Innovative Applications of Salted Duck Egg By-Product (Liquid Albumen): Evaluating Substitutions in Pickled Pork Casings for Chinese Sausage Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing of Samples and Pickling Solutions

2.2.1. Desalting of Commercially Available Salted HC

2.2.2. Processing of Pickling Solution

2.2.3. Pickling Process

2.2.4. Preparation of Chinese Sausages

2.3. Proximate Analysis

2.4. Determining the Color of HCs

2.5. TPA

2.6. Aroma Analysis

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties of the Sausage

3.1.1. Moisture Content

3.1.2. AW

3.1.3. Color

3.1.4. TPA

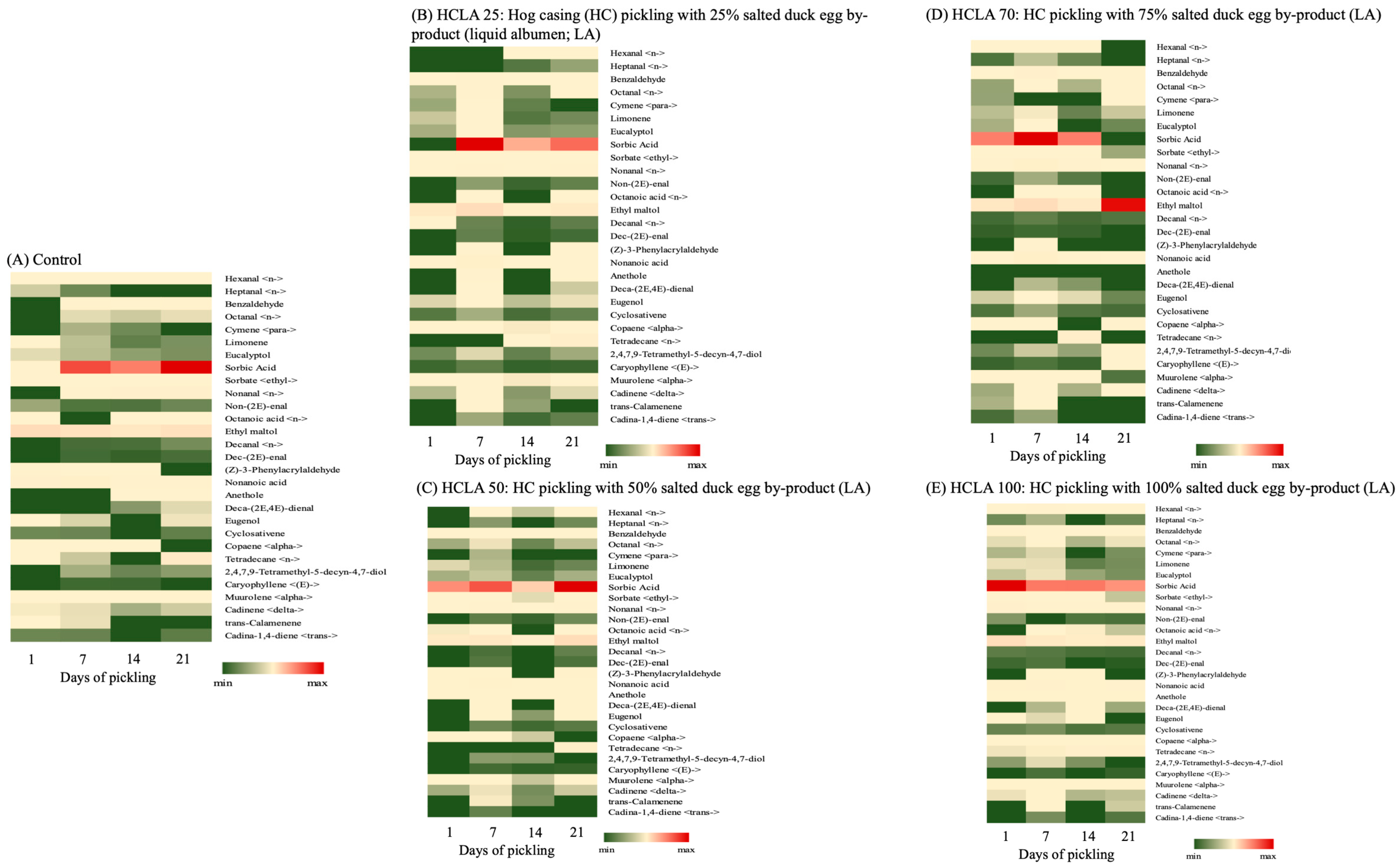

3.1.5. Aroma Heat-Map Analysis

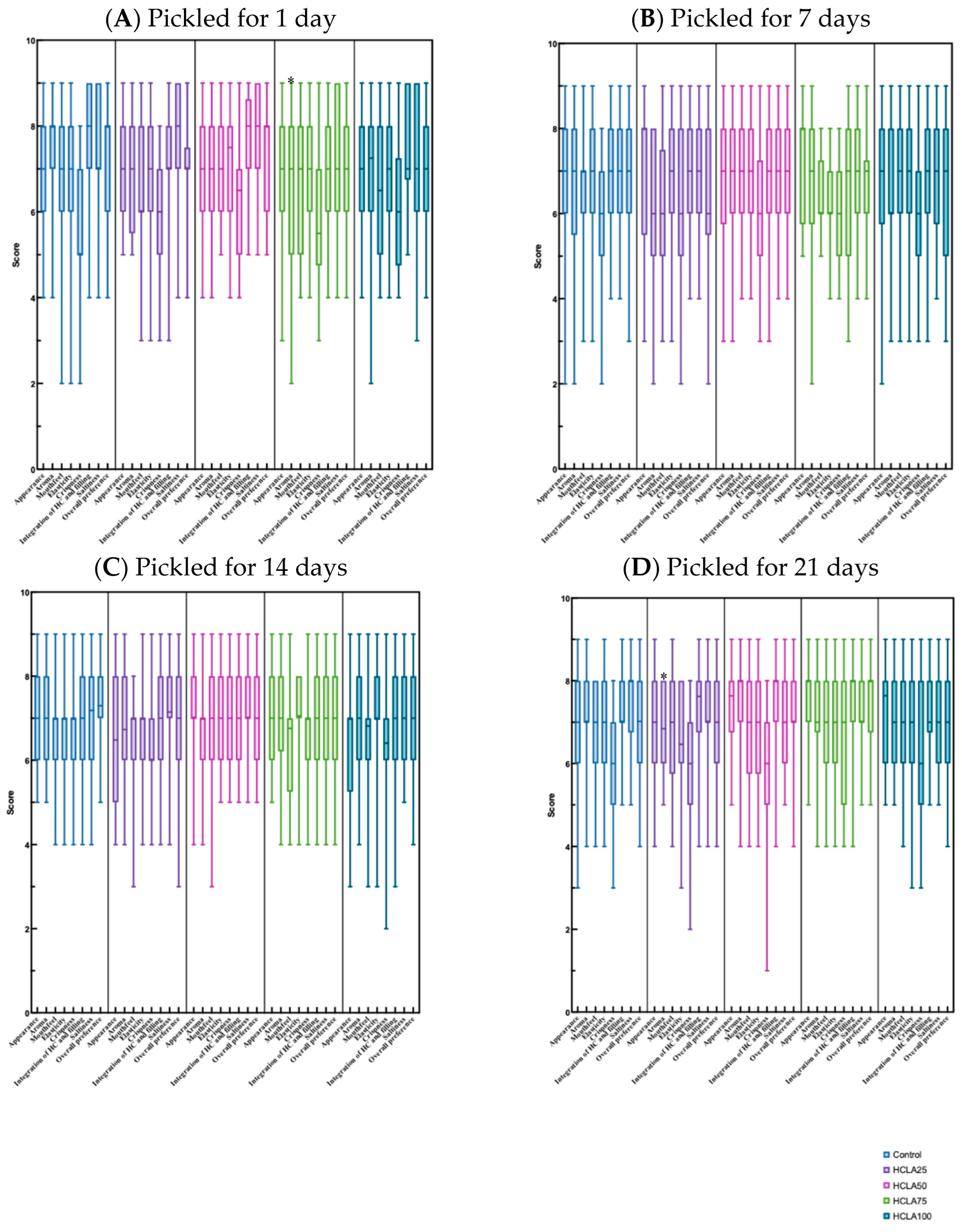

3.2. Sensory Evaluation

3.3. Proximate Composition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LA | Liquid albumen |

| HC | Hog casing |

| TPA | Textural profile analysis |

| CAGR | Conservative compound annual growth rate |

| DW | Deionized water |

| AW | Water activity |

| N | Newton |

| SPME | Solid-phase microextraction |

| DVB/PDMS | Divinylbenzene/polydimethylsiloxane |

| GC-MS | Gas chromatography–mass spectrometry |

| RI | Retention index |

| NIST | National Institute of Standards and Technology |

| FFNSC | Flavors/fragrances |

| SD | Standard deviation |

| ANOVA | Analysis of variance |

| WVP | Water vapor permeability |

| MR | Maillard reaction |

| Phe | Phenylalanine |

| ED2 | 3,4′-di-O-butanoylresveratrol |

| ED4 | 3-O-butanoylresveratrol |

Appendix A

| Ingredient | Weight | Ratio | |

|---|---|---|---|

| (g) | (%) | ||

| Lean pork | 20,000 | 69.79 | |

| Back fat | 5000 | 17.45 | |

| Seasonings | Salt | 358.3 | 1.25 |

| Sugar | 2278.47 | 7.95 | |

| Monosodium glutamate (MSG) | 126.1 | 0.44 | |

| Five-spice powder | 11.5 | 0.04 | |

| White pepper | 74.5 | 0.26 | |

| Cooking rice wine | 753.8 | 2.63 | |

| Polyphosphate | 51.6 | 0.18 | |

| Sodium nitrite | 2.5 | 0.01 | |

| Total | 28,656.77 | 100 | |

| Item | Control | HCs Pickled in 50% Salted Duck Egg By-Product (LA) for 7 Days HCLA50 | ||

|---|---|---|---|---|

| Each Serving (40 g) | Per 100 g | Each Serving (40 g) | Per 100 g | |

| Calories (kcal) | 115.8 | 289.6 | 130.5 | 326.3 |

| Protein (g) | 5.5 | 13.7 | 5.2 | 13.1 |

| Fat (g) | 9.3 | 23.3 | 14.4 | 28.6 |

| Saturated fat (g) | 3.5 | 8.6 | 4.4 | 11.1 |

| Trans fat (g) | 0 | |||

| Carbohydrate (g) | 2.5 | 6.2 | 1.7 | 4.3 |

| Sugar (g) | 2.6 | 6.5 | 2.4 | 6 |

| Sodium (g) | 235 | 587 | 214 | 535 |

References

- Wongnen, C.; Panpipat, W.; Saelee, N.; Rawdkuen, S.; Grossmann, L.; Chaijan, M. A novel approach for the production of mildly salted duck egg using ozonized brine salting. Foods 2023, 12, 2261. [Google Scholar] [CrossRef]

- Ye, Y.; Wu, N.; Yao, Y.; Chen, S.; Xu, L.; Zhao, Y.; Tu, Y. Effects of ammonium chloride on physicochemical properties, aggregation behavior and microstructure of duck egg yolk induced by salt. LWT 2025, 229, 118151. [Google Scholar] [CrossRef]

- DiMarket. Salted Duck Egg Analysis Uncovered: Market Drivers and Forecasts 2025–2033; PRDUA Research & Media Private Limited: Pune, Maharashtra, India, 2025; Available online: https://www.datainsightsmarket.com/reports/salted-duck-egg-1236257#segments (accessed on 8 August 2025).

- Wang, H.-C.; Chen, Y.-C.; Chen, J.-W. The Current Production and Export Situation of the Duck Egg Industry in Taiwan. FFTC Agricultural Policy Platform (FFTC-AP). 2025. Available online: https://ap.fftc.org.tw/article/3766 (accessed on 7 August 2025).

- Wang, X.; Zhang, J.; Vidyarthi, S.K.; Xu, M.; Liu, Z.; Zhang, C.; Xiao, H. A comprehensive review on salted eggs: Quality formation mechanisms, innovative pickling technologies and value-added applications. Sustain. Food Technol. 2024, 2, 1409–1427. [Google Scholar] [CrossRef]

- Cui, Y.; Lu, W.; Zalewski, P.; He, J.; Li, X.; Cao, Y.; Zhao, Y.; Sun, C.; Wu, J.; Chen, H.; et al. Innovative approaches to sodium reduction in pickled foods: A review of recent developments. Trends Food Sci. Technol. 2025, 163, 105133. [Google Scholar] [CrossRef]

- Suurs, P.; Barbut, S. Collagen use for co-extruded sausage casings—A review. Trends Food Sci. Technol. 2020, 102, 91–101. [Google Scholar] [CrossRef]

- Global-Market-Insights. Sausage Casings Market Size; Global Market Insights Inc.: Selbyville, DE, USA, 2023; Available online: https://www.gminsights.com/industry-analysis/sausage-casings-market (accessed on 8 August 2025).

- Anuradha. Natural Sausage Casings Market Research Report 2033; Growth Market Reports: Ontario, CA, USA, 2024; 288p, Available online: https://growthmarketreports.com/report/natural-sausage-casings-market (accessed on 8 August 2025).

- Venugopal, V. Green processing of seafood waste biomass towards blue economy. Curr. Res. Environ. Sustain. 2022, 4, 100164. [Google Scholar] [CrossRef]

- Lin, C.-H.; Huang, Y.-T.; Ciou, J.-Y.; Cheng, C.-M.; Wang, G.-T.; You, C.-M.; Huang, P.-H.; Hou, C.-Y. Circular economy and sustainable recovery of taiwanese tilapia (Oreochromis mossambicus) byproduct—The large-scale production of umami-rich seasoning material application. Foods 2023, 12, 1921. [Google Scholar] [CrossRef]

- Huang, P.-H.; Chen, Y.-W.; Chen, C.-H.; Fan, H.-J.; Hsieh, C.-W.; Tain, Y.-L.; Tsai, W.-T.; Shih, M.-K.; Hou, C.-Y. Characterization and evaluation of the adsorption of uremic toxins through the pyrolysis of pineapple leaves and peels and by forming a bio-complex with sodium alginate. Int. J. Biol. Macromol. 2025, 302, 138843. [Google Scholar] [CrossRef]

- Chung, P.-L.; Lufaniyao, K.-S.; Gavahian, M. Development of Chinese-style sausage enriched with djulis (Chenopodium formosanum Koidz) using taguchi method: Applying modern optimization to indigenous people’s traditional food. Foods 2024, 13, 91. [Google Scholar] [CrossRef]

- Huang, P.-H.; Chen, Y.-W.; Shie, C.-K.; Chen, S.-Y.; Lee, B.-H.; Yin, L.-J.; Hou, C.-Y.; Shih, M.-K. Chinese sausage simulates high calorie–induced obesity in vivo, identifying the potential benefits of weight loss and metabolic syndrome of resveratrol butyrate monomer derivatives. J. Nutr. Metab. 2025, 2025, 8414627. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis. In Official Methods of Analysis of AOAC International, 22nd ed.; Latimer, G.W., Jr., Latimer, G.W., Jr., Eds.; Oxford University Press: Oxford, UK, 2023. [Google Scholar]

- Lin, Y.-W.; Tsai, C.-L.; Chen, C.-J.; Li, P.-L.; Huang, P.-H. Insights into the effects of multiple frequency ultrasound combined with acid treatments on the physicochemical and thermal properties of brown rice postcooking. LWT 2023, 188, 115423. [Google Scholar] [CrossRef]

- Huang, P.-H.; Wu, Y.-Y.; Lin, C.-M.; Chen, H.-L.; Chen, M.-H.; Shih, M.-K.; Hou, C.-Y. Characterization of the effects of micro-bubble treatment on the cleanliness of intestinal sludge, physicochemical properties, and textural quality of shrimp (Litopenaeus vannamei). Food Chem. 2025, 472, 142909. [Google Scholar] [CrossRef]

- Wang, B.-H.; Huang, P.-H.; Lo, C.-Y.; Chang, W.-C. Metabolomic analysis elucidates the dynamic changes in aroma compounds and the milk aroma mechanism across various portions of tea leaves during different stages of oolong tea processing. Food Res. Int. 2025, 209, 116203. [Google Scholar] [CrossRef]

- Huang, P.; Chen, Y.; Fan, H.; Chen, S.; Tain, Y.; Hsieh, C.; Hou, C.; Shih, M. Application of resveratrol butyric acid derivatives in the processing, physicochemical characterization, and the shelf-life extension of Chinese sausages low in sodium nitrite. J. Food Saf. 2024, 44, e13144. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, J.; Qian, Q.; Ma, H.; Zhou, J.; Lin, Y.; Zhang, P.; Chen, Q.; Zeng, Q.; Li, Q.; et al. Effect of isolated bacteria on nitrite degradation and quality of Sichuan dry sausages. LWT 2024, 212, 117039. [Google Scholar] [CrossRef]

- Guan, D.; Yang, X.; Tao, J.; Zhan, F.; Qiu, Y.; Jin, J.; Zhao, L. Novel biodegradable polyamide 4/chitosan casing films for enhanced fermented sausage packaging. Food Packag. Shelf Life 2025, 47, 101444. [Google Scholar] [CrossRef]

- Liu, Y.; Mijiti, M.; Xu, Z.; Abulikemu, B. Effect of a combination of probiotics on the flavor profiling and biogenic amines of composite fermented mutton sausages. Food Biosci. 2024, 61, 104835. [Google Scholar] [CrossRef]

- Seibt, A.C.M.D.; Nerhing, P.; Pinton, M.B.; Santos, S.P.; Leães, Y.S.V.; Oliveira, F.D.C.D.; Robalo, S.S.; Casarin, B.C.; Dos Santos, B.A.; Barin, J.S.; et al. Green technologies applied to low-NaCl fresh sausages production: Impact on oxidative stability, color formation, microbiological properties, volatile compounds, and sensory profile. Meat Sci. 2024, 209, 109418. [Google Scholar] [CrossRef]

- Dai, Y.; Yuan, Y.; Chen, J.-X.; Chen, S.-Y.; Li, C.-H.; Huang, Y.; Chang, H.-J. Quality properties of Chinese Sichuan-style sausages as affected by Chinese red wine, yellow rice wine and beer. Int. J. Food Prop. 2023, 26, 3291–3304. [Google Scholar] [CrossRef]

- Huang, J.; Wei, H.; Luo, Z.; Li, L.; Liu, Z.; Xie, N. Enhancing the textural properties of Tibetan pig sausages via zanthoxylum bungeanum aqueous extract: Polyphenol-mediated quality improvements. Foods 2025, 14, 1639. [Google Scholar] [CrossRef]

- Huang, R.; Fang, Y.; Yin, H.; Zhong, Y.; Lu, W.; Deng, Y. Al-optimized synergy of KCl and κ-carrageenan in low-sodium sausages: Integrated enhancement of saltiness perception, gel stability, and protein digestibility. Food Hydrocoll. 2025, 168, 111574. [Google Scholar] [CrossRef]

- Karla dos Santos, A.; da Silva, N.M.; Matiucci, M.A.; de Marins, A.R.; de Campos, T.A.F.; de Brito Sodré, L.W.; Bezerra, R.A.D.; Alcalde, C.R.; Feihrmann, A.C. Use of encapsulated açaí oil with antioxidant potential in fresh sausage. LWT 2024, 204, 116469. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Kong, B.; Cao, C.; Sun, F.; Zhang, H.; Liu, Q. Application of lysine as a potential alternative to sodium salt in frankfurters: With emphasis on quality profile promotion and saltiness compensation. Meat Sci. 2024, 217, 109609. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Wang, L.; Ge, Y.; An, Y.; Sun, X.; Xue, K.; Xie, H.; Wang, R.; Li, J.; Chen, L. Screening, identification, and application of superior starter cultures for fermented sausage production from traditional meat products. Fermentation 2025, 11, 306. [Google Scholar] [CrossRef]

- Xu, B.; Qiu, W.; Liu, Y.; Gong, F.; Liu, Q.; Chen, J.; Tang, Y.; Su, C.; Tang, J.; Zhang, D.; et al. Exploring the regulation of metabolic changes mediated by different combined starter cultures on the characteristic flavor compounds and quality of Sichuan-style fermented sausages. Food Res. Int. 2025, 208, 116114. [Google Scholar] [CrossRef]

- Feng, T.; Ye, R.; Zhuang, H.; Rong, Z.; Fang, Z.; Wang, Y.; Gu, Z.; Jin, Z. Physicochemical properties and sensory evaluation of mesona blumes gum/rice starch mixed gels as fat-substitutes in Chinese Cantonese-style sausage. Food Res. Int. 2013, 50, 85–93. [Google Scholar] [CrossRef]

- Sriwattana, S.; Chokumnoyporn, N.; Prinyawiwatkul, W. Reduced-sodium Vienna sausage: Selected quality characteristics, optimized salt mixture, and commercial scale-up production. J. Food Sci. 2021, 86, 3939–3950. [Google Scholar] [CrossRef]

- Zhao, P.; An, Y.; Dong, Z.; Sun, X.; Zhang, W.; Wang, H.; Yang, B.; Yan, J.; Fang, B.; Ren, F.; et al. Comparative analysis of commercially available flavor oil sausages and smoked sausages. Molecules 2024, 29, 3772. [Google Scholar] [CrossRef]

- Zhang, Q.; Shen, J.; Meng, G.; Liu, C.; Wang, H.; Zhang, Q.; Zhu, C.; Zhao, G.; Wang, X. Characterization of wheat bran nanocellulose and its application in low-fat emulsified sausage. Cellulose 2024, 31, 11101–11114. [Google Scholar] [CrossRef]

- He, W.; Liu, Z.; Liu, H.; Sun, J.; Chen, H.; Sun, B. Characterization of key volatile flavor compounds in dried sausages by HS-SPME and safe, which combined with GC-MS, GC-O and OAV. J. Food Compos. Anal. 2024, 133, 106438. [Google Scholar] [CrossRef]

- Bleicher, J.; Ebner, E.E.; Bak, K.H. Formation and analysis of volatile and odor compounds in meat—A review. Molecules 2022, 27, 6703. [Google Scholar] [CrossRef]

- Cai, X.; Zeng, Y.; Zhu, K.; Peng, Y.; Xv, P.; Dong, P.; Qiao, M.; Fan, W. Characterization of the quality and flavor in Chinese sausage: Comparison between Cantonese, five-spice, and mala sausages. Foods 2025, 14, 1982. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, J.; Liu, Q.; Wang, Y.; Ren, J.; Chen, Q.; Kong, B. Unraveling the difference in flavor characteristics of dry sausages inoculated with different autochthonous lactic acid bacteria. Food Biosci. 2022, 47, 101778. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, B.; Zhang, S.; Wu, Q.; Zhu, N.; Li, S.; Pan, X.; Wang, S.; Qiao, X. Development of volatiles and odor-active compounds in Chinese dry sausage at different stages of process and storage. Food Sci. Hum. Wellness 2021, 10, 316–326. [Google Scholar] [CrossRef]

- Chen, X.; Yan, F.; Qu, D.; Wan, T.; Xi, L.; Hu, C.Y. Aroma characterization of Sichuan and Cantonese sausages using electronic nose, gas chromatography–mass spectrometry, gas chromatography-olfactometry, odor activity values and metagenomic. Food Chem. X 2024, 24, 101924. [Google Scholar] [CrossRef] [PubMed]

- Mei, L.; Pan, D.; Guo, T.; Ren, H.; Wang, L. Role of Lactobacillus plantarum with antioxidation properties on Chinese sausages. LWT 2022, 162, 113427. [Google Scholar] [CrossRef]

- Xia, L.; Qian, M.; Cheng, F.; Wang, Y.; Han, J.; Xu, Y.; Zhang, K.; Tian, J.; Jin, Y. The effect of lactic acid bacteria on lipid metabolism and flavor of fermented sausages. Food Biosci. 2023, 56, 103172. [Google Scholar] [CrossRef]

- Xing, B.; Zhou, T.; Gao, H.; Wu, L.; Zhao, D.; Wu, J.; Li, C. Flavor evolution of normal- and low-fat Chinese sausage during natural fermentation. Food Res. Int. 2023, 169, 112937. [Google Scholar] [CrossRef]

- Zhou, T.; Sheng, B.; Gao, H.; Nie, X.; Sun, H.; Xing, B.; Wu, L.; Zhao, D.; Wu, J.; Li, C. Effect of fat concentration on protein digestibility of Chinese sausage. Food Res. Int. 2024, 177, 113922. [Google Scholar] [CrossRef]

- Zheng, S.-S.; Wang, C.-Y.; Hu, Y.-Y.; Yang, L.; Xu, B.-C. Enhancement of fermented sausage quality driven by mixed starter cultures: Elucidating the perspective of flavor profile and microbial communities. Food Res. Int. 2024, 178, 113951. [Google Scholar] [CrossRef]

- Wang, Y.; Lv, C.; Zhang, P.; Wang, F.; Zhang, T.; Ma, Y.; Xu, M. Formulation optimization and quality evaluation of walnut protein sausage based on fuzzy mathematics sensory evaluation combined with random centroid optimization. Food Sci. Nutr. 2025, 13, e70747. [Google Scholar] [CrossRef] [PubMed]

| Analysis | Days of Pickling | Control (Commercially Available Salted HC) | HCLA | ||||

|---|---|---|---|---|---|---|---|

| LA Concentration (%) | 25 | 50 | 75 | 100 | |||

| Deionized Water (DW; %) | 75 | 50 | 25 | 0 | |||

| Moisture content (%) | 1 | 34.49 ± 2.58 a | 30.71 ± 0.09 b | 33.26 ± 1.33 ab | 27.73 ± 1.28 cd | 26.36 ± 2.95 d | |

| 7 | 33.97 ± 1.60 a | 34.91 ± 1.35 a | 36.37 ± 4.15 a | 32.17 ± 2.34 a | 33.76 ± 1.34 a | ||

| 14 | 41.19 ± 3.42 ab | 38.69 ± 3.84 ab | 44.34 ± 2.25 a | 38.30 ± 4.09 b | 36.62 ± 1.82 b | ||

| 21 | 34.71 ± 8.10 a | 29.65 ± 0.46 a | 22.57 ± 5.78 a | 29.30 ± 2.81 a | 31.14 ± 3.75 a | ||

| Water activity (AW) | 1 | 0.92 ± 0.01 b | 0.93 ± 0.01 ab | 0.94 ± 0.01 a | 0.94 ± 0.00 a | 0.94 ± 0.00 a | |

| 7 | 0.94 ± 0.01 a | 0.94 ± 0.01 a | 0.94 ± 0.00 a | 0.94 ± 0.00 a | 0.95 ± 0.00 a | ||

| 14 | 0.96 ± 0.01 a | 0.95 ± 0.01 a | 0.96 ± 0.00 a | 0.95 ± 0.01 a | 0.96 ± 0.00 a | ||

| 21 | 0.93 ± 0.01 b | 0.94 ± 0.01 ab | 0.93 ± 0.01 b | 0.94 ± 0.01 bc | 0.95 ± 0.00 a | ||

| L* | 1 | 51.40 ± 0.46 d | 54.43 ± 0.15 c | 58.60 ± 0.10 a | 55.33 ± 0.42 b | 48.23 ± 0.21 e | |

| 7 | 50.67 ± 0.29 c | 51.43 ± 0.15 b | 51.80 ± 0.10 a | 50.13 ± 0.15 d | 51.27 ± 0.15 b | ||

| 14 | 53.57 ± 0.46 b | 49.23 ± 0.32 d | 50.60 ± 0.26 c | 50.33 ± 0.29 c | 54.53 ± 0.15 a | ||

| 21 | 42.27 ± 0.21 a | 46.63 ± 0.29 b | 45.43 ± 0.12 c | 48.90 ± 0.46 d | 39.27 ± 0.46 e | ||

| a* | 1 | 9.60 ± 0.89 b | 7.90 ± 0.56 c | 6.87 ± 0.95 c | 7.80 ± 0.98 c | 12.27 ± 1.02 a | |

| 7 | 9.57 ± 1.10 b | 8.53 ± 1.00 b | 10.33 ± 0.78 b | 13.37 ± 1.10 a | 9.23 ± 1.85 b | ||

| 14 | 7.40 ± 0.62 b | 9.67 ± 0.55 a | 8.63 ± 0.57 ab | 8.10 ± 1.44 b | 4.07 ± 0.06 c | ||

| 21 | 11.70 ± 1.18 ab | 10.10 ± 1.31 b | 13.13 ± 0.65 a | 10.20 ± 2.26 b | 12.80 ± 0.20 ab | ||

| b* | 1 | 15.50 ± 1.91 ab | 12.37 ± 3.29 b | 20.73 ± 1.12 a | 21.20 ± 3.51 a | 15.27 ± 3.07 b | |

| 7 | 13.43 ± 1.80 b | 13.90 ± 1.37 b | 15.77 ± 2.61 b | 23.87 ± 0.55 a | 20.63 ± 6.61 ab | ||

| 14 | 13.87 ± 1.97 ab | 17.73 ± 2.51 a | 16.97 ± 4.97 ab | 19.73 ± 1.60 a | 11.73 ± 0.45 b | ||

| 21 | 18.00 ± 4.07 a | 13.47 ± 2.27 b | 18.93 ± 1.50 a | 16.97 ± 1.90 ab | 18.53 ± 0.60 a | ||

| Analysis | Days of Pickling | Control (Commercially Available Salted HCs) | HCLA | ||||

|---|---|---|---|---|---|---|---|

| LA Concentration (%) | 25 | 50 | 75 | 100 | |||

| Deionized Water (DW; %) | 75 | 50 | 25 | 0 | |||

| Hardness (Newton; N) | 1 | 123.58 ± 22.75 ab | 84.71 ± 9.34 d | 115.22 ± 8.08 bc | 146.03 ± 19.25 a | 106.05 ± 6.82 cd | |

| 7 | 72.59 ± 5.38 b | 130.22 ± 34.57 a | 84.79 ± 6.69 ab | 72.86 ± 7.25 b | 74.28 ± 6.62 b | ||

| 14 | 104.13 ± 13.23 b | 64.95 ± 7.36 c | 142.36 ± 16.26 a | 128.73 ± 8.00 ab | 60.27 ± 3.87 c | ||

| 21 | 105.74 ± 12.07 bc | 95.78 ± 6.21 c | 103.62 ± 2.17 bc | 139.72 ± 17.97 a | 127.20 ± 14.97 ab | ||

| Springiness | 1 | 0.78 ± 0.05 b | 0.89 ± 0.03 ab | 0.93 ± 0.03a | 0.84 ± 0.14 ab | 0.46 ± 0.04 c | |

| 7 | 0.57 ± 0.02 bc | 0.65 ± 0.08 bc | 0.93 ± 0.10 ab | 1.02 ± 0.35 a | 0.41 ± 0.06 c | ||

| 14 | 0.47 ± 0.08 ab | 0.53 ± 0.03 a | 0.45 ± 0.05 b | 0.48 ± 0.03 ab | 0.34 ± 0.05 c | ||

| 21 | 0.26 ± 0.01 c | 0.42 ± 0.11 b | 0.44 ± 0.04 b | 0.56 ± 0.05 a | 0.50 ± 0.02 ab | ||

| Cohesiveness | 1 | 0.24 ± 0.08 b | 0.54 ± 0.18 a | 0.40 ± 0.03 ab | 0.51 ± 0.12 a | 0.34 ± 0.09 ab | |

| 7 | 0.27 ± 0.10 b | 0.58 ± 0.13 a | 0.38 ± 0.19 ab | 0.60 ± 0.25 a | 0.25 ± 0.02 b | ||

| 14 | 0.37 ± 0.09 b | 0.79 ± 0.03 a | 0.77 ± 0.03 a | 0.85 ± 0.05 a | 0.79 ± 0.01 a | ||

| 21 | 0.86 ± 0.04 a | 0.79 ± 0.02 ab | 0.53 ± 0.06 c | 0.75 ± 0.07 b | 0.80 ± 0.02 ab | ||

| Gumminess | 1 | 28.08 ± 3.75 b | 46.55 ± 20.56 b | 46.68 ± 6.59 b | 74.09 ± 13.52 a | 35.70 ± 7.27 b | |

| 7 | 19.21 ± 6.41 c | 72.83 ± 6.44 a | 31.48 ± 13.59 bc | 43.86 ± 19.70 b | 18.93 ± 3.02 c | ||

| 14 | 38.86 ± 12.40 b | 51.42 ± 7.27 b | 109.53 ± 8.19 a | 109.77 ± 1.12 a | 47.86 ± 2.77 b | ||

| 21 | 90.77 ± 12.81 a | 75.97 ± 6.47 ab | 54.62 ± 5.61 b | 106.10 ± 22.84 a | 101.27 ± 13.17 a | ||

| Chewiness (N) | 1 | 21.84 ± 3.72 bc | 41.20 ± 16.84 ab | 43.68 ± 7.34 ab | 63.59 ± 20.23 a | 16.58 ± 4.28 c | |

| 7 | 10.88 ± 3.66 b | 47.99 ± 10.35 a | 28.60 ± 9.61 ab | 49.07 ± 32.41 a | 7.83 ± 2.20 b | ||

| 14 | 18.24 ± 7.52 bc | 27.41 ± 5.12 b | 49.00 ± 5.02 a | 52.49 ± 3.23 a | 16.43 ± 3.33 c | ||

| 21 | 23.51 ± 4.07 c | 32.47 ± 10.98 bc | 24.22 ± 3.76 c | 59.94 ± 15.36 a | 50.64 ± 7.09 ab | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, W.-C.; Hou, W.-T.; Huang, P.-H. Innovative Applications of Salted Duck Egg By-Product (Liquid Albumen): Evaluating Substitutions in Pickled Pork Casings for Chinese Sausage Manufacturing. Processes 2025, 13, 3974. https://doi.org/10.3390/pr13123974

Chang W-C, Hou W-T, Huang P-H. Innovative Applications of Salted Duck Egg By-Product (Liquid Albumen): Evaluating Substitutions in Pickled Pork Casings for Chinese Sausage Manufacturing. Processes. 2025; 13(12):3974. https://doi.org/10.3390/pr13123974

Chicago/Turabian StyleChang, Wen-Chang, Wei-Ting Hou, and Ping-Hsiu Huang. 2025. "Innovative Applications of Salted Duck Egg By-Product (Liquid Albumen): Evaluating Substitutions in Pickled Pork Casings for Chinese Sausage Manufacturing" Processes 13, no. 12: 3974. https://doi.org/10.3390/pr13123974

APA StyleChang, W.-C., Hou, W.-T., & Huang, P.-H. (2025). Innovative Applications of Salted Duck Egg By-Product (Liquid Albumen): Evaluating Substitutions in Pickled Pork Casings for Chinese Sausage Manufacturing. Processes, 13(12), 3974. https://doi.org/10.3390/pr13123974