A Predictive Maintenance Approach for Composting Plants Based on ERP and Digital Twin Integration

Abstract

1. Introduction

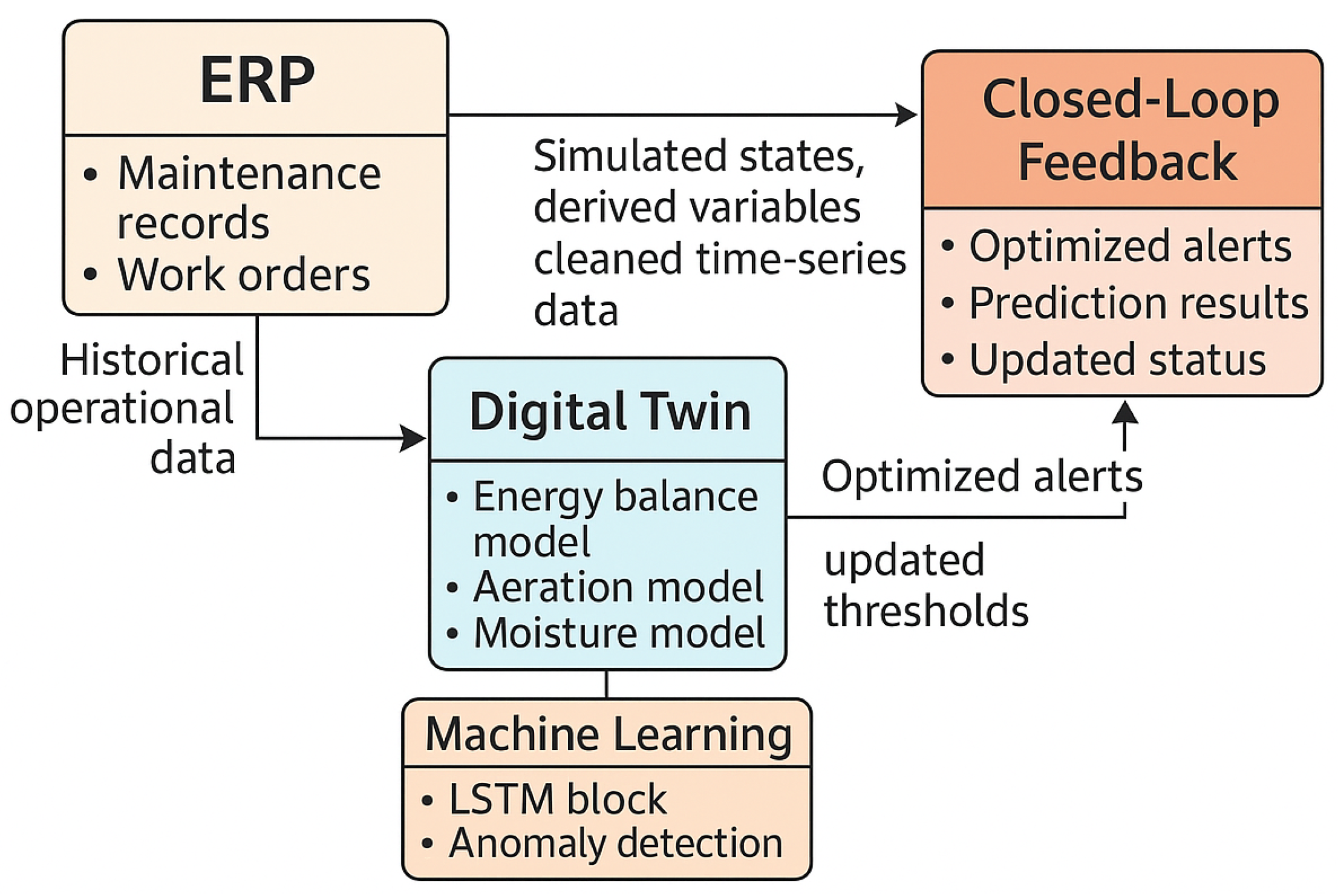

- Providing an integrated DT–ERP–PdM architecture that enables two-way interaction between the physical model, deep learning, and operational decision-making.

- Developing a real-time mechanism for updating maintenance policies in ERP based on digital twin outputs, which, to the best of the authors’ knowledge, has not been systematically addressed in previous studies.

- Designing a hybrid DT–LSTM model that manages and stabilizes noisy and discontinuous data in the industrial environment.

- Evaluating the proposed framework in a real industrial composting pilot and measuring its economic and operational impacts, including MTTF, MTTR, and ROI.

2. Literature Review

3. Conceptual Framework and Integrated System Architecture

3.1. ERP Layer: Information Management and Maintenance Control

3.2. Digital Twin Layer: Machine-Level Modeling and Real-Time Simulation

3.3. Predictive Analytics Layer: Intelligent Diagnostics and Decision Support

- Physics-based models capture the fundamental mechanical and thermodynamic behavior of the equipment.

- Data-driven models, such as long short-term memory (LSTM) networks, analyze time series data to predict anomalies and failure probabilities.

3.4. Data Flow and System Integration

3.5. System Overview

4. Research Methodology

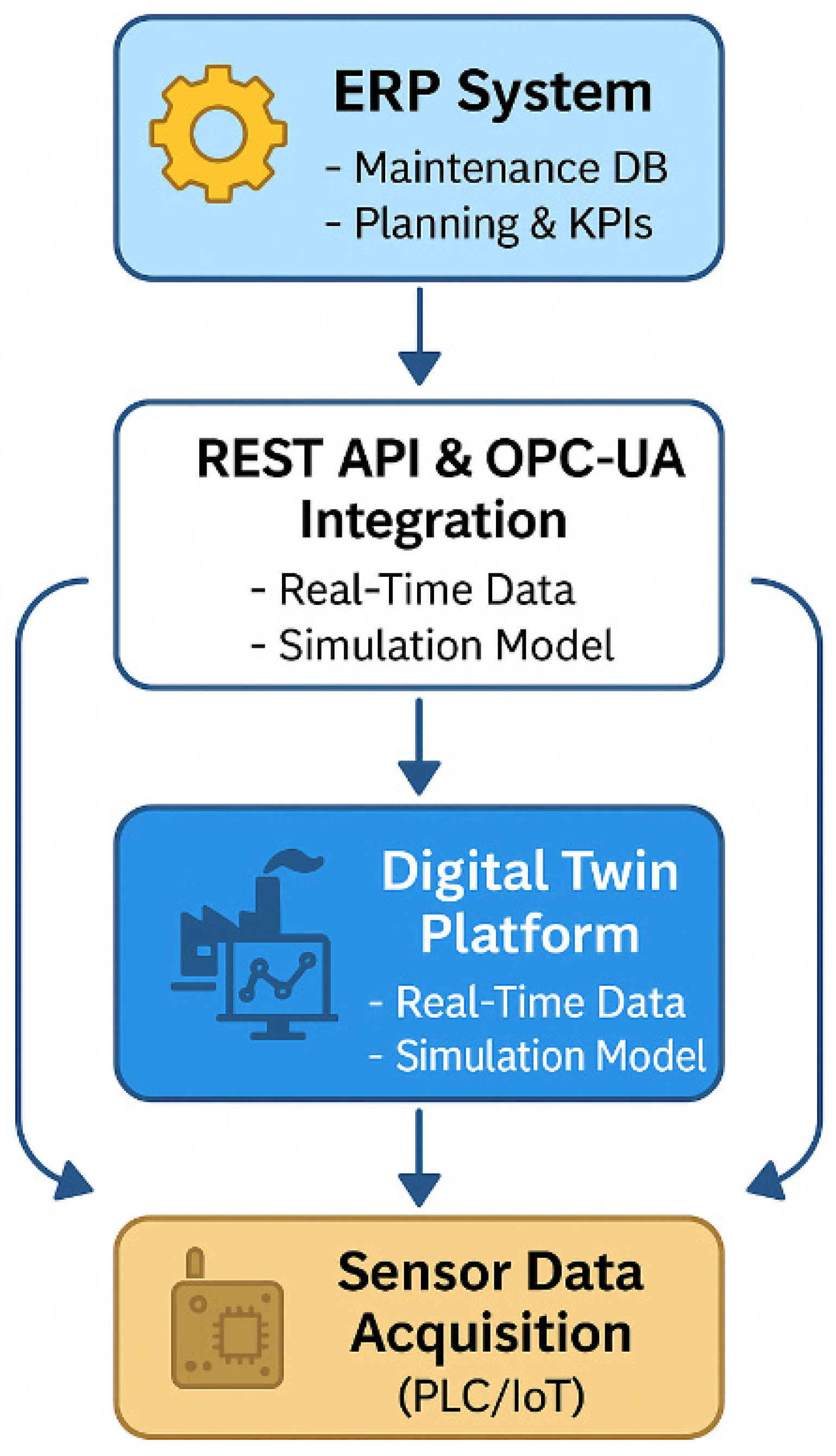

4.1. Stage 1—Construction of the Digital Twin Architecture

4.2. Stage 2—Development of Hybrid Predictive Algorithms

4.3. Stage 3—Implementation and Validation of the Predictive Maintenance Workflow

4.4. Stage 4—Deployment and Integration with the ERP Environment

- Transmission of sensor data (temperature, vibration, motor current, aeration pressure) to the digital twin.

- Analysis of the data in the modeling environment and prediction of anomalies using the LSTM-based model.

- Feedback of predictive results to the ERP system through REST API.

- Recording and execution of maintenance actions in the ERP module.

4.5. Stage 5—Performance Evaluation and Key Indicators

5. Case Study and Experimental Setup

5.1. Plant Description and Equipment Mapping

5.2. Data Collection and Integration

- Historical data, including three years of logged maintenance events and operational records;

- Real-time sensor data, collected continuously during the experimental period through IoT-enabled industrial sensors.

5.3. Implementation of the Integrated System

- The raw sensor data from the machinery were streamed to the digital twin.

- Analytical models predicted the equipment’s condition and identified abnormal behaviors.

- Predictive results were sent to the ERP dashboard, updating maintenance KPIs.

- Maintenance activities executed in the field were recorded back into the ERP, closing the feedback loop.

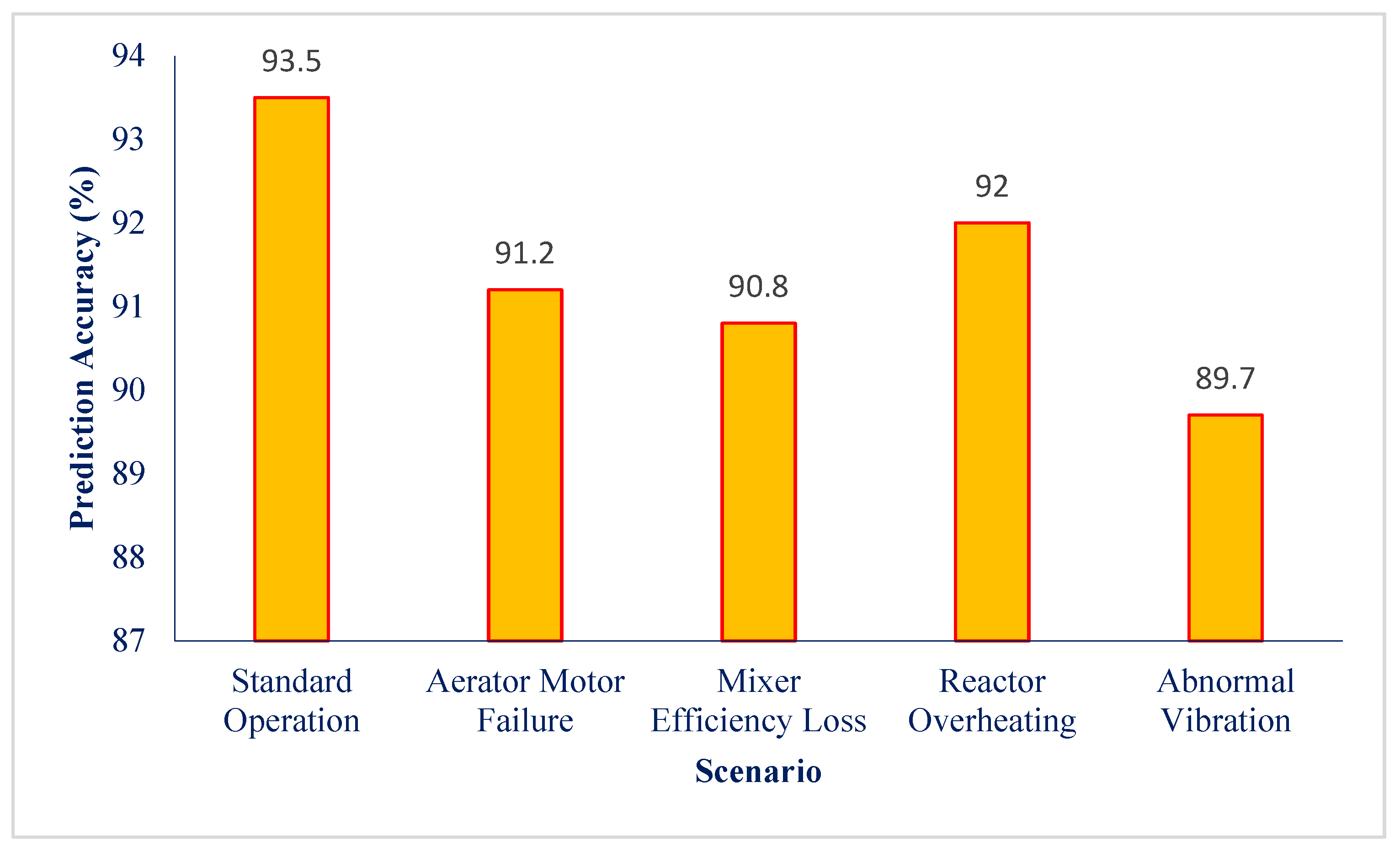

5.4. Test Scenarios and Experimental Conditions

- Mechanical failure in aeration motors;

- Reduced transmission efficiency in mixer shafts;

- Abnormal temperature peaks in compost reactors;

- Detection of atypical vibration patterns in power transmission systems.

- Prediction accuracy and time-to-detection;

- Sensitivity to different operating conditions;

- Effectiveness of ERP-based maintenance scheduling;

- Robustness of communication and data flow under varying load conditions.

5.5. Data Reliability and Calibration

6. Analysis of Results

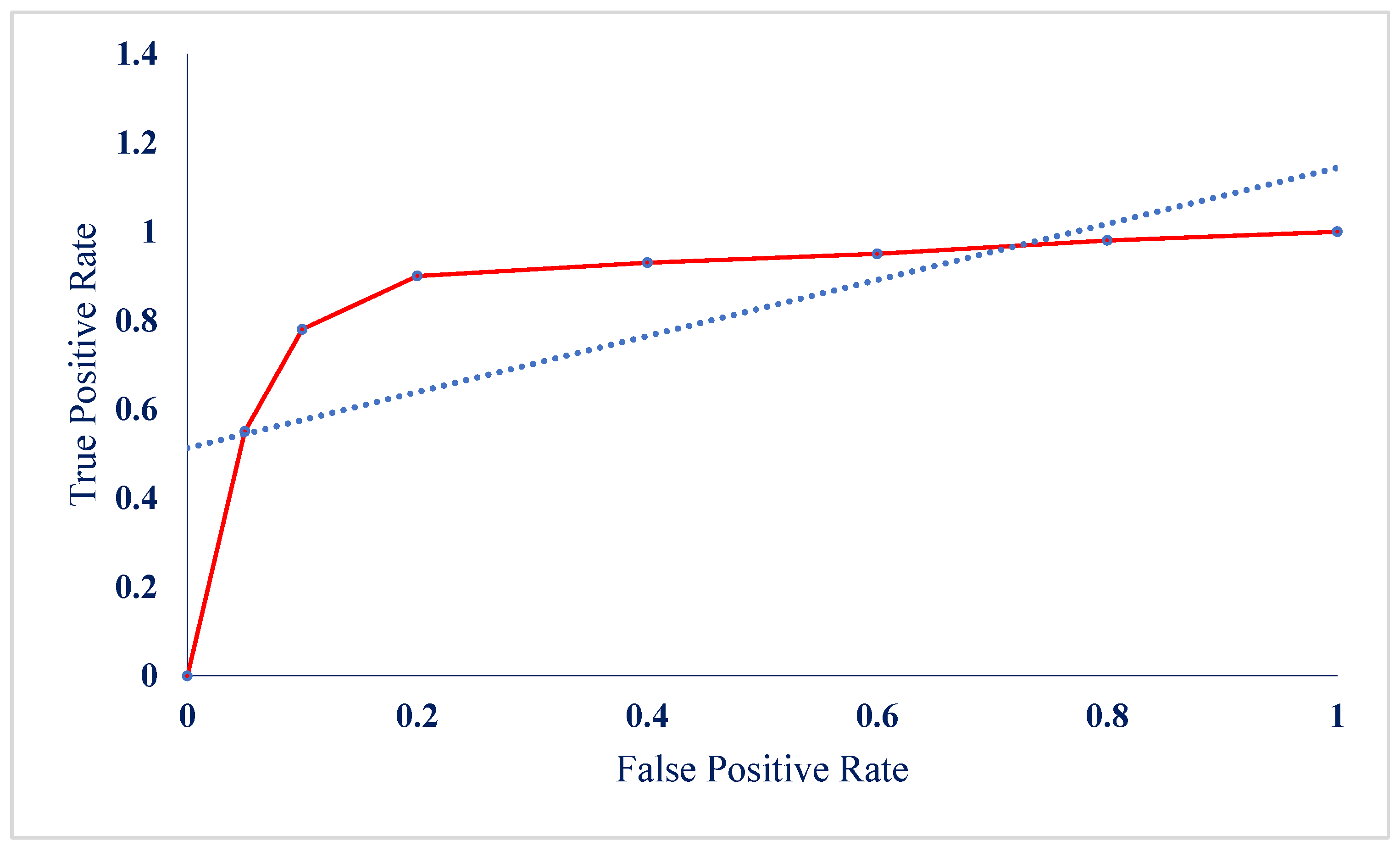

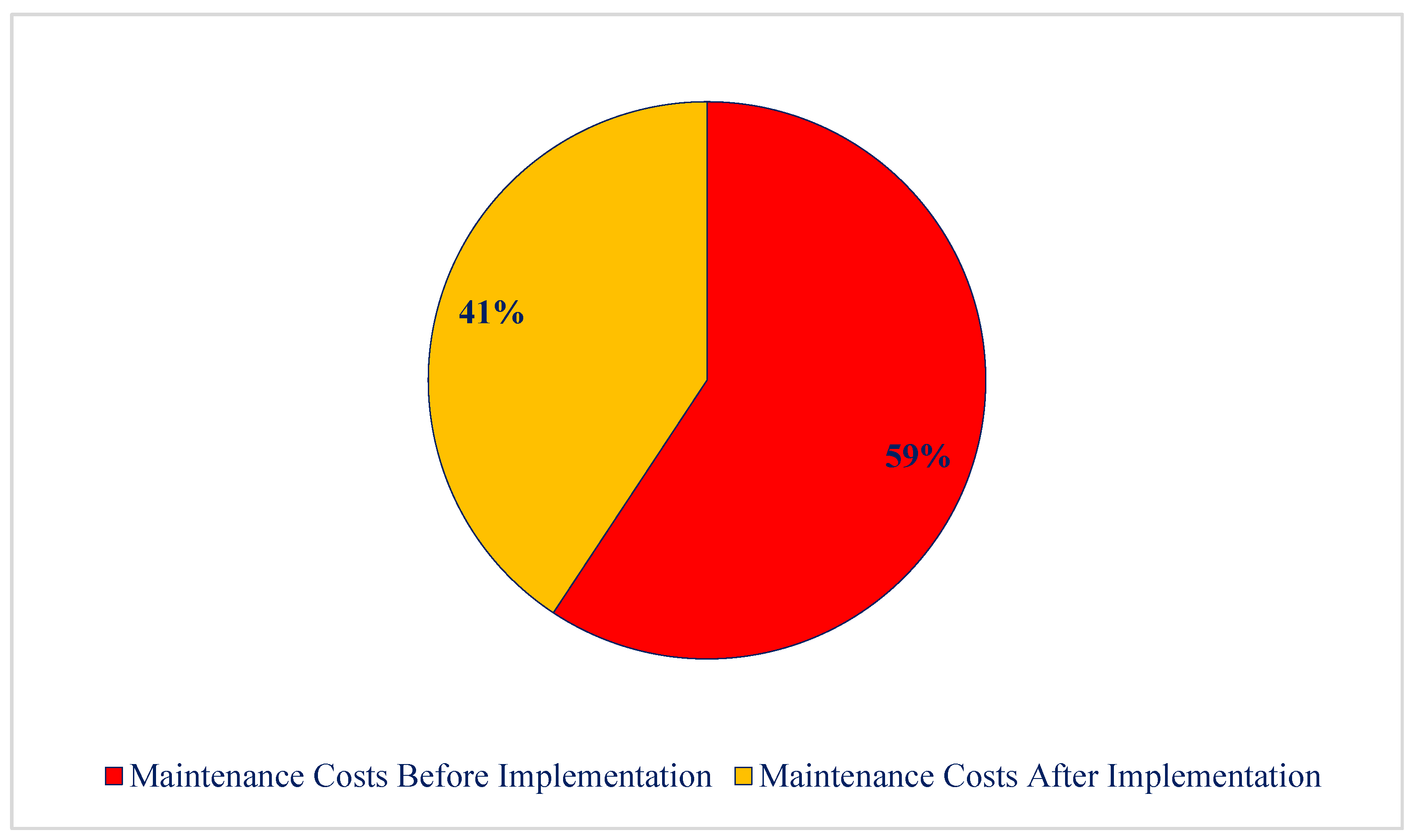

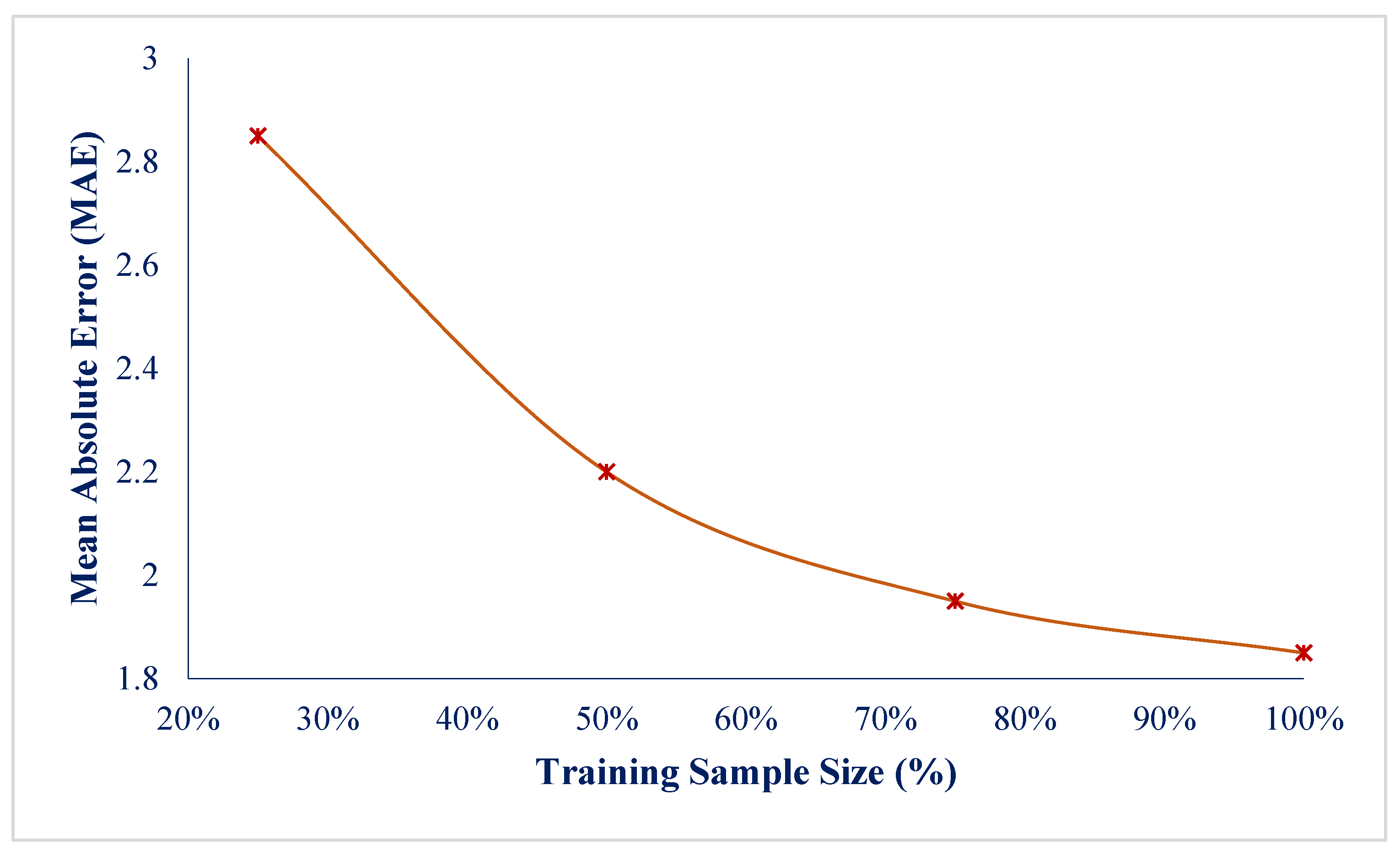

Model Performance Evaluation

- Low prediction error (MAE < 2%);

- High classification accuracy (AUC = 0.92);

- Substantial reliability gains (MTTF ↑ 40%);

- Significant cost savings (ROI = 42.5%).

- It continuously monitors the condition of critical assets.

- It learns from historical and real-time data.

- It adapts maintenance actions based on evolving operational states.

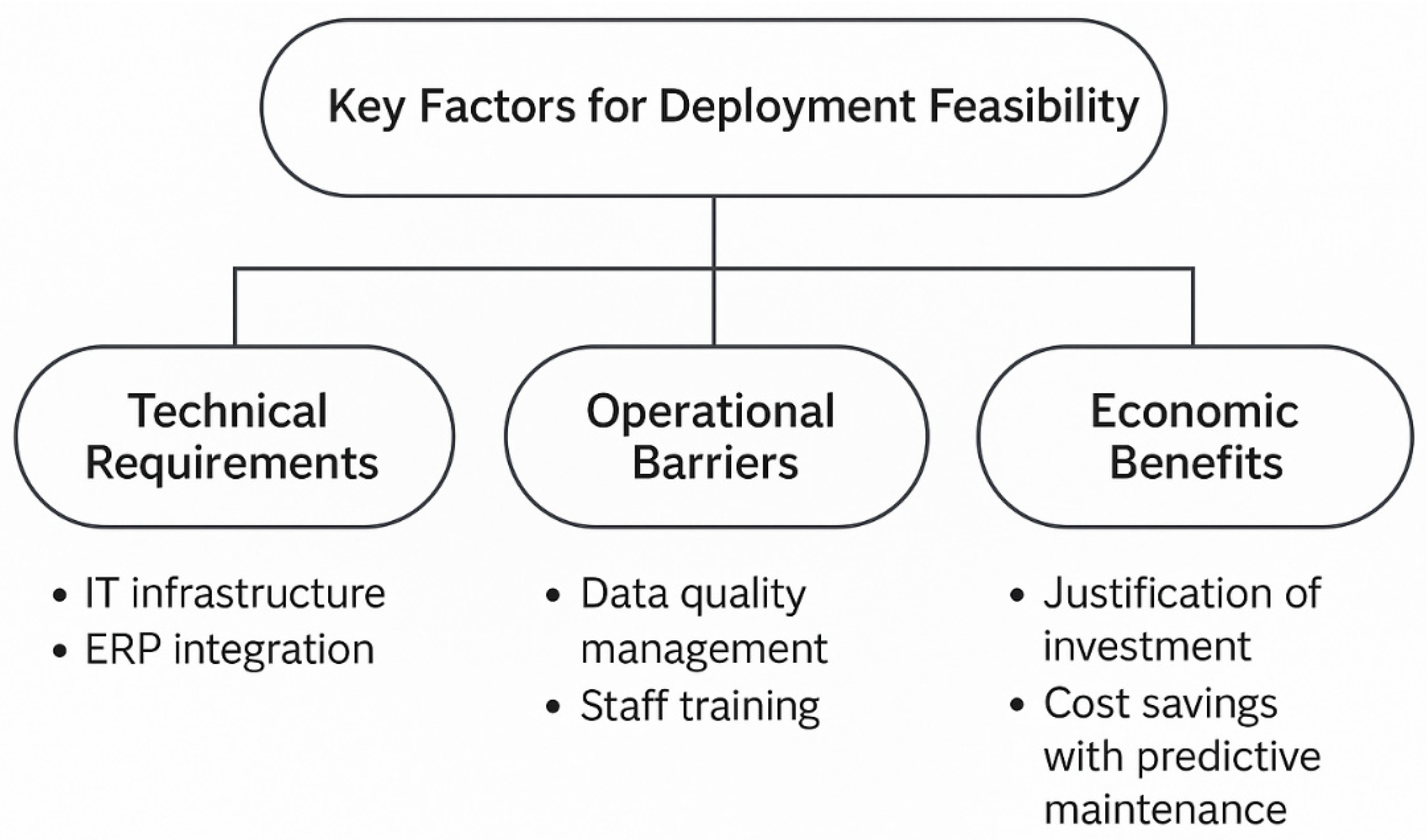

7. Deployment Feasibility Analysis

- Sensor and data acquisition infrastructure capable of real-time monitoring of key parameters such as vibration, temperature, and power consumption;

- Reliable connectivity with programmable logic controllers (PLCs) to ensure data synchronization between equipment and digital twin models;

- Stable local or cloud-based servers with sufficient computational capacity for real-time simulation and predictive model execution;

- ERP system compatibility with external analytical and simulation environments through RESTful API integration.

- Procurement of additional industrial sensors and PLC interfaces;

- Expansion of server and network infrastructure;

- Customization of ERP modules and APIs;

- Staff training and change management programs.

- Scalable deployment across multiple production lines or facilities;

- Custom adaptation to different machinery types or process industries;

- Progressive integration of advanced analytics, such as reinforcement learning or multi-agent optimization, for self-adaptive control;

- This scalability ensures that the system can evolve alongside industrial digitalization initiatives and accommodate future expansions without major structural modifications.

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vargas, J.M.; Castrillon, O.D.; Giraldo, J.A. Implementation and Field Validation of a Digital twin Methodology to Enhance Production and Service Systems in Waste Management. Appl. Sci. 2025, 15, 6733. [Google Scholar] [CrossRef]

- Monteiro, J.; Barata, J. A Circular Digital twin for Climate-Smart Soils through Community Composting. In Advances in Information Systems Development: Exploring New Horizons and Opportunities; Springer Nature: Cham, Switzerland, 2025; pp. 167–188. [Google Scholar]

- Abd Wahab, N.H.; Hasikin, K.; Lai, K.W.; Xia, K.; Bei, L.; Huang, K.; Wu, X. Systematic review of predictive maintenance and digital twin technologies challenges, opportunities, and best practices. PeerJ Comput. Sci. 2024, 10, e1943. [Google Scholar] [CrossRef] [PubMed]

- Aliahmadi, A.; Nozari, H.; Ghahremani-Nahr, J.; Szmelter-Jarosz, A. Evaluation of key impression of resilient supply chain based on artificial intelligence of things (AIoT). arXiv 2022, arXiv:2207.13174. [Google Scholar] [CrossRef]

- Nasirinejad, M.; Afshari, H.; Sampalli, S. The Adoption of Digital Twin Technologies for Maintenance in Small and Medium-Sized Enterprises: Challenges and Benefits; SSRN eLibrary: Rochester, NY, USA, 2025. [Google Scholar] [CrossRef]

- Jesus, V.; Kalaitzi, D.; Batista, L.; Lopez, N.L. Digital twins of Supply Chains: A Systems Approach. IEEE Trans. Eng. Manag. 2024, 71, 14915–14932. [Google Scholar] [CrossRef]

- Kannan, S. Transforming Agriculture for the Digital Age: Integrating Artificial Intelligence, Cloud Computing, and Big Data Solutions for Sustainable and Smart Farming Systems; Deep Science Publishing: San Francisco, CA, USA, 2025. [Google Scholar]

- Koç, E. Measurement and Assessment of Supply Chain Sustainability Performance. In Developing Dynamic and Sustainable Supply Chains to Achieve Sustainable Development Goals; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 179–200. [Google Scholar]

- Abdulhayan, S.; Quadri, S.A. Artificial Intelligence, IoT, and Fuzzy Systems for Sustainable Development and Industry 5.0; Deep Science Publishing: San Francisco, CA, USA, 2025. [Google Scholar]

- Tsai, W.H.; Lai, S.Y. Green production planning and control model with ABC under industry 4.0 for the paper in-dustry. Sustainability 2018, 10, 2932. [Google Scholar] [CrossRef]

- Singh, R.; Dwivedi, G. Agri-food Supply Chain Management: A Review Using Bibliometric, Network, and Content Analyses. Oper. Res. Forum 2025, 6, 62. [Google Scholar] [CrossRef]

- Aliahmadi, A.; Nozari, H. Evaluation of security metrics in AIoT and blockchain-based supply chain by Neutrosophic decision-making method. Supply Chain Forum Int. J. 2023, 24, 31–42. [Google Scholar] [CrossRef]

- Emmanuel, A.T. An Evaluation of Production Operations at Skretting’s Stavanger Plant, Norway, & an Overview of Skretting’s Supply Chain Based on Lean Concepts. Ph.D. Dissertation, Royal Institute of Technology, Stockholm, Sweden, 2008. [Google Scholar]

- Chen, K.; Zhao, B.; Zhou, H.; Zhou, L.; Niu, K.; Jin, X.; Li, R.; Yuan, Y.; Zheng, Y. Digital twins in plant factory: A five-dimensional modeling method for plant factory transplanter digital twins. Agriculture 2023, 13, 1336. [Google Scholar] [CrossRef]

- Montreuil, B. Transforming the Composting Industry Towards Industry 4.0 and Physical Internet Capabilities. Ph.D. Dissertation, Georgia Institute of Technology, Atlanta, GA, USA, 2024. [Google Scholar]

- Cichocki, M.; Landschützer, C.; Hick, H. Development of a Sharing Concept for Industrial Compost Turners Using Model-Based Systems Engineering, Under Consideration of Technical and Logistical Aspects. Sustainability 2022, 14, 10694. [Google Scholar] [CrossRef]

- Barbosa, J.M.V.; Gomez, O.D.C.; García, J.A.G. Digital twin Application Methodology for the Improvement of Production and Service Systems. Application to Waste Management Processes. In Proceedings of the Sustainable Smart Cities and Territories International Conference, Manizales, Colombia, 21–23 June 2023; Springer Nature: Cham, Switzerland, 2023; pp. 25–36. [Google Scholar]

- Danilo, J.M.V.B.O.; Gomez, C.; Piso, B.Q. Digital twin Application Methodology for the Improvement of Production and Service. Trends Sustain. Smart Cities Territ. 2023, 732, 25. [Google Scholar]

- Shamia, D.; Suganyadevi, S.; Satheeswaran, V.; Balasamy, K. Digital twins in precision agriculture monitoring using artificial intelligence. In Digital Twin for Smart Manufacturing; Academic Press: Cambridge, MA, USA, 2023; pp. 243–265. [Google Scholar]

- Giel, R.; Dąbrowska, A. Digital twin Concept for Manual Waste Sorting Management. Environ. Prot. Eng. 2025, 51, 1. [Google Scholar] [CrossRef]

- Nyakudya, P.; Madushele, N.; Madyira, D.M.; Matare, E.E. Embracing Digital twin Technology to Enhance Efficacy of Industrial Symbiosis: A Path to Sustainability. In Proceedings of the 2024 International Conference on Electrical and Computer Engineering Researches (ICECER), Gaborone, Botswana, 4–6 December 2024; IEEE: Los Alamitos, CA, USA, 2024; pp. 1–6. [Google Scholar]

- Mohammadi, H.; Ghazanfari, M.; Nozari, H.; Shafiezad, O. Combining the theory of constraints with system dynamics: A general model (case study of the subsidized milk industry). Int. J. Manag. Sci. Eng. Manag. 2015, 10, 102–108. [Google Scholar] [CrossRef]

- Vanjare, S.; Musale, J.; More, P.; Sayyad, T.; Gupta, Y.; Shikre, S. Implementation of Digital twin Technology for Predictive Crop Disease Monitoring. In Proceedings of the International Conference on Recent Advancements and Modernisations in Sustainable Intelligent Technologies and Applications (RAMSITA 2025), Indore, India, 7–8 February 2025; Atlantis Press: Dordrecht, The Netherlands, 2025; pp. 654–665. [Google Scholar]

- dos Santos Silva, J.; Matos de Oliveira, A.; Veríssimo de Oliveira, J.; Bouzon, M. Barriers to digital transformation in fruit and vegetable supply chains: A multicriteria analysis using ISM and MICMAC. OPSEARCH 2025, 62, 460–482. [Google Scholar] [CrossRef]

- Zaballos, A.; Briones, A.; Massa, A.; Centelles, P.; Caballero, V. A smart campus’ digital twin for sustainable comfort monitoring. Sustainability 2020, 12, 9196. [Google Scholar] [CrossRef]

- Yang, B.; Lv, Z.; Wang, F. Digital twins for intelligent green buildings. Buildings 2022, 12, 856. [Google Scholar] [CrossRef]

| Data Type | Data Source | Sampling Interval | Data Range | Number of Samples |

|---|---|---|---|---|

| Reactor Temperature | Industrial Sensors | Every 5 min | 35–80 °C | 10,800 |

| Aerator Vibration | Vibration Sensors (IoT) | Every 1 min | 0.1–2.5 mm/s | 54,000 |

| Mixer Motor Current | PLC Monitoring System | Every 10 min | 10–45 A | 5400 |

| Aeration System Pressure | Pressure Transmitters | Every 5 min | 0.5–2.0 bar | 10,800 |

| Metric | Predictive Model (Regression) | Detection Model (Classification) |

|---|---|---|

| MAE | 0.18 | - |

| RMSE | 0.27 | - |

| Accuracy | - | 0.94 |

| AUC | - | 0.92 |

| Precision | - | 0.92 |

| Recall | - | 0.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nozari, H.; Szmelter-Jarosz, A. A Predictive Maintenance Approach for Composting Plants Based on ERP and Digital Twin Integration. Machines 2025, 13, 1123. https://doi.org/10.3390/machines13121123

Nozari H, Szmelter-Jarosz A. A Predictive Maintenance Approach for Composting Plants Based on ERP and Digital Twin Integration. Machines. 2025; 13(12):1123. https://doi.org/10.3390/machines13121123

Chicago/Turabian StyleNozari, Hamed, and Agnieszka Szmelter-Jarosz. 2025. "A Predictive Maintenance Approach for Composting Plants Based on ERP and Digital Twin Integration" Machines 13, no. 12: 1123. https://doi.org/10.3390/machines13121123

APA StyleNozari, H., & Szmelter-Jarosz, A. (2025). A Predictive Maintenance Approach for Composting Plants Based on ERP and Digital Twin Integration. Machines, 13(12), 1123. https://doi.org/10.3390/machines13121123