- 1.8Impact Factor

- 4.0CiteScore

- 22 daysTime to First Decision

Pipe Flow: Research and Applications, 2nd Edition

This special issue belongs to the section “Mathematical and Computational Fluid Mechanics“.

Special Issue Information

Dear Colleagues,

The flow of fluids through pipes is an engineering problem of long-standing practical importance, with applications ranging from household water and gas supply to sewage flows to the transportation of chemicals and petroleum in the chemical and oil industries. It is also currently used in numerous heating and cooling applications.

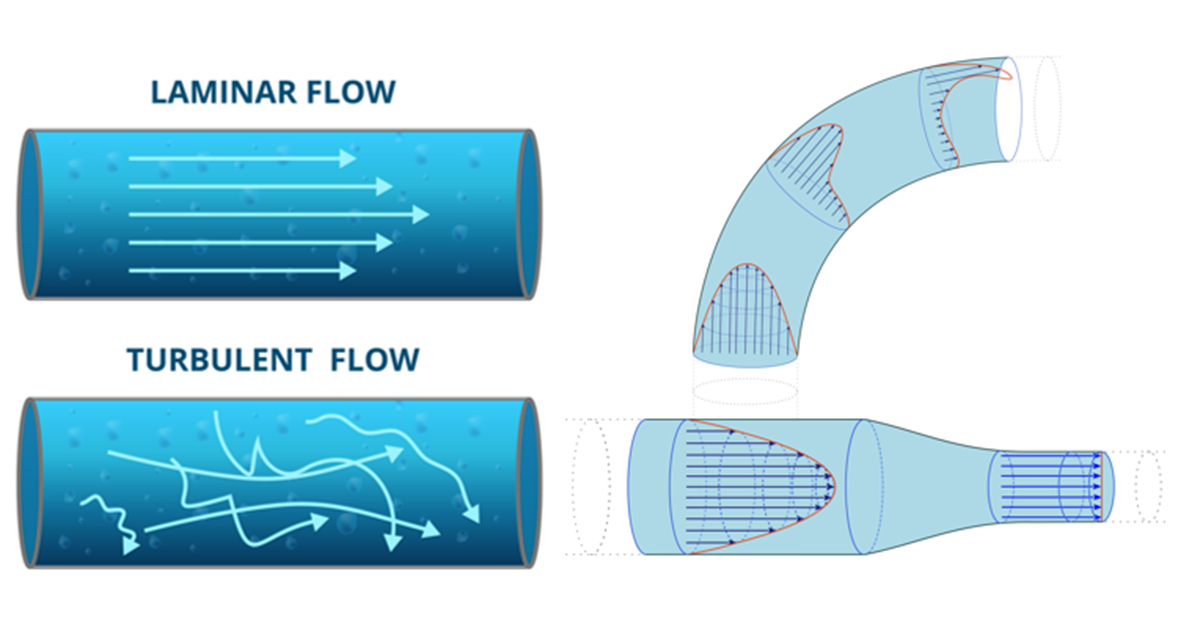

The first scientific studies on pipe flow began to appear in 1839, when Hagen and then Poiseuille performed the first experiments on water flow through straight pipes of various sizes to determine pressure losses. Later on, Reynolds, in 1883, observed that the transition from Hagen–Poiseuille (i.e., laminar) to turbulent flow in pipes occurs above a certain critical value, known today as the critical Reynolds number. Since then, pipe flow has received particular interest as a gateway to turbulence, not only at high Reynolds numbers in straight pipes but also at relatively slower flows through pipe elbows, bends, and restrictors.

While experimental work on pipe flow has continued until the present day, from the beginning of this century, there has been renewed interest in the investigation of pipe flow due to the emergence of ever more sophisticated numerical techniques and increased computational facilities. Many numerical flow models exist in the literature that have improved our knowledge of what happens inside a pipe for both single and multiphase flows. Numerical work has become of great importance not only to interpret experimental data but also to predict, under certain conditions, the resulting flow pattern. This aspect has been particularly important for complex multiphase flows where transitions to one or more flow patterns may occur. Topics of interest for this Special Issue include the following: biofluid dynamics involving the study of the motion of biological fluids, as blood flow in arteries and respiratory airflow, non-Newtonian pipe flows and applications to microfluidic devices, spiral and helical coil tube heat exchangers for cooling and heating applications, ventilation and air conditioning, among other problems and applications. This Special Issue, entitled “Pipe Flow: Research and Applications”, is devoted to collating recent advances in experiments and numerical simulations of fluid flow in pipes of different cross-sectional shapes as well as geometries.

Prof. Dr. Leonardo Di G. Sigalotti

Dr. Carlos Enrique Alvarado-Rodríguez

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Fluids is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 1800 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- pipe flow

- pressure drop

- curved pipes

- pipe bend

- laminar flow

- turbulent flow

- secondary flow

- flow separation

- particle image velocimetry

- flow measurement

- helically coiled pipes

- pulsatile flow

- computational fluid dynamics

- particle methods

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.