- Article

Micro- and Nanoscale Flow Mechanisms in Shale Oil: A Fluid–Solid Coupling Model Integrating Adsorption, Slip, and Stress Sensitivity

- Zupeng Liu,

- Zhibin Yi and

- Xinlong Zhang

- + 3 authors

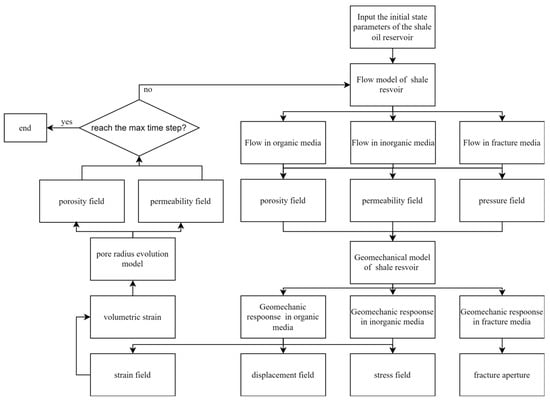

Shale oil reservoirs are complex multi-scale nanoporous media where fluid transport is governed by coupled micro-mechanisms, demanding a robust modeling framework. This study presents a novel fluid–solid coupling (FSC) numerical model that rigorously integrates the three primary scale-dependent transport phenomena: adsorption in organic nanopores, slip effects in inorganic micropores, and stress-sensitive conductivity in fractures. The model provides essential quantitative insights into the dynamic interaction between fluid withdrawal and reservoir deformation. Simulation results reveal that microstructural properties dictate the reservoir’s mechanical stability. Specifically, larger pore diameters and higher porosity enhance stress dissipation, promoting long-term stress relaxation and mitigating permeability decay. Crucially, tortuosity governs the mechanical response by controlling pressure transmission pathways: low tortuosity causes localized stress concentration, leading to rapid micro-channel closure, while high tortuosity ensures stress homogenization, preserving long-term permeability. Furthermore, high fracture conductivity induces a severe, heterogeneous stress field near the wellbore, which dictates early-stage mechanical failure. This work provides a powerful, mechanism-based tool for optimizing micro-structure and production strategies in unconventional resources.

21 January 2026

![(a) (i) Schematic illustration of the ultraflexible sensor (UFS). (ii) Dynamic pressure response of the UFS under static conditions at applied forces of 500, 1000, and 1500 mN. Adapted with permission from Ref. [84]. Copyright 2003 John Wiley and Sons. (b) A flexible sensing array composed of an Ecoflex film and a TPU nanofiber composite layer. (i) Structural schematic of a single sensor unit. (ii) Measured signals of pulse monitoring at multiple localized positions on the wrist. Adapted from Ref. [88]. (c) Fabrication process of the TENG for smart fabric (SF) applications and its corresponding response signals. Adapted with permission from Ref. [90]. Copyright 2021 American Chemical Society. (d) Structure, sensitivity, and pulse wave experimental measurements of a triboelectric all-fiber-structured pressure sensor for pulse wave monitoring. (i) Design schematic of the textile-based sensor. (ii) Real-time output signals when the sensor fabric is worn on the wrist. Adapted with permission from Ref. [84]. Copyright 2020 American Chemical Society.](https://mdpi-res.com/nanomaterials/nanomaterials-16-00141/article_deploy/html/images/nanomaterials-16-00141-ag-550.jpg)