1. Introduction

Efficient scheduling in materials manufacturing systems is essential for improving productivity, minimizing idle time, and optimizing the use of limited resources such as machines, labor, and raw materials. In industrial environments like metal fabrication, composite molding, and thermal processing, multiple operations often compete for shared machinery under limited time and resource constraints. In such scenarios, poor scheduling can lead to production delays, increased operational costs, and underutilization of expensive equipment.

Traditional scheduling methods, including manual adjustments or simple heuristics like First Come First Serve (FCFS), may be suitable for small-scale systems but often fail when applied to complex or high-throughput manufacturing setups. As the scale and complexity of operations increases, more intelligent and adaptive solutions are needed. Hybrid GA methods have proven effective for RCPSP with material ordering, particularly GA–GA which outperformed SA–GA in scheduling efficiency [

1]. Recent research highlights the growing use of AI in materials science for optimizing material behavior, particularly in systems like fuel cells and electrolyzers [

2]. A priority-based Genetic Algorithm was employed to solve the RCPSP using serial and parallel scheduling schemes, demonstrating effective project duration minimization on benchmark instances [

3]. A hybrid metaheuristic combining Genetic Algorithm and Neighborhood Search Strategy was proposed for RCPSP, achieving competitive makespan reductions on PSPLIB benchmarks through resource-based ranking and multi-crossover strategies [

4].

This study focuses on the development and application of a Genetic Algorithm with Guided Mutation (GA-GM) tailored to solve resource-constrained scheduling problems in materials manufacturing systems. The objective is to achieve shorter processing times and higher resource utilization by intelligently sequencing activities and resolving conflicts related to shared equipment and material limitations.

1.1. Problem Statement

In manufacturing environments, scheduling refers to the planning of activities to ensure the efficient use of available machines, labor, and materials. A typical workflow might assume a predefined sequence of operations where each activity starts after the previous one finishes. However, real-world manufacturing processes are more complex due to limited resource availability and parallel operations that must compete for the same machines or material inputs.

Such constraints introduce scheduling conflicts that cannot be resolved by simple logic or fixed sequencing alone. These conflicts can result in production bottlenecks, increased processing time, and reduced throughput. For example, in a composite molding facility, multiple parts may require the same curing oven, but limited oven capacity forces some parts to wait. These delays are not caused by process dependencies but by resource constraints, leading to dynamic changes in the production timeline.

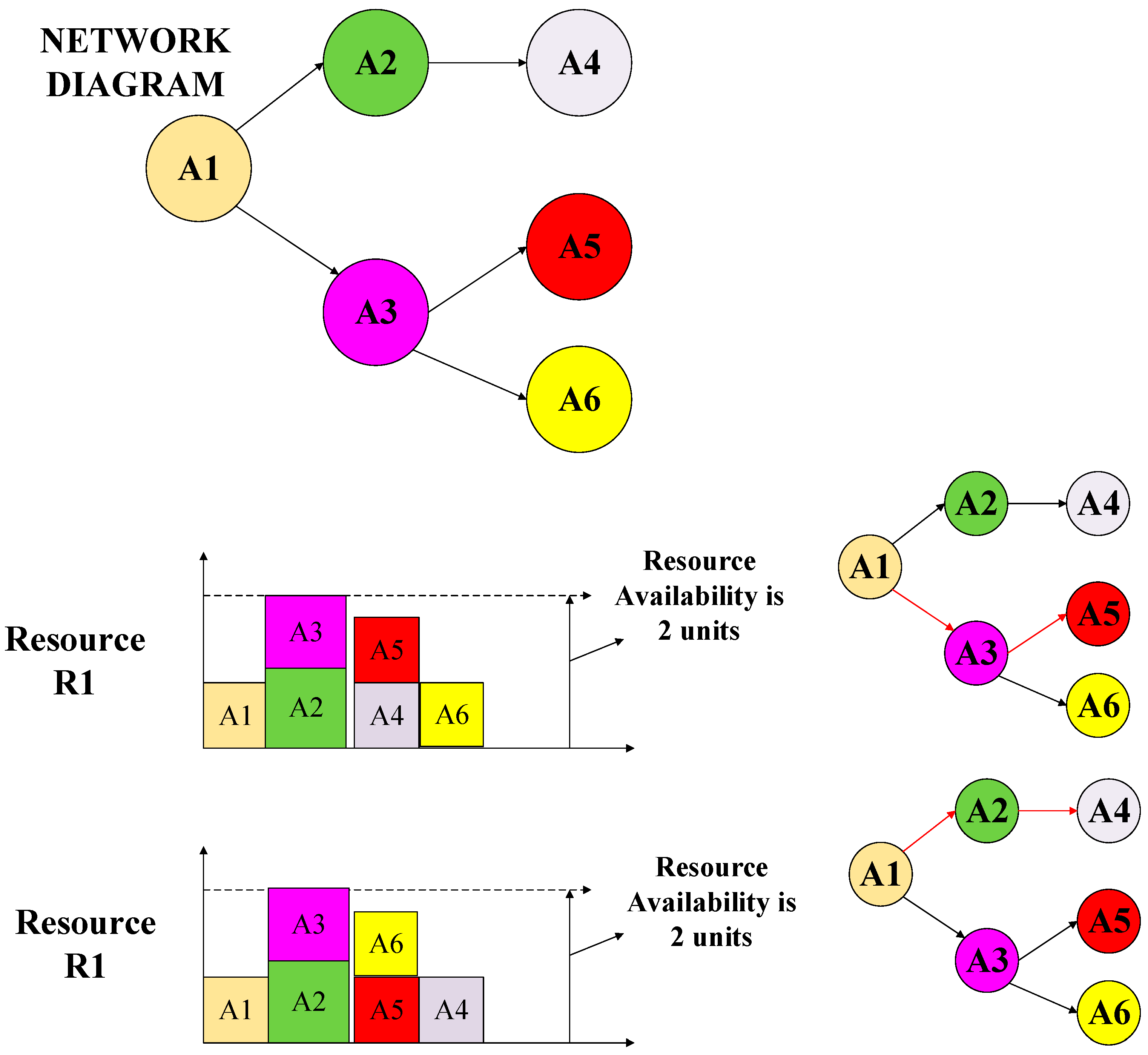

Figure 1 illustrates how limited machinery availability influences scheduling decisions in a materials manufacturing environment. The process flow diagram in the top left shows the sequence of operations such as preparation, processing, and inspection, where each activity depends on the completion of others. The bar charts in the bottom left display how multiple operations compete for a shared machine resource like a furnace or press, which has a fixed availability of two units. The right side of the figure compares two scheduling outcomes based on different choices for machine assignment. When specific activities are prioritized for machine access, others are delayed not due to process sequence but because of equipment constraints. This shift alters the critical path and increases the total processing time. Such challenges are common in materials laboratories and production environments where multiple procedures rely on limited, high-demand equipment.

The primary goal of this research is to develop an improved Genetic Algorithm that can effectively manage such scheduling challenges in materials manufacturing. By automatically adjusting activity sequences and resolving conflicts caused by shared resources, the proposed algorithm aims to minimize the total processing time (makespan) and optimize efficiency across the entire system.

1.2. Notations and Definitions

Below are the key symbols used in our scheduling model:

A = {A1, A2, A3, …, An} denotes the set of manufacturing operations (e.g., mixing, casting, curing, inspection);

Ti denotes the start time of operation Ai;

Di denotes the duration of operation Ai;

Rs denotes the set of available machinery/equipment types (e.g., furnace, molding station);

ri denotes the resource units required for operation Ai;

Ra denotes the total available units of a specific resource at any time t;

Cmax denotes the overall manufacturing completion time;

P denotes the set of precedence constraints that define required order of operations (e.g., trimming can only start after demolding);

Is(t) denotes the set of operations in progress at time t;

S denotes the set of feasible schedules that meet both precedence and resource constraints.

The model consists of two key constraints and one objective function:

The primary objective in materials manufacturing scheduling is to minimize the total processing time, denoted as C

max:

This objective ensures that the maximum completion time among all operations is as short as possible, leading to early process completion.

Each operation can only begin once its required preceding steps are completed. Mathematically,

represents a precedence relationship where operation i must finish before operation j can start, reflecting the sequential nature of material processing workflows.

In practical manufacturing environments, machine capacity and resource availability are limited. At any time t, the total usage of shared machinery or input material must not exceed the available capacity R

a. The constraint is defined as

where I

s(t) represents the set of operations being performed at time t, r

i represents the resource or machine units required by operation i requirement of activity i, and R

a represents the total available capacity of the shared manufacturing resource.

2. Materials and Methods

This study focuses on optimizing resource-constrained scheduling in materials manufacturing systems using an improved metaheuristic technique called the Genetic Algorithm with Guided Mutation (GA-GM). The objective is to enhance the sequencing of operations such as molding, curing, inspection, or machining under practical resource limitations. The proposed algorithm seeks to minimize the total processing time while improving the utilization of shared machinery and material inputs. To evaluate its effectiveness, the results from GA-GM are compared with conventional scheduling strategies including First Come First Serve (FCFS), Shortest Job First (SJF), and Priority Based Scheduling (PBS).

The methodology includes four main stages. First, operational data is synthetically generated to reflect typical scenarios in materials manufacturing environment. Second, the data is cleaned and formatted to ensure compatibility. Third, the proposed algorithm is implemented and executed to solve the scheduling problem under resource constraints. Finally, the results are validated by comparing them with outcomes from baseline scheduling approaches.

2.1. Data Collection and Preprocessing

The input data for this study was synthetically generated to represent the sequence of operations in the materials manufacturing environment. The dataset includes essential attributes such as operation IDs, operation names (e.g., molding, curing, machining), precedence relationships, operation durations, resource requirements, and availability of shared machines.

The synthetic dataset was created and structured in Microsoft Excel to ensure flexibility in modeling various processing scenarios. It was carefully reviewed to eliminate missing values, logical inconsistencies, or duplicates. Once cleaned, the data was imported into a Python-based simulation environment configured in Visual Studio Code (version 1.100.3) for further analysis and optimization.

2.2. Methodology Adopted

The Guided Mutation Genetic Algorithm builds upon the traditional Genetic Algorithm framework by directing mutations toward critical areas of the solution. Specifically, it focuses on operations that share limited resources or significantly influence the critical path. By prioritizing these high-impact regions during mutation, the algorithm enhances solution quality and convergence speed. This targeted strategy improves the algorithm’s effectiveness in solving complex scheduling and optimization problems in resource-constrained manufacturing environments.

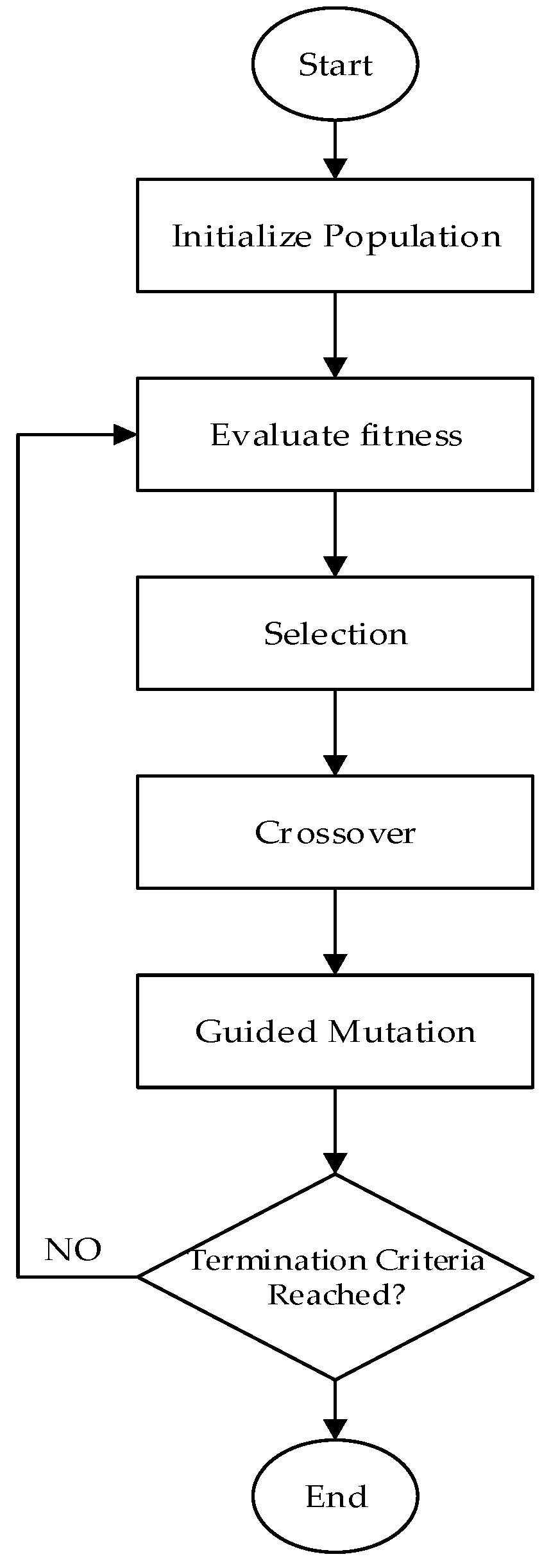

Figure 2 represents the flowchart of the proposed Genetic Algorithm with Guided Mutation, detailing the complete process from initialization to termination for optimizing scheduling in materials manufacturing setups. The algorithm is specifically designed to improve operation sequences under shared machinery and input material constraints. The process begins by generating an initial population of potential schedules. Each individual solution (chromosome) encodes a sequence of manufacturing operations (e.g., molding, trimming, inspection) and corresponding resource allocations. These chromosomes simulate feasible production timelines within a resource-constrained environment.

Each chromosome is evaluated using a fitness function that reflects the efficiency of the schedule. The goal is to minimize the total processing time (makespan) and reduce conflicts caused by limited machinery or material availability.

Genetic Algorithm with Guided Mutation

The fitness function used in this case is as follows:

To guide the evolution of better schedules, the algorithm uses Tournament Selection with a tournament size of 3. In each round, three chromosomes are randomly picked and the one with the best fitness is selected as a parent. This method balances exploration and exploitation by preferring high-quality solutions while maintaining diversity. Additionally, elitism is applied by directly transferring the top 5 chromosomes to the next generation, ensuring the preservation of the best-performing schedules.

Order Crossover (OX) is used to generate new offspring. This method ensures that the sequence of operations is maintained properly, which is a critical requirement in manufacturing where specific process flows must be respected.

Instead of performing random mutations, the proposed Guided Mutation approach targets operations that share critical resources (e.g., furnaces, molding stations, or material inputs). The algorithm identifies bottleneck operations and attempts feasible swaps that respect precedence and resource constraints. After each mutation, the critical path is recalculated, and only beneficial changes that reduce makespan are retained. This focused mutation improves convergence speed and overall scheduling quality. The algorithm runs for 100 generations. Once convergence is achieved or a satisfactory solution is found, the best-performing schedule is finalized.

2.3. Software and Genetic Algorithm Implementation

The proposed scheduling approach was implemented using the Python programming language within the Visual Studio Code environment (1.100.3). Libraries such as pandas, numpy, and matplotlib were used for data processing, numerical operations, and visualizations. The manufacturing operations dataset, after being manually structured and cleaned in Microsoft Excel, was imported into Python where the Genetic Algorithm with Guided Mutation (GA-GM) was applied to optimize operation sequencing under shared machinery and material constraints.

In addition to the GA-GM approach, three traditional scheduling heuristics were implemented for comparison purposes. First Come First Serve (FCFS) scheduled the operations strictly in the order in which they appeared in the dataset, without considering their duration or resource demand. Shortest Job First (SJF) prioritized operations based on their processing time, giving preference to shorter operations. Priority Based Scheduling (PBS) selected operations based on assigned priority such as resource availability, while also considering the required order of operations defined by the precedence relationships. Each of these scheduling techniques was executed on the same dataset, and their results were analyzed by comparing total processing times, resource utilization, and the nature of the resulting critical paths.

3. Results

To evaluate the performance of the proposed Genetic Algorithm with Guided Mutation (GA-GM), experiments were conducted on a synthetic dataset designed to simulate operations in materials manufacturing environment. The primary evaluation metrics were total processing time (makespan) and efficiency of shared resource utilization, particularly focusing on constrained machinery and input material flow. The benchmark comparison involved three classical scheduling heuristics: First Come First Serve (FCFS), Shortest Job First (SJF), and Priority Based Scheduling (PBS). Each method was applied to the same dataset, representing a typical manufacturing workflow where operations were scheduled using shared resources such as the material handling system, molding machine, and inspection bench.

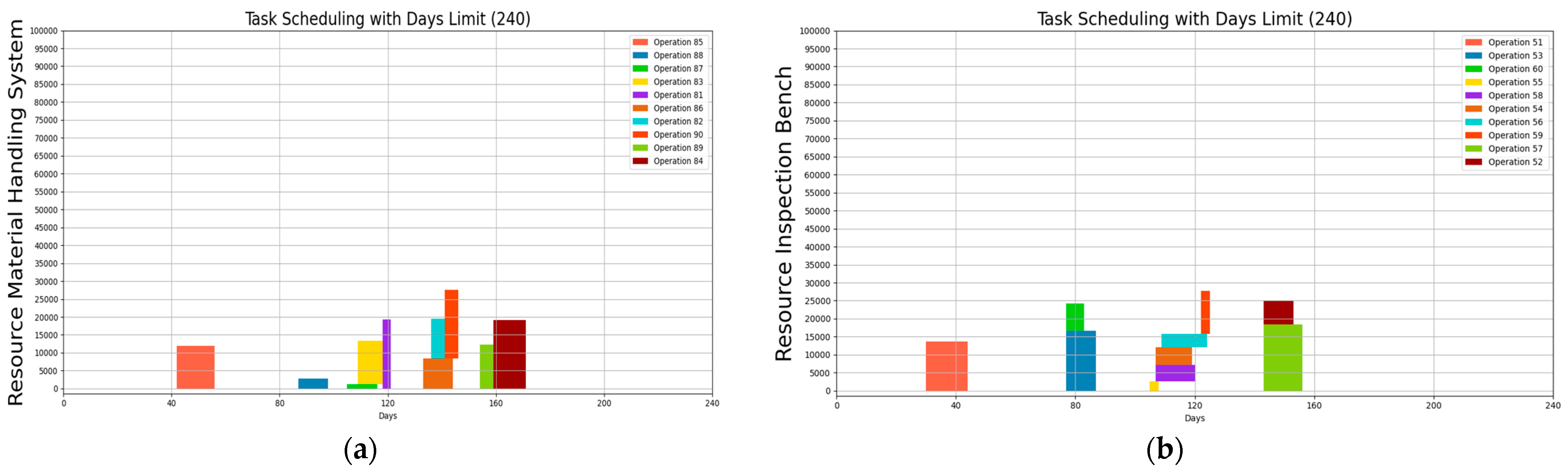

As part of the simulation process, detailed resource utilization graphs were generated to visualize how operations competed for limited equipment and materials. All approaches were tested under a fixed resource capacity of 30,000 units, representing the total available machinery and material resources for the system.

Figure 3 shows the resource utilization trends for two operational resources: (a) the Material Handling System and (b) the Inspection Bench. These graphs illustrate how operations utilize available resources over time within the manufacturing setup.

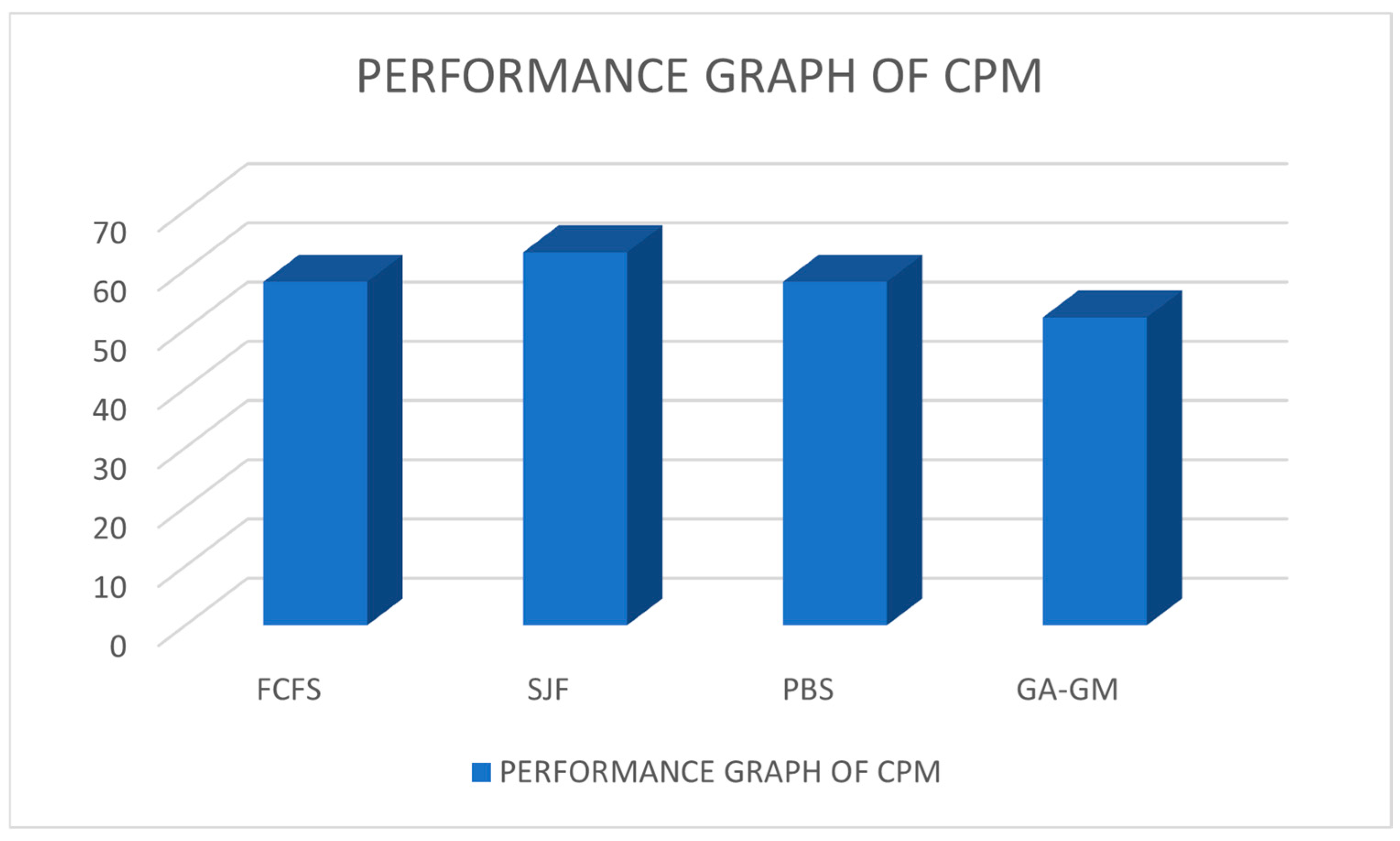

To assess the effectiveness of the proposed Genetic Algorithm with Guided Mutation (GA-GM), its results were compared with conventional scheduling techniques based on their ability to minimize total processing time and improve operation sequencing.

Table 1 presents the Critical Path Method (CPM) durations obtained from each technique, along with the corresponding sequences of operations forming the critical path. Among all methods, GA-GM achieved the shortest completion time, demonstrating superior performance in managing both precedence relationships and resource limitations.

4. Conclusions

This study proposed and implemented a Genetic Algorithm Guided Mutation (GA-GM) to solve the Resource-Constrained Project Scheduling Problem (RCPSP). The algorithm was specifically designed to enhance the sequencing of operations under machinery and material limitations, resulting in optimized schedules and improved critical paths.

Experimental results demonstrate that the GA-GM reduced the total processing time to 52 days, compared to 58 days for FCFS, 63 days for SJF, and 58 days for PBS. These outcomes highlight the algorithm’s efficiency in addressing scheduling challenges within materials manufacturing environments. Overall, GA-GM proved to be an effective and adaptable approach for resource-constrained operation scheduling.

Author Contributions

Conceptualization, W.A. and S.U.; methodology, S.U.; software, K.A.; validation, W.A., S.U. and K.A.; formal analysis, K.A.; investigation, K.A.; resources, K.A.; data curation, K.A.; writing—original draft preparation, K.A.; writing—review and editing, W.A., S.U. and K.A.; visualization, K.A.; supervision, W.A., S.U.; project administration, W.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used in this study was synthetically generated to simulate materials manufacturing scenarios. It does not involve any proprietary or confidential industrial data. The dataset and code are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zoraghi, N.; Najafi, A.A.; Niaki, S.T.A. Resource Constrained Project Scheduling with Material Ordering: Two Hybridized Meta-Heuristic Approaches. Int. J. Eng. 2015, 28, 896–902. [Google Scholar] [CrossRef]

- Batool, M.; Sanumi, O.; Jankovic, J. Application of artificial intelligence in the materials science, with a special focus on fuel cells and electrolyzers. Energy AI 2024, 18, 100424. [Google Scholar] [CrossRef]

- Wang, J. Optimization and Simulation of Resource Constrained Scheduling Problem Using Genetic Algorithm. Sci. J. Bus. Manag. 2016, 4, 229. [Google Scholar] [CrossRef]

- Goncharov, E. A hybrid heuristic algorithm for the resource-constrained project scheduling problem. arXiv 2025, arXiv:arXiv:2502.18330. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).