Abstract

The use of petroleum-based packaging and its disposal in the environment poses several environmental problems, driving research into the development of biopolymers as substitutes for conventional polymers. Therefore, this study used the by-product of potato industrialization as the main raw material, xanthan gum as a plasticizer, and natural oat fiber as reinforcement to develop a biodegradable foam through thermo-pressing. The morphology, mechanical properties, and biodegradability of the final product were investigated. The water absorption and solubility index were highest in the sample with 20% plasticizer and 20% fiber. The water activity was not affected by variations in additives. The samples with the highest concentration of additives had the highest mechanical tensile strength, but there was a limit to these levels for foam resistance. The most accentuated visual effect was the yellow color. It is believed that hydrolysis was the main foam degradation mechanism, which took between 14 and 20 days for total decomposition. The combination of a by-product from potato industrialization with xanthan gum and natural oat fiber made it possible to produce a promising substitute for synthetic polymers, providing an environmentally friendly solution for both the use of agro-industrial by-products and reducing the volume of petroleum-based packaging waste.

1. Introduction

The use of petroleum-derived polymers has accelerated in recent years. The largest percentage of plastic is derived from fossil fuels, which exerts excessive pressure on non-renewable sources, and also degrades very slowly over periods between 100 and 450 years. This degradation involves its fragmentation into smaller particles, which causes impacts on water, air, and soil that directly affect the environment and health [1,2]. The authors [1] propose that this effect can be reduced by managing solid by-products.

The environmental problems caused by the disposal of non-biodegradable materials has led to research and development into how biodegradable materials can be used in the production of packaging on a commercial scale [3]. From an economic point of view, when comparing biodegradable packaging with synthetic materials, those produced from bioproducts are not always competitively priced in the short-term. The use of agricultural by-products, or those generated by industry, can, therefore, provide an alternative form of packaging within the market [4].

Agricultural-derived materials are emerging as promising raw material for several products [5,6,7]. With an increase in potato processing industries, the complete use of raw materials is becoming increasingly important to meet urgent demands for reduced by-products and to address environmental concerns [8].

Among natural polymers, starch has been identified as one of the most promising materials for biopolymer development [9]. Starch is widely available and an easily biodegradable natural resource. High levels of water or plasticizers are required to produce a starch-based film. These plasticized materials (via the application of thermal and mechanical energy) are called thermoplastic starch (TPS), and provide an alternative to synthetic polymers [10].

The application of starch derived from an agro-industrial by-product is considered of environmental and economic interest as the basis of biodegradable packaging, because although they are generally rich in bioactive compounds and fibers, they are discarded ultimately during the production process [11]. Some studies indicate that the combination of starch with a variety of plasticizers (natural or synthetic) and/or other additives, such as natural fibers, allows the production of new foam-like polymer materials with better properties. Edhirej et al. [12], for example, developed a hybrid composite from cassava bagasse, a starchy material, and sugar palm fiber, using fructose as a plasticizer. The addition of the fiber significantly influenced the physical properties, with increased thickness and reduced density, water content, solubility, and water absorption. Machado et al. [13] found that foams containing broken rice, also rich in starch, were thinner and showed higher density, greater tensile strain, and maximum flexural stress values compared to control foams. Kaisangsri et al. [14] observed that the water absorption and water solubility index were lower in trays with higher concentrations of zein and gluten protein. Finally, Stoffel et al. [15] studied oat fibers as reinforcements or fillers in native and cationic cassava starch/PVA biodegradable materials and concluded that these fibers have good dispersion and compatibility with the polymer matrix.

Although biodegradable foam trays have been developed with mixtures of starch and natural fibers, there are no scientific reports of the use of starch from the by-products of the potato industry. This work deals, therefore, with biodegradable foams prepared from starch raw materials produced from the by-products of the potato industry. The potato (Solanum tuberosum L.) is an economically important but highly polluting crop due to the high concentration of organic contaminants, such as starch, lipids, saccharides, proteins, and other soluble substances [16,17]. Because the packaging components are biodegradable, the final compound is also expected to have this same characteristic. Therefore, this material can be considered a truly ecological packaging, since its use contributes to a reduction in the use of synthetic plastics derived from non-renewable sources and in environmental problems caused by the disposal of non-biodegradable plastic materials, as well as making it possible to attribute value to by-products normally discarded by the industry or destined for low-value products.

Xanthan gum, a natural polymer that is widely applied in the food industry, was added because it is an efficient thickener; the solution’s viscosity is increased, even at a very low concentration, in an aqueous solution presenting pseudoplastic behavior. The combination of gum with starches and other plasticizing agents has been used in the development of films, improving stabilization, gelatinization, and retrogradation characteristics [18,19]. Natural oat fiber was used as a foam reinforcer. According to Zanela et al. [20], this material can be used for reinforcement of biodegradable materials produced by injection molding, and previous studies have demonstrated the potential use of oat fiber in biodegradable materials. The aim of this research is, therefore, to develop a biodegradable packaging material from the by-products of the potato industry.

2. Material and Methods

2.1. Material

The foams used in this study were obtained from the wet by-product of processing steamed potatoes, which were vacuum-packed and sterilized and provided by an agribusiness in the Campos Gerais region, Paraná, Brazil. This by-product was generated during the selection stage, in which the potatoes were already peeled and go through a process of visual quality control to remove imperfections. This process promotes the disposal of a considerable amount of pulp that is deposited in plastic containers. The collection was carried out directly after this processing step, and the by-product was packed in airtight packaging and refrigerated at 4 °C until use. The characterization of the dry portion of the by-product was composed of approximately 77% of carbohydrates, with 60% of starch, 15% of total fiber, and 7% protein in a raw material with 82% moisture (unpublished data). Crude oat fiber (Quaker SA, Mauá da Serra, Brazil) was then added as a reinforcer. Xanthan gum (Proteic Ingredients) was used as a blowing agent and plasticizer. Sodium benzoate was also added to the dough as a preservative agent.

2.2. Foam Preparation

To initially prepare the dough, a gel was obtained by mixing the by-product with sodium benzoate (0.5% w/w) and heating at 80 °C for 40 min. To obtain the three different formulations, following the cooling of the gel, each additive (oat fiber and xanthan gum) was added at the levels of 10% (C10), 15% (C15), and 20% (C20), at room temperature (on average 24 °C), which was based on previous tests of mass stability (unpublished data).

The components were then mixed for 5 min at a medium speed of 120 rpm using a mechanical stirrer (Cadence Orbital Electronic, Piçarras, Brazil, 400 W), until complete homogenization. For complete filling of the mold, the dough (about 100 g) was deposited on a Teflon mold (Mini Grill Philco, Manaus, Brazil) that had been preheated at a cooking temperature of approximately 200 °C. The upper part of the mold was then completely closed to start the thermo-expansion process without pressure control. Through this process, the high temperature solidified the material, and consequently, the foam was obtained, taking approximately 15 min to complete. The minimum required cooking times were determined in preliminary tests to prevent the formation of cracks in the trays as a result of overcooking. After the required time, the mold was opened so that the foam could cool to room temperature (on average 24 °C) before being carefully removed from the mold. The foams were packaged in vacuum plastic (Vacuum Sealer 110 V) and then stored in a greenhouse (EletroLab Model EL202, São Paulo, Brazil) at a controlled temperature of 20 ± 2 °C for seven days before their characterization.

2.3. Solubility

Tests concerning the solubility of the forms were performed in triplicate following the methodology proposed by Torres et al. [21]. More specifically, 3 × 3 cm samples were cut and stored for seven days in a desiccator with silica, with an ambient temperature of approximately 24 °C. The samples were then weighed and placed in glass beakers containing 80 mL of distilled water. They were kept in a state of constant agitation for 1 h at 25 °C. Immediately afterward, the samples were removed from the solution and dried at 60 °C for 4 h. The percentage of the total soluble material was calculated according to Equation (1):

2.4. Water Absorption Index

The water absorption index was determined according to ABNT NBR NM ISO 535 [22], whereby the foams were weighed following the addition of 100 mL of water for 60 min at room temperature. Thereafter, the excess water was removed using a dry paper towel and the foam was weighed again. The water absorption capacity of the foam was calculated using Equation (2), with the final measurements of the three samples being the average for each formulation.

where is the wet mass, and refers to dry mass.

2.5. Water Activity

The water activity test was performed in triplicate using the AquaLab Series 4TE instrument (Pullman, WA, USA). Samples of each foam formulation were placed in their own containers and then introduced into the water activity reader at an average temperature of 25.0 ± 0.12 °C.

2.6. Density

The density was calculated according to the method proposed by Shogren et al. [23], which was used to analyze the ratio between the mass and the volume of the foams in triplicate. The density tests were performed using rectangular foam strips (100 × 25 mm). Each sample was weighed, and the volume was calculated by multiplying the length by the width and thickness. The reported density values were the averages of five samples for each formulation.

2.7. Mechanical Analysis

To evaluate the mechanical properties of the foams, flexion and tensile tests were performed on a universal testing machine, brand EMIC, model DL10000 (Dublin, OH, USA), using a 100 kN load cell. Before carrying out the tests, samples with dimensions of 2.5 cm × 10 cm were stored for 10 days. The tensile tests were performed according to ASTM D 638–02a, with an initial distance between the claws of 50 mm and a traction speed of 2 mm/s. From the tests, stress–strain curves were obtained, which made it possible to determine the values of the maximum tensile strength and maximum force that could be supported by the samples. The tests were performed for 10 samples for each formulation.

2.8. Color Parameters

The foam color was determined using a HunterLab bench spectrophotometer model UltraScan Pro (Reston, VA, USA). The methodology of Fernandes et al. [24] was used in the analysis, whose values were defined by L*, a* and b*. The coordinate L* corresponds to luminosity that ranges from 0 for dark colors to 100 for light colors, while a* and b* refer to the chromaticity coordinates: green (−)/red (+), and blue (−)/yellow (+), respectively, with values of −60 to +60. The measurements were performed in triplicate, and the device was calibrated previously.

2.9. Biodegradability Analysis

The foam biodegradability was determined by measuring the mass loss of material exposed to the soil, following the ASTM 6400-99 Standard (Standard Specification for Compostable Plastics) with some modifications. Seven samples of each foam composition were buried 3 cm from the surface in a container containing commercial black soil composed of black soil, fertilizer, organic vegetable compost, and limestone. The containers were kept at room temperature under aerobic conditions and water (100 mL) was sprayed on the samples once a day to ensure the system’s humidity throughout the experiment. The test lasted 21 days and the samples were recovered, cleaned, and weighed every seven days. This loss of mass resulted from the actions of microorganisms and chemical reactions. After each weighing, the samples were reintroduced to the soil for further testing.

2.10. Statistical Analysis

The data obtained in the mass stability analysis and mechanical characterization of the foams were compared using the Analysis of Variance (ANOVA), in the Tukey method with a 95% confidence interval, using Sasm-Agri software.

3. Results and Discussion

3.1. Solubility Index, Water Absorption, and Water Activity

Starch-based foams are known to be susceptible to moisture. Water molecules affect the hydrogen bonds of starch, weakening them and reducing their functional properties. In this manner, water resistance is a parameter that needs to be considered in research in order to improve the applications of these foams.

Solubility index and water absorption analyses can be performed to determine the resistance of starch foams to moisture. With the addition of different concentrations of plasticizer and natural fiber (C10, C15, and C20 xanthan gum/oats), the solubility of foams varied between 20% and 25%. As demonstrated in Table 1, the C10 package offers greater solubility as compared to other concentrations, and the samples do not differ statistically (p < 0.05) owing to the high standard deviation between the samples.

Table 1.

Solubility index, water absorption index, and water activity of foams based on potato by-products.

Although both solubility and water absorption were influenced by the interaction of the xanthan gum/oat concentration, the water absorption analysis revealed a statistically significant difference between the samples (p < 0.05). The C20 packaging presented the lowest water absorption index, which, in turn, is desirable for packaging. On the other hand, the C10 packaging showed the highest absorption after 60 min of immersion. Guan and Hanna [25], Kaisangsri et al. [14], and Slavutsky and Bertuzzi [26] reported similar observations in their studies. According to these authors, the addition of cellulosic fibers can reduce the moisture sensitivity of starch foams by acting as a hydrophobic agent, thus decreasing the foams’ water absorption.

When water activity is observed as a function of xanthan gum/oat content (Table 1), all formulations were found to exhibit similar behavior and without any statistical difference (p < 0.05).

3.2. Mechanical Analysis of Foam

For the purpose of ensuring the economic viability of the product, we allowed for the non-standardization of the potato by-product through unitary operations such as drying and sifting. This, in turn, led to a significant variation in mechanical behavior between the same formulation’s analyzed samples. Through the identification of samples cured in the center and ends of the mold, it was also observed that the heterogeneity of the heat distribution within the mold affected the mechanical characteristics of the final packaging. As assessed through mechanical testing using a universal testing machine, in the presence of different concentrations of plasticizers, the foam-type packages showed significant differences with respect to tensile strength and the maximum strength supported prior to rupture (p < 0.05), as can be seen from the data presented in Table 2.

Table 2.

Mechanical properties and densities of foams based on potato by-products.

According to Kabir, Saha, and Jeelani [27], a higher density foam generally leads to greater resistance. Among the analyzed samples, the C15 package showed greater resistance to tension (42%), a higher maximum strength (25 N), and an average density when compared to the other formulations.

It was observed that the resistance (20%) and the maximum breaking force (5 N) decreased with the reduction of xanthan gum/oats in the C10 package as, during the process, the mass was more viscous due to the lower amount of plasticizer and fiber, meaning that it expanded less and so resulted in denser, thinner packaging.

In their study, Guan and Hanna [25] reported that, as the temperature increased, the rate of expansion initially increased and then decreased as the temperature continued to rise. This was explained by the fact that the lower viscosity of the mass at a very high temperature prevented expansion.

However, an increased concentration (C20) also resulted in a decreased resistance to tension (24%), decreased strength (21 N), and lower density. An increase in the concentration of the plasticizer increased the expansion rate of the compressed foams, which led to a decrease in the foam density [28].

The results indicate that there was an improvement in the mechanical properties of the samples due to the effect of the fiber, although there is a limit to the extent to which the addition of plasticizer and fiber can improve the resistance of foam packaging.

Sheng et al. [29], in their work on the performance of xanthan gum in foams, obtained a slight increase in the surface tension of foam solutions with an increase in the content of xanthan gum. The viscosity changed significantly with the addition of xanthan gum: the foaming capacity was hardly affected, but the foam stability was evidently improved.

Carr et al. [30] investigated the influence of the addition of wheat fibers on the improvement of the mechanical properties of cassava starch foams. They concluded that an increase in the number of fibers resulted in foams with higher density and less flexibility, regardless of the type of fiber. Most of the amounts of fibers tested did not improve the foam strength.

Glenn et al. [31] described how cooked foam panels made with wheat and corn starches showed a higher density (±0.15 g/cm3) than panels made with potato and tapioca (±0.12 g/cm3). Shey et al. [32] also showed that cooked starch foams based on wheat, potatoes, and waxy corn starches obtained different densities, of 0.20 g/cm3, 0.15 g/cm3, and 0.13 g/cm3, respectively. In this work, higher density was observed for all formulations compared to the studies cited.

3.3. Color

The color parameters of the foams were significantly affected by the concentration of xanthan gum/oats (p < 0.05), as shown in Table 3:

Table 3.

Color parameters of foams developed from potato by-products.

Formulation C10 showed a significantly higher luminosity (L*) (p < 0.05) value than that of samples with greater levels of fiber addition. The increase in oat content resulted in a decrease in the L* value. These results were similar to those of Famá et al. [33], Mali et al. [5], and Mello and Mali [34], who reported a decrease in the L* value as an increasing amount of fibers was added to the compositions.

The parameter a*, which indicates foam redness, was not influenced by the increase in the content of xanthan gum/oats since the a* value of C10 did not differ significantly from that of the other formulations. However, the most accentuated visual effect was that of the yellowish color, indicated by the parameter b*. The results of this parameter may have been influenced by caramelization and the Maillard reaction due to the high levels of carbohydrates and proteins in the potato by-product and the high temperatures used during the process [35].

The obtained results were close to those of Mali et al. [5], who observed an increasing yellowish visual effect (b*) in foam containing sugarcane fiber, with increasing fiber proportions in the formulations. Debiagi et al. [1] indicated an increase in b* when high chitosan proportions were used in the foam formulations.

Famá et al. [33] found that the color parameters of starch biocomposites increased significantly with the addition of xanthan gum/oat fibers, which limits the use of this reinforcing agent in food applications. On the other hand, changes in the cellulose fiber concentration did not result in significant color differences, but an increase in the protein content of the formulation intensified the yellow parameter b* [35].

3.4. Biodegradability

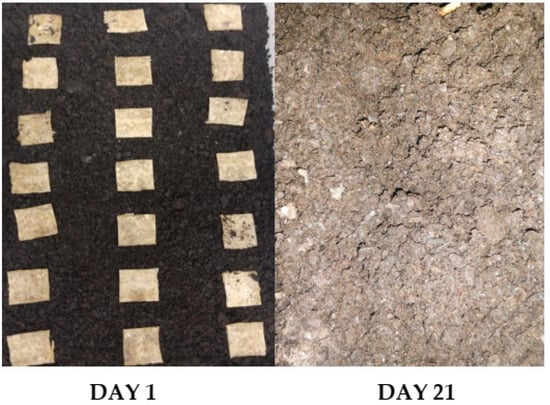

After the test, we tried to dig up the samples of foam. However, the packaging had completely degraded and adhered to the earth, exhibiting no residual material capable of being weighed (as shown in Figure 1).

Figure 1.

Samples of foam developed from the potato by-products on the first and twenty-first days of the biodegradability analysis.

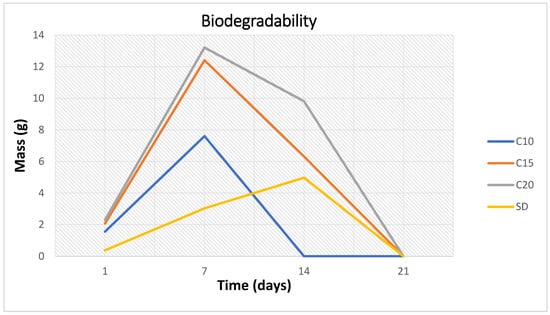

The result of the loss of mass as a function of the time during which the package remained buried has been shown in Figure 2. The figure also shows the standard deviation (SD), which indicates that the data is more dispersed during days 1–14, after which it exhibits little variation.

Figure 2.

Biodegradation timeline of foams developed from the potato by-products that were buried in black soil.

With respect to biodegradability, it is observed that hydrolysis may have been the main mechanism of foam degradation. Other factors that could have influenced biodegradability include biological activity (especially the activity of enzymes released by microorganisms present in the soil) and abiotic degradation, such as photodegradation [36].

The biodegradation of starch is achieved by hydrolysis of the acetal bond by enzymes (present in the experiment). The amylases attack the α-1,4 bond while the glucosidases attack the α-1,6 bond. It should be noted that the degradation products do not have any toxic characteristics. As shown in Figure 2, there was an increase in mass in the first seven days. A similar result was reported by Sanhawong et al. [37], with their samples showing visible swelling after seven days of soil burial testing. The authors claim that water could have reacted with the hydroxyl groups of the starch molecules: the hydrogen bond and the molecular interaction among the starch molecules were potentially destroyed, thereby increasing the swelling.

The use of sodium benzoate as a preserving agent does not appear to have impacted biodegradability. This is because the compound is readily biodegradable, with 90–93% of the biodegradation occurring in seven days [38].

Piñeros-Hernandez et al. [39] verified the decomposition of films of cassava starch, glycerol, and natural polyphenols extracted from rosemary leaves and observed that the decomposition occurred almost entirely after 14 days of testing. During this period, the integrity of the films was better preserved, indicating that biodegradation was delayed by the presence of rosemary extract.

These findings can be applied to future work: other agro-industrial residues with high production can be tested to replace oats, such as those from the brewing industry, and rice husks. The proportion of components can be optimized through factorial planning, aiding in the search for suitable packaging material. The design of portable equipment capable of the temperature and pressure control necessary to mold the dough in the desired format is crucial for standardization of the process; such equipment would also facilitate tests on an industrial scale.

4. Conclusions

Biodegradable edible foams using a by-product of potato industrialization, xanthan gum as a plasticizer, and natural oat fiber reinforcement were successfully produced. With an increased proportion of plasticizer and fiber, the foam showed higher water absorption and solubility index values, suggesting that the xanthan gum/oat interaction interfered with these properties. Regarding the mechanical properties, it was observed that the lack of standardization of the raw material and the heat heterogeneity of the mold resulted in significant differences between samples with the same formulation. After 20 days, all samples fully adhered to the soil without residue.

The starch foam material from the potato by-product can be used in small disposable products or alternative packaging for dry foods, or applied to agriculture in seed trays, packaging for the transportation of plant seedlings, or compost containers. Future studies could deeply analyze other agro-industrial residues with high production can be tested to replace oats, such as those from the brewing industry, and rice husks.

Author Contributions

N.H.P.R., M.H.G.C. and A.C.d.F. conceptualized the study. N.H.P.R., R.L.R., and A.C.d.F. assisted in the methodology. N.H.P.R. worked with the software. Analysis was executed by N.H.P.R., J.T.d.S., M.H.G.C. and S.M.K.T. Validation was done by N.H.P.R., J.T.d.S., R.L.R., S.M.K.T., M.H.G.C. and A.C.d.F. The original draft was written by N.H.P.R., M.H.G.C. and A.C.d.F. Review and editing were done by N.H.P.R., J.T.d.S., and M.H.G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Coordination of Improvement of Higher Education Personnel (CAPES) and the National Council for Scientific and Technological Development (CNPq).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Debiagi, F.; Mali, S.; Grossmann, M.V.E.; Yamashita, F. Biodegradable foams based on starch, polyvinyl alcohol, chitosan and sugarcane fibers obtained by extrusion. Braz. Arch. Biol. Technol. 2011, 54, 1043–1052. [Google Scholar] [CrossRef]

- Mercado, G.; Dominguez, M.; Herrera, I.; Melgoza, R. Are Polymers Toxic? Case Study: Environmental Impact of a Biopolymer. J. Environ. Sci. Eng. B 2017, 6, 121–126. [Google Scholar]

- Solano, A.C.V.; de Gante, C.R. Development of biodegradable films based on blue corn flour with potential applications in food packaging. Effects of plasticizers on mechanical, thermal, and microstructural properties of flour films. J. Cereal Sci. 2014, 60, 60–66. [Google Scholar] [CrossRef]

- Maniglia, B.C. Development of Biodegradable Films from the Residue of the Extraction of the Pigment from Turmeric. Ph.D. Thesis, Faculdade de Filosofia, Ciências e Letras de Ribeirão Preto, Ribeirão Preto, Brazil, 2012. [Google Scholar]

- Mali, S.; Debiagi, F.; Grossmann, M.V.E.; Yamashita, F. Starch, sugarcane bagasse fibre, and polyvinyl alcohol effects on extruded foam properties: A mixture design approach. Ind. Crops Prod. 2010, 32, 353–359. [Google Scholar] [CrossRef]

- Izmirlioglu, G.; Demirci, A. Ethanol Production from Waste Potato Mash by Using Saccharomyces Cerevisiae. Appl. Sci. 2012, 2, 738–753. [Google Scholar] [CrossRef]

- Venturi, F.; Bartolini, S.; Sanmartin, C.; Orlando, M.; Taglieri, I.; Macaluso, M.; Lucchesini, M.; Trivellini, A.; Zinnai, A.; Mensuali, A. Potato Peels as a Source of Novel Green Extracts Suitable as Antioxidant Additives for Fresh-Cut Fruits. Appl. Sci. 2019, 9, 2431. [Google Scholar] [CrossRef]

- Wu, D. Recycle Technology for Potato Peel Waste Processing: A Review. Procedia Environ. Sci. 2016, 31, 103–107. [Google Scholar] [CrossRef]

- Ghanbari, A.; Tabarsa, T.; Ashori, A.; Shakeri, A.; Mashkour, M. Thermoplastic starch foamed composites reinforced with cellulose nanofibers: Thermal and mechanical properties. Carbohydr. Polym. 2018, 197, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Peelman, N.; Ragaert, P.; De Meulenaer, B.; Adons, D.; Peeters, R.; Cardon, L.; Van Impe, F.; Devlieghere, F. Application of bioplastics for food packaging. Trends Food Sci. Technol. 2013, 32, 128–141. [Google Scholar] [CrossRef]

- Luchese, C.L.; Pavoni, J.M.F.; Spada, J.C.; Tessaro, I.C. Evaluation of the influence of different agro-industrial residues incorporation in cassava starch-based films. Braz. J. Anim. Environ. Res. 2019, 2, 802–812. [Google Scholar]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Machado, C.M.; Longhi, E.M.; Spada, J.C.; Tessaro, I.C. Effect of Broken Rice Flour Addition on Cassava Starch-Based Foams. Starch-Stärke 2018, 70, 1700191. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kerdchoechuen, O.; Laohakunjit, N. Characterization of cassava starch based foam blended with plant proteins, kraft fiber, and palm oil. Carbohydr. Polym. 2014, 110, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Stoffel, F.; Barreto, L.P.; Zeni, M. Preparation of Cassava Starch-based Trays with Glycerol, Sorbitol and Poly (Vinyl Alcohol): Properties and Influence for Use as Food Packaging. Res. Rev. J. Food Sci. Technol. 2018, 4, 45–52. [Google Scholar]

- Wang, R.; Wang, Y.; Ma, G.-P.; He, Y.-F.; Zhao, Y.-Q. Efficiency of porous burnt-coke carrier on treatment of potato starch wastewater with an anaerobic–aerobic bioreactor. Chem. Eng. J. 2009, 148, 35–40. [Google Scholar] [CrossRef]

- Wang, W.; Cai, Z.; Yu, J.; Xia, Z. Changes in composition, structure, and properties of jute fibers after chemical treatments. Fibers Polym. 2009, 10, 776–780. [Google Scholar] [CrossRef]

- Petri, D.F.S. Xanthan gum: A versatile biopolymer for biomedical and technological applications. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Gomes, G.V.P. Produção Simultânea de Goma Xantana e Microfibrilas de Celulose Pela Bioconversão de Bagaço de Cana Por Xanthomonas. Ph.D. Thesis, Universidade Federal da Bahia, Salvador, Brazil, 2014. [Google Scholar]

- Zanela, J.; Bilck, A.P.; Casagrande, M.; Grossmann, M.V.E.; Yamashita, F. Oat Fiber as Reinforcement for Starch/Polyvinyl Alcohol Materials Produced by Injection Molding. Starch-Stärke 2018, 70, 1700248. [Google Scholar] [CrossRef]

- Vargas-Torres, A.; Palma-Rodriguez, H.M.; Berrios, J.D.J.; Glenn, G.; Salgado-Delgado, R.; Olarte-Paredes, A.; Prieto-Mendez, J.; Hernandez-Uribe, J.P. Biodegradable baked foam made with chayotextle starch mixed with plantain flour and wood fiber. J. Appl. Polym. Sci. 2017, 134, 45565. [Google Scholar] [CrossRef]

- ABNT. Paper and Board-Determination of Water Absorptiveness-Coob Method; ABNT: Rio de Janeiro, Brazil, 1999. [Google Scholar]

- Shogren, R.L.; Lawton, J.W.; Doane, W.M.; Tiefenbacher, K.F. Structure and morphology of baked starch foams. Polymer 1998, 39, 6649–6655. [Google Scholar] [CrossRef]

- Fernandes, A.M.; Soratto, R.P.; Evangelista, R.M.; Nardin, I. Physicochemical and frying quality of potato cultivars in winter season. Hortic. Bras. 2010, 28, 299–304. [Google Scholar] [CrossRef]

- Guan, J.; Hanna, M.A. Selected morphological and functional properties of extruded acetylated starch–cellulose foams. Bioresour. Technol. 2006, 97, 1716–1726. [Google Scholar] [CrossRef] [PubMed]

- Slavutsky, A.M.; Bertuzzi, M.A. Water barrier properties of starch films reinforced with cellulose nanocrystals obtained from sugarcane bagasse. Carbohydr. Polym. 2014, 110, 53–61. [Google Scholar] [CrossRef]

- Kabir, M.E.; Saha, M.C.; Jeelani, S. Tensile and fracture behavior of polymer foams. Mater. Sci. Eng. A 2006, 429, 225–235. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Thanomsilp, C.; Suwantong, O. A review: Starch-based composite foams. Compos. Part A Appl. Sci. Manuf. 2015, 78, 246–263. [Google Scholar] [CrossRef]

- Sheng, Y.; Lu, S.; Xu, M.; Wu, X.; Li, C. Effect of Xanthan Gum on the Performance of Aqueous Film-Forming Foam. J. Dispers. Sci. Technol. 2016, 37, 1664–1670. [Google Scholar] [CrossRef]

- Carr, L.G. Development of Biodegradable Packaging, a Starch Foam, Obtained by Cassava Starch. Ph.D. Thesis, Escola Politécncia da Universidade de São Paulo, São Paulo, Brazil, 2007. [Google Scholar]

- Glenn, G.M.; Orts, W.J.; Nobes, G.A.R. Starch, fiber and CaCO3 effects on the physical properties of foams made by a baking process. Ind. Crops Prod. 2001, 14, 201–212. [Google Scholar] [CrossRef]

- Shey, J.; Imam, S.H.; Glenn, G.M.; Orts, W.J. Properties of baked starch foam with natural rubber latex. Ind. Crops Prod. 2006, 24, 34–40. [Google Scholar] [CrossRef]

- Famá, L.; Gerschenson, L.; Goyanes, S. Starch-vegetable fibre composites to protect food products. Carbohydr. Polym. 2009, 75, 230–235. [Google Scholar] [CrossRef]

- Mello, L.R.P.F.; Mali, S. Use of malt bagasse to produce biodegradable baked foams made from cassava starch. Ind. Crops Prod. 2014, 55, 187–193. [Google Scholar] [CrossRef]

- Salgado, P.R.; Schmidt, V.C.; Ortiz, S.E.M.; Mauri, A.N.; Laurindo, J.B. Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. J. Food Eng. 2008, 85, 435–443. [Google Scholar] [CrossRef]

- Bastioli, C. Handbook of Biodegradable Polymers, 1st ed.; Smithers Rapra Publishing: Shropshire, UK, 2005. [Google Scholar]

- Sanhawong, W.; Banhalee, P.; Boonsang, S.; Kaewpirom, S. Effect of concentrated natural rubber latex on the properties and degradation behavior of cotton-fiber-reinforced cassava starch biofoam. Ind. Crops Prod. 2017, 108, 756–766. [Google Scholar] [CrossRef]

- Sodium Benzoate (CAS #532-32-1) GreenScreenTM Assessment. Available online: https://www.healthandenvironment.org/uploads/docs/532-32-1_Sodium_benzoate_GS-100_v1.2_Dec_2012.pdf (accessed on 10 February 2020).

- Piñeros-Hernandez, D.; Medina-Jaramillo, C.; López-Córdoba, A.; Goyanes, S. Edible cassava starch films carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocoll. 2017, 63, 488–495. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).