Abstract

This study evaluates the thermal performance of a prototype vacuum-tube solar cooker adapted to the climatic conditions of the Amazon region, Peru. Four grain types (Zea mays L., Triticum aestivum, Zea mays var. morochon, and Hordeum vulgare) were tested to assess temperature evolution, exposure time, and incident solar radiation. Hordeum vulgare was selected as a food model for calibration due to its well-characterized thermophysical properties and reproducible heating behavior. The results showed individual thermal efficiencies ranging from 19.3% to 35.3%, with an average of 27.3% across the three tubes. The most efficient treatment, obtained with Zea mays L., reached 180 °C under an irradiance of approximately 980 W/m2. A direct relationship was observed between solar radiation intensity, exposure time, and thermal efficiency. These findings confirm that the proposed hybrid design combining a cylindrical parabolic collector with vacuum U-tubes achieves higher and more stable performance than conventional box-type cookers. The system allows complete grain cooking without fossil fuels, demonstrating its potential as a sustainable and low-cost solution for rural communities in the Andean Amazonian region, promoting clean energy adoption and reducing environmental impact.

1. Introduction

Food cooking is one of the sectors with the highest energy demand worldwide, especially in developing countries, where approximately 28.8% of the rural population depends on this activity as a basic necessity [1]. In rural areas with limited economic resources, firewood continues to be the main source of domestic energy. However, the constant use of biomass as fuel has significant negative impacts on health, including chronic respiratory diseases, eye irritation, and burns, due to prolonged exposure to the smoke generated during combustion [2]. Furthermore, this practice contributes to environmental degradation and deforestation, which exacerbates the vulnerability of these communities [3].

Despite advances in cooking technologies, a large portion of the rural population continues to use wood or charcoal stoves, resulting in low thermal efficiency, deforestation, indoor air pollution, and respiratory and ocular diseases due to smoke exposure. The burning of these fuels releases harmful pollutants like SO2 and NO2, whose impact is more pronounced in rural areas where wood is commonly used. Additionally, factors such as temperature, wind speed, and relative humidity influence the number of pollutants released [4]. For all these reasons, it is urgent to reduce biomass burning and promote cleaner technologies. Solar cookers, which harness renewable energy, are a perfect alternative. By not generating emissions, they would not only improve indoor air quality but also reduce the local carbon footprint, aiding in the fight against climate change and enhancing the lives of rural communities [5]. Furthermore, solar cookers have the potential to significantly reduce the health risks associated with the inhalation of smoke from traditional biomass stoves, such as respiratory diseases and eye irritation, which are prevalent in rural areas with limited access to clean cooking technologies [6,7]. Moreover, recent studies have identified the inefficient burning of biomass as one of the main sources of black carbon emissions, which significantly contribute to climate change. Lignin, a byproduct of biomass, emerges as a promising source for the production of sustainable chemical compounds [8]. The hydrodeoxygenation of lignin, supported by carbon-based catalysts, could be a key solution to reducing dependence on petroleum-derived products, while also contributing to the mitigation of black carbon emissions [9].

At the same time, sustained growth in energy demand has highlighted the limited capacity of fossil fuels to meet this increase in a sustainable manner. Their scarce availability, price volatility, and high contribution to greenhouse gas emissions have intensified interest in clean and renewable sources [10]. In this context, technologies such as solar thermal energy have gained prominence as viable alternatives for reducing the environmental footprint and improving the quality of life of rural communities [11].

In light of the growing environmental and health challenges associated with the use of traditional fuels in domestic cooking, the use of solar energy is emerging as a strategic and sustainable solution. This renewable, inexhaustible, and low-environmental-impact energy source can be used effectively in everyday thermal applications, such as food preparation, thereby reducing dependence on firewood and coal in vulnerable communities [12]. As a free and widely available resource in most rural regions of the world, solar energy represents one of the most promising alternatives for promoting a just energy transition, improving quality of life, and reducing the ecological footprint of households [13].

Currently, renewable sources meet about 14% of global energy demand, a percentage that is expected to increase due to growing interest in sustainable energy models [14]. Solar energy, with an average global irradiance of approximately 170 and 180 W/m2 and instantaneous values that can reach 1000 W/m2 under clear-sky conditions, has the potential to cover up to 45% of global demand in the next 25 years [15].

One of the most notable applications of solar energy in the domestic sphere is cooking with solar cookers; these technologies represent a practical, accessible, and environmentally responsible solution in regions with energy shortages. They allow cooking without resorting to fossil fuels, thus reducing operating costs and pressure on forest ecosystems [11]. Due to their low maintenance and lack of fuel consumption, solar water pumping systems have been widely promoted by various organizations as an efficient solution to the energy and climate crisis [16]. Accurate prediction of the generated photovoltaic energy is crucial for the optimal management of these systems, ensuring a proper balance between the available energy and the pumping requirements, previous studies have demonstrated that the use of advanced models, such as the Adaptive Neuro-Fuzzy Inference System (ANFIS), is highly effective in predicting the generated photovoltaic energy, facilitating the implementation of more efficient management algorithms for water pumping [17]. From an environmental perspective the use of solar cookers is particularly relevant as a clean alternative. These technologies are classified as zero-emission devices, as they do not generate CO2 during operation, which reinforces their role in mitigating climate change and reducing energy dependence [18,19]. They estimated that daily consumption could replace approximately 0.035 kg of natural gas, avoiding up to 375.22 kg of annual CO2 emissions per household. This represents a significant improvement over conventional LPG-based cooking, which emits between 0.087 and 0.180 kg of CO2 from cooking in comparable processes.

Weather conditions and the type of technology determine the efficiency and performance of solar cookers, as each system has advantages depending on the level of irradiation and cloud cover in the environment. Direct technologies are more efficient in tropical areas with high radiation and clear skies, while indirect technologies work better in temperate regions with moderate radiation. CSTs with thermal energy storage (TES) and hybrid CSTs are suitable for variable climates, combining solar energy with complementary sources. In contrast, concentrated technologies are ideal for high-temperature cooking in desert areas, and non-concentrated technologies are ideal for low temperatures in areas with moderate radiation. In summary, the choice of solar technology should be based on local climatic conditions to ensure efficient and sustainable performance [6]. Although there have been significant advances, there is still much to learn in the high Andean contexts of Peru.

In order to address the energy and climate crisis, virtual power plant (VPP) networks have emerged as a viable alternative to conventional fossil fuel-based power plants. These networks consist of small-scale distributed energy resources (DER), which are combined to create an interconnected system capable of more efficiently meeting energy needs [20]. In addition to providing economic benefits to network members, such as prosumers and system operators, VPPs also contribute to emissions reduction, as most of the energy sources that make up the network are renewable. The optimization of the scheduling of these resources is crucial to maximize the network’s performance and can be achieved through the use of advanced optimization techniques, such as the Marine Predator Optimization Algorithm (MPOA), which has proven effective in improving net benefits and significantly reducing emission [21].

Among the most common models are: (1) the box-type cooker, which concentrates radiation using reflectors toward an insulated chamber [22]; (2) the parabolic cooker, with curved systems that focus radiation at the base of the container; and (3) the vacuum tube collector cooker, which combines collectors, heat pipes, and a thermal chamber. However, these have limitations such as low temperatures (≤140 °C), low thermal efficiency, long cooking times, and sensitivity to changes in solar irradiance [23].

In order to overcome these limitations, this research proposed the design, construction, and validation of a hybrid solar cooker prototype based on a compound parabolic cylindrical solar collector (CPC) and a U-shaped vacuum tube. This system seeks to maximize solar energy capture and transfer, improving thermal performance and operational stability even under variable radiation conditions. The evaluation included energy analysis based on local weather conditions and an estimate of the potential for CO2 emissions reduction compared to conventional fossil fuel-powered cookers.

2. Materials and Methods

2.1. Study Area

The vacuum U-tube solar cooker was installed on the campus of the Toribio Rodríguez de Mendoza National University of Amazonas, located in the district and province of Chachapoyas, Amazonas region, Peru. The implementation was carried out specifically in the area assigned to the PROCICEA project, whose geographical coordinates are latitude 6°13′59.69″ S and longitude 77°51′0.40″ W. The climatic conditions of the site are characterized by an average relative humidity of 71%, minimum and maximum temperatures of 9.5 °C and 29.04 °C, respectively, an average corrected daily precipitation of 0.77 mm, and an average annual cloud cover of 77.5%.

2.2. Technical Description of the Solar Cooker Prototype

The solar cooker (Figure 1) was developed based on the design proposed by [24]. Who optimized a compound parabolic solar cooker for semi-arid Moroccan conditions in this work, their configuration was modified to suit the Andean–Amazonian climate of northeastern Peru, characterized by variable solar irradiance and high relative humidity. The parabolic concentrator was constructed from locally available reflective aluminum (0.8 mm thick) with a useful area of 2.09 m2, mounted on a wooden frame (1.80 m × 1.06 m) for cost-effective stability and ease of manual alignment. Unlike the original design, the present prototype incorporated three U-shaped vacuum tubes to enhance heat transfer and maintain temperature uniformity under fluctuating irradiance, providing improved thermal performance and regional applicability.

Figure 1.

Solar cooker.

Three glass vacuum tubes were installed in the collector’s focal line, each 1.80 m long, with external and internal diameters of 2 1/8 inches (≈54 mm) and 1 3/4 inches (≈44 mm), respectively. Inside these tubes, cylindrical metal containers 1.75 m long and 1 1/4 inches (≈32 mm) in diameter were placed, designed to hold food during the cooking process. This configuration promotes efficient heat transfer through direct solar concentration, enabling sustainable and emission-free thermal operation, in line with the principles of circular economy and energy transition in rural areas.

For a better understanding of the components used, Table 1 summarizes the main technical specifications of the three vacuum tubes installed in the CPC. While all the tubes are the same model, slight differences in position within the concentrator were taken into account during performance evaluation.

Table 1.

Technical specifications and comparison of the three vacuum tubes used in the solar cooker.

2.3. Energy Performance

This section presents the evaluation of the energy performance of the prototype according to the main parameters that influence its operation, which together determine the overall thermal behavior of the system.

2.3.1. Evaluation Period

The energy performance of the solar cooker prototype was analyzed between 25 June and 15 August 2024. During this period, continuous measurements were taken from Monday to Friday, excluding weekends and holidays. The monitoring sessions took place daily between 8:30 a.m. and 3:00 p.m. in order to capture the thermal performance of the system under conditions representative of the region’s solar radiation and climate variability. This interval allowed sufficient information to be collected to evaluate the energy and operational efficiency of the prototype in a real rural application context.

2.3.2. Radiation

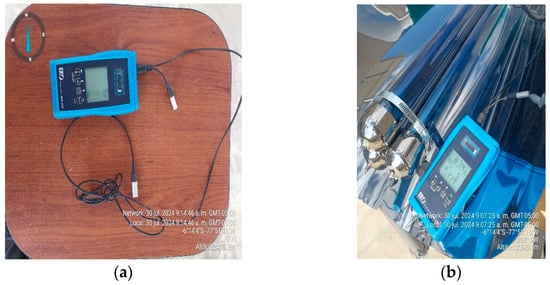

Solar radiation was measured every 15 min on the evaluation days. This information was recorded by an EKO MS-02, Tokyo, Japan digital pyranometer (Figure 2), which was loaned from the laboratories of the Research Institute for Sustainable Development of Ceja de Selva (INDES-CES) at the Toribio Rodríguez de Mendoza National University of Amazonas (UNTRM-A).

Figure 2.

(a) Radiation measuring equipment. (b) Taking measurements in the solar cooker.

2.3.3. Temperature

Temperature measurements were taken using a Hazet 1991-1 digital thermometer Hazet-Werk Hermann Zerver GmbH & Co. KG, Remscheid, Alemania (Figure 3), applying a thermal coefficient of 0.089 (metal) at 15 min intervals on each day of the evaluation. Ambient temperature data was requested from the INDES-CES weather station.

Figure 3.

Temperature measurement.

2.4. Energy Efficiency

The efficiency of the solar cooker is determined by the following equation [25]

where

- : Solar cooker efficiency (%)

- : Food mass (kg)

- : Specific heat of food

- : Difference between maximum temperature and ambient temperature (K)

- : Average solar radiation

- : Area of the solar cooker’s food collector (m2)

- : Cooking time required (s)

Using the following information on the specific heat of each food:

Cooking Power of the Prototype

The following equation was used to measure the cooking power of the prototype [26]:

where

- : Cooking power (W)

- = Difference between maximum temperature and ambient temperature (°C)

- : Cooking time (s)

- : Food mass (kg)

- : Specific heat of food ()

3. Results

3.1. Energy Behavior with Food

The thermal behavior of the solar cooker was evaluated using different types of grains to determine the system’s performance under real solar radiation conditions. Each test was carried out independently to monitor temperature evolution inside the three vacuum tubes and to assess the correlation between incident solar radiation and the heating capacity of the prototype.

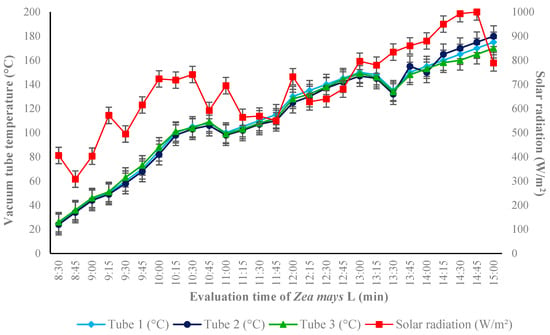

3.1.1. White Corn (Zea mays L.)

Figure 4 shows the evolution of the temperature in three vacuum tubes, as well as the intensity of solar radiation during the cooking process of Zea mays L. between 8:30 a.m. and 3:00 p.m. There is a sustained increase in the temperature of the tubes, reaching values above 180 °C as time progresses. This behavior is strongly correlated with the dynamics of solar radiation, which varied between 600 and 980 W/m2 during the period evaluated. The corn reached the desired cooking point after 1 h and 45 min, under an average solar radiation of 888 W/m2, demonstrating the system’s ability to efficiently transfer solar energy to the food. The three temperature curves showed consistent thermal behavior, with minimal variability between tubes, attributable to the uniform distribution of incident radiation in the collector. The associated error bars reflect adequate experimental repeatability.

Figure 4.

Variation in the temperature of the vacuum tubes and solar radiation during cooking Zea mays L.

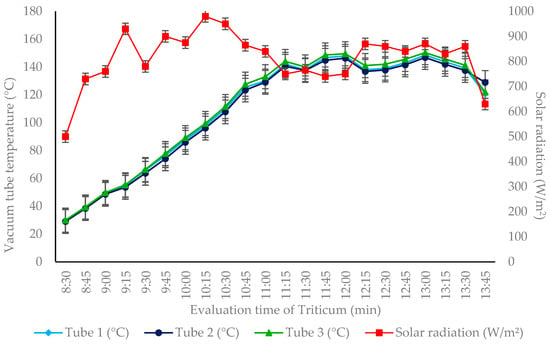

3.1.2. Wheat (Triticum)

In Figure 5, the wheat reached the cooking point after 3 h and 15 min, under an average solar radiation of 855 W/m2. A progressive increase in temperature is observed in the three tubes until approximately 12:00 p.m., reaching values close to 150 °C, after which it stabilizes with slight oscillations. The solar radiation curve showed fluctuations throughout the evaluation period, with a maximum peak at around 10:45 a.m. and a gradual decline after midday. The concordance between the thermal profiles of the tubes suggests adequate heat capture and retention by the cooking system. The error bars indicate moderate variability, attributed to changes in atmospheric conditions during the evaluation.

Figure 5.

Temperature evolution of vacuum tubes and solar radiation during Triticum cooking.

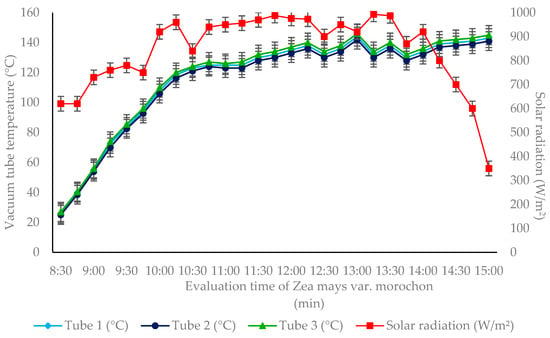

3.1.3. Corn (Zea mays Variety morochon)

In Figure 6, the product reached the desired cooking point after 1 h and 45 min, under average solar radiation of 910 W/m2. A progressive rise in temperature is observed in the three tubes from 8:30 a.m. to approximately 11:00 a.m., with temperatures exceeding 120 °C, subsequently stabilizing with slight variations. Solar radiation reached maximum values between 10:30 a.m. and 1:30 p.m., peaking at close to 990 W/m2. The homogeneous thermal trend among the tubes indicates good heat distribution, while the error bars reflect acceptable variability between measurements. These results show that the solar conditions were adequate for efficient corn cooking without requiring auxiliary heat sources.

Figure 6.

Evolution of the temperature of the vacuum tubes and solar radiation during the cooking of Zea mays var. morochon.

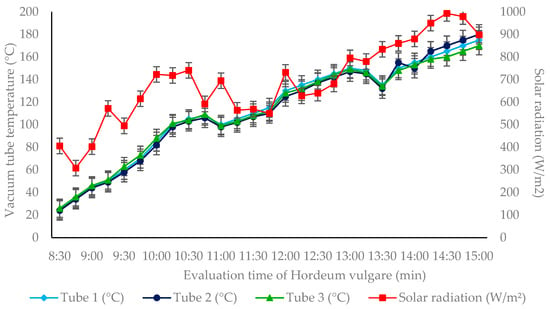

Figure 7 shows a sustained increase in the temperature of the three tubes between 8:30 a.m. and 3:00 p.m., reaching values close to 180 °C in tube 1. Solar radiation showed a variable trend with maximum peaks between 09:45 and 10:30, reaching an irradiance close to 960 W/m2, and then stabilizing between 700 and 900 W/m2. The thermal behavior reflects adequate progressive heating, favored by solar collection during the evaluated period. The desired cooking point was reached after approximately 2 h and 30 min, under an average solar radiation of 880 W/m2, demonstrating the efficiency of the thermal collection system in processing H. vulgare without additional energy assistance.

Figure 7.

Evolution of the temperature of vacuum tubes and solar radiation during heat treatment of Hordeum vulgare.

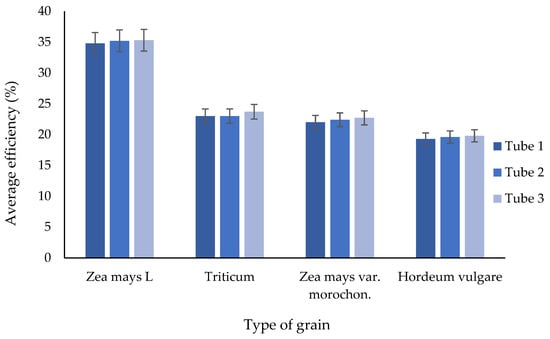

3.2. Energy Efficiency (%)

Figure 8 shows the average thermal efficiency (%) achieved in three tubes of the collector system when using different types of grains: Zea mays L., Triticum, Zea mays var. morochon, and Hordeum vulgare. The data were obtained under controlled experimental conditions and are accompanied by their respective error bars to illustrate the variability of the system.

Figure 8.

Average thermal efficiency (%) by grain type and tube.

The results indicate that the highest efficiency was obtained when Zea mays L. was used, reaching values of 34.8%, 35.2%, and 35.3% in tubes 1, 2, and 3, respectively. This behavior suggests that this grain has a greater capacity to absorb and transfer heat in the system, possibly due to physical properties such as its internal composition, surface reflectance, or particle size.

In second place in terms of performance was Triticum, with average efficiencies of 23%, 23% and 23.7%, followed by Zea mays var. morochon, with values of 22%, 22.4% and 22.7%. These results reflect a slight advantage for wheat over morocho corn, although with marginal differences between the two.

On the other hand, the lowest thermal efficiency values were recorded in Hordeum vulgare, with efficiencies of 19.3%, 19.6%, and 19.8% depending on the corresponding tube. Despite presenting a lower thermal response, consistency was maintained between the tubes, demonstrating adequate thermal distribution in the collector system.

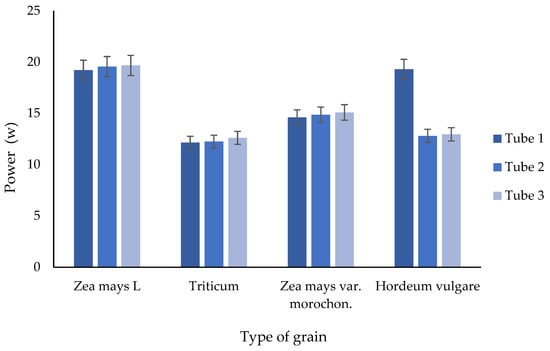

3.3. Cooking Power (W)

Figure 9 shows the average thermal power (W) recorded in three tubes of the solar collector system, using different types of grains: Zea mays L., Triticum, Zea mays var. morochon, and Hordeum vulgare. The tests were carried out under controlled conditions of thermal flow and uniform load, and the reported values correspond to averages obtained after multiple experimental repetitions.

Figure 9.

Average thermal power (W) by grain type and tube.

It was found that the highest thermal performance was achieved when Zea mays L. was used, with average powers of 19.22, 19.56, and 19.67 W for tubes 1, 2, and 3, respectively. These values indicate that this grain favors greater thermal energy capture and transfer, possibly due to physical properties such as its volumetric mass, surface coloration, or internal structure, which influence radiation absorption.

Secondly, Zea mays var. morochon. presented an intermediate power, with values ranging between 14.61 and 15.09 W. In contrast, the lowest values were obtained with the use of Triticum and Hordeum vulgare, whose average powers ranged between 12.15 and 12.95 W. These differences suggest that the type of grain directly influences the efficiency of the collector system, with factors such as grain size, specific heat capacity, or porosity possibly influencing energy transfer.

A consistent trend was also observed among the three tubes, with slight variations that did not significantly affect the overall behavior of each grain, suggesting that the thermal distribution system operated uniformly.

4. Discussion

The solar cooker prototype was evaluated based on its energy performance, efficiency, cooking capacity, and emissions reduction. This is especially relevant given that traditional cookers have negative effects on both health and the environment. In contrast, solar cookers, being a clean technology that does not use fuels, represent an ecological and pollution-free alternative [27]. This option is particularly valuable for the 2.3 billion people who depend on polluting fuels, such as wood and coal, and who are seeking solutions to energy shortages. However, one of the limitations of solar cookers is that their operation depends on the availability of sunlight, which is generally available for approximately 12 h a day [28].

The analysis carried out by [28] highlights a system that combines vacuum tubes and mirror strips installed at precise angles, which heat a heat transfer fluid in an internal chamber. In addition, it incorporated a low-power DC motor that tracks the sun’s movement using a rack and pinion mechanism, improving the system’s automation and ensuring optimal solar collection throughout the day [29], also used vacuum tubes to reduce heat loss in solar thermal systems. Their research highlights the importance of thermal fluids for energy transfer and the proper selection of these fluids for system performance. In addition, the use of phase change materials (PCM) allows heat to be retained and cooking to take place even without sunlight. The difference between the aforementioned studies and the evaluated prototype is that the use of phase change materials yielded optimal results.

In studies by [30], which sought to improve the thermal performance of a box-type solar stove, recorded a maximum temperature reached of 131 °C and average solar radiation of 770 W/m2. On the other hand, with studies by [31] who recorded the thermal performance of an evacuated tube collector integrated with heat pipes containing different refrigerants, obtained data that between 11:00 a.m. and 2:30 p.m., the oil temperature reached 175 °C with a radiation range of 450 to 1100 W/m2. While the research in this article showed that the prototype solar stove using vacuum tubes and a parabolic trough collector composed with reflective metal plate, with radiation intervals of 300 W/m2 to 1250 W/m2, managed to obtain temperatures above 150 °C and below 230 °C during 8:30 a.m. until 3:00 p.m. indicating that the experimental results of solar stoves using vacuum tubes indicate a higher heat absorption capacity than that of a conventional box-type solar stove [28].

The anticipated practical implications of the solar cooker prototype go beyond its technical efficiency, offering a viable, sustainable solution for rural communities in the Andean-Amazonian region. The system presents a significant reduction in health risks by eliminating the use of biomass fuels, which are a major source of indoor air pollution and respiratory illnesses. Moreover, the adoption of solar cookers could reduce the deforestation rates and environmental degradation caused by firewood collection. Beyond environmental benefits, the solar cooker provides an opportunity for cost savings, as it operates without the need for expensive fuels. Furthermore, this technology supports local communities by utilizing locally sourced materials, promoting sustainable production methods and fostering local entrepreneurship. Ultimately, the solar cooker represents not only a technical innovation but also a tool for sustainable development, improving quality of life and contributing to the fight against climate change.

The efficiency obtained in this study varies between 19% and 46% being an acceptable range for the cooking of cereals that the cooking time is between 30 min and 345 min, in comparison with results such as research by [28] with a stove that combines vacuum tubes with mirror strips installed at precise angles determined that the maximum energy efficiency ranged between 20% and 25% using a time of 50 min to 240 min, while for the experiments performed on box-type solar stoves in the study of [32,33] an evaluated thermal efficiency of 25.22% was obtained, using a time of 120 min. The difference in thermal efficiency between the studies may be due to the design, materials, climatic conditions and cooking time.

On the other hand, the cooking power for this prototype solar stove with vacuum tubes is between 12 and 27 Watts in 5 different experiments varying the food while for [28] using a stove combining vacuum tubes with mirror strips the power obtained varies between 23.1 and 36.9 Watts in 4 experiments performed with different weights of water. Complementing this study for the study performed by [32] who used a box type solar stove obtaining a measured cooking power is 53.51 Watts determined from 2 different experiments. The differences in cooking power observed between the studies are due to variations in the design of the solar cookers, the experimental conditions and the properties of the food.

Regarding the thermal efficiency of the system (Figure 8), it shows the proportion of incident solar energy that is converted into heat for cooking, which depends on optical absorption, convective and radiative losses [33], as well as on the thermophysical properties of the food materials [34]. The higher efficiency obtained with Zea mays L. can be attributed to its lower bulk density and higher thermal effusivity, which favor internal heat transfer. This behavior was also reported by [25], who indicated that the energy efficiency of solar cookers increases when there is a higher absorptance–emittance ratio and lower heat loss coefficients. Likewise, [31] found that evacuated tube collectors tend to achieve efficiencies above 50% due to the reduction in convective losses compared to box-type cookers [35]. Additionally [28], reported that evacuated tube solar cookers exhibit stable performance even under fluctuating irradiance, confirming that collector geometry and insulation are key factors determining system efficiency. Taken together, these findings confirm that the variations in efficiency among grains are mainly due to their thermal properties and the system’s ability to maintain a stable energy balance.

The cooking power (Figure 9) represents the rate of heat transfer (W) delivered to the load, which is directly influenced by the solar flux, temperature gradient, and optical efficiency of the collector [25]. The value obtained for Zea mays L. indicates a more effective conversion of solar thermal energy, similar to what was reported in the Proposal for a New World Standard for Testing Solar Cookers, where cooking power was found to increase linearly with solar irradiance until reaching thermal equilibrium. However, a decrease in cooking power can be attributed to higher mass and moisture content, which lead to greater specific heat requirements and a slower temperature rise phenomena also described by [36]. Likewise [30], emphasize that variations in cooking power are mainly controlled by the type of material, time, heat capacity of the medium, and the optical concentration ratio, confirming that the observed differences are due to the physical energy transfer dynamics within the U-tube system rather than experimental randomness.

Table 2 summarizes recent results on solar cookers. While box-type systems with optimized containers have improved cooking efficiency up to 77.06% [32], and concentrator systems with tracking and thermal storage maintain operation under variable conditions [36], the CPC + U-tube configuration developed in this study achieved Tmax > 76 °C, η = 40.3%, and 56.4 W, comparable to the upper range reported for evacuated tube technologies and exhibiting better stability under humid and intermittently cloudy climates. Furthermore, efficiency and power metrics are discussed within standardized evaluation frameworks, reinforcing the novelty and reproducibility of the proposed approach.

Table 2.

Comparison of the performances of the various types of solar cookers.

Solar stoves offer a clean alternative to traditional energy sources, reducing dependence on fossil fuels and, therefore, reducing greenhouse gas emissions. This contributes to the reduction in environmental pollution, improving human health and protecting us from diseases related to exposure to pollutants [36]; therefore, in this study, using the solar stove prototype allows one to know that it can be reduced from 57 to 61 (), complementing it has the study conducted by [42] was shown that the mitigation of emissions is 60. 55 , resulting those solar stoves can contribute to emissions mitigation, since the results obtained are optimal for various types of solar stoves.

Beyond the thermal and physical interpretation, these results demonstrate the practical potential of the hybrid solar cooker as a sustainable solution for rural households. By achieving stable temperatures above 150 °C and thermal efficiencies up to 35%, the system enables complete food cooking without fossil fuels or electricity. This reduces indoor air pollution, decreases deforestation pressure, and lowers household energy costs. The integration of locally available materials and simple manual operation reinforces its applicability in Andean Amazonian communities, contributing to the promotion of clean energy and sustainable rural development.

The incorporation of Phase Change Materials (PCM) in solar thermal systems has proven to be an effective strategy for improving thermal efficiency, particularly in solar cooking applications [43]. PCMs allow for the controlled storage and release of heat, enhancing the operational stability of solar thermal systems under fluctuating solar radiation conditions [44]. Studies [27,28], have demonstrated how the integration of PCMs in box-type and evacuated tube solar cookers can extend cooking times without the need for constant direct radiation. PCMs are especially useful in climates with variable solar radiation, as they enable the system to maintain stable temperatures during periods of low radiation. Moreover, recent research by [29] has shown that PCMs not only improve thermal efficiency but also help reduce heat losses through radiation and convection, optimizing the use of available solar energy. These improvements in thermal efficiency are crucial for the development of more effective solar cookers, particularly in rural areas where energy resources are limited. Thus, the integration of PCMs in solar collectors significantly contributes to the sustainability of solar thermal technologies by enabling their use for longer periods, even when irradiance is low.

5. Conclusions

The developed hybrid solar cooker demonstrated adequate and stable thermal performance under real-world climatic conditions in the High Andean region. The system consistently achieved temperatures above 150 °C, thermal efficiencies of up to 40.3%, and cooking powers close to 56 W, values that equal or exceed those of conventional box and parabolic systems tested in similar irradiance ranges. These results confirm the superior heat transfer capacity and optical concentration achieved by the CPC + U-tube configuration. Beyond its technical performance, the prototype makes important contributions to the field of solar thermal applications. It validates that hybrid designs based on evacuated tubes can maintain high efficiency even under intermittent cloudy and humid conditions, which are typical barriers to the adoption of solar cookers in High Andean regions. This resilience expands the geographical applicability of solar thermal cooking systems, offering a practical alternative for rural communities in the region, where access to the electricity grid and fuel affordability remain limited. This work demonstrates the feasibility of combining low-cost local manufacturing with highly efficient solar concentration principles. The reproducibility of the design and its simple operation make it suitable for technology transfer, rural entrepreneurship, and integration into community energy programs. Future studies should explore the inclusion of phase-change materials and automatic tracking systems to extend usability after sunset and thermal autonomy. Therefore, the developed hybrid solar cooker represents a technically sound, socially inclusive, and sustainable innovation that strengthens the scientific evidence supporting solar thermal technologies as viable solutions for the energy transition in developing regions.

Author Contributions

M.Y.C.: Methodology, Visualization, Validation, Formal analysis; W.G.A.: Investigation, writing—review and editing, Conceptualization, Methodology, Data curation. H.S.G.: Investigation, Conceptualization, writing—review and editing, Formal analysis; H.J.H.V.: Writing—original draft, Investigation, Conceptualization, Funding acquisition. D.C.M.S.: Writing—review and editing, Visualization, Conceptualization. M.O.-C.: Validation, Supervision, Conceptualization. O.G.T.: Writing—review and editing, Visualization, F.I.E.C.: Data curation, Formal analysis, Methodology. C.O.R.: Data curation, Formal analysis. M.Á.B.G.: Writing—original draft, Validation, Resources, Investigation. All authors will be updated at each stage of manuscript processing, including submission, revision, and revision reminder, via emails from our system or the assigned Assistant Editor. All authors have read and agreed to the published version of the manuscript.

Funding

The study was funded by the Instituto de Investigación para el Desarrollo Sustentable de Ceja de Selva (INDES-CES) in the project PROCICEA (C.U.I. N° 2314875—PROCICEA), Centro de Investigación en Climatología, Energías Renovables, Tecnología Ambiental y Construcciones Sostenibles (CINCERCOS) of the Universidad Nacional Toribio Rodríguez de Mendoza de Amazonas del Perú.

Data Availability Statement

The original contributions presented in the study are included in the article; Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors wish to express their gratitude to the CUI N°2314875 project “Creación de los Servicios del Centro de Investigación en Climatología y Energías Alternativas de la Universidad Nacional Toribio Rodríguez de Mendoza-Región Amazonas”—PROCICEA. In addition, they thank the Vice Rectorate of Research of the National University Toribio Rodríguez de Mendoza of Amazonas.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Mperejekumana, P.; Shen, L.; Gaballah, M.S.; Zhong, S. Exploring the potential and challenges of energy transition and household cooking sustainability in sub-sahara Africa. Renew. Sustain. Energy Rev. 2024, 199, 114534. [Google Scholar] [CrossRef]

- Bailis, R.; Drigo, R.; Ghilardi, A.; Masera, O. The carbon footprint of traditional woodfuels. Nat. Clim. Chang. 2015, 5, 266–272. [Google Scholar] [CrossRef]

- Rosenthal, J.; Quinn, A.; Grieshop, A.P.; Pillarisetti, A.; Glass, R.I. Clean cooking and the SDGs: Integrated analytical approaches to guide energy interventions for health and environment goals. Energy Sustain. Dev. 2018, 42, 152–159. [Google Scholar] [CrossRef]

- Bonjour, S.; Adair-Rohani, H.; Wolf, J.; Bruce, N.G.; Mehta, S.; Prüss-Ustün, A.; Lahiff, M.; Rehfuess, E.A.; Mishra, V.; Smith, K.R. Solid fuel use for household cooking: Country and regional estimates for 1980-2010. Environ. Health Perspect. 2013, 121, 784–790. [Google Scholar] [CrossRef]

- Bruce, N.; de Cuevas, R.A.; Cooper, J.; Enonchong, B.; Ronzi, S.; Puzzolo, E.; Mbatchou, B.; Pope, D. The Government-led initiative for LPG scale-up in Cameroon: Programme development and initial evaluation. Energy Sustain. Dev. 2018, 46, 103–110. [Google Scholar] [CrossRef]

- Verma, A.; El-Bayeh, C.Z.; Buddhi, D.; Amir, M.; Ahmad, F.; Singh, H. Socio-economic impact of solar cooking technologies on community kitchens under different climate conditions: A review. Eng. Rep. 2024, 6, e12998. [Google Scholar] [CrossRef]

- Poddar, M.; Chakrabarti, S. Indoor air pollution and women’s health in India: An exploratory analysis. Environ. Dev. Sustain. 2016, 18, 669–677. [Google Scholar] [CrossRef]

- Roden, C.A.; Bond, T.C.; Conway, S.; Pinel, A.B.O.; MacCarty, N.; Still, D. Laboratory and field investigations of particulate and carbon monoxide emissions from traditional and improved cookstoves. Atmos. Environ. 2009, 43, 1170–1181. [Google Scholar] [CrossRef]

- Sharma, V.; Getahun, T.; Verma, M.; Villa, A.; Gupta, N. Carbon based catalysts for the hydrodeoxygenation of lignin and related molecules: A powerful tool for the generation of non-petroleum chemical products including hydrocarbons. Renew. Sustain. Energy Rev. 2020, 133, 110280. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Paramati, S.R.; Ozturk, I.; Bhattacharya, S. The effect of renewable energy consumption on economic growth: Evidence from top 38 countries. Appl. Energy 2016, 162, 733–741. [Google Scholar] [CrossRef]

- Fontes, C.H.d.O.; Freires, F.G.M. Sustainable and renewable energy supply chain: A system dynamics overview. Renew. Sustain. Energy Rev. 2018, 82, 247–259. [Google Scholar] [CrossRef]

- Imran, M.; Haglind, F.; Asim, M.; Alvi, J.Z. Recent research trends in organic Rankine cycle technology: A bibliometric approach. Renew. Sustain. Energy Rev. 2018, 81, 552–562. [Google Scholar] [CrossRef]

- Pan, M.; Pan, C.; Li, C.; Zhao, J. A review of membranes in proton exchange membrane fuel cells: Transport phenomena, performance and durability. Renew. Sustain. Energy Rev. 2021, 141, 11077. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Corwin, K.A.; Burkhardt, J.; Corr, C.A.; Stackhouse, P.W.; Munshi, A.; Fischer, E.V. Solar energy resource availability under extreme and historical wildfire smoke conditions. Nat. Commun. 2025, 16, 245. [Google Scholar] [CrossRef]

- Ammar, R.B.; Ammar, M.B.; Oualha, A. Photovoltaic power forecast using empirical models and artificial intelligence approaches for water pumping systems. Renew. Energy 2020, 153, 1016–1028. [Google Scholar] [CrossRef]

- Hayashi, H.; Chantana, J.; Kawano, Y.; Nishimura, T.; Mavlonov, A.; Minemoto, T. Zn1−xMgxO second buffer layer of Cu2Sn1−xGexS3 thin-film solar cell for minimizing carrier recombination and open-circuit voltage deficit. Sol. Energy 2020, 204, 769–776. [Google Scholar] [CrossRef]

- Javed, A.H.; Shahzad, N.; Khan, M.A.; Ayub, M.; Iqbal, N.; Hassan, M.; Hussain, N.; Rameel, M.I.; Shahzad, M.I. Effect of ZnO nanostructures on the performance of dye sensitized solar cells. Sol. Energy 2021, 230, 492–500. [Google Scholar] [CrossRef]

- Gil, R.R.; Muñoz, B.C.; González-Bravo, H.E.; Rodríguez, R.D. Development and experimental evaluation of a parabolic solar cooker for sustainable cooking in monsoon climates. J. Clean. Prod. 2025, 523, 146416. [Google Scholar] [CrossRef]

- Pandey, A.K.; Jadoun, V.K.; Jayalakshmi, N.S. Exploring the Potential and Avenues of Renewable Integrated Energy Resources Through Virtual Power Plant. In Intelligent Computing Techniques for Smart Energy Systems; Lecture Notes in Electrical Engineering; Springer: Singapore, 2025; Volume 1276, pp. 231–244. [Google Scholar] [CrossRef]

- Pandey, A.K.; Jadoun, V.K.; Sabhahit, J.N. Scheduling and assessment of multi-area virtual power plant including flexible resources using swarm intelligence technique. Electr. Power Syst. Res. 2025, 238, 111139. [Google Scholar] [CrossRef]

- Dan, A.; Chattopadhyay, K.; Barshilia, H.C.; Basu, B. Shifting of the absorption edge in TiB2/TiB(N)/Si3N4 solar selective coating for enhanced photothermal conversion. Sol. Energy 2018, 173, 192–200. [Google Scholar] [CrossRef]

- Adeyemi, I.; Arink, T.; Janajreh, I. Numerical Modeling of the Entrained Flow Gasification (EFG) of Kentucky Coal and Biomass. Energy Procedia 2015, 75, 232–239. [Google Scholar] [CrossRef]

- El Moussaoui, N.; Talbi, S.; Atmane, I.; Kassmi, K.; Schwarzer, K.; Chayeb, H.; Bachiri, N. Feasibility of a new design of a Parabolic Trough Solar Thermal Cooker (PSTC). Sol. Energy 2020, 201, 866–871. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Ibrahim, A. Experimental testing of a box-type solar cooker using the standard procedure of cooking power. Renew. Energy 2005, 30, 1861–1871. [Google Scholar] [CrossRef]

- Kundapur, A.; Sudhir, C.V. Proposal for new world standard for testing solar cookers. J. Eng. Sci. Technol. 2009, 4, 272–281. [Google Scholar]

- Bigelow, A.W.; Tabatchnick, J.; Hughes, C. Testing solar cookers for cooking efficiency. Sol. Energy Adv. 2024, 4, 100053. [Google Scholar] [CrossRef]

- Farooqui, S.Z. A vacuum tube based improved solar cooker. Sustain. Energy Technol. Assess. 2013, 3, 33–39. [Google Scholar] [CrossRef]

- Hebbar, G.; Hegde, S.; Sanketh, B.; Sanith, L.R.; Udupa, R. Design of solar cooker using evacuated tube solar collector with phase change material. Mater. Today Proc. 2021, 46, 2888–2893. [Google Scholar] [CrossRef]

- Khatri, R.; Goyal, R.; Sharma, R.K. Advances in the developments of solar cooker for sustainable development: A comprehensive review. Renew. Sustain. Energy Rev. 2021, 145, 111166. [Google Scholar] [CrossRef]

- Esen, M. Thermal performance of a solar cooker integrated vacuum-tube collector with heat pipes containing different refrigerants. Sol. Energy 2004, 76, 751–757. [Google Scholar] [CrossRef]

- Goyal, R.K.; Eswaramoorthy, M. Thermal performance enhancement on a box-type solar cooker using a triangular fin over a conventional cooking pot. Sol. Energy 2023, 258, 339–350. [Google Scholar] [CrossRef]

- Kumar, S. Thermal performance study of box type solar cooker from heating characteristic curves. Energy Convers. Manag. 2004, 45, 127–139. [Google Scholar] [CrossRef]

- Farooqui, S.Z. A review of vacuum tube based solar cookers with the experimental determination of energy and exergy efficiencies of a single vacuum tube based prototype. Renew. Sustain. Energy Rev. 2014, 31, 439–445. [Google Scholar] [CrossRef]

- Bhowmik, M.; Muthukumar, P.; Patil, A. Analysis of heat transfer characteristics and optimization of U-tube based solar evacuated tube collector system with different flow conditioning inserts. Therm. Sci. Eng. Prog. 2023, 39, 101709. [Google Scholar] [CrossRef]

- Komolafe, C.A.; Okonkwo, C.E. Design, Fabrication, and Thermal Evaluation of a Solar Cooking System Integrated with Tracking Device and Sensible Heat Storage Materials. Front. Energy Res. 2022, 10, 821098. [Google Scholar] [CrossRef]

- Weldu, A.; Zhao, L.; Deng, S.; Mulugeta, N.; Zhang, Y.; Nie, X.; Xu, W. Performance evaluation on solar box cooker with reflector tracking at optimal angle under Bahir Dar climate. Sol. Energy 2019, 180, 664–677. [Google Scholar] [CrossRef]

- Sivakumar, R.; Sakthivel, G.; Mohanraj, T.; Lakshmipathi, J.; Jeagdesshwaran, R.; Manickavasagam, P.; Govardhan, Y.S. Solar thermal cooking device for domestic cooking applications: Bridging sustainable development goals and innovation. Heliyon 2024, 10, e38415. [Google Scholar] [CrossRef]

- Aragaw, Y.T.; Adem, K.D. Development and performance evaluation of tube-type direct solar oven for baking bread. Heliyon 2022, 8, e11502. [Google Scholar] [CrossRef] [PubMed]

- Baylon, J.S.; González, M.P.; Morán, Y.G.; Gómez, A.T.; López, J.M.G. Design and evaluation of a solar cooker with reused evacuated tube: Enhancing thermal efficiency for food cooking. South Fla. J. Dev. 2024, 5, e4830. [Google Scholar] [CrossRef]

- Ebersviller, S.M.; Jetter, J.J. Evaluation of performance of household solar cookers. Sol. Energy 2020, 208, 166. [Google Scholar] [CrossRef]

- Herez, A.; Ramadan, M.; Khaled, M. Review on solar cooker systems: Economic and environmental study for different Lebanese scenarios. Renew. Sustain. Energy Rev. 2018, 81, 421–432. [Google Scholar] [CrossRef]

- Jamal, S.; Alkhabbaz, A.; Hamzah, H.; Sahin, B. Thermal analysis of a solar panel unit using PCM and various fin arrangements. Int. J. Heat Fluid Flow 2026, 117, 110108. [Google Scholar] [CrossRef]

- Thirugnanam, C.; Karthikeyan, S.; Kalaimurugan, K. Study of phase change materials and its application in solar cooker. Mater. Today Proc. 2020, 33, 2890–2896. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).