Abstract

This systematic review focuses on intelligent navigation as a core enabler of autonomy in smart warehouses, where mobile robots must dynamically perceive, reason, and act in complex, human-shared environments. By synthesizing advancements in AI-driven decision-making, SLAM, and multi-sensor fusion, the study highlights how intelligent navigation architectures reduce operational uncertainty and enhance task efficiency in logistics automation. Smart warehouses, powered by mobile robots and AGVs and integrated with AI and algorithms, are enabling more efficient storage with less human labour. This systematic review followed PRISMA 2020 guidelines to systematically identify, screen, and synthesize evidence from 106 peer-reviewed scientific articles (including pri-mary studies, technical papers, and reviews) published between 2020–2025, sourced from Web of Science. Thematic synthesis was conducted across 8 domains: AI, SLAM, sensor fusion, safety, network, path planning, implementation, and design. The transition to smart warehouses requires modern technologies to automate tasks and optimize resources. This article examines how intelligent systems can be integrated with mathematical models to improve navigation accuracy, reduce costs and prioritize human safety. Real-time data management with precise information for AMRs and AGVs is crucial for low-risk operation. This article studies AI, the IoT, LiDAR, machine learning (ML), SLAM and other new technologies for the successful implementation of mobile robots in smart warehouses. Modern technologies such as reinforcement learning optimize the routes and tasks of mobile robots. Data and sensor fusion methods integrate information from various sources to provide a more precise understanding of the indoor environment and inventory. Semantic mapping enables mobile robots to navigate and interact with complex warehouse environments with high accuracy in real time. The article also analyses how virtual reality (VR) can improve the spatial orientation of mobile robots by developing sophisticated navigation solutions that reduce time and financial costs.

1. Introduction

Intelligent warehouses, also known as smart warehouses, have become a revolutionary element in the logistics sector. They utilize advanced technologies to improve operational processes, increase efficiency, and reduce costs. Through the integration of Internet of Things (IoT) devices, autonomous mobile robots (AMRs), and artificial intelligence (AI), those systems provide exceptional automation capabilities and facilitate real-time, data-informed decision-making [1,2]. The incorporation of AI and machine learning algorithms allows intelligent warehouses to deliver robust real-time inventory management, significantly simplifying order fulfillment via automated product handling [3]. The active development of autonomous robots connected to artificial intelligence systems enables the transition of warehouse processes and product handling levels, leading to the emergence of smart warehouses [4]. When we look at digital, intelligent warehouses—often called ‘smart’ warehouses—we see an increasing use of autonomous mobile robots (AMRs) and automated guided vehicles (AGVs). These robots and vehicles carry more powerful autonomous robots that can transport specific products more precisely in real time [5].

According to the authors, to achieve accurate AMR operation in smart warehouses, it is necessary to implement Internet of Things (IoT) technology [6]. This involves first determining the essential factors that contribute to the successful implementation of IoT-based smart warehouse infrastructure, and then conducting a simulation of real storage. This allows the creation of a final, sustainable system for designing IoT-based smart warehouse infrastructure. The authors [7] state that highly developed smart warehouse technology is required to track and control inventory effectively in cyber-physical manufacturing environments. The authors [8] take a similar stance on optimization, stating that a smart storage system can maximize floor space when expansion is not an option. They also state that a mobile racking vehicle system enables smart warehouse management to be more available, reliable and sustainable.

The authors [9] state that the transition to smart warehouses requires the use of the most modern technologies (IoT, automation, robotization, and communication standards). If these requirements are met, the dehumanization of warehouses can be achieved, i.e., the relief of human resources from product manipulation through the use of Industry 4.0. The authors [10] point out that smart warehouses are a very important part of Industry 4.0 and can offer users smart advice and operational constraints while improving work efficiency, which directly affects the growth of logistics companies and retailers. According to [11], the development of smart warehouses in Industry 4.0 is realizing a new trend: the deployment of fleets of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) for transporting and stacking products. In smart warehouses, these vehicles and robots receive instructions from a higher-level AGV layout system and can independently react to their working environment. This method of self-navigation is made possible by integrating vehicle or robot sensors, which significantly increases information flow within the warehouse.

According to authors [12], Industry 4.0 technology achieves the high digitization of all warehouse operations, ultimately resulting in cost savings, increased work efficiency, better exploitation of AMRs and AGVs, and a more environmentally friendly approach for smart warehouses. In addition to Industry 4.0, authors [13,14] state that a Robotic Mobile Fulfillment System (RMFS) is used for the successful operation of autonomous mobile robots. The authors [15,16] state that the aforementioned RMFS is being used more and more in modern smart warehouses for the transportation of products for large retailers. Order picking is the most important part of the warehouse system. To successfully implement the dehumanization of warehouses and realize the potential of smart warehouses, the authors [17] state that RMFS enables AMRs to carry out picking by transporting products on their mobile shelves to workers waiting at picking stations. Using RMFS significantly increases the level of commissioning compared to traditional methods. The same authors state that the second most important RMFS task is replenishing stocks in smart warehouses because up to 80% of time and energy is spent on filling and removing goods. Due to the above-mentioned values of time and energy consumption, the purpose of this paper is to present and explain new systems for serving people through the use of AMRs in new smart warehouses, highlighting the significance of the transition from traditional warehouses to intelligent ones.

The key issue with the dehumanization of warehouses and transition to modern ones is the cost of introducing robotization relative to the level of need. One potential solution is to use AMRs and AGVs at the level for which the smart warehouse is designed. In the ongoing dehumanization of warehouse environments, a notable research gap emerges in the domain of human safety. The authors [18] report that numerous studies examined in their review employed no safety measures whatsoever and failed to implement any form of workspace safeguarding, which directly and adversely impacts human safety—and, by extension, the quality and effectiveness of human–robot interaction (HRI). According to [19] the successful advancement of HRI depends on safety being a top priority and an integral component of any HRI application. Achieving a high level of human safety requires strict adherence to ISO 10218 [20,21]—Robots and Robotic Devices—Safety Requirements—and the implementation of safety-oriented methods such as safety through control, motion planning, prediction, and consideration of psychological factors (robot behavior adaptation).

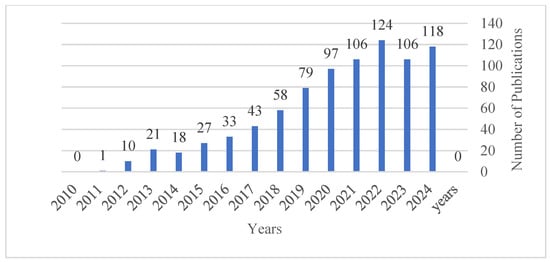

The analysis of scholarly output in the Web of Science database reveals a significant increase in research on smart warehouse systems between 2010 and 2024. While the early period (2010–2016) yielded only a handful of publications, a marked acceleration is observed from 2017 onward, with a particularly steep rise beginning in 2020. This inflection point aligns with the global disruptions caused by the COVID-19 pandemic, which catalyzed urgent investments in resilient, contactless, and highly automated logistics infrastructures. Smart warehouse technologies—encompassing autonomous mobile robots, real-time inventory tracking, AI-driven optimization, and human–machine coordination—emerged as critical enablers of supply chain continuity and operational agility. Consequently, academic interest surged in parallel with industrial adoption, reflected in the growing volume of peer-reviewed studies addressing automation, safety, and efficiency in warehouse environments. Notably, the year 2025 was excluded from this analysis, as it remains incomplete at the time of writing and thus lacks sufficient data for reliable trend assessment. The observed publication trajectory underscores a broader shift toward intelligent, adaptive, and human-centered logistics systems, positioning the smart warehouse as a cornerstone of next-generation supply chain innovation. This is illustrated in Figure 1. The technologies highlighted in this paragraph—autonomous mobile robots, AI-driven optimization, real-time sensor fusion, and human–machine coordination—are not merely enablers of warehouse automation; they collectively constitute the functional pillars of intelligent navigation in dynamic indoor environments. Rather than an isolated module, intelligent navigation emerges organically from their synergistic integration, reflecting a systemic shift in post-2020 smart warehouse research toward adaptive, perception-aware robotic autonomy.

Figure 1.

Annual number of peer-reviewed publications on smart warehouse systems (2010–2024), based on Web of Science data.

The thematic analysis of 131 peer-reviewed publications on smart warehouse systems reveals a dominant focus on Industry 4.0 technologies (87.79%), followed by warehouse optimization (66.41%) and IoT and edge computing (35.11%). This overwhelming emphasis on Industry 4.0 is not coincidental: smart warehouses are widely regarded as a cornerstone of the fourth industrial revolution. Industry 4.0 envisions highly interconnected, data-driven, and autonomous production and logistics ecosystems, where real-time decision-making, cyber-physical integration, and human–machine synergy are essential. Within this paradigm, the smart warehouse functions as a critical node that bridges manufacturing, supply chain, and distribution through technologies such as digital twins, autonomous mobile robots (AMRs), cloud/edge computing, and AI-enabled predictive analytics. Consequently, research on smart warehouses is inherently embedded in the broader Industry 4.0 framework, which explains the high co-occurrence of these thematic categories. Given that multiple thematic labels may apply to a single publication, the sum of percentages exceeds 100%, reflecting the inherently multidisciplinary and integrative nature of smart warehouse research—spanning logistics, robotics, information systems, and industrial automation (Table 1).

Table 1.

Thematic distribution of publications related to smart warehouse systems based on Web of Science Citation Topics Micro (N = 131).

This systematic review aimed to synthesize evidence on intelligent navigation and cost optimization in smart warehouses. The review question was structured using a modified PICOS framework:

- Population: smart warehouses utilizing mobile robots (AMRs/AGVs),

- Intervention/Exposure: integration of AI, SLAM, sensor fusion, IoT, reinforcement learning, semantic mapping,

- Comparator: traditional warehouses or non-integrated robotic systems (where re-ported),

- Outcomes: navigation accuracy, operational cost reduction, safety improvements, implementation challenges and

- Study designs: peer-reviewed primary research, technical papers, and reviews published in English (2020–2025).

In this review, intelligent navigation is conceptualized not as an isolated function but as the integrative outcome of synergistically combining AI, SLAM, sensor fusion, IoT, reinforcement learning, and semantic mapping—precisely the intervention components defined in the PICOS framework—thereby positioning it as the unifying lens through which navigation accuracy, safety, and operational efficiency in smart warehouses are evaluated

2. Database Search Methods: Web of Science Core Collection, IEEE Xplore, and Scopus

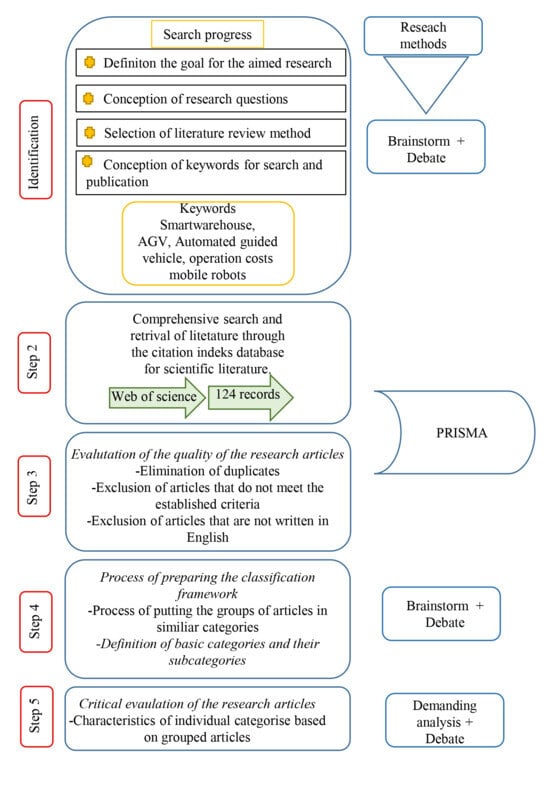

An examination protocol is developed internally for the search strategy, eligibility criteria, data extraction, and synthesis methods. No deviations from the planned methodology occurred. According to the research presented in [18], this method is considered extremely effective in observing and investigating the level of knowledge and degree of development of scientific conclusions on the integration of modern technologies into smart warehouses. Many scientists use this method to identify, collect and classify similar research (see, for example, [19,22]). This research and the procedure itself will detect all empirical evidence that meets the pre-set inclusion criteria in order to answer the research questions [23]. The research process comprises five steps. This is illustrated in Figure 2.

Figure 2.

Steps of preparation for research progress.

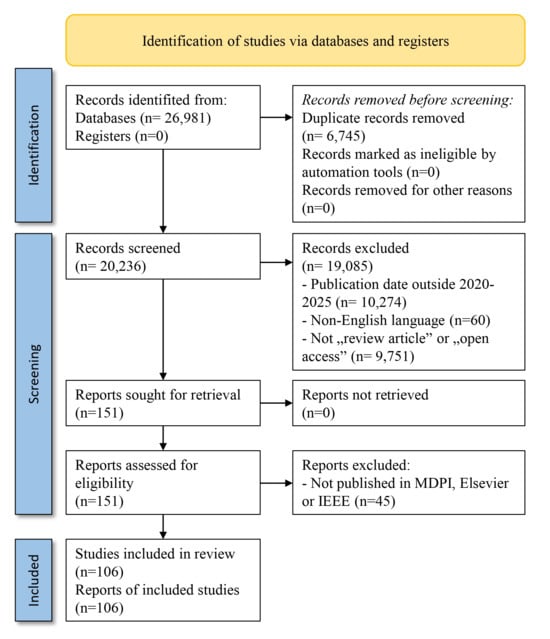

The research procedure was conceptualised using the PRISMA programme, which employs a four-stage flow chart. Essentially, the flow chart is a descriptive tool that viualises the systematic and transparent process of reviewing the initial set of identified literature to arrive at the final set of studies included in the review. The diagram shows the number of records at each stage and the reasons for exclusion, providing a clear audit trail of the search process and the final number of literature selections. Study selection was conducted in two phases: 1. title/abstract screening—two reviewers (D.Z. and M.J.) independently screened records using Rayyan v1.0 (https://rayyan.ai, accessed on 2 November 2025). Conflicts were resolved by a third reviewer (H.G.); and 2. full-text review—the same reviewers assessed full texts for eligibility. Reasons for exclusion were documented (e.g., “wrong population”, “not synthesizable,” “no relevant outcomes”). A PRISMA flow diagram (Figure 3) documents the selection process.

Figure 3.

PRISMA—Flow diagram of the systematic selection literature for the research area.

2.1. Identification

The primary database searched was Web of Science Core Collection, selected for its coverage of high-impact engineering and technology journals. To mitigate database bias, we also conducted supplemental searches in: IEEE Xplore (for robotics and control systems literature), Scopus (for broader multidisciplinary coverage), and Google Scholar (for grey literature and highly cited reviews). The collection of organized and structured data is from the Web of Science because it is one of the most important areas of technical research repositories frequently employed in literature reviews like this one [24]. This digital repository was utilized due to the superior quality of the documents contained within it.

A systematic review of articles was conducted to identify the most frequently utilized keywords [7,9,25], which recognized the expressions most relevant to smart warehouses integrated with automated guided vehicles and mobile robots. The search strategy combined keywords related to setting (“smart warehouse*”, “automated warehouse*”, “logistic* center”), technology (“AGV”, “automated guided vehicle*”, “AMR”, “autonomous mobile robot*”, “mobile robot*”), methods (“AI”, “artificial intelligence”, “SLAM”, “sensor fusion”, “LiDAR”, “reinforcement learning”, “semantic mapping”), and outcomes (“cost”, “navigation”, “safety”, “path planning”, “efficiency”).

The identification process was conducted in three sequential phases with specific keyword combinations:

Initial search with “smartwarehouse” and “agv” yielded 11 records

Subsequent search with “automated guided vehicle” and “operation costs” yielded 3862 records

Final search with “mobile robots” yielded 23,108 records

Example search string for Web of Science: TS = ((“smart warehouse*” OR “automated warehouse*”) AND (“AGV” OR “automated guided vehicle*” OR “AMR” OR “autonomous mobile robot*”) AND (“AI” OR “artificial intelligence” OR “SLAM” OR “sensor fusion”)). The combined search results from all databases totaled 26,981 records. Following identification, duplicate records were removed (n = 0), as the search was conducted sequentially with non-overlapping keyword sets, resulting in 26,981 unique records proceeding to the screening stage.

2.2. Screening

For the screening phase of PRISMA, we applied sequential filters to the 26,981 identified records:

First, we filtered for publication date (January 2020 to May 2025), which reduced the records to 9962. This time period was selected because the COVID-19 pandemic significantly increased the demand for mobile robots across various fields [26].

Second, we applied a language filter, retaining only English-language articles, which further reduced the records to 9902.

Third, we filtered for article type, selecting only peer-reviewed articles (primary research, technical papers, or reviews) with open access status to ensure full-text availability for all team members, which resulted in 151 records.

All referenced documents reflect the most recent findings in scientific research and adhere to the standards of peer-reviewed publications, thereby validating the quality of the presented results.

2.3. Eligibility

Full-text eligibility was assessed based on substantive relevance through an additional publisher filter. Records were required to meet all of the following criteria:

Focus on smart warehouses or automated logistics environments

Discussion of mobile robots (AMRs/AGVs) and their navigation, cost, or safety systems

Coverage of at least one key technology: AI, SLAM, LiDAR, sensor fusion, IoT, reinforcement learning, or semantic mapping

Publication in one of the three selected publishers: MDPI, Elsevier, or IEEE

The 151 records that passed screening were assessed for eligibility. Records were excluded if they:

Focused solely on non-warehouse robotics (e.g., surgical, space, or agricultural robots without warehouse relevance)

Were editorials, opinion pieces, or conference abstracts without full review content

Did not provide synthesizable findings on navigation, cost, or safety

Were not published in MDPI, Elsevier, or IEEE journals

After applying these eligibility criteria, 45 records were excluded, leaving 106 records for inclusion in the review.

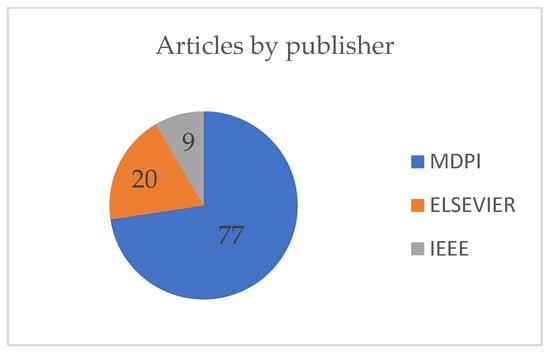

2.4. Included

According to the identification, screening, and eligibility procedures, 106 papers were accepted for further analysis. These papers were published across three major publishers: 77 from MDPI, 20 from Elsevier, and 9 from IEEE. These substantial papers will form the basis for the development of a two-level framework for qualifying publications in the analyzed area in the next phases of the research. The included studies represent the most relevant and methodologically sound research on smart warehouses and mobile robot integration published between 2020–2025.

2.5. Data Extraction

A standardized data extraction form was developed in Microsoft Excel, pilot-tested for 5 articles, and refined. Two reviewers (D.Z. and I.P.) independently extracted study characteristics (author, year, journal, review type), technologies covered (AI, SLAM, etc.), key findings on navigation, cost, safety, and study limitations (if reported). Inconsistency were resolved through discussion or arbitration by a third reviewer (Ž.B.). Extracted data items included bibliographic details (author, year, title, journal), study type (primary research, technical paper, review), technologies evaluated (AI, SLAM, sensor fusion, etc.), reported outcomes: (navigation accuracy metrics, cost reduction %, safety incidents, implementation barriers), sample size or simulation scale (if applicable), and funding source and conflicts of interest (if reported).

2.6. Data Synthesis

Given the heterogeneity of included studies (primary research, technical papers, re-views), a thematic synthesis approach was employed. Initial codes were developed induc-tively from the data, then grouped into 8 thematic categories (AI, Safety, Network, etc.) through iterative discussion among reviewers. Findings were synthesized narratively, with emphasis on consensus across reviews, contradictions or gaps, and evolution of technologies over time (2020–2025). A meta-analysis was not performed because of the heterogeneity present in outcome reporting and study designs. The following software tools were used:

- Rayyan (https://rayyan.ai, accessed on 2 November 2025) for title/abstract screening,

- Microsoft Excel for data extraction and management,

- VOSviewer v1.6.20 for co-occurrence analysis,

- PRISMA Flow Diagram Generator (http://prisma-statement.org, accessed on 2 November 2025) for Figure 1 and Figure 2.

We followed the PRISMA 2020 checklist when preparing this systematic review to ensure transparency and completeness of reporting [27].

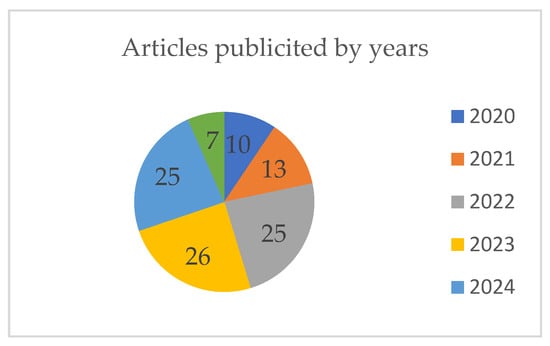

2.7. Bibliometric Analysis

A bibliometric analysis was conducted on 106 files selected for evaluation. This research presents the findings from examination existing literature conducted for quantitative and qualitative datasets, depicting all articles researched. Figure 4 shows a clear upward trend from 2020 to 2024. The number of publications increases over the research period. Following the onset of the pandemic, the number of articles published doubled in 2022, which is entirely logical. This large number of publications indicates the ongoing need for research and publication in the field of mobile robots and smart warehouse storage until the end of 2024. As this paper is based on the research and analysis of published papers, it was not possible to analyze the year 2025 in full; therefore, only seven papers were published in that year. According to the growing trend, it is expected that this number will remain the same or increase, given that smart warehouses and mobile robots are being used more widely across all industry sectors (Figure 5).

Figure 4.

Publications by year.

Figure 5.

A display of 203 examples of robot use for COVID-19 applications (brown-ground and blue-aerial robots) by [26].

Figure 6 shows the number of articles published by MDPI, Elsevier and IEEE. MDPI is the publisher with the most articles, with 71 publications. This is entirely understandable, given that this publishing house is one of the most renowned for publications on innovative technologies and engineering solutions. Second place went to the Elsevier publishing house, with a total of 20 publications—25.97% of MDPI’s total. Elsevier also has numerous articles concerning contemporary technologies and their application in technical systems. These two publishing houses have received positive feedback from scientists because they can publish articles very quickly. The IEEE is a publishing house with nine published articles, accounting for 11.68% of MDPI’s total. This study only examined review and open access papers to gain a better understanding and enable full access to papers without paying expensive fees.

Figure 6.

Publication by the publisher.

Table 2 presents the Web of Science categories directly connected with the publication’s research area, which is related to smart warehouses and mobile robots. The largest number of articles came from the journal Engineering Electrical Electronic, with 32 articles (12.90%). The use of smart warehouses and AMRs is also mentioned in an article from the journal Chemistry Analytical, with 17 articles and a percentage of 6.85%. The same percentage applies to ‘INSTRUMENTS INSTRUMENTATION’. Other Web of Science categories also have articles on the topic of smart warehouses and AMRs, but they have published 15 or fewer papers.

Table 2.

Research categories.

The bibliometric analysis of the 106 included studies, conducted using the AI-powered tool Bibliometrix, reveals a clear hierarchy of thematic focus, with “mobile robot” emerging as the most frequently occurring keyword (40 occurrences), underscoring its centrality to the research domain. Keywords such as “navigation” (30 occurrences) and “system” (23 occurrences) further delineate the core technical challenges addressed in contemporary literature, reflecting an emphasis on operational frameworks and spatial autonomy. The co-occurrence of terms like “algorithm,” “path planning,” and “simultaneous localization” highlights the methodological convergence toward computational intelligence for enabling precise and adaptive robotic behavior in dynamic warehouse environments (Figure 7).

Figure 7.

Quantitative Analysis of Keyword Prevalence in Smart Warehouse Navigation Research using the AI-powered tool Bibliometrix.

The temporal evolution of research themes, visualized through Bibliometrix, indicates a significant shift toward AI-driven methodologies, with “neural-network” showing a marked increase in frequency from 2020 onwards, signaling its growing importance in intelligent navigation systems. Concurrently, foundational concepts such as “mobile robot,” “navigation,” and “system” have maintained consistent prominence throughout the period 2014–2024, suggesting their enduring relevance as structural pillars of the field. The emergence of “autonomous mobile robot” as a distinct trend term after 2020 reflects the maturation of the discipline, moving beyond generic automation toward fully self-governing systems capable of complex decision-making in unstructured indoor spaces (Table 3). This evolution reflects a paradigmatic shift from reactive automation toward intelligent navigation—a capability that emerges not in isolation, but through the tight integration of AI-driven reasoning, real-time sensor fusion, SLAM-based spatial awareness, and adaptive path planning, all of which are increasingly treated as interdependent components rather than standalone modules in contemporary smart warehouse research.

Table 3.

Temporal Evolution of Key Research Themes in Smart Warehouse Robotics.

Table 4 presents a structured synthesis of the state-of-the-art across eight core domains: Artificial Intelligence (AI), Simultaneous Localization and Mapping (SLAM), Sensor Fusion, Safety, Networking, Path Planning, Implementation, and System Design. For each category, the table systematically aggregates representative methods, their innovative contributions, and the corresponding literature (2020–2025). This organization enables a direct, cross-sectional comparison of algorithmic paradigms—such as CNNs and deep reinforcement learning in AI, ORB-SLAM and semantic SLAM in mapping, or Kalman-based versus deep fusion frameworks in perception—while highlighting their distinct advantages (e.g., end-to-end learning, real-time semantic anchoring, or multi-sensor robustness) and contextual applicability within smart warehouse environments.

Table 4.

Comparative Overview of Core Technological Categories in Intelligent Mobile Robot Navigation for Smart Warehouses.

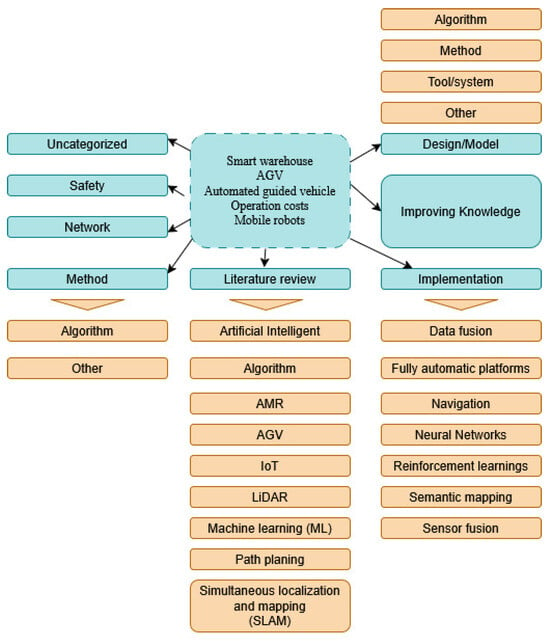

3. Analysis of Search Results from the Database

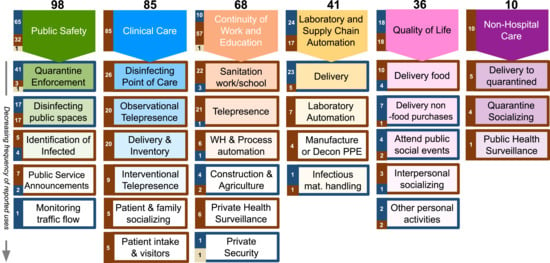

After researching and analysing all the articles, the final number relating to the keywords ‘smart warehouse’, ‘AGV’ (automated guided vehicle), ‘operation cost’ and ‘mobile robots’ is 106. Figure 8 shows the categorisation of the articles, which are divided into eight main categories, four of which are divided into a further 21 subcategories. Some categories could not be divided into subcategories because they were too small. During the research, it was noticed that certain articles could fit into multiple categories. To avoid duplication, the “Uncategorised” category was created.

Figure 8.

Category mapping of articles.

3.1. Literature Review

The examination of existing literature chapter illustrates the most significant component of the research work, as it collects highly scientific articles and organizes them to offer an understanding of the present condition of smart warehouses to extent, which are automated. The literature review identified and categorized 43 papers, sorting them into eight subcategories mentioned below:

- AI [28,29,30,31,32,33,34,35,36,37,38];

- AMR [77];

- AGV [77,81];

- IoT [60,61];

- LiDAR [45,82,83,84,85];

- Machine learning (ML) [39,40];

- Path planning [32,41,51,58,63,64,65,66,67,68,69,70,71,72];

- Simultaneous localization and mapping (SLAM) [34,43,44,45,46,47,48,49,50].

3.2. Design/Model

Ten articles were classified and segmented into four subcategories according to the analysis conducted within this category. Initially subcategory is ‘Algorithm’, with two papers. Creators of these articles briefly review and discuss computational geometry (CG) and practical algorithms for resolving geometric input and output, with a focus on their application to automated path planning in single- and multi-robot systems. The papers in this subcategory describe the optimization of practical algorithms relating to CG-based single-robot path planning and the winner’s algorithms in the CG-SHOP 2021 competition [3]. The second article provides an overview of nine different algorithms used for obstacle avoidance with sensors and their respective levels of efficiency [25]. The second subcategory contains four articles on methods. The articles present path planning and environmental modelling methods. Methods of environmental modelling include the grid method, the topology method, the geometric feature method, and the mixed representation method [3]. Modelling and simulation methodologies for TGMRs (tracked ground mobile robots) use the Open Dynamics Engine, Microsoft Robotics Developer Studio, Gazebo, and the Robotic Operating System (ROS) [37]. To improve presentation and understanding, the authors created the function using MatLab software (MathWorks, Natick, MA, USA) [77] and classified the sensing method [78]. Two articles were found in the subcategory ‘Tool/system’. The first article analyzed and presented performance reports of quadrupedal robots and outlined future developments in cognitive robotics, focusing on robots exhibiting intelligent behavior [7]. The second set of authors provides an overview of the robot system and presents the vertical dynamic model of the Crawler Unit, paving the way for the development of autonomous navigation algorithms for the aforementioned unit [79]. The final subcategory, ‘Other’, also contains two articles. The first article presents active mapping and robot exploration through a 2D ASLAM system for mapping dynamic indoor environments [80]. The second article presents the handling of an indoor environment through a pipe. The authors conclude that the robot’s adaptation mechanisms must provide adequate pressing forces throughout navigation to ensure stable traction and flexible locomotion.

3.3. Improving Knowledge

Today, every industry is changing rapidly, and it is expected that current technology and techniques will also continue to develop positively. Nine articles will be explained below. AMRs have become increasingly prominent over the last few years due to their many advantages over human labour. AMRs are now being used in all large, smart warehouses. The authors explain navigation and movement planning organization. They also explain obstacle avoidance using sensor fusion [1]. The authors explain metaheuristic algorithms, which are extensively utilized to solve multiple optimization complications associated with their algorithmic intelligence. This makes them the most efficient algorithm for solving sophisticated optimization challenges in the domain of mobile robot trajectory planning. The article [4] presents a research gap that could be filled by those researching the design and operation of AGV systems, also known as AMRs. This research gap could be addressed by employing design of intelligent systems techniques for MR controllers with cognitive actions, including ANNs, FLC, and computational search and optimization methods [9]. According to [55], the most common solution in robotics is to use small robots dedicated exclusively to monitoring tasks, equipped with vision and cloud point sensors. Author [30] states that mobile robots are part of Industry 5.0 and that humans are expected to coexist and work alongside them in a shared environment, making use of modern power source technologies and artificial intelligence. Robots need systems such as the RMFS with AS/RS to successfully execute work operations [86]. The authors [87] state that, in addition to robots operating successfully, including them in various work tasks can reduce the cost of the final product while improving overall production results and increasing product quality. This is possible through the use of machine vision and sensor integration. Similar thoughts are shared by the authors [88], who state that data frameworks, remote detection, stereo vision systems, and image editing software, as well as augmented and virtual reality, are among the most important technologies. Within this technological ecosystem, Artificial Neural Networks (ANNs) and Fuzzy Logic Control (FLC) provide the cognitive and reactive layers essential for intelligent navigation, enabling mobile robots to interpret uncertain sensor data and execute human-like, context-aware maneuvers in dynamic warehouse environments.

Complementing these, computational search and optimization methods—such as genetic algorithms, particle swarm optimization, and A*-based planners—form the deliberative core of intelligent navigation by generating safe, efficient, and adaptive trajectories that respond in real time to environmental changes and operational constraints.

3.4. Implementation

One of the technological requirements for developing smart warehouses and integrating mobile robots is implementing new technologies. The list below presents technologies used for the faster dehumanization of warehouses:

- Data fusion [36,74];

- Fully automated platforms [89];

- Navigation [52,53];

- Neural network [42,66,75];

- Reinforcement learning (RL) [11];

- Semantic mapping [76];

- Sensor fusion [33,54].

3.5. Method

A total of six papers were presented in the ‘Method’ category, which was divided into two subcategories: Algorithm and Other. In the ‘Algorithm’ subcategory, researchers analysed classical techniques for path planning and presented a review of SLAM algorithms for the navigation and control of 2D robotic vehicles. Mentioned techniques present LiDAR, VFH plus APF/VFF. The influence of virtual obstacles (VOs) on the effectiveness of algorithms and sensors in a robotic machine designed for self-propulsion was also explained [8]. Local navigation for mobile robots (MRs) was also presented by [9]. The authors state that sensor fusion methods and artificial intelligence methods are increasingly utilized for the assessment of gathered information, controlling robotic trajectories, and their creation. Common methods include sensor fusion with a Kalman filter, deep learning for sensor fusion, and sensor fusion with path following methodology. In [26], the authors present a graph search algorithm for path planning. The A* algorithm: The A* heuristic algorithm is a classical graph search algorithm for calculating the least-cost path on a weighted graph, as well as an extension of A*. The D* Lite algorithm works in the opposite direction, from the goal to the start. In addition to the aforementioned algorithms, the following are also presented: Tabu search, genetic algorithms, particle swarm optimization, ant colony algorithms, and simulated annealing. In the Other subcategory, the authors present Bio-inspired Population-based Optimization (BPO) methodologies for generating efficient paths for path planning, using mathematical models to optimize cost and achieve the greatest possible improvement. The mathematical models used in this research were: ISpSA and IWOA. Depending on the time available for processing, the more favourable model is chosen. The authors [73] have observed that path planning is much more effective with deep reinforcement learning, especially when cameras, or sensors that report the distances to surrounding objects in an image format, and 3D LiDAR are used. Therefore, the authors propose hybrid reinforcement learning for motion planning. A new mixed reward function reduces the likelihood of collisions in overfilled indoor spaces during path planning. The authors [90] have observed that simulating the robot’s movements in a virtual environment can assist with path planning by identifying the shortest route while avoiding obstacles. The same authors present several types of extended reality (XR), namely virtual reality (VR), augmented reality (AR) and mixed reality (MR). VR tools allow technical visualisation of processes in 3D space. Virtual reality (VR) is commonly utilized for monotonous tasks, and with the incorporation of supplementary sensors, it can ensure the precise arrangement of objects, which is very important for mobile robots. Augmented reality (AR) technological advancements supply visualisation of elements that cover the actual world. AR can help with navigation in large environments. Mixed reality is similar to AR; however, it is more engaging with both augmented and actual environments. Mixed reality technology has been utilized in the concepts of Industry 5.0, which prioritize human–robot interaction.

3.6. Network

In today’s smart homes, information is sent via a specific network, such as an internal Wi-Fi connection, to mobile robots. AGVs, AMRs and similar devices are consistent with Industry 4.0 and must be sufficiently linked to one another to operate effectively. In addition to using standard networks for human–robot communication and a smart warehouse, the authors [62] suggest creating an unmanned land vehicle that acts as an autonomous mobile network. These authors also state that, due to simultaneous work, the amount of data received is very large, which makes it difficult to interpret, transfer and use the collected data. The authors of [60] state that using a conventional Wi-Fi network like WPAN Low Rate Alternative PHY for AGV logistics and controlling are not so ideal for applications requiring high-level precision like AGV port, because of problems with precision and due to issues with accuracy, reliability and data transfer accessibility. These authors propose using latest Wi-Fi bands for better Automated Guided Vehicles usage.

3.7. Safety

One of the primary obstacles in contemporary mobile robotics is ensuring safety in human–robot collaboration. When using mobile robots in smart warehouses, it is crucial to prioritise the safety of people. The integration of modern technology must not compromise health and safety when working with mobile robots, but rather reduce the negative impact of digital transformation. The authors of [5] state that the safety of people is in danger because of AGVs operating in anthropotechnical systems. To improve safety, the authors suggest better navigation and path planning, as well as improving the accuracy of braking systems in relation to obstacles. Authors [12] have a similar point of view and note that robotic path planning is very important, and that traversability grid maps are necessary for better estimation. Another approach to safety is to use a robot instead of a human. The authors [19] state that autonomous robots can determine and execute tasks independently with the assistance of a perception system. According to [56], robots equipped with sensors for early warning systems can carry out safety tasks such as disease detection instead of people. The authors of [56] state how semantic maps can reduce risks with robots by providing them with semantic knowledge. More precisely, this allows robots to work using geometric representations, mainly for localization, path planning and navigation. The role of obstacle avoidance algorithms is fundamental in the functionality of autonomous vehicles. Authors [57] state that these algorithms allow robots to traverse their surroundings effectively, reducing the likelihood of collisions and safely circumventing obstacles. According to [55,58], autonomous navigation systems utilized by mobile robots necessitate continuously updated location data to guarantee optimal manoeuvre with a secure approach to the given final location. An operation for mobile machines in smart warehouses may result in collisions and, ultimately, damage of varying severity. To avoid this, the authors propose using ultra-wideband (UWB) technology and UWB systems based on technology to ascertain location with great precision.

3.8. Uncategorized

The ‘Uncategorized’ group contains articles presenting research results that are not directly related to the highlighted research areas of smart warehouses and mobile robots. While the articles are partially based on the research topic, they focus more on other areas that are not the main focus of this article, such as industrial waste, food studies, UVAs and wastewater treatment. Smart warehouses and mobile robots are mentioned in the research articles as part of an analysis of a process. The articles have been incorporated into the analysis as they were found in the search results and are pertinent to smart warehouses and mobile robots, or because they were researched using keywords. The research encompassed the following aspects:

- ➢

- Most used simulation software for swarm robotics [22];

- ➢

- Advanced mobility applications for robotic wheelchairs with designs focused on technological adaptations [91];

- ➢

- The evolution of robotic technologies for operation in wooded areas [60];

- ➢

- Applications of agricultural robotic systems for the execution of land preparation [92];

- ➢

- Research concerning the primary packaging of proteins and peptides, as well as the formulation and development of drug product manufacturing processes [93];

- ➢

- Pigment bioprocessing operation costs [94];

- ➢

- Recurrent averaging inequalities in multi-agent control and social dynamics modeling [95];

- ➢

- Thermochemical transformation of biomass into biochar and its decoration with CO(2) methanation catalysts [96];

- ➢

- Exploring multi-use platforms- marine, with applications (M4s) [97];

- ➢

- Solar greenhouse is an agricultural facility in alpine regions [98];

- ➢

- The employment of UAVs in particular tasks in the electrical sector [99];

- ➢

- The integration of carbon dioxide capture and conversion by means of metal oxides [100];

- ➢

- Techno-Energetic, Economic and Environmental Performance for Remote Power Generation [101];

- ➢

- Green building technologies for identifying the future roadmap [102];

- ➢

- Development for Oil and Gas Infrastructure [103];

- ➢

- astewater Treatment Using Membrane Bioreactor Technologies [104];

- ➢

- Wind energy’s role in sustainable development goals [105];

- ➢

- Dam and powerhouse operation sustainability with reduce of hydropower [106];

- ➢

- The importance of fossil fuels, predominantly coal, in the worldwide energy structure [107];

- ➢

- Optimization systems optimally operate with power systems [108];

- ➢

- Microbial fuel cells and microbial desalination cells represent a novel approach owing to their capacity to process wastewater [109];

- ➢

- Formulating sustainable strategies associated with the deployment of solar photovoltaic (PV) and concentrated solar power (CSP) systems [38];

- ➢

- Chemical mechanical polishing and post-CMP cleaning [110];

- ➢

- The efficient treatment of olive mill wastewater (OMW) with SR-AOPs [111];

- ➢

- Overview of the Rh metal recovery from spent catalysts [112];

- ➢

- Improved waste management for the production of FeCr [113];

4. Main Research Gaps and Future Considerations

The development of robotics and smart warehouses is driving technological progress. Traditional warehouses and internal logistics are undergoing significant digital transformation. The use of mobile robots, AGVs and smart applications for planning has led to increased research into new technologies such as artificial intelligence, SLAM, path planning, the Internet of Things (IoT), sensor fusion and LiDAR technology. The dehumanisation of warehouses and the digitisation of warehouse processes can only be achieved by integrating new methods and algorithms.

4.1. Analysis of the Obtained Results

This examination of existing literature regarding research emphasized eight main categories, which were then divided into 21 subcategories. The main focus of the research was smart warehouses and mobile robots, with a particular focus on navigation, path planning, the Internet of Things (IoT), autonomous mobile robots (AMRs), simultaneous localisation and mapping (SLAM), LiDAR technology and other similar technologies for the digitalisation of modern smart warehouses. The research results presented show the use of computational geometry (CG) and practical algorithms for fixing geometric input and output in practice with optimisation. These algorithms were also used for obstacle avoidance with environment modelling methods for path planning and the environment (Section 4.2). The usage of 2D SLAM for active mapping was presented for indoor environments. Section 4.3 presented the scope of the research relating to smart warehouses and mobile robots, which is very comprehensive as can be seen from the eight main categories and subcategories, as well as the extensive collection of articles categorized as ‘Uncategorized’category. Much of the research is already familiar from other published articles, e.g., SLAM [10,24,32,35,37,48,114,115], path planning [7,11,17,23,41,49,50,56,69,70,71], or AI [15,16,17,18,33,34,35,36,37,38]. The ‘Uncategorized’ category contains many articles, mainly because smart warehouses with their robots and AGVs are included in articles on similar topics, such as operational costs in various fields of science and industry. The development of smart warehouses with new technologies is ongoing due to the gradual dehumanisation of manufacturing processes and their digitisation and automation. It is important to highlight that the majority of articles concentrate mainly on the advantages of utilizing mobile robots within warehouse settings, such as improving safety conditions through precise path planning. Future research directions must integrate the researched technologies with the sixth generation of cellular networks (6G).

4.2. Identification of the Research Gap

Through the examination of existing literature, two research gaps were identified: safety and networking. Human safety should be prioritized over the dehumanization of the warehouse. Only eight articles in the Safety category deal with human safety. More precisely, articles [5,12,19,55,56,57,58] pay attention to the working environment of the mobile robot and its successful performance of the task, while operator health is considered only as an additional factor. With regard to human health, secondary steps are taken to protect operators through good, precise path planning. The second research gap concerns networks, with only two articles directly connected to human safety. The main reason for this is the lack of accuracy when operating mobile robots in a smart warehouse. One group of authors (99) proposes creating an autonomous mobile network, while another group (40) suggests applying 5G-based wireless networks to improve AGV control. Future research directions should review and compare the fifth and sixth generations of cellular networks.

4.3. State-of-the-Art Technologies That Could Narrow Research Gaps

The growth of automation—which encompasses industrial robots, advanced networked devices, and cutting-edge technologies such as AI and IoT—introduces multiple considerations, including security, cyber-physical systems, and human safety through participation. 5G is already impacting industrial automation, while the implementation of 6G mobile systems is expected to facilitate more seamless communication among production machines, robots, and software, enabling faster and more reliable data transmission. The application of 6G enables better integration of sensors, controllers, and human–machine interfaces, thereby improving the control, monitoring, and optimization of production processes [72]. The authors [43] state that 6G enables fully autonomous driving through ultra-reliable, low-latency communications, thereby ensuring a high level of human safety. The authors [116] state that the synergy between humans and robots facilitates more intuitive and efficient communication over 6G networks, with significant advances achieved in network architecture, device interoperability, and security. According to [117,118], human–robot interaction is categorized into three levels: coexistence, cooperation, and collaboration. To enable safe, efficient, and intuitive interaction between humans and robots in a shared workspace, human–robot collaboration (HRC) systems are employed. These systems incorporate standardized safety mechanisms defined in ISO/TS 15066 [59], namely: Safety-Rated Monitored Stop (SRMS), Hand Guiding (HG), Speed and Separation Monitoring (SSM), and Power and Force Limiting (PFL). Overall, HRC systems represent integrated approaches that facilitate safe and efficient human–robot cooperation through a combination of safety protocols, sensor systems, intelligent algorithms, and natural interaction modalities.

4.4. Summary of the Discussion

In summarising the conclusions of this article, it is crucial to highlight the uniqueness of the findings, which are classified in the following manner:

- An overview of examination of existing literature was conducted.Section 4.1 introduces a collection of review articles concerning smart warehouses utilizzing mobile robots and AGVs. Most of the articles reviewed presented results that focused on specific research problems, such as path planning, and the application of specific technological solutions (SLAM, IoT, VR, AI, ML and neural networks). In these reviews, smart warehouses and mobile robots appeared as elements of a research area due to the complexity of problem solving, which requires the integration of multiple factors.

- Identification of two research deficiencies in the reviewed literature analysis:A critical analysis of examination of existing literature has identified two research gaps. The first relates to the safety of human operators due to a lack of accuracy, and the second relates to the network, which is directly connected to poor navigation of mobile robots and indirectly connected to human safety. To avoid these problems in smart warehouses, robots need to be equipped with sensors for early warnings and UWB technology needs to be installed.

4.5. Limitations

This systematic review has several limitations:

- database restriction—reliance on Web of Science may have missed relevant studies in some other relevant databases,

- language bias—inclusion of only English-language reviews excludes potentially valuable non-English literature,

- quality variability—many included studies were technical papers with limited validation or reviews with methodological weaknesses,

- no meta-analysis—quantitative synthesis was not feasible due to heterogeneity in out-come reporting,

- rapidly evolving field—reviews from 2020–2023 may not reflect the latest advances in 2024–2025.

Future reviews should register protocols, use multiple databases, and prioritize studies with robust validation.

5. Conclusions

The research presented a list of 106 articles recognized in the study process, applying a PRISMA methodology. Mentioned articles are part of the research area, either directly or indirectly, such as smart warehouses, mobile robots or AGVs. The outcome shown demonstrates the large amount of research in this area. By observing the research article and the knowledge gained, it can be determined how this article can benefit scientists and people planning to create a smart warehouse managed by mobile robots or to dehumanize a traditional warehouse. The insights obtained from this article can assist the industry in comprehending the primary technologies employed in smart warehouses and provide essential data on how to prepare mobile robots and AGVs for indoor environments without compromising accuracy, which is crucial for human and robot safety. The article also outlines future research directions for optimizing the technology and creating high-quality systems for indoor environments.

Author Contributions

Conceptualization, D.Z. and I.P.; methodology, D.Z.; validation, D.Z., Ž.B. and H.G.; formal analysis, D.Z.; investigation, D.R.; resources, R.B.; data curation, D.Z.; writing—original draft preparation, D.Z.; writing—review and editing, D.Z.; visualization, Ž.B. and M.J.; supervision, Ž.B. and I.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This research was supported by the scientific project “Prediction of maize yield potential using machine learning models based on vegetation indices and phenological metrics from Sentinel-2 multispectral satellite images (AgroVeFe)–581–UNIOS–30” from the European union–NextGenerationEU. The authors would like to thank the reviewers for the insightful comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhen, L.; Li, H. A Literature Review of Smart Warehouse Operations Management. Front. Eng. Manag. 2022, 9, 31–55. [Google Scholar] [CrossRef]

- Kamali, D.A. Smart Warehouse vs. Traditional Warehouse—Review. Autom. Auton. Syst. 2019, 11, 9–16. [Google Scholar] [CrossRef]

- Liu, X.; Cao, J.; Yang, Y.; Jiang, S. CPS-Based Smart Warehouse for Industry 4.0: A Survey of the Underlying Technologies. Computers 2018, 7, 13. [Google Scholar] [CrossRef]

- Zunic, E.; Delalić, S.; Hodžić, K.; Beširević, A.; Hindija, H. Smart Warehouse Management System Concept with Implementation. In Proceedings of the 2018 14th Symposium on Neural Networks and Applications (NEUREL), Belgrade, Serbia, 20–21 November 2018; p. 5. [Google Scholar]

- Bashir, M. An Improved Method of Particle Swarm Optimization for Path Planning of Mobile Robot. J. Control. Sci. Eng. 2020, 2020, 3857894. [Google Scholar] [CrossRef]

- Affia, I.; Aamer, A. An Internet of Things-Based Smart Warehouse Infrastructure: Design and Application. J. Sci. Technol. Policy Manag. 2021, 13, 90–109. [Google Scholar] [CrossRef]

- Fernando, Y.; Suhaini, A.; Tseng, M.L.; Abideen, A.Z.; Shaharudin, M.S. A Smart Warehouse Framework, Architecture and System Aspects under Industry 4.0: A Bibliometric Networks Visualisation and Analysis. Int. J. Logist. Res. Appl. 2024, 27, 2688–2711. [Google Scholar] [CrossRef]

- Hung, B.M.; You, S.-S.; Phuc, B.D.H.; Kim, H.-S. Motion Control with Robust String Stability of Mobile-Rack Vehicles in Autonomous Logistics. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 2347–2359. [Google Scholar] [CrossRef]

- Żuchowski, W. The Smart Warehouse Trend: Actual Level of Technology Availability. Logforum 2022, 18, 227–235. [Google Scholar] [CrossRef]

- Zhou, L.; Lin, C.; Cao, Z. Reinforcement-Learning-Based Local Search Approach to Integrated Order Batching: Driving Growth for Logistics and Retail. IEEE Robot. Autom. Mag. 2023, 30, 34–45. [Google Scholar] [CrossRef]

- Yang, Q.; Lian, Y.; Liu, Y.; Xie, W.; Yang, Y. Multi-AGV Tracking System Based on Global Vision and AprilTag in Smart Warehouse. J. Intell. Robot. Syst. 2022, 104, 42. [Google Scholar] [CrossRef]

- Ali, S.S.; Kaur, R.; Gupta, H.; Ahmad, Z.; Jebahi, K. A decision-making framework for determinants of an organisation’s readiness for smart warehouse. Prod. Plan. Control 2024, 35, 1887–1908. [Google Scholar] [CrossRef]

- Wurman, P.R.; D’Andrea, R.; Mountz, M. Coordinating Hundreds of Cooperative, Autonomous Vehicles in Warehouses. AI Mag. 2008, 29, 9. [Google Scholar] [CrossRef]

- Benavides-Robles, M.T.; Valencia-Rivera, G.H.; Cruz-Duarte, J.M.; Amaya, I.; Ortiz-Bayliss, J.C. Robotic Mobile Fulfillment System: A Systematic Review. IEEE Access 2024, 12, 16767–16782. Available online: https://ieeexplore.ieee.org/abstract/document/10415441 (accessed on 22 October 2025). [CrossRef]

- Boysen, N.; de Koster, R.; Weidinger, F. Warehousing in the E-Commerce Era: A Survey. Eur. J. Oper. Res. 2019, 277, 396–411. [Google Scholar] [CrossRef]

- Banker, S. Robots In The Warehouse: It’s Not Just Amazon. Available online: https://www.forbes.com/sites/stevebanker/2016/01/11/robots-in-the-warehouse-its-not-just-amazon/ (accessed on 22 October 2025).

- Merschformann, M.; Lamballais, T.; de Koster, M.B.M.; Suhl, L. Decision Rules for Robotic Mobile Fulfillment Systems. Oper. Res. Perspect. 2019, 6, 100128. [Google Scholar] [CrossRef]

- Arents, J.; Abolins, V.; Judvaitis, J.; Vismanis, O.; Oraby, A.; Ozols, K. Human–Robot Collaboration Trends and Safety Aspects: A Systematic Review. J. Sens. Actuator Netw. 2021, 10, 48. [Google Scholar] [CrossRef]

- Lasota, P.A.; Fong, T.; Shah, J.A. A Survey of Methods for Safe Human-Robot Interaction. Found. Trends® Robot. 2017, 5, 261–349. [Google Scholar] [CrossRef]

- ISO 10218-1:2023; Robots and Robotic Devices—Safety Requirements—Part 1: Industrial Robots. ISO: Geneva, Switzerland, 2023.

- ISO 10218-2:2023; Robots and Robotic Devices—Safety Requirements—Part 2: Robot Systems and Integration. ISO: Geneva, Switzerland, 2023.

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence--Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Davis, J.; Mengersen, K.; Bennett, S.; Mazerolle, L. Viewing Systematic Reviews and Meta-Analysis in Social Research through Different Lenses. SpringerPlus 2014, 3, 511. [Google Scholar] [CrossRef]

- Kable, A.K.; Pich, J.; Maslin-Prothero, S.E. A Structured Approach to Documenting a Search Strategy for Publication: A 12 Step Guideline for Authors. Nurse Educ. Today 2012, 32, 878–886. [Google Scholar] [CrossRef]

- Snyder, H. Literature Review as a Research Methodology: An Overview and Guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Carter, C.R.; Liane Easton, P. Sustainable Supply Chain Management: Evolution and Future Directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Gareis, M.; Hehn, M.; Stief, P.; Körner, G.; Birkenhauer, C.; Trabert, J.; Mehner, T.; Vossiek, M.; Carlowitz, C. Novel UHF-RFID Listener Hardware Architecture and System Concept for a Mobile Robot Based MIMO SAR RFID Localization. IEEE Access 2021, 9, 497–510. [Google Scholar] [CrossRef]

- Murphy, R.R.; Gandudi, V.B.M.; Adams, J. Applications of Robots for COVID-19 Response 2020. arXiv 2020, arXiv:2008.06976. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Tiozzo Fasiolo, D.; Scalera, L.; Maset, E.; Gasparetto, A. Towards Autonomous Mapping in Agriculture: A Review of Supportive Technologies for Ground Robotics. Robot. Auton. Syst. 2023, 169, 104514. [Google Scholar] [CrossRef]

- Zhang, C.; Cen, C.; Huang, J. An Overview of Model-Free Adaptive Control for the Wheeled Mobile Robot. World Electr. Veh. J. 2024, 15, 396. [Google Scholar] [CrossRef]

- Yang, L.; Li, P.; Qian, S.; Quan, H.; Miao, J.; Liu, M.; Hu, Y.; Memetimin, E. Path Planning Technique for Mobile Robots: A Review. Machines 2023, 11, 980. [Google Scholar] [CrossRef]

- Raj, R.; Kos, A. A Comprehensive Study of Mobile Robot: History, Developments, Applications, and Future Research Perspectives. Appl. Sci. 2022, 12, 6951. [Google Scholar] [CrossRef]

- Wang, S.; Ahmad, N.S. AI-Based Approaches for Improving Autonomous Mobile Robot Localization in Indoor Environments: A Comprehensive Review. Eng. Sci. Technol. Int. J. 2025, 63, 101977. [Google Scholar] [CrossRef]

- Luo, J.; Zhou, X.; Zeng, C.; Jiang, Y.; Qi, W.; Xiang, K.; Pang, M.; Tang, B. Robotics Perception and Control: Key Technologies and Applications. Micromachines 2024, 15, 531. [Google Scholar] [CrossRef]

- Liang, C.-J.; Le, T.-H.; Ham, Y.; Mantha, B.R.K.; Cheng, M.H.; Lin, J.J. Ethics of Artificial Intelligence and Robotics in the Architecture, Engineering, and Construction Industry. Autom. Constr. 2024, 162, 105369. [Google Scholar] [CrossRef]

- Lai, T. A Review on Visual-SLAM: Advancements from Geometric Modelling to Learning-Based Semantic Scene Understanding Using Multi-Modal Sensor Fusion. Sensors 2022, 22, 7265. [Google Scholar] [CrossRef]

- Wakchaure, M.; Patle, B.K.; Mahindrakar, A.K. Application of AI Techniques and Robotics in Agriculture: A Review. Artif. Intell. Life Sci. 2023, 3, 100057. [Google Scholar] [CrossRef]

- Bujňák, M.; Pirník, R.; Rástočný, K.; Janota, A.; Nemec, D.; Kuchár, P.; Tichý, T.; Łukasik, Z. Spherical Robots for Special Purposes: A Review on Current Possibilities. Sensors 2022, 22, 1413. [Google Scholar] [CrossRef]

- Altuntas, C. Review of Scanning and Pixel Array-Based LiDAR Point-Cloud Measurement Techniques to Capture 3D Shape or Motion. Appl. Sci. 2023, 13, 6488. [Google Scholar] [CrossRef]

- Singh, R.; Ren, J.; Lin, X. A Review of Deep Reinforcement Learning Algorithms for Mobile Robot Path Planning. Vehicles 2023, 5, 1423–1451. [Google Scholar] [CrossRef]

- Wang, J.; Lin, S.; Liu, A. Bioinspired Perception and Navigation of Service Robots in Indoor Environments: A Review. Biomimetics 2023, 8, 350. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Liu, H.; Wang, X.; Li, J.; Wang, P.; Liu, S.; Zou, J.; Yang, X. Application of Path Planning and Tracking Control Technology in Mower Robots. Agronomy 2024, 14, 2473. [Google Scholar] [CrossRef]

- Chakraborty, S.; Elangovan, D.; Govindarajan, P.L.; ELnaggar, M.F.; Alrashed, M.M.; Kamel, S. A Comprehensive Review of Path Planning for Agricultural Ground Robots. Sustainability 2022, 14, 9156. [Google Scholar] [CrossRef]

- Chen, W.; Zhou, C.; Shang, G.; Wang, X.; Li, Z.; Xu, C.; Hu, K. SLAM Overview: From Single Sensor to Heterogeneous Fusion. Remote Sens. 2022, 14, 6033. [Google Scholar] [CrossRef]

- Panigrahi, P.K.; Bisoy, S.K. Localization Strategies for Autonomous Mobile Robots: A Review. J. King Saud Univ.—Comput. Inf. Sci. 2022, 34, 6019–6039. [Google Scholar] [CrossRef]

- Fang, Y.; Panah, A.; Masoudi, J.; Barzegar, B.; Fatehi, S. Adaptive Unscented Kalman Filter for Robot Navigation Problem (Adaptive Unscented Kalman Filter Using Incorporating Intuitionistic Fuzzy Logic for Concurrent Localization and Mapping). IEEE Access 2022, 10, 101869–101879. [Google Scholar] [CrossRef]

- Abaspur Kazerouni, I.; Fitzgerald, L.; Dooly, G.; Toal, D. A Survey of State-of-the-Art on Visual SLAM. Expert Syst. Appl. 2022, 205, 117734. [Google Scholar] [CrossRef]

- Chen, W.; Wang, X.; Gao, S.; Shang, G.; Zhou, C.; Li, Z.; Xu, C.; Hu, K. Overview of Multi-Robot Collaborative SLAM from the Perspective of Data Fusion. Machines 2023, 11, 653. [Google Scholar] [CrossRef]

- Wu, H.; Chen, Y.; Yang, Q.; Yan, B.; Yang, X. A Review of Underwater Robot Localization in Confined Spaces. J. Mar. Sci. Eng. 2024, 12, 428. [Google Scholar] [CrossRef]

- Ušinskis, V.; Nowicki, M.; Dzedzickis, A.; Bučinskas, V. Sensor-Fusion Based Navigation for Autonomous Mobile Robot. Sensors 2025, 25, 1248. [Google Scholar] [CrossRef]

- Jusoh, S.; Almajali, S. A Systematic Review on Fusion Techniques and Approaches Used in Applications. IEEE Access 2020, 8, 14424–14439. [Google Scholar] [CrossRef]

- Taraglio, S.; Chiesa, S.; De Vito, S.; Paoloni, M.; Piantadosi, G.; Zanela, A.; Di Francia, G. Robots for the Energy Transition: A Review. Processes 2024, 12, 1982. [Google Scholar] [CrossRef]

- Badrloo, S.; Varshosaz, M.; Pirasteh, S.; Li, J. Image-Based Obstacle Detection Methods for the Safe Navigation of Unmanned Vehicles: A Review. Remote Sens. 2022, 14, 3824. [Google Scholar] [CrossRef]

- Leggieri, S.; Canali, C.; Caldwell, D.G. Design, Modeling, and Experimental Analysis of the Crawler Unit for Inspection in Constrained Space. Annu. Rev. Control. 2024, 57, 100950. [Google Scholar] [CrossRef]

- Shatokhin, O.; Dzedzickis, A.; Pečiulienė, M.; Bučinskas, V. Extended Reality: Types and Applications. Appl. Sci. 2025, 15, 3282. [Google Scholar] [CrossRef]

- Lewis, T.; Bhaganagar, K. A Comprehensive Review of Plume Source Detection Using Unmanned Vehicles for Environmental Sensing. Sci. Total Environ. 2021, 762, 144029. [Google Scholar] [CrossRef]

- Gul, F.; Mir, I.; Abualigah, L.; Sumari, P.; Forestiero, A. A Consolidated Review of Path Planning and Optimization Techniques: Technical Perspectives and Future Directions. Electronics 2021, 10, 2250. [Google Scholar] [CrossRef]

- ISO/TS 15066:2016; Robots and Robotic Devices—Collaborative Robots. ISO: Geneva, Switzerland, 2016.

- Fragapane, G.; De Koster, R.; Sgarbossa, F.; Strandhagen, J.O. Planning and Control of Autonomous Mobile Robots for Intralogistics: Literature Review and Research Agenda. Eur. J. Oper. Res. 2021, 94, 405–426. [Google Scholar] [CrossRef]

- Oyekanlu, E.A.; Smith, A.C.; Thomas, W.P.; Mulroy, G.; Hitesh, D.; Ramsey, M.; Kuhn, D.J.; Mcghinnis, J.D.; Buonavita, S.C.; Looper, N.A.; et al. A Review of Recent Advances in Automated Guided Vehicle Technologies: Integration Challenges and Research Areas for 5G-Based Smart Manufacturing Applications. IEEE Access 2020, 8, 202312–202353. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, W.; Yu, R.; Zhang, Y. Motion planning for mobile robots—Focusing on deep reinforcement learning: A systematic review. IEEE Access 2021, 9, 69061–69081. Available online: https://ieeexplore.ieee.org/document/9419029 (accessed on 23 October 2025). [CrossRef]

- Rybczak, M.; Popowniak, N.; Lazarowska, A. A Survey of Machine Learning Approaches for Mobile Robot Control. Robotics 2024, 13, 12. [Google Scholar] [CrossRef]

- Han, X.; Guffanti, D.; Brunete, A. A Comprehensive Review of Vision-Based Sensor Systems for Human Gait Analysis. Sensors 2025, 25, 498. [Google Scholar] [CrossRef]

- Almazrouei, K.; Kamel, I.; Rabie, T. Dynamic Obstacle Avoidance and Path Planning through Reinforcement Learning. Appl. Sci. 2023, 13, 8174. [Google Scholar] [CrossRef]

- Qin, H.; Shao, S.; Wang, T.; Yu, X.; Jiang, Y.; Cao, Z. Review of Autonomous Path Planning Algorithms for Mobile Robots. Drones 2023, 7, 211. [Google Scholar] [CrossRef]

- Tan, C.S.; Mohd-Mokhtar, R.; Arshad, M.R. A Comprehensive Review of Coverage Path Planning in Robotics Using Classical and Heuristic Algorithms. IEEE Access 2021, 9, 119310–119342. [Google Scholar] [CrossRef]

- Loganathan, A.; Ahmad, N.S. A Systematic Review on Recent Advances in Autonomous Mobile Robot Navigation. Eng. Sci. Technol. Int. J. 2023, 40, 101343. [Google Scholar] [CrossRef]

- Tang, Y.; Zakaria, M.A.; Younas, M. Path Planning Trends for Autonomous Mobile Robot Navigation: A Review. Sensors 2025, 25, 1206. [Google Scholar] [CrossRef]

- Abdulsaheb, J.A.; Kadhim, D.J. Classical and Heuristic Approaches for Mobile Robot Path Planning: A Survey. Robotics 2023, 12, 93. [Google Scholar] [CrossRef]

- Achour, A.; Al-Assaad, H.; Dupuis, Y.; El Zaher, M. Collaborative Mobile Robotics for Semantic Mapping: A Survey. Appl. Sci. 2022, 12, 10316. [Google Scholar] [CrossRef]

- Yao, Z.; Zhao, C.; Zhang, T. Agricultural Machinery Automatic Navigation Technology. iScience 2024, 27, 108714. [Google Scholar] [CrossRef]

- Han, X.; Li, S.; Wang, X.; Zhou, W. Semantic Mapping for Mobile Robots in Indoor Scenes: A Survey. Information 2021, 12, 92. [Google Scholar] [CrossRef]

- Sánchez-Molina, J.A.; Rodríguez, F.; Moreno, J.C.; Sánchez-Hermosilla, J.; Giménez, A. Robotics in Greenhouses. Scoping Review. Comput. Electron. Agric. 2024, 219, 108750. [Google Scholar] [CrossRef]

- Sagar, M.M.; Konara, M.; Picard, N.; Park, K. State-of-the-Art Navigation Systems and Sensors for Unmanned Underwater Vehicles (UUVs). Appl. Mech. 2025, 6, 10. [Google Scholar] [CrossRef]

- Raj, R.; Kos, A. An Extensive Study of Convolutional Neural Networks: Applications in Computer Vision for Improved Robotics Perceptions. Sensors 2025, 25, 1033. [Google Scholar] [CrossRef]

- Bavle, H.; Sanchez-Lopez, J.L.; Cimarelli, C.; Tourani, A.; Voos, H. From SLAM to Situational Awareness: Challenges and Survey. Sensors 2023, 23, 4849. [Google Scholar] [CrossRef]

- Bruzzone, L.; Nodehi, S.E.; Fanghella, P. Tracked Locomotion Systems for Ground Mobile Robots: A Review. Machines 2022, 10, 648. [Google Scholar] [CrossRef]

- Pappalettera, A.; Bottiglione, F.; Mantriota, G.; Reina, G. Watch the Next Step: A Comprehensive Survey of Stair-Climbing Vehicles. Robotics 2023, 12, 74. [Google Scholar] [CrossRef]

- Seo, T.; Ryu, S.; Won, J.H.; Kim, Y.; Kim, H.S. Stair-Climbing Robots: A Review on Mechanism, Sensing, and Performance Evaluation. IEEE Access 2023, 11, 60539–60561. [Google Scholar] [CrossRef]

- Hsieh, C.-H.; Chang, C.-Y.; Hsiao, Y.-K.; Chen, C.-C.A.; Tu, C.-C.; Kuo, H.-C. Recent Advances In Silicon Carbide Chemical Mechanical Polishing Technologies. Micromachines 2022, 13, 1752. [Google Scholar] [CrossRef]

- Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Forest Robotics: A State-of-the-Art Survey. Robotics 2021, 10, 53. [Google Scholar] [CrossRef]

- Gonzalez-de-Santos, P.; Fernández, R.; Sepúlveda, D.; Navas, E.; Emmi, L.; Armada, M. Field Robots for Intelligent Farms—Inhering Features from Industry. Agronomy 2020, 10, 1638. [Google Scholar] [CrossRef]

- Kolar, P.; Benavidez, P.; Jamshidi, M. Survey of Datafusion Techniques for Laser and Vision Based Sensor Integration for Autonomous Navigation. Sensors 2020, 20, 2180. [Google Scholar] [CrossRef]

- Romero, L.M.; Guerrero, J.A.; Romero, G. Road Curb Detection: A Historical Survey. Sensors 2021, 21, 6952. [Google Scholar] [CrossRef]

- Lluvia, I.; Lazkano, E.; Ansuategi, A. Active Mapping and Robot Exploration: A Survey. Sensors 2021, 21, 2445. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Chen, T.; He, J.; Wang, Z.; Gao, B. Review on Security Range Perception Methods and Path-Planning Techniques for Substation Mobile Robots. Energies 2024, 17, 4106. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Jiang, D. Order-Picking Efficiency in E-Commerce Warehouses: A Literature Review. J. Theor. Appl. Electron. Commer. Res. 2022, 17, 1812–1830. [Google Scholar] [CrossRef]

- Le, N.; Tran, D.; Sturgill, R. Content Analysis of Three-Dimensional Model Technologies and Applications for Construction: Current Trends and Future Directions. Sensors 2024, 24, 3838. [Google Scholar] [CrossRef]

- Ušinskis, V.; Makulavičius, M.; Petkevičius, S.; Dzedzickis, A.; Bučinskas, V. Towards Autonomous Driving: Technologies and Data for Vehicles-to-Everything Communication. Sensors 2024, 24, 3411. [Google Scholar] [CrossRef]

- Katona, K.; Neamah, H.A.; Korondi, P. Obstacle Avoidance and Path Planning Methods for Autonomous Navigation of Mobile Robot. Sensors 2024, 24, 3573. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Junginger, S.; Roddelkopf, T.; Thurow, K. UWB-based real-time indoor positioning systems: A comprehensive review. Appl. Sci. 2024, 14, 11005. Available online: https://www.mdpi.com/2076-3417/14/23/11005 (accessed on 23 October 2025). [CrossRef]

- Sivakanthan, S.; Candiotti, J.L.; Sundaram, S.A.; Duvall, J.A.; Sergeant, J.J.G.; Cooper, R.; Satpute, S.; Turner, R.L.; Cooper, R.A. Mini-Review: Robotic Wheelchair Taxonomy and Readiness. Neurosci. Lett. 2022, 772, 136482. [Google Scholar] [CrossRef]

- Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Agriculture Robotics: A State-of-the-Art Review and Challenges Ahead. Robotics 2021, 10, 52. [Google Scholar] [CrossRef]

- Migoń, D.; Wasilewski, T.; Suchy, D. Application of QCM in Peptide and Protein-Based Drug Product Development. Molecules 2020, 25, 3950. [Google Scholar] [CrossRef]

- Pagels, F.; Pereira, R.N.; Vicente, A.A.; Guedes, A.C. Extraction of Pigments from Microalgae and Cyanobacteria—A Review on Current Methodologies. Appl. Sci. 2021, 11, 5187. [Google Scholar] [CrossRef]

- Proskurnikov, A.V.; Calafiore, G.C.; Cao, M. Recurrent Averaging Inequalities in Multi-Agent Control and Social Dynamics Modeling. Annu. Rev. Control. 2020, 49, 95–112. [Google Scholar] [CrossRef]

- Tang, M.; Gamal, A.; Bhakta, A.K.; Jlassi, K.; Abdullah, A.M.; Chehimi, M.M. Carbon Dioxide Methanation Enabled by Biochar-Nanocatalyst Composite Materials: A Mini-Review. Catalysts 2024, 14, 155. [Google Scholar] [CrossRef]

- Xylia, M.; Passos, M.V.; Piseddu, T.; Barquet, K. Exploring Multi-Use Platforms: A Literature Review of Marine, Multifunctional, Modular, and Mobile Applications (M4s). Heliyon 2023, 9, e16372. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Fang, H.; Zhang, Y.; Li, K.; Xu, D. Photothermal and Photovoltaic Utilization for Improving the Thermal Environment of Chinese Solar Greenhouses: A Review. Energies 2023, 16, 6816. [Google Scholar] [CrossRef]

- Sánchez-Zuluaga, G.J.; Isaza-Giraldo, L.; Zapata-Madrigal, G.D.; García-Sierra, R.; Candelo-Becerra, J.E. Unmanned Aircraft Systems: A Latin American Review and Analysis from the Colombian Context. Appl. Sci. 2023, 13, 1801. [Google Scholar] [CrossRef]

- Tan, W.J.; Gunawan, P. Integration of CO2 Capture and Conversion by Employing Metal Oxides as Dual Function Materials: Recent Development and Future Outlook. Inorganics 2023, 11, 464. [Google Scholar] [CrossRef]

- Da Lio, L.; Lazzaretto, A. Remote Power Generation for Applications to Natural Gas Grid: A Comprehensive Market Review of Techno-Energetic, Economic and Environmental Performance. Energies 2022, 15, 5065. [Google Scholar] [CrossRef]

- Meena, C.S.; Kumar, A.; Jain, S.; Rehman, A.U.; Mishra, S.; Sharma, N.K.; Bajaj, M.; Shafiq, M.; Eldin, E.T. Innovation in Green Building Sector for Sustainable Future. Energies 2022, 15, 6631. [Google Scholar] [CrossRef]

- Mahmood, Y.; Afrin, T.; Huang, Y.; Yodo, N. Sustainable Development for Oil and Gas Infrastructure from Risk, Reliability, and Resilience Perspectives. Sustainability 2023, 15, 4953. [Google Scholar] [CrossRef]

- Khan, M.J.; Wibowo, A.; Karim, Z.; Posoknistakul, P.; Matsagar, B.M.; Wu, K.C.-W.; Sakdaronnarong, C. Wastewater Treatment Using Membrane Bioreactor Technologies: Removal of Phenolic Contaminants from Oil and Coal Refineries and Pharmaceutical Industries. Polymers 2024, 16, 443. [Google Scholar] [CrossRef]

- Olabi, A.G.; Obaideen, K.; Abdelkareem, M.A.; AlMallahi, M.N.; Shehata, N.; Alami, A.H.; Mdallal, A.; Hassan, A.A.M.; Sayed, E.T. Wind Energy Contribution to the Sustainable Development Goals: Case Study on London Array. Sustainability 2023, 15, 4641. [Google Scholar] [CrossRef]

- Yaseen, Z.M.; Ameen, A.M.S.; Aldlemy, M.S.; Ali, M.; Abdulmohsin Afan, H.; Zhu, S.; Sami Al-Janabi, A.M.; Al-Ansari, N.; Tiyasha, T.; Tao, H. State-of-the Art-Powerhouse, Dam Structure, and Turbine Operation and Vibrations. Sustainability 2020, 12, 1676. [Google Scholar] [CrossRef]

- Aguirre-Villegas, H.A.; Benson, C.H. Expectations for Coal Demand in Response to Evolving Carbon Policy and Climate Change Awareness. Energies 2022, 15, 3739. [Google Scholar] [CrossRef]

- Vysocky, J.; Misak, S. Review of Trends and Targets of Complex Systems for Power System Optimization. Energies 2020, 13, 1079. [Google Scholar] [CrossRef]

- Farahani, H.; Haghighi, M.; Behvand Usefi, M.M.; Ghasemi, M. Overview of Sustainable Water Treatment Using Microbial Fuel Cells and Microbial Desalination Cells. Sustainability 2024, 16, 10458. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Guzmán, V.; Catriñir, P. Renewable Solar Energy Facilities in South America—The Road to a Low-Carbon Sustainable Energy Matrix: A Systematic Review. Energies 2024, 17, 5532. [Google Scholar] [CrossRef]

- Vaz, T.; Quina, M.M.J.; Martins, R.C.; Gomes, J. Olive Mill Wastewater Treatment Strategies to Obtain Quality Water for Irrigation: A Review. Sci. Total Environ. 2024, 931, 172676. [Google Scholar] [CrossRef]

- Jia, M.; Jiang, G.; Chen, H.; Pang, Y.; Yuan, F.; Zhang, Z.; Miao, N.; Zheng, C.; Song, J.; Li, Y.; et al. Recent Developments on Processes for Recovery of Rhodium Metal from Spent Catalysts. Catalysts 2022, 12, 1415. [Google Scholar] [CrossRef]

- du Preez, S.P.; van Kaam, T.P.M.; Ringdalen, E.; Tangstad, M.; Morita, K.; Bessarabov, D.G.; van Zyl, P.G.; Beukes, J.P. An Overview of Currently Applied Ferrochrome Production Processes and Their Waste Management Practices. Minerals 2023, 13, 809. [Google Scholar] [CrossRef]

- Zeydan, E.; Arslan, S.; Turk, Y. 6G Wireless Communications for Industrial Automation: Scenarios, Requirements and Challenges. J. Ind. Inf. Integr. 2024, 42, 100732. [Google Scholar] [CrossRef]

- Banafaa, M.; Shayea, I.; Din, J.; Hadri Azmi, M.; Alashbi, A.; Ibrahim Daradkeh, Y.; Alhammadi, A. 6G Mobile Communication Technology: Requirements, Targets, Applications, Challenges, Advantages, and Opportunities. Alex. Eng. J. 2023, 64, 245–274. [Google Scholar] [CrossRef]

- Chen, J.; Gao, Y.; Liu, Y.; Li, D.; Xingguang, W.; Liu, Z. Toward 6G Technology: Intent-Driven Autonomous Intelligent Wireless Communication Network. In Proceedings of the 2024 IEEE Globecom Workshops (GC Wkshps), Cape Town, South Africa, 8–12 December 2024; pp. 1–5. [Google Scholar]