Abstract

Traditional soil stabilization methods are usually associated with high energy consumption, carbon emissions, and long-term environmental impact. Recent developments have shown the potential use of bio-based techniques as eco-friendly alternatives for soil stabilization. The present work studies the effects of the addition of the biopolymers xanthan gum (XG) or carboxymethyl cellulose (CMC) to a mine residue soil, combined or not with biostimulation and bioaugmentation techniques, in terms of compressive stress–strain behavior. Unconfined compressive strength (UCS) tests were performed on previously disturbed samples (two cycles of percolation, extraction and homogenization) to evaluate if the biostimulation and bioremediation remain active in a real adverse scenario. The results allowed for us to conclude that both biopolymers, when applied individually (with a content of 1%), are effective stabilizers (CMC allows for unconfined compressive strength increases of up to 109%), showing better results for CMC than Portland cement. The biostimulation of the autochthonous community of the mine residue soil was revealed to be a non-effective technique, even when combined with the biopolymers. However, good results were observed when the bioaugmentation was combined with xanthan gum, with unconfined compressive strength improvements of up to 27%. The study revealed that these bio-based techniques are promising soil engineering techniques, offering environmentally friendly alternatives for sustainable soil stabilization and contributing to a greener and more sustainable future.

1. Introduction

The global population growth has presented significant socio-economic challenges, particularly in terms of resource consumption and infrastructure development. The exponential increase in population has led to an excessive need for natural resources, resulting in the large-scale production of mining waste and associated environmental liabilities and safety risks (e.g., contaminant leaching, acid mine waters, and the collapse of tailing dams). Additionally, the expansion of societies has required the construction of extensive infrastructures, often in areas characterized by soils with poor mechanical properties (low bearing capacity, high compressibility, or poor drainage characteristics) [1,2]. Both situations pose substantial engineering challenges that may be solved by ground improvement techniques.

Ground improvement is a crucial aspect of geotechnical engineering, aimed at improving the mechanical properties and durability of soils [3,4]. There is a wide range of ground improvement techniques for multiple applications. Within ground improvement techniques, soil stabilization has emerged as one of the most versatile and promising techniques, being applied all over the world [1,5,6]. Traditional soil stabilization methods often rely on chemical binders, which have demonstrated significant advantages but also pose environmental concerns. These binders, such as cement and lime, have proven effective in enhancing soil strength, reducing permeability, and mitigating environmental hazards [7]. However, the use of these binders raises concerns due to their high energy consumption, carbon emissions, and long-term environmental impact [4,8,9,10]. To address these challenges, researchers have turned their attention to sustainable alternatives for soil stabilization. Indeed, recent developments in the field have explored the use of biopolymers and bioremediation techniques as eco-friendly alternatives to soil stabilization. Biopolymers, derived from natural sources, offer promising advantages in terms of their sustainability, biodegradability, and low environmental impact. Bio-techniques, such as biostimulation and bioaugmentation, utilize microbial activity to enhance soil properties and/or remediate contaminants.

Biopolymers, such as xanthan gum, guar gum, carboxymethyl cellulose, and chitosan, have gained attention in geotechnical engineering due to their unique properties and environmental compatibility. These biopolymers, derived from natural sources, exhibit an ability to improve soil strength, reduce permeability, and control erosion [4,11]. It is important to note that biopolymers differ in terms of their origins and specific characteristics [12]. The choice of biopolymer for soil stabilization depends, among others, on the type of soil and its compatibility with the biopolymer, biopolymer content, curing time, thermal treatment, and mixing methods [13]. The identification and efficient design of biopolymers for stabilized soil systems rely on the Armistead et al. [8] methodology: (1) a rapid membrane-enabled bio-mineral affinity screening approach, (2) supported by mineral binding characterization and complemented by geotechnical verification. Another aspect that should also be considered is the price of biopolymers, which can vary depending on factors such as production scale, purity, and market demand.

Here, some results are highlighted for two of the most widely used biopolymers in soil stabilization, xanthan gum and carboxymethyl cellulose, due to their potential suitability to stabilize acid mine residue soils [8].

Xanthan gum (XG) is an anionic polysaccharide biopolymer produced by the bacterium Xanthomonas campestris [9,14]. It is commonly used in various industries, including geotechnical engineering, where it is applied in contents ranging from 0.5 to 5% of the soil weight. XG forms a highly viscous gel when hydrated, coating soil particles and creating bonds between soil particles, namely clay particles, via electrostatic (ionic and hydrogen) interactions [4,9,12], promoting an increase in the shear strength and stiffness of the bio-stabilized soil [8,9,11,13], increasing the optimum water content and the plasticity characteristics (mainly the liquid limit) [13,15], reducing permeability [16], and enhancing erosion resistance [4,17]. The high molecular weight and long-chain structure of XG contribute to its effectiveness in soil stabilization. Regarding the mine residue soils, a very limited number of studies have been published on the subject. Studies from Chen et al. [17] and Bonal et al. [18] indicated that the addition of XG effectively reduced mine tailings/residue erosion. Nevertheless, it is not clear what effect the addition of XG to a mine residue soil has in terms of unconfined compressive strength and stiffness.

Carboxymethyl cellulose (CMC) is a biopolymer derived from cellulose, a major component of plant cell walls, and on wooden barks of trees [3]. CMC is widely used in various industries [19] due to its high water-retaining capacity, adhesion, ability to change the viscosity of the system [7], and film-forming properties. In soil stabilization, CMC acts as a binder and a water-retaining agent, filling the voids between soil particles and forming a cohesive matrix. These features result in reduced soil permeability and water infiltration rate [3,7,20], increased optimum water content and decreased maximum dry unit weight [10], and increased cohesion between particles, and therefore the strength and stiffness of the bio-stabilized soil [3,19,20,21], which promotes vegetation growth and increases soil erosion resistance [20], contributing to the enhancement of soil properties [20]. Regarding the effect of CMC in contaminated soils, a field assessment of CMC-bridged chlorapatite microparticles was performed by Li and co-authors [22], who demonstrated the effectiveness, long-term stability, and mechanism of CMC in reducing the mobility of lead in contaminated soil, with the best results achieved at a CMC content of 0.5%. The effect of CMC on mine residue soils has not yet been studied, and its effect in terms of unconfined compressive strength and stiffness is unknown.

Bioremediation techniques offer another avenue for soil stabilization by harnessing the power of microbial activity to enhance soil properties and/or degrade contaminants. Biostimulation involves stimulating the native microbial population in soils by providing suitable growth conditions, such as nutrients or oxygen. This stimulation enhances microbial activity, leading to the degradation or transformation of contaminants or improvements in soil properties. Mendonça et al. [16] demonstrated a reduction in soil permeability using bacteria-produced biopolymers through biostimulation. On the other hand, bioaugmentation involves the introduction of specific microorganisms or microbial communities into the soil to remediate contaminants or improve soil properties. These microorganisms can degrade pollutants or transform them into less harmful substances, or induce the calcium carbonate precipitation that binds soil particles [4]. Su et al. [23] explored the combined application of CMC-stabilized nanosized Fe0 and mixed anaerobic microorganisms for the enhanced stabilization of chromium (VI) in soil. The authors observed that CMC enhanced the dispersion of nanosized Fe0 and at the same time promoted the activity of microorganisms.

Despite the research to date, there are still gaps in the knowledge regarding the application of these bio-techniques (biopolymers and bioremediation) to mine residue soils. In addition, the combined application of these two bio-techniques is a subject that has been less discussed but can bring technical benefits and therefore deserves to be studied. Thus, the novelty of the present work is to add to the existing knowledge about the compressive stress–strain behavior of a mine residue soil stabilized with a combination of two promising bio-techniques (biopolymers and bioremediation), contributing to a greener and more sustainable future.

The present work studies the impact of two bio-techniques on the compressive strength behavior of mine residue soil. The effects of the addition of the biopolymers XG or CMC to the soil, combined or not with the biostimulation and bioaugmentation techniques, will be studied in terms of compressive stress–strain behavior. To achieve such goals, the following experimental testing program was designed: (i) unconfined compressive strength (UCS) tests performed with the mine residue soil samples stabilized with the biopolymers applied in a content of 1%; (ii) UCS tests performed with the mine residue soil samples biostimulated (BS) or bioaugmentated (BA), combined or not with the addition of the two biopolymers. In both cases, the results are compared with the control (soil without biopolymer) and the addition of Portland cement (content of 1%).

2. Materials and Methods

2.1. Materials

The soil selected for this study came from a tungsten mine (Panasqueira mine, Fundão, Portugal), collected at Basin 1, as described in previous work [24], and stored at 4 °C until sample preparation. The soil is characterized by a grain size composition of sand, silt and clay content of 61.6%, 35.7%, and 2.7%, respectively (evaluated by the wet sieving method [25]), a porosity of 52.4% and a water content of 19% [25]. Table 1 summarizes the main metals identified in the soil, revealing toxicity. The mine residue soil microbiome contains different strains of bacteria (heterotrophic and facultative anaerobic); the most common are Acinetobacter, Bacillus, Pseudomonas, Streptococcus, Cellulomonas and Rothia [24].

Table 1.

Main metals identified in the Panasqueira mine soil, Basin 1—results from XRF test (performed at Trace Analysis and Imaging Laboratory, University of Coimbra).

The soil was stabilized with one of the following three stabilizers: biopolymer xanthan gum (Sigma-Aldrich, St. Louis, MO, USA), biopolymer sodium carboxymethyl cellulose (Sigma-Aldrich), and Portland cement type I 42.5 R (Cimpor, Coimbra, Portugal). Considering the biopolymer contents usually used in soil stabilization, as presented in the introduction, all stabilizers were added to the mine residue soil in a content of 1% of the dry unit weight of the soil.

The biostimulation of the native bacteria from the mine residue soil was performed with Reasoner’s 2A broth (R2Ab) 10-fold diluted (culture media), which percolated through the samples in 2 cycles of 7 days each. For the bioaugmentation tests, the strain Diaphorobacter polyhydroxybutyrativorans B2A2W2 [26] was selected, which was grown in R2Ab medium for 48 h at 25 °C and 140 rpm. After centrifuging and washing steps, a bacterial suspension with an OD600 of approximately 1 was obtained and stored on ice until its use in the bioaugmentation tests.

2.2. Testing Program and Sample Preparation

Table 2 summarizes the experimental testing program.

Table 2.

Experimental testing program.

The laboratory testing program started with the homogenization of the mine residue soil. After air-drying the soil, a Proctor test [27] was performed to evaluate the optimum water content (19.5%) to be added to the soil to achieve the “best” compaction conditions. The wet mine residue soil sample was introduced in a PVC mold (76 mm height, 37 mm diameter) in three layers. For each layer, the sample was statically compacted with a steel bar 20 times; the surface of the first and second layers was scarified before the introduction of the next layer; the top surface was smoothed with a spatula. The samples were cured for seven days in a room with temperature (20 ± 2 °C) and humidity (95 ± 5%), which served as the control.

For the samples stabilized with biopolymer (XG or CMC) or Portland cement, the dry mass of each stabilizer was mixed with the wet mine residue soil and then introduced into the PVC mold following the previously described procedure.

For the bioaugmentated samples, a bacterial B2A2W2 suspension of approximately 5.0 × 107 cells per gram of the dry mine residue soil was added to the top layer, following the remaining part of the procedure described above.

For the BS and BA samples, the testing procedure can be summarized in the following steps: (i) mix all the materials and introduce the samples to the PVC mold, as described above; (ii) percolate the culture media R2Ab through the samples for 7 days; (iii) extract the sample from the PVC mold to undergo homogenization, followed by the re-introduction of the samples to the PVC mold, as described previously, and curing for 7 days; (iv) repeat steps (ii) and (iii). The extraction and homogenization steps, followed by the re-introduction of the sample to the PVC mold, aim to evaluate if the tested bio-based techniques remain active in a real adverse scenario where the sample has been disturbed.

The percolation system is a constant head permeability test with the modifications proposed in [28]. The tests were performed under a constant head of 5 kPa.

Finally, the samples were extracted from the PVC mold and weighted, and UCS tests were performed to assess the stress–strain compressive behavior. The UCS test was carried out in a universal testing machine (Wykeham Farrance Tristar 5000 kg) under a constant axial strain rate of 1%/min, as stated in the standard [29]. The maximum uniaxial compressive strength (qu max) of the samples is a fundamental design parameter obtained from the stress–strain curve [30], as well as the strain at failure (εf) and the undrained Young’s modulus, defined for 50% of qu max (Eu 50).

3. Results

Table 3 summarizes the results from the UCS tests that were performed, namely, the parameters obtained from the stress–strain curves (qu max, εf and Eu 50) that allow for a characterization of the compressive behavior in terms of strength and stiffness. In general, the variability of the unconfined compressive strength results is less than ±15% of the average value [31], with some discrepancies explained by the experimental nature of the study. In the following figures, only the stress–strain curve of one of the two UCS tests is presented for clarity in the discussion of the results.

Table 3.

UCS results.

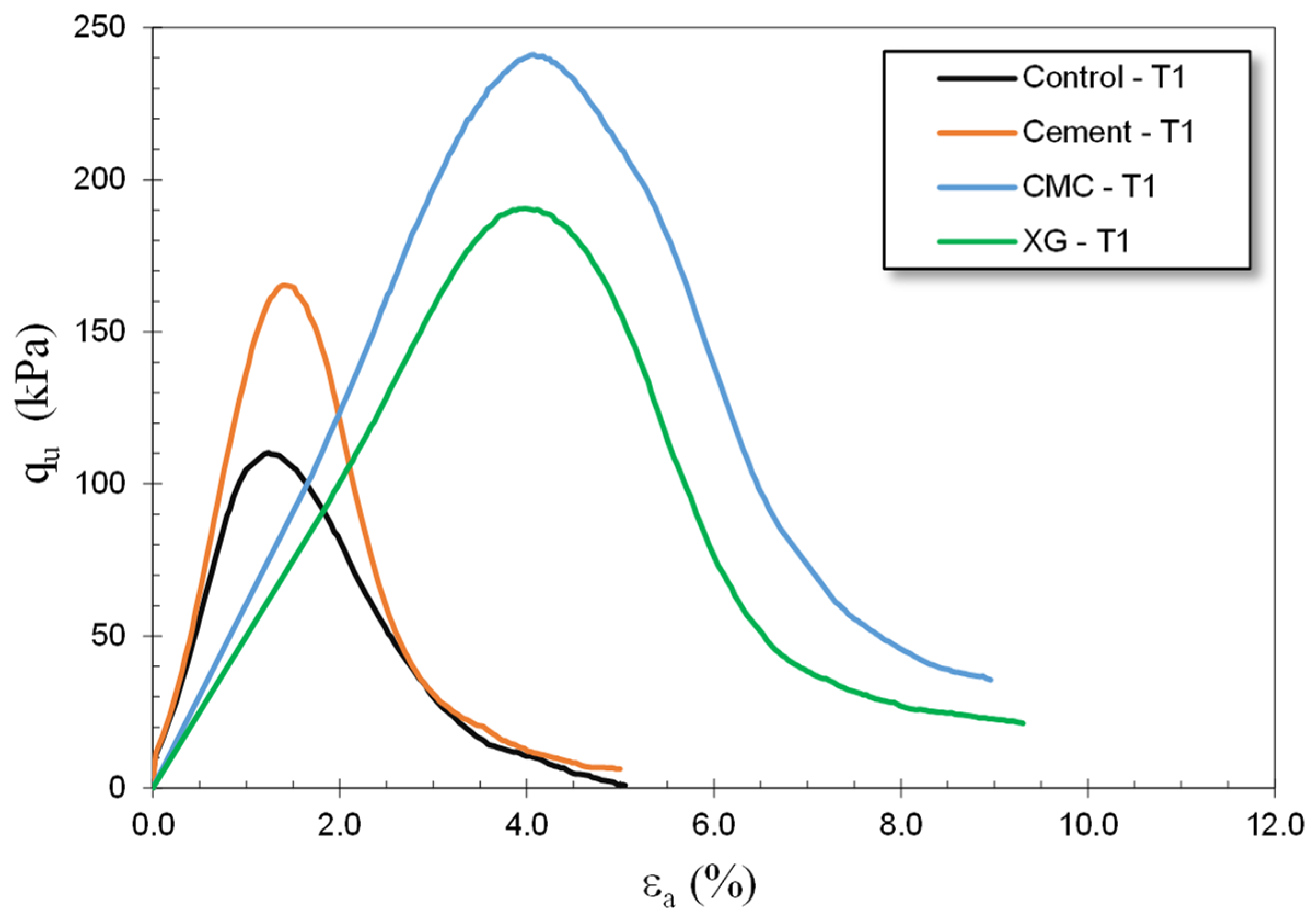

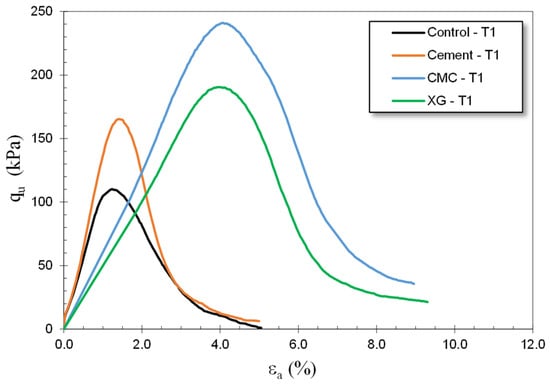

3.1. Effect of the Stabilizers Applied Individually

From Figure 1 and Table 3, the addition of the applied individually stabilizers is shown to have a tremendous impact on the stress–strain compressive behavior of the mine residue soil. The addition of Portland cement (the most common binder used in soil stabilization) enhanced the maximum unconfined compressive strength significantly, whereas stiffness was enhanced only slightly. However, the addition of any of the biopolymers (XG or CMC) promoted significant changes in the stress–strain behavior, increasing the compressive strength and the strain at failure. Comparing both biopolymers, the CMC exhibits a better performance than XG, which may be explained by the higher viscosity induced by the CMC [14], conferring a higher adhesion/cohesion between particles. Indeed, in the case of CMC, the strength more than doubled the control value and is above the cement value, while for the case of XG, the results can be compared with the samples stabilized with cement, in agreement with the findings of Armistead et al. [8]. These results clearly show the good performance of both biopolymers, and their ability to be used as stabilizers in mine residue soils. The stress–strain curves also showed that the samples stabilized with biopolymers exhibit a more ductile behavior, characterized by a higher strain at failure. This means that the bio-stabilized material can deform as the compressive strength is mobilized, avoiding catastrophic failure without previous warning.

Figure 1.

UCS results—effect of the stabilizers applied individually (CMC = carboxymethyl cellulose; XG = xanthan gum).

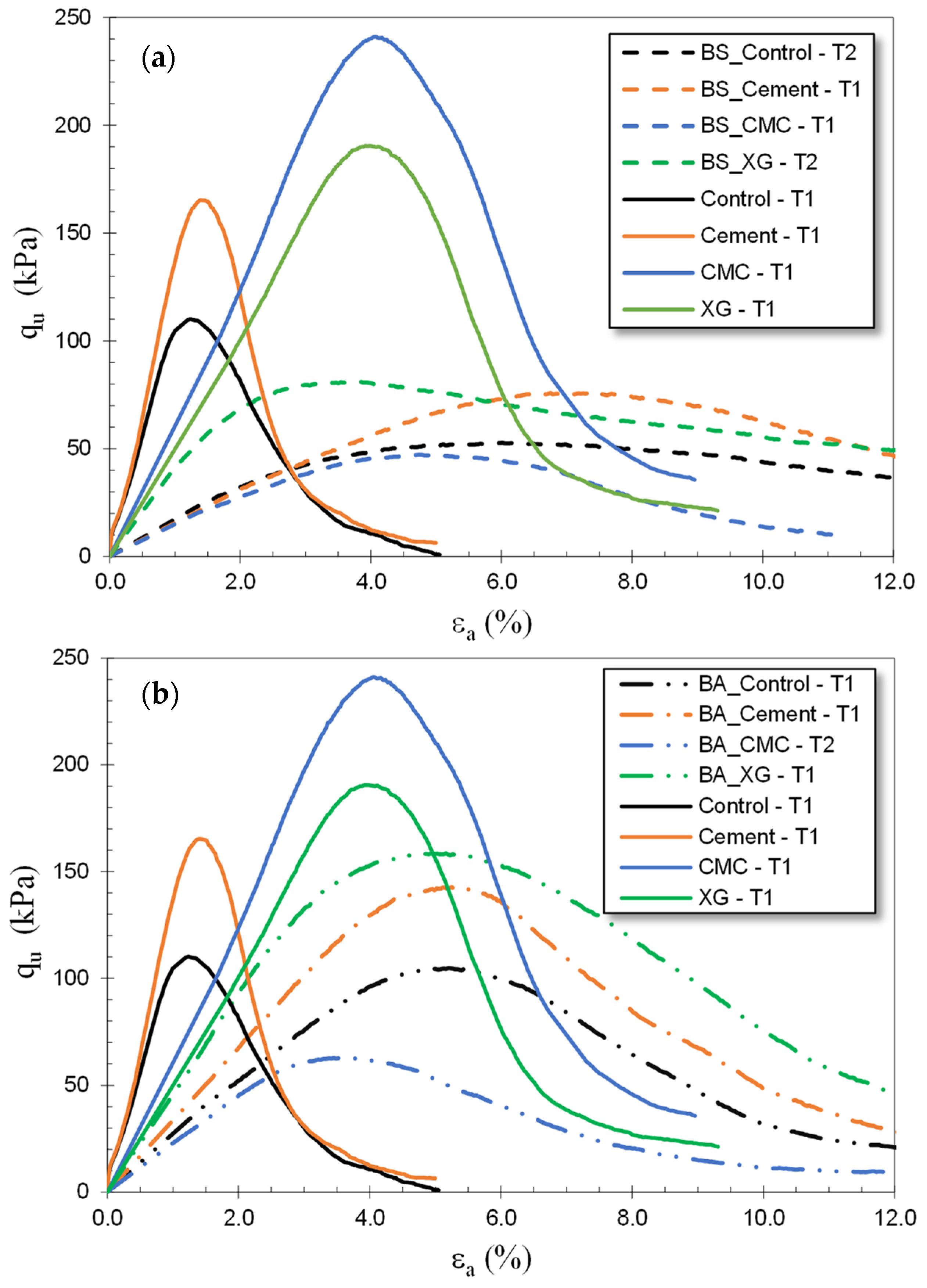

3.2. Effect of the Biostimulation and Bioaugmentation Techniques

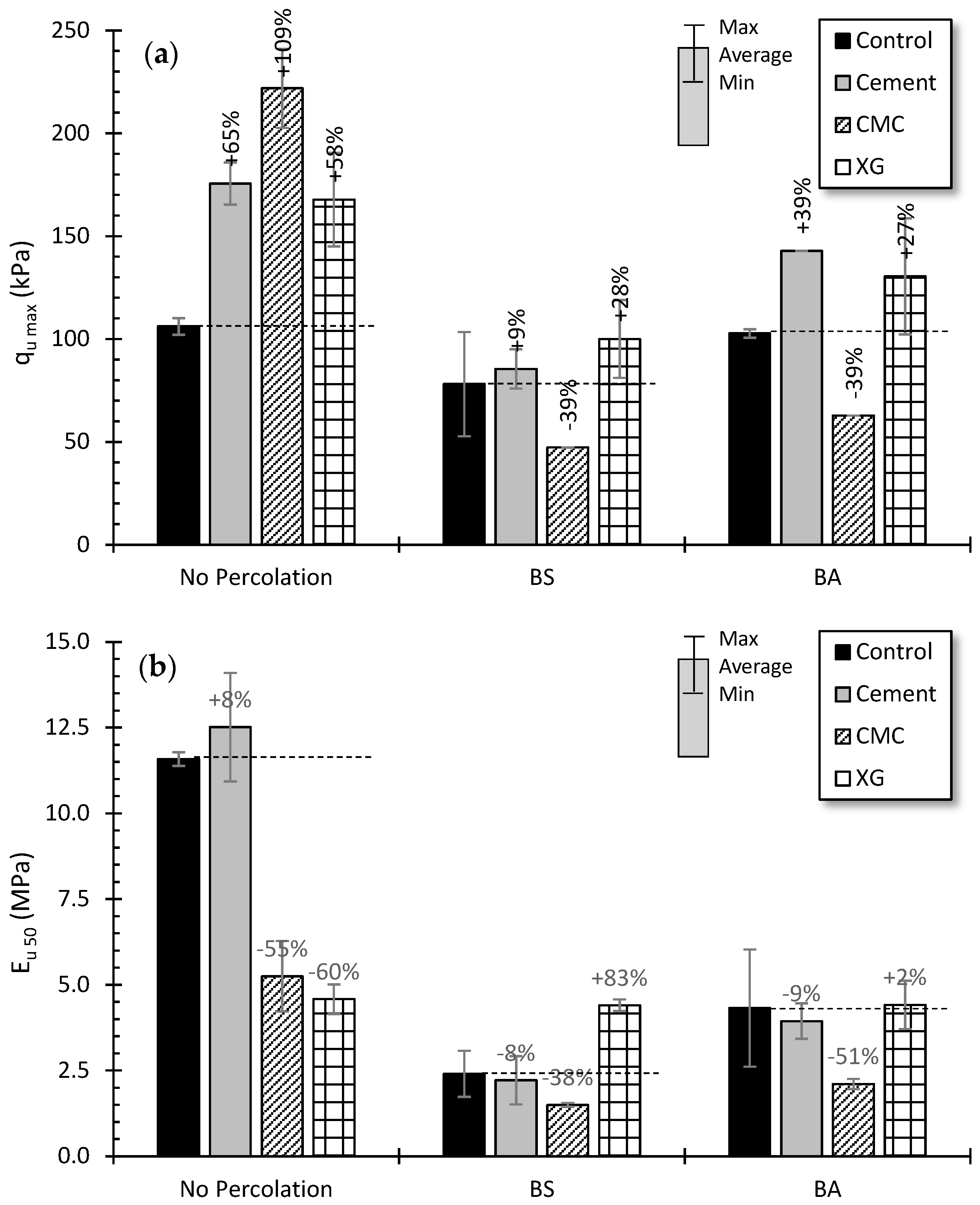

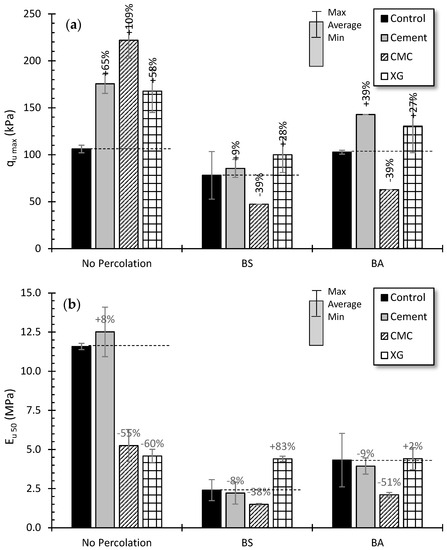

Figure 2 and Figure 3 and Table 3 summarize the results from the UCS tests performed with the mine residue soil samples that were biostimulated (BS, Figure 2a) or bioaugmentated (BA, Figure 2b), whether or not they were combined with the addition of the two biopolymers (XG or CMC). In both cases, the results are compared with the control (soil without biopolymer but BS or BA) and with the addition of Portland cement combined with BS and BA. Figure 2 also includes the results of the UCS tests of the individually applied stabilizers to assist in the interpretation and discussion of the results. Figure 3 illustrates the variation between the unconfined compressive strength (qu max) and undrained Young’s modulus defined for 50% of qu max (Eu 50) for all the tested samples, representing the average values, the variability regarding the average value and the increase or decrease in the respective control value.

Figure 2.

UCS results—effect of two different bio-techniques: (a) biostimulation (BS); (b) bioaugmentation (BA). (CMC = carboxymethyl cellulose; XG = xanthan gum).

Figure 3.

UCS results—the impact of the bio-techniques in terms of: (a) qu max; (b) Eu 50. (CMC = carboxymethyl cellulose; XG = xanthan gum; BS = biostimulation; BA = bioaugmentation).

In general, it may be concluded that the biostimulation of the native bacteria produces worse results than the bioaugmentation technique. Indeed, independently of the combination of biostimulation and any of the studied stabilizers, the results are always below the control test (Control), revealing that biostimulation after two percolation cycles is not effective. Moreover, no substantial difference was observed between the biostimulated samples, even when combined with any of the stabilizers, which supports the conclusion that this technique is not effective for this particular mine residue soil.

However, in the case of the bioaugmentation technique, the stress–strain compressive behavior is characterized by a higher strain at failure, inducing a more ductile behavior, and by an unconfined compressive strength that is higher than the control values (control and BA-control) for the stabilizers XG (BA-XG) and Portland cement (BA-cement). The poor performance of the biopolymer CMC (BA-CMC) may be due to the combination of percolation cycles and the extraction and homogenization steps, where some of the bonds promoted by the CMC seemed to be washed and/or destroyed, suggesting that CMC shows a poor mechanical behavior over time. Another possible explanation is the degradation of the biopolymer CMC by the bacteria, which needs to be confirmed. The best unconfined compressive strength result obtained with the biopolymer XG (BA-XG) is supported by the studies of Soldo and Miletić [9], Bozyigit et al. [11] and Ni et al. [13]. Moreover, Bozyigit et al. [11] observed that the addition of XG to soil promoted a significant increase in the unconfined compressive strength over time (up to three years), i.e., the XG exhibits a very good performance and stability over time. Thus, it may be concluded that despite the disturbance associated with the percolation, extraction and homogenization steps, the biopolymer XG continues to be active, and is able to stabilize the mine residue soil. Comparing the samples containing Portland cement, it may be seen that the percolation, extraction and homogenization steps induced the destruction of a great majority of the cementitious bonds responsible for the enhancement of the mechanical properties of the cement-stabilized soil. This justifies the lower unconfined compressive strength of the BA-cement sample compared to the cement sample. However, it is known that the Portland cement develops cementitious bonds (due to hydrated reactions) over long periods, during months or even years [32], justifying the increase in the unconfined compressive strength of the sample BA-cement when compared to the control sample (BA-control). Thus, it may be concluded that Portland cement remains active in the presence of the bioaugmentation technique.

4. Conclusions

Based on the UCS tests performed on previously disturbed samples (two cycles of percolation, extraction and homogenization) of mine residue soil stabilized with Portland cement, or with the biopolymers XG and CMC, applied individually or combined with the biostimulation and bioaugmentation techniques, allowed for the following conclusions:

- Both biopolymers (XG and CMC), when applied individually, are effective stabilizers of the mine residue soil, showing better CMC results in terms of unconfined compressive strength than Portland cement when applied with the same content (1% of the dry unit weight of the soil);

- The biostimulation of the autochthonous community of the mine residue soil was revealed to be a non-effective technique, even when combined with the biopolymers or with the Portland cement;

- The bioaugmentation of the mine residue soil with the bacterial strain Diaphorobacter polyhydroxybutyrativorans B2A2W2, when combined with the biopolymer xanthan gum (XG), exhibited a good performance in terms of stress–strain compressive behavior, even after the samples were disturbed. Improvements in the unconfined compressive strength of up to 27% were observed compared to the respective control test.

Through further research and application, these bio-techniques have the potential to revolutionize soil engineering practices, offering environmentally friendly alternatives for sustainable soil stabilization, and contributing to a greener and more sustainable future.

Author Contributions

Conceptualization, A.A.S.C. and P.V.M.; methodology, A.A.S.C. and P.V.M.; validation, A.A.S.C., J.B.C. and P.V.M.; formal analysis, A.A.S.C., J.B.C., R.B. and P.V.M. investigation, J.B.C.; resources, A.A.S.C. and P.V.M.; data curation, A.A.S.C. and J.B.C.; writing—original draft preparation, A.A.S.C.; writing—review and editing, J.B.C., R.B. and P.V.M.; supervision, A.A.S.C. and P.V.M.; project administration, A.A.S.C. and P.V.M.; funding acquisition, P.V.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by FEDER funds through the program COMPETE—Programa Operacional Factores de Competitividade and by national funds through FCT—Fundação para a Ciência e Tecnologia, under the projects UID/EMS/00285/2020, UIDB/00102/2020, and LA/P/0112/2020, by the Project ERA-MIN-2019_67-Reviving and by BIORECOVER Horizon2020 under grant agreement No 821096, supported under Horizon 2020 the European Union’s Framework for Research and Innovation. Joana B. Caldeira was supported by a PhD research grant (2022.13542.BD) from FCT/MCTES through national funds.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all data, models, or code generated or used during the study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to express their thanks to CIMPOR for supplying the Portland cement used in the research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Correia, A.A.S.; Venda Oliveira, P.J.; Lemos, L.J.L. Strength assessment of chemically stabilised soft soils. Proc. Inst. Civ. Eng. Geotech. Eng. 2019, 172, 218–227. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Correia, A.A.S.; Lemos, L.J.L. Numerical prediction of the creep behaviour of an unstabilised and a chemically stabilised soft soil. Comput. Geotech. 2017, 87, 20–31. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Kannan, G. An Investigation on the Potential of Cellulose for Soil Stabilization. Sustainability 2022, 14, 6277. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.-M.; Im, J.; Cho, G.-C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Venda Oliveira, P.J.; Teles, J.M.N.P.C.; Pedro, A.M.G. Strength of a stabilised soil reinforced with steel fibres. Proc. Inst. Civ. Eng. Geotech. Eng. 2017, 170, 312–321. [Google Scholar] [CrossRef]

- Kitazume, M.; Terashi, M. The Deep Mixing Method; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Ghorab, H.Y.; Hassan, A.H.E.; Ahmed, H.E.D.H. Stabilization of the swelling soil for earth construction. Cem.-Wapno-Beton Cem. Lime Concr. 2020, 25, 198–207. [Google Scholar] [CrossRef]

- Armistead, S.J.; Rawlings, A.E.; Smith, C.C.; Staniland, S.S. Biopolymer Stabilization/Solidification of Soils: A Rapid, Micro-Macro, Cross-Disciplinary Approach. Environ. Sci. Technol. 2020, 54, 13963–13972. [Google Scholar] [CrossRef] [PubMed]

- Soldo, A.; Miletić, M. Study on Shear Strength of Xanthan Gum-Amended Soil. Sustainability 2019, 11, 6142. [Google Scholar] [CrossRef]

- Ojuri, O.O.; Ramdas, V.; Aderibigbe, E.A.; Williams, C.G.; Ramchuran, S.; Al-Nageim, H. Improving strength and hydraulic characteristics of regional clayey soils using biopolymers. Case Stud. Constr. Mater. 2022, 17, e01319. [Google Scholar] [CrossRef]

- Bozyigit, I.; Javadi, A.; Altun, S. Strength properties of xanthan gum and guar gum treated kaolin at different water contents. J. Rock Mech. Geotech. Eng. 2021, 13, 1160–1172. [Google Scholar] [CrossRef]

- Kwon, Y.M.; Chang, I.; Cho, G.C. The Effect of Pore Fluid Chemistry on the Behavior of Xanthan Gum-Treated Kaolinite. In Geotechnical Engineering in the XXI Century: Lessons Learned and Future Challenges; IOS Press: Amsterdam, The Netherlands, 2019; pp. 2388–2395. [Google Scholar]

- Ni, J.; Li, S.S.; Ma, L.; Geng, X.Y. Performance of soils enhanced with eco-friendly biopolymers in unconfined compression strength tests and fatigue loading tests. Constr. Build. Mater. 2020, 263, 120039. [Google Scholar] [CrossRef]

- Khatami, H.; O’Kelly, B.C. Prevention of bleeding of particulate grouts using biopolymers. Constr. Build. Mater. 2018, 192, 202–209. [Google Scholar] [CrossRef]

- Ni, J.; Hao, G.L.; Chen, J.-Q.; Ma, L.; Geng, X.-Y. The Optimisation Analysis of Sand-Clay Mixtures Stabilised with Xanthan Gum Biopolymers. Sustainability 2021, 13, 3732. [Google Scholar] [CrossRef]

- Mendonça, A.; Morais, P.V.; Pires, A.C.; Chung, A.P.; Venda Oliveira, P.J. Reducing Soil Permeability Using Bacteria-Produced Biopolymer. Appl. Sci. 2021, 11, 7278. [Google Scholar] [CrossRef]

- Chen, R.; Ding, X.; Lai, H.; Zhang, L. Improving dust resistance of mine tailings using green biopolymer. Environ. Geotech. 2021, 8, 382–391. [Google Scholar] [CrossRef]

- Bonal, N.S.; Prasad, A.; Verma, A.K. Use of biopolymers to enhance the geotechnical properties of coal mine overburden waste. Géotechnique Lett. 2020, 10, 179–185. [Google Scholar] [CrossRef]

- Ma, H.; Ma, Q. Experimental Studies on the Mechanical Properties of Loess Stabilized with Sodium Carboxymethyl Cellulose. Adv. Mater. Sci. Eng. 2019, 2019, 9375685. [Google Scholar] [CrossRef]

- Yang, Q.-W.; Pei, X.-J.; Huang, R.-Q. Impact of polymer mixtures on the stabilization and erosion control of silty sand slope. J. Mt. Sci. 2019, 16, 470–485. [Google Scholar] [CrossRef]

- Zinchenko, A.; Sakai, T.; Morikawa, K.; Nakano, M. Efficient stabilization of soil, sand, and clay by a polymer network of biomass-derived chitosan and carboxymethyl cellulose. J. Environ. Chem. Eng. 2022, 10, 107084. [Google Scholar] [CrossRef]

- Li, Z.; Gong, Y.; Zhao, D.; Deng, H.; Dang, Z.; Lin, Z. Field assessment of carboxymethyl cellulose bridged chlorapatite microparticles for immobilization of lead in soil: Effectiveness, long-term stability, and mechanism. Sci. Total Environ. 2021, 781, 146757. [Google Scholar] [CrossRef]

- Su, M.; Yin, W.; Liu, L.; Li, P.; Fang, Z.; Fang, Y.; Chiang, P.; Wu, J. Enhanced Cr(VI) stabilization in soil by carboxymethyl cellulose-stabilized nanosized Fe0 (CMC-nFe0) and mixed anaerobic microorganisms. J. Environ. Manag. 2020, 257, 109951. [Google Scholar] [CrossRef] [PubMed]

- Chung, A.P.; Coimbra, C.; Farias, P.; Francisco, R.; Branco, R.; Simão, F.V.; Gomes, E.; Pereira, A.; Vila, M.C.; Fiúza, A.; et al. Tailings microbial community profile and prediction of its functionality in basins of tungsten mine. Sci. Rep. 2019, 9, 19596. [Google Scholar] [CrossRef] [PubMed]

- BS-1377-2; Methods of Test for Soils for Civil Engineering Purposes. Part 2: Classification Tests. British Standards Institution: London, UK, 1990.

- Rito, B.; Almeida, D.; Coimbra, C.; Vicente, D.; Francisco, R.; Branco, R.; Weigand, H.; Morais, P.V. Post-measurement compressed calibration for ICP-MS-based metal quantification in mine residues bioleaching. Sci. Rep. 2022, 12, 16007. [Google Scholar] [CrossRef] [PubMed]

- BS-1377-4; Methods of Test for Soils for Civil Engineering Purposes. Compaction-Related Tests. British Standards Institution: London, UK, 1990.

- Correia, A.A.S.; Matos, M.P.S.R.; Gomes, A.R.; Rasteiro, M.G. Immobilization of Heavy Metals in Contaminated Soils—Performance Assessment in Conditions Similar to a Real Scenario. Appl. Sci. 2020, 10, 7950. [Google Scholar] [CrossRef]

- BS-1377-7; Methods of Test for Soils for Civil Engineering Purposes. Shear Strength Tests (Total Stress). British Standards Institution: London, UK, 1990.

- Tinoco, J.; Correia, A.A.S.; Venda Oliveira, P.J.; Correia, A.G.; Lemos, L.J.L. A Data-driven Approach for qu Prediction of Laboratory Soil-cement Mixtures. Procedia Eng. 2016, 143, 566–573. [Google Scholar] [CrossRef][Green Version]

- EN-206-1; Concrete—Part 1: Specification, Performance, Production and Conformity. European Committee for Standardization: Bruxelles, Belgium, 2007.

- Taylor, H. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).