Abstract

In the rapidly evolving field of renewable energy, integrating Artificial Intelligence (AI) and the Internet of Things (IoT) has become a transformative strategy for improving solar energy monitoring and control. This paper provides a comprehensive survey of Artificial Intelligence of Things (AIoT) applications in solar energy, illustrating how IoT technologies enable real-time monitoring, system optimization through techniques such as Maximum Power Point Tracking (MPPT), solar tracking, and automated cleaning. Simultaneously, AI boosts these capabilities through energy forecasting, optimization, predictive maintenance, and fault detection, significantly enhancing system performance and reliability. This review highlights key advancements, challenges, and practical applications of AIoT in the solar energy sector, emphasizing its role in advancing energy efficiency and sustainability.

1. Introduction

Approximately 75% of the world’s fossil fuel consumption is used to generate heat and electricity, which has significant consequences for the environment and public health [1]. The combustion of fossil fuels such as coal, natural gas, and petroleum releases toxic pollutants that contribute to land and air pollution, global warming, and various health risks [2]. Additionally, fossil fuels are finite. Some projections estimate that, if current consumption trends continue, oil and gas reserves could decline to 14% and 18%, respectively, by 2050 [3]. These concerns emphasize the urgent need to transition to renewable and sustainable energy sources to reduce environmental harm and conserve resources for future generations. Governments worldwide are increasingly adopting clean energy policies, with solar energy gaining particular attention due to its wide availability. The Earth receives an average solar radiation of 343 W/m2. In China, which is the leading emitter of carbon dioxide, solar photovoltaic (PV) technology has the potential to generate 131.942 petawatt-hours (PWh) of energy—an amount estimated to be nearly 23 times the country’s total electricity demand [4]. In 2024, global solar PV capacity grew by a record 553 gigawatts (GW), increasing the total installed capacity to approximately 1200 GW [5]. Major installations in China, the United States, and India were key drivers of this growth. As a result, solar energy generation exceeded 2000 terawatt-hours (TWh) globally, contributing around 6.9% of the world’s electricity supply [6]. This rapid expansion underscores the central role of solar energy in the transition toward cleaner power systems. To fully capitalize on this resource, effective monitoring and control systems are essential. These systems ensure optimal management of energy production and meet rising electricity demands. Solar energy monitoring relies on components such as sensors and microcontrollers that support real-time tracking and performance optimization [7]. Alongside monitoring, control systems are critical for adjusting panel operations dynamically based on real-time data, improving efficiency and responsiveness. Fault detection also plays a vital role in maintaining system performance and extending operational lifespan. Recent advancements have introduced intelligent and automated methods for identifying faults in PV systems. By using IoT-enabled monitoring devices, these technologies support real-time detection of issues, enhancing the overall reliability and effectiveness of solar energy systems [8]. Building upon IoT capabilities, AI introduces advanced data analytics to improve energy forecasting, optimize panel orientation, and reduce operational costs. AI algorithms analyze both real-time and historical data to anticipate weather patterns, detect faults, and schedule maintenance proactively. These capabilities help avoid system failures and improve the longevity of PV installations. Moreover, AI contributes to smart grid integration by accurately predicting energy demand, further improving the stability and scalability of solar power networks [9,10,11,12,13]. Together, AI and IoT—known as AIoT—represent a unified approach that combines intelligent data processing with connected devices to maximize the performance of solar energy systems.

This survey examines the integration of AIoT in solar energy systems, focusing on IoT-enabled technologies for real-time monitoring, energy optimization through tracking and cleaning systems, and AI-driven applications for fault detection, predictive maintenance, and energy forecasting.

1.1. Existing Reviews and Our Contributions

Previous surveys have examined the role of AI and IoT in solar energy monitoring and control, but most studies focus on these technologies in isolation rather than exploring their combined potential. While some reviews address AI-driven energy forecasting and optimization techniques, others concentrate on IoT-enabled monitoring and automation systems. However, significant gaps remain in the literature, including the absence of a unified framework for AIoT in solar energy systems, limited analysis of how AI and IoT collaboratively optimize performance, and a lack of comprehensive taxonomies categorizing their applications. To fill these gaps, this survey offers a structured taxonomy and a detailed analysis of AIoT applications in solar energy. We classify AIoT implementations into key areas such as fault detection, predictive maintenance, energy forecasting, solar monitoring systems, and optimization techniques like MPPT, solar tracking, and automated cleaning. Furthermore, we compare existing studies to highlight differences in methodologies, findings, and technological approaches, providing a broader perspective on AIoT’s role in solar energy. By consolidating advancements, identifying challenges, and analyzing key differences across studies, this paper aims to offer valuable insights that can inform future research and development in AIoT-driven solar energy solutions.

Table 1 summarizes the strengths and weaknesses of existing reviews and highlights the research gaps that our survey addresses.

Table 1.

Summary of strengths, weaknesses, and gaps in existing reviews.

1.2. Survey Methodology

To ensure a comprehensive and systematic review, we employed a structured methodology to select, analyze, and compare relevant studies on AIoT in solar energy.

Search Process: We conducted a systematic search using Google Scholar to identify relevant articles, the majority of the results sourced from IEEE, as well as journals published by MDPI and Elsevier. The search focused on peer-reviewed journal articles, conference papers, and review studies related to AI, IoT, and their integration in solar energy management. Keywords included “AIoT in solar energy”, “IoT-based solar monitoring”, “AI in photovoltaic systems”, and “fault detection in PV systems”.

Inclusion Criteria: Our selection criteria ensured that we included studies specifically addressing AIoT applications in solar energy monitoring, optimization, fault detection, and predictive maintenance. In addition, we incorporated papers that provided fundamental definitions of AI and IoT to establish a strong theoretical foundation for our survey. Although we primarily focused on recent research, we also included some older articles that remain highly cited and influential in shaping AI and IoT applications in solar energy. These older studies were necessary for understanding the historical evolution of AIoT technologies and their impact on current advancements.

Exclusion: we excluded general AI or IoT research without a clear focus on solar energy, non-peer-reviewed articles, and outdated studies with limited relevance to modern AIoT applications.

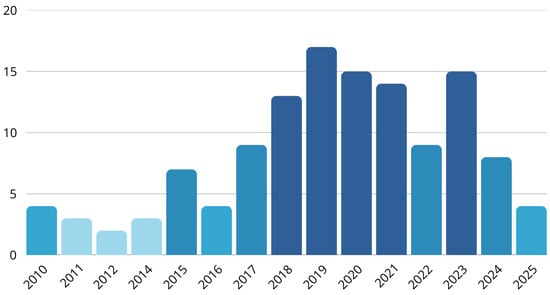

Bibliometric Analysis: Our survey is based on a thorough review of 199 research papers, of which 127 specifically focus on the application of AI and IoT in PV systems. The distribution of these 127 papers over the years is shown in Figure 1. The remaining studies cover various aspects, including foundational definitions. The primary focus was on studies published between 2015 and 2025, ensuring that we captured the most recent advancements and emerging trends in the field.

Figure 1.

Distribution of surveyed papers on AI and IoT applications in PV systems over the years.

1.3. Survey Organization

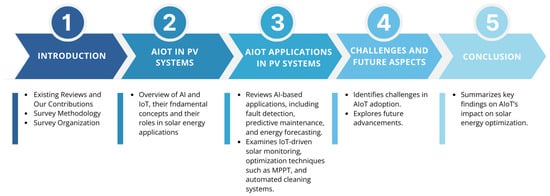

To ensure a structured and comprehensive review, this paper is organized as follows: Section 2 provides an overview of AI and IoT, explaining their fundamental concepts and roles in solar energy applications. It also highlights key enabling technologies for AIoT, including machine learning algorithms, deep learning models, IoT sensors, communication protocols, and cloud computing. Section 3 categorizes and discusses AIoT applications in solar energy, including monitoring systems, fault detection and diagnosis in PV systems, predictive maintenance, energy forecasting, and optimization techniques such as MPPT, solar tracking, and automated cleaning systems to enhance energy efficiency. Section 4 discusses the key challenges in AIoT-based solar energy systems and offers insights for future optimization of their functionality. Section 5 concludes with a summary of the key findings of this survey. Figure 2 provides a structured overview of the survey, outlining its key sections and the main topics covered.

Figure 2.

Survey roadmap: key topics and structure.

2. AIoT in PV Systems: Background

The integration of AIoT in PV systems is revolutionizing the monitoring, control, and optimization of solar energy. This section offers an overview of the key components of AIoT, including AI techniques that enhance PV system performance and the role of IoT in enabling seamless connectivity and data collection.

2.1. Artificial Intelligence Techniques

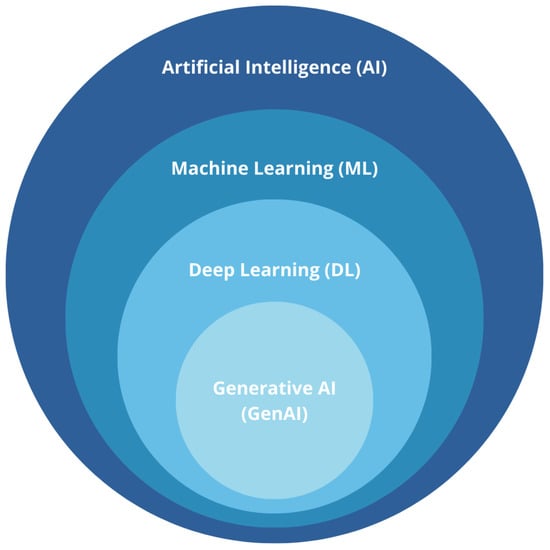

Artificial Intelligence (AI) refers to the development of systems capable of performing tasks that typically require human intelligence, such as reasoning, learning, problem-solving, and language understanding [14]. AI encompasses a broad range of techniques and methodologies designed to enable machines to replicate or enhance human capabilities.

According to the literature, machine learning (ML) is especially effective for addressing complex problems where traditional techniques either fail or are difficult to apply. ML excels in dynamic environments, as it can easily adapt to new data. Unlike traditional methods, ML is particularly advantageous in situations where there is no clear or direct relationship between inputs and outputs, making it ideal for problems that involve long and complex rules.

Deep learning (DL) builds on machine learning by providing enhanced accuracy in classification and prediction tasks, particularly when trained on large datasets. DL algorithms can process raw data directly and automatically extract relevant features, eliminating the need for manual feature engineering. This makes DL especially suitable for solving complex problems that go beyond the capabilities of traditional ML approaches. However, when data are limited, ML algorithms often outperform DL methods due to their lower data requirements.

Recently, Generative AI (GenAI), a cutting-edge field within AI, has garnered significant attention. Unlike traditional AI models, which perform deterministic tasks based on predefined rules, GenAI models learn patterns and structures from large datasets to generate text, images, audio, and even synthetic data that are virtually indistinguishable from real data [15].

Importantly, there are no universal rules for selecting the most suitable AI technique for a given application [16]. The choice depends on several factors: the nature of the problem, the volume of available data, the complexity of the algorithm, the implementation difficulty, and the desired accuracy and generalization capability.

This variability underscores the importance of understanding both the problem and the available tools when selecting the most appropriate technique.

The Venn diagram in Figure 3 illustrates the relationships and overlaps among AI, ML, DL, and GenAI, highlighting both their unique features and shared capabilities. This representation emphasizes the hierarchical structure and interrelated nature of these technologies.

Figure 3.

Venn diagram representing AI, ML, DL, and GenAI.

2.1.1. Machine Learning

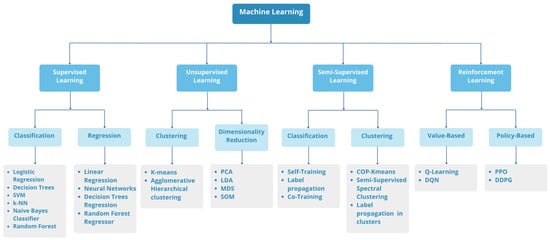

Machine learning (ML) is a subset of Artificial Intelligence that enables systems to learn from data and improve their performance over time without being explicitly programmed. It focuses on developing algorithms that can identify patterns and make decisions with minimal human intervention [17].

ML is broadly categorized into the following paradigms, each suited to specific types of problems:

- Supervised Learning: Models are trained on labeled datasets, where each input has a corresponding output. This approach is ideal for both regression and classification tasks [14]. In solar panel monitoring, it can be used to classify panel conditions (e.g., normal, dusty, or damaged) based on labeled historical data.

- Semi-Supervised Learning: This hybrid approach leverages a small amount of labeled data alongside a large volume of unlabeled data. The model learns correlations between labeled and unlabeled instances, then uses the labeled data to guide the labeling of the remaining dataset [18]. This is particularly useful in PV system analysis, where labeled fault data may be limited, but abundant sensor or image data are available.

- Unsupervised Learning: This approach works with unlabeled data to discover hidden patterns or groupings, using techniques such as clustering and dimensionality reduction [19]. It is suitable for anomaly detection or grouping similar fault types in PV systems without requiring labeled data.

- Reinforcement Learning: Models learn by interacting with an environment and receiving feedback through rewards or penalties [20]. This method can be applied to optimize cleaning schedules for solar panels or manage adaptive control of energy flow in solar farms.

Figure 4 outlines the key ML algorithms commonly associated with each learning paradigm.

Figure 4.

Categorization of ML algorithms by paradigm.

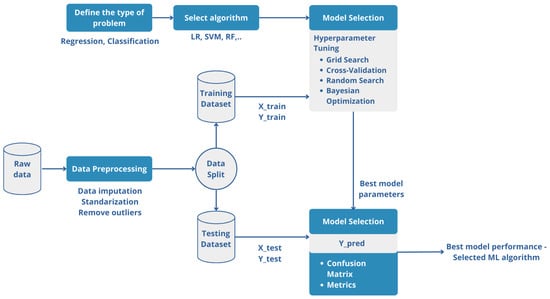

A typical machine learning workflow is illustrated in Figure 5. It begins with data collection and preprocessing to ensure data quality and consistency. The process continues with identifying the problem type classification or regression, which determines the selection of an appropriate algorithm. The dataset is split into training and test sets. Model selection is carried out using cross-validation and hyperparameter tuning. This procedure can be repeated for different machine learning algorithms, allowing performance metrics to be compared. The model with the highest evaluation score is then selected as the final candidate.

Figure 5.

Workflow for the development of a machine learning model.

2.1.2. Deep Learning

Deep learning (DL) is a specialized subset of machine learning, inspired by the structure and function of the human brain. It utilizes Artificial Neural Networks—particularly Deep Neural Networks—to process and learn from large volumes of data [21].

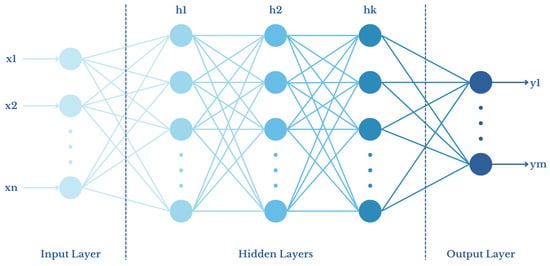

DL relies on neural networks composed of interconnected layers. These include the input layer, which receives raw data; one or more hidden layers, where computations are performed through nodes (neurons) using activation functions; and the output layer, which produces the final prediction or classification [22] (see Figure 6). This layered architecture enables DL models to process complex data and extract meaningful patterns effectively.

Figure 6.

DL neural network architecture.

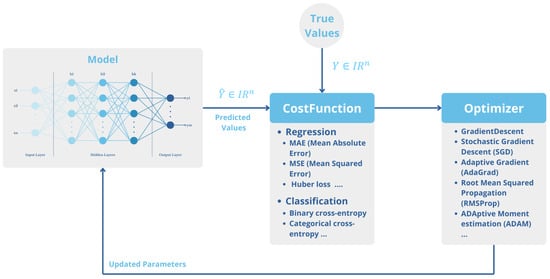

A fundamental mechanism that enables deep learning is backpropagation, an optimization technique used to minimize prediction errors by adjusting the weights of a neural network. It operates by propagating the error backward from the output layer to the earlier layers, allowing the model to iteratively update its parameters and refine its predictions. Backpropagation is essential for efficiently training deep networks, enabling them to learn complex patterns, improve performance, and generalize effectively across diverse datasets (see Figure 7).

Figure 7.

Backpropagation workflow in deep learning.

There are several types of architectures in DL, each suited for different tasks.

- Convolutional Neural Networks (CNNs): These are particularly effective for image and video processing, utilizing convolutional layers to detect spatial hierarchies and patterns in data [21]. In the context of solar panel monitoring, CNNs can analyze UAV or satellite imagery to detect faults such as cracks, hot spots, or dust accumulation.

- Recurrent Neural Networks (RNNs): Designed for sequential data, RNNs are well suited to tasks involving time series or natural language processing, where temporal dependencies are critical. In solar energy systems, RNNs can be employed to forecast energy production by analyzing historical weather and energy data, thereby aiding in performance optimization.

- Long short-term memory (LSTM): A specialized form of RNN, LSTMs are engineered to capture long-term dependencies and retain information over extended time intervals [23]. They are particularly useful in predictive maintenance by identifying temporal patterns in time series sensor data that may signal potential equipment failures.

Training deep learning models typically requires large amounts of labeled data. During the learning phase, these models utilize optimization techniques such as gradient descent and backpropagation to adjust network weights and minimize prediction errors. Gradient descent iteratively updates model parameters by moving in the direction that reduces the cost function, thereby finding the optimal solution. Backpropagation complements this process by computing the gradient of the cost function with respect to each weight using the chain rule, allowing the error to be propagated backward from the output layer to the input layer [24].

Deep learning models thrive on large datasets, often requiring thousands or even millions of samples to achieve optimal performance. The increasing availability of vast datasets and computational power has been a key driver of recent advancements in DL, enabling the development of highly accurate models that frequently outperform traditional machine learning approaches across a wide range of applications [25].

2.1.3. Generative AI

Generative AI (GenAI) represents a transformative branch of Artificial Intelligence focused on generating new content by learning patterns from existing data. It employs advanced machine learning techniques, particularly deep learning models [26], which are trained on large volumes of unstructured data. This enables the models to learn the underlying structures and relationships within the data. As a result, GenAI has led to significant breakthroughs across various domains, including natural language processing, image synthesis, and autonomous decision-making. In the context of PV system monitoring and control, GenAI can enhance fault detection, predictive maintenance, and energy forecasting by generating realistic simulations, detecting anomalies, and automating control strategies.

Core components of GenAI include the following:

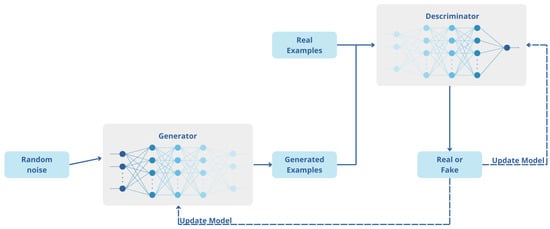

- Generative Adversarial Networks (GANs): GANs consist of two neural networks—the generator and the discriminator—that are trained simultaneously in a competitive process. The generator creates synthetic data, while the discriminator assesses its authenticity. Through this adversarial training process, the generator gradually improves its ability to produce realistic data [27] (see Figure 8). GANs can be particularly useful for generating synthetic sensor data in cases where real-world datasets are limited or incomplete. This capability is especially valuable for PV fault detection and anomaly prediction, as GANs can simulate a range of fault scenarios (e.g., shading, panel degradation), enhancing the robustness of AI models.

Figure 8. GAN architecture.

Figure 8. GAN architecture. - Variational Autoencoders (VAEs): VAEs are another powerful technique within Generative AI. They work by encoding input data into a latent space, which is then decoded back into the original data space. This encoding–decoding process enables VAEs to generate new data points by sampling from the latent space, making them highly suitable for applications such as image generation and data augmentation [28]. In the context of PV systems, VAEs can be employed for anomaly detection by learning the normal operational behavior of solar panels and identifying deviations that may signal potential faults. This capability supports real-time monitoring and proactive maintenance by detecting early signs of performance degradation or energy losses.

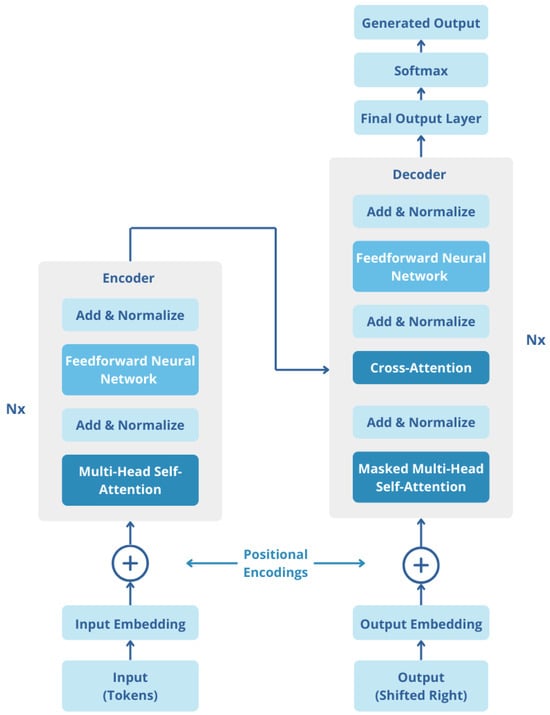

- Transformers: Transformers are a type of architecture used for natural language generation and understanding. Models like GPT (Generative Pre-trained Transformer) and BERT are based on the Transformer architecture. These models use self-attention mechanisms to capture dependencies and relationships within text, making them the backbone of large language models (LLMs) [29]. The Transformer architecture follows a structured workflow, as illustrated in Figure 9, where input text is first tokenized and converted into dense vector representations through an embedding layer, followed by positional encoding to incorporate order information. The encoder layers then apply multi-head self-attention mechanisms to capture relationships between tokens while processing information in parallel. The decoder layers generate output step by step using masked self-attention and cross-attention with encoder outputs, ultimately producing a probability distribution over the vocabulary through a final softmax layer to generate meaningful responses. Transformer-based models, such as LLMs, can enhance PV system monitoring through automated analysis of maintenance logs, fault reports, and operational data. By processing large volumes of text data, LLMs can assist engineers in diagnosing faults, summarizing reports, and even predicting optimal maintenance schedules.

Figure 9. Transformer architecture.

Figure 9. Transformer architecture. - Diffusion Models: Recently popularized for generating high-quality images, diffusion models operate by progressively refining random noise into detailed outputs. These models iteratively enhance image quality, making them highly effective for tasks that require generating realistic images from scratch [30]. In the context of photovoltaic (PV) system performance optimization, diffusion models can simulate environmental conditions, such as cloud cover and temperature fluctuations, to predict their impact on energy generation. Additionally, these models can generate high-resolution simulations of weather patterns, which can support energy forecasting and grid integration planning.

Generative AI has the potential to revolutionize photovoltaic (PV) system monitoring by enhancing predictive capabilities, optimizing energy management strategies, and reducing operational risks. However, challenges such as high computational demands, data bias, and issues with interpretability must be addressed to ensure the reliable, ethical, and effective deployment of GenAI-driven solutions in solar energy management.

2.2. Internet of Things

The advent of the internet has been a significant boon to humanity, unlocking countless applications and enabling seamless communication between devices. This emerging technology, known as the Internet of Things (IoT), leverages the internet to facilitate connectivity between physical devices, or “things” [31].

By utilizing sensors and communication networks, these devices can collect valuable data and offer a wide range of services. These include applications such as remote monitoring and control, predictive maintenance, energy optimization, and other functionalities designed to maximize solar energy generation, enhance system reliability, and ensure efficient energy management.

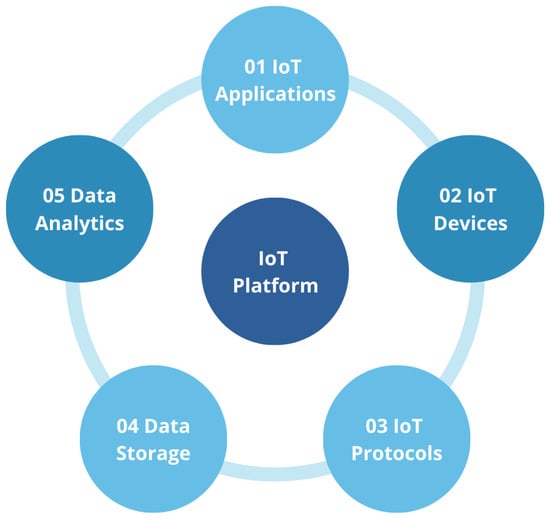

When designing IoT systems, the first step is to define the application, which refers to the use case or the problem the system will address. This is followed by selecting the appropriate components, such as sensor devices, communication protocols, data storage, and computational infrastructure. An IoT platform requires the integration of environmental sensors and suitable communication technologies to effectively achieve its objectives [32]. The components of an IoT platform are illustrated in Figure 10.

Figure 10.

Diagram describing the components of an IoT platform.

Core Technologies Enabling IoT Systems

Technologies enabling IoT systems are revolutionizing the management of photovoltaic (PV) systems by enhancing efficiency, reliability, and performance. IoT integrates advanced sensors, actuators, communication technologies, and computing methods to monitor parameters such as solar irradiance, panel temperature, and energy output in real time. These capabilities support remote monitoring, predictive maintenance, and rapid fault detection, significantly reducing operational costs and downtime. The ongoing evolution of IoT highlights its crucial role in advancing renewable energy solutions and ensuring optimal energy generation. This section delves into the core technologies that enable IoT in PV systems.

Sensors are crucial components in IoT systems, enabling real-time data collection and improving system efficiency [33]. In photovoltaic (PV) systems, sensors monitor key parameters such as solar irradiance and temperature, helping optimize performance and facilitating smart energy management for both cost and energy savings [34]. One such sensor is the temperature sensor, which plays a vital role in monitoring the temperature of PV panels and inverters. These sensors help detect overheating issues and optimize cooling mechanisms, ensuring consistent energy output. High temperatures, if not managed properly, can significantly reduce panel efficiency [33,35].

Additionally, humidity sensors are valuable in assessing environmental conditions that may impact panel performance, such as moisture accumulation, which can lead to degradation or electrical leakage [36]. Light sensors, on the other hand, are essential for tracking solar irradiance and sunlight intensity. These data help optimize panel alignment in solar tracking systems, ensuring maximum energy generation by adjusting the panels to varying light conditions [37,38].

Current and voltage sensors are integral to PV systems, as they monitor the electrical output of the panels and inverters, helping detect inefficiencies or faults in energy production. Additionally, dust and soiling sensors track the accumulation of dust and debris on PV panels, which can significantly reduce energy efficiency. By providing these data, these sensors enable the scheduling of timely cleaning to maintain optimal panel performance [39]. Furthermore, pyranometers are used to measure global solar radiation, providing essential data for evaluating system performance relative to expected energy generation.

Once the sensors collect and analyze data, the system activates actuators to perform the necessary mechanical actions, ensuring optimal operation. In PV systems, actuators play a crucial role in optimizing performance by adjusting the angles of solar panels in tracking systems, automating cleaning mechanisms, and enabling remote control of switches and inverters. This integration enhances automation, efficiency, and overall energy management [40]. Pneumatic actuators use compressed air to generate motion and are occasionally employed in PV systems, particularly in cleaning systems, where they provide quick and precise movement for panel maintenance and debris removal. In contrast, electric actuators rely on external energy sources, such as batteries, to produce linear or rotary motion. These are widely used in PV systems to adjust the tilt and orientation of solar panels in solar tracking systems, ensuring panels follow the sun’s path to maximize energy capture. Electric actuators are also integral to automated cleaning systems, helping maintain panel efficiency by removing dust and debris.

Wireless communication technologies are integral to the functionality of IoT systems, enabling seamless data transfer between sensor devices, IoT gateways, and other system components. These technologies vary based on factors such as communication range, bandwidth, and power efficiency. In PV systems, ensuring reliable communication is particularly important, especially in remote locations where solar plants are often situated. Therefore, selecting technologies that support continuous, real-time, and energy-efficient data transfer is crucial for monitoring performance, managing energy generation, and enabling remote maintenance [41]. Short-range technologies are well suited for localized monitoring and control, ensuring the efficient operation and integration of PV components within smart energy networks. Wi-Fi, for instance, is commonly used for monitoring energy production and system performance, allowing remote access and control. However, its high power consumption makes it less ideal for energy-sensitive applications like PV systems, where energy efficiency is paramount [41,42]. Bluetooth Low Energy (BLE) is a cost-effective communication technology with a range of up to 30 m, making it ideal for small-scale IoT applications in PV systems. BLE is particularly useful in energy management systems for monitoring and controlling PV systems in smart homes and offices, enabling optimized energy consumption through enhanced communication between devices [43,44]. Zigbee, designed for low-power applications with a communication range of up to 100 m (extendable through mesh networks), is widely used in PV systems. It supports smart grid integration, energy monitoring, and home automation, optimizing energy usage by enabling seamless communication between PV components such as inverters, sensors, and controllers [45,46]. Low-Power Wide Area Network (LPWAN) technologies are crucial for enabling long-range, energy-efficient communication in IoT systems. These technologies are particularly valuable for remote monitoring and management of PV systems, especially in large-scale or isolated installations. LoRa, a widely adopted LPWAN technology, offers long-range communication (over 10 km in rural areas) with low power consumption, making it ideal for smart grids and building automation. In PV systems, LoRa is used for energy management and monitoring over large distances, particularly in remote areas [47,48]. Satellite technologies play a crucial role in PV systems, especially in remote or off-grid areas where traditional communication networks are unavailable. These technologies enable seamless data transmission between PV systems and central monitoring centers, ensuring continuous performance tracking, fault detection, and maintenance planning. For large-scale solar farms or isolated installations, satellite communication provides a reliable means to monitor parameters such as energy generation, weather conditions, and system efficiency. This ensures that operators can remotely manage and optimize PV systems, reducing the need for on-site intervention and lowering operational costs [49,50]. Table 2 presents a comparison of wireless communication technologies in PV systems.

Table 2.

Comparison of wireless communication technologies in PV systems.

Wired communication protocols ensure reliable, low-latency data transfer and seamless integration in IoT systems, particularly in industrial and energy applications. PROFINET is an industrial Ethernet protocol for fast and secure data communication in automation systems [51]. In PV systems, PROFINET plays a key role in connecting components like PLCs (Programmable Logic Controllers), inverters, and sensors to allow real-time monitoring and control. It helps transfer essential data such as voltage, current, and temperature from the field to the control center, making the system more efficient. PROFINET can also link PV systems with SCADA software platforms for centralized supervision, fault detection, and performance analysis. Its high-speed and reliable communication makes it especially useful for large-scale solar setups and smart grid integration. On the other hand, Modbus protocol is essential for enabling communication between devices in automation systems, allowing data to be exchanged through regular polling. It supports interdependent control variables across different hardware, ensuring coordinated updates [52]. Modbus has a long-standing presence in industrial automation, and its TCP version is widely adopted in advanced industrial contexts such as Industry 4.0 and the Industrial Internet of Things (IIoT) [53]. In PV systems, Modbus can monitor and control various components like inverters, batteries, and environmental sensors, ensuring real-time data acquisition and effective system management. Together, Modbus and PROFINET can complement each other, with PROFINET handling high-speed communication and Modbus managing data exchange across various devices, creating an integrated and efficient system. Another well-known protocol is RS-485, also referred to as EIA-485. This protocol supports networks with up to 32 nodes. It operates on a master–slave communication model, where packets exchange data. The transmission speed can reach up to 10 Mbps over short distances (around 12 m) and up to 100 kbps for longer distances, with a maximum range of approximately 1333 m [54]. In PV systems, RS-485 is commonly used for wired communication between inverters, energy meters, and monitoring devices. Its long-distance capability and noise resistance make it ideal for transmitting data such as voltage, current, power output, and fault signals from solar inverters to a central controller or data logger. This enables real-time performance tracking, fault detection, and integration with SCADA systems in both residential and large-scale solar installations. MQTT, or Message Queuing Telemetry Transport, is a lightweight, efficient protocol widely used in IoT for communication between resource-constrained devices due to its low power consumption, scalability, and reliable message delivery. However, it faces security concerns, leading to research on vulnerabilities and defense mechanisms [55]. In PV systems, MQTT enables real-time monitoring and efficient data transfer between solar panels, inverters, batteries, and monitoring systems, helping track performance metrics like voltage and current, while facilitating remote monitoring and analysis.

IoT data analysis is important for optimizing PV systems, improving energy efficiency, and enabling timely decision-making. PV systems generate large volumes of data, which present challenges due to their high volume, speed, and variety. Traditional methods struggle with these “Big Data”, necessitating advanced computing techniques like edge computing, cloud computing, or fog computing to process and extract insights. These methods enable real-time decision-making, predictive maintenance, and optimization of energy output, especially for large-scale or remote PV installations [56,57,58]. Starting with the edge computing paradigm, widely applied, it involves processing data closer to the source of generation, which in this case is the solar panel. In PV systems, edge computing enables real-time monitoring of energy production, system performance, and environmental conditions by analyzing data locally, without relying heavily on distant cloud servers. This results in reduced latency, quicker response times for control systems, and enhanced efficiency in energy management. By decentralizing computation, edge computing improves scalability and reliability in remote PV installations, ensuring continuous operation even in areas with unreliable internet access [59]. Additionally, it strengthens security and privacy by limiting the transmission of sensitive data to the cloud, reducing vulnerability to cyber threats [60]. Cloud computing refers to delivering computing services, applications, storage, and processing over the internet. It relies on centralized hardware systems located in data centers to handle vast amounts of IoT data, providing robust computational capabilities [61,62]. It is cost-reduced since it eliminates the need for expensive hardware and software [63]; also, it offers enhanced capacity by increasing computational power and storage through multi-core architectures [64], and it enables efficient analysis of large IoT datasets from any location [65]. Additionally, cloud computing minimizes the energy required for local data processing, offering an environmentally friendly solution. Its secure infrastructure further ensures reliable data storage and management [65]. In the context of PV systems, cloud computing is used to store and analyze vast amounts of data generated by IoT devices embedded in solar panels, inverters, and other system components. This enables remote monitoring, predictive maintenance, and optimization of energy generation, ensuring the efficient operation of PV systems. Cloud platforms provide the scalability needed to manage data from large-scale solar farms or multiple PV systems, while offering high-level data-processing capabilities that enhance the overall management and performance of solar energy operations. While fog computing extends cloud computing by decentralizing data processing and moving it closer to the edge of the network, near IoT devices, this distributed paradigm addresses issues of latency and bandwidth limitations associated with centralized systems [66]. Devices such as personal computers, routers, and industrial controllers serve as fog nodes, processing data on site [67], offering faster response times and reduced network traffic compared to cloud computing [68], as well as ensuring secure processing and storage for applications requiring real-time decision-making [68]. Fog computing’s ability to deliver faster, localized, and secure services makes it an efficient complement to cloud computing, especially for IoT applications that demand quick responses. In PV systems, fog computing is used to reduce the latency involved in data processing, allowing real-time analysis of energy generation and consumption data from solar panels and other PV components. By processing data closer to the source, such as at solar inverters or energy meters, fog computing minimizes the need to send large amounts of data to the cloud, improving both the speed and efficiency of monitoring and control processes. This localized computing also helps ensure that critical decisions, such as system adjustments and fault detection, can be made with minimal delay, enhancing the overall performance and reliability of PV systems. Table 3 presents a comparison of edge, cloud, and fog computing in PV Systems.

Table 3.

Comparison of edge, cloud, and fog computing in PV systems.

3. AIoT Applications in PV Systems: A Comprehensive Review

With advancements in AI and the IoT, their applications in PV systems have become increasingly diverse and sophisticated. AI techniques enhance operational efficiency by detecting faults early, predicting maintenance needs, and improving energy forecasting. Meanwhile, IoT facilitates real-time data collection, remote monitoring, and automated control, ensuring optimal system performance.

This section explores AI-driven applications in PV systems, covering fault detection and diagnosis, predictive maintenance, and energy forecasting. Additionally, it examines IoT-based advancements, such as solar monitoring systems and optimization techniques like MPPT, solar tracking, and automated cleaning systems. These technologies collectively contribute to smarter, more efficient solar energy management.

3.1. Applications of AI in PV Systems

The integration of AI in PV systems has gained significant attention due to its potential to enhance efficiency, reliability, and predictability. This part explores the recent advancements and applications of AI techniques in PV systems, focusing on fault detection and diagnosis, predictive maintenance, and energy forecasting and optimization.

3.1.1. Fault Detection and Diagnosis

Fault detection and diagnosis are critical for maintaining the performance and reliability of PV systems. Timely detection and accurate classification of faults, such as short circuits, open circuits, and shading, are essential to minimize energy losses, prevent equipment damage, and reduce maintenance costs. Traditional fault detection methods often rely on manual inspections or simple threshold-based techniques, which may be insufficient for handling the complexity and variability of modern PV systems. Recent advancements in Artificial Intelligence have enabled the development of more sophisticated and efficient approaches for detecting and diagnosing a wide range of faults, even under dynamic and uncertain operating conditions.

Several studies have demonstrated the effectiveness of combining UAV imagery with AI algorithms for fault identification. For instance, Naveen et al. [69] developed an ensemble-based Deep Neural Network (DNN) model designed for the autonomous detection of visual faults in PV modules, such as glass breakage, burn marks, discoloration, and delamination. Utilizing an image dataset captured by an RGB camera mounted on an unmanned aerial vehicle (UAV), the process begins with image preprocessing, which involves extracting spatial and frequency domain features using methods like discrete Wavelet Transform (DWT), texture analysis, grey level co-occurrence matrix (GLCM), fast Fourier transform (FFT), and grey level difference method (GLDM). The processed images are then input into the DNN model for fault detection. Similarly, Prabhakaran et al. [70] applied a deep learning model with Region-Based Histogram Approach (RHA) preprocessing on RGB images, followed by the Grey Scale Quantization algorithm (GSQA) to refine image details, detecting panel defects such as spots, cracks, dust, and microcracks. The model was tested with different dataset sizes (500, 1000, and 2000 images), highlighting improved performance with larger datasets. Also, Singh et al. [71] employed a Support Vector Machine (SVM) with Histogram Equalization (HE) preprocessing to detect microcracks in PV cells based on the ELPV dataset. While highly accurate, the reliance on RGB images alone might miss thermal anomalies, such as hot spots, which are better captured by IR imaging.

Yin et al. [72] developed PV-YOLO, a modified YOLOX model, to detect and classify multiple faults in PV panels using drone-captured infrared (IR) images. This method demonstrates high accuracy in detecting multiple faults but may struggle under diverse environmental conditions that affect IR image quality.

Huang et al. [73] modified YOLOv5 to detect defects that pose electrical hazards in PV panels. While Ozer et al. [74] proposed a YOLOv5s model enhanced with Gaussian and Wavelet Transform preprocessing to detect panel conditions. In [75], researchers proposed a solution for automatically detecting and classifying the condition of PV panels using deep learning and UAV technology. The method combines YOLO-based deep learning models (YOLOv5, YOLOv7, and YOLOv8) with drone-captured images to classify panels as normal, dusty, or damaged. The system involves a dataset of 1100 RGB images processed with Histogram Equalization to enhance image quality before being fed into the model. Real-time testing with a Raspberry Pi 4B on a UAV demonstrated the method’s effectiveness in accurately detecting and categorizing faults in solar panels.

UAV-based methods provide high-resolution imaging and scalability, making them invaluable for large-scale solar installations. However, they face challenges such as dependency on environmental conditions, infrastructure requirements, and the need for robust preprocessing to enhance image quality. Additionally, their reliance on periodic inspections rather than continuous monitoring limits their effectiveness for real-time fault detection.

A detailed comparison of the UAV-based approaches is provided in Table 4, summarizing their methodologies, metrics, and limitations.

Table 4.

Summary of UAV-based approaches on fault detection.

While UAV-based methods excel in capturing high-resolution imagery, sensor-based approaches offer the advantage of real-time monitoring and fault detection. These techniques rely on electrical and environmental sensors to continuously monitor PV system performance.

Jiang and Maskell [76] combined Artificial Neural Networks (ANNs) with analytical models for automated fault detection and diagnosis in PV systems. Their method forecasts power output based on irradiance and temperature, comparing predicted and actual values to identify faults, offering a compact and high-accuracy solution by integrating parameters such as open-circuit voltage and short-circuit current for fault validation. Similarly, Abdallah et al. [77] proposed an intelligent solar panel monitoring system integrating ANNs and IoT platforms to detect shading and other PV faults. The ANN model estimates optimal power output using irradiance and temperature data, while discrepancies between predicted and actual output indicate performance issues. The IoT platform enables real-time visualization and fault alerting, enhancing energy efficiency and reducing maintenance costs. Benkercha and Moulahoum [78] utilized the C4.5 decision tree algorithm for fault detection and diagnosis in grid-connected photovoltaic systems (GCPVS). Their approach processes ambient temperature, irradiation, and power ratio data to identify faults such as string faults, short circuits, and line–line faults. Over a five-day testing period, the model demonstrated high detection accuracy of 99.87% and diagnostic accuracy of 99.80%, proving its robustness for real-world applications. Similarly, Harrou et al. [79] introduced a k-nearest neighbors (kNN)-based fault detection technique, integrating Shewhart and exponentially weighted moving average (EWMA) monitoring schemes. The method uses residuals from simulation models combined with parametric and nonparametric thresholds for anomaly detection. Validated on a 9.54 kWp grid-connected PV system, the kNN-based approach achieved high accuracy and robustness against noise, outperforming traditional monitoring techniques and enhancing PV system reliability.

Dust accumulation is a common issue impacting PV efficiency. Hossain et al. [80] addressed the impact of dust on PV systems by developing an ML-based dust detection method and an automated cleaning system. The study implemented various ML classifiers, with the ANN model achieving the highest accuracy of 98.11%. Upon detecting dust, the system activates a water sprinkler to clean the panels, restoring efficiency to 14.87%. In a related effort, Mekki et al. [81] proposed an Artificial Neural Network-Based Model (ANNBM) to estimate power loss due to partial shading. The system uses a Multilayer Perceptron (MLP) to detect deviations between predicted and actual outputs, providing a computationally efficient alternative to complex mathematical models. Syafaruddin et al. [82] designed a three-layer ANN model targeting short-circuit fault localization in PV modules. While highly effective in identifying faulty modules, the system requires extensive data training for scalability across large PV installations. In the realm of arc fault detection, Lu et al. [83] introduced a novel DL-based methodology, DA-DCGAN (Domain Adaptation and Deep Convolutional Generative Adversarial Network). This technique generates synthetic arcing data from normal PV loop current data using a DCGAN and applies domain adaptation to train a lightweight CNN classifier for accurate cross-domain fault diagnosis. The approach was validated through real-time experiments on a 1.5 kW grid-connected PV system and pre-recorded data, achieving high detection accuracy. The DA-DCGAN eliminates reliance on real fault datasets, making it highly practical for real-world applications where labeled fault data are scarce.

Additional research has focused on improving fault classification accuracy. Chao et al. [84] developed a modified neural network model for fault diagnosis, integrating extension theory to improve learning efficiency and reduce memory consumption. The model achieved high accuracy in identifying 10 types of PV faults, outperforming traditional MLP networks. Similarly, Akram and Lotfifard [85] employed a Probabilistic Neural Network (PNN) for detecting, classifying, and locating faults in PV arrays. The method leverages environmental and electrical data to enhance fault detection accuracy. Based on manufacturer datasheet information, a novel PV system modeling technique was introduced to validate the approach. Building on the idea of Decision Tree algorithms, Zhao et al. [86] developed a Decision Tree (DT) model for fault detection and classification trained on 764,529 PV instances under 28 fault conditions, achieving high accuracy in both fault detection (up to 99.98%) and classification (up to 99.8%) and integrating into a microcontroller-based system for real-time monitoring. In parallel, Chen et al. [87] implemented a Random Forest (RF)-based fault detection model, analyzing array voltage and string currents without requiring environmental condition inputs such as irradiance or temperature to identify various PV faults, including line–line faults, degradation, open circuits, and partial shading. Their RF system, tested in MATLAB and real PV setups, achieved 99.994% detection accuracy and 99.952% classification accuracy but depended on large labeled datasets for training. Madeti and Singh [88] employed a kNN-based fault detection and classification technique, focusing on real-time monitoring of faults like open circuit, line–line faults, and partial shading scenarios. The method, validated on experimental I-V characteristic data under varying irradiance and temperature conditions, achieved a high classification accuracy of 98.70%. Also, Zhao et al. [89] proposed a PV array fault diagnosis method combining Fuzzy C-Mean (FCM) clustering and fuzzy membership algorithms to improve accuracy and robustness in fault classification. The method clusters fault sample data into six fault types, such as short circuits and shading, using FCM and calculates membership degrees for fault diagnosis based on fuzzy normal distribution. The approach achieved 96% diagnostic accuracy in simulations and experiments, demonstrating scalability to new fault types and adaptability to transient conditions. This method is computationally efficient, independent of labeled datasets, and suitable for integration into SCADA (Supervisory Control and Data Acquisition) systems for real-time monitoring in complex environments. Lu et al. [90] introduced a fault diagnosis method leveraging CNNs and Electrical Time Series Graphs (ETSGs). Their approach converts sequential voltage and current data into 2D ETSGs, allowing the CNN architecture to automatically extract features. The model achieved over 99% accuracy in diagnosing open-circuit and line–line faults in experimental case studies. To address the challenges of manual feature extraction, Appiah et al. [91] presented a novel fault diagnosis technique using LSTM networks to automatically extract features from raw data for fault classification. The LSTM model outperformed traditional methods such as SVMs, ANNs, and PNNs, achieving high diagnostic accuracy even with noisy data, thereby eliminating the need for manual feature extraction. Similarly, Chen et al. [92] proposed a deep residual network (ResNet)-based fault detection and diagnosis model that addresses the limitations of manual feature extraction. By utilizing raw I-V curves, irradiance, and temperature data, the ResNet model demonstrated superior accuracy, reliability, and training efficiency compared to CNNs and other techniques, proving effective across simulated and real-world datasets.

Several studies focused on addressing uncertainties in PV systems. Cheng et al. [93] introduced a data fusion approach using fuzzy mathematics and evidence theory, which consolidates differences between measured and predicted values to improve fault localization in large-scale PV systems. Bonsignore et al. [94] employed a Neuro-Fuzzy approach for PV module parameter estimation under different conditions. Their AI-based diagnostic system accurately differentiates between normal and faulty operations, even in noisy environments. Additionally, Hempelmann et al. [95] evaluated unsupervised anomaly detection models for identifying rare faults in PV systems. Their study compared multiple models, with VAE achieving the highest detection rate of 92.06%, demonstrating the potential of unsupervised learning for real-time monitoring in environments with limited labeled data.

While much attention has been given to fault detection in PV modules and arrays, recent works have also explored fault diagnosis in the associated power conversion systems, which are crucial to ensure stable energy transfer and grid integration. In this regard, Kou et al. [96] proposed a novel fault diagnosis method combining feature transformation and Random Forests to identify open-circuit faults in IGBT switches within a three-phase PWM rectifier. Their approach leverages current trajectory slopes as features to enhance classification performance across varying load conditions, achieving high accuracy in localizing switch faults. Veerasamy et al. [97] developed an LSTM-based fault detection method for identifying High Impedance Faults (HIFs) using Wavelet-Transformed current features to enhance diagnostic accuracy in solar-integrated grids. Validated on a PV-integrated IEEE 13-bus system, the model achieved over 91% accuracy, outperforming other classifiers and confirming the efficacy of deep learning in grid fault classification. In addition, Li et al. [98] introduced a hybrid-driven approach based on model data to detect open switch faults in converters. By fusing model-based analysis with ANN learning, their method offers near-instantaneous fault diagnosis under dynamic conditions, achieving high robustness and low computational burden.

Although sensor-based approaches offer significant advantages, challenges such as computational efficiency, data requirements, and scalability remain areas for future research. Integrating lightweight AI models and hybrid techniques could further enhance the effectiveness of sensor-based fault detection in large-scale PV systems.

Table 5 provides a comparative analysis of these studies, summarizing their techniques, metrics, strengths, and limitations.

Table 5.

Summary of sensor-based approaches on fault detection.

This analysis explores different strategies for PV system fault detection and diagnosis, focusing on both UAV-based and sensor-based approaches. UAV-based methods excel in capturing high-resolution imagery and are effective for visual fault detection, but they face challenges such as environmental dependency and limited real-time monitoring capabilities. On the other hand, sensor-based methods provide the advantage of continuous monitoring and real-time fault detection. However, these methods also present computational efficiency, data dependency, and scalability challenges. A horizontal comparison of these approaches reveals that while UAV-based methods are advantageous for large-scale solar installations with their ability to cover extensive areas quickly, sensor-based methods may offer better performance in fault detection with a continuous monitoring system. The choice between these approaches depends on specific application scenarios, such as the scale of the PV system, the importance of real-time monitoring, and the type of faults being targeted.

3.1.2. Predictive Maintenance

Predictive maintenance is a proactive approach that leverages advanced techniques to anticipate equipment failures before they occur, ensuring timely interventions to maintain system efficiency and reliability. In the context of PV systems, predictive maintenance plays a critical role in minimizing system downtime, reducing operational costs, and improving energy output. By analyzing environmental and performance data, AI-based methods, such as ANNs and other statistical models, are capable of forecasting maintenance needs, identifying degradation trends, and detecting anomalies that might lead to potential faults. These approaches represent a significant advancement over traditional reactive or preventive maintenance strategies.

Several studies have demonstrated the application of predictive maintenance techniques in PV systems, showcasing their potential to improve system reliability and optimize maintenance planning.

Riley and Johnson [99] developed a Prognostics and Health Management (PHM) system leveraging ANNs to predict power output based on environmental inputs such as irradiance, wind, and temperature. The PHM system monitors system health, identifying faults like soiling, degradation, and inverter failures by detecting performance deviations. This approach allows proactive maintenance scheduling and tracks system degradation over time, ensuring long-term reliability and preventing catastrophic failures. De Benedetti et al. [100] proposed an advanced anomaly detection approach combining ANNs and Triangular Moving Average (TMA) analysis to identify long-term degradation trends. Their model compares predicted AC power output, derived from solar irradiance and temperature data, with real-time measurements to detect deviations, issuing alerts that enable maintenance to be scheduled weeks in advance. This method achieved over 90% accuracy in anomaly detection and demonstrated significant potential for reducing power losses and preventing failures. Additionally, Samara et al. [101] introduced a low-cost intelligent monitoring system that employs a compact ANN to predict the standard operational activity of PV panels based on environmental conditions. By comparing predicted performance with actual output, the system detects anomalies that indicate the need for maintenance and automatically notifies administrators or maintenance teams via internet-based alerts. However, the system lacks functionality for isolating or removing malfunctioning panels.

Extending these efforts, Huuhtanen and Jung [102] applied CNNs to predictive maintenance by analyzing power output curves of panels. Their method predicted the daily power curve of a target panel using neighboring panels’ power curves, flagging large deviations as indicators of malfunction. By addressing challenges like dynamic weather variations and regular shadowing, the unshared convolutional model demonstrated superior performance, showcasing the potential of CNNs for accurate anomaly detection in PV systems. Betti et al. [103] further advanced predictive maintenance strategies by introducing a big data-driven framework for PV plants. Their dual-model architecture combined a Supervision-Diagnosis Model (SDM), which employed Self-Organizing Maps (SOMs) for detecting operational deviations, and a Short-Term Fault Prediction Model (FPM), which utilized a Pattern Recognition Neural Network (ANN) to forecast specific fault classes. Tested on six PV plants, the system demonstrated the ability to predict faults up to 7 days in advance with high sensitivity and specificity, enhancing reliability and reducing downtime.

To address the scalability challenges of large PV plants, Zulfauzi et al. [104] proposed a hybrid ML approach integrating K-Means clustering and LSTM networks. The K-Means algorithm clustered operational patterns based on meteorological data, while LSTM accurately predicted deviations in electrical currents for precise anomaly detection. This hybrid approach demonstrated superior performance over conventional ANN models, offering a scalable and cost-effective solution for predictive maintenance in large-scale PV systems. Similarly, Marangis et al. [105] developed a data-driven routine combining XGBoost, One-Class SVM, and the Facebook Prophet algorithm. Their methodology analyzed performance trends to generate predictive maintenance alerts up to 7 days in advance. Validated on a 1.8 MW PV power plant, the system achieved a sensitivity of 92.9% and a predictive accuracy of 99.4%, demonstrating its robustness in detecting underperformance conditions such as inverter shutdowns and string disconnections.

Table 6 provides a comparative overview of these studies, highlighting their methodologies, data requirements, fault types addressed, key contributions, and limitations.

Table 6.

Comparative table for predictive maintenance in PV systems.

The reviewed predictive maintenance approaches for PV systems highlight a shift toward AI-driven fault detection and performance optimization strategies. These methods, ranging from ANN-based models for anomaly detection to advanced hybrid models incorporating deep learning and ensemble techniques, show promising results in identifying faults before failures occur. However, the reliance on specific datasets and system configurations limits their generalizability. Future research should focus on developing adaptable models capable of handling diverse environmental conditions and PV setups while integrating robust fault isolation mechanisms. The trade-off between model complexity and predictive accuracy requires consideration of data dependencies, scalability, and computational resources. Hybrid models and scalable architectures offer potential solutions for improving the applicability and efficiency of predictive maintenance in PV systems.

3.1.3. Energy Forecasting and Optimization

Accurately forecasting solar energy production and optimizing energy management are vital for enhancing the efficiency and reliability of PV systems. Researchers have explored diverse methodologies to address these challenges, leveraging advanced machine learning techniques, hybrid models, and optimization frameworks. A wide range of studies has focused on improving forecasting accuracy, handling weather variability, optimizing energy dispatch, and managing uncertainties, with approaches varying across different forecasting horizons.

Early efforts to improve forecasting accuracy include the work of Huang et al. [106], who compared physical models and neural network (NN)-based statistical models for day-ahead PV power forecasting. Their study demonstrated the superior performance of NN models, achieving a normalized Root Mean Square Error (nRMSE) of 10.5%, compared to 12.45% for physical models. Similarly, Paoli et al. [107] employed ANNs with time series preprocessing to predict day-ahead solar irradiation, reducing forecasting errors by 5–6% compared to traditional methods such as ARIMA. For short-term predictions, Dahmani et al. [108] focused on a 5 min forecasting model for tilted surfaces, achieving high accuracy with an nRMSE of 8.81%. These studies highlighted the importance of high-quality input data and preprocessing techniques for achieving reliable predictions. Brofferio et al. [109] contributed to improving forecasting accuracy by introducing a hybrid Estimation Model (EM) using Adaptive Resonance Theory (ART) neural networks. This model refined power predictions from single-diode models, enhancing accuracy for nonlinear system behavior. Saberian et al. [110] compared General Regression Neural Networks (GRNNs) and Feedforward Backpropagation Neural Networks (FFBP) for solar power forecasting, finding FFBP to outperform GRNNs in terms of accuracy when predicting power output from temperature and irradiance data. Building on these foundational works, Pedro and Coimbra [111] introduced a short-term solar irradiance forecasting framework using optimized kNN and ANN models. Their approach incorporated feature extraction techniques to improve forecasting for time horizons ranging from 15 min to 2 h. Ramsami and Oree [112] proposed a hybrid method for forecasting the 24 h ahead energy output of PV systems based on daily weather forecasts. Their approach integrates stepwise regression to identify the most significant meteorological variables, which are then used as inputs for three single-stage models: GRNN, feedforward neural network (FFNN), and multiple linear regression (MLR). The hybrid models demonstrated superior performance compared to their single-stage counterparts, with the stepwise regression–feedforward neural network (SR-FFNN) model achieving the best results. In contrast, Bouquet et al. [113] applied LSTM models to forecast PV power output across multiple time horizons, ranging from 15 min to several days, improving grid stability and reducing dependency on non-renewable energy.

Weather variability remains a significant challenge in solar energy forecasting. Sivaneasan et al. [114] tackled this issue by integrating fuzzy logic preprocessing with ANN models to classify weather changes and introduced an error correction mechanism for 5 min short-term forecasts. Wang et al. [115] further addressed weather-related challenges by combining GANs with CNNs to augment weather datasets and improve day-ahead predictions. Similarly, Lu and Chang [116] proposed a hybrid Radial Basis Function Neural Network (RBFNN) and Grey Theory model for day-ahead forecasts, enhancing forecasting precision by improving data regularity. Ling et al. [117] advanced this area by introducing HCISEM-GAN, a real-time solar energy management system that combines GANs with Human–Computer Interaction to achieve a 20% improvement in prediction accuracy.

In the context of energy dispatch and load management, Wen et al. [118] proposed a DRNN-LSTM model for forecasting residential load and PV output in microgrids. This model enabled optimal energy dispatch by integrating PV forecasts with energy storage systems (ESS) and electric vehicles (EVs), reducing peak loads and operational costs by 8.97%. Similarly, VanDeventer et al. [119] utilized a Genetic algorithm–Support Vector Machine (GASVM) framework to optimize short-term PV power predictions, achieving significant reductions in RMSE and MAPE errors.

Efforts to enhance solar panel performance have also contributed to the field. Shirbhate and Barve [120] developed a Hidden Markov Model (HMM)-based approach for predicting solar energy generation using time series meteorological data. Their system optimized smart solar system performance by capturing the probabilistic correlation between past and future values, closely replicating actual power output. Sujatha et al. [121] employed ANN models to estimate azimuth angles for solar tracking, optimizing panel orientation under various weather conditions. Additionally, Tharakan et al. [122] developed a dual-axis solar tracker based on the Naive Bayes algorithm to predict optimal panel orientation, significantly increasing energy harvesting efficiency.

Addressing uncertainties in PV energy forecasting has been another area of focus. Sharifzadeh et al. [123] conducted a comparative analysis of ANNs, Support Vector Regression (SVR), and Gaussian Process Regression (GPR), finding ANNs to be the most accurate model despite challenges in parameter optimization. Galván et al. [124] proposed a multi-objective approach using neural networks combined with Multi-Objective Particle Swarm Optimization (MOPSO) to optimize prediction intervals, minimizing interval width while maximizing coverage probability. This method provided a reliable balance between prediction accuracy and uncertainty reduction, though it faced computational challenges due to the evolutionary optimization process. Al-Omary et al. [125] further improved ANN-based forecasting by optimizing input features and network structure, achieving prediction errors below 2%. Kaur et al. [126] proposed a VAE-Bayesian BiLSTM framework to quantify uncertainties and enhance reliability, demonstrating its potential for managing variability in energy predictions.

Table 7 provides a comparative overview of these studies, highlighting their methodologies, forecasting horizons, data requirements, key contributions, and limitations.

Table 7.

Comparative analysis of related works in energy forecasting and optimization.

These studies collectively highlight significant advancements in PV energy forecasting, focusing on improving accuracy, optimizing energy dispatch, and managing uncertainties. Integrating advanced AI techniques and hybrid models has enhanced the ability to handle weather-induced variability, temporal dependencies, and energy storage optimization. Short-term forecasting, in particular, benefits from neural networks and hybrid architectures such as LSTM, GANs, and ART-based models, which outperform traditional statistical methods. Long-term and day-ahead predictions are strengthened through model ensembles and feature selection techniques, improving robustness and generalizability. Despite these advancements, challenges such as computational complexity, reliance on high-quality data, and scalability persist. Energy dispatch optimization increasingly integrates forecasting with storage and demand-side elements (e.g., ESS, EVs), illustrating a shift toward more comprehensive energy management systems. However, practical constraints remain, especially for real-time applications.

3.2. Applications of IoT in PV Systems

With the growing adoption of solar energy as a key renewable resource, the need for smarter, more efficient PV systems has become paramount. IoT technologies have paved the way for innovative solutions tailored to the unique challenges faced by PV systems, such as real-time monitoring, maintenance optimization, energy management, solar tracking, and fault detection. This section delves into specific applications of IoT in PV systems, showcasing how these technologies are driving advancements in automation, performance optimization, and system reliability.

3.2.1. Solar Monitoring Systems

Solar monitoring systems track real-time data from PV systems, such as solar irradiance, temperature, and power output, to optimize performance. By identifying issues and predicting maintenance needs, these systems ensure efficient and reliable solar energy production. IoT integration enables remote monitoring and proactive maintenance.