temperature at which the martensite phase transformation starts decreases. The temperature at which the transition to the martensite phase transformation starts is Ms = 286 °C for La0.5, Ms = 257 °C for La1, and Ms = 210 °C for La2. For Ti-Ni binary alloys, the Ni content has a greater influence on the phase transition temperature than the Ti content [13]. However, for NiTiHf-based alloys, the Hf content has a greater influence than the Ti content. In the case of the Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2) alloy, it is believed that the decrease in the temperature at which the transition to the martensite phase transformation starts is due to the formation of an La-rich second phase on the surface of the alloy.

Table 2.

Phase transformation temperatures of Ni-Ti-Hf-La alloys and data from the literature.

Table 2.

Phase transformation temperatures of Ni-Ti-Hf-La alloys and data from the literature.

| Alloys | Ms (°C) | Mf (°C) | As (°C) | Af (°C) | Source |

|---|---|---|---|---|---|

| Ni50Ti30Hf20 | 320 | 261 | 308 | 374 | This study |

| Ni50Ti30Hf19.5La0.5 | 286 | 242 | 302 | 353 | |

| Ni50Ti30Hf19La1 | 257 | 212 | 282 | 306 | |

| Ni50Ti30Hf18La2 | 210 | 178 | 239 | 276 | |

| Ni49.4Ti38.6Hf12 | 195 | 100 | 180 | 247 | [14] |

| Ni49.8Ti30.2Hf20 | 299.9 | 273.3 | 322.7 | 337.5 | [15] |

| Ni50.3Ti29.7Hf20 | 146.4 | 116.6 | 160.4 | 177.4 | [16] |

| Ni50.3Ti24.7Hf25 | 252.3 | 220.1 | 264.1 | 288.8 | |

| Ni50Ti29Hf21 | 314.1 ± 0.2 | 253.9 ± 0.3 | 306.6 ± 0.3 | 358.8 ± 0.3 | [11] |

| Ni50Ti29Hf20Nd1 | 201.2 ± 0.3 | 146.5 ± 0.3 | 180.9 ± 0.3 | 233.2 ± 0.2 | |

| Ni50Ti29Hf19Nd2 | 150.4 ± 0.2 | 65.3 ± 0.3 | 105.5 ± 0.3 | 195.2 ± 0.3 | |

| Ni50.3Ti29.7Hf20 | 193.25 | 155.21 | 203.85 | 226.13 | [17] |

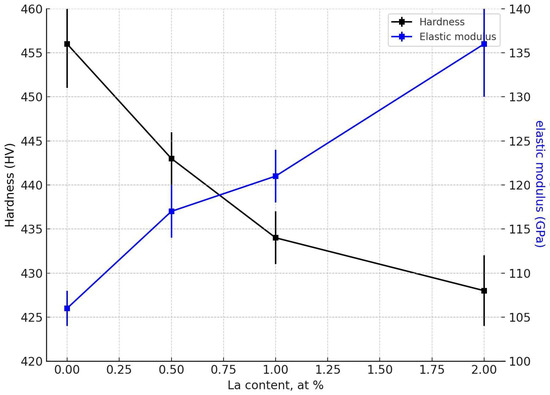

Mechanical testing (Figure 3) revealed that the hardness of the alloys decreased slightly with the addition of La, with the highest hardness value (456 HV) exhibited by the La-free sample (Table 3). This value is considerably higher than the 261 HV reported for binary Ni50.3Ti49.3 alloys [12], indicating that the incorporation of Hf significantly enhances the hardness of the alloy. The increase in hardness upon the addition of Hf can be attributed to solid-solution strengthening and the possible formation of Hf-rich precipitates, which act as barriers to dislocation motion and thereby improve resistance to plastic deformation. The highest hardness value (456 HV) was observed in the La-free Ni50Ti30Hf20 alloy, indicating that Hf plays a critical role in strengthening the matrix phase. According to the EDS analysis of the alloys, as the La content increases, the corresponding fraction of Hf decreases, which can be considered one of the main factors contributing to the overall reduction in hardness [16].

Figure 3.

Hardness and elastic modulus of Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2) alloys.

Table 3.

Hardness and elastic modulus of Ni-Ti-Hf-La alloys.

Although lanthanum is a hard rare-earth metal, its addition caused a decrease in hardness, likely due to its influence on the microstructure and second phase distribution. The addition of La could have promoted the formation of softer eutectic structures or La-rich intermetallic phases that do not contribute effectively to hardening. La might also alter the solidification path and grain structure, potentially leading to coarser microstructures or a decrease in the quantity of hard secondary phases. These microstructural changes may offset any potential hardening effects associated with La as an individual element.

In contrast, the elastic modulus exhibited a clear increasing trend with an increase in La content, reaching a maximum value of 136 GPa for the Ni50Ti30Hf18La2 alloy (Table 3). This result suggests that La incorporation, although detrimental to hardness, contributes positively to the stiffness of the alloy. Similarly, the observed decrease in hardness and increase in elastic modulus with increasing La content can be attributed to the concomitant reduction in Hf content. Therefore, the primary factor governing these changes appears to be the decrease in Hf concentration. The decrease in Hf content in the Ni-Ti-Hf alloy may have led to a reduction in matrix strengthening, resulting in an increase in the elastic modulus.

4. Conclusions

This investigation provides a comprehensive assessment of the effects of incorporating La into Ni-Ti-Hf shape memory alloys, specifically Ni50Ti30Hf20−xLax (x = 0, 0.5, 1, 2). The experimental findings confirm that the addition of La leads to the formation of Ni-Ti-Hf matrix phases and La-rich second phases, which are largely excluded from the matrix because of atomic size mismatch. These La-rich second phases introduce a microstructure that plays a significant role in depressing the martensitic start temperature. The Ni-Ti-Hf-La alloys have a one-step martensitic transformation. Concurrently, mechanical characterization indicates a moderate decrease in hardness and a notable increase in elastic modulus with a higher La content.

Author Contributions

Conceptualization, D.B. and M.D.; methodology, M.D.; software, D.B.; validation, D.B. and M.D.; formal analysis, M.D.; investigation, D.B. and M.D.; resources, D.B.; data curation, D.B. and M.D.; writing—original draft preparation, M.D.; writing—review and editing, M.D.; visualization, D.B.; supervision, M.D.; project administration, M.D.; funding acquisition, M.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data are available in the main text.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Otsuka, K.; Ren, X. Recent developments in the research of shape memory alloys. Intermetallics 1999, 7, 511–528. [Google Scholar] [CrossRef]

- Amadi, A.; Mohyaldinn, M.; Ridha, S.; Ola, V. Advancing engineering frontiers with NiTi shape memory alloys: A multifaceted review of properties, fabrication, and application potentials. J. Alloys Compd. 2024, 976, 173227. [Google Scholar] [CrossRef]

- Patel, S.K.; Behera, B.; Swain, B.; Roshan, R.; Sahoo, D.; Behera, A. A review on NiTi alloys for biomedical applications and their biocompatibility. Mater. Today 2020, 33, 5548–5551. [Google Scholar] [CrossRef]

- Pérez-Sierra, A.M.; Pons, J.; Santamarta, R.; Karaman, I.; Noebe, R.D. Stability of a Ni-rich Ni-Ti-Zr high temperature shape memory alloy upon low temperature aging and thermal cycling. Scr. Mater. 2016, 124, 47–50. [Google Scholar] [CrossRef]

- Pérez-Cerrato, M.; Maass, B.; Nó, M.L.; Juan, J.M.S. Ni–Ti-Hf high-temperature shape memory alloy: Measure of the Clausius-Clapeyron coefficient through mechanical spectroscopy. J. Alloys Compd. 2021, 856, 157948. [Google Scholar] [CrossRef]

- Casalena, L.; Coughlin, D.R.; Yang, F. Transformation and deformation characterization of NiTiHf and NiTiAu high temperature shape memory alloys. Microsc. Microanal. 2015, 21, 607–608. [Google Scholar] [CrossRef]

- Coppa, A.C.; Kapoor, M.; Noebe, R.; Thompson, G.B. The compositional stability of the P-phase in Ni–Ti–Pd shape memory alloys. Intermetallics 2015, 67, 56–62. [Google Scholar] [CrossRef]

- Ma, J.; Karaman, I.; Noebe, R.D. High temperature shape memory alloys. Int. Mater. Rev. 2010, 55, 257–315. [Google Scholar] [CrossRef]

- Meng, X.L.; Cai, W.; Fu, Y.D.; Li, Q.F.; Zhang, J.X.; Zhao, L.C. Shape memory behaviors in an aged Ni-rich TiNiHf high temperature shape-memory alloy. Intermetallics 2008, 16, 698–705. [Google Scholar] [CrossRef]

- Yi, X.Y.; Gao, W.H.; Meng, X.L.; Gao, Z.Y.; Cai, W.; Zhao, L.C. Martensitic transformation behaviors and mechanical properties of (Ti36Ni49Hf15)100−xYx high temperature shape memory alloys. J. Alloys Compd. 2017, 705, 98–104. [Google Scholar] [CrossRef]

- Zhao, C.; Zhao, S. Structure, phase transformation, and hardness of NiTiHfNd alloys. SN Appl. Sci. 2021, 3, 565. [Google Scholar] [CrossRef]

- Prasad, R.V.S.; Park, C.H.; Kim, S.W.; Hong, J.K.; Yeom, J.T. Microstructure and phase transformation behavior of a new high temperature NiTiHf–Ta shape memory alloy with excellent formability. J. Alloys Compd. 2017, 697, 55–61. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Suresh, K.S.; Kim, D.I.; Bhaumik, S.K.; Suwas, S. Evolution and stability of phases in a high temperature shape memory alloy Ni49.4Ti38.6Hf12. Intermetallics 2014, 44, 18–25. [Google Scholar] [CrossRef]

- Frenzel, J.; Wieczorek, A.; Opahle, I.; Maaß, B.; Drautz, R.; Eggeler, G. On the effect of alloy composition on martensite start temperatures and latent heats in Ni–Ti-based shape memory alloys. Acta Mater. 2015, 90, 213–231. [Google Scholar] [CrossRef]

- Prasher, M.; Sen, D.; Tewari, R.; Krishna, P.S.R.; Babu, P.D.; Krishnan, M. Effect of Hf solute addition on the phase transformation behavior and hardness of a Ni-rich NiTi alloy. Mater. Chem. Phys. 2020, 247, 122890. [Google Scholar] [CrossRef]

- Dabbaghi, H.; Pourshams, M.; Nematollahi, M.; Poorganji, B.; Kirka, M.M.; Smith, S.; Chinnasamy, C.; Elahinia, M. LPBF Processability of NiTiHf Alloys: Systematic Modeling and Single-Track Studies. Materials 2024, 17, 4150. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).