Abstract

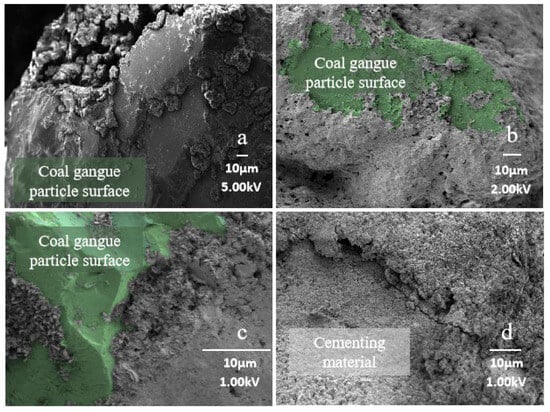

This study investigates the effectiveness of magnesium oxide (MgO) and coal gangue in improving expansive soil roadbeds through wet–dry cycle tests, unconfined compressive strength tests, and direct shear tests. The results demonstrate that coal gangue effectively suppresses non-load-induced swelling rates in expansive soil. At 15% coal gangue content, the unconfined compressive strength peaked at 0.6 MPa. Further incorporation of MgO at 2%, 4%, 6%, 8%, and 10% concentrations showed that 10% MgO significantly enhanced strength to 3.1 MPa, surpassing both the untreated soil (0.07 MPa) and coal gangue-only treatment (0.6 MPa). While wet–dry cycle tests revealed a gradual decrease in strength with repeated cycles, increasing MgO content mitigated this decline, resulting in coal gangue–MgO-stabilized soil with excellent water stability. Scanning electron microscopy revealed MgO-hydrated cementitious materials encapsulating expansive soil particles and connecting coal gangue particles, though fine cracks were observed near coal gangue surfaces.

1. Introduction

Expansive soil, exhibiting pronounced swelling and shrinkage behavior in response to moisture fluctuations [1,2], presents considerable challenges in highway engineering, frequently resulting in subgrade failures and substantial economic losses worldwide [3,4]. While conventional stabilizers, such as cement and lime, are extensively employed, their usage raises environmental concerns owing to significant carbon emissions and high energy consumption [5]. In light of these issues, considerable research interest has recently been directed toward the development of sustainable, low-carbon alternatives for soil stabilization.

Substantial efforts have been devoted to exploring the utilization of industrial by-products and alternative binders to replace or supplement traditional stabilizers. For example, alkali-activated slag systems have proven effective in stabilizing aeolian sand [6], with the incorporation of rubber granules further improving material toughness and energy absorption capacity [7]. Similarly, bio-cemented sand treated via microbial-induced carbonate precipitation (MICP) has exhibited outstanding mechanical performance and durability, demonstrating strong potential as a road base material [8]. Additionally, the application of recycled concrete aggregates combined with waste tire rubber and drywall waste has been proposed as a sustainable option for subbase construction, offering notable economic and environmental advantages [7,9]. Collectively, these studies underscore the feasibility and promise of waste valorization and low-carbon technologies within geotechnical engineering.

Among the emerging eco-friendly binders, reactive magnesium oxide (MgO) has attracted increasing attention due to its lower calcination temperature relative to Portland cement and its capacity to sequester CO2 during carbonation curing [10,11,12]. Several investigations have examined the efficacy of MgO in soil stabilization. For instance [13,14], Liu et al. [15] successfully stabilized silt and silty clay using active MgO, and Wu [16] reported that microbial-active MgO effectively mitigated shrinkage in red clay. Further reinforcing its utility, Li et al. [17] demonstrated that MgO-composite cement can suppress ettringite formation in sulfate-rich soils. These findings affirm the viability of MgO as a soil stabilizer; however, its combined application with solid waste aggregates in expansive soils remains inadequately investigated.

Coal gangue, a solid waste by-product generated during coal mining and processing, constitutes approximately 10–25% of total raw coal output [18]. Its accumulation not only occupies extensive land resources but also poses serious environmental risks [19]. Previous research has explored the potential of coal gangue in soil stabilization. Zhang et al. [20] observed that coal gangue can mitigate the adverse effects of wet–dry cycles on the pore structure of expansive soil. When used in conjunction with lime, it markedly reduces both free and loaded expansion rates while improving unconfined compressive strength [21]. Wang et al. [22] further reported that coal gangue effectively diminishes shrinkage deformation in stabilized expansive soil. According to Zhao et al. [23], amorphous SiO2 and Al2O3 present in coal gangue can react with Ca(OH)2 to form C-S-H gels, thereby enhancing the density of cement-based matrices. Moreover, Wang et al. [24] indicated that MgO contributes to the optimization of pore structures and improves the overall performance of coal gangue-based foamed ceramics.

Despite these advancements, a systematic investigation into the synergistic stabilization of expansive soil using reactive MgO as a binder and coal gangue as a functional aggregate has not yet been conducted. This combination not only facilitates the utilization of two types of industrial waste but also aligns with the principles of a circular economy and low-carbon geotechnical practice. Therefore, the present study aims to evaluate the mechanical properties and water stability of coal gangue–MgO-stabilized expansive soil, compare its performance with conventional stabilizers such as cement and lime; assess its durability under wet–dry cycling and immersion conditions, and elucidate the microstructural mechanisms underlying the stabilization process.

2. Materials and Methods

2.1. Material

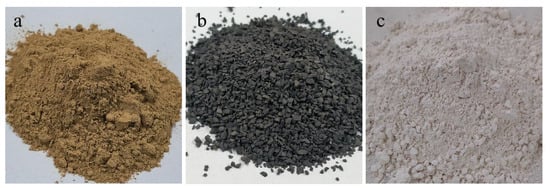

The test soil samples (as shown in Figure 1) were collected from a specific section of the Qinyang–Yichuan Expressway project. The project area contains poorly lithified Triassic and Triassic mudstone and sandy mudstone, with fractures filled with montmorillonite-rich materials that disintegrate easily upon water contact. The fractured rock mass exhibits a slippery texture when touched, demonstrating characteristic features of water-induced disintegration and dehydration-induced cracking. Soil samples were collected at depths of 1.0–1.5 m. The main physical properties after pre-treatment, including air-drying, crushing, and sieving, are listed in Table 1, The content of each component is shown in Table 2. The coal gangue powder used in the experiment consisted of particles from coal gangue along the project route (Figure 1), with its key physical properties detailed in Table 3. Elemental analysis of the coal gangue particles revealed its major components, as shown in Table 4. Five different coal gangue concentrations were applied: 0%, 5%, 10%, 15%, and 20%. The magnesium oxide was produced by Shanxi Yunsheng Chemical as light-magnesium oxide, with addition rates set at 4%, 6%, 8%, and 10%.

Figure 1.

Test materials: (a) expansive soil; (b) coal gangue; (c) magnesium oxide.

Table 1.

Basic physical properties of expansive soil.

Table 2.

Main elements contained in expansive soil.

Table 3.

Basic physical properties of coal gangue.

Table 4.

Main elements contained in coal gangue.

2.2. Methods

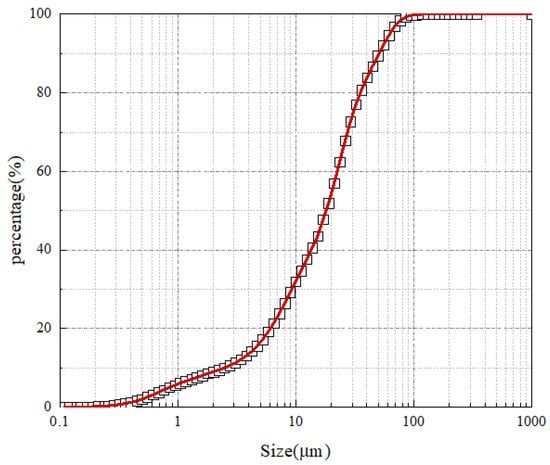

Using the laser particle size analyzer, the particle size curve of the test expansive soil is shown in Figure 2. According to Figure 2, d10 (the mass of soil particles smaller than this particle size accounting for 10% of the total mass of soil particles) = 0.002 mm, d30 (the mass of soil particles smaller than this particle size accounting for 30% of the total mass of soil particles) = 0.009 mm, d60 (the mass of soil particles smaller than this particle size accounting for 60% of the total mass of soil particles) = 0.022 mm, the unevenness coefficient and curvature coefficient Cu (coefficient of nonuniformity) = 11, and Cc (coefficient of curvature) = 1.84, indicating that the expansive soil has good gradation.

Figure 2.

Particle size curve of expansive soil.

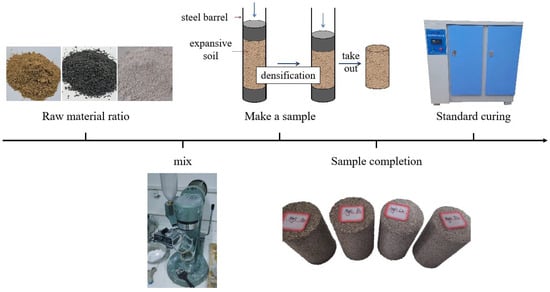

The soil improvement samples were prepared using different proportions of amendments, with the specific mixing ratios shown in Table 5. The sample preparation process is illustrated in Figure 3. Firstly, expansive soil, magnesium oxide, and coal gangue particles were accurately weighed according to the designated mix proportions and thoroughly mixed. The uniformly mixed improved soil was then poured into a mortar mixer, and water was added for mixing, with the water content controlled based on the optimum moisture content of the expansive soil. After mixing, the soil mixture was transferred into a molding mold to fabricate cylindrical specimens with a diameter of 50 mm and a height of 100 mm. The mold assembly consisted of a steel cylinder and steel end plates, and pressure was applied to the end plates to compact the soil into shape. Upon demolding, the specimens were carefully wrapped in plastic film to prevent moisture loss and subsequently placed in a standard curing chamber (temperature: 20 °C, relative humidity: 90%) for curing. After 28 days of curing, the specimens were removed for subsequent testing.

Table 5.

Sample preparation.

Figure 3.

Sample preparation process.

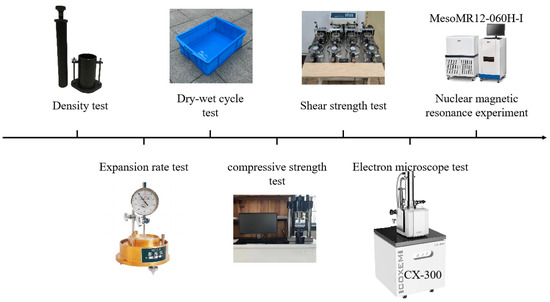

The testing procedure is shown in Figure 4. The uniformly mixed soil was placed into a light compaction apparatus to perform compaction tests, determining the maximum dry density and optimum moisture content of the improved soil under different mix proportions. For swell potential tests, specimens with a diameter of 61.8 mm and a height of 20 mm were used. These specimens were placed in a swell apparatus, which consisted of a consolidation ring, a displacement transducer, a lateral anti-swelling guide ring, and a water container, to measure the swell strain of the expansive soil upon immersion. During the wet–dry cycle tests, each cycle involved saturating the specimens by immersion for 24 h, followed by drying in a 40 °C environment until its mass stabilized (approximately 40 h). At the end of the 0, 1, 3, 5, 7, and 10th cycles, three unconfined compression test specimens and twelve direct shear test specimens were taken from each group, weighed, and their water contents determined before proceeding with the respective tests.

Figure 4.

Test flow.

Unconfined Compressive Strength (UCS) tests were conducted using a cement mortar tension-compression testing machine, capable of accurate load measurement. The tests were performed at a strain rate of 1 mm/min until specimen failure. The peak load was determined from the load–displacement curve, and the unconfined compressive strength was calculated. Direct shear tests were performed in accordance with the “Standard for Geotechnical Testing Methods” (GB/T 50123-2019) [25] using an electric quadruple direct shear apparatus. A shear rate of 0.8 mm/min was maintained during the test, which was terminated when the shear displacement reached 4 mm. The peak shear stresses under different normal stresses were obtained, and the cohesion and internal friction angle of the specimens were determined via linear fitting.

Microstructural analysis was conducted using a CX-300 (Beijing, China) scanning electron microscope (SEM) with a magnification range of 9 to 500,000×. Nuclear Magnetic Resonance (NMR) tests were performed using a MesoMR12-060H-I low-field NMR analyzer (Suzhou City, China) with a magnetic field strength of 0.3 T, to analyze the internal pore structure and moisture distribution characteristics of the specimens.

Nuclear magnetic resonance (NMR) analysis of porous media utilizes hydrogen protons in fluids as probes, primarily focusing on the transverse relaxation processes of hydrogen atoms [26]. In their natural state, hydrogen atoms possess intrinsic angular momentum (i.e., spin). When an RF pulse is applied to a hydrogen atom’s spin system, it transitions from a lower-energy state to a higher-energy state through nuclear magnetic resonance. Upon termination of the RF pulse, the nuclear spin system reverts to equilibrium through relaxation. The transverse relaxation time (T2) refers to the relaxation time of the macroscopic magnetization vector component perpendicular to the applied static magnetic field (X-Y plane). For rocks, the transverse relaxation process in pore fluids involves three mechanisms: free relaxation, surface relaxation, and diffusion relaxation [27].

where is the transverse surface relaxation time; is the transverse free relaxation time; is the transverse diffusion relaxation time.

Surface relaxation occurs at the contact interface between fluids and soil particles, influenced by soil properties. Free relaxation and diffusion relaxation processes are governed by fluid physical characteristics, magnetic field intensity, and the echo interval of CMPG pulse sequences. In comparison, these two processes are relatively weak. In geotechnical engineering applications involving Lf-NMR research, T2 can be approximated as equivalent to [27]:

where is the transverse surface relaxation strength; is the pore surface area; is the pore volume; is the shape factor; is the pore radius.

3. Results

3.1. Influence of Coal Gangue Content on Compactness and Expansion Rate

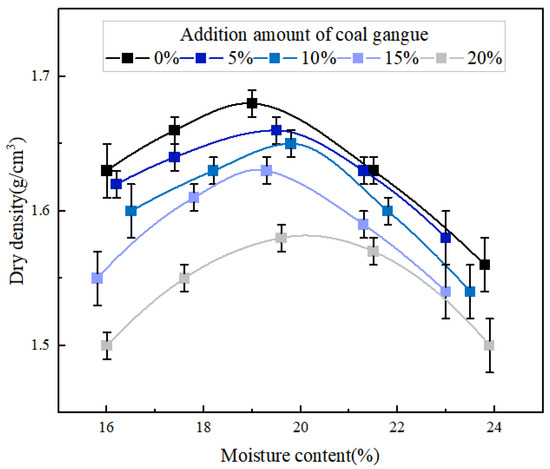

The compaction curves obtained with different coal gangue addition rates are shown in Figure 5. As the coal gangue content increased, the maximum dry density of the samples decreased from 1.68 g/cm3 in pure soil to 1.52 g/cm3 at the 20% coal gangue addition rate. This occurs because the particle size difference between the coal gangue and expansive soil particles is significant. At lower addition rates, larger coal gangue particles remain encapsulated within the expansive soil matrix, resulting in reduced overall density. However, as coal gangue content rises, its particles gradually interlock to form a skeletal structure. During this phase, the interlocking of larger coal gangue particles prevents the expansion soil particles from filling gaps between these skeletal contact points, leading to a more pronounced decrease in density.

Figure 5.

The compaction curves.

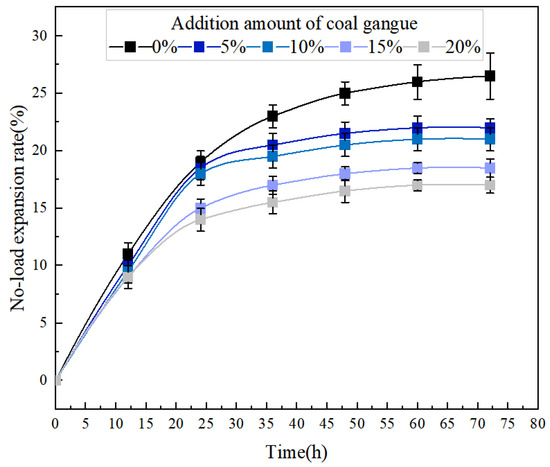

Figure 6 shows the unloading expansion rates of different coal gangue proportions. The results demonstrate that incorporating coal gangue effectively suppresses the unloading expansion rate of expansive soil. Within the 0–20% coal gangue range, higher additions resulted in lower stabilized rates. The unstabilized soil showed an unloading expansion rate of 25.9% after 60 h, while the stabilized soil with 20% coal gangue powder exhibited a rate of 18.05% after the same period, representing a 7.85% reduction. The unloading expansion rates remained stable at all tested proportions after 60 h, confirming successful completion of the trials. Notably, when coal gangue proportion exceeded 20%, the improvement became minimal with slight increases in rate, while the 20% addition achieved the lowest no-loading expansion rate.

Figure 6.

Influence of coal gangue content on expansion rate.

3.2. Influence of Coal Gangue and Magnesium Oxide on Unconfined Compressive Strength

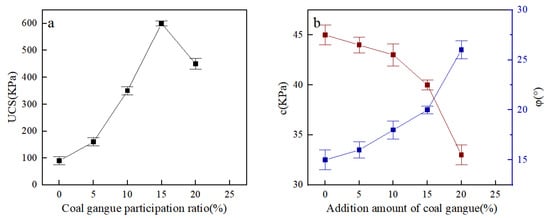

Figure 7a shows the unconfined compressive strength curves of expansive soil with varying coal gangue addition rates. As the coal gangue content increased, the unconfined compressive strength initially rose before decreasing. At 15% coal gangue addition, the strength peaked at 0.6 MPa, indicating that coal gangue formed a skeletal structure within the expansive soil. However, further increases in coal gangue content led to a decline in strength. This occurred because soil strength is governed by both the internal friction angle (φ) and cohesion (c). While coal gangue enhances the internal friction angle, it contributes minimally to cohesion enhancement. The reduction in fine particle proportion within expansive soil results in greater decreases in cohesive strength than the increase in the internal friction angle from coal gangue particles. An optimal coal gangue addition rate of 15% was observed. Excessive addition significantly reduced cohesive strength, as the coarse coal gangue particles disrupted the continuity of the fine-grained soil matrix, thereby compromising the uniform distribution of cohesive forces within the sample. The curves of internal friction angle and internal friction force obtained in the direct shear test (Figure 7b) under different coal gangue dosages also show that there was an optimal value of 15% coal gangue content. When the dosage was too high, the cohesion of the sample was significantly reduced, which is because more coal gangue particles divide the original fine particles into multiple regions, reducing the integrity of the cohesion distribution in the sample.

Figure 7.

Relationship between coal gangue content and strength: (a) relationship between unconfined compressive strength and coal gangue content; (b) relationship between cohesion and coal gangue content in internal friction angle.

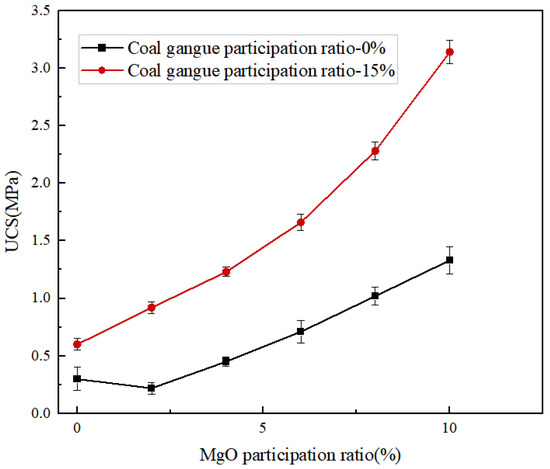

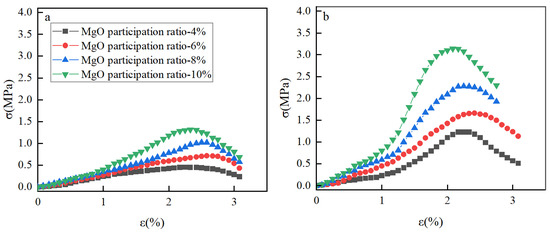

By testing the density and compressive strength of coal gangue-stabilized soil, we determined that 15% was the optimal coal gangue addition ratio. Four MgO concentrations (4%, 6%, 8%, and 10%) were combined with coal gangue to modify expansive soil samples, and their compressive strength was compared with that of direct MgO addition. Figure 8 shows the unconfined compressive strength of samples stabilized with MgO alone, 15% coal gangue, or both. The strength increased significantly with MgO addition. At 10% MgO content, the unconfined compressive strength reached 3.1 MPa, far exceeding the 0.07 MPa of untreated soil and 0.6 MPa of pure coal gangue. According to DB36/T 2169-2025 Technical Specification for the Application of Solidified Soil in Highway Engineering [28], the unconfined compressive strength of subbase of expressway and first-class highway is required to be 2.5–4.5 MPa under heavy traffic conditions. During the MgO addition process from 0% to 10%, the composite-stabilized soil showed a much faster strength growth rate compared to untreated soil. In contrast, when adding 10% cement to improve expansive soil, the unconfined compressive strength after 28 days of curing is about 1.2 MPa [29], which is very close to the unconfined compressive strength of expansive soil samples improved by adding only 10% magnesium oxide of 1.33 MPa. The unconfined compressive strength of the composite system of 0.4% basalt fiber and 6% cement is only 1.72 MPa [30], and that of composite stabilizer composed of 30% iron tailings and 10% carbide slag is only 2.9 MPa [31]. Obviously, the composite improvement effect of coal gangue and magnesium oxide is better. Figure 9 illustrates stress–strain curves at different MgO concentrations (0% and 15%). As the MgO content increased, the strain corresponding to peak strength decreased while overall brittleness increased. The addition of coal gangue introduced coarse particles into the expansive soil, improving its gradation. The framework formed by these coarse particles enhanced the cementing effect of MgO-hydrolyzed materials. With increasing MgO addition, the cementing substances gradually established stronger bonding structures from lower initial concentrations, leading to significant strength gains.

Figure 8.

Curve of intensity variation with MgO.

Figure 9.

Stress–strain curves at different MgO levels: (a) the content of coal gangue is 0%; (b) the content of coal gangue is 15%.

3.3. Distribution of Pore Size

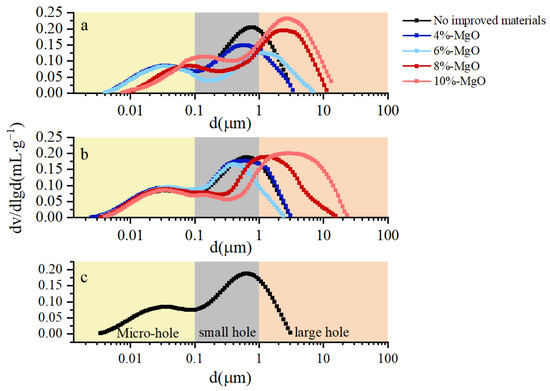

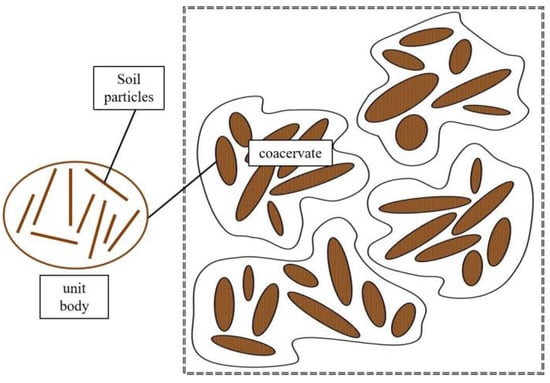

Through low-field nuclear magnetic resonance (LNR) analysis, T2 spectra of expansive soil samples were obtained. Based on Equation (2) and the T2 spectrum distribution, pore size distributions under different magnesium oxide addition levels were calculated. The dual-peak pore size distribution curve of this expansive soil is shown in Figure 10c. Typically, compacted expansive soil structures are shown in Figure 11: soil particles first form individual units through specific arrangements, which then aggregate into clusters. These clusters collectively constitute the macroscopic soil mass. Three types of pores exist in the soil structure—unit internal pores, cluster internal pores, and inter-cluster pores—classifying them as micropores, small pores, and macropores, respectively [27,32]. During preparation of stabilized expansive soil specimens, magnesium oxide is uniformly blended with the soil and mixed with water. Magnesium oxide tends to fill inter-cluster spaces. As it reacts with water and carbon dioxide to form binding materials, volume expansion occurs. However, since both individual units have low inherent strength and weak interconnections, the binding materials not only fill pores but also compress the soil particles within units, causing deformation and displacement of the structural units. When magnesium oxide was added to expansive soil, the pore size distribution curve of the samples exhibited distinct changes, as shown in Figure 10b. The addition of magnesium oxide caused varying degrees of alteration in micro-pores, small pores, and macropores. At 4% and 6% magnesium oxide content, the micro-pores remained relatively stable, while the porosity of small and macropores decreased significantly. With 8% and 10% magnesium oxide content, the micro-pores showed minimal change, but the macropore porosity increased markedly. This demonstrates that low magnesium oxide concentrations effectively filled interparticle voids and enhanced soil compaction. However, when the magnesium oxide content reached 8%, volume expansion from water absorption and its reaction with carbon dioxide to form basic magnesium carbonate disrupted the particle structure, causing internal microcracks. The expansive soil particles exhibited a narrow size range, with most having a particle size around 0.02mm. This limited particle span results in slight irregularities in cementitious materials produced by magnesium oxide carbonization. Variations in reaction rates and spatial distribution of these materials may lead to the misalignment of pore structures, ultimately altering porosity characteristics.

Figure 10.

Pore size distribution curves: (a) composite improvement with coal gangue and MgO; (b) MgO improvement; (c) no improved materials.

Figure 11.

Schematic diagram of particle arrangement in expansive soil.

Coal gangue particles possess high strength and significantly larger particle sizes compared to expansive soil particles. When 15% coal gangue is added to expansive soil, the coal gangue particles form an interconnected framework within the soil matrix. The volume expansion from magnesium oxide reactions cannot displace this framework structure, allowing the cementitious material formed by expansive soil–magnesium oxide to fill the interstitial spaces between coal gangue particles. Figure 10a shows the pore distribution curve of magnesium oxide-stabilized soil with 15% coal gangue content. The results demonstrate that the magnesium oxide-induced cementitious material effectively fills the interstitial spaces between soil particles. Notably, the enhanced pore filling efficiency within the stabilized soil is attributed to the structural constraints provided by the coal gangue framework, surpassing that achieved with magnesium oxide alone.

3.4. Effect of Dry and Wet Cycle on Unconfined Compressive Strength

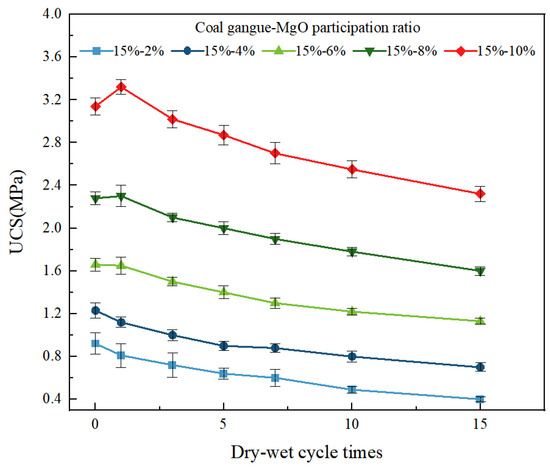

During the wet–dry cycle, expansive clay undergoes volume expansion and contraction. Untreated soil samples disintegrated when soaked in water. The stabilized materials containing coal gangue and MgO formed internal bonding structures that stabilized the soil and enhanced its water resistance. However, these structural improvements can still be compromised by moisture fluctuations, which also displace soil particles and degrade the overall structure of the stabilized material.

Figure 12 illustrates the relationship between the unconfined compressive strength (UCS) of composite-stabilized samples and the number of wet–dry cycles. As the number of cycles increased, UCS gradually decreased. The trend analysis reveals three distinct phases: In the initial cycles, samples with lower MgO content initially showed reduced UCS, while those with higher MgO content demonstrated enhanced strength. Specifically, the 15% coal gangue–10%MgO mixture exhibited an approximately 5% strength gain. This occurred because residual MgO and coal gangue components remained reactive during curing. During subsequent cycles, periodic moisture changes and temperature increases caused continuous reactions of carbonate and aluminate active substances in coal gangue, mitigating the deterioration effects of wet–dry cycles. This led to a phenomenon known as autogenous healing, which resulted in minimal strength loss or even a slight strength gain. Conversely, samples with 10%MgO alone experienced a 22% decrease from 1.43 MPa to 0.93 MPa after one cycle, with continued decline thereafter. As cycles progressed, the remaining active substances in coal gangue became exhausted, leading to more pronounced deterioration effects. By the third cycle, UCS across all MgO levels showed significant reduction with increasing cycles. In the third stage, the reduction rate of unconfined compressive strength slowed down with the progression of dry and wet cycles. At this time, the internal structure of the sample gradually stabilized, the sensitivity decreased, and the deterioration effect of dry and wet cycles on the internal structure gradually weakened.

Figure 12.

Unconfined compressive strength with wet–dry cycle times.

The ratio of wet–dry cycle-stabilized unconfined compressive strength () to 28-day cured unconfined compressive strength () is defined as the wet–dry cycle stability coefficient , where . As the cycles progressed, the value gradually decreased. After 15 cycles, the 15% coal gangue–2%MgO-stabilized soil exhibited a θ of 0.43, indicating over 50% strength loss and poor stability. The stability coefficient increased with the MgO dosage from 0.43 to 0.74, though the growth rate slowed with higher MgO content. At high MgO levels, early MgO reactions accelerated. Subsequent reactions from coal gangue’s active components disrupted previously formed cementitious structures, creating microcracks that weakened the strength. These microcracks made the soil more susceptible to deterioration during wet–dry cycles.

Table 6 presents the unconfined compressive strength of soils treated with different stabilizing agents and the retained strength after wet–dry cycles. As shown, the composite stabilizer with 30% iron tailings +10% carbide slag, with a total incorporation rate of 45%, exhibited approximately 40% strength reduction after 15 wet–dry cycles. The sample with 0.2% grass roots showed strength approaching 0 MPa after just five cycles, indicating poor durability. The composite system with 0.4% basalt fiber +6% cement achieved an unconfined compressive strength of only 1.72 MPa, attributed to potential poor fiber dispersion within the soil matrix or weak bonding at the fiber–cement–soil interface transition zone, leading to low stress transfer efficiency.

Table 6.

Comparison of improved soil with different materials.

3.5. Microstructural Analysis

During the initial mixing of coal gangue with expansive soil, ion exchange and agglomeration occur. The presence of high-valent cations, like Ca2+ and Mg2+, in coal gangue triggers an ion exchange process with low-valent cations, such as K+ and Na+, on soil surfaces [36,37]. This exchange between high-valent and low-valent cations on clay particles reduces the thickness of water films adsorbed by soil particles. The resulting ion exchange process decreases active substances in the soil, thereby enhancing its stability [38]. Figure 13a shows the microscopic state of coal gangue surfaces without bound materials, appearing relatively smooth. Figure 13b illustrates the reaction between active substances in coal gangue and those in MgO and expansive soil, resulting in surface adhesion. It can be observed that MgO hydration products encapsulate and adhere to coal gangue particles, creating interconnections between coal gangue and soil particles through the formation of bound materials. Figure 13c,d reveal cracks and pores at the interface between cemented materials and coal gangue particles. These microcracks arise from asynchronous ion reactions during curing and moisture cycles, as well as the carbonation process of MgO. The volume instability of MgO hydration products subsequently generates splitting forces within pre-formed bound materials, leading to microcrack development in MgO-stabilized soil matrix. The formation of these microcracks affects the overall strength, durability, and performance of MgO–soil mixtures. The framework structure formed by coal gangue, combined with its reactive components, expansive soil, and cementitious products generated through reactions with MgO, creates a network-like configuration. The alteration structures induced by the incorporation of coal gangue and MgO reduce the contact probability between expansive soil particles and water. This diminished interaction enhances soil strength and water stability. By minimizing particle–water contact, the system effectively reduces both quantitative variations and water-induced swelling potential, thereby improving overall soil stability and structural integrity.

Figure 13.

Microstructure of samples: (a) coal gangue surface; (b) cementing material wraps coal gangue particles; (c) pores exist at the edge of cementing material; (d) micro-cracks exist in cemented materials.

4. Conclusions

In this paper, the research object is expansive soil, and the strength characteristics and improvement micro-mechanism of expansive soil under different addition rates are revealed through coal gangue–MgO composite improvement tests. The main conclusions are as follows:

- (1)

- The particle diameter of coal gangue is much larger than that of expansive soil. When mixed with expansive soil, the much larger coal gangue particles form an interlocking skeleton within the finer soil matrix, effectively inhibiting the overall swelling of the composite material.

- (2)

- Compared with coal gangue alone, the MgO–coal gangue composite-improved samples can react with the carbonate, aluminate, and other active substances in the coal gangue due to the reactive activity of MgO. The synergistic effect of these two materials significantly improved the soil strength, increasing it from 0.6 MPa (for soil stabilized with only 15% coal gangue) to 3.1 MPa (for soil stabilized with 15% coal gangue and 10% MgO). We think that 15% coal gangue and 10% magnesium oxide can effectively improve the engineering application effect of expansive soil.

- (3)

- After 15 wet–dry cycles, the strength of the stabilized expansive soil decreased by 26–57%. With the increase in MgO content, the decrease in strength was reduced. The active substances contained in the wet–dry cycle continued to react, which offset some of the strength loss caused by the wet–dry cycle.

- (4)

- The cementing material produced by the hydration of MgO envelops the expansive soil particles and connects the coal gangue particles, forming a three-dimensional structure composed of coal gangue skeleton, MgO connections, and expansive soil particle filling. However, the hydrated MgO products near the surface of the coal gangue particles will produce fine cracks due to the delayed reaction of some substances.

Author Contributions

Conceptualization, X.Q. and W.L.; methodology, X.Q.; software, X.Q.; validation, X.Q., Q.Y. and B.P.; formal analysis, X.Q.; investigation, X.Q., Q.Y. and B.P.; resources, J.Z.; data curation, X.Q.; writing—original draft preparation, X.Q.; writing—review and editing, X.Q. and W.L.; visualization, X.Q.; supervision, W.L.; project administration, W.L.; funding acquisition, W.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the General Project of the Xizang Natural Science Foundation (XZ202501ZR0114), the 2024 Jiangsu Province Construction System Research Project (2024ZD052), the Jiangsu Province Industry University Research Project (FZ20241807), and the Xizang Civil Water Conservancy and Electric Power Engineering Technology Research Center Open Project (XZA202405CHP2008B).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Xiaoyan Qin, Qiangzhen Yan and Bo Peng were employed by Gansu Engineering Geology Research Institute. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Li, J.D.; Zhang, Y.J.; Wang, X.; Jiang, D.J.; Wang, X.G. Research situation and prospect of expansive soil solidified by new soil stabilizer. Mater. Rep. 2023, 37, 21030148-11. [Google Scholar] [CrossRef]

- Wang, F.; Kong, L.; Zhou, Z. Study on pore structure and mechanical property of expansive soil under different dehydration conditions. Appl. Sci. 2022, 12, 5981. [Google Scholar] [CrossRef]

- Shi, B.X.; Zheng, C.F.; Wu, J.K. Research progress on expansive soil cracks under changing environment. Sci. World J. 2014, 2014, 816759. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Zhai, J.Y.; Cai, X.Y. Strength characteristics and slope stability of expansive soil from Pingdingshan, China. Adv. Mater. Sci. Eng. 2018, 2018, 3293619. [Google Scholar] [CrossRef]

- Fuerhaiti, A.; Hou, T.; Huang, R.; Li, J.; Fan, L.; Bao, W. Laboratory Study of Dynamic Durability and Material Properties of Bio-Cemented Sand for Green Road Base Applications. Materials 2025, 18, 4178. [Google Scholar] [CrossRef]

- Afaq, A.; Syed, K.; Numan, A.; Umair, A.; Adnan, A.; Muhammad, J. Feasibility of utilizing recycled concrete aggregate blended with waste tire rubber and drywall waste as pavement subbase material. J. Mater. Cycles Waste Manag. 2024, 26, 2278–2293. [Google Scholar] [CrossRef]

- Zhang, X.; Geng, J.; Hu, G.; Su, L.; Li, T.; Wang, Y.; Zheng, C.; Li, W.; Zhang, X. Toughening characteristics of rubber granule-improved alkali-activated slag-stabilized aeolian sand. Constr. Build. Mater. 2024, 6, 137059. [Google Scholar] [CrossRef]

- Wang, B.; Jia, C.; Wang, G.; Zhang, H. Study on cementation effect of tailing sand by magnesium oxide combined with microorganism or by MICP. Ind. Constr. 2022, 52, 79–83. [Google Scholar] [CrossRef]

- Yao, Y.; Wu, G.; Yang, K.; Zhang, H.; Qi, J.; Hu, Y.; Wang, J.; Zhou, H. Tensile performance of pre-cracked UHPC under the coupled actions of sustained loading and corrosive media. Cem. Concr. Compos. 2025, 12, 105915. [Google Scholar] [CrossRef]

- Ilman, B.; Balkis, A. Sustainable biopolymer stabilized earthen: Utilization of chitosan biopolymer on mechanical, durability, and microstructural properties. J. Build. Eng. 2023, 76, 107220. [Google Scholar] [CrossRef]

- Lin, B.; Liu, J. Estimating coal production peak and trends of coal imports in China. Energy Policy 2010, 38, 512–519. [Google Scholar] [CrossRef]

- Wang, M.; Liu, H.; Xie, Y.; Gao, S.; Ding, J.; Wang, Y. Study of carbon dioxide capture by modified magnesium oxide. Ion Exch. Adsorpt. 2021, 37, 314–322. [Google Scholar] [CrossRef]

- Wang, L.; Liu, S.; Cai, G.; Tang, H. Permeability properties of carbonated reactive MgO-stabilized soils. Chin. J. Geotech. Eng. 2018, 40, 953–959. [Google Scholar] [CrossRef]

- Mohamed, H.; Abdullahi, A.M.; Umair, A.; Hammad, R.K.; Asad, H. Magnesia-based binders for stabilizing and improving soft soils. Comput. Aided Chem. Eng. 2024, 53, 1381–1386. [Google Scholar] [CrossRef]

- Liu, S.; Cao, J.; Cai, G. Microstructural mechanism of reactive magnesia carbonated and stabilized silty clays. Rock Soil Mech. 2018, 39, 1543–1552+1563. [Google Scholar] [CrossRef]

- Wu, S.; Jia, C.; Wang, G. Experimental study on microbial-active magnesia solidified red clay. Yangtze River 2022, 53, 167–172. [Google Scholar] [CrossRef]

- Li, W.; Sun, Z.; Zhuang, Y.; Xiao, H.; Fu, Z.; Zhou, X. Mechanical and swelling properties, as well as micro-mechanism of sulfate-bearing soil stabilized by magnesium oxide and cement. Chinese J. Geotech. Eng. 2024, 46, 1840–1848. [Google Scholar] [CrossRef]

- Li, Q. Research progress on properties and comprehensive utilization of coal gangue. Appl. Chem. Ind. 2023, 52, 1576–1581. [Google Scholar] [CrossRef]

- Liu, Y.; Qi, X.; Luo, D.; Zhang, Y.; Qin, J. Detection of spontaneous combustion areas of coal gangue dumps and comprehensive governance technologies: A case study. ACS Omega 2023, 8, 47690–47700. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, X.; Liu, T. Strength properties of solidified expansive soil with coal gangue and its pore structure characterization under condition of optimum dosage. Trans. Chin. Soc. Agric. Eng. 2018, 34, 267–274. [Google Scholar] [CrossRef]

- Zhang, Y.; Kng, X.; Guo, L. Engineering properties of expansive soil improved by lime and coal gangue. Bull. Chin. Ceram. Soc. 2015, 34, 2720–2724+2730. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Y.; Yin, X. Microstructure characteristics of expansive soil with coal gangue based on Menger sponge model. Trans. Chin. Soc. Agric. Eng. 2020, 36, 124–130. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, Q.; Zhang, Z.; Jiang, F.; Luo, S.; Gao, S. Research on the activity excitation and mechanism of coal gangue-assisted cementitious materials. Cement 2025, 2, 15–25. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, L.; Yao, L.; Meng, F.; Li, Z.; Effects of flux CaO and MgO on the Properties and Pore Structure of Coal Gangue Based Ceramic Foams. Clean Coal Technol. 2025. Available online: https://link.cnki.net/urlid/11.3676.td.20250507.1757.016 (accessed on 23 November 2025).

- GB/T 50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Jia, H.; Ding, S.; Wang, Y.; Zi, F.; Sun, Q.; Yang, G. An NMR-based investigation of pore water freezing process in sandstone. Cold Reg. Sci. Technol. 2019, 168, 102893. [Google Scholar] [CrossRef]

- DB36/T 2169-2025; Technical Specification for Application of Solidified Soil in Highway Engineering. Jiangxi Provincial Administration for Market Regulation: Nanchang, China, 2025.

- Liang, S.; Wang, Y.; Feng, D. Experimental Study on Strength and Dry–Wet Cycle Characteristics of South China Coastal Soft Soil Solidified by Cement Collaborating Sand Particles. Appl. Sci. 2023, 13, 8844. [Google Scholar] [CrossRef]

- Chen, J.; Mu, J.; Chen, A.; Long, Y.; Zhang, Y.; Zou, J. Experimental Study on the Properties of Basalt Fiber–Cement-Stabilized Expansive Soil. Sustainability 2024, 16, 7579. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Fu, P.; Shi, J. Mechanical Properties and Durability Performance of Low Liquid Limit Soil Stabilized by Industrial Solid Waste. Materials 2025, 18, 469. [Google Scholar] [CrossRef]

- Westphal, H.; Surholt, I.; Kiesl, C.; Thern, H.F.; Kruspe, T. NMR measurements in carbonate rocks: Problems and an approach to a solution. Pure Appl. Geophys. 2005, 162, 549–570. [Google Scholar] [CrossRef]

- Ma, Q.; Wu, N.; Xiao, H.; Li, Z.; Li, W. Effect of Bermuda grass root on mechanical properties of soil under dry–wet cycles. Bull. Eng. Geol. Environ. 2021, 80, 7083–7097. [Google Scholar] [CrossRef]

- Wang, G.; Kong, X.; Zhang, Y.; Zhao, Q.; Feng, X. Stability and Micro-mechanisms of Lignin-Improved Soil in a Drying-Wetting Environment. KSCE J. Civ. Eng. 2022, 26, 3314–3324. [Google Scholar] [CrossRef]

- Ma, X.; Liu, Y.; Yin, W.; Wang, X.; Guo, S. Experimental Study on Strength and Microstructure of Loess Improved by CG-2 Curing Agent and Cement. Buildings 2024, 14, 877. [Google Scholar] [CrossRef]

- Zhang, J. Alkali-Excited Gangue Geopolymer Properties Study and Microanalysis; Inner Mongolia Agricultural University: Inner Mongolia, China, 2024. [Google Scholar] [CrossRef]

- Jijo, J.; Sivapriya, V.; Eyo, E. Stress-Strain Characteristics and Mineralogy of an Expansive Soil Stabilized Using Lime and Phosphogypsum. Appl. Sci. 2023, 13, 123. [Google Scholar] [CrossRef]

- Armistead, S.J.; Smith, C.C.; Staniland, S.S. Sustainable biopolymer soil stabilisation: The effect of microscale chemical characteristics on macroscale mechanical properties. Acta Geotech. 2022, 18, 3213–3227. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).