Analysis of Fatigue Crack Paths in Cold Drawn Pearlitic Steel

Abstract

:1. Introduction

2. Experimental Method

3. Experimental Results

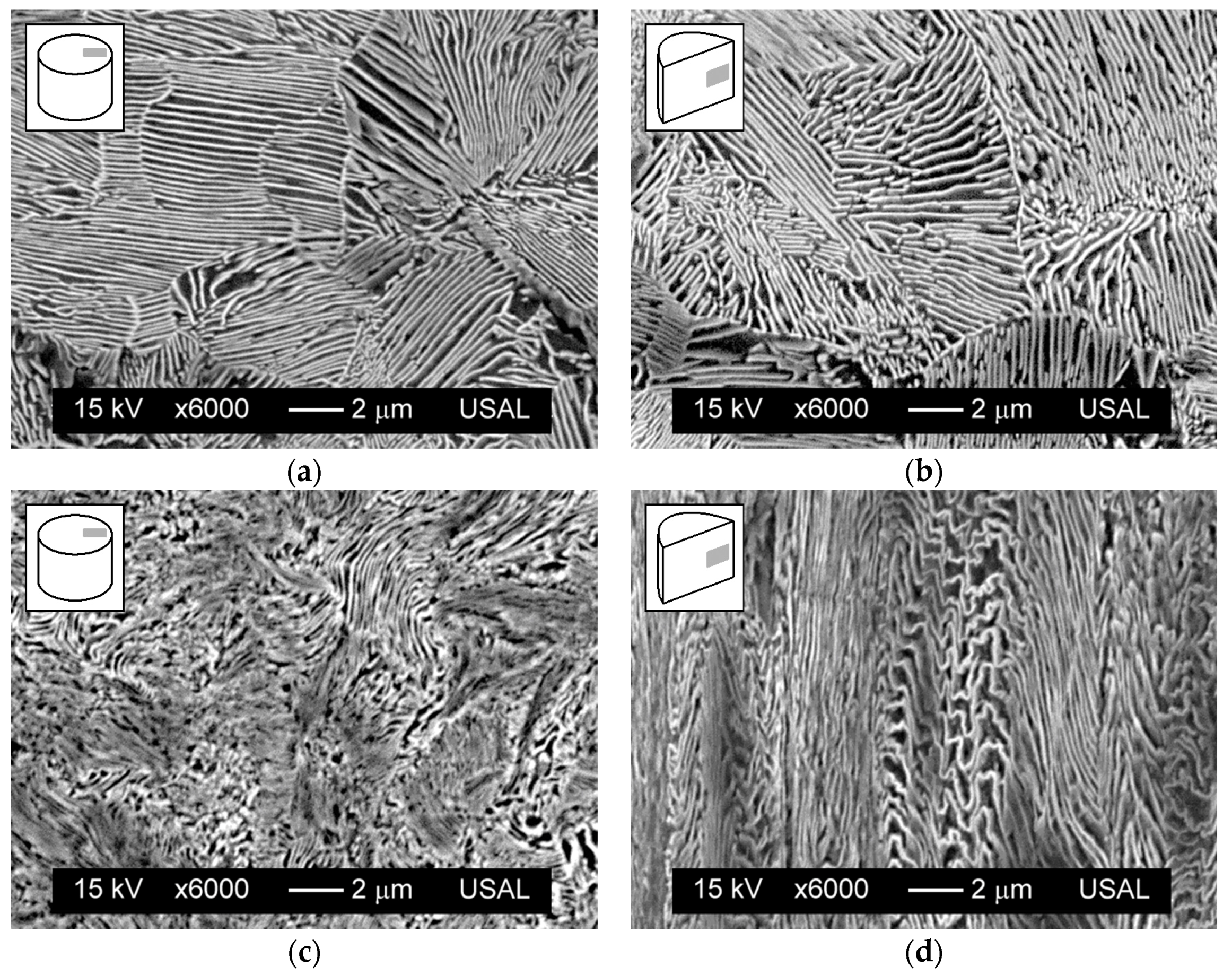

3.1. Microstructural Analysis

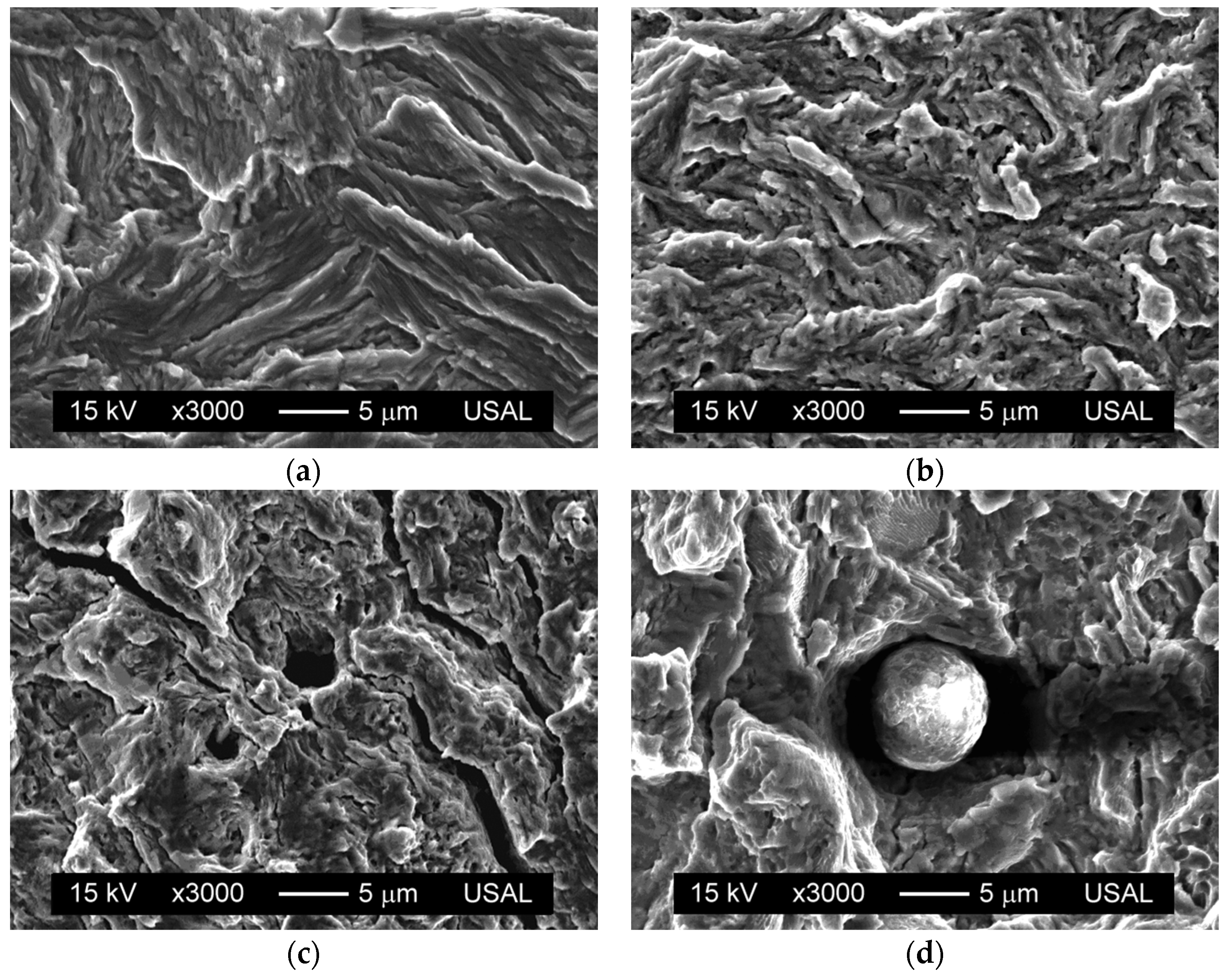

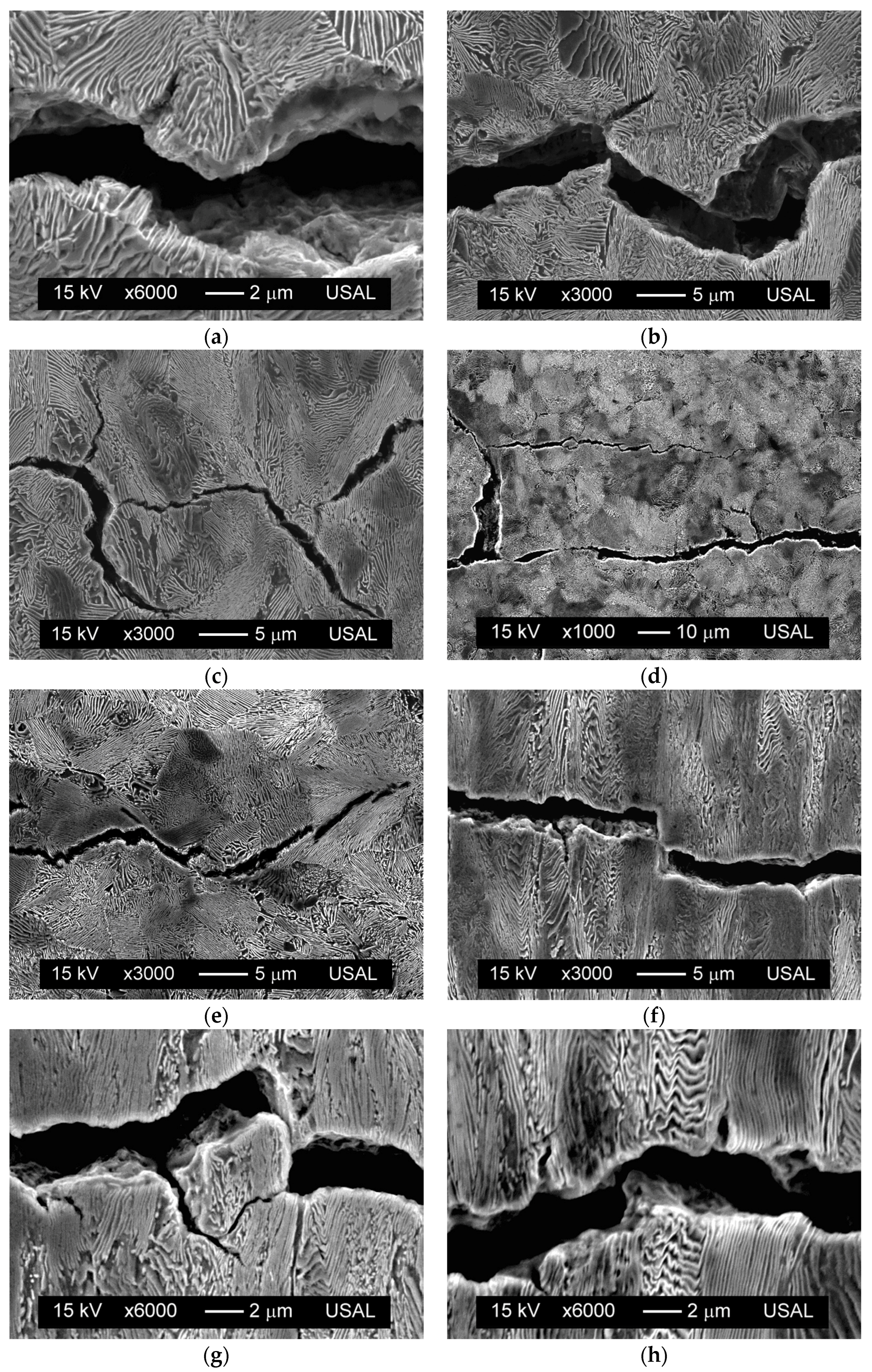

3.2. Fractographic Analysis

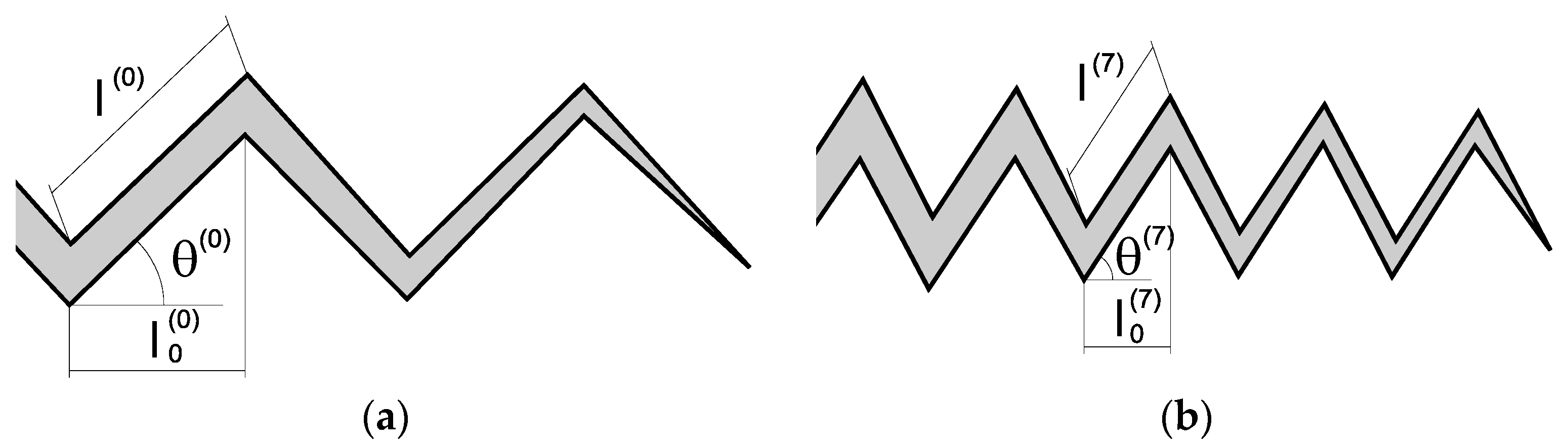

4. Discussion

5. Conclusions

- (i)

- From the microscopic point of view, fatigue cracks in pearlitic steel develop exhibiting micro-plastic tearing. This fact is consistent with an evidence of cyclic micro-damage and crack advance produced by a mechanism of plastic strain concentration. The cold drawn wire exhibits a pattern resembling micro-tearing, these events being of lower size and more curved aspect than those associated with the hot rolled bar.

- (ii)

- Cracking paths produced by fatigue (cyclic) loading develop in the form of trans-colonial advance and tending to fracture a certain proportion of pearlitic lamellae in the corresponding colony of pearlite. As a matter of fact, fatigue crack propagation can be classified as tortuous, with certain quantity of micro-discontinuities, branchings (frequently, bifurcations also appear), as well as local deflections, thereby producing a sort of roughness (at the microstructural level) with associated non-uniform crack opening displacement distribution.

- (iii)

- The fractographic analysis of the cracked surface produced by fatigue fracture in the cold drawn pearlitic wire exhibits an appearance consisting of micro-roughness. In this case, the total fractured surface (including the afore-said micro-discontinuities, branchings, bifurcations and local deflections) is greater than in the case of the hot rolled bar (base material). The reason is that the deflections in the fatigue crack path are more frequent and with greater angle in the cold drawn wire than in the hot rolled bar. The increase of the stress intensity factor (SIF) range, ∆K, also produces higher micro-roughness in the fracture surface.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sadananda, K.; Vasudevan, A.K. Crack tip driving forces and crack growth representation under fatigue. Int. J. Fatigue 2004, 26, 39–47. [Google Scholar] [CrossRef]

- Stoychev, S.; Kujawski, D. Analysis of crack propagation using ΔK and Kmax. Int. J. Fatigue 2005, 27, 1425–1431. [Google Scholar] [CrossRef]

- Zhang, J.; He, X.D.; Du, S.Y. Analyses of the fatigue crack propagation process and stress ratio effects using the two parameter method. Int. J. Fatigue 2005, 27, 1314–1318. [Google Scholar] [CrossRef]

- Kujawski, D. A fatigue crack driving force parameter with load ratio effects. Int. J. Fatigue 2001, 23, S239–S246. [Google Scholar] [CrossRef]

- Marci, G.; Khotsyanovskii, A.O. Testing procedures for fatigue crack propagation and the ΔKeff-concept. Strength Mater. 1995, 27, 363–378. [Google Scholar] [CrossRef]

- Elber, W. Fatigue crack closure under cyclic tension. Eng. Fract. Mech. 1970, 2, 37–44. [Google Scholar] [CrossRef]

- Walther, F.; Eifler, D. Local cyclic deformation behavior and microstructure of railway wheel materials. Mater. Sci. Eng. A 2004, 387–389, 481–485. [Google Scholar] [CrossRef]

- Korda, A.A.; Mutoh, Y.; Miyashita, Y.; Sadasue, T. Effects of pearlite morphology and specimen thickness on fatigue crack growth resistance in ferritic-pearlitic steels. Mater. Sci. Eng. A 2006, 428, 262–269. [Google Scholar] [CrossRef]

- Toribio, J.; Matos, J.C.; González, B. Micro- and macro-approach to the fatigue crack growth in progressively drawn pearlitic steels at different R-ratios. Int. J. Fatigue 2009, 31, 2014–2021. [Google Scholar] [CrossRef]

- Korda, A.A.; Mutoh, Y.; Miyashita, Y.; Sadasue, T.; Mannan, S.L. In situ observation of fatigue crack retardation in banded ferrite-pearlite microstructure due to crack branching. Scr. Mater. 2006, 54, 1835–1840. [Google Scholar] [CrossRef]

- Wetscher, F.; Stock, R.; Pippan, R. Changes in the mechanical properties of a pearlitic steel due to large shear deformation. Mater. Sci. Eng. A 2007, 445–446, 237–243. [Google Scholar] [CrossRef]

- Kitagawa, H.; Yuuki, R.; Ohira, T. Crack-morphological aspects in fracture mechanics. Eng. Fract. Mech. 1975, 7, 515–529. [Google Scholar] [CrossRef]

- Suresh, S. Crack deflection: Implications for the growth of long and short fatigue cracks. Metall. Trans. A 1983, 14, 2375–2385. [Google Scholar] [CrossRef]

- Carpinteri, A.; Spagnoli, S.; Vantadori, S.; Viappiani, D. Influence of the crack morphology on the fatigue crack growth rate: A continuously-kinked crack model based on fractals. Eng. Fract. Mech. 2008, 75, 579–589. [Google Scholar] [CrossRef]

- Astiz, M.A. An incompatible singular elastic element for two- and three-dimensional crack problems. Int. J. Fracture 1986, 31, 105–124. [Google Scholar] [CrossRef]

- Mutoh, Y.; Korda, A.A.; Miyashita, Y.; Sadasue, T. Stress shielding and fatigue crack growth resistance in ferritic-pearlitic steel. Mater. Sci. Eng. A 2007, 468–470, 114–119. [Google Scholar] [CrossRef]

- Okayasu, M.; Chen, D.; Wang, Z. Experimental study of the effect of loading condition on fracture surface contact features and crack closure behavior in a carbon steel. Eng. Fract. Mech. 2006, 73, 1117–1132. [Google Scholar] [CrossRef]

- Toribio, J.; Ovejero, E.; Toledano, M. Microstructural bases of anisotropic fracture behaviour of heavily drawn steel. Int. J. Fract. 1997, 87, L83–L88. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toribio, J.; González, B.; Matos, J.-C. Analysis of Fatigue Crack Paths in Cold Drawn Pearlitic Steel. Materials 2015, 8, 7439-7446. https://doi.org/10.3390/ma8115388

Toribio J, González B, Matos J-C. Analysis of Fatigue Crack Paths in Cold Drawn Pearlitic Steel. Materials. 2015; 8(11):7439-7446. https://doi.org/10.3390/ma8115388

Chicago/Turabian StyleToribio, Jesús, Beatriz González, and Juan-Carlos Matos. 2015. "Analysis of Fatigue Crack Paths in Cold Drawn Pearlitic Steel" Materials 8, no. 11: 7439-7446. https://doi.org/10.3390/ma8115388