- Proceeding Paper

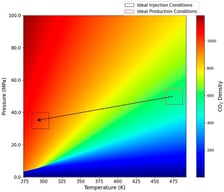

The design of functional paper coatings with excellent barrier properties, including water repellence, anti-microbial properties, and recyclability, is highly demanded in view of the sustainable use of paper as flexible substrates for various industrial applications such as packaging. The enhanced coating functionalities should be incorporated through a combination of selected bio-based materials and the creation of appropriate surface textures enhancing coating performance. The bio-inspired approaches through the replication of hierarchical surface structures with multi-scale dimensional features in combination with selection of appropriate bio-based functional groups offer new concepts for coating design. In this short perspective paper, concepts in the field are illustrated with a focus on the combination of hydrophobic and anti-microbial properties. Based on long-term work with the available toolbox of bio-based building blocks and nanoscale architectures, they can be processed into applicable aqueous suspensions for sprayable paper coatings. The macroscopic roughness profile of paper substrates can be complemented through the decoration of nanoscale bio-based polymer particles of polyhydroxybutyrate or vegetable oil capsules with dimensions in the range of 20–50 nm or 100–500 nm depending on the synthesis conditions. The anti-microbial properties can be provided by the surface modification of nanocellulose with biologically active molecules sourced from nature. Besides the more fundamental issues in design and synthesis, the industrial application of the bio-inspired coatings through spray-coating becomes relevant.

17 April 2025

![Illustrative examples of biomimicry in creating water-repellent paper coatings with hierarchical surface structures based on (a) vegetable-oil nanocapsules [16], (b) polyhydroxybutyrate particles [17], (c) intercalated kaolinite clay [18], and (d) biowax precipitation [19].](https://mdpi-res.com/cdn-cgi/image/w=470,h=317/https://mdpi-res.com/materproc/materproc-20-00008/article_deploy/html/images/materproc-20-00008-g001-550.jpg)