Abstract

Zirconia has generated tremendous interest in the esthetic materials used for dental restorations. However, using conventional zirconia has some limitations especially in highly esthetically demanding situations, as it lacks the translucency that other ceramic materials possess. This study aimed to evaluate and compare the optical properties (shade, translucency, and opalescence) of three CAD-CAM monolithic multilayer zirconia ceramics (GNX; Ceramill Zolid® Gen-X, ZCP; IPS e.max® ZirCAD, and UPC; Upcera® Esthetic Explore Prime) and one CAD-CAM monolithic multilayer polymer-infiltrated hybrid ceramic (ENM; Vita® Enamic) with a CAD-CAM monolithic lithium disilicate ceramic as control (EMX; IPS e.max® CAD). 200 discs (GNX = 40, ZCP = 40, UPC = 40, ENM = 40, and EMX = 40) were cut, polished, and fully crystallized. Half of the samples for each group were subjected to hydrothermal aging. Descriptive analysis and ANOVA tests were used to compare the groups. Zirconia GNX, ZCP, and UPC groups showed significantly lower optical properties than ENM and EMX groups for both the non-aged and aged samples (p < 0.05). UPC and ENM groups showed a significant decrease in translucency and opalescence after aging (p < 0.05). The optical properties of monolithic multilayer zirconia ceramics were lower than monolithic multilayer polymer-infiltrated hybrid ceramic and lithium disilicate ceramic. Polymer-infiltrated hybrid ceramic was significantly affected by aging.

1. Introduction

With the increasing interest in more esthetically and biologically compatible restorations, all-ceramic restorations have obtained significant popularity over the last decade, which is attributed to the technical improvements and physical appearance of ceramic materials [1]. Despite these advantages, there have been restrictions to their use in areas with high occlusal forces due to the highly brittle nature and tendency to cause excessive wear of the opposing natural teeth [2,3]. The introduction of CAD-CAM technology allowed high-strength ceramic materials, such as alumina and zirconia, to be used in clinical settings [4]. Zirconia is a white crystalline oxide of the element “zirconium” obtainable in three allotropic forms which are temperature-dependent [5]. The monoclinic form exists in equilibrium between room temperature and 1170 °C, the tetragonal form between 1170 °C and 2370 °C, and the cubic form above 2370 °C to its melting point of 2715 °C [6]. Zirconia has been meta-stabilized in its tetragonal form at room temperature by adding stabilizing oxides, such as CaO, MgO, CeO2, and Y2O2 [7]. Three types of zirconia systems are used in dentistry at present; yttrium cation-doped tetragonal zirconia polycrystals (3Y-TZP), magnesium cation-doped partially stabilized zirconia (Mg-PSZ), and zirconia-toughened alumina (ZTA) [6].

Conventional zirconia systems are composed of 3 mol% yttria-stabilized tetragonal zirconia polycrystals (3Y-TZP); they are opaque and can mask tooth discolorations. However, this chalky appearance is troublesome when trying to match the natural tooth color. So, conventional zirconia needed to be layered, and this mandated the removal of more tooth structures. Consequently, chipping of the veneered zirconia restorations was the most common complication, due to the lower strengths of feldspathic veneering porcelain layers, compared to the underlying zirconia cores. Monolithic (single bulk) zirconia restorations were developed to overcome this clinically significant problem. These new materials have good mechanical properties, reflected in the preservation of more tooth structures during preparation. However, their ability to achieve optimal esthetics is still challenged in situ. Alterations in the composition (commonly by reducing alumina content) and firing recommendations for CAD-CAM monolithic zirconia ceramic systems, allowed for an increase in their translucency and an improvement in their optical properties [8]. Recently, the new generations of CAD-CAM monolithic zirconia ceramic systems had also increased the yttria content to approximately 4 and 5 mol% Y-TZP. These structures have more cubic polycrystals with enhanced optical properties. A type of this generation is called “multilayer” and has layers of polychromatic and translucent zirconia gradients running from enamel to dentin shades in the single block before milling. Both posterior and anterior restorations are possible using these recent multilayer zirconia materials [8].

At present, further varieties of materials such as resin nanoceramics and polymer-infiltrated ceramics are commercially available for constructing monolithic restorations. The hybrid materials benefit from the structural and property combination of high-strength ceramics and more compliant resin polymers [9]. Resin-based ceramic (RBC) CAD-CAM blocks are divided into two subclasses according to their novel microstructure, namely, resin nanoceramics and polymer-infiltrated ceramics (PIC) [10]. The RBCs seem to have gained more popularity and have increased their usage gradually because they are easier to mill, less expensive, and easier to repair than ceramic-based blocks. Moreover, they possess elastic moduli that are similar to natural dentition [11]. A novel type of hybrid material is Enamic (VITA-Zahnfabrik H. Rauter-GmbH-Germany), which is PIC material, developed through the infiltration of a pre-sintered porous ceramic network (80% volume fraction) by the resin which fills the residual porosity of the ceramic and creates a dual network of ceramic and resin [12].

Zirconia has some disadvantages that might influence its clinical behavior. One of these disadvantages is “aging” or “low-temperature degradation” (LTD), defined as the spontaneous transformation of the metastable tetragonal zirconia state into the more stable monoclinic form. This transformation happens in relatively low temperatures (65–300 °C) in a humid environment [13,14,15]. It can happen when zirconia is exposed to various oral conditions, such as exposure to an aqueous environment, temperature changes, acidification of food, and cyclic loading during chewing cycles [16]. This transformation can be beneficial to the zirconia structure as it increases the compressive layer on the surface, which would improve its mechanical properties. However, further aging would negatively affect the zirconia properties [17] as it induces the propagation of macro and micro-cracks, grain pull-out, and surface roughening [6,15]. Thus, to reduce the detrimental consequences of the LTD process, adding alumina in a small amount (0.15–0.5 wt.%) can reduce the rate of the tetragonal-monoclinic phase transformation and LTD accordingly, but does not prevent it. Reducing the alumina content to <0.15 wt.% can help enhance translucency but may increase the ability of the material to develop LTD [14].

Translucency has been considered one of the important optical characteristics for achieving an acceptable shade match to the natural tooth color [18]. It occurs when light partially scatters or reflects while passing through an object. The greater the amount of light that passes through the object, the higher the translucency of the material [19]. The translucency of a natural tooth is evident when a detectable amount of light passes through its incisal and/or proximal regions due to the presence of a high proportion of enamel compared to the underlying dentin. One of the most general methods of quantitatively measuring the translucency of dental materials is the translucency parameter (TP). TP measures the difference between the amount of light reflected through the sample over a high reflectance backing (white background) and that of a high absorbent backing (black background). TP values were measured using CIE L* a* b* color coordinates obtained from a dental spectrophotometer. A spectrophotometer has been used in several studies to measure the translucency of different ceramic systems [20,21,22]. Various factors influence the translucency of dental ceramics. Some factors relate to the ceramic system itself, such as thickness, shade, surface texture, porosity, and number of crystals. Other factors relate to the measurement procedure, such as illumination and edge-loss; a phenomenon when the light cannot be detected by the sensor of a color measurement device [19,23,24,25,26].

Opalescence is an optical property that takes its name because it was first seen in opal stones [27]. It is a property of translucent materials to appear red-yellow in transmitted light, and blue in reflected light [28]. In natural teeth, it essentially happens in enamel because of hydroxyapatite crystals acting as prisms, so that when illuminated, the enamel will allow the transmittance of longer wavelengths (red, yellow) and scatter shorter wavelengths (blue) [29,30].

Dental esthetic restorations should have optical properties comparable to natural teeth in terms of opalescence [31,32]. In dental ceramic materials, opalescence has been able to solve esthetic dilemmas related to value and translucency, making it possible to produce unnoticeable restorations [33]. The parameter for measuring the opalescence of dental materials is the opalescence parameter (OP), which is calculated as the difference in the yellow-blue and red-green color coordinates between the reflected and transmitted colors [34].

As excellent tooth color matching is the ultimate optical goal of any dental restoration, clinical color changes may be assessed and rated according to the color difference (ΔE) before and after aging of the restorative esthetic material [23,28]. When the ΔE value is 0–1, the color difference is described as ‘‘normally invisible difference; 1–2 is ‘‘a very small difference, only obvious to a trained eye’’; 2–3.5 is ‘‘medium difference, obvious to an untrained eye’’; and 3.5–5 is ‘‘an obvious difference’’ and >6 is “a very obvious difference’’ [20,35].

As the number of esthetic ceramic systems used for monolithic restorations is increasing, the need for investigating the full ranges of their properties is of paramount importance. However, not all marketed materials have been backed up by independent scientific published articles, nor have many of the published articles used the ISO standards for sample production. Thus, this study aimed to evaluate and compare the optical properties of five introduced CAD-CAM esthetic ceramic systems used for monolithic restorations.

The null hypothesis to be tested is that there is no difference in the optical properties (translucency and opalescence) among zirconia ceramics, hybrid ceramic, and lithium disilicate ceramic under ISO standards. Artificial aging does not affect the optical properties of the tested ceramic materials.

2. Materials and Methods

Three CAD-CAM monolithic multilayer zirconia ceramics, one CAD-CAM monolithic multilayer hybrid ceramic, and one CAD-CAM monolithic lithium disilicate ceramic (control), all pre-shaded (A2) and introduced in the market as esthetic ceramic materials, were investigated in this study. The tested ceramic materials in this study are summarized in Table 1.

Table 1.

Ceramic materials used in this study.

Power analysis using G*Power statistical software (G*Power Ver. 3.0.10, Franz Faul, Universität Kiel, Germany) was performed to determine the sample size. Samples per group were set considering: Power: 0.8, α: 0.05, and effect size: 0.5; a sample size of 20 was set for testing the optical properties in each group [36].

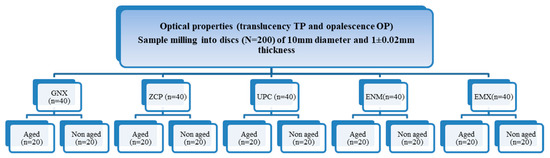

A total of 200 samples, comprising 5 groups, were produced. Each group represented one of the 5 tested materials and comprised of 40 samples (n = 40) divided as follows: 20 samples were subjected to hydrothermal aging and 20 samples remained unaged Figure 1.

Figure 1.

Flowchart of workflow for testing the samples.

The GNX (n = 40), ZCP (n = 40), and UPC (n = 40) samples with the required dimensions for each test were milled without water from partially sintered zirconia blanks by using a CAM-machine (Ceramill® motion 2; Amann Girrbach, Germany). Cutting dimensions of the samples were determined, taking into account that a 20–25% shrinkage occurs during dense sintering for monolithic zirconia type [6]. The ENM (n = 40) and EMX (n = 40) samples were cut out from respective blocks using water-cooled milling CAM machine (Ceramill® motion 2; Amann Girrbach, Germany). Cutting dimensions of the samples were determined taking into account that a 0.2–0.3% shrinkage is encountered during the crystallization process of EMX [37]. No need for sintering of ENM hybrid ceramic as recommended by the manufacturer’s instructions. The final dimensions of the sample discs were checked using a digital caliper (Guanglu, Gullin, China) to achieve a disc of 10 mm in diameter and 1 ± 0.02 mm in thickness.

The samples were consecutively polished with 600, 800, and 1000 grit silicon carbide (SiC) papers without water in a grinding device (echo LAB POLI-1X/250, Devco S.r.l, Paderno Dugnano, Milan, Italy) for zirconia samples, and with water for lithium disilicate and hybrid ceramic samples as recommended by the manufacturers. Each polishing step was carried out for 60 s at 300 rpm by one single operator [38].

After that, the zirconia samples GNX, UPC, and ZCP were fully crystallized in the sintering furnace (Ceramill Therm, Amann Girrbach, Germany), lithium disilicate EMX samples were crystallized in the furnace (Programat EP5010, Ivoclar-Vivadent, Schaan, Liechtenstein) according to the manufacturer’s guidelines. ENM did not require sintering after milling as it is composed of fully sintered material, Table 2.

Table 2.

Sintering/crystallization parameters used for tested materials. * ENM: It is composed of fully-sintered material, which does not require a ceramic furnace after milling.

Samples were also polished after the final sintering with polishing paste at 5000 rpm (5100000, all-in-one, Renfert GmbH, Germany). The dimensions of all samples were checked individually with a digital caliper which has a 0.02 mm accuracy (Guanglu, Gullin, China).

2.1. Aging Procedure

Half of each group (n = 20 × 5 = 100) was subjected to a hydrothermal cycle of 5 h (15–20 years of aging) in a steam autoclave (Euronda B type, Italy) at 134 °C and 2 bars (200 KPa). This protocol had been chosen because one-hour autoclave accelerated aging with 134 °C, 2 bar (200 KPa) corresponds to 3–4 years of clinical use and promotes an extensive tetragonal-monoclinic phase transformation (approximately 55–80% monoclinic phase content) [39]. Samples were placed in sterilization sealing packs and separated from each other using separators.

2.2. Translucency Parameter Measurement

One trained operator performed all the measurements under the same standardized testing conditions using the same device. The A2 shade was used as the standard shade for all the samples.

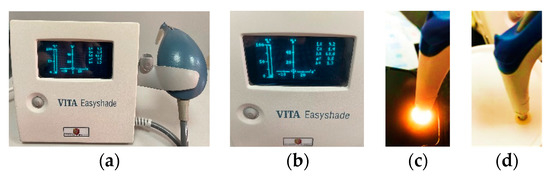

After sintering and polishing, the samples were cleaned in an ultrasonic bath of isopropyl alcohol for 5 min before proceeding with the measurements. A spectrophotometer Vita® Easyshade (VITA Easyshade, VITA Zahnfabrik, Bad Säckingen, Germany) with a calibration plate was used to record the CIELAB coordinates (L*, a* and b*) of the ceramic discs, at a wavelength of 555 nm to compare the samples; since the human eye is sensitive to wavelengths ranging between 380 and 780 nm with being most sensitive to 555 nm. This wavelength was selected based on the definition of the International Commission on Illumination (CIE S 017) and the Japanese Industrial Standard (JIS Z 8113). A thin layer of petroleum jelly was put between the sample and the background for better optical contact. The optical handpiece was held at a 90° angle to the discs. The measuring process was carried out in a research lab room with no incandescent lights. A probe tip was inserted into the calibration port aperture of the device after each measurement to enable calibration of the device for each sample as recommended by the manufacturer.

The translucency parameter (TP) was determined by calculating the color difference between the same sample against black and white backgrounds (Figure 2), according to the following equation [40]:

where ΔL* refers to the difference in lightness between black and white backgrounds, Δa* refers to the difference in red-green between black and white backgrounds, Δb* refers to the difference in yellow-blue between black and white backgrounds. TP values can range from 0 (for a totally opaque material) to 100 (for a totally transparent material).

TP = [(ΔL*)2 + (Δa*)2 + (Δb*)2]1/2

Figure 2.

The Vita Easyshade device used to measure the L*, a*, and b* color coordinates for each sample in the non-aged and aged groups (a,b). Samples tested with black and white backgrounds (c,d).

2.3. Opalescence Parameter Measurement

The opalescence parameter was calculated from the values a* and b* coordinates that were recorded using the dental spectrophotometer (VITA Easyshade, VITA Zahnfabrik, Bad Säckingen, from Germany) from the ceramic samples placed on black (B) and white (W) backgrounds (Figure 2), according to the following equation [41]:

Δa* refers to the difference in red-green between black and white backgrounds, Δb* refers to the difference in yellow-blue between black and white backgrounds.

OP = [(Δa*)2 + (Δb*)2]1/2

2.4. Shade Evaluation

The color difference (ΔE) is defined as the difference between two colors in an L*a*b* color space. Its value is evaluated by calculating the difference in color measurements of the non-aged and aged samples by using the following formula:

ΔE = [(ΔL*)2 + (Δa*)2 + (Δb*)2]1/2

ΔL* = L1 − L2

Δa* = a1 − a2

Δb* = b1 − b2

Terms L1, a1, and b1 were the color data measured for the non-aged groups, while L2, a2, and b2 were for the aged groups.

3. Results

Descriptive statistics (means and standard deviations) were computed for each property (translucency parameter and opalescence parameter) within each material. Measured data were analyzed statistically by using statistical software (SPSS Statistics v25.0; Chicago, IL, USA). Normalities of distributions were explored, and the groups were found to be distributed normally. Data were analyzed with one-way analysis of variance (ANOVA) with correction to adjust for multiple comparisons among groups. Statistical significance was set at p < 0.05. Outliers were deleted because they increased the variability in the data, which decreased statistical power.

3.1. Shade Stability

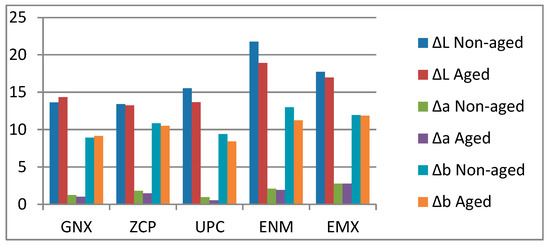

The CIE ΔL Δa Δb values on white and black backgrounds for non-aged and aged groups are shown in Table 3 and represented by a bar graph in Figure 3.

Table 3.

Descriptive CIE ΔL Δa Δb values on white and black background with and without aging. Shaded cells indicate significant differences p < 0.5.

Figure 3.

CIE ΔL Δa Δb values on white and black backgrounds for the non-aged and aged groups.

ΔL showed a statistically significant higher value for non-aged compared to aged UPC and ENM groups (p < 0.05), and showed a statistically insignificant higher value for non-aged compared to aged ZCP and EMX groups (p > 0.05), but showed a statistically insignificant lower value for non-aged compared to aged GNX group (p > 0.05). Δa showed a statistically significant higher value for non-aged compared to aged GNX and ZCP groups (p < 0.05), and showed a statistically insignificant higher value for non-aged compared to aged UPC and ENM groups (p > 0.05), but showed a statistically insignificant lower value for non-aged compared to aged EMX group (p > 0.05). Δb showed a statistically significant higher value for non-aged compared to aged UPC and ENM groups (p < 0.05), and showed a statistically insignificant higher value for non-aged compared to aged ZCP and EMX groups (p > 0.05), but showed a statistically insignificant lower value for non-aged compared to aged GNX group (p > 0.05).

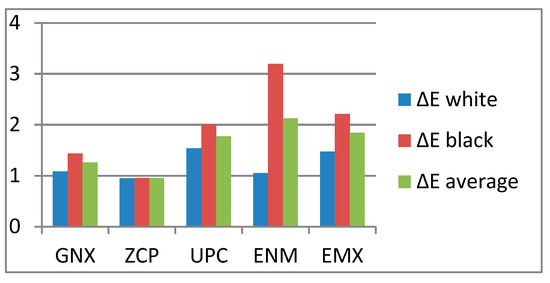

The shade difference ΔE mean values for the non-aged and aged groups on white, black, and white/black backgrounds are shown in Table 4 and represented by a bar graph in Figure 4. ENM had the highest shade difference of 2.12, whereas ZCP had the lowest of 0.95; with a range of only 1.17.

Table 4.

Descriptive ΔE values of the non-aged and aged groups on white and/or black backgrounds.

Figure 4.

Descriptive ΔE values for the non-aged and aged groups on white and black backgrounds.

3.2. TP Evaluation

- TP for the non-aged groups:

The mean and standard deviation values of the TP for the non-aged groups are summarized in Table 5. The general ranking of the mean TP values for the non-aged tested materials is 23.8405, 21.5661, 18.2139, 17.3539, and 16.3669 for ENM > EMX > UPC > ZCP > GNX groups respectively.

Table 5.

Descriptive TP values for the non-aged groups. * Outliers were deleted.

Multiple comparisons among the TP values for the tested non-aged groups are shown in Table 6. All comparisons were statistically significant except for GNX compared to ZCP and ZCP compared to UPC.

Table 6.

Multiple comparisons between TP values for the non-aged groups. Shaded cells indicate significant differences p < 0.5.

- TP for the aged groups:

The mean and standard deviation values of the TP for the aged groups are summarized in Table 7. The general ranking of the mean TP values for the aged tested materials is 22.0976, 20.8905, 16.9788, 16.3750, and 16.1179 for ENM > EMX > ZCP > GNX > UPC groups respectively.

Table 7.

Descriptive TP values for the aged groups. * Outliers were deleted.

Multiple comparisons among the TP values for the tested aged groups are shown in Table 8. All comparisons were statistically significant except for GNX compared to ZCP and UPC.

Table 8.

Multiple comparisons between TP values for the aged groups. Shaded cells indicate significant differences p < 0.5.

- -

- Comparison of TP values within same material group; non-aged and aged

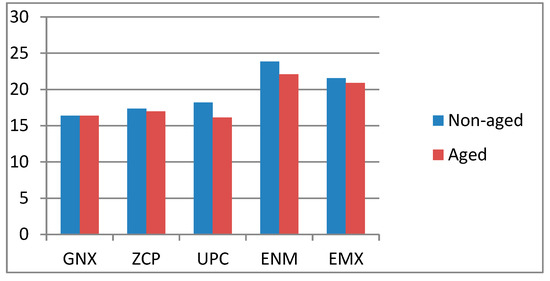

A comparison between non-aged and aged TP mean values within each group is shown in Table 9 and represented as a bar graph in Figure 5. The only statistically significant comparison was for ENM and UPC groups.

Table 9.

Comparison of TP values within same material group; non-aged and aged. Shaded cells indicate significant differences p < 0.5. * Outliers were deleted.

Figure 5.

TP values of materials within same material group; non-aged and aged.

3.3. OP Evaluation

- OP for the non-aged groups:

The mean and standard deviation values of the OP for the non-aged groups are summarized in Table 10. The general ranking of the mean OP values for the non-aged tested materials is 12.3994, 12.3362, 11.0044, 9.4533, 9.0072 for ENM > EMX > ZCP > UPC > GNX respectively.

Table 10.

Descriptive OP values for the non-aged groups. * Outliers were deleted.

Multiple comparisons among the OP values for the tested non-aged groups are shown in Table 11. All comparisons were statistically significant except for GNX compared to UPC and ENM compared to EMX.

Table 11.

Multiple comparisons between OP values for the non-aged groups. Shaded cells indicate significant differences p < 0.5.

- OP for the aged groups:

The mean and standard deviation values of the OP for the aged groups are summarized in Table 12. The general ranking of the mean OP values for the aged tested materials is 12.1734, 11.4080, 10.6088, 8.9048, 8.5016 for EMX > ENM > ZCP > GNX > UPC groups respectively.

Table 12.

Descriptive OP values for the aged groups. * Outliers were deleted.

Multiple comparisons among the OP values for the tested aged groups are shown in Table 13. All comparisons were statistically significant except for GNX compared to UPC.

Table 13.

Multiple comparisons between OP values for the aged groups. Shaded cells indicate significant differences p < 0.5.

- -

- Comparison of OP values within same material group; non-aged and aged

A comparison between non-aged and aged OP mean values within each group is shown in Table 14 and represented as a bar graph in Figure 6. The only statistically significant comparison was for ENM and UPC groups, similar to that in TP comparison.

Table 14.

Comparison of OP values within same material group; non-aged and aged. Shaded cells indicate significant differences p < 0.5. * Outliers were deleted.

Figure 6.

OP values of materials within same material group; non-aged and aged.

4. Discussion

In vitro studies in any area of dentistry represent an attempt to simulate clinical conditions; but no matter how well an experiment is designed, it cannot reproduce all the relevant clinical features. It does, however, allow examination of factors which influence clinical performance but cannot be tested in vivo for ethical or practical reasons [42]. The in vitro study may also be expected to highlight variables in clinical techniques which are of significance, and the findings of such studies are therefore of direct clinical application [42].

Over the past 10 years, new dental restorative materials have been introduced as a result of growing demand for restorations with improved esthetic and mechanical properties which are capable of serving as an alternative to metal and metal-ceramic restorations. However, strengths and weaknesses of these newly introduced materials have to be assessed and tested to guide the clinicians in minimizing the risks of failures of such systems.

In consistence with previous studies [43,44,45], samples of all groups have been designed and milled using computerized technology (Ceramill CAD-CAM System, Amann Girrbach) following the recommendations by ISO:6872-2015. The samples represented three main groups of ceramic systems used for esthetic/translucent monolithic restorations: three yttria-stabilized tetragonal zirconia polycrystals with different yttria and alumina contents to control the LTD and optical properties, polymer-infiltrated hybrid ceramic with a 75% by volume ceramic network predominantly composed of silica and alumina to control the optical and mechanical properties, and lithium disilicate glass-ceramic predominantly composed of silica (control group), Table 1.

The human eye has cones for three colors: red, green, and blue. This receptiveness helped define color spaces. By varying the amount of red, green, and blue light, we can realize our eyes’ sensitivity to light stimulus for the three receptors. When plotted, a sphere helps us visualize all colors. Three dimensions create the spectrum: black and white in the z-axis, red and green in the y-axis, and blue and yellow in the x-axis. The three dimensions are generally assigned (L) for lightness (+ = lighter, − = darker), (a) for red/green (+ = redder, − = greener) and (b) for blue/yellow (+ = yellower, − = bluer) [46].

VITA® Easyshade is a spot measurement device which is susceptible to variation under different measurement conditions and measures a small area on the tooth determined by the diameter of the optical device aperture. In the present study, the center of each disc was measured three times and the average was recorded. Spectrophotometers present an accurate aid in dental shade measurement; it has been reported that it is five times more likely to correctly match shades using Vita® Easyshade spectrophotometer than the visual method [47].

The combination of thermal and mechanical cycling has been proposed to best simulate the oral environment [48]. In the present study, the samples were subjected to a hydrothermal aging of 134 °C, 2 bar (200 KPa) for 5 h. This protocol had been chosen because one-hour autoclave aging with 134 °C, 2 bar (200 KPa) corresponds to 3–4 years of clinical use and promotes an extensive tetragonal-monoclinic phase transformation (approximately 55–80% monoclinic phase content) [39]. Despite the criticism that this test does not correspond to actual clinical conditions and that it may underestimate the actual degradation of zirconia ceramics in the oral environment, it remains an efficient method to estimate the long-term performance of these materials [49].

4.1. Shade Stability

After groups being subjected to artificial hydrothermal aging, the (L) value reduced for all groups except GNX suggesting that all groups tended to become darker except GNX became lighter. The (a) value decreased in all groups except EMX suggesting that all groups tended to become greenish except EMX became reddish. The (b) value only increased in the GNX group suggesting a yellower material, other materials tended to be bluer, Table 3, Figure 3.

Bagis and Turgut [50] found that, after aging, (L) and (a) coordinates decreased, while only (b) coordinate increased. Hamza et al. [51] found only a reduction in the (a) value. The difference may be attributed to the difference in the material used and the aging protocol applied.

The clinical acceptability level was determined to be 3.7 ΔE units, as determined by many studies [52,53]. All groups in this study showed clinically acceptable color stability after accelerated aging as all groups showed a color change of less than 3.7, Table 4 and Figure 4. Similar results were found in previous studies [50,54].

The largest amount of color change was observed in the ENM group, with a mean of 2.13 ΔE units showing a medium difference that is obvious to an untrained eye. This change might be attributed to the presence of methacrylate polymer network. The lowest value of color change was observed in the ZCP group, with a mean of 0.95 ΔE units showing a normally invisible difference. GNX, UPC, and EMX had 1.26, 1.77, and 1.84 respectively, showing a very small difference, only obvious to a trained eye, Table 4, Figure 4.

4.2. Translucency Parameter (TP)

Translucency is the ability of the colored object to allow the appearance of an underlying background to show through [55]. It is an essential optical property that must be considered when choosing restoration in the esthetic zone. Optimal translucency is required to achieve lifelike restorations [56]. Previous studies have reported the mean TP for a 1 mm section of natural human tooth enamel and dentin to be 18.7 and 16.4, respectively [57].

However, in situations where restorations are required to mask discolored teeth or metal posts and cores, materials with lower translucency and higher masking ability are required [22]. Therefore, good knowledge about the translucency of the newly introduced monolithic CAD-CAM materials is essential to choose the most appropriate material for a specific case. It was documented in the literature [58] that translucency of the dental ceramics is affected by chemical composition, crystalline structure, grain size, additives, and pores.

In the present study, statistically different values were obtained for the non-aged ceramic materials regarding TP values, Table 5. GNX group had the lowest TP value compared to the other groups while ENM had the highest. All comparisons were significant except between GNX compared to ZCP and ZCP compared to UPC, Table 6. Statistically different values were obtained for the aged ceramic materials regarding TP values, Table 7. All comparisons were significant except between GNX compared to ZCP and UPC, Table 8. ENM had the highest TP among the non-aged and aged groups, whereas GNX had the lowest TP among the non-aged groups and UPC had the lowest TP among the aged groups. The variance was suggested to be related to variations in the elements and microstructure of these materials.

Grain size has a major influence on the material’s TP value. Large crystals are present in the high translucency materials, whereas the low translucency materials contain a large number of smaller crystals [59]. This explains the higher TP value of the large lithium crystals containing materials compared to the four to eight times smaller zirconia crystals [60]. It also shows that, in general, E-max and Enamic have greater translucency than zirconia materials which is consistent with previous studies [61,62]. Niu et al. [63] stated that the higher strength ceramic system tends to be more opaque because of the required increased crystalline content.

ENM group showed a statistically significant higher TP value compared to EMX group (p < 0.05). This result is not in agreement with Alfouzan et al. [64] who showed that E-max is considered to have a statistically significant higher translucency than Enamic. Shirani et al. [65] showed an agreement; as E-max had lower translucency than Enamic. These contradictory findings might be attributed to the fact that silica contents for both ENM and EMX are almost comparable with a higher range for EMX, while the alumina content is much higher for ENM compared to EMX, Table 1; hence, the resemblances and differences in the compositions and microstructures of these two ceramic materials might explain their close resultant optical properties. After aging, UPC group showed decrease in TP values, to be the lowest TP between all groups.

When comparing TP values within the same material, non-aged vs. aged; GNX interestingly showed a statistically insignificant lower TP for the non-aged group compared to the aged one. Kim and Kim [66] reported a significant increase in TP for monolithic zirconia after being subjected to autoclave hydrothermal aging (134 °C and 2 bars pressure) for 0, 1, 3, and 5 h. But in this study, the increase of TP was insignificant. Certain metal oxides, such as coloring pigments promote the formation of cubic zirconia which reduces light scattering from the grain boundaries of cubic zirconia, resulting in higher TP values with rising aging time [66]. ZCP and EMX groups showed a statistically insignificant lower TP values after aging, whereas UPC and ENM groups showed a statistically significant lower TP values after aging, Table 9 and Figure 5.

The different structuring of the ceramic groups may have influenced the amount of change in color caused by artificial accelerated aging. Grain pull-out is reported as a sequel of the proposed aging process, which results in adverse effects on the optical properties and surface finish of these restorations. This surface roughness may adversely influence their optical properties [15]. Another possible factor for the slight color change observed after aging in these groups may be due to the metal oxide content break down of the colorants added to the ceramic itself [67].

On the other hand, aging might result in the IPS e.max surface silica network dissolution, resulting in a reduction of surface crystallinity and consequently a rougher surface. Furthermore, the presence of other than lithium disilicate phases, such as lithium trisilicate, might have induced additional grain boundaries, facilitating water diffusion and rendering the material prone to dissolution [68]. In a previous study [69], one mm thickness IPS e.max CAD TP value of 23.14 before aging decreased to 19.9 after aging, which agreed with this research as EMX decreased from 21.57 to 20.89, but not statistically significant.

Fathy et al. [70] and Alghazzawi [71] stated that translucency of colored samples decreased significantly after accelerated aging. On the other hand, Kurt et al. [72] reported that, the TP values decreased in the zirconia group after aging, but this decrease was not statistically significant. Abdelbary et al. [73] stated that 0.5 mm-thick samples exhibited statistically significant decrease in the TP value, whereas the TP values of 0.8 mm, 1 mm and 1.2 mm-thick samples exhibited statistically insignificant change.

Furthermore, it is difficult to compare the TP values obtained in the present study with other literature because of variation in color [74], thickness [63], protocol of aging [75], zirconia composition (type and amount of stabilizing oxide), presence of cubic phase [76], amount of pores [77], grain size [8], sintering conditions [77], CIE L*a*b* of black and white backgrounds [55], and color measuring device [78].

4.3. Opalescence Parameter (OP)

It is a property of translucent materials to appear red-yellow in transmitted light, and blue in reflected light [28]. An optimal dental restoration should have opalescence equal to that of the adjacent teeth [79]. The mean OP value for human enamel reported by Lee et al. [80] was 22.9 ± 1.9 at a thickness range of 0.9–1.3 mm. The particle size and opalescence are enhanced by increasing the time and temperature of zirconia sintering, which can improve translucency as well. However, glazing the zirconia reduces opalescence without changing the translucency. In spite of the improved opalescence of recently introduced monolithic ceramics, maintaining high translucency is needed [79].

In the present study, statistically different values were obtained for the non-aged ceramic materials regarding OP values, Table 10. GNX group had the lowest OP value compared to the other groups while ENM had the highest. All comparisons were significant except between GNX compared to UPC and ENM compared to EMX, Table 11. Statistically different values were obtained for the aged ceramic materials regarding OP values, Table 12. All comparisons were significant except between GNX compared to UPC, Table 13. ENM had the highest OP among the non-aged groups and EMX had the highest OP among the aged groups; this might be attributed to the fact that both of them have predominantly glass-ceramic content (SiO2) besides that ENM has high alumina (AlO2) and methacrylate polymer contents. GNX had the lowest OP among the non-aged groups and UPC had the lowest OP among the aged groups. The variance among all groups was suggested to be related to variations in the elements and microstructure of these materials. The OP values of the measured products in this research were less than that of human enamel opalescence. Bona et al. [41] compared the OP values of various CAD-CAM materials of different shades at a thickness of 1 mm and stated that IPS e.max CAD LT of shade A2 was (6.58 ± 0.51); less than that observed in the analysis of materials in this study (8.5016–12.3994). In contrast, Shiraishi et al. [81] reported OP values to range from 5.27–12.11 for 1 mm thick porcelain with most values in the range comparable to those found in the current study. This variation was attributed to the variance in the tested ceramic system, shade, and thickness used. The higher the chromatic shade, the higher the oxides such as ZrO2, Y2O3, SnO2, and V2O5, which influences OP values.

When comparing OP values within the same material, non-aged vs. aged; GNX, ZCP, and EMX groups showed a statistically insignificant higher OP for the non-aged groups compared to the aged ones. UPC and ENM groups showed a statistically significant higher OP for the non-aged groups compared to the aged ones, Table 14 and Figure 6. Abbasimoghaddam et al. [82] showed an agreement with decreasing of OP values of 1.2 mm translucent zirconia after aging in autoclave for 10 h from 14.8643 to 13.2740.

Looking more into the differences and effects of chemical composition on the optical properties of materials is needed. The improvements in the translucency and opalescence of recent zirconia were performed by changing the yttria content, the amount of chemical impurities, and using various grain sizes, but further research is essential. By decreasing the alumina and increasing the yttria content, the latest monolithic zirconia brands manufacturers enhanced the translucency of 3Y-TZP [83]. The yttria content of the GNX (4Y-TZP) is up to 6–7%, and that of UPC (4Y-TZP and 5Y-TZP) is up to 5.8–9.7%, while the yttria content of the ZCP (3Y-TZP and 5Y-TZP) is up to 4.5–7%, being less than the others. Using a higher yttria content led to a greater content of the cubic phase (approximately 50%) of zirconia, which enhances the translucency property but reduces the mechanical properties [8]. The alumina contents of the tested materials were different, GNX and UPC contained a lower amount of alumina (<0.5%) compared with ZCP (<1%) monolithic zirconia, while ENM had (20–23% alumina) and EMX had (0–5% alumina), Table 1.

The sintering/crystallization temperature also affects translucency and opalescence. Various manufacturers’ recommendations were followed for each material; i.e., heating rate, holding time, and cooling. The higher sintering temperatures, in the range of 1510–1550 °C, close residual pores at the grain boundaries level, thus increasing the density of the material, and decreasing the refractive index and light scattering [84]. Temperatures used by this study were: (1450 °C for GNX, 1530 °C for UPC, 1500 °C for ZCP, 850 °C for EMX); no sintering after milling was required for ENM, Table 2.

Based on the results of the present study, the null hypothesis, that stated “no difference in the optical properties between monolithic ceramic restorations”, was rejected as there were statistically significant differences between most of the groups. The second component of the null hypothesis, that stated “artificial aging has no effect on the color stability” was partially rejected as UPC and ENM groups showed a statistically significant higher TP and OP before aging.

4.4. Limitations

This study was limited by the in vitro evaluation for a design of flat samples with only A2- shade. Also, the effects of the luting cement and dental tissues on the resulting shade were not considered. Furthermore, in the clinical scenario, only the outer surface of the restoration is exposed to the oral environment rather than all surfaces. Lack of surface roughness assessment before and after accelerated aging was another limitation of this study as it is assumed that the change in surface roughness can affect the color changes of the samples [85]. Different aging methods that simulate more closely the oral environment might be used for such a study, such as the use of cyclic loading machine that applies different directions of forces and the use of artificial saliva media.

5. Conclusions

Based on the results obtained and within the limitations of this study, the following conclusions can be derived:

- At baselines, the lithium disilicate ceramic (EMX) showed higher optical properties (translucency and opalescence) than the monolithic zirconia groups (GNX, ZCP, and UPC), while the hybrid ceramic (ENM) showed the highest optical properties among all groups.

- All groups showed to some extent a change in the optical properties (translucency and opalescence) after aging, but that was within the clinical acceptability range.

Author Contributions

Conceptualization, S.N.A. and L.A.A.-N.; Formal analysis, B.A.; Funding acquisition, B.A.; Investigation, S.N.A., B.A. and L.A.A.-N.; Methodology, S.N.A. and L.A.A.-N.; Project administration, S.N.A. and L.A.A.-N.; Supervision, S.N.A. and L.A.A.-N.; Writing—original draft, S.N.A., B.A. and L.A.A.-N.; Writing—review & editing, S.N.A. and B.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Faculty of Scientific Research (grant number 20210249-7984) at Jordan University of Science and Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Beuer, F.; Schweiger, J.; Eichberger, M.; Kappert, H.F.; Gernet, W.; Edelhoff, D. High-Strength CAD/CAM-Fabricated Veneering Material Sintered to Zirconia Copings—A New Fabrication Mode for All-Ceramic Restorations. Dent. Mater. 2009, 25, 121–128. [Google Scholar] [CrossRef]

- Drummond, J.; King, T.; Bapna, M.; Koperski, R. Mechanical Property Evaluation of Pressable Restorative Ceramics. Dent. Mater. 2000, 16, 226–233. [Google Scholar] [CrossRef]

- Yip, K.H.-K.; Smales, R.J.; Kaidonis, J.A. Differential Wear of Teeth and Restorative Materials: Clinical Implications. Int. J. Prosthodont. 2004, 17, 350–356. [Google Scholar]

- Rosentritt, M.; Sikora, M.; Behr, M.; Handel, G. In Vitro Fracture Resistance and Marginal Adaptation of Metallic and Tooth-Coloured Post Systems. J. Oral Rehabil. 2004, 31, 675–681. [Google Scholar] [CrossRef]

- Kisi, E.H.; Howard, C. Crystal Structures of Zirconia Phases and Their Inter-Relation. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 1998; Volume 153, pp. 1–36. [Google Scholar]

- Denry, I.; Kelly, J.R. State of The Art of Zirconia for Dental Applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef] [PubMed]

- Ruff, O. Ceramics of Highly Refractory Materials: I. Z. Anorg. Allg. Chem. 1929, 180, 19–41. [Google Scholar] [CrossRef]

- Zhang, Y. Making Yttria-Stabilized Tetragonal Zirconia Translucent. Dent. Mater. 2014, 30, 1195–1203. [Google Scholar] [CrossRef]

- Lambert, H.; Durand, J.-C.; Jacquot, B.; Fages, M. Dental Biomaterials for Chairside CAD/CAM: State of The Art. J. Adv. Prosthodont. 2017, 9, 486–495. [Google Scholar] [CrossRef] [PubMed]

- Mainjot, A.; Dupont, N.; Oudkerk, J.; Dewael, T.; Sadoun, M. From Artisanal to CAD-CAM Blocks: State of The Art of Indirect Composites. J. Dent. Res. 2016, 95, 487–495. [Google Scholar] [CrossRef] [PubMed]

- Wiegand, A.; Stucki, L.; Hoffmann, R.; Attin, T.; Stawarczyk, B. Repairability of CAD/CAM High-Density PMMA and Composite-Based Polymers. Clin. Oral Investig. 2015, 19, 2007–2013. [Google Scholar] [CrossRef] [PubMed]

- Ruse, N.; Sadoun, M. Resin-Composite Blocks for Dental CAD/CAM Applications. J. Dent. Res. 2014, 93, 1232–1234. [Google Scholar] [CrossRef] [PubMed]

- Sato, T.; Ohtaki, S.; Endo, T.; Shimada, M. Transformation of Yttria-Doped Tetragonal ZrO2 Polycrystals by Annealing under Controlled Humidity Conditions. J. Am. Ceram. Soc. 1985, 68, 320–322. [Google Scholar] [CrossRef]

- Lawson, S. Environmental Degradation of Zirconia Ceramics. J. Eur. Ceram. Soc. 1995, 15, 485–502. [Google Scholar] [CrossRef]

- Cattani-Lorente, M.; Scherrer, S.S.; Ammann, P.; Jobin, M.; Wiskott, H.A. Low Temperature Degradation of a Y-TZP Dental Ceramic. Acta Biomater. 2011, 7, 858–865. [Google Scholar] [CrossRef]

- Amat, N.F.; Muchtar, A.; Amril, M.S.; Ghazali, M.J.; Yahaya, N. Effect of Sintering Temperature on the Aging Resistance and Mechanical Properties of Monolithic Zirconia. J. Mater. Res. Technol. 2019, 8, 1092–1101. [Google Scholar] [CrossRef]

- Watanabe, W.; Iiu, S.; Fukuura, I. Aging Behavior of Y-TZP. In Science and Technology of Zirconia II; American Ceramic Society, Inc.: Columbus, OH, USA, 1983; Volume 4, pp. 391–398. [Google Scholar]

- Kelly, J.R.; Nishimura, I.; Campbell, S.D. Ceramics in Dentistry: Historical Roots and Current Perspectives. J. Prosthet. Dent. 1996, 75, 18–32. [Google Scholar] [CrossRef]

- Brodbelt, R.; O’brien, W.; Fan, P. Translucency of Dental Porcelains. J. Dent. Res. 1980, 59, 70–75. [Google Scholar] [CrossRef]

- Chaiyabutr, Y.; Kois, J.C.; LeBeau, D.; Nunokawa, G. Effect of Abutment Tooth Color, Cement Color, and Ceramic Thickness on the Resulting Optical Color of a CAD/CAM Glass-Ceramic Lithium Disilicate-Reinforced Crown. J. Prosthet. Dent. 2011, 105, 83–90. [Google Scholar] [CrossRef]

- Wang, F.; Takahashi, H.; Iwasaki, N. Translucency of Dental Ceramics with Different Thicknesses. J. Prosthet. Dent. 2013, 110, 14–20. [Google Scholar] [CrossRef]

- Ilie, N.; Hickel, R. Correlation between Ceramics Translucency and Polymerization Efficiency Through Ceramics. Dent. Mater. 2008, 24, 908–914. [Google Scholar] [CrossRef]

- Heffernan, M.J.; Aquilino, S.A.; Diaz-Arnold, A.M.; Haselton, D.R.; Stanford, C.M.; Vargas, M.A. Relative Translucency of Six All-Ceramic Systems. Part I: Core Materials. J. Prosthet. Dent. 2002, 88, 4–9. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.; Ahn, J.-S.; Lee, Y.-K. Measurement of Translucency of Tooth Enamel and Dentin. Acta Odontol. Scand. 2009, 67, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, O.; Uludag, B.; Usumez, A.; Sahin, V.; Celik, G. The Effect of Ceramic Thickness and Number of Firings on The Color of Two All-Ceramic Systems. J. Prosthet. Dent. 2008, 100, 99–106. [Google Scholar] [CrossRef]

- Chu, F.C.; Chow, T.W.; Chai, J. Contrast Ratios and Masking Ability of Three Types of Ceramic Veneers. J. Prosthet. Dent. 2007, 98, 359–364. [Google Scholar] [CrossRef]

- Primus, C.M.; Chu, C.C.; Shelby, J.E.; Buldrini, E.; Heckle, C.E. Opalescence of Dental Porcelain Enamels. Quintessence Int. 2002, 33, 439–449. [Google Scholar]

- Fondriest, J. Shade Matching in Restorative Dentistry: The Science and Strategies. Int. J. Periodontics Restor. Dent. 2003, 23, 467–480. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Lu, H.; Powers, J.M. Measurement of Opalescence of Resin Composites. Dent. Mater. 2005, 21, 1068–1074. [Google Scholar] [CrossRef]

- Cho, M.-S.; Yu, B.; Lee, Y.-K. Opalescence of All-Ceramic Core and Veneer Materials. Dent. Mater. 2009, 25, 695–702. [Google Scholar] [CrossRef]

- Vanini, L. Light and Color in Anterior Composite Restorations. Pract. Periodontics Aesthetic Dent. 1996, 8, 673–682. [Google Scholar]

- Monteiro, P.; Brito, P.; Pereira, J.; Alves, R. The Importance of the Optical Properties in Dental Silica-Based Ceramics. J. Calif. Dent. Assoc. 2012, 40, 476–481. [Google Scholar]

- Ward, M.; Tate, W.; Powers, J. Surface Roughness of Opalescent Porcelains after Polishing. Oper. Dent. 1995, 20, 106–110. [Google Scholar] [PubMed]

- Lee, Y.-K. Opalescence of Human Teeth and Dental Esthetic Restorative Materials. Dent. Mater. J. 2016, 35, 845–854. [Google Scholar] [CrossRef] [PubMed]

- Delta E, Delta H, Delta T: What Does It Mean? Available online: https://help.efi.com/fieryxf/KnowledgeBase/color/Delta%20E_H_T.pdf (accessed on 23 September 2022).

- Alshali, S.A.; Kazim, S.A.; Nageeb, R.; Almarshoud, H.S. Comparative Evaluation of the Translucency of Monolithic Zirconia. J. Contemp. Dent. Pract. 2020, 21, 51–55. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Oh, S.; Uhm, S.-H. Effect of The Crystallization Process on the Marginal and Internal Gaps of Lithium Disilicate CAD/CAM Crowns. BioMed Res. Int. 2016, 2016, 8635483. [Google Scholar] [CrossRef] [PubMed]

- Ziyad, T.A.; Abu-Naba’a, L.A.; Almohammed, S.N. Optical Properties of CAD-CAM Monolithic Systems Compared: Three Multi-Layered Zirconia and One Lithium Disilicate System. Heliyon 2021, 7, e08151. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L.; Deville, S. Low-Temperature Degradation of Zirconia and Implications for Biomedical Implants. Annu. Rev. Mater. Res. 2007, 37, 1–32. [Google Scholar] [CrossRef]

- Zhang, F.; Inokoshi, M.; Batuk, M.; Hadermann, J.; Naert, I.; Van Meerbeek, B.; Vleugels, J. Strength, Toughness and Aging Stability of Highly-Translucent Y-TZP Ceramics for Dental Restorations. Dent. Mater. 2016, 32, 327–337. [Google Scholar] [CrossRef]

- Della Bona, A.; Nogueira, A.D.; Pecho, O.E. Optical Properties of CAD–CAM Ceramic Systems. J. Dent. 2014, 42, 1202–1209. [Google Scholar] [CrossRef]

- Yoshinari, M.; Dérand, T. Fracture Strength of All-Ceramic Crowns. Int. J. Prosthodont. 1994, 7, 329–338. [Google Scholar]

- Dapieve, K.S.; Silvestri, T.; Rippe, M.P.; Pereira, G.K.R.; Valandro, L.F. Mechanical Performance of Y-TZP Monolithic Ceramic after Grinding and Aging: Survival Estimates and Fatigue Strength. J. Mech. Behav. Biomed. Mater. 2018, 87, 288–295. [Google Scholar] [CrossRef]

- Pereira, G.; Muller, C.; Wandscher, V.; Rippe, M.; Kleverlaan, C.; Valandro, L. Comparison of Different Low-Temperature Aging Protocols: Its Effects on The Mechanical Behavior of Y-TZP Ceramics. J. Mech. Behav. Biomed. Mater. 2016, 100, 324–330. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.; Silvestri, T.; Amaral, M.; Rippe, M.; Kleverlaan, C.; Valandro, L. Fatigue Limit of Polycrystalline Zirconium Oxide Ceramics: Effect of Grinding and Low-Temperature Aging. J. Mech. Behav. Biomed. Mater. 2016, 100, 45–54. [Google Scholar] [CrossRef] [PubMed]

- Thompson, D. How to Use Color Spaces to Talk about Color. First Source Worldwide, LLC. 2017. Available online: http://www.fsw.cc/color-spaces/ (accessed on 15 February 2020).

- Judeh, A.; Al-Wahadni, A. A Comparison between Conventional Visual and Spectrophotometric Methods for Shade Selection. Quintessence Int. 2009, 40, 69–79. [Google Scholar]

- Schmitter, M.; Mueller, D.; Rues, S. In Vitro Chipping Behaviour of All-Ceramic Crowns with a Zirconia Framework and Feldspathic Veneering: Comparison of CAD/CAM-Produced Veneer with Manually Layered Veneer. J. Oral Rehabil. 2013, 40, 519–525. [Google Scholar] [CrossRef] [PubMed]

- Chevalier, J.; Cales, B.; Drouin, J.M. Low-Temperature Aging of Y-TZP Ceramics. J. Am. Ceram. Soc. 1999, 82, 2150–2154. [Google Scholar] [CrossRef]

- Bagis, B.; Turgut, S. Optical Properties of Current Ceramics Systems for Laminate Veneers. J. Dent. 2013, 41, 24–30. [Google Scholar] [CrossRef]

- Hamza, T.A.; Al-Baili, M.A.; Abdel-Aziz, M.H. Effect of Artificially Accelerated Aging on Margin Fit and Color Stability of Laminate Veneers. Stomatol. Dis. Sci. 2018, 2, 1. [Google Scholar] [CrossRef][Green Version]

- Paravina, R.D.; Ontiveros, J.C.; Powers, J.M. Accelerated Aging Effects on Color and Translucency of Bleaching-Shade Composites. J. Esthet. Restor. Dent. 2004, 16, 117–126. [Google Scholar] [CrossRef]

- Johnston, W.; Kao, E. Assessment of Appearance Match by Visual Observatin and Clinical Colorimetry. J. Dent. Res. 1989, 68, 819–822. [Google Scholar] [CrossRef]

- Papageorgiou-Kyrana, A.; Kokoti, M.; Kontonasaki, E.; Koidis, P. Evaluation of Color Stability of Preshaded and Liquid-Shaded Monolithic Zirconia. J. Prosthet. Dent. 2018, 119, 467–472. [Google Scholar] [CrossRef]

- Johnston, W.M.; Ma, T.; Kienle, B.H. Translucency Parameter of Colorants for Maxillofacial Prostheses. Int. J. Prosthodont. 1995, 8, 79–86. [Google Scholar] [PubMed]

- Vichi, A.; Carrabba, M.; Paravina, R.; Ferrari, M. Translucency of Ceramic Materials for CEREC CAD/CAM System. J. Esthet. Restor. Dent. 2014, 26, 224–231. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-K. Translucency of Human Teeth and Dental Restorative Materials and Its Clinical Relevance. J. Biomed. Opt. 2015, 20, 45002. [Google Scholar] [CrossRef]

- Lee, Y.-K. Influence of Scattering/Absorption Characteristics on the Color of Resin Composites. Dent. Mater. 2007, 23, 124–131. [Google Scholar] [CrossRef] [PubMed]

- Awad, D.; Stawarczyk, B.; Liebermann, A.; Ilie, N. Translucency of Esthetic Dental Restorative CAD/CAM Materials and Composite Resins with Respect to Thickness and Surface Roughness. J. Prosthet. Dent. 2015, 113, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Sen, N.; Us, Y.O. Mechanical and Optical Properties of Monolithic CAD-CAM Restorative Materials. J. Prosthet. Dent. 2018, 119, 593–599. [Google Scholar] [CrossRef]

- Carrabba, M.; Keeling, A.J.; Aziz, A.; Vichi, A.; Fonzar, R.F.; Wood, D.; Ferrari, M. Translucent Zirconia in The Ceramic Scenario for Monolithic Restorations: A Flexural Strength and Translucency Comparison Test. J. Dent. 2017, 60, 70–76. [Google Scholar] [CrossRef]

- Barizon, K.T.L. Relative Translucency of Ceramic Systems for Porcelain Veneers. J. Dent. 2011, 39, 165–175. [Google Scholar]

- Niu, E.; Agustin, M.; Douglas, R.D. Color Match of Machinable Lithium Disilicate Ceramics: Effects of Cement Color and Thickness. J. Prosthet. Dent. 2014, 111, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Alfouzan, A.F.; Al-Otaibi, H.; Labban, N.; Al Taweel, S.M.; Al-Tuwaijri, S.; Al-Maha, S. Effects of Thickness and Background Color on The Translucency of CAD/CAM Ceramic Materials. Ceram.–Silikáty 2020, 64, 418–422. [Google Scholar] [CrossRef]

- Shirani, M.; Savabi, O.; Mosharraf, R.; Akhavankhaleghi, M.; Hebibkhodaei, M.; Isler, S. Comparison of Translucency and Opalescence among Different Dental Monolithic Ceramics. J. Prosthet. Dent. 2021, 126, 446.e1–446.e6. [Google Scholar] [CrossRef]

- Kim, H.-K.; Kim, S.-H. Effect of Hydrothermal Aging on the Optical Properties of Precolored Dental Monolithic Zirconia Ceramics. J. Prosthet. Dent. 2019, 121, 676–682. [Google Scholar] [CrossRef]

- Hamza, T.A.; Alameldin, A.A.; Elkouedi, A.Y.; Wee, A.G. Effect of Artificial Accelerated Aging on Surface Roughness and Color Stability of Different Ceramic Restorations. Stomatol. Dis. Sci. 2017, 1, 8–13. [Google Scholar] [CrossRef][Green Version]

- Haralur, S.B.; Alqahtani, R.S.; Alhassan Mujayri, F. Effect of Hydrothermal Aging and Beverages on Color Stability of Lithium Disilicate and Zirconia Based Ceramics. Medicina 2019, 55, 749. [Google Scholar] [CrossRef] [PubMed]

- Morsi, T.S.; Wahba, M.M. Effect of Hydrothermal Aging on Translucency of Different Types of Zirconia and Lithium Disilicate at Variable Thicknesses. Future Dent. J. 2021, 7, 69–74. [Google Scholar] [CrossRef]

- Fathy, S.M.; El-Fallal, A.A.; El-Negoly, S.A.; El Bedawy, A.B. Translucency of Monolithic and Core Zirconia after Hydrothermal Aging. Acta Biomater. Odontol. Scand. 2015, 1, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Alghazzawi, T.F. The Effect of Extended Aging on The Optical Properties of Different Zirconia Materials. J. Prosthodont. Res. 2017, 61, 305–314. [Google Scholar] [CrossRef] [PubMed]

- Kurt, M.; Bal, B.T. Effects of Accelerated Artificial Aging on The Translucency and Color Stability of Monolithic Ceramics with Different Surface Treatments. J. Prosthet. Dent. 2019, 121, 712.e1–712.e8. [Google Scholar] [CrossRef] [PubMed]

- Abdelbary, O.; Wahsh, M.; Sherif, A.; Salah, T. Effect of Accelerated Aging on Translucency of Monolithic Zirconia. Future Dent. J. 2016, 2, 65–69. [Google Scholar] [CrossRef]

- Barizon, K.T.; Bergeron, C.; Vargas, M.A.; Qian, F.; Cobb, D.S.; Gratton, D.G.; Geraldeli, S. Ceramic Materials for Porcelain Veneers: Part II. Effect of Material, Shade, and Thickness on Translucency. J. Prosthet. Dent. 2014, 112, 864–870. [Google Scholar] [CrossRef]

- Dikicier, S.; Ayyildiz, S.; Ozen, J.; Sipahi, C. Effect of Varying Core Thicknesses and Artificial Aging on the Color Difference of Different All-Ceramic Materials. Acta Odontol. Scand. 2014, 72, 623–629. [Google Scholar] [CrossRef] [PubMed]

- Inokoshi, M.; Zhang, F.; De Munck, J.; Minakuchi, S.; Naert, I.; Vleugels, J.; Van Meerbeek, B.; Vanmeensel, K. Influence of Sintering Conditions on Low-Temperature Degradation of Dental Zirconia. Dent. Mater. 2014, 30, 669–678. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Liao, Y.; Wan, Q.; Li, W. Effects of Sintering Temperature and Particle Size on the Translucency of Zirconium Dioxide Dental Ceramic. J. Mater. Sci. Mater. Med. 2011, 22, 2429–2435. [Google Scholar] [CrossRef]

- Kim, H.-K.; Kim, S.-H. Effect of The Number of Coloring Liquid Applications on the Optical Properties of Monolithic Zirconia. Dent. Mater. 2014, 30, e229–e237. [Google Scholar] [CrossRef] [PubMed]

- Juntavee, N.; Attashu, S. Effect of Sintering Process on Color Parameters of Nano-Sized Yttria Partially Stabilized Tetragonal Monolithic Zirconia. J. Clin. Exp. Dent. 2018, 10, 794–804. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Yu, B. Measurement of Opalescence of Tooth Enamel. J. Dent. 2007, 35, 690–694. [Google Scholar] [CrossRef] [PubMed]

- Shiraishi, T.; Wood, D.J.; Shinozaki, N.; van Noort, R. Optical Properties of Base Dentin Ceramics for All-Ceramic Restorations. Dent. Mater. 2011, 27, 165–172. [Google Scholar] [CrossRef]

- Abbasimoghaddam, S.; Hakimaneh, S.M.R.; Hooshmand, T.; Shayegh, S.S. Effects of Aging on Mechanical and Optical Properties of Translucent and Opaque Zirconia. J. Iran. Dent. Assoc. 2021, 33, 22–32. [Google Scholar]

- Yamashita, I.; Tsukuma, K. Light Scattering by Residual Pores in Transparent Zirconia Ceramics. J. Ceram. Soc. Jpn. 2011, 119, 133–135. [Google Scholar] [CrossRef]

- Ilie, N.; Stawarczyk, B. Quantification of The Amount of Blue Light Passing Through Monolithic Zirconia with Respect to Thickness and Polymerization Conditions. J. Prosthet. Dent. 2015, 113, 114–121. [Google Scholar] [CrossRef]

- Koseoglu, M.; Albayrak, B.; Gül, P.; Bayindir, F. Effect of Thermocycle Aging on Color Stability of Monolithic Zirconia. Open J. Stomatol. 2019, 9, 75–85. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).