1. Introduction

Non-destructive evaluation (NDE) methods based on stress wave propagation have contributed to quality assurance and failure prevention in many industries [

1,

2,

3]. The methods include ultrasonic testing (UT), which uses active interrogation of target components, and acoustic emission (AE) testing, which relies primarily on “acoustic” signals emitted from the target. In recent years, their roles have expanded into continual monitoring and preventive maintenance of wide-ranging products and infrastructures, offering useful tools for structural health monitoring [

4,

5,

6,

7]. As the size of structures being inspected increases, the attenuation of stress waves becomes a concern, especially for components of modern fiber-reinforced composites and other high damping materials. In a preceding report [

7], a section was devoted to collecting available data on structural alloys, polymers, and fiber-reinforced composites. Despite long-standing scientific and engineering interests in this subject going back to the work of Mason and McSkimin in the 1940s [

8], available ultrasonic attenuation data were found to be limited. Most of the attenuation values collected in [

7] were for longitudinal waves, while the data for transverse waves were even more sparse, lacking an adequate theoretical foundation, as appropriate diffraction correction has been unavailable. As data from some reports were given as ranges in [

7], the total tabulated data count exceeded 80, but this number was still less than 200 for only about 40 different types of materials. Most polymer data, with about 50 being available in [

9,

10,

11], were not included, in part because the test frequency was in the low kHz region or below and was often unidentified. Technical standards for their measurements and validation were also inadequate [

12,

13]. In order to fill the gap in the presently inadequate database, a study was initiated examining experimental techniques and which culminated with a comprehensive report.

Papadakis [

14,

15] provided a thorough review of this subject and application examples of a buffer rod method, which he and his colleagues had developed earlier [

16]. Their method and its variations have been used by many works cited in [

7], including ASTM Standard C1332 [

12], as well as in [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26]. Margetan et al. [

27] published a tutorial for another approach for attenuation measurement, namely the immersion methods. While these methods require advanced ultrasonic instrumentation capable of precise sensor–sample alignment, water coupling allows the inspection of curved surfaces of engineering components. Margetan and his coworkers [

28,

29,

30,

31] applied the methods to detect the hard inclusions in aerospace Ti alloys and to evaluate the cleanliness of steel samples.

Here, it is necessary to define terms that will be used, as wave attenuation is characterized using several different parameters. Attenuation coefficient α is often used in UT and AE to represent an exponential decay. Taking the initial and attenuated wave amplitude in the displacement, A

o and A, and the propagation distance, x, we have

The commonly used unit for α is dB/m. However, it is sometimes convenient to use Np/m, whereby 8.686 dB = 1 Np. Np stands for Neper, a non-dimensional unit that is useful in numerical computation. In this work, only longitudinal waves are considered and no subscript is used for wave types. Previously in [

7], α was denoted by α

p. This α is related to the damping (or loss) factor η by η = αλ/π, where λ is the wave length and α is given in the unit of Np/m. Here, 2πη is the ratio of energy dissipated per cycle to maximum energy stored per cycle; η is often denoted as Q

−1 in seismology [

32] and in electrical engineering, and η is also equal to the loss tangent, tan δ. This tan δ is defined as the ratio of the imaginary part (E”) to the real part (E’) of a complex elastic modulus, E* = E’ −

iE”, with

i2 = −1.

The damping factor (or loss tangent) is often used in dealing with vibration damping at lower frequencies, especially in polymers, where attenuation arises from viscous damping or hysteretic behavior. When η is independent of frequency, the attenuation coefficient due to viscous damping, α

d, is given by

where f is the frequency and v

L is the longitudinal wave velocity; that is, attenuation coefficient α

d increases linearly with frequency, with C

d as a constant for attenuation due to damping of longitudinal waves. This α

d, which is proportional to frequency, was initially attributed to elastic hysteresis [

8], and early works on damping factors (η = Q

−1) of metals were tabulated in [

32]. The damping phenomena were also called internal friction, for which log decrement ∆ = ln (A

o/A) was commonly used and ∆ = π η.

The origin of α

d was correlated to dislocation damping in metals [

33,

34], known as the Koehler–Granato–Lücke (KGL) theory. Dislocation damping is attributed to phonon and electron drags in dislocation oscillations, thermoelastic damping, and mode conversion losses. This and related topics were thoroughly reviewed in [

35,

36,

37], and most available experimental data were compiled in a handbook by Blanter et al. [

37]. Additional works on ultrasonic absorption not cited in [

37] also demonstrated that (i) magnetic damping effects constitute the bulk of α

d in a steel [

38], (ii) dislocation damping increased with plastic strain in Al single crystals [

39], and (iii) α

d in pure Fe diminished with annealing [

40]. Material damping at lower frequencies is an important issue in structural design. Sugimoto provided a review with a compilation of the Q

−1 values vs. tensile strength for 25 alloys [

41]. More recently, Blanter and Golovin [

42] gave an updated review of this topic and covered high damping metals in depth. In a book on high intensity ultrasound technology, Abramov [

43] provided damping data and showed that the damping factors of common metals, such as Al, Cu, Ni, Fe, and Zn, exceed 0.01 at high strain amplitudes in excess of 10

−4; that is, these metals under high intensity ultrasound (below ~100 kHz) have damping factors higher than that of polymethyl methacrylate (PMMA) under normal ultrasonic test conditions (i.e., strain amplitude of ~10

−7). Methods for testing high damping materials were reviewed in [

44]. These works demonstrated that materials with low ultrasonic attenuation, such as Al, Mg, and Fe-Cr alloys, can double as high damping materials at low frequencies and at high strain amplitude [

41,

42,

43,

44].

For polymers, this hysteresis effect comes from molecular rearrangements [

9,

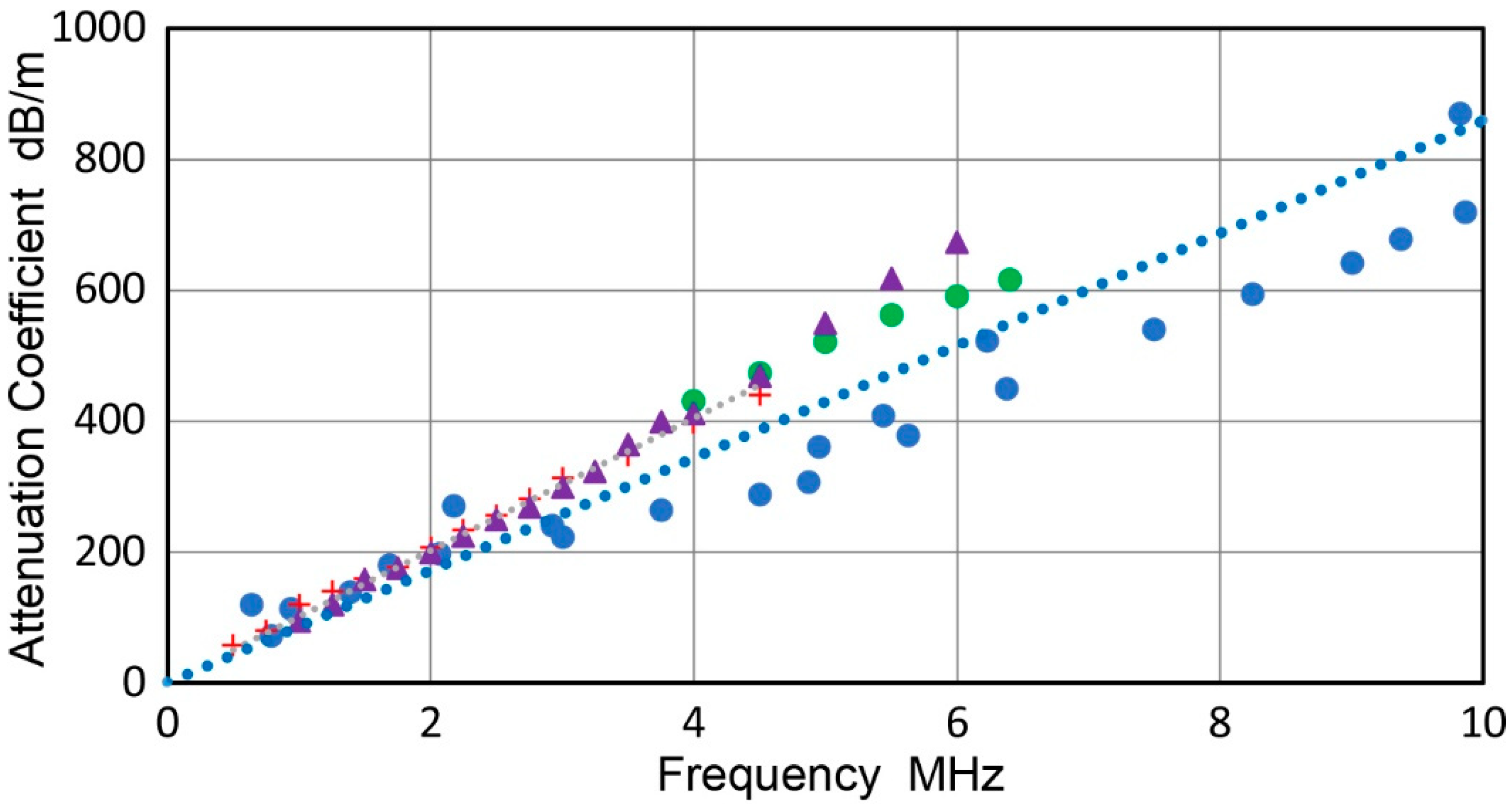

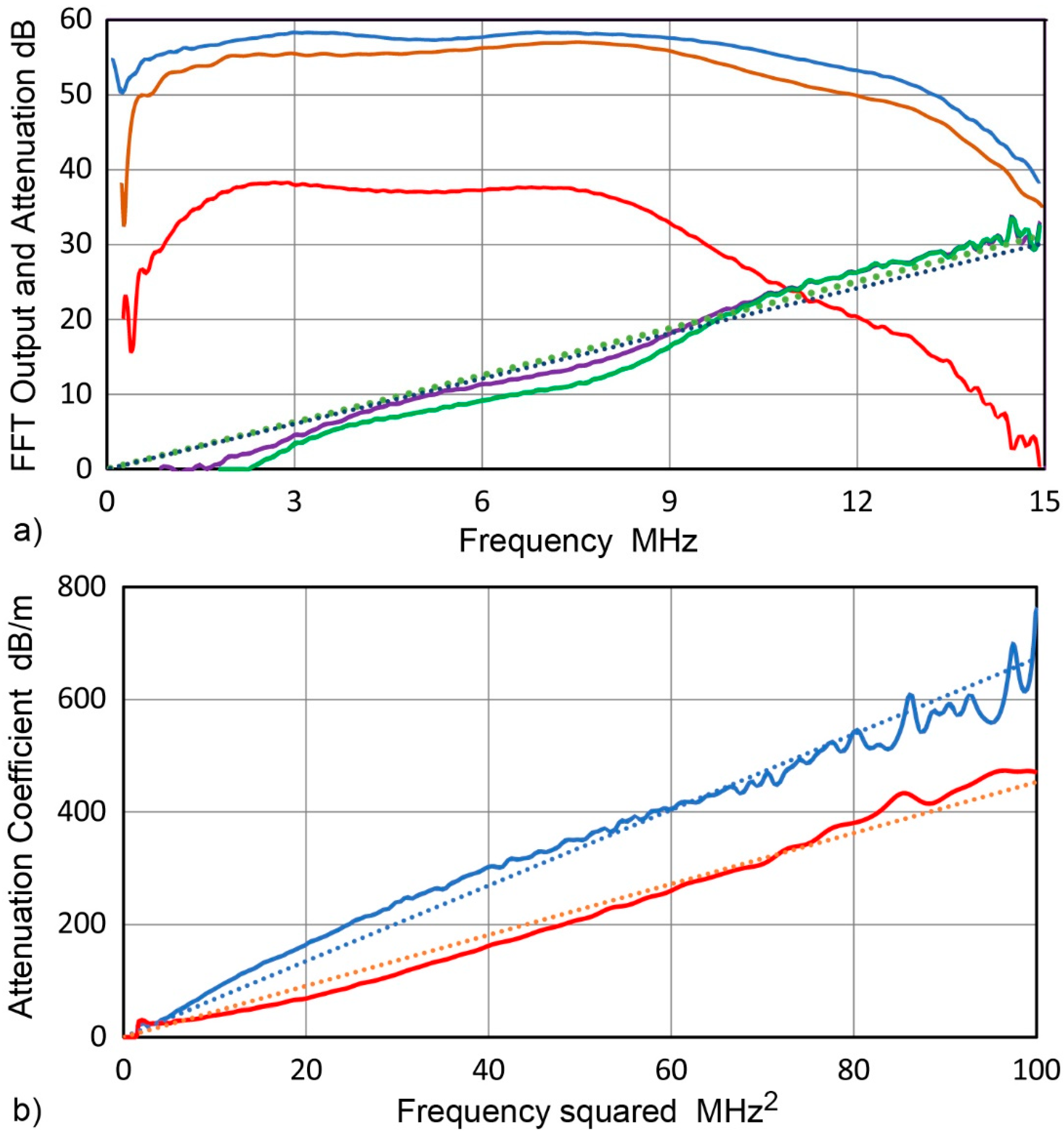

10]. An example of the frequency dependence of this hysteretic damping is shown in

Figure 1 for PMMA. In this plot, data points from multiple sources are combined, including Kline [

19], Pouet and Rasolofosaon [

24], Carlson et al. [

25], and Treiber et al. [

26], resulting in a linear regression fit with C

d = 85.9 dB/m/MHz (shown by the blue dotted line). The data points formed two groups, with a smaller slope for Kline’s older collected data from six studies and a larger slope for another group that was more recent [

24,

25,

26]. Data from both groups exhibited linear frequency dependence in the MHz range. However, the damping factor started to increase below 1 MHz by a factor of 3 to 5, showing a maximum at 50 Hz (3 Hz for torsional vibration) [

7]. For rocks, attenuation studies covered similarly wide frequency ranges, and α

d was found to show linear frequency dependence from 1 kHz to 1 MHz; that is, Q values were constant [

45].

Scattering is another cause of wave attenuation. Rayleigh scattering that depends on the fourth power of frequency, f

4, arises from random scattering centers, such as grain boundaries and distributed second phase particles [

8]. This occurs when the distance between scattering centers, d, is much less than λ, or λ >> d. For single phase alloys, polycrystalline grain size is used as d, which is of the order of 10 to 100 µm for most structural metallic alloys. Thus, this Rayleigh scattering effect, denoted by the attenuation coefficient due to scattering, α

s, becomes significant above 5 to 10 MHz. Because of the 4th power frequency dependence, this attenuation effect shows a steep decrease with decreasing frequency, often becoming negligible in the low MHz region. This behavior was reported by [

8,

18,

20,

46]. Using a constant C

R for Rayleigh scattering, we have

Mason and McSkimin [

8] used the sum of α

d and α

s to represent their attenuation data for large-grained Al. This is given as

and will be referred to as the Mason–McSkimin relation.

Stanke and Kino [

47] formulated a unified theory, which provides a smooth transition between three types of scattering in Rayleigh, stochastic, and geometric regions. Stochastic scattering gives f

2-dependence, and is applicable when the wave length λ is of the order of the mean spacing of scattering centers, such as grain boundaries and second-phase particles; this is above 20 MHz for typical metals. The geometric scattering types appear to be insignificant in usual NDE applications below 20 MHz and are not considered in this work. Other power law attenuation effects may exist and can be described as α

n = C

n f

n. This has been used when it is needed to fit experimental observation. It is known that water attenuation follows the quadratic form, while other liquids exhibit slightly lower n values [

1,

48,

49]. For the case of n = 2, attenuation can also arise from dislocation damping in crystalline solids [

20,

33,

34,

35,

36], with α written as

That is, the KGL theory predicts quadratic frequency dependence, and it is necessary to investigate the mechanisms of dislocation damping, which predict the linear frequency dependence, as in the case of polymer damping. This will be discussed in the next section.

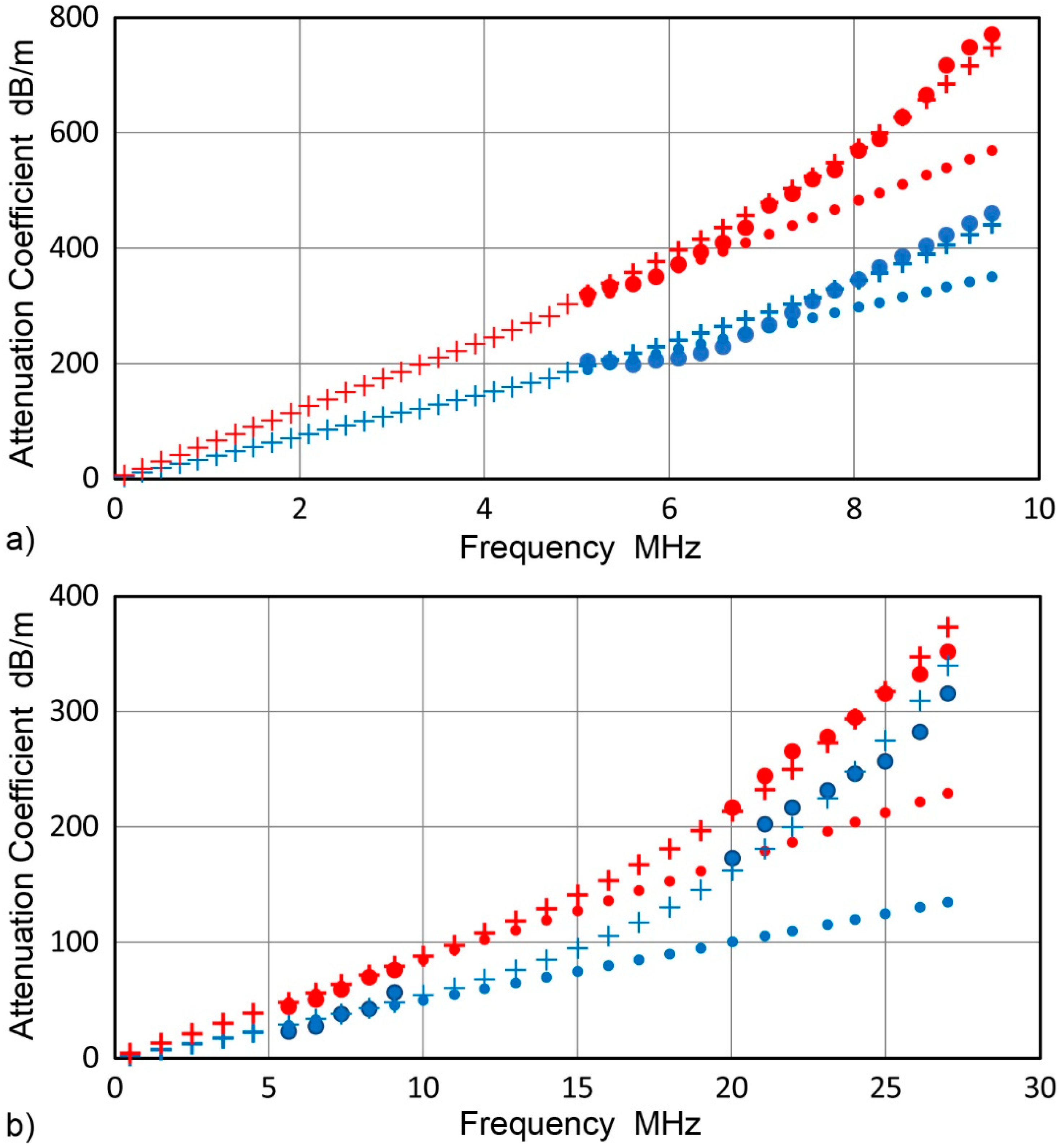

Another quadratic frequency dependence of attenuation was observed in particulate–epoxy composites. Kinra et al. [

50] observed a sharp rise in attenuation with frequency using 0.3-mm diameter glass spheres finely distributed in epoxy matrix. The α data for the case of 0.451 volume fraction is plotted in

Figure 2a after converting the unit for α into dB/m. A second-order polynomial curve fits the data well, with R

2 = 0.987. This is a combination of Equations (2) and (5), or

with C

d = 36.3 dB/m/MHz and C

2 = 545 dB/MHz

2. This will be referred to as the Datta–Kinra relation (with or without C

d term), as it is based on theoretical works by Datta [

51,

52]. These types of spectra were seen for gray cast iron data, in addition to 26 other cases.

For unidirectional fiber-reinforced composites, Biwa and coworkers [

53,

54] modeled longitudinal wave attenuation in the normal fiber direction and provided graphical data of a scattering cross-section vs. frequency (both in normalized values). Reading selective data points from [

53] and converting the frequency for the case they analyzed,

Figure 2b shows the results. Biwa data can be fitted well (R

2 = 0.998) to a cubic frequency dependence, or

with C

3 = 550 dB/m/MHz

3. Again, the damping term is usually non-zero, giving the Biwa relation given by

In the present study, this Biwa relation fitted to eight out of 13 observed composite attenuation datasets in the surface normal direction. In one of them (Kevlar composite), the cubic spectrum (Equation (7)) best described the attenuation.

In early attenuation studies of metals, viscous damping effects were shown to be low by Mason and McSkimin [

8] and others (see [

7,

14] for earlier works). Krautkramer’s book [

1] listed α values as less than 10 dB/m at 2 MHz for most structural alloys (except for copper-based alloys) in the first edition in 1969. In subsequent years, research activity on this topic, especially below 5 MHz, has been sparse. In addition to absorption studies noted above [

37,

38,

39], Smith et al. [

18] separated α

d terms of steels of various carbon (C) contents. The levels of attenuation were low, with C

d values of 0.7 to 3.5 dB/m/MHz. In most other attenuation studies, only the scattering terms have been examined. However, some works reported results showing that it is unwise to ignore the damping term.

Figure 3 gives some examples. Observed attenuation coefficients are plotted as circles (in blue or red) for a low-C steel (

Figure 3a, with data from [

55]) and for pure niobium (

Figure 3b, with data from [

56]). For steel, Ahn and Lee [

55] normalized 0.2% C steel samples at 900 and 1100 °C, and obtained α values for 5 to 9 MHz, fitting them using a power law, with n measuring approximately 1.5. However, such power law fits have no rational basis from existing theories. These data sets can be modeled using the Mason–McSkimin relation (Equation (4)), assuming that the low-frequency region possesses linear frequency dependence from damping, while the Rayleigh scattering law is obeyed at higher frequencies. The fitted data points are shown by blue or red + symbols, while blue or red dots represent the extension of the linear fit at low frequencies. In the niobium (Nb) case, the data from Zeng et al. [

56] is plotted in

Figure 3b, indicating α values for two grain sizes (blue for 32 µm and red for 60 µm). Here, available Nb data jumps from 9 to 20 MHz, giving two frequency bands. Zeng et al. [

56] compared their data sets with the Stanke–Kino theory [

47], but no match was achieved. Using the Mason–McSkimin relation, it is possible to combine damping and scattering components, as shown by blue or red + symbols in

Figure 3b. The match was poorer than for steel, however, as the frequency range extends to 27 MHz in this Nb study. While the combined damping–scattering attenuation apparently rationalizes the observed behavior, no theoretical basis is currently available to explain the level of damping, including the KGL theory noted above [

33,

34,

35,

36,

37].

Since the damping term was not often utilized after 1960 outside the composite field, one of the objectives of the present study is to examine how broadly the Mason–McSkimin relation exists in various materials. It is anticipated that more detailed studies on dislocation effects, including atomistic or molecular dynamic simulations, will be required to establish improved quantitative mechanisms for damping. The extent of applicability of Datta–Kinra and Biwa relations is also of interest as these have not been tested with real attenuation data. These three relations (Mason–McSkimin, Datta–Kinra, and Biwa) are named in this report. Other aims of this work are to experimentally obtain the attenuation coefficients (α) of a wide range of materials in the low MHz range (below 15 MHz), so as to present them in tabular form, to give information that is useful in material selection, and to provide rational interpretation of attenuation behavior. This information will also aid in improving model calculations for distance–amplitude curves for UT and predicting the detectability of AE signals on large structures. Over 300 samples were used, mainly based on the availability in the author’s laboratory, as well as some new acquisitions. Experimental procedures describe transmission difference methods used for attenuation measurements without requiring the reflectivity of interfaces. The Results and Discussion section provides separate tables for different types of materials, metals (steels, non-ferrous alloys, and cast iron), polymers and wood, fiber-reinforced composites, and ceramics and rocks. This part covers general observations and includes comments on peculiar material behavior observed for some groups, such as cold-worked metals and cast iron. Also noteworthy is a transition discovered in mortar spectral results, which changed from the Mason–McSkimin to Datta–Kinra spectrum when void content exceeded 20%. This represented a change from independent to multiple scattering.

2. Dislocation damping

Dislocation damping has been analyzed based on the Koehler vibrating string model [

33]. Koehler–Granato–Lücke (KGL) formulation showed a linear frequency dependence of damping factor η below the resonance frequency of around 20 MHz [

34,

35,

36]. In terms of attenuation coefficient α, this becomes quadratic frequency dependence through Equation (1). Heiple and Birnbaum [

57] derived an explicit equation for this linear part between logarithmic decrement (∆ = π η) and angular frequency. The logarithmic decrement for Cu was measured in multiple studies at kHz frequencies. At 20 to 25 kHz, ∆ was found to vary on the low side, ranging from 0.001 [

58] to 0.0037 [

57] and as high as 0.08 [

59], with a median value of 0.007. This ∆ range agreed with the prediction of the KGL model using the dislocation drag factor obtained from theory, experiments and atomistic simulations [

60,

61,

62]. Low-frequency internal friction studies used a strain amplitude range of 10

−7 to 10

−5 [

58,

59,

60], but one study used an amplitude of up to 3 × 10

−4 [

58]. In ultrasonic attenuation studies, the strain amplitude is slightly lower at 10

−6 to 10

−7, since most transducers can only generate 1 to 10 nm peak output [

63] and samples are over 10 mm. The two approaches cover comparable strain amplitude ranges. These kHz data were extrapolated to 1 MHz and converted to α values to compare them with ultrasonic attenuation. The α values from internal friction studies were 0.22 to 8.65 dB/m and the median α was 1.5 dB/m at 1 MHz. In contrast, ultrasonically obtained α values for Cu were 3–100 times higher and typically exhibited the linear frequency dependence (except in two cases in a slightly cold-worked plate). The linear frequency dependence of α was the dominant feature of the present study for various solids. Thus, it is necessary to explore another source of dislocation damping that depends linearly on frequency.

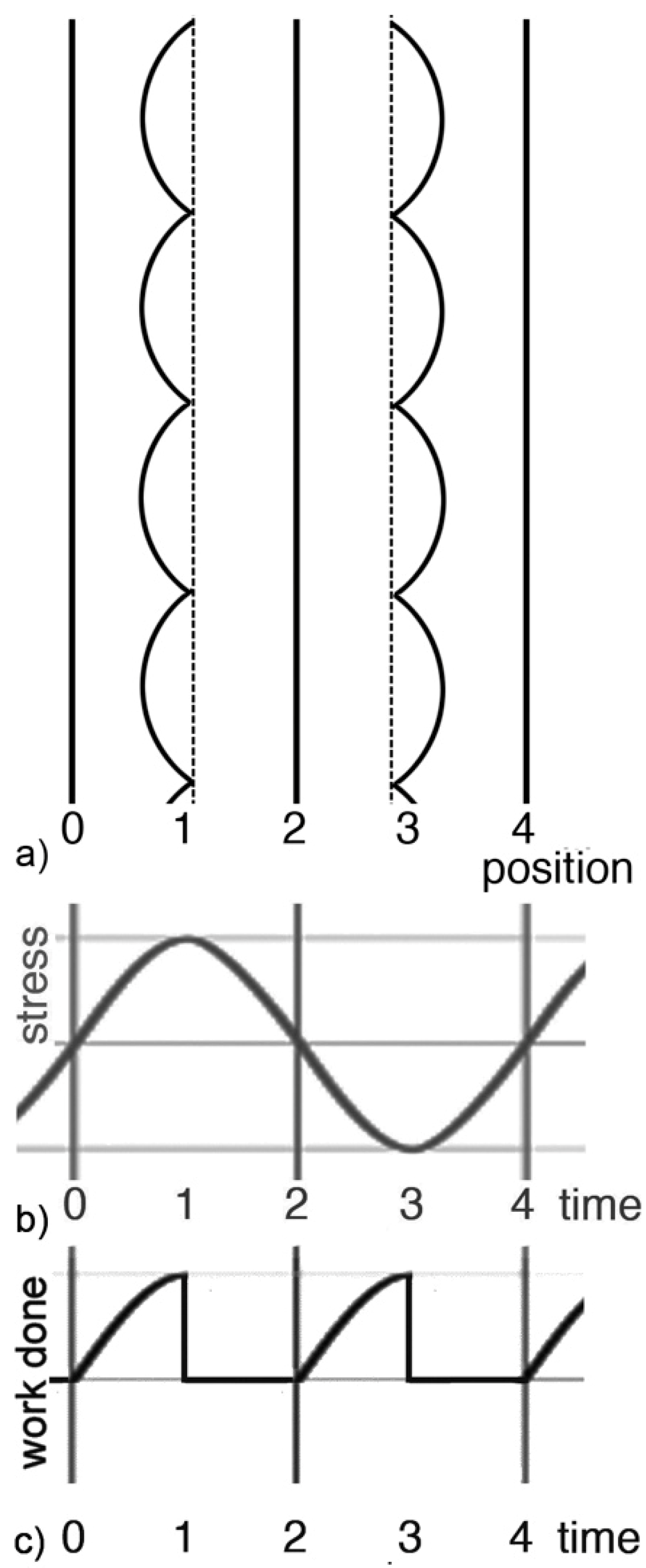

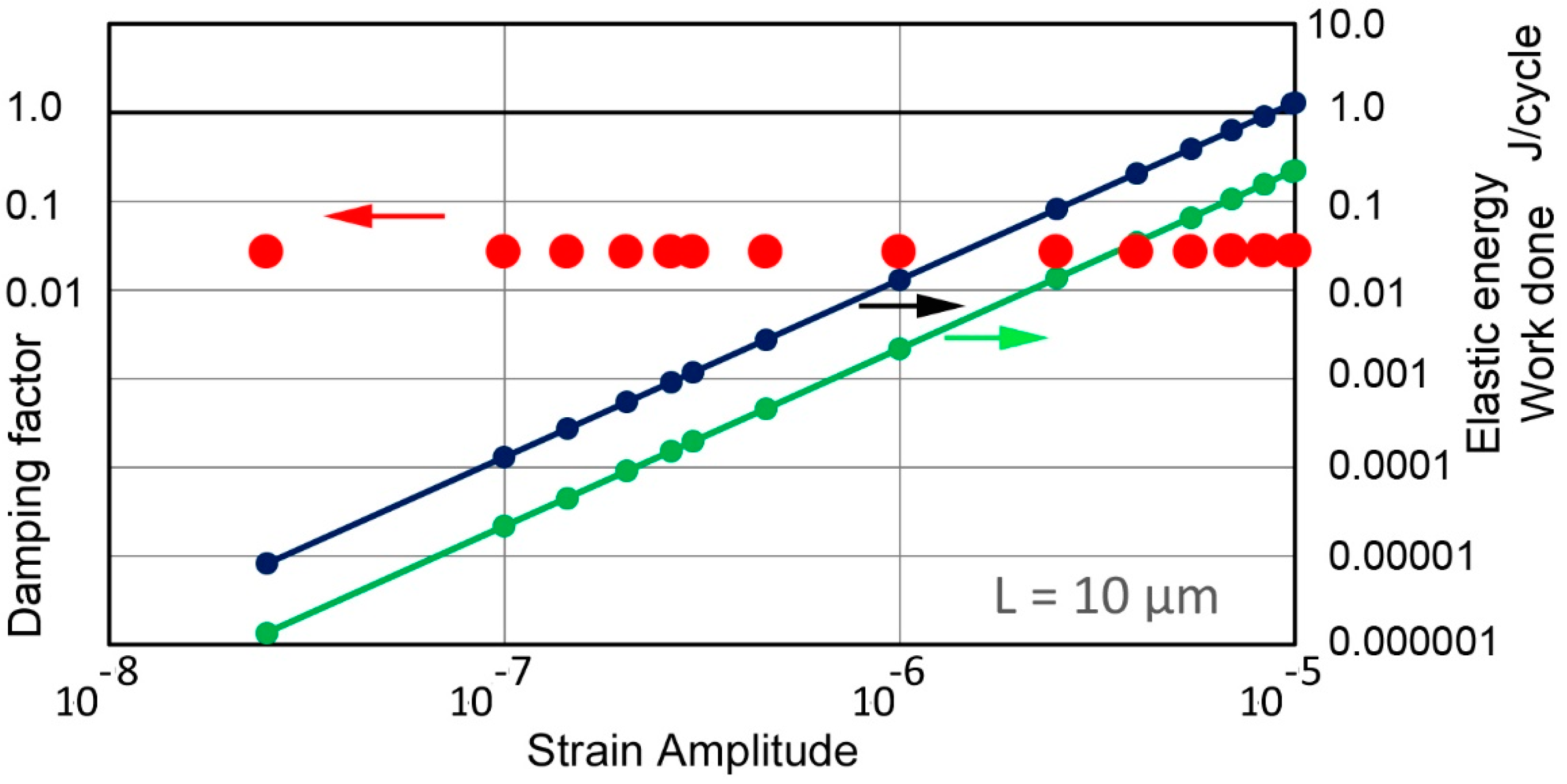

When pinned dislocation segments are cyclically stressed, they oscillate, as shown in

Figure 4a. It is assumed that they have a constant segment length, L, and are distributed uniformly in space. Low lattice resistance for dislocation motion in solids with non-local bonding is also assumed, as shown by Gilman [

64]. Starting from a straight line at stress position 0 and at time 0, each segment bows out to the left in the first quarter-cycle under applied stress (

Figure 4b) and becomes a series of circle segments at position 1 and time 1. Between 0 and 1, stress increases to the positive peak and work is added by moving the dislocation segments while lengthening the segments, which increases the elastic energy stored in the solid medium. The added work, shown in

Figure 4c, is lost as heat. Between times 1 and 2, the dislocation returns to the straight line (position 2). This is driven by the shrinkage of the lengthened dislocation as the dislocation segments are moving against positive stress. This is repeated from positions 2 to 4 in reverse manner, again generating energy loss in the form of work done by the moving dislocation segments, pushed by negative applied stress. As will be shown below, dislocation motion is quasi-static, but the dislocation drag term still acts against the motion. For each cycle, energy loss occurs twice during the positive and negative half-cycles, contributing to damping, which is proportional to frequency. This linear behavior originates from the work caused by dislocation motion during each half-cycle. The amount of work caused by the bow-out process can be calculated from the basic dislocation theory [

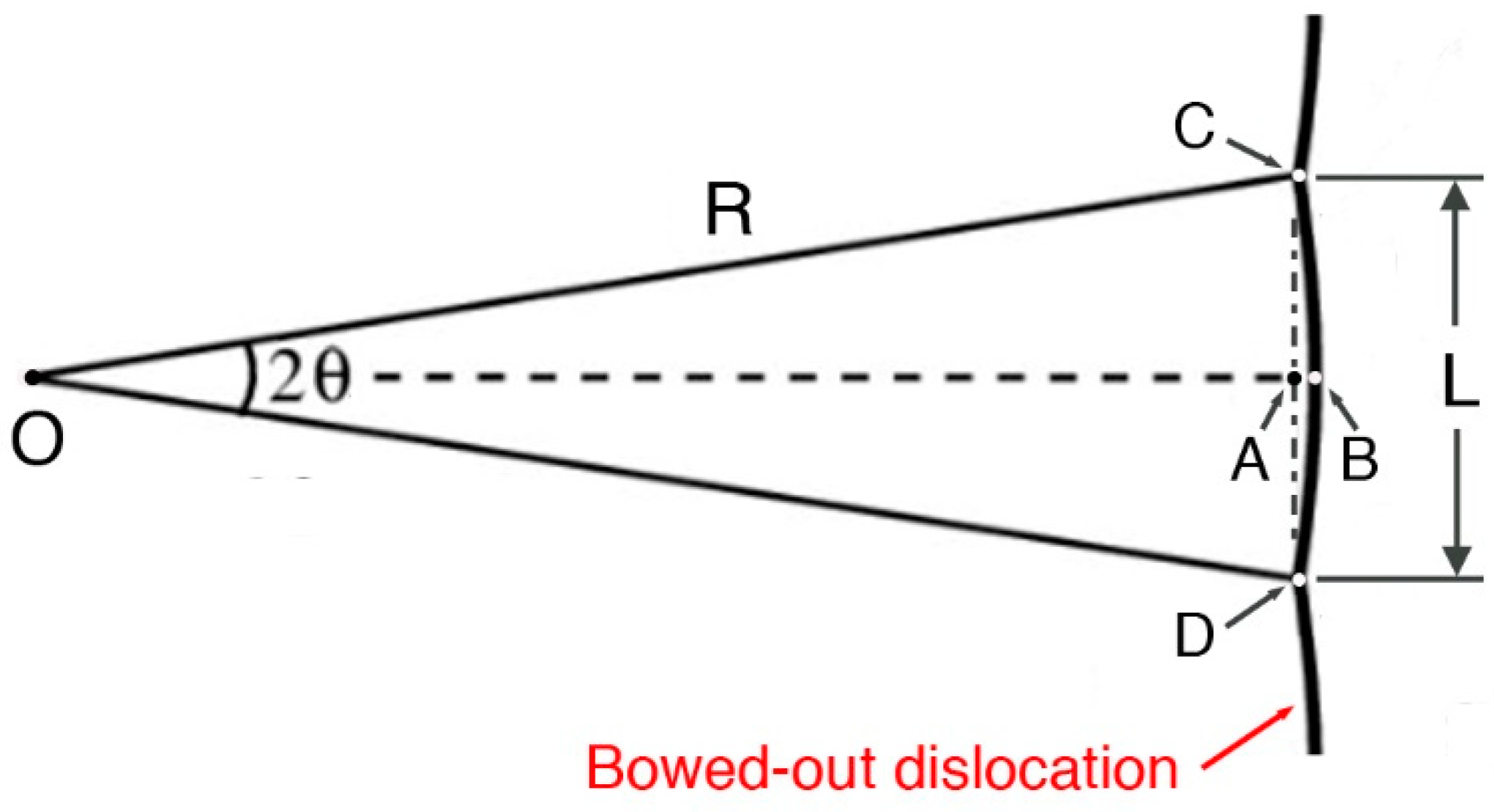

65]. A bowed-out segment with Burgers vector magnitude, b, is shown in

Figure 5 under shear stress τ acting on the slip plane. The distance of the bow-out is equal to length from A to B, defined as [AB]. Here, square brackets indicate length. L is equal to [CD], and the radius of the curvature of the bowed-out segment (arc CBD) is denoted as R = [OB] = [OC] = [OD]. The angle 2θ is defined by lines OC and OD. For this geometry, R is given by

The force on the bowed-out segment (arc CBD) is equal to τ bL, and this is balanced by the opposing components of the line tension (= 2a

T Gb

2 sin θ), where a

T is a line-tension constant of 0.5 and G the shear modulus. Expressing stress using a strain a

S with the shear modulus G, or τ = a

S G, and using Equation (9), we have [

65]

which reduces to

which relates the strain amplitude a

S to R; that is, given a

S and pinned segment length L, the values of θ and R can be determined, allowing one to calculate the area of the bow-out A

B (bounded by ACBD), as below.

This leads to the work done by each bow-out by multiplying τ b/2 = a

S Gb/2. Here, a factor of half is needed because applied stress is cyclic, and another factor of half is also needed since the second quarter-cycle contributed no work. It should also be noted that A

B/L corresponds to the average distance of dislocation motion. When the work done per half-cycle, a

S Gb A

B/4, for each elemental volume of L

3 is doubled (for positive and negative motion) and divided by L

3, the unit volume value of work done per cycle is obtained. The applied strain energy per unit volume per cycle is G a

S2/2. The ratio of work done to the applied strain energy gives the damping factor η at the strain amplitude a

S by adding 2π in the denominator, since η = (energy loss)/2π (stored energy). Then, one gets

For a

T = 0.5, G = 26 GPa, b = 0.3 nm, and L = 10 µm, the work done, applied strain energy, and damping factor were calculated for a

S of 2 × 10

−8 to 10

−5 and plotted in

Figure 6.

For the strain amplitude range of 2 × 10

−8 to 10

−5, η values remain almost unchanged at 0.027. This is a very high value for metals and is high even for polymers. When the wave length of Al is used at 1 MHz, the η value corresponds to α = 117 dB/m. The range of a

S is wide and the maximum a

S corresponds to stress, which is one-third of the Orowan stress of unstable bow-out (or break-away stress). Here, the maximum bow-out distance was 0.86 µm under 260 kPa, indicating the maximum dislocation velocity was 3.4 m/s at 1 MHz excitation. This is about 1000 times slower than the shear wave velocity of Al (3.1 km/s) and the dislocation motion can be regarded as quasi-static. On the other end of low a

S, the maximum bow-out under 0.52 kPa was 2.1 nm, with a dislocation velocity of 8.4 mm/s. Still, the same level of damping is predicted. Such dislocation velocities were well below the velocities limited by the dislocation damping coefficient, B. Hikata et al. [

60] experimentally obtained B = 5.0 × 10

−6 Pa·s at 300 K, while Olmsted et al. [

61] found B = 1.4 × 10

−5 Pa·s at 342 K via a molecular dynamics (MD) approach. Another MD result [

62] gives B = 2.8 × 10

−5 Pa·s at 100 K (averaging screw and edge values). At 260 kPa, these B values predict dislocation velocities of 5.5 to 156 m/s, all exceeding the maximum dislocation velocities needed in the proposed bow-out mechanism of dislocation damping; that is, the bow-out damping mechanism operates in the quasi-static regime.

When L is reduced to 1 µm, η values are almost unchanged at 0.027. Each elemental volume contributes less, but their number increase by 1000-fold. When a

T is reduced, dislocation becomes flexible and damping increases substantially. Lower values of a

T (of 0.1 to 0.5) are sometimes used in atomistic calculations [

66]. At a

T = 0.1, the work done is 90% of the applied elastic energy, increasing η by five-fold; that is, η varies in proportion to a

T. It appears that low line tension of a

T below 0.1 is unrealistic. Thus, as long as dislocations are mobile with low stress, oscillating dislocations provide the basis for rationalizing the linear frequency-dependent damping behavior. However, the lack of effect of pinning length reduction on η values is surprising, as this was initially thought to offer a clue in understanding cold working effects. The explanation of two contradictory cold working effects will have to be sought elsewhere [

67].

The dislocation bow-out mechanism proposed above is based on shear deformation, so the attenuation is for the shear wave propagation. However, the attenuation also applies to the longitudinal wave mode, as the normal and shear stresses (or strains) are related via the Taylor factor, M (or 1/M) [

68]. Consequently, the strain energy and external work terms are unaffected by the coordinate transformation involved; that is, the attenuation coefficients from dislocation damping are identical in the longitudinal and shear modes of wave propagation. Mason and McSkimin [

8] and Papadakis [

41] made the only known direct comparison of attenuation coefficients between the longitudinal and shear modes, reporting 2.5- to 8-fold increase for the shear attenuation for five metallic materials. However, most of these were taken at 10–15 MHz, where the Rayleigh scattering caused the attenuation. Further study is needed to find if similar differences persist at lower frequencies, as was the case of 2017 Al alloy [

8]. If so, the above prediction of the bow-out mechanism will have to be reconsidered.

Many mechanisms can lower attenuation to the ranges of observed α values, including higher lattice resistance to dislocation, dislocation–dislocation interactions, solute atmospheres, and distribution of the second phase. However, the dislocation bow-out mechanism introduced here does provide a new approach to account for the linear frequency dependence of the attenuation coefficient in non-viscoelastic solids. The main limitation of this mechanism is its inability to explain the attenuation of hard solids. These have low dislocation mobility due to their intrinsic strength and their linear attenuation behavior remains unresolved.

3. Materials and Experimental Procedures

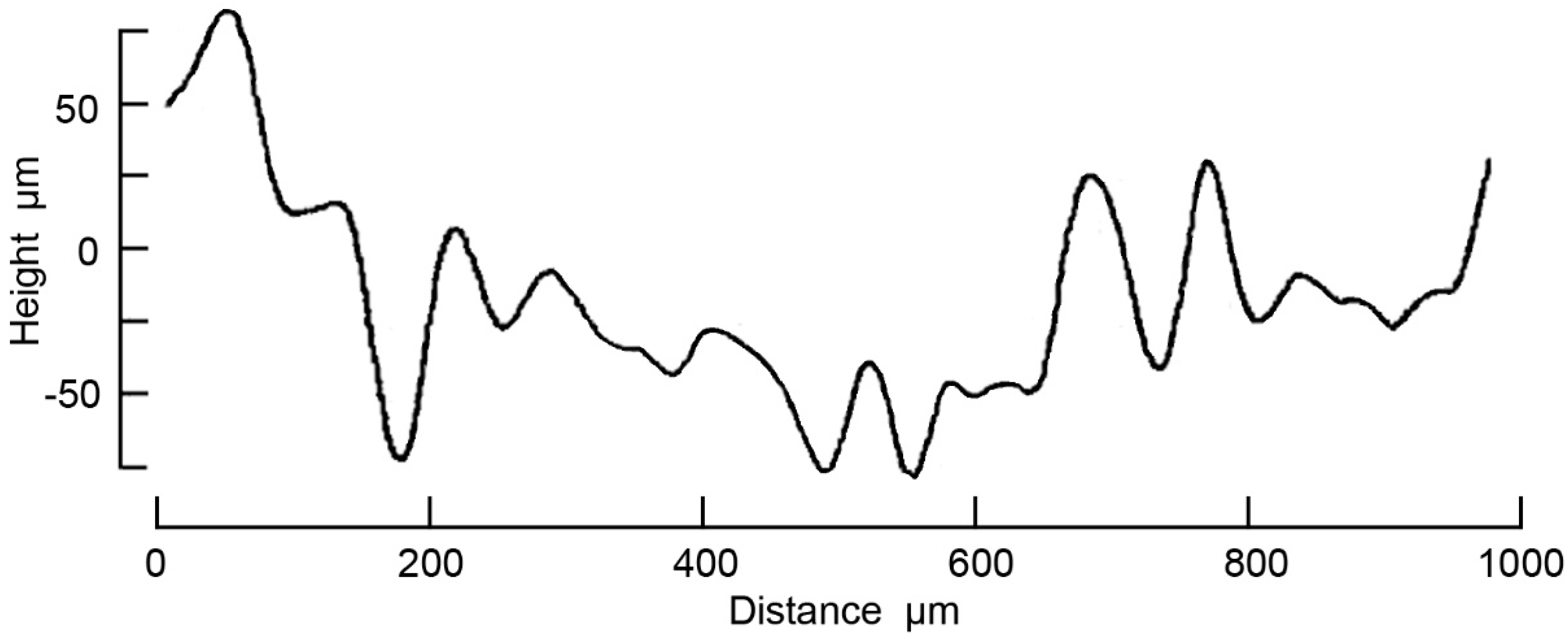

Attenuation measurements were conducted on solid samples with two parallel surfaces. Over 300 tests were completed and their results will be reported in the following sections. Most materials tested were on hand from previous research or instructional work, with detailed characteristics for some, but without for most. About a dozen samples were newly acquired for testing, mainly of rocks and wood materials to supplement existing stock. While some had known sources, chemical compositions, and heat treatment history, most were only identifiable by material types. In order to provide indications of material conditions, hardness tests (Vickers and Rockwell) were conducted for metal samples. For others, density was measured. The longitudinal wave velocity was determined for all, giving additional clues to material conditions. In limiting cases when multiple samples are available, heat treatment was applied to find the effects of microstructural changes on attenuation. However, metallography was not used, as suitable sample preparation facilities were unavailable.

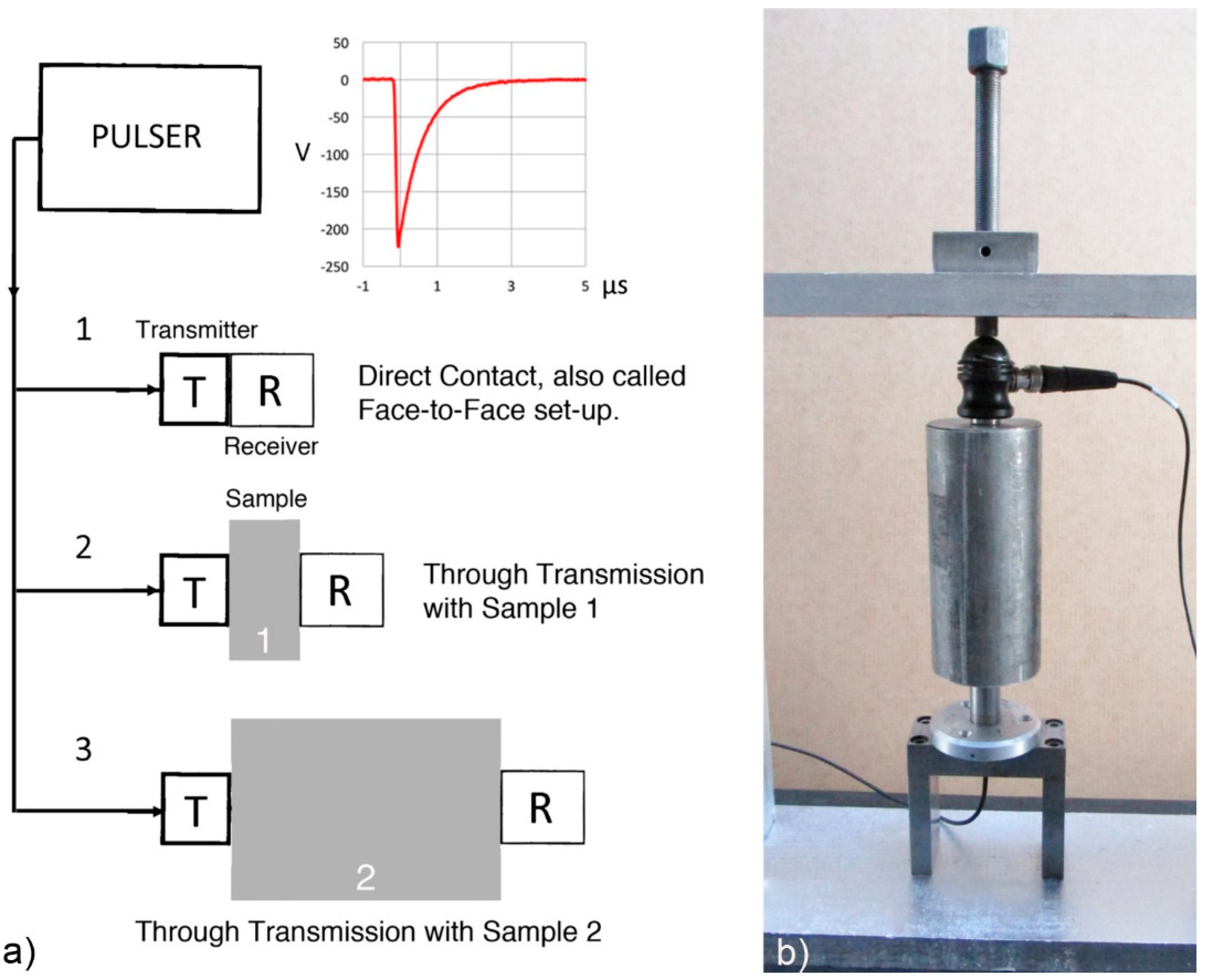

Attenuation measurements were utilized through transmission setups. This method uses damped, wideband transducers, as in the buffer rod methods of Papadakis et al. [

16], and relies on two transducer setups, as in [

26]. However, the present method avoids using the reflectivity parameter in the attenuation calculation [

16,

26]. The present approach uses setups shown schematically in

Figure 7a. Also included is a photograph of one of the jigs used to hold samples (with an Al rod shown) and transducers (

Figure 7b). Setup 1 is used for direct contact of the transmitter and receiver, giving the voltage output V

1 from the receiver as a result of transmitter excitation by a pulser. This is often called face-to-face testing. Setup 2 contains sample 1 between the transmitter and receiver, while Setup 3 contains sample 2 between the transmitter and receiver. These yield V

2 and V

3, respectively, in response to pulser excitation. By applying a fast Fourier transform (FFT) on V

1, V

2, and V

3, one gets the corresponding frequency domain spectra R

1, R

2, and R

3, expressed in dB (in reference to 0 dB at 1 V). Expressing the transmitter output (in reference to 0 dB at 1 nm) and receiver sensitivity (in reference to 0 dB at 1 V/nm) as T and R (also in dB), one obtains

where X

1 and X

2 are the thickness of samples 1 and 2, D

1 and D

2 (= –20 log D) are the diffraction corrections of samples 1 and 2 (D is given in Equation (15) below), and T

c is the transmission coefficient of the sample going from the transmitter to the receiver (Equation (16)). The diffraction loss D for sample thickness x using two circular transducers of the active radius, a, is given by [

69]

where s = x v

L/f a

2, with v

L being the longitudinal wave velocity. This is due to Rogers and van Buren [

69], who integrated the Lommel integral for a circular piston motion received over the same sized area, located at distance x. D is frequency-dependent and was first obtained numerically by Seki et al. [

70]. Notice that the D calculations relied on the isotropic elasticity theory. In materials with highly anisotropic elastic moduli, such as unidirectional fiber composites, this condition is absent and D is omitted, as it leads to overcorrections. Diffraction correction in more complicated conditions can be obtained by combining multiple Gaussian beams from a piston source [

71]. T

c arises from the differences in acoustic impedances of the transducer face (Z

t) and sample (Z

s), and is given by [

1]

This expression for Tc assumes the usual condition of the planar wave front. Because the transducer face material is alumina (Zt = 38 Mrayl), Tc may be omitted when a sample has Zs larger than 30 Mrayl (for an error of 0.1 dB), unless attenuation values are low. Both Dn (n = 1 or 2) and Tc are expressed in dB. Dn is frequency-dependent, while Tc is assumed to be a constant. Note that Dn increases linearly with frequencies below 0.1 to 2 MHz for the typical experimental conditions used in the present study. Here, Dn values often exceeded observed attenuation effects and useful attenuation data were only obtained in the near-field region, where Dn values varied slowly with frequency (e.g., at f >2 MHz for 66 mm Al and >0.2 MHz for 10 mm PMMA).

By using two of the three equations (Equations (14a), (14b), and (14c)) given above, one gets

As Equations (17b) and (17c) are equivalent, two distinct methods can be utilized. The first uses setups 2 and 3 with Equation (17a). This approach cancels out the effects of the transmission coefficient due to acoustic impedance mismatch. Coupling layer effects are also canceled. The second method utilizes setups 1 and 2 with Equation (17b). These two approaches will be called transmission difference methods 1 and 2, with TDM-1 and TDM-2 as abbreviated terms. That is, TDM-1 uses two sample thicknesses, x1 and x2, with setups 2 and 3, and obtains the value of α from Equation (17a). In contrast, TDM-2 uses one sample thickness, x, with setups 1 and 2 (or 3). The value of α comes from Equations (17b) or (17c). This is more convenient than TDM-1 because only one sample is needed, but requiring the use of Tc. Preparing two samples of different thicknesses is not practical for materials that are difficult to machine, but the effects of one extra coupling layer remain.

There is no direct way to measure the value of T

c, but when attenuation results are obtained by using both TDM-1 and TDM-2, the value of T

c can be estimated. By comparing the estimated and calculated T

c, a transmission coefficient correction (TCC) is obtained. This requires adjusting the T

c value in the determination of α by TDM-2, so that its result matches the TDM-1 result. TCC can be applied to TDM-2 results from similar test conditions. In

Section 4.1, three materials will be tested using TDM-1 and TDM-2. Results will be compared between them. If these two sets provide good agreement in the values of α, TDM-2 may be used in lieu of TDM-1, utilizing calculated T

c values. It was found that comparison provided no matching α values, but TDM-2 gave α values of 10% to 25% lower than those from TDM-1 tests. The differences were corrected by applying a TCC term of 2 to 7 dB. Even when TCC is not used, α values from TDM-2 can be treated as approximations. Thus, α values of most materials will be measured using TDM-2. Whenever multiple samples are available, TDM-1 will be used, since its results were less sensitive to the inadequacy in sample preparation and provided more reliable attenuation spectra with minimal couplant effects. The variability of reflectivity coefficients was shown by Generazio [

25] and Treiber et al. [

26] under different conditions. This indicates that transmission methods, such as TDM-1 and TDM-2, with no reflectivity terms are preferable.

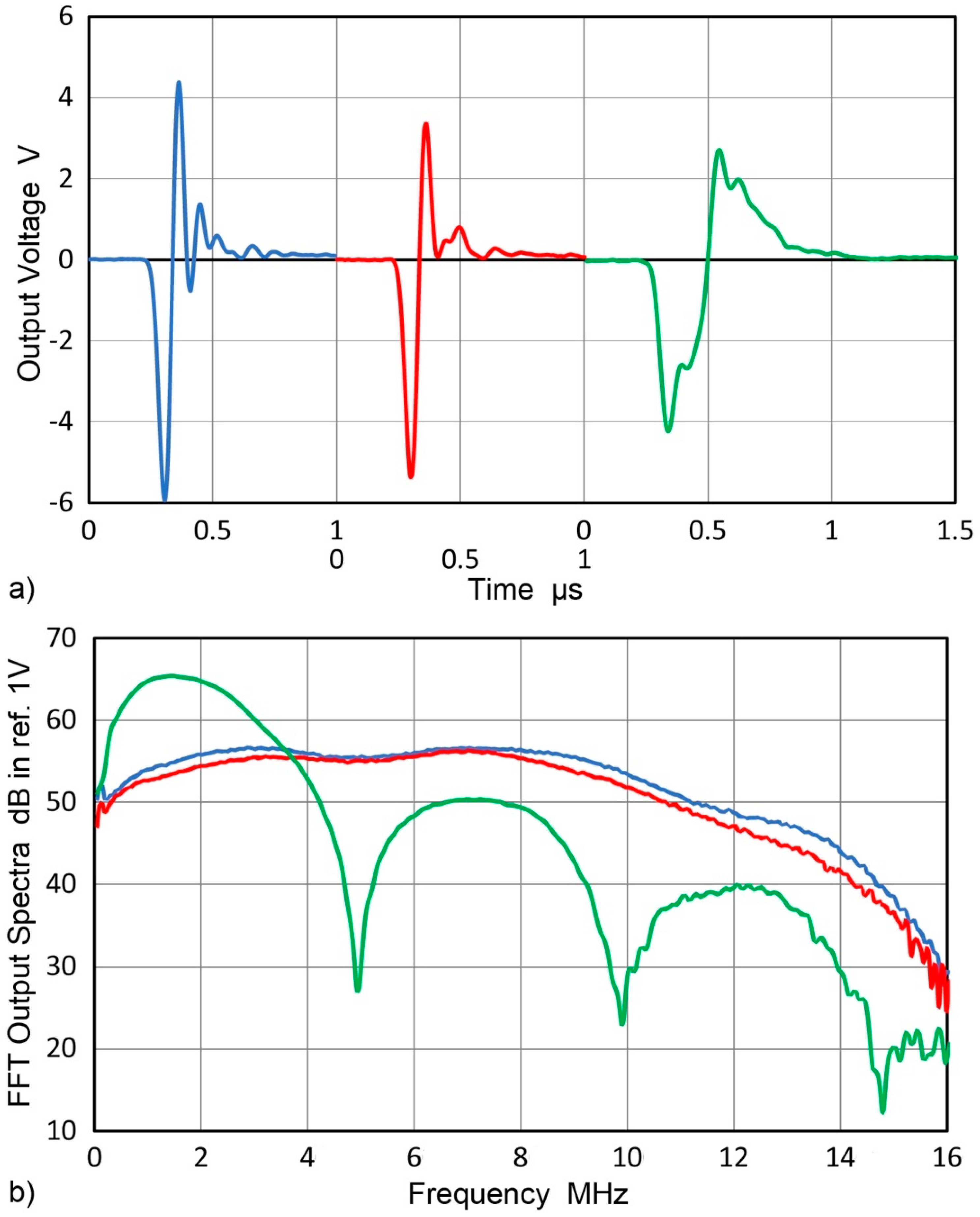

The diffraction loss D from Equation (15) depends on the transducer radius (a) through the s-parameter (s = xv

L /fa

2), sometimes known as the Seki parameter [

70]. For this work, four transducers with an element radius of 6.35 mm were used. These were an Olympus V111 and V103, Panametrics V1030 (Olympus NDT, Waltham, MA, USA), and NDT Systems C16 (from NDT Systems, Huntington Beach, CA, USA). Their nominal center frequencies are 10, 1, 10, and 2.25 MHz, respectively. For most experiments, the V111 and V1030 pair was used, but other pairings of low-frequency transducers were also used when the attenuation was high. Additionally, two Olympus transducers with a 12.7-mm radius—V104 (2.25 MHz) and V107 (5 MHz)—were used to determine the transmission coefficient correction (TCC). Examples of the face-to-face responses (V

1 waveforms and R

1 spectra) are shown in

Figure 8a,b. Careful alignment was essential in maximizing receiver output. In order to achieve good transducer–sample coupling with Vaseline couplant, it was necessary to apply approximately 200 N force for at least 30 min. Longer holding times were needed for setup 2 (and 3) before the output was stabilized. Peak-to-peak receiver voltages for direct contact were 7 to 10 V into a PicoScope 5242D (14 bit, 8 ns intervals, input impedance of 1 MΩ; Pico Technology, St. Neots, UK), showing useful signal levels to 15 MHz for pairs of 10 MHz transducers. Despite its low resonance frequency, C16 provided adequate transmitter output to 14 MHz, except at anti-resonance dips. FFT was performed with Noesis software (Enviroacoustics, Athens, Greece, ver. 5.8).

4. Results and Discussion

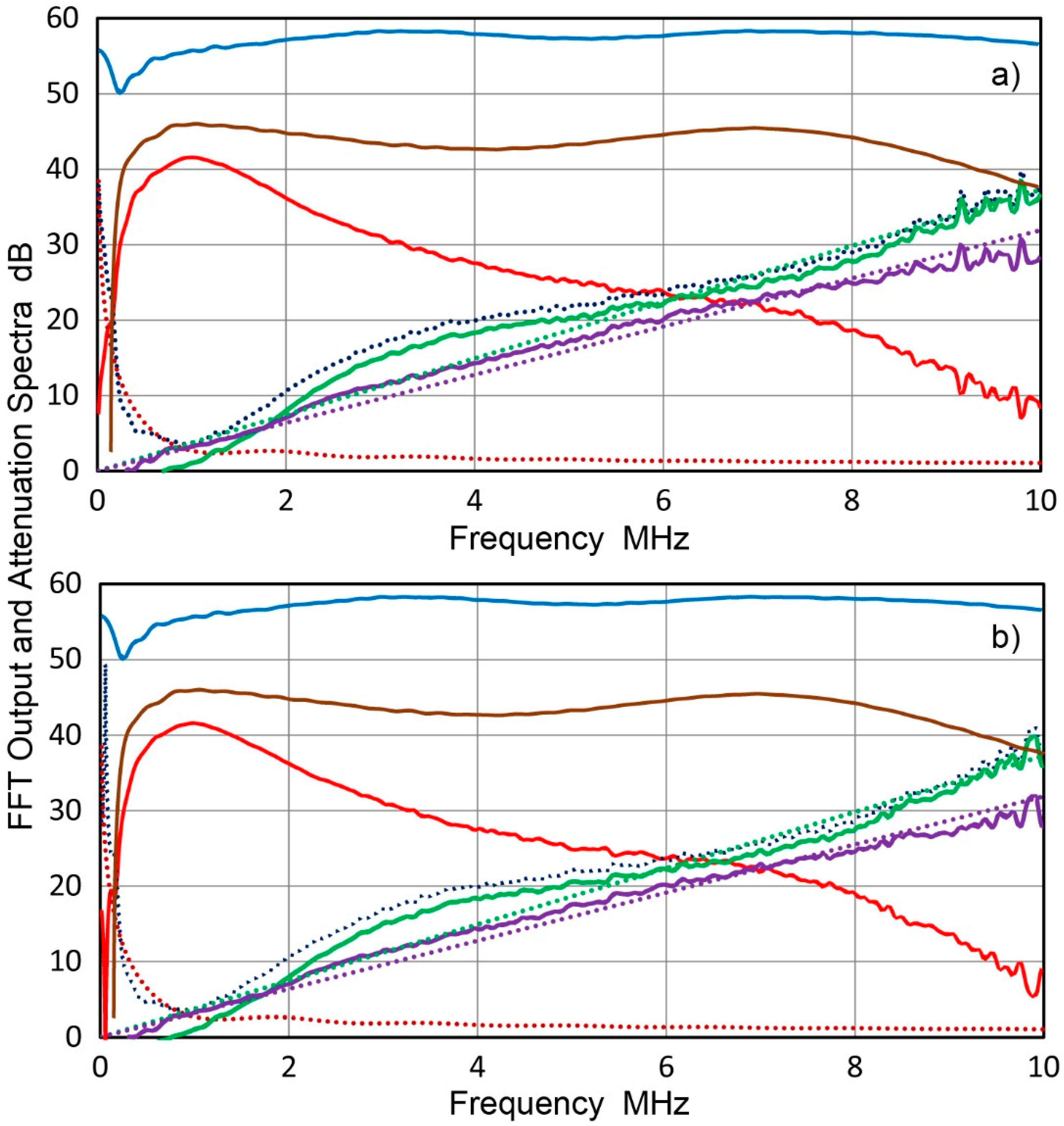

4.1. Comparison of TDM-1 and TDM-2

Two test methods, TDM-1 and TDM-2, were used on three polymeric materials with varying acoustic impedance. These were PMMA, polycarbonate (PC), and polyvinylchloride (PVC), as these had large values of transmission coefficient, Tc (PMMA: 10.4 dB, PC: 12.2 dB, PVC: 10.6 dB). These tests were conducted to determine values of transmission coefficient corrections (TCC) needed to adjust the attenuation coefficients from TDM-2 in-line with those from TDM-1, which are independent of transmission coefficient, Tc.

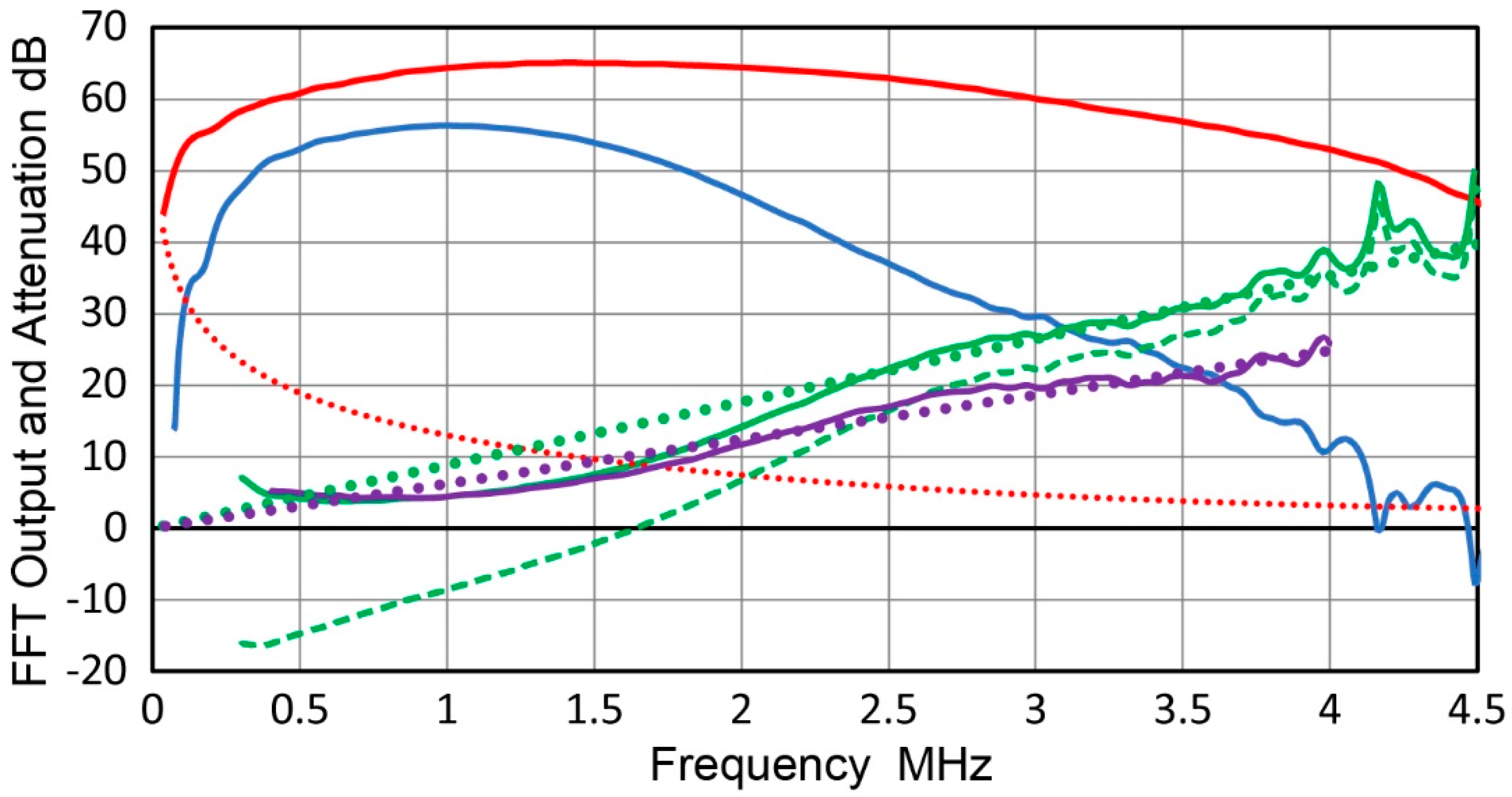

Figure 9a illustrates results of the two methods for PMMA samples with x

1 = 9.0 mm and x

2 = 45.6 mm. The thick sample was made from the same 9.0 mm plate as the thin sample, using epoxy glue measuring approximately 40 µm per adhesive layer. The blue, brown, and red curves represent R

1, R

2, and R

3 FFT spectra, respectively, corresponding to the outputs of direct contact, and with thin and thick samples. The difference between R

1 and R

3 is given by the blue dotted curve, and the brown dotted curve shows diffraction correction D

2 for the thick sample. Note that these two were close to each other below 1 MHz, where attenuation was low (for some transducer pairs of larger or smaller radii, differences were larger, indicating that a = 6.35 mm is an appropriate choice.) Purple and green curves show attenuation results for TDM-1 and TDM-2 for the propagation distances of (x

2 − x

1) for TDM-1 and of x

2 for TDM-2. For the TDM-2 data, a T

c value of 10.4 dB was included in the computation of Equation (17c). In both cases, diffraction correction was applied according to Equation (15). Linear regression fits for these curves are plotted by purple and green dotted lines. When the slopes of the linear equations are normalized by propagation distance, α values are obtained with Equation (2) using C

d, measured in dB/m/MHz, as follows (also in

Table 1):

Cd = 92.3 (R2 = 0.962) for TDM-1 and Cd = 83.7 (R2 = 0.937) for TDM-2.

Both TDM-1 results for Cd and R2 were higher than those of TDM-2. The difference of R2 values was small, but deviations were much higher in TDM-2, implying that careful slope estimation is needed based on FFT spectral behavior. In the present case, both R2 and R3 spectra showed broad reduction over 2 to 6 MHz, producing a positive deviation for the green curve. In this case, the regression fit for TDMA-2 appears justified, although α for TDM-2 was lower than α for TDM-1.

Figure 9b shows a similar graph, again for the two methods, but this time the thick sample came from a different plate with a thickness of 43.2 mm. TDM-2 results for the thick sample used the T

c term as required. For these cases, C

d values (in dB/m/MHz) were obtained as follows:

Cd = 98.7 dB/m (R2 = 0.971) for TDM-1 and Cd = 88.3 (R2 = 0.927) for TDM-2.

Results were slightly improved compared to those in

Figure 9a. In both comparisons, C

d values were within 9 to 10 dB/m/MHz. The second comparison also indicates that when their properties are similar, TDM-1 can still be used even with different raw stocks.

Seven additional comparison tests were conducted and all the results are summarized in

Table 1. From these nine sets of attenuation spectra, the average C

d value was 91.4 ± 4.9 dB/m/MHz for TDM-1 and 79.7 ± 8.8 dB/m/MHz for TDM-2, with an 11.4% higher C

d value for TDM-1. One of the PMMA tests used a set of larger transducers (12.7 mm diameter), which produced a much lower α value for TDM-2. The obtained TDM-1 α value was close to the average of three recent studies [

24,

25,

26], which was 103.3 dB/m/MHz. The averaged TDM-2 value was between the average data in

Figure 1 (85.9 dB/m/MHz) and averaged C

d value of 75.1 dB/m/MHz from the older studies collected by Kline [

19]. The averages of R

2 values were close, although visually TDM-1 plots were closer to straight lines. In all the attenuation spectra, no effect of scattering induced attenuation was observed for the amorphous polymers evaluated.

These test data were utilized to determine values of transmission coefficient corrections (TCC). Once a TCC is obtained, the TDM-1 attenuation coefficient can be estimated from TDM-2 tests. The results in dB were tabulated along with the corrected TDM-2 C

d values (see

Table 1). For eight PMMA tests using 6.4-mm diameter transducers, the TCC ranged from 1.9 to 3 dB, while it was 4.7 dB for the larger transducer pair; that is, the TDM-2 test could not approximate the TDM-1 test using 12.7-mm transducers without applying TCC, as its error was almost 40% without correction. However, the use of TCC is always recommended whenever the amount of attenuation through a sample is low.

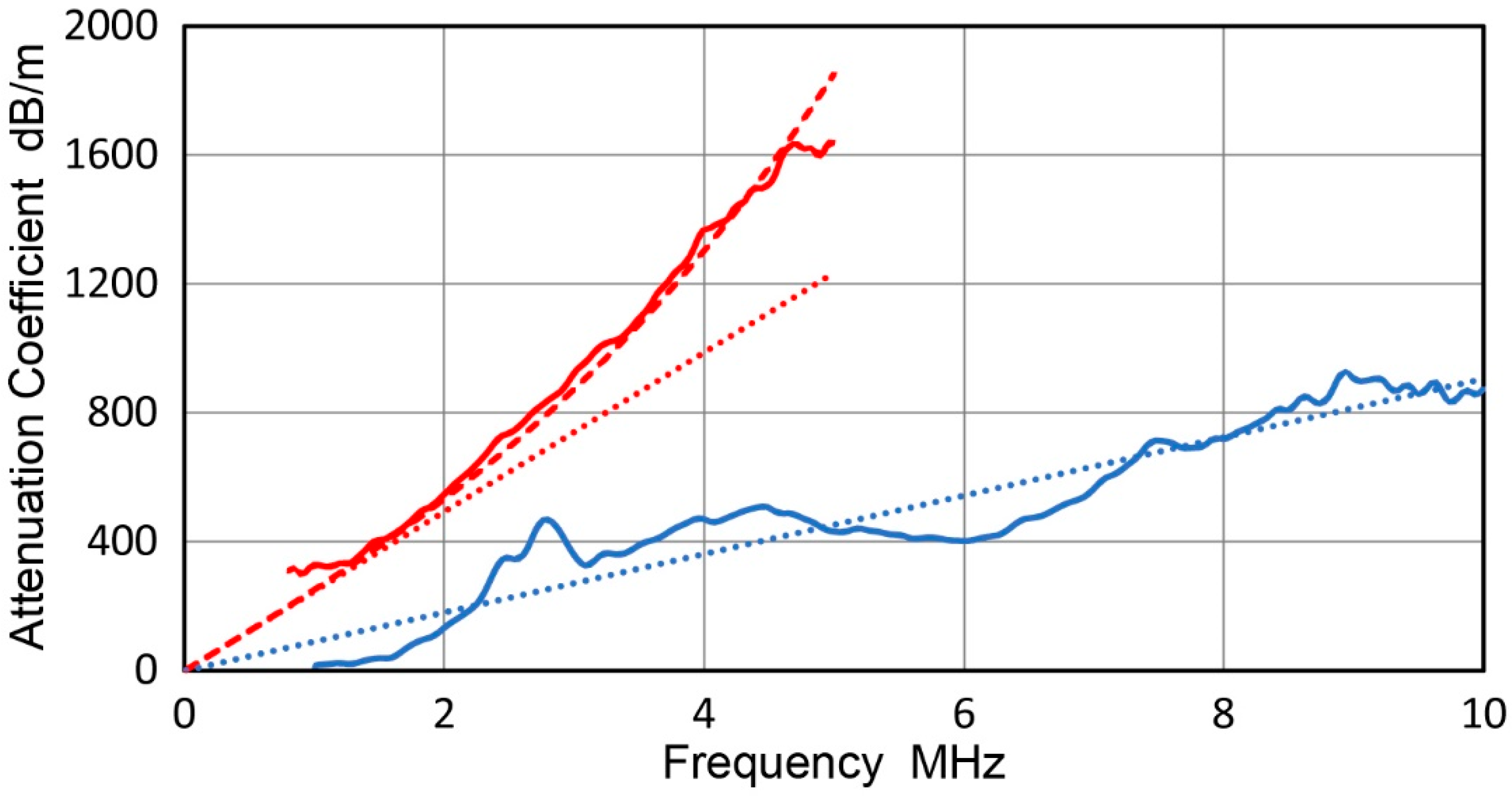

Two more polymers, PVC and PC, were tested similarly by comparing TDM-1 and TDM-2. The attenuation spectra after distance normalization are shown in

Figure 10. The attenuation data shown used Equations (17a) and (17c) by dividing amplitude difference spectra ((R

2 + D

1 − R

3 − D

2) for TDM-1 and (R

1 − R

3 − D

2 − T

c) for TDM-2 with the propagation distances of (x

2 − x

1) for TDM-1 and of x

2 for TDM-2. PVC results with x

1 = 4.5 mm and x

2 = 17.5 mm are plotted in dark blue and blue curves extending to 10 MHz, while PC data with x

1 = 4.6 mm and x

2 = 9.4 mm are in dark red and red curves up to 8 MHz. For the PC tests, an NDT System C16 transmitter was used, producing anti-resonance dips at 5 MHz causing oscillations. The attenuation spectra were fitted to linear frequency dependence as before and C

d values in dB/m/MHz (R

2 values) were as follows (also in

Table 1):

PVC: Cd = 239 (R2 = 0.963) for TDM-1 and Cd = 190 (R2 = 0.947) for TDM-2.

PC: Cd = 638 (R2 = 0.983) for TDM-1 and Cd = 581 (R2 = 0.991) for TDM-2.

Here, values for PVC are averaged data. For both PVC and PC, results for α values from the two methods matched from 10% to 25%, which were comparable with PMMA. All four R2 values for PVC and PC were slightly better than the corresponding R2 values in PMMA. Thus, these cases also support the use of calculated Tc in the TDM-2 method for approximation. However, the use of TCC, which ranged from 1.8 to 7.3 dB, provides a good estimate of TDM-1 attenuation data. The largest TCC was for a pair of 12.7-mm diameter transducers. This means the TCC application is mandatory when a larger transducer pair is used.

From the results for three polymeric materials, linear frequency-dependent attenuation behavior can approximate observed data up to 5 to 10 MHz. This approximation corresponds to a constant damping factor η for these polymers in the low MHz region. It was noted that η for PMMA peaked at 50 Hz and reached an apparent asymptote of ~0.01 at 1 to 10 MHz [

7]. However, available data are inadequate to conclude a constant η. Upon close inspection, all the TDM-1 plots of α vs. f consistently exhibited positive deviations from the linearity at low frequencies. Possible variation of η with frequency needs to be probed by using a single starting material. This requires varying the thickness and obtaining well-prepared samples.

This section shows that TDM-1 is the superior method for measuring attenuation coefficients, but the more convenient TDM-2 can be used for approximate determination of α values when multiple samples are not readily available. For PMMA, measured α values were close to the averaged literature values and their frequency dependence was well represented by linear behavior, except systematic deviations were noticeable at lower MHz frequencies. No scattering effects were found. The correction method for the transmission coefficient was demonstrated with 13 examples for three polymers.

4.2. Attenuation Behavior of Ferrous Alloys

Pure iron and 46 types of iron-based alloys were tested. For five alloys, multiple samples were used with different heat treatments, while directional effects were also evaluated for plate samples when it was possible to identify three directions. TDM-2 was used in all but three cases, when a short sample was prepared from a long rod. Since the transmission coefficients for this group are small (~0.06 dB), TDM-2 was deemed adequate in this regard. In comparing the observed data with the literature values of attenuation coefficients, the varied material processing conditions make this difficult. However, the range of observed α values overlaps with those of reported data. At 5 MHz,

Table 2 shows the range to be 8 to 855 dB/m, while it was 10 to 340 dB/m in the collected list [

7], which covered about 20 steel grades.

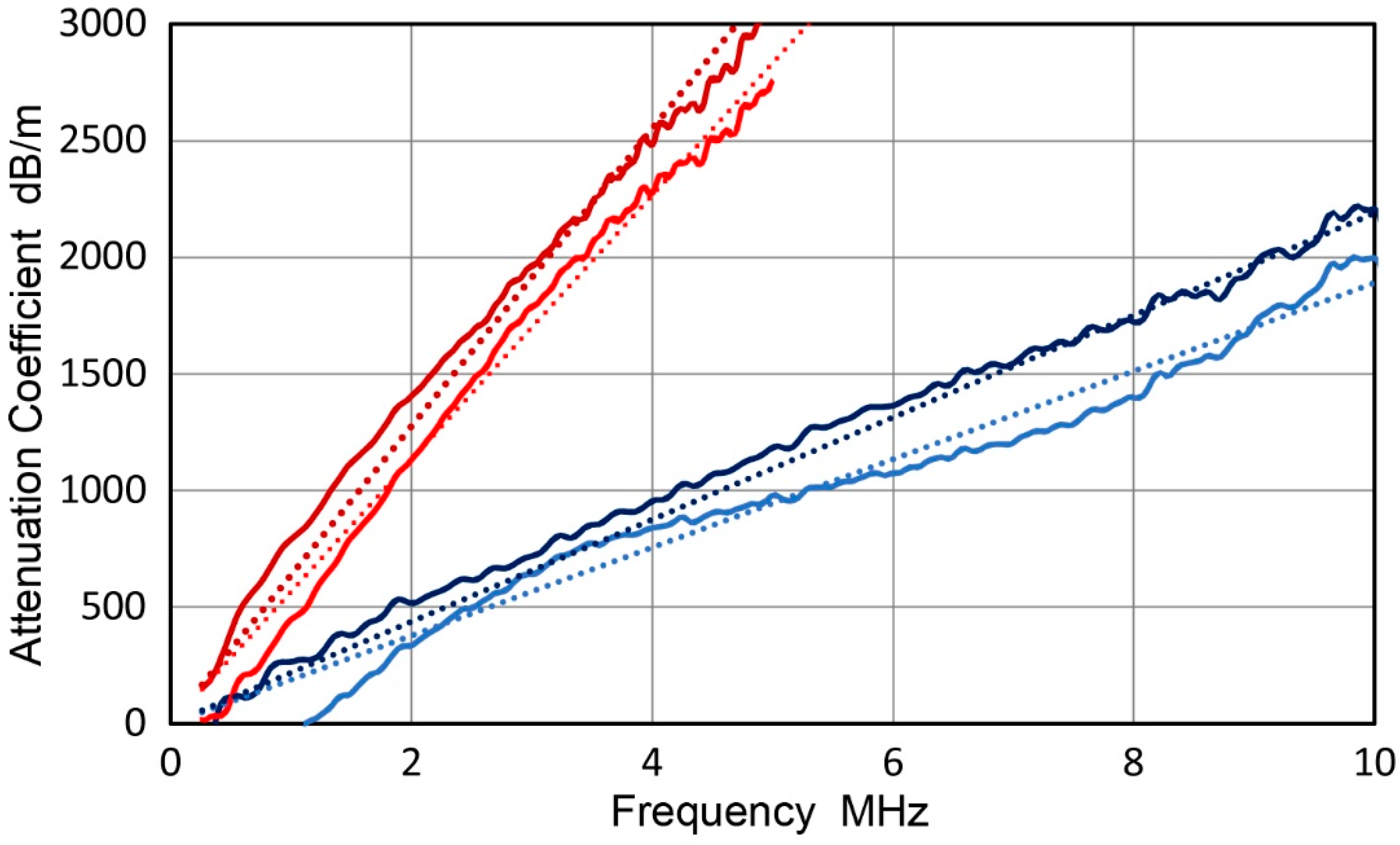

For this group, α values mostly exhibited two frequency dependencies of the linear type (Equation (2)) and the Mason–McSkimin relation (Equation (4)). Two examples for the two types are shown in

Figure 11. Here, the α values are given as dB/m after normalization of propagation distances.

Figure 11a gives two widely used steel grades—4340 (UNS 43400) shown by the blue curve and 1020 (UNS G10200) in red. Note that UNS stands for unified numbering system. For 4340 steel, the linear regression fit is also given as a blue dotted line, which is given by Equation (2) with C

d = 9.14 dB/m/MHz (R

2 = 0.936). In this case, the linear frequency dependence was observed to 15 MHz. For 1020 steel, the linear region was limited to 6 MHz, above which additional attenuation from Rayleigh scattering became significant. A best fit curve according to the Mason–McSkimin relation is plotted by a dashed red curve and its linear part is shown by a red dotted line. This curve fitting was performed by visual estimate of good fit and its R

2 value was 0.995 using the definition of R

2 = 1 − (squared residual sum)/(squared total sum) [

72]. The fitted curve in terms of frequency f (MHz) is

The attenuation data from Klinman et al. [

17,

73] is also plotted in this figure in green circles, with the fitted expression given as

These data are for a medium-C steel (C = 0.38%) with a ferritic-pearlitic microstructure. The ferrite grain size was 56 to 60 µm and pearlite content was 27%. This data further reinforces the viability of the Mason–McSkimin relation, which combines damping and Rayleigh scattering [

8].

The next examples are shown in

Figure 11b. The material is A286 austenitic stainless steel (UNS S66286), which can be precipitation-hardened. Both solution-treated and hardened conditions were tested. This steel showed the highest and second highest attenuation among the ferrous group. The solution-treated A286 showed linear dependence (blue curve), while hardened A286 showed combined linear and f

4 dependence (red curve). Linear regression and visually estimated fits provided the following expressions of

and

Note that at 10 MHz, both equations give similar α values (1709 and 987 + 788 = 1775 dB/m). These are plotted in blue dots and red dashes, with the linear part of Equation (19b) given in red dots. The C

R value for the hardened A286 alloy was approximately ten times larger than that of 1020 steel. For Equation (19a), the regression fit gave R

2 = 0.990, while the R

2 value for visually fitted Equation (19b) was 0.974. Although the meaning of R

2 for the latter is complex, the fitted expression models the observed frequency dependence well from 3.5 to 12.5 MHz. These examples represent two different frequency dependencies occurring in nearly all ferrous materials. For the hardened A286 alloy, another spectral function can also represent the observed response. This is a quadratic-type function (Equation (5)), given by

with an R

2 value of 0.985, indicating a better fit than the Mason–McSkimin relation. This quadratic spectrum is shown in

Figure 8b by a purple dashed curve. This quadratic relation is of the form of the Datta–Kinra scattering [

50,

51,

52]. Both solution-treated and aged A286 steel samples typically showed dispersed Laves phase particles, with average spacing of under 20 µm [

74]. Thus, the Datta–Kinra scattering of the Laves particles can possibly explain the quadratic spectrum. However, the solution-treated samples showed the linear spectrum without the scattering term but with intermetallic particles still present. More work is needed here. The quadratic spectrum was also found to describe observed spectra in several more cases of low-C steel, Cu, and brass plates. This is a seldom observed frequency dependence for metallic alloys that will be discussed further.

Table 2 presents the attenuation data for 101 tests. For each test, the test number and results for C

d, C

R, α value at 5 MHz, wave velocity (v

L), thickness (or length), and Vickers hardness number are listed, along with the condition of the sample. When the C

R column is blank, only the linear frequency dependence of α was observed. The C

2 value is given here in parentheses when applicable. As the Rayleigh scattering term can be ignored at 1 MHz, the C

d value equals the α value at 1 MHz. Observed α values at 1 MHz ranged from 1.5 dB/m for 304 stainless steel (test F85; UNS S30400) to 170.9 dB/m for A286 steel (test F96, see

Figure 11b above). Two other tests (pure iron) showed α values at 1 MHz exceeding 100 and ten more tests gave α > 50 dB/m at 1 MHz. In three cases, α values were low and only estimated ranges were given (tests F49, F50, and F70). Most structural steels showed α values at 1 MHz of 5 to 30 dB/m. Most of the austenitic stainless steels belonged to this group of relatively low attenuation steels.

Tests on cold-worked plates revealed anisotropic and unusual attenuation responses. Tests F12 and F13 of a low-carbon steel plate produced different attenuation spectra. These spectra can be fitted to α = C

2f

2 or the quadratic spectrum that was seen for A286 steel (see

Figure 11b). This quadratic dependence, which is well-known for water, now has two mechanisms to explain the attenuation in solids; that is, dislocation-based theory [

33,

34,

35,

36,

37] and Datta–Kinra scattering [

50,

51,

52], as introduced in

Section 1. It was also used to describe the attenuation spectra of two plates of Cu, a brass rod and a brass plate, Al–SiC composites, and in ten cast iron cases, as will be shown later. Tests F12 and F13 corresponded to the longitudinal (L) and transverse (T) directions of the lightly cold-worked steel plate (Vickers hardness 164), giving

and

For these two equations, small linear terms can be added without changing R

2 values much. However, the thickness (S) direction of the same plate sample (test F14) yielded the usual Mason–McSkimin relation of

When this plate was annealed (850°C, 1 h), reducing the Vickers hardness to 126, the quadratic spectrum for the T direction (test F15) disappeared, becoming the Mason–McSkimin type, except with a weak Rayleigh term. The spectrum for the S direction (test F16) showed the linear frequency dependence, losing the Rayleigh scattering contribution, as given below:

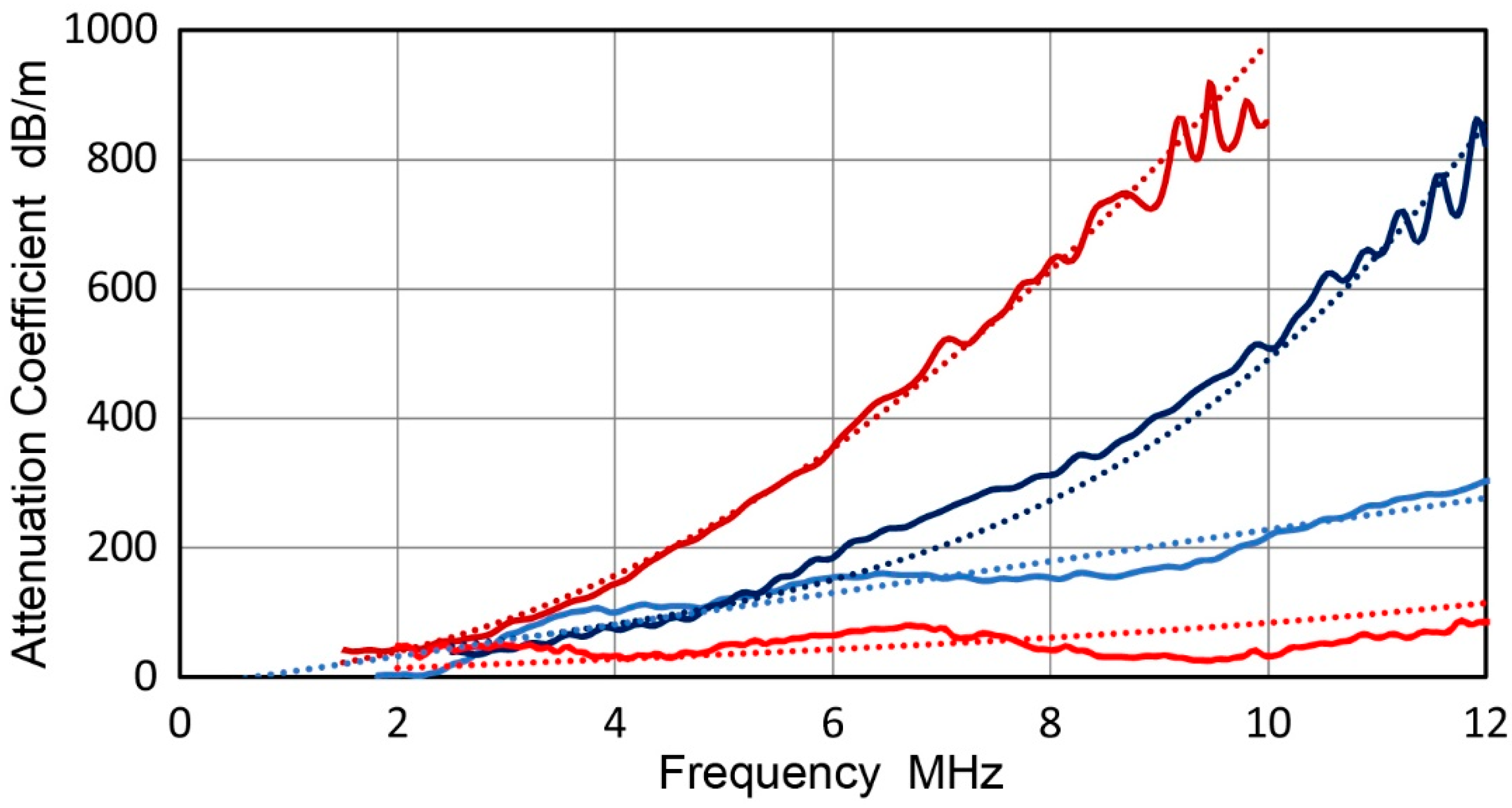

Four of these spectra are shown in

Figure 12. Model equations gave moderate to good fits (R

2 values of 0.915 to 0.990), except for Equation (21a), as the attenuation levels were very low. It appears that the observed behaviors of the in-plane directions, L and T, come from quadratic damping effects introduced by cold rolling [

20,

35,

36,

57], but more work is needed to clarify the underlying dislocation mechanisms.

Reduction in attenuation in the annealed condition was higher for the T direction and it increased with frequency. The S direction also showed frequency-dependent reduction in α values above 6 MHz, but the amount of the reduction was about one-third that observed in the T direction. These changes in α can be attributed to reduced dislocation densities after annealing, in accordance with the findings of [

39,

40]. However, the observed anisotropy in the amount of reduction in α values requires additional effects for reconciliation. Another apparent disagreement was noted for pure iron cases. Tests F1 and F2 for pure Fe gave comparable high attenuation. Apparently, annealing for test F2 (800°C, 1 h) was inadequate, unlike the 1080°C annealing temperature used in [

40].

In the above examples, cold working (CW) increased attenuation levels, corresponding to a higher hardness number and higher α value. Annealing decreased both hardness and attenuation. This will be referred to as the type-p CW effect.

In 302 and 304 stainless steels, the opposite effect of cold working was observed; that is, CW decreased the attenuation effect (higher hardness number and lower α value), which will be called the type-n CW effect. This behavior was also observed in copper, nickel, and a beta-Ti alloy (Beta-III), which will be shown in the next section. The case of 304 stainless steel (UNS S30400) is the most dramatic. Test F85 showed the lowest α value measured in all of the ferrous alloys tested, and this sample had a Vickers hardness of 321, corresponding to 20% to 25% plastic deformation [

75]. In practical terms, this steel was in the quarter-hard condition. Softer 304 stainless steel samples (tests F86-F88) gave more than ten-times higher attenuation. These had Vickers hardness values of 193 to 199, corresponding to the no deformation case in [

75], but this was higher than the Vickers hardness of 129 listed for soft 304 stainless steel [

76]. In 302 stainless steel (UNS S30200), the same trend was evident as with tests F82 and F83 (low hardness and high α), compared to test F84 (high hardness and low α). Such attenuation behavior may possibly be rationalized if residual dislocations in annealed states are highly mobile, while this dislocation damping is suppressed in work-hardened states from interlocking conditions. In both stainless steels, interstitial segregation to dislocations is unlikely and no carbide precipitation occurs, offering no possible mechanism for dislocation locking. This differs from a low-C steel that has interstitial C atoms forming the Cottrell atmospheres [

77]. The resultant dislocation locking reduces α. The cold-worked 304 sample was weakly magnetic due to strain-induced martensitic transformation. The pre-martensitic state may possibly contribute to attenuation, but this effect is absent in 302 steel samples, as all the 302 steel samples are faintly magnetic. In any event, copper and Beta-III Ti alloy have no magnetism and only dislocations can explain observed changes in damping behavior with or without prior deformation. This dislocation-related attenuation has received scant attention in recent decades and more work is certainly needed to elucidate its base cause. The concept of two different attenuation levels for high or low dislocation density makes no sense if all dislocations behave equally. Thus, some currently unknown dislocation interactions are needed to vary the damping contributions, and no rational account for the contradictory observations can be offered at present.

Anisotropic directional effects on attenuation were found in eight more cases, in addition to the cold-worked steel plate. These occurred in two 4340 plates (tests F38-F40 and F41-F43; UNS G43400), 4142 (tests F44 and F45; UNS G41420), a high-strength, low-alloy (HSLA) steel (tests F58-F60), two A533B pressure vessel steel plates (tests F62-F64, F66, and F67), a 1Cr-Mo-V turbine rotor steel (tests F68 and F69), and 304 stainless steel (tests F86-F88). Their α values at 1 MHz in the through-thickness (S) direction were 1.7 to 10.7 times higher than the longitudinal (L) or transverse (T) direction of the same sample, except for one case of 4340 steel. The S direction in rolled steel plates often has reduced ductility from non-metallic inclusions (mainly MnS) that are flattened by hot rolling, which contribute to lamellar tearing and heightened acoustic emission activities [

78,

79]. The acoustic emission is a manifestation of the decohesion of MnS inclusion during loading. On the other hand, one heat-treated 4340 (tests F38-F40) did not show this anisotropy. This difference is expected from better impurity control for high-strength steels, with dispersed spherical oxide inclusions being more common [

78]. Further tests on the electro-slag remelted (ESR) 4340 plate (tests F36 and F37) may offer additional clues, as it showed medium α values.

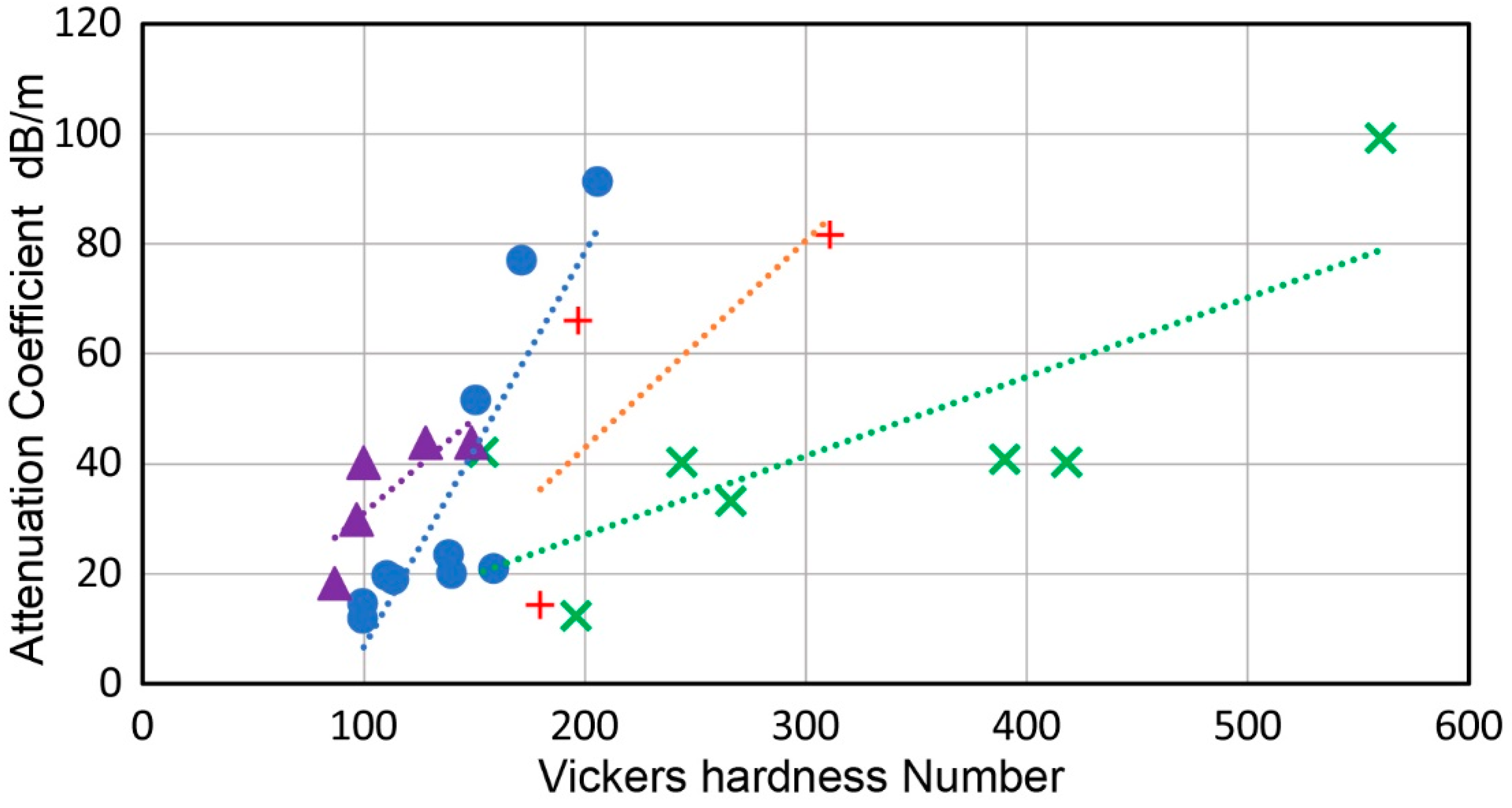

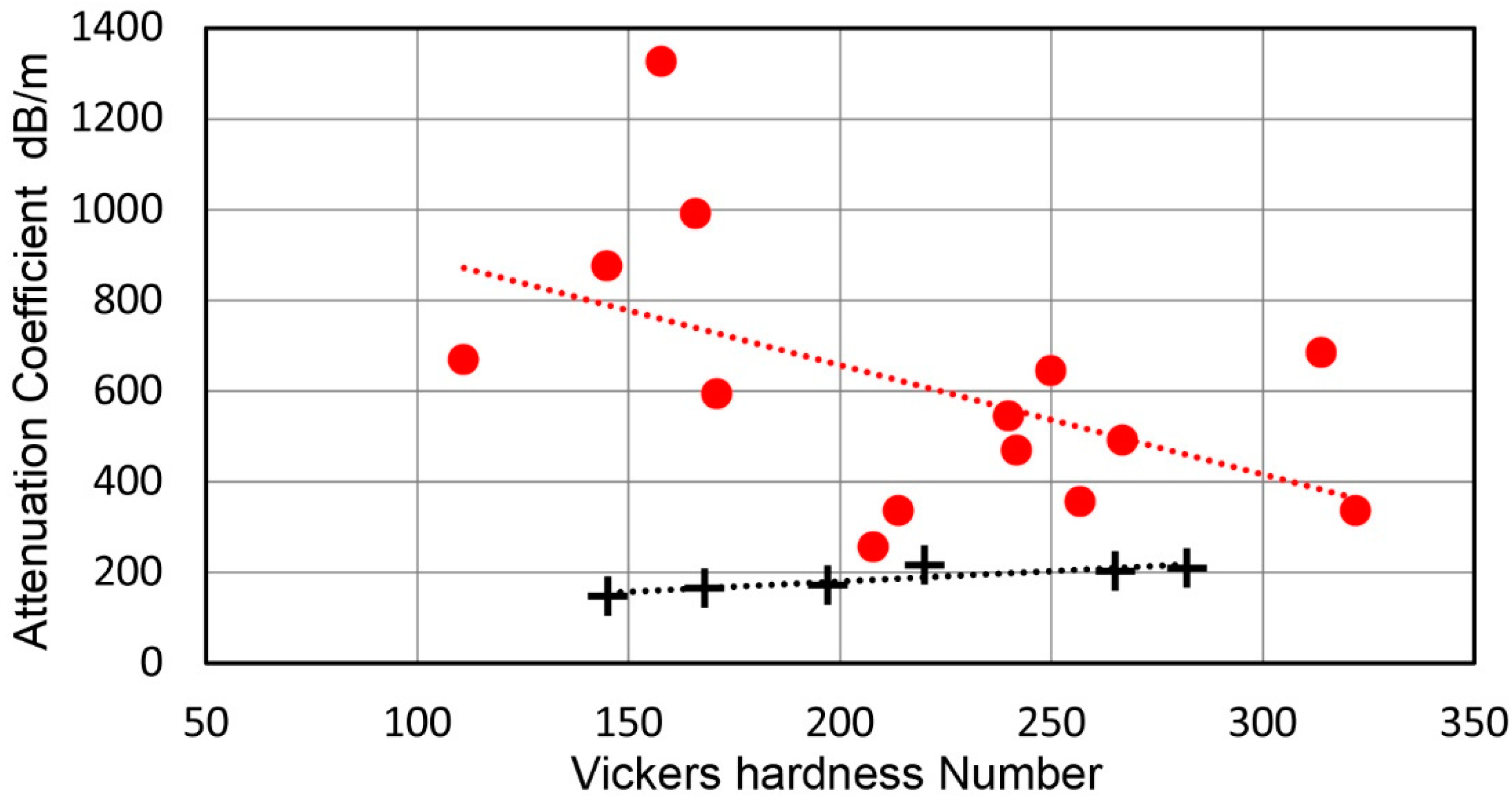

In addition to the CW and directional effects on attenuation discussed in the previous paragraphs, the presence of some phase transformation products increased attenuation in low- to medium-carbon steels. The effects of heat treatment were examined using three grades of steels (1020, F30, and F50). These steel samples were water-quenched and had high hardness for respective C levels (estimated to be 0.2, 0.25, and 0.3%C), with the initial Vickers hardness values being 206, 311, and 576 (from Vickers tests at 1 kg load; tests F4, F19, and F24). These showed high α values at 1 MHz of 91.1, 81.6, and 99.3 dB/m, respectively. With tempering, the Vickers hardness gradually decreased to 114, 180, and 196, while α values at 1 MHz also dropped to 18.8, 14.3, and 12.3 dB/m, respectively. These changes are shown in

Figure 13, along with the data for brass, which showed a similar decrease with annealing (to be discussed in the next section). For most cases of steel tempering (or annealing of brass), the linear frequency dependence was retained. Tempering of low- to medium-carbon steels results from carbide precipitation and the loss of dislocations from displacive phase transformation [

77,

80]. It appears that high attenuation in acicular ferrite and martensite from water quenching arises from high dislocation densities in these fine microstructures. As tempering progresses, dislocation densities gradually decrease, causing the loss of dislocation-induced damping. Simultaneously, fine carbide precipitation reduces the dislocation mobility, contributing to reduced damping. This is similar to the type-p CW effect discussed above.

When C levels were higher in hardness calibration blocks (tests F73-F77), hardened conditions with Vickers hardness values of 434 to 695 produced only moderate attenuation of α values at 1 MHz of 25 to 37 dB/m. These blocks are typically heat-treated into tempered martensite for increased stability in hardness, which is likely to lead to C segregation at dislocations, unlike in the as-quenched hypoeutectoid steels discussed above. Such segregation suppresses dislocation damping. In the present study, this aspect was explored further using 4142 steel samples (tests F46-F48). Water quenching (WQ) caused increased hardness (Vickers 529) and a higher α value (49.6 dB/m), followed reduction of these values upon tempering at 200°C (test F47) and 400°C (test F48). However, changes were smaller than in lower C steels discussed above. On the other hand, when the same 4142 steel sample was oil-quenched (OQ), its hardness increased moderately to a Vickers value of 327 (test F49), but its α value was reduced to a level not measurable using 19-mm thick samples (only maximum level of α estimated as 3 dB/m). Tempering at 400°C hardly affected the α value, but tempering at 700°C increased it to 13.2 dB/m, which is comparable to the range of α values of annealed structural steels (tests F50 and F51). The different responses to quenching speed are expected to arise from the transformation products—martensite for fast WQ and bainite for moderate OQ [

77]. High dislocation densities remain in martensite, together with super-saturation of C interstitials, while fine carbide distributions were formed in bainite with lower dislocation densities, stabilized by C interstitials [

80].

Low attenuation of medium- to high-C steels (4150 and 52100) was observed in earlier works [

81,

82]. For 1% C bearing steel (52100), Papadakis found α values at 5 MHz (the lowest frequency used) of 5 to 9 dB/m [

81]. In most of his plots, α values did not decrease much below 10 MHz in contrast to the high slope with frequencies above 10 MHz. Papadakis’ study on 4150 steel [

82] reported 11.9 dB/m at 1.8 MHz for a ferritic-pearlitic microstructure, again showing a flattened frequency dependence below 10 MHz. For bainite, the α value was 6.8 dB/m at 14 MHz (the lowest frequency used for hardened 4150 steel samples). These results are consistent with α values found in the present study. On the other hand, martensitic microstructures showed even lower α values, which reached 3 dB/m when extrapolated down to 10 MHz from data at 22 MHz and higher. This trend was also observed in an earlier study [

83]. This low value for martensitic 4142 disagrees with the present results. In Papadakis [

82], the martensitic samples were oil-quenched in the form of a 5 cm bar stock and machined out of the center portion. If the bar was a square bar measuring 5 cm by 5 cm, the cooling speed was much lower than needed for martensitic transformation throughout the bar, producing bainite in the mid-section of the “martensitic” samples. Unfortunately, no hardness data were reported. In this case, the earlier work does not contradict the present high attenuation results for martensitic microstructures. Still, further work on martensitic and bainitic samples is desirable. For practical consideration, low attenuation results for bainite are welcome, since many structural steels are most commonly utilized in applications with heavy sections, such as pressure vessels [

80].

Another noteworthy observation is the contrast between two of the precipitation hardening stainless steels, A286 and 17-4PH. In the solution-treated conditions, A286 showed the highest attenuation (see

Figure 11b), while 17-4PH showed α = 9.0 dB/m at 1 MHz with the addition of the f

4-scattering effect. This steel belongs to the lowest attenuation group of ferrous alloys. In the aged conditions, α decreased in A286 but increased in 17-4PH. The observed precipitation effects were opposite in these two alloy steels. No rational explanation can be given at present and repeat tests with various heat treatments are needed for clarification.

Rayleigh scattering with the 4th power frequency dependence appeared in 26 out of 101 tests, as shown in

Table 2. Over a half of these tests were for stainless steels and one-quarter of the tests were for annealed low-C steels. The stainless-steel group contains single-phase materials, except for the nano-scale precipitates in aged 17-4PH (test F101). Grain boundaries are the commonly accepted source of Rayleigh scattering. The latter group of low-C steels is expected to have ferritic-pearlitic microstructures, with ferrite grain boundaries acting as scattering centers. Similar attenuation spectra were reported by Klinman et al. [

73] (see

Figure 11a), and they attributed the entire observed attenuation to Rayleigh scattering. However, the Mason–McSkimin relation can describe their spectra more rationally, with the addition of the f-dependent damping term at lower frequencies.

This section presents the attenuation behavior of ferrous alloys. Most structural steels exhibited low to medium attenuation coefficients composed of the f-dependent damping term and f4-dependent term due to Rayleigh scattering or the Mason–McSkimin relation. The Rayleigh term is limited to one-quarter of the samples tested, consisting of ferritic-pearlitic low-C steels and austenitic stainless steels. CW and phase transformation resulted in vast changes in α values, with two contradictory CW effects—type-p and type-n. The CW effects require further studies to fully understand the observed behavior. Precipitation hardening effects also showed contrasting behavior. Another urgent task is obtaining a quantitative explanation of the observed damping, since existing dislocation-based theories, including the proposed bow-out damping, are inadequate.

4.3. Attenuation Behavior of Non-Ferrous Alloys

This section covers the attenuation behavior of non-ferrous alloys and metal matrix composites.

Table 3 summarizes 99 test results. Each row provides the test number; results of C

d, C

R, and α values at 5 MHz; wave velocity (v

L); thickness (or length); Vickers hardness number; and condition of the sample. As with the iron-based materials, α values were primarily dependent on frequency in a linear manner or the Mason–McSkimin relation, in combination with the linearly dependent damping term with Rayleigh scattering of the 4th power of frequency. An example of the test results for a large (307 mm × 305 mm × 156 mm) block of Al 2024 (UNS A92024) is given in

Figure 14a. The attenuation spectra from both TDM-1 and TDM-2 showed good to moderate linearity, with R

2 values of 0.974 and 0.928, respectively. Seven tests showed high attenuation of above 100 dB/m at 1 MHz. These included low melting point metals (Cd, Pb, and Zn), a Cu single crystal, two large-grained Ni

3Al cast ingots, and a soft Ni alloy. The Cu single crystal orientation is <111>, it has a moderately high hardness, and showed high attenuation. This appears to be the type-p CW effect. Ni

3Al cast ingots have large grain diameters of 5 to 10 mm and high attenuation is expected. Some grain boundary separation seems to be present as well. Al alloys, pure Mg, and Mg alloy showed low attenuation, as expected from early works [

8,

27], while most other structural alloys had low to medium levels of attenuation, in agreement with general expectations [

1]. Only limited comparison with past data is possible, as a previous review found only nine α values [

7]. Using C

d values, the Mason data values for pure Mg [

8] were one-half to three-quarters of the values from tests N66-N68, while the Papadakis values for brass 360 [

46] was one-quarter or less of the values from tests N48-N58. These early works used directly bonded quartz transducers, achieving low-loss measurements. Even though Papadakis showed the equivalence of using low-loss quartz and damped transducers [

14,

15,

16], this aspect may need further evaluation. A recent work by van Pamel reported α values for Inconel 617 at 1.8 to 2.7 MHz [

84]. At 2 MHz, he reported α = 27 dB/m, which compares to observed α values of 7.2 and 31 dB/m at 2 MHz for cold-worked Inconel 625 in the L direction (tests N76,N77), matching well with test N77. In this comparison, the test methods and alloy types were similar, but test materials may have had different processing conditions. In the S direction, the attenuation of the 625 alloy was twice as large (test N78). In another Ni alloy with Ni

3Al strengthening (Waspaloy), Ohtani et al. [

85] found shear attenuation coefficient of 15.1 dB/m/MHz. This value is comparable to α values of solution-strengthened Inconel 617 and 625, discussed above.

Attenuation spectra that cannot be fitted to Equation (2) or Equation (4) were found on Cu plate (UNS C11000) and brass plate (UNS C26000) samples. A copper plate (90.5 mm × 75.9 mm × 50.5 mm) showed quadratic frequency dependencies in the longitudinal (L) and transverse (T) directions (tests N38 and N39 in

Table 3), similarly to the case of the low-C steel (tests F12-F14) discussed previously. In the L direction, three models were compared to the observed spectrum as follows:

The first model gave a good fit according to the R

2 values, while the f

2.5-dependence provided the best fit. In the T direction, model equations are

As in the L direction, the f

2-dependence provided a good (not the best) fit, which was chosen for correlation with dislocation damping. The best-fitting power law curves (Equations (22c) and (23c)) were not selected, since no theoretical basis exists. The observed attenuation curves with fitted quadratic (f

2) models of Equations (22a) and (23a) are shown in

Figure 14b, using squared frequency as the abscissa (and using the linear regression to find constants for Equations (22a) and (23a)). This quadratic behavior may be due to the KGL theory, but the dominance of the linear behavior makes it difficult to assign the KGL-based spectra to a small number of cases. Attenuation followed the usual Mason–McSkimin relation in the thickness (S) direction. Since this Cu plate was finished by cold-rolling processes with an increased Vickers hardness, CW effects caused the anisotropic attenuation with quadratic spectra for the in-plane directions. There were two other cases of lightly cold-worked 70-30 brass plates (tests N41- N43; UNS C26000). For the L and T directions, the quadratic spectra did offer a similar moderate fit, namely,

and the Mason–McSkimin relation again was found to have a good fit in the S direction:

In both Cu and brass plates, the amount of CW was small, as the Vickers hardness values were 97.5 and 91, and large changes in grain structures are unlikely. This implies that the anisotropy is related to dislocation behavior, but specific mechanisms are unavailable. Another cold-worked Cu plate sample was cut into two pieces. One piece was annealed, reducing the Vickers hardness from 99 to 54. Both of them were tested in the L and S directions (tests N33-N36). These two samples in the L direction showed the quadratic behavior, but annealing reduced attenuation by more than a factor of two in terms of C

2 values. Annealing also reduced attenuation in the S direction, but the attenuation spectrum followed the Mason–McSkimin relation. The quadratic behavior was also observed in 60-40 brass (tests N46,N47; UNS C28000). These 60-40 brass samples were heavily cold-worked, showing twice the Vickers hardness of annealed alloy. In the present study, it is shown that quadratic attenuation spectra were found in cold-worked plates of steel, Cu, and brass, suggestive of a common dislocation damping mechanism from the KGL formulation [

33,

34,

35,

36,

37].

These Cu and brass plates also exhibited anisotropic directional effects similar to those of ferrous plates. The directional anisotropy was also found in two plates of Al 7075 (tests N19-N24; UNS A97075) and in Inconel 625 (tests N77,N78; UNS N06625). In all cases, the S direction had higher attenuation. Flattened grain microstructures in Al 7075 are known to cause exfoliation corrosion damages [

86] and act as large effective grain sizes in the S direction. Similar microstructures were not documented in Cu and brass, but are plausible as the processing methods are similar. These flattened microstructures lead to higher attenuation. Attenuation behavior due to anisotropic distribution of inclusions was studied by Margetan et al. [

28,

29,

30], as noted earlier.

Aluminum alloy samples showed low attenuation of less than 10 dB/m at 1 MHz in 19 of 24 tests. These low α values were always for hardened conditions of T3 and T6 temper. Two higher α values were found in annealed 6061 alloy (UNS A60610), while 6061-T6 showed lower α values by a factor of 3 to 5. One 2024-T6 sample (test N8) was annealed (at 370°C, 1 h), after which the α value more than doubled (test N13). While the sample count is small, it appears that annealed Al alloys have higher α values in comparison to the hardened conditions. This hardening originated from precipitation, but the attenuation behavior is common with the type-n CW effect discussed in the previous section.

The effects of annealing were evaluated using two sets of cold-worked brass 360 samples (UNS C36000, tests N48-N55). In the hardened conditions, α values were high (e.g., tests N48 and N53 (Vickers values of 149 and 124) had α values of 43.8 and 61.6 dB/m, respectively, at 1 MHz). With annealing, both α values and hardness decreased, as plotted in

Figure 13 (in purple triangles), exhibiting the type-p CW effect. This finding seems to imply that higher dislocation densities in cold-worked conditions contribute to more damping, increasing the α values. As seen in

Table 3, C

R terms are zero, except in one case (test N49), indicating Rayleigh scattering has no influence on cold-working effects in brass.

Some samples of Cu, Ni, and a beta-Ti alloy (Beta-III, UNS R58030) also received cold working and showed increased hardness values with low α values (type-n behavior). Two Cu samples were annealed to reduce hardness, allowing direct comparison between the two states. Higher α values resulted, again showing the type-n CW effect. For three cold-worked Ni 200 samples (UNS N02200) plus one Ni 211 sample (UNS N02211), a clear trend was visible of low α values with high hardness. In beta-III Ti (UNS R58030), 10% cold working increased the hardness and reduced α values by nearly a factor of four (test N91). In contrast with the brass tests given above, these were not as systematic, yet a clear trend emerged.

Table 4 summarizes the available data, albeit with limited data counts. This observed trend was opposite to the annealing effects found in brass, where α values decreased with decreased hardness of the test samples. The type-n behavior is more difficult to rationalize in terms of the dislocation damping, since it is difficult to rationalize the fact that more dislocations cause less damping. At this stage, no plausible mechanisms exist and new explanations or mechanisms must be found for both types of cold work effects.

The last group of six tests examined the attenuation behavior of three metal matrix composites (MMCs). Tests N94 and N95 used an extruded plate of 2124 Al matrix with 14.1 wt% SiC whiskers (ARCO Silag Div., Green, SC, USA). Their attenuation spectra above 8 MHz showed quadratic dependence of the Datta–Kinra type, but attenuation was absent at lower frequencies. Attenuation was much higher in the extrusion direction than in the thickness direction. This difference reflects the alignment of whiskers (0.1 to 1 µm in diameter and 0.4 to 4 µm in length). Next, the MMC plate was reinforced by SiC particulates at 30 wt%. This plate was also finished by extrusion with the 2124 Al matrix (made at DWC Specialty Composites, Chatsworth, CA, USA). SiC particles had a platelet shape, with sizes ranging 5-10 µm and aspect ratios ranging from 1 to 4 (see [

87] for their mechanical and AE behavior). This MMC showed higher attenuation than most Al alloys, but the general trend was similar to the others, despite the presence of a large amount of SiC particles. The third MMC comprised 75% Be particles by weight and had the lowest density (2.06), except for Mg. This was an experimental MMC made at Lockheed Aircrafts (Burbank, CA, USA). The attenuation was linear in frequency and attenuation coefficients were moderate. This group showed low to moderate attenuation levels.

The attenuation spectra of most non-ferrous metallic materials were in-line with the linear frequency spectra or Mason–McSkimin relation, indicating dislocation damping and Rayleigh scattering as the main mechanisms. The levels of attenuation were low in Al and Mg, but most others were comparable to typical ferrous alloys. However, available sample materials did not include certain alloy groups known for their high attenuation, such as cast brass and bronze samples. Two cold-worked plates in the in-plane orientations showed anisotropic behavior with quadratic frequency spectra, which was most likely a form of dislocation damping in these homogeneous materials. This behavior is predicted by the KGL theory [

33,

34,

35,

36,

37], but the limited appearance of quadratic spectra makes this explanation less than convincing. The quadratic frequency spectra of Cu and brass are expected to vanish with annealing if they follow the trend found for low-C steel. In one test (test N35), this did not occur, indicating the need for further work. Other anisotropic attenuation behavior was observed, appearing to arise from mechanical processing steps, since the thickness direction typically showed higher attenuation. This behavior seems to be previously unreported.

4.4. Attenuation Behavior of Cast Iron

Twenty-one cast iron samples were tested and their attenuation parameters are given in

Table 5, using the same format as in

Table 2 and

Table 3. Here, two columns are added. One is for C

2, since 11 samples had the quadratic spectra. Another is for damping factor, which is calculated using Equation (1). However, when the C

d term vanishes, it is improper to use damping factors. For these cases, apparent damping factor, [η], is obtained assuming a linear attenuation spectrum below 1 MHz. These values are in brackets to distinguish them from normally obtained η values. All but two samples were supplied by the Iron Casting Research Institute (Columbus, OH, USA). Additionally, one sample was a continuously cast gray iron bar of 490 MPa class (FC-50; Nippon Chuzo, Kawasaki, Japan) and another was a common gray iron from a broken vise. These represent four types of cast iron, namely gray iron, ductile (nodular) iron, malleable iron, and compacted graphite iron [

88]. They all have a ferrite matrix with varying morphologies of graphite. In gray iron, graphite appears as irregular, interconnected flakes. During slow cooling, carbon in molten iron separates and forms graphite flakes that are interconnected within each eutectic cell, resulting in the characteristic flake shape. In ductile iron, graphite is changed into nodular shapes by the addition of controlled amounts of Mg and Ce, while compacted graphite iron is of the intermediate type between gray and ductile irons. The malleable iron sample was of the ferritic type and was heat-treated from white cast iron, forming irregular graphite nodules in the ferrite matrix. Twenty other samples were in as-cast condition. Two of the as-cast samples were mislabeled; that is, ductile A and ductile B showed the majority of their graphite to be in flakey forms, so they should be grouped with gray irons. In fact, their wave velocities were comparable to the gray iron of class 20 to 40. The hardness values were low to moderate, with Vickers values ranging from 111 to 322. Their α values at 5 MHz were in the range of 147 to 1325 dB/m, with low values found in ductile, malleable, and compacted graphite types, while high values were observed in gray irons. Papadakis [

89] conducted attenuation measurements of ductile iron with α values of 200 to 500 dB/m at 10 MHz. These are in the same range as the lower α values found in malleable and ductile irons (tests I17–I21), but much lower than α values observed for some gray irons (tests I1–I4).

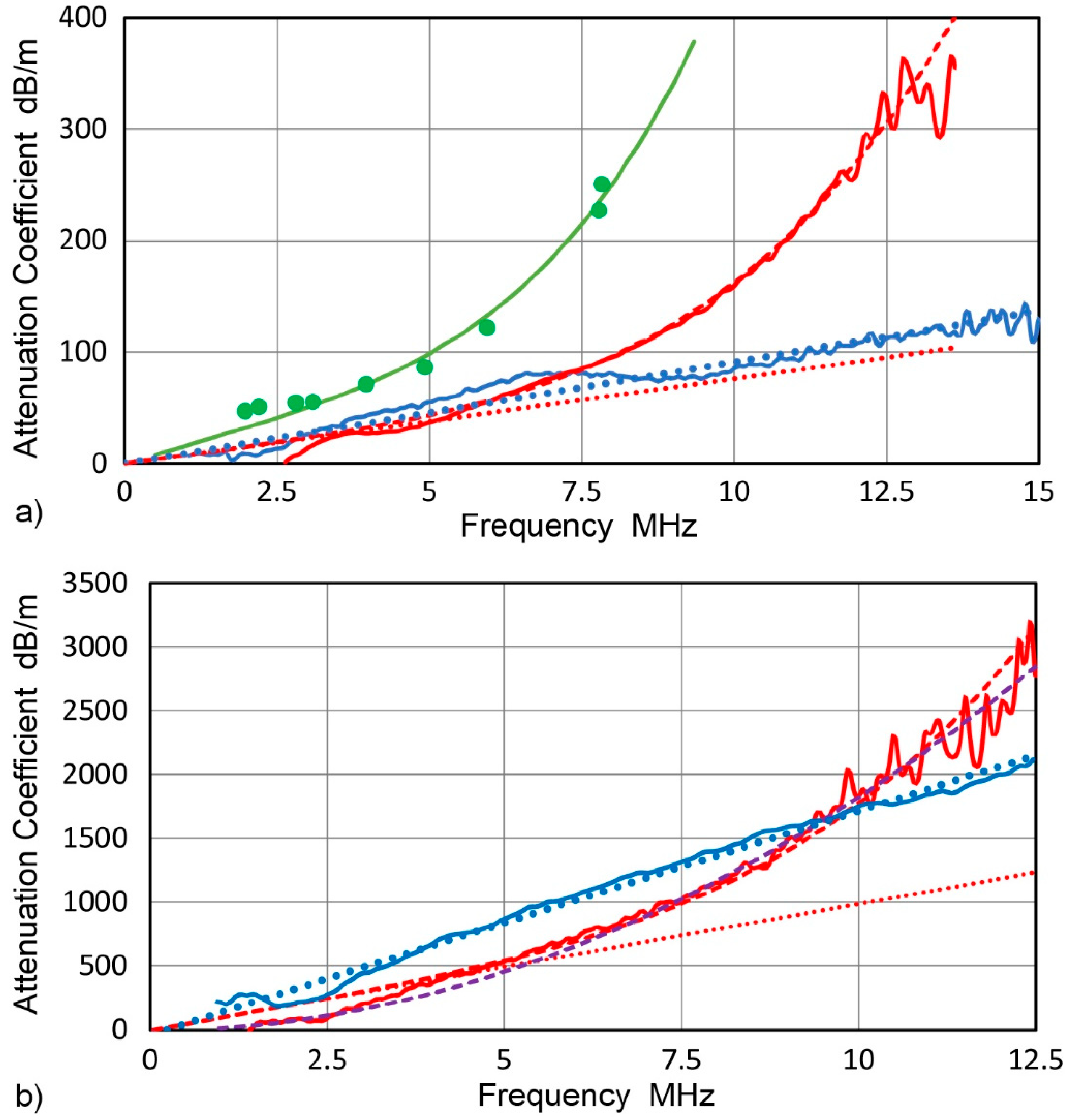

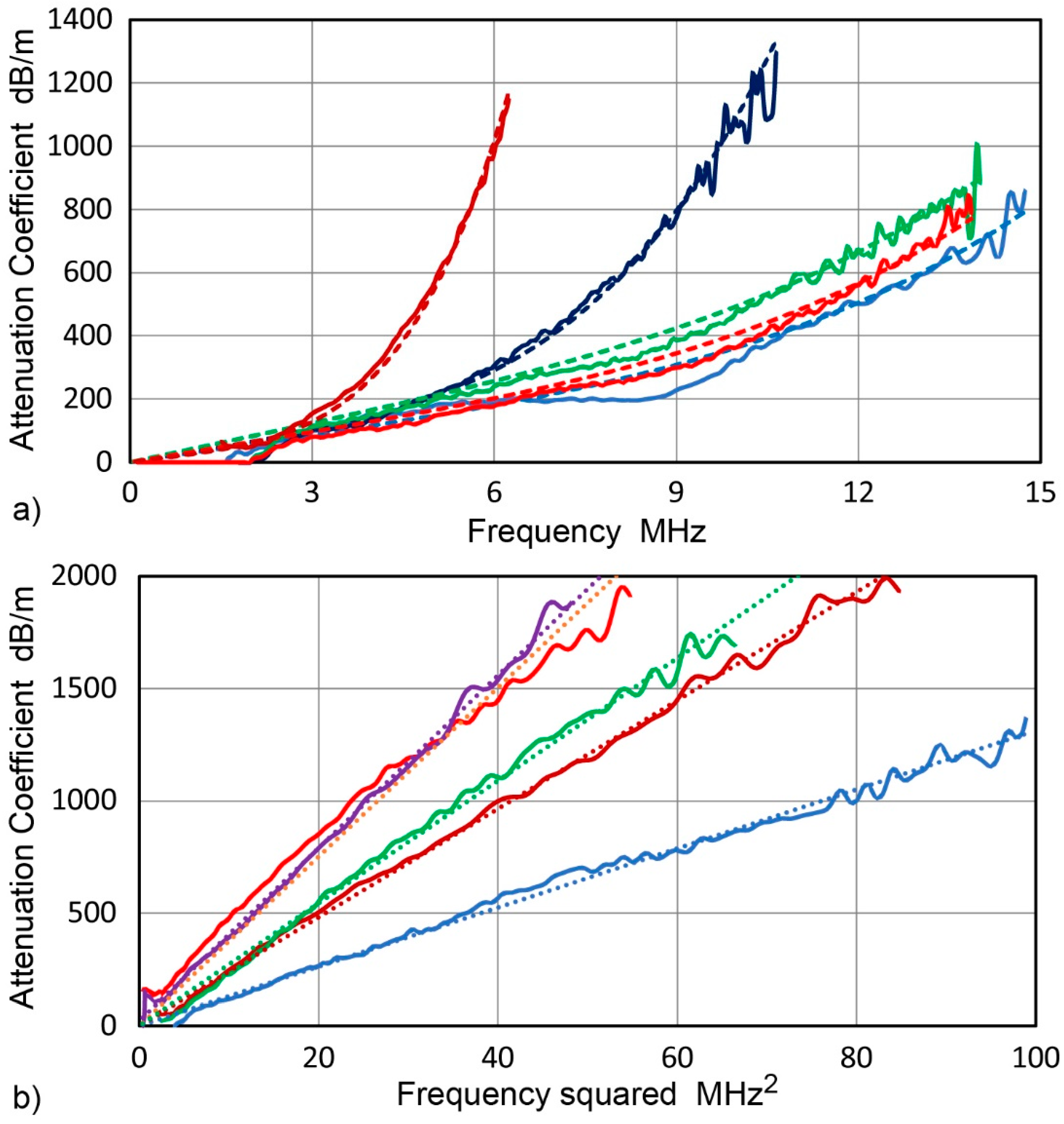

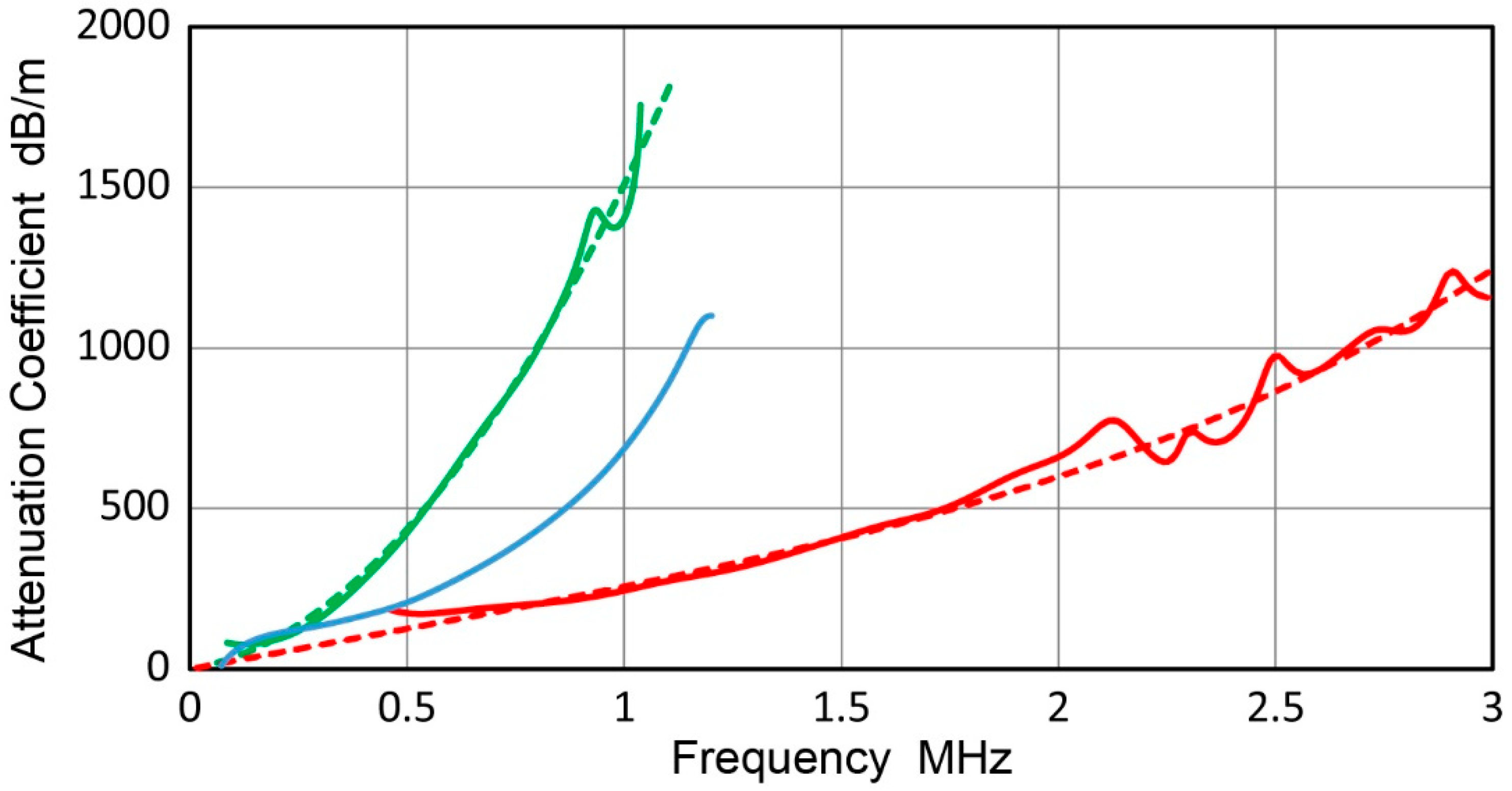

Representative attenuation spectra for cast iron are shown in

Figure 15a,b. Two types of spectral behavior were observed. One followed the Mason–McSkimin relation (Equation (4)), as given in

Figure 15a. Plotted in