Virtual Tryout: Case Study on Simulation-Based Design and Die Spotting of Forming Tools †

Abstract

1. Introduction and Motivation

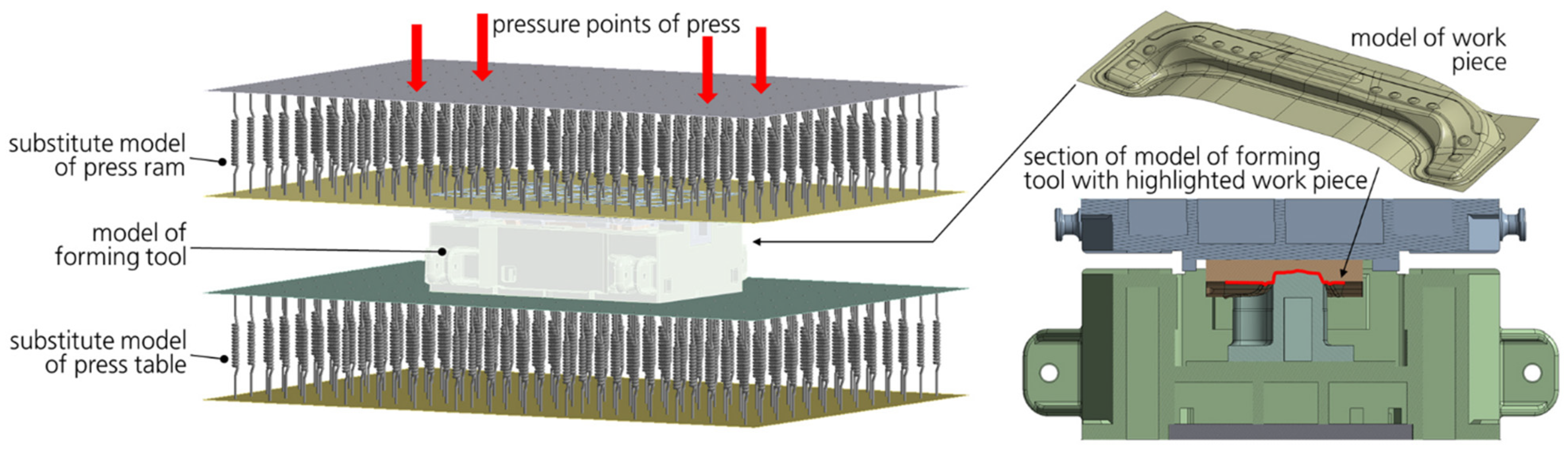

2. Methodology for Creating Reduced Models Representing the Elastic Characteristic of Press Ram and Press Table

2.1. Metrological Survey of Machine Components

2.2. Processing of Deflections

2.3. Structure and Generation of Reduced Fe Models for Clamping Surfaces of the Machine

3. Reduction of Potential Rework by Usage Elastic Models in Design Phase

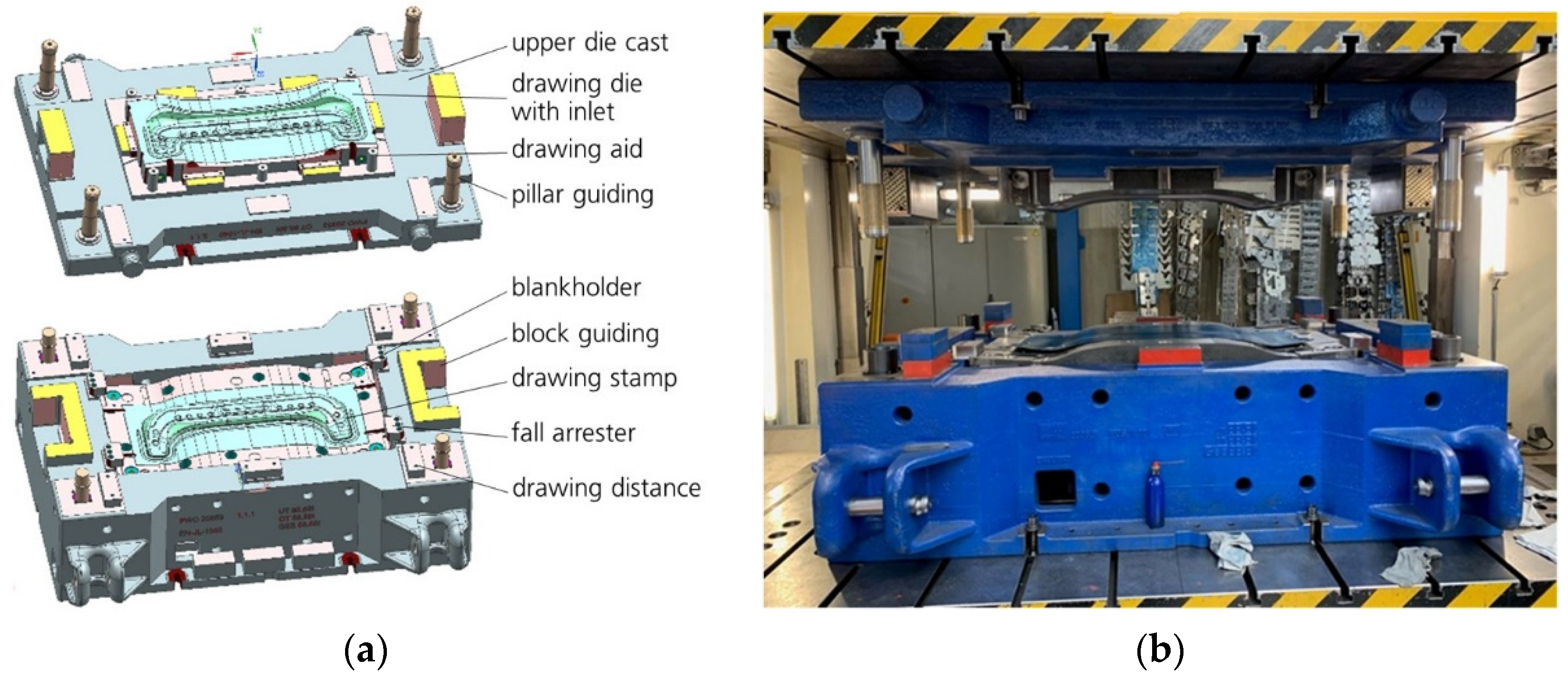

3.1. Demonstrator Forming Tool Manufactured for Experimental Validation

3.2. Elastic Deflection of Forming Tool and Machine

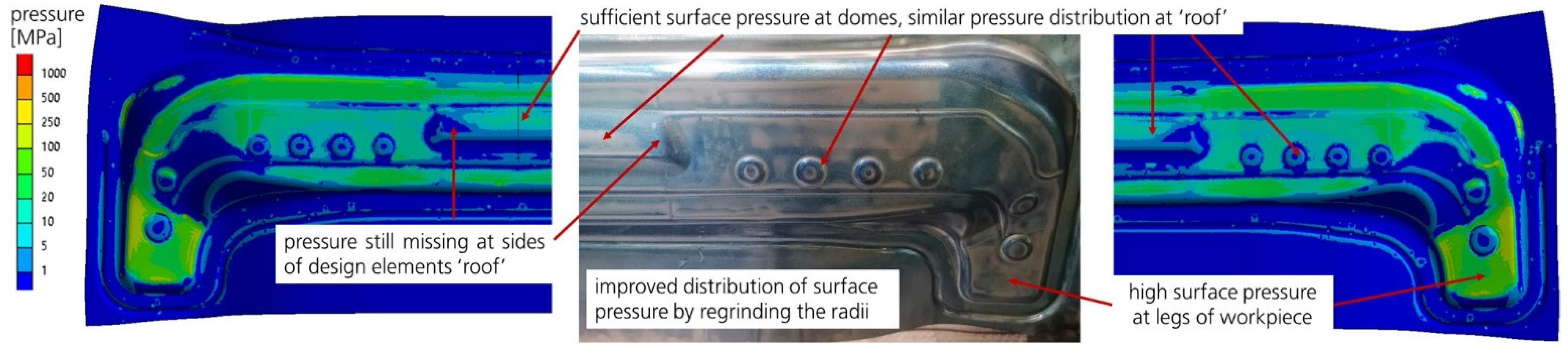

4. Virtual Tryout Process: Virtual Spotting Pattern

4.1. Comparison of Real and Corresponding Virtual Spotting Pattern

4.2. FE Model for the Calculation of the Virtual Spotting Pattern

4.3. Reference Simulation as State of the Art and Influence of Sheet Thinning

4.4. Influence of Geometric Adjustment on the Virtual Spotting Pattern

5. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zgoll, F. Methodik zur Maschinenoptimalen Werkzeugeinarbeitung Durch Virtuelle Kompensation der Werkzeug- und Pres- sendurchbiegung. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2021. [Google Scholar]

- Brecher, C.; Esser, M.; Witt, S. Interaction of manufacturing process and machine tool. CIRP Ann. 2009, 58, 588–607. [Google Scholar] [CrossRef]

- Struck, R.; Kulp, S.; Behrens, B.A.; Krimm, R. Improving the press tonnage prediction in sheet metal forming simulation incor- porating the elastic tool and press deformation. In Proceedings of the 14th International Conference on Simulation in Vehicle Engineering (SIMVEC), Baden-Baden, Germany, 26–27 November 2008; pp. 185–199. [Google Scholar]

- Behrens, B.A.; Bouguecha, A.; Krimm, R.; Matthias, T.; Czora, M. Consideration of the Machine Influence on Multistage Sheet Metal Forming Processes. In Process Machine Interactions; Denkena, B., Hollmann, F., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 403–417. [Google Scholar]

- Tehel, R.; Päßler, T.; Mihm, M. Modeling elastic behavior of forming machine components to reduce tool manufacturing time. Procedia Manuf. 2019, 27, 177–184. [Google Scholar] [CrossRef]

- Tehel, R.; Päßler, T.; Bergmann, M. Effective FE-models for simulating the elasto-mechanical characteristics of forming ma- chines. Int. J. Adv. Manuf. Technol. 2020, 58, 3505–3514. [Google Scholar] [CrossRef]

- Chen, J.; Xu, D.; Xia, G.; Li, X.; Chen, J.; Zhang, J.; Yan, W.; Li, Y. Geometric compensation for automotive stamping die design integrating structure deflection and blank thinning. Int. J. Adv. Manuf. Technol. 2013, 66, 1449–1456. [Google Scholar] [CrossRef]

- Neto, D.M.; Coër, J.; Oliveira, M.C.; Alves, J.L.; Manach, P.Y.; Menezes, L.F. Numerical analysis on the elastic deformation of the tools in sheet metal forming processes. Int. J. Solids Struct. 2016, 100–101, 270–285. [Google Scholar] [CrossRef]

- Bogon, P. Notwendige Kennwerte zur Beschreibung der Eigenschaften von Pressmaschinen zur Herstellung von großflächigen Karosseriebauteilen. In Fabrik der Zukunft-5 Jahre Erfahrung mit Servopressen; Europäische Forschungsgesellschaft für Blechverarbeitung: Hannover, Germany, 2014; pp. 143–181. (In German) [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tehel, R.; Päßler, T.; Kurth, R.; Nagel, M.; Reichert, W.; Ihlenfeldt, S. Virtual Tryout: Case Study on Simulation-Based Design and Die Spotting of Forming Tools. Eng. Proc. 2022, 26, 9. https://doi.org/10.3390/engproc2022026009

Tehel R, Päßler T, Kurth R, Nagel M, Reichert W, Ihlenfeldt S. Virtual Tryout: Case Study on Simulation-Based Design and Die Spotting of Forming Tools. Engineering Proceedings. 2022; 26(1):9. https://doi.org/10.3390/engproc2022026009

Chicago/Turabian StyleTehel, Robert, Thomas Päßler, Robin Kurth, Matthias Nagel, Willy Reichert, and Steffen Ihlenfeldt. 2022. "Virtual Tryout: Case Study on Simulation-Based Design and Die Spotting of Forming Tools" Engineering Proceedings 26, no. 1: 9. https://doi.org/10.3390/engproc2022026009

APA StyleTehel, R., Päßler, T., Kurth, R., Nagel, M., Reichert, W., & Ihlenfeldt, S. (2022). Virtual Tryout: Case Study on Simulation-Based Design and Die Spotting of Forming Tools. Engineering Proceedings, 26(1), 9. https://doi.org/10.3390/engproc2022026009