Abstract

The paper primarily focuses on the control strategy of an electric dump truck equipped with an M100 methanol range extender. In response to the significant adverse impact of the constant power control strategy on the lifespan of power batteries and the large rotational speed fluctuations of range extenders under the power-following control strategy, a constant-speed and variable-torque range extender control strategy based on the rule-based control strategy is proposed. This strategy enables power following within the range of 70 kW to 130 kW and fixed-point operation at 50 kW and 150 kW. Through co-simulation using AVL Cruise and MATLAB R2022b/Simulink, the results indicate that under the China Heavy-duty Commercial Vehicle Test Cycle-Dynamic (CHTC-D), with an average vehicle speed of 23.19 km/h, the constant-speed and variable-torque range extender control strategy achieves a higher methanol saving rate compared to both the constant power control strategy and the power-following control strategy, thereby demonstrating better fuel economy. The methanol consumption per 100 km for the dump truck using the constant power control strategy, the power-following control strategy, and the constant-speed and variable-torque control strategy are 62.89 L, 64.49 L, and 62.53 L, respectively. Compared with the same type of diesel range-extended electric dump truck, its fuel usage cost has a significant advantage.

1. Introduction

The range-extended electric dump truck is a type of hybrid dump truck. The range extender, which consists of an engine and a generator, does not directly drive the vehicle but only provides electrical energy for the drive motor and power battery, and can well make up for the shortcoming of the short driving range of pure electric dump trucks [1]. Dump trucks are characterized by large total mass, high power demand, and long continuous working hours. Combining the structural advantages of range-extended electric dump trucks with the clean, efficient, and low-cost benefits of methanol fuel, using methanol engines as the power source for the range extender is of great significance for reducing carbon emissions in the transportation sector and enhancing cost-effectiveness in industries such as construction.

For the M100 methanol range-extended electric dump truck, the effectiveness of the control strategy directly impacts the vehicle’s performance, fuel economy, and consequently its emissions. Considering the differences in characteristics between methanol engines and traditional fuel engines [2], as well as the complex working environment of dump trucks, the control strategy for the M100 methanol range-extended electric dump truck must ensure good fuel economy under various operating conditions, maximize the structural advantages of the range-extended electric dump truck, and reasonably distribute energy between the range extender and power battery on the premise of meeting the overall vehicle power demand, so as to achieve efficient utilization of the vehicle’s total energy. Thus, it is necessary to develop a reasonable control strategy for the range-extended electric dump truck.

Different control strategies can have varying degrees of impact on vehicle performance. The control strategies for range-extended power systems can be divided into the rule-based control strategy and the optimization-based control strategy [3].

The rule-based control strategy primarily sets different control parameters and fixed thresholds based on the performance parameters of the power system and the engineering experience of the designer to control and switch between different operating states of the vehicle. The main control variables include the state of charge (SOC) of the power battery, the power demand of the vehicle, and real-time vehicle speed. Rule-based control strategies can generally be divided into four types: constant power control strategy, power-following control strategy, multi-point control strategy, and fuzzy control strategy [4,5,6,7].

Liu et al. [8] conducted a comparative analysis of the fuel economy of the M100 methanol range extender using constant power control, multi-point control, and fuzzy control strategies under four different test cycles (NEDC, WLTC, CLTC-P, TYDC) with respect to its actual performance. Liu et al. [9] adopted a multi-point control strategy to reduce the operating time of the range extender, which improved the energy consumption and emissions of the entire vehicle while slowing down the degradation rate of the power battery capacity. Yang et al. [10] coordinated the power battery with the supercapacitor, and under the power-following control strategy, this coordination reduced the vehicle’s fuel consumption by 11.33% while effectively extending the lifespan of the power battery. Wang et al. [11] proposed a range extender power-following control strategy based on the particle swarm optimization (PSO) algorithm, which enables a better balance among the vehicle’s fuel economy, emissions, and power battery lifespan. Liu et al. [12] proposed a range extender power-following control strategy based on the particle swarm optimization (PSO) algorithm, which enables a better balance among the vehicle’s fuel economy, emissions, and power battery lifespan. Altun et al. [13] proposed a mathematical model for a power-splitting hybrid electric vehicle power system and validated the model’s accuracy using a rule-based control strategy under UDDS cycle conditions. Zhong et al. [14] proposed that the power-following control strategy would also activate the range-extending operation when the driving motor has low power demand, which is not conducive to emissions and economy. Nie et al. [15] developed an adaptive fuzzy energy management strategy for extended-range electric vehicles (EREV) that integrates deep learning. In the CLTC-P cycle, this strategy achieved 11.9% lower fuel consumption compared to conventional fuzzy approaches.

The rule-based control strategies do not require complex system calculations, have low dependence on sensors, feature controllable costs and strong practicality, and can ensure stable operation of vehicles under complex working conditions; however, they are highly dependent on engineering experience, and the rationality of the rules has a significant impact on the fuel economy of the entire vehicle.

The optimization-based control strategies achieve optimal vehicle fuel economy and offer advantages in improving fuel efficiency and optimizing power distribution by defining a vehicle energy optimization objective function and solving for the optimal parameter solutions via various optimization algorithms, which can be divided into global optimization control strategy and instantaneous optimization control strategy [16,17,18,19].

Manfredi et al. [20] aimed for the most effective use of overall vehicle fuel and power battery energy, developing a global optimal control strategy for range-extended electric light trucks offline, solving for optimal control parameters using dynamic programming, and studying the impact of power battery types and qualities on control strategies. Niu et al. [21] proposed a fuzzy control strategy for extended-range electric vehicles (EREVs) based on a global optimization algorithm, which takes fuel economy as the optimization objective and uses the particle swarm optimization (PSO) algorithm to optimize the vehicle’s power components and membership function parameters, thereby achieving a globally optimal energy distribution for EREVs. Gao et al. [22] proposed a global optimization control strategy considering real-time operating condition feedback, which possesses the characteristics of both global and instantaneous optimization control strategies and achieves both globally optimal and real-time optimal energy distribution. Yang et al. [23] proposed an adaptive real-time optimal control strategy based on the Equivalent Consumption Minimization Strategy (ECMS), which updates the equivalent factor in real time using the vehicle’s powertrain, navigation, and geographic location information, thereby protecting the lifespan of the power battery and achieving optimal power distribution. Wang et al. [24] proposed a real-time optimal control method based on range extender switching system optimization and vehicle energy management optimization, and adopted the Nondominated Sorting Genetic Algorithm II (NSGA-II) to optimize the control parameters. Yao et al. [25] proposed a quadratic programming-based analytical solution method for the equivalent factor in the ECMS control strategy, simplifying the process of solving for the equivalent factor and establishing an adaptive real-time updating rule for the SOC of the power battery to correct the impact of parameter errors during vehicle operation.

The optimization-based control strategies rely excessively on precise system models and real-time vehicle driving data, demanding high accuracy from sensors for battery state estimation, driving condition prediction, etc. Their optimization algorithms struggle to achieve real-time energy control, and frequent adjustments to the range extender’s operating points may compromise the reliability of the vehicle’s powertrain. Therefore, such strategies are still in the initial verification stage and have not yet been widely applied in engineering practice.

Starting from engineering practice, aiming at the problems existing in the constant power control strategy and power-following control strategy, a constant speed and variable torque control strategy based on the rule-based control strategy for the extended-range electric dump truck fueled with M100 methanol is proposed to ensure the dump truck has favorable fuel economy. The paper is organized as follows. In Chapter 2, the basic parameters and performance indicators of the vehicle are determined based on the usage environment and performance requirements of the dump truck, and the vehicle’s power system is established. In Chapter 3, based on the experimental performance of the range extender, constant power control strategy, power-following control strategy, constant speed and variable torque control strategy, and braking energy recovery strategy are developed. In Chapter 4, the AVL Cruise vehicle model and the MATLAB R2022b/Simulink control model are integrated to establish a complete vehicle power simulation model, and the results of the vehicle power matching are simulated and verified, analyzing the fuel economy of the control strategies under different driving cycles.

2. Power System Design for Range-Extended Electric Dump Trucks

2.1. Vehicle Power System

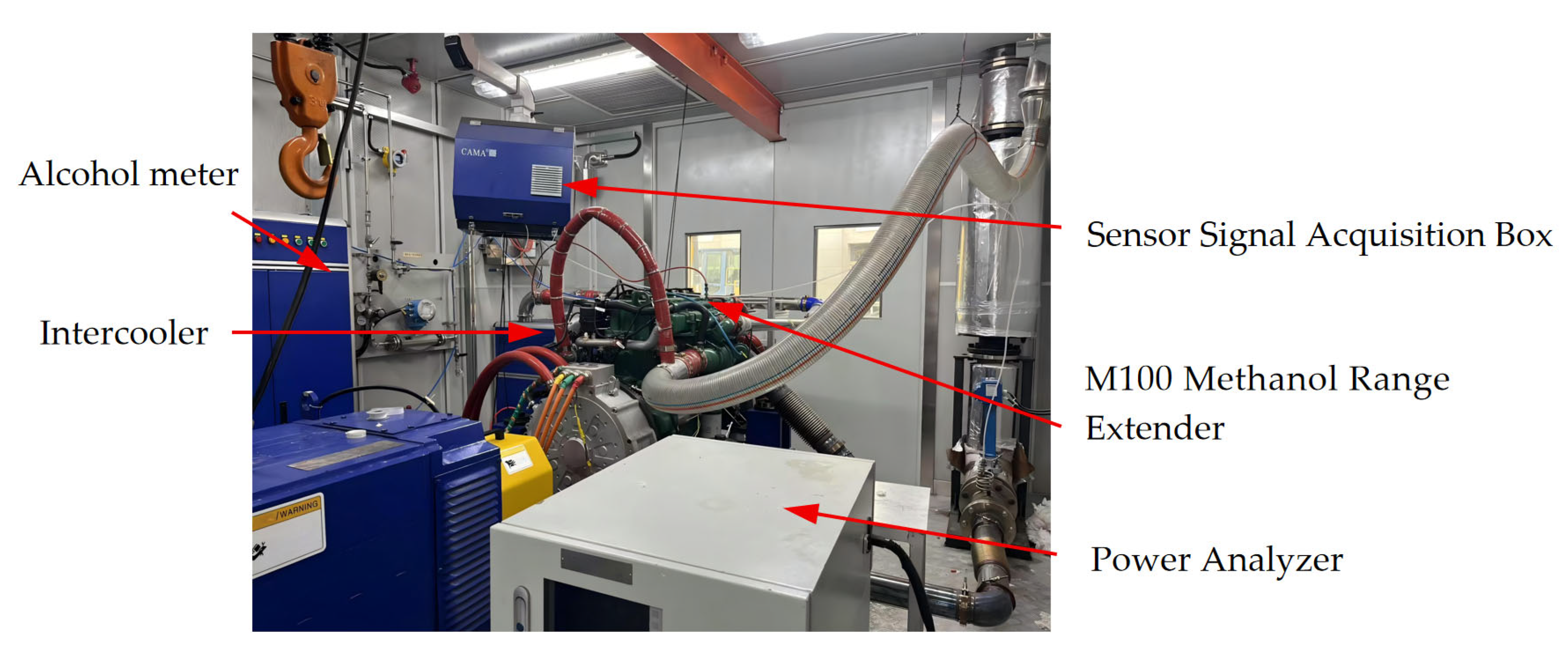

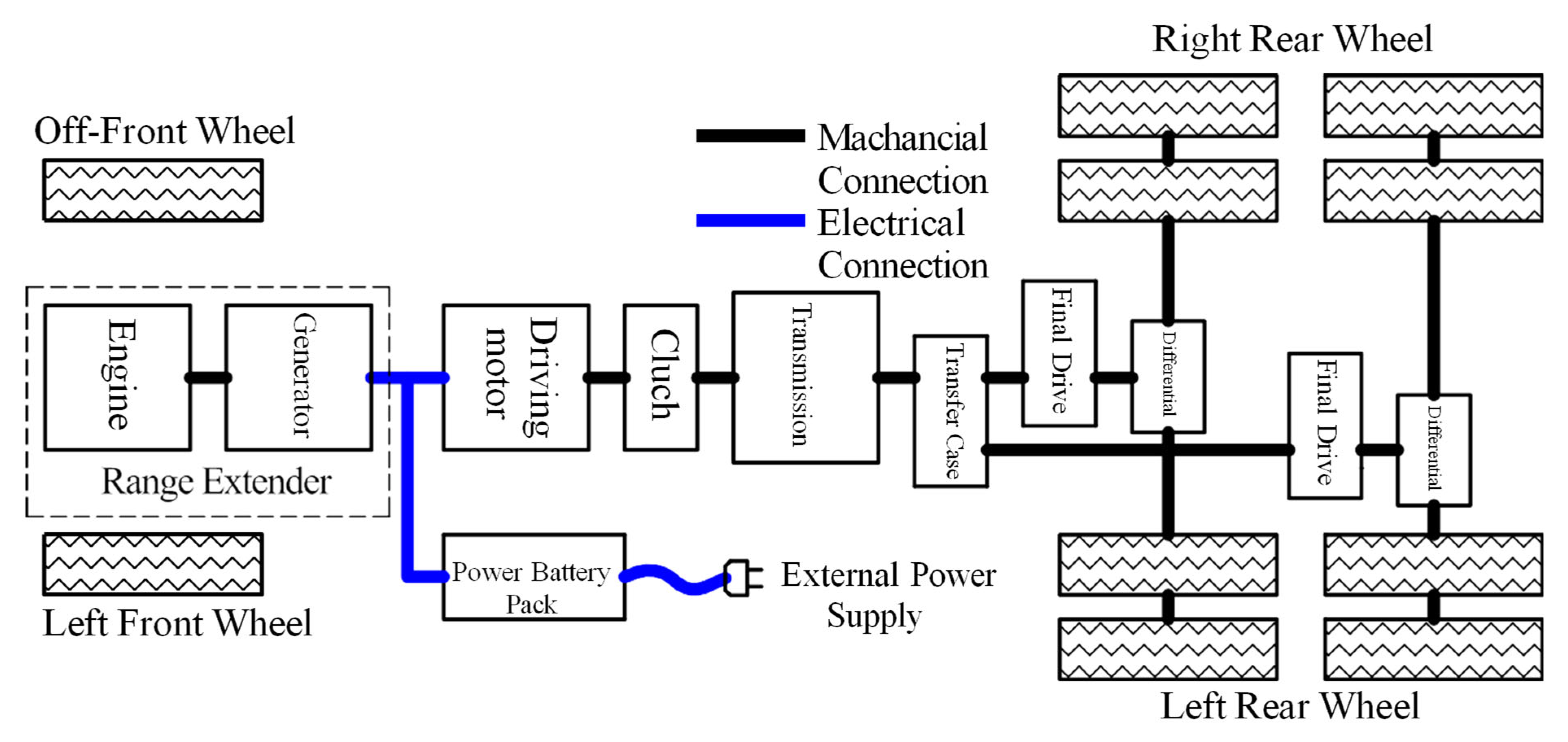

In this paper, the range extender of the dump truck is composed of an M100 methanol engine and a permanent magnet synchronous generator (PMSG), which is illustrated in Figure 1.

Figure 1.

M100 Methanol Range Extender.

The M100 methanol engine is modified from the prototype of an inline six-cylinder natural gas engine, whose primary technical specifications are summarized in Table 1.

Table 1.

Main Technical Parameters of the M100 Methanol Engine.

The basic parameters of the PMSG are shown in Table 2.

Table 2.

Basic Parameters of the PMSG.

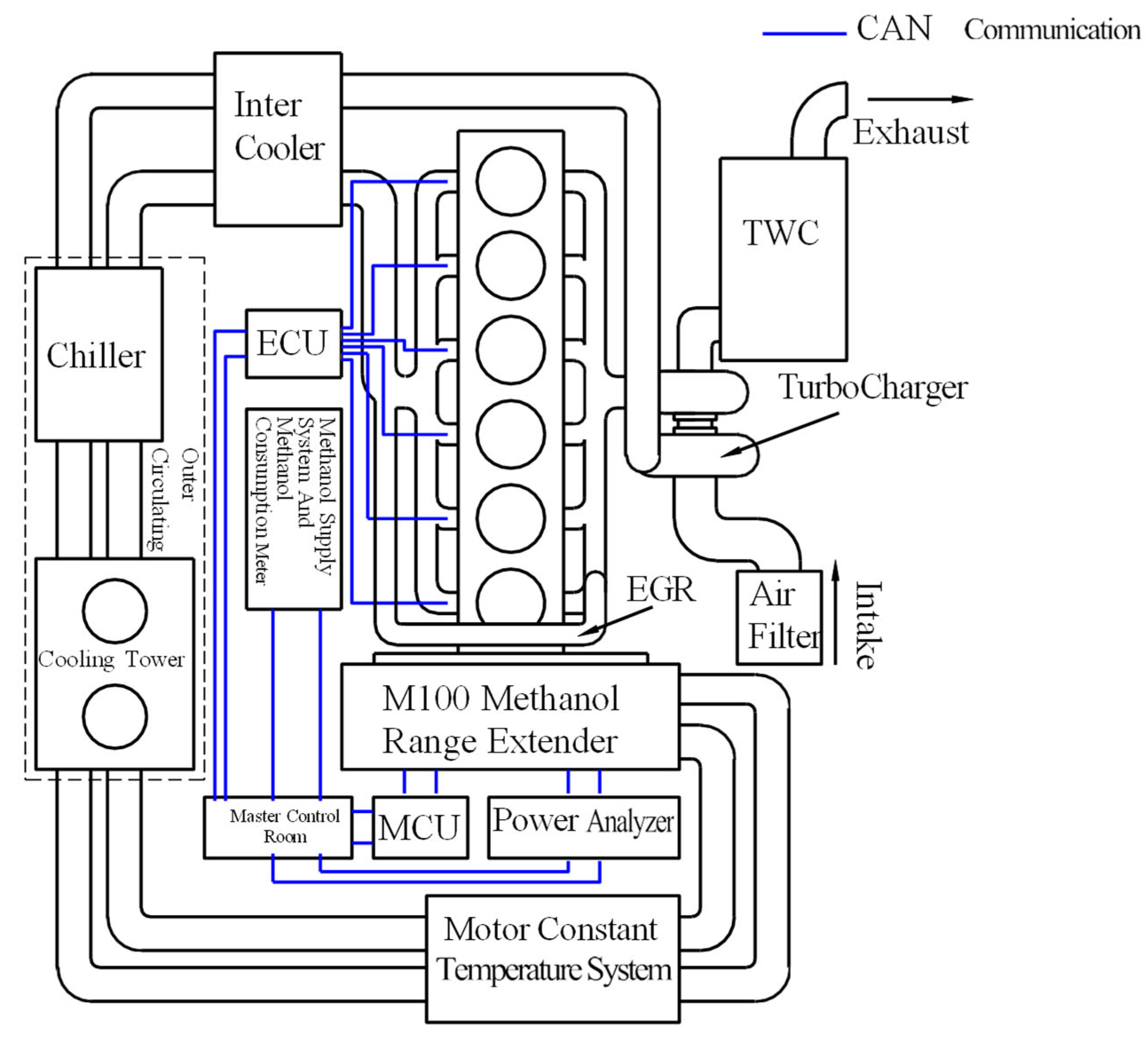

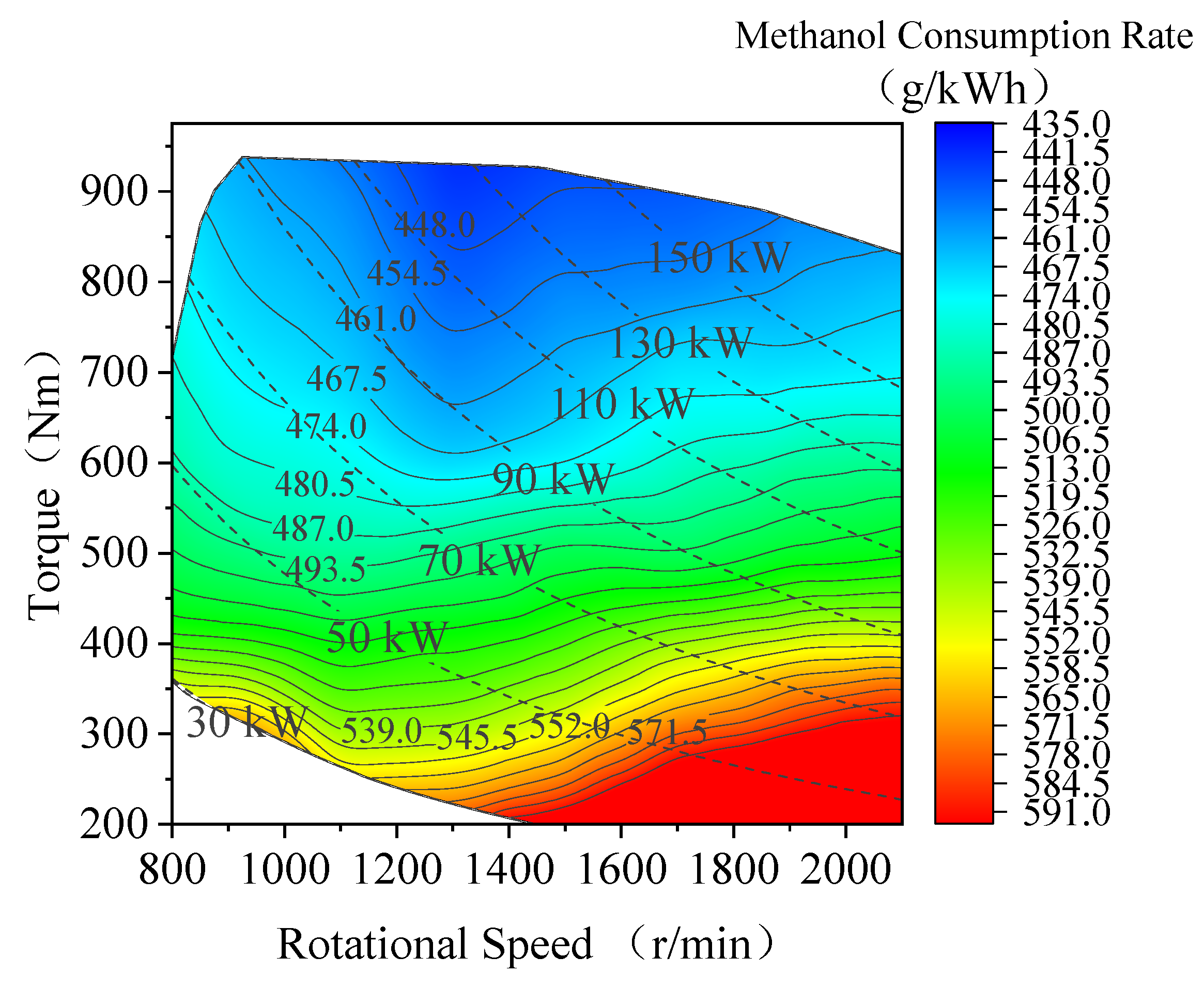

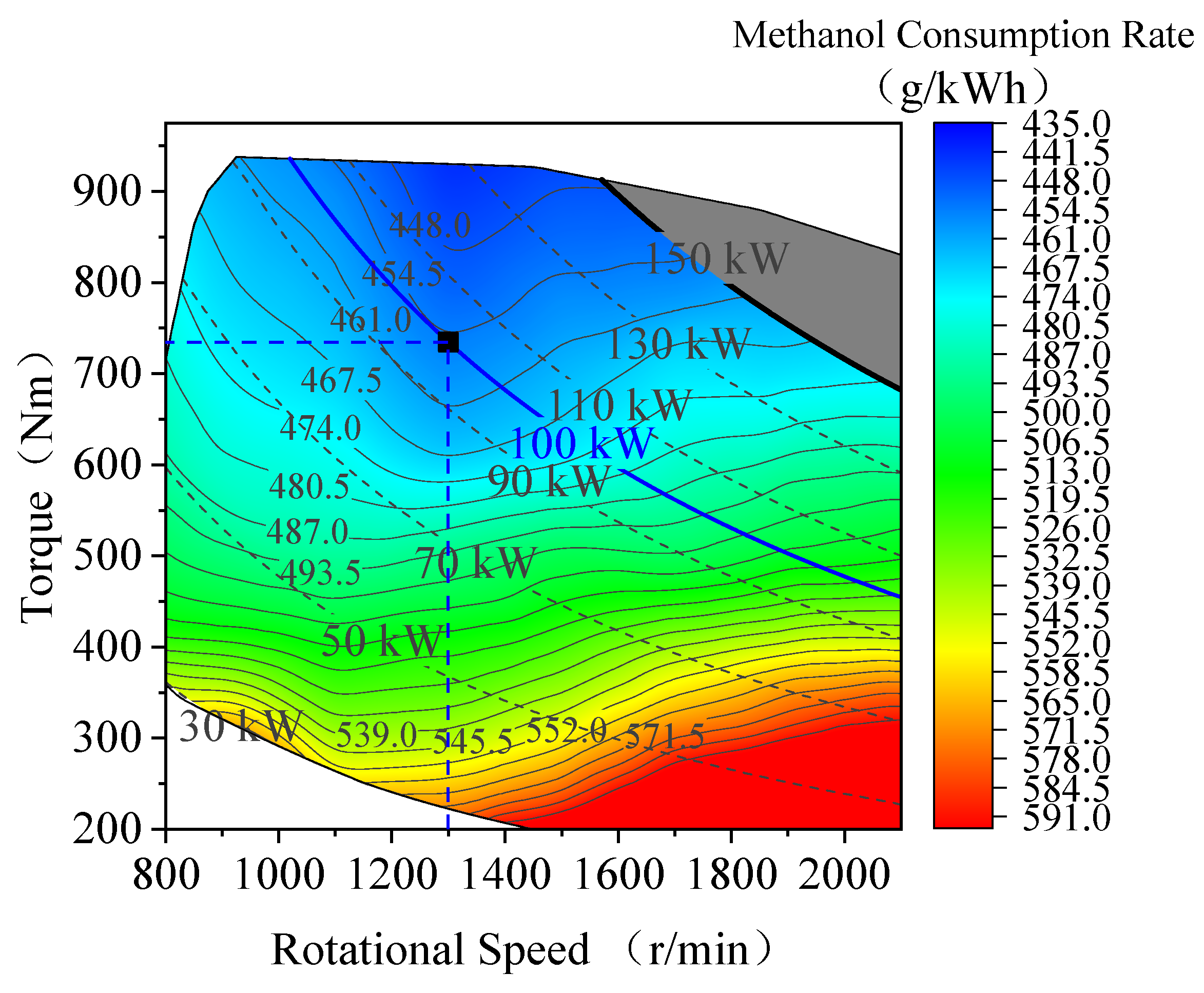

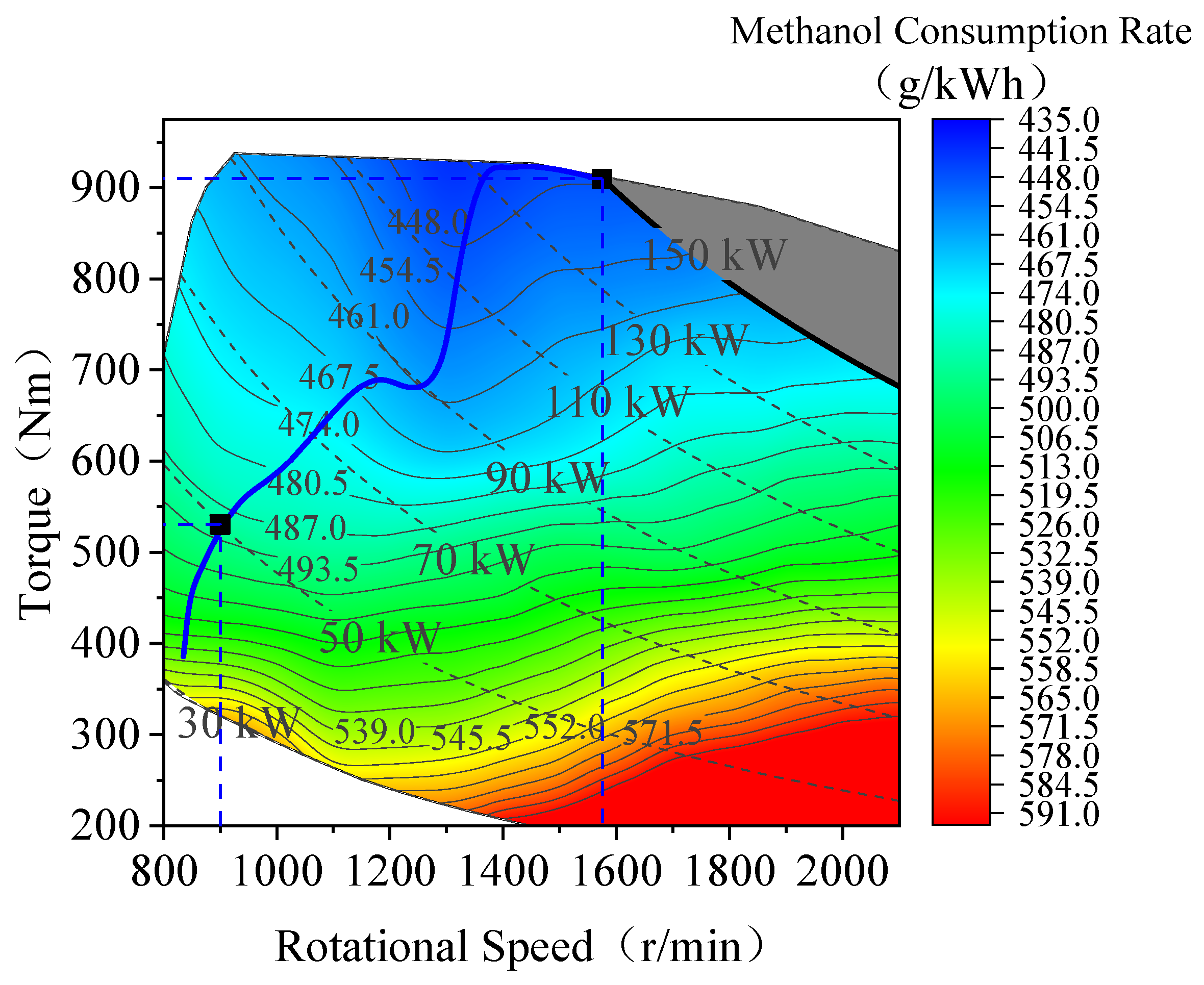

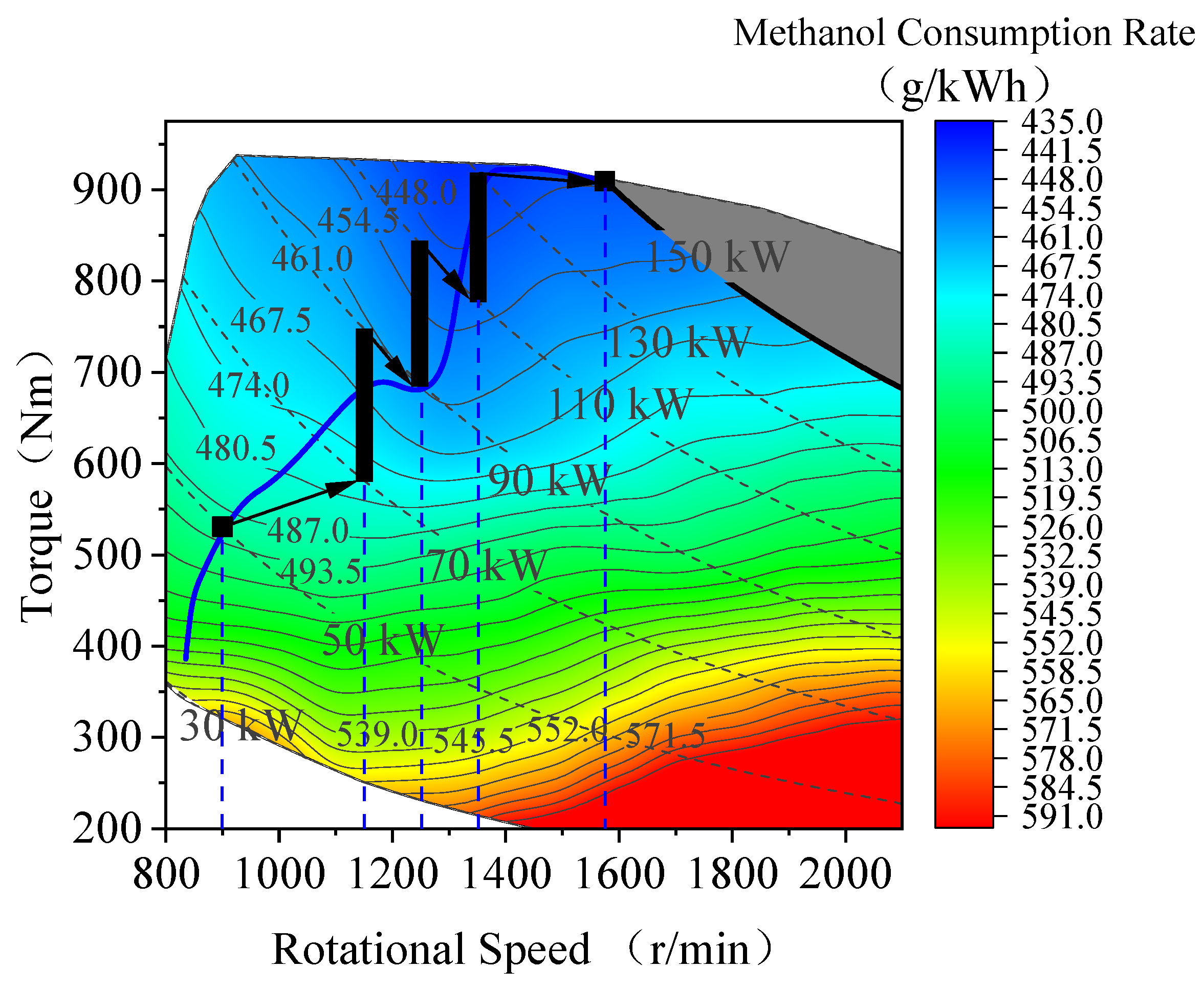

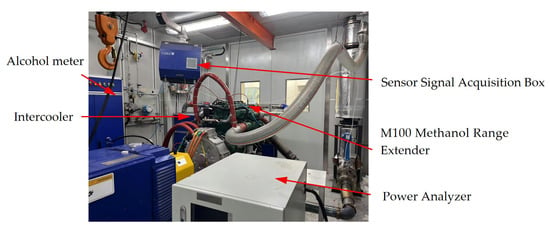

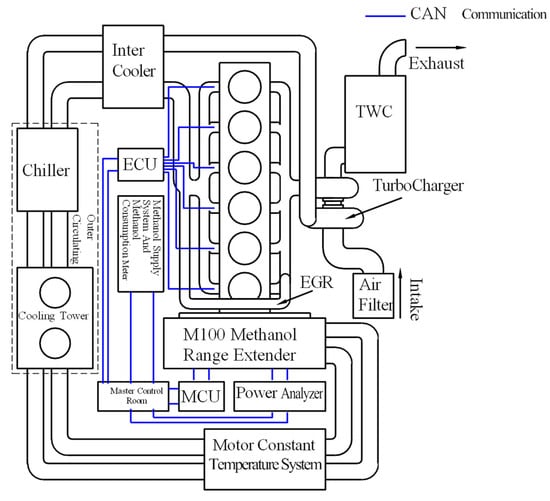

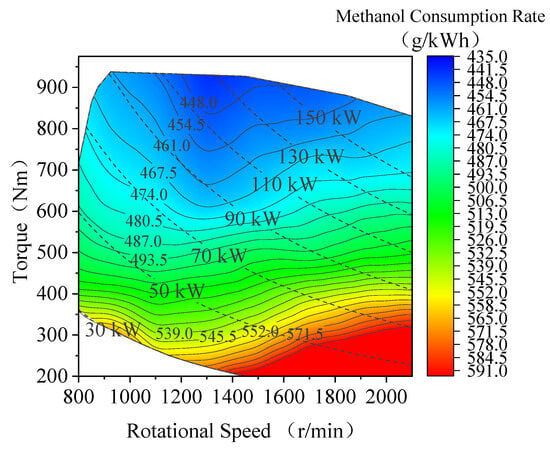

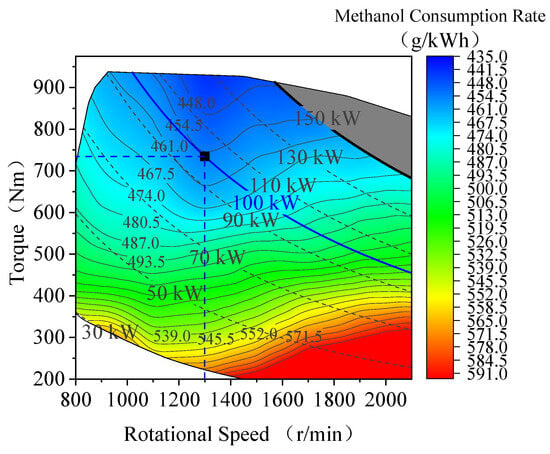

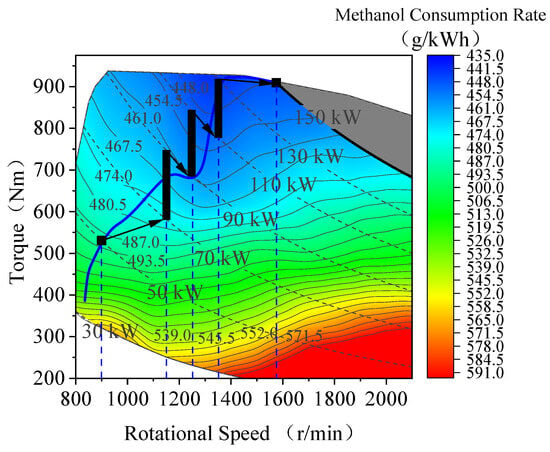

The layout diagram of the range extender on the test bench is illustrated in Figure 2, while the corresponding layout schematic is presented in Figure 3. The generator is cooled by a motor constant temperature system, which conducts direct external heat exchange with the cooling tower. The closed-loop control of the range extender’s speed and torque is achieved through the ECU and Motor Control Unit (MCU), while the WT1804E power analyzer calculates the range extender’s power generation in real time. The measured universal characteristic map of the M100 methanol range extender is shown in Figure 4. In Figure 4, the solid lines represent the constant methanol consumption rate lines, and the dashed lines represent the constant power lines.

Figure 2.

The layout diagram of the range extender on the test bench.

Figure 3.

Arrangement of the M100 methanol range extender.

Figure 4.

Universal characteristic of the M100 methanol range extender.

The main performance test results of the M100 methanol range extender and the design parameters of other components in the power system are shown in Table 3. All data on the range extender’s main performance results are derived from laboratory tests. The calculation method of maximum power generation efficiency is “(Range Extender’s Generated Power/Engine’s Output Power) × 100%”. The maximum generation efficiency of the range extender, reaching 99.93%, occurs when the range extender operates at 1950 r/min. At this operating point, the range extender’s generated power is 80.07 kW, and the engine’s output power is 80.13 kW.

Table 3.

The results and the parameters of the power system.

2.2. Basic Structure and Performance Indicators of the Vehicle

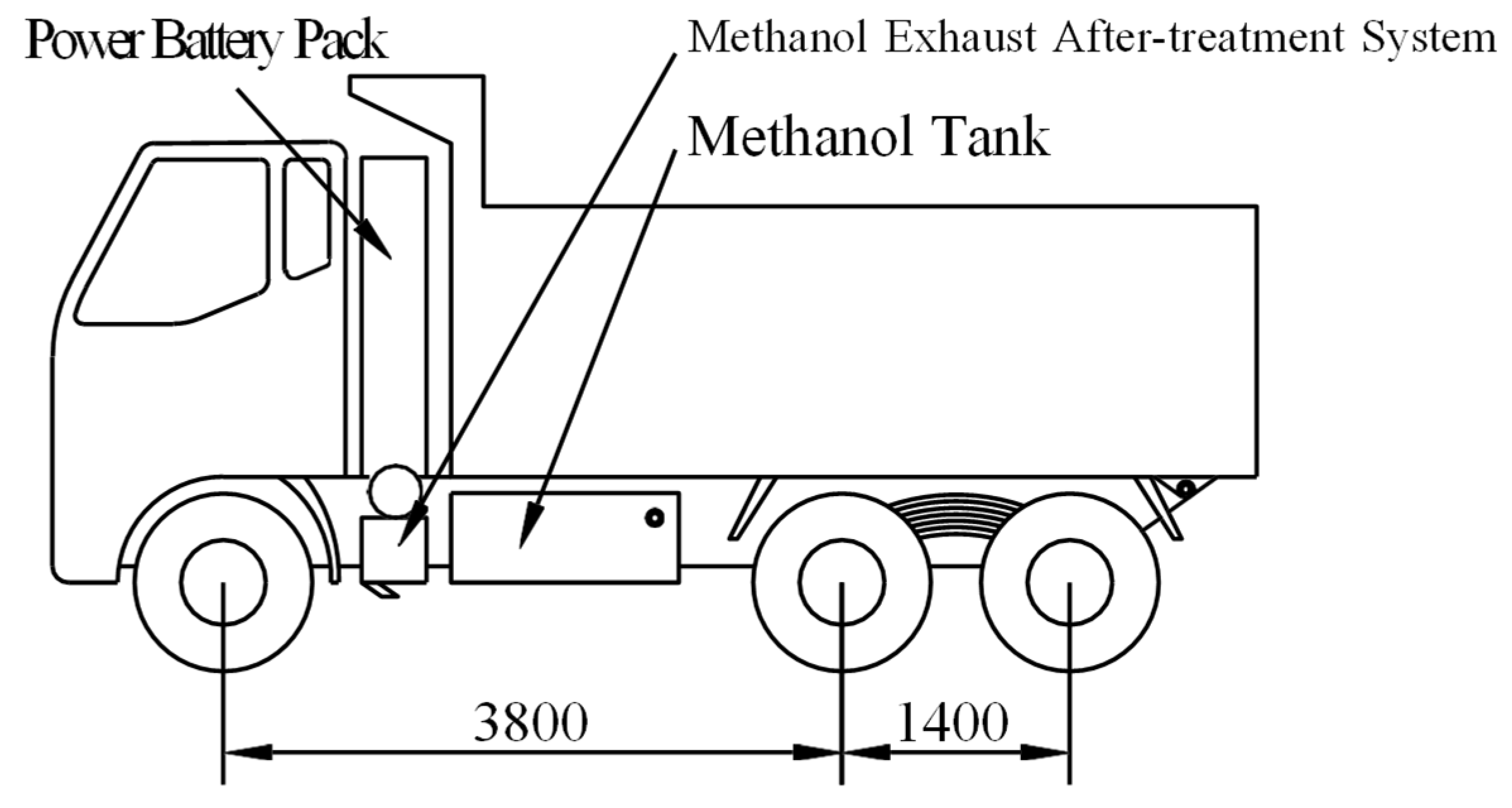

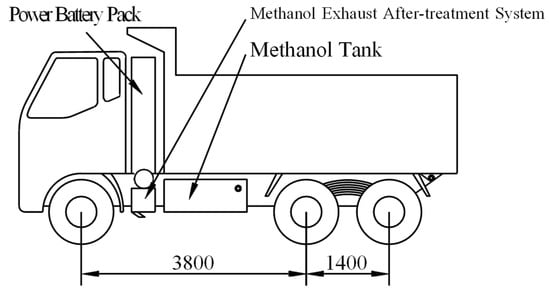

The dump truck adopts a three-axle 6 × 4 drive configuration with a maximum total mass of 25 t, and its appearance schematic diagram is shown in Figure 5.

Figure 5.

Schematic diagram of the dump truck’s appearance.

The dump truck uses the chassis of the original fuel-powered model, with a methanol tank installed at the position of the original fuel tank, and its power battery placed between the cab and the cargo box. The basic parameters of the vehicle are shown in Table 4.

Table 4.

Basic parameters of Dump Trucks.

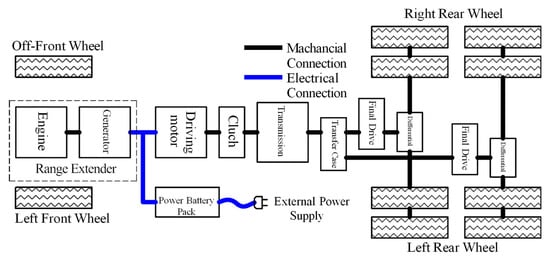

The structure of the dump truck power system is shown in Figure 6. The dump truck’s electric drive system adopts a 540V high-voltage electrical architecture, enabling “fast charging and fast discharging” of the vehicle’s electrical energy. At the same time, it reduces Joule loss during power transmission through the “high-voltage and low-current” method, decreases circuit heating, and ensures safety during operation. The dump truck supports charging of the power battery by an external power source when parked. Under startup conditions, the dump truck’s power battery has sufficient capacity (high SOC), which can effectively reduce the startup frequency of the range extender and lower the vehicle’s fuel consumption. When the battery SOC drops to the threshold, the range extender can ensure that the dump truck operates continuously without shutdown for long periods, over long distances, and under high loads.

Figure 6.

Structure of the Dump Truck Power System.

Under the design requirements of ensuring the dump truck’s high-speed transfer capability, acceleration capability, and climbing capability, the vehicle performance indicators and energy consumption limits are shown in Table 5.

Table 5.

The vehicle performance indicators and energy consumption limits.

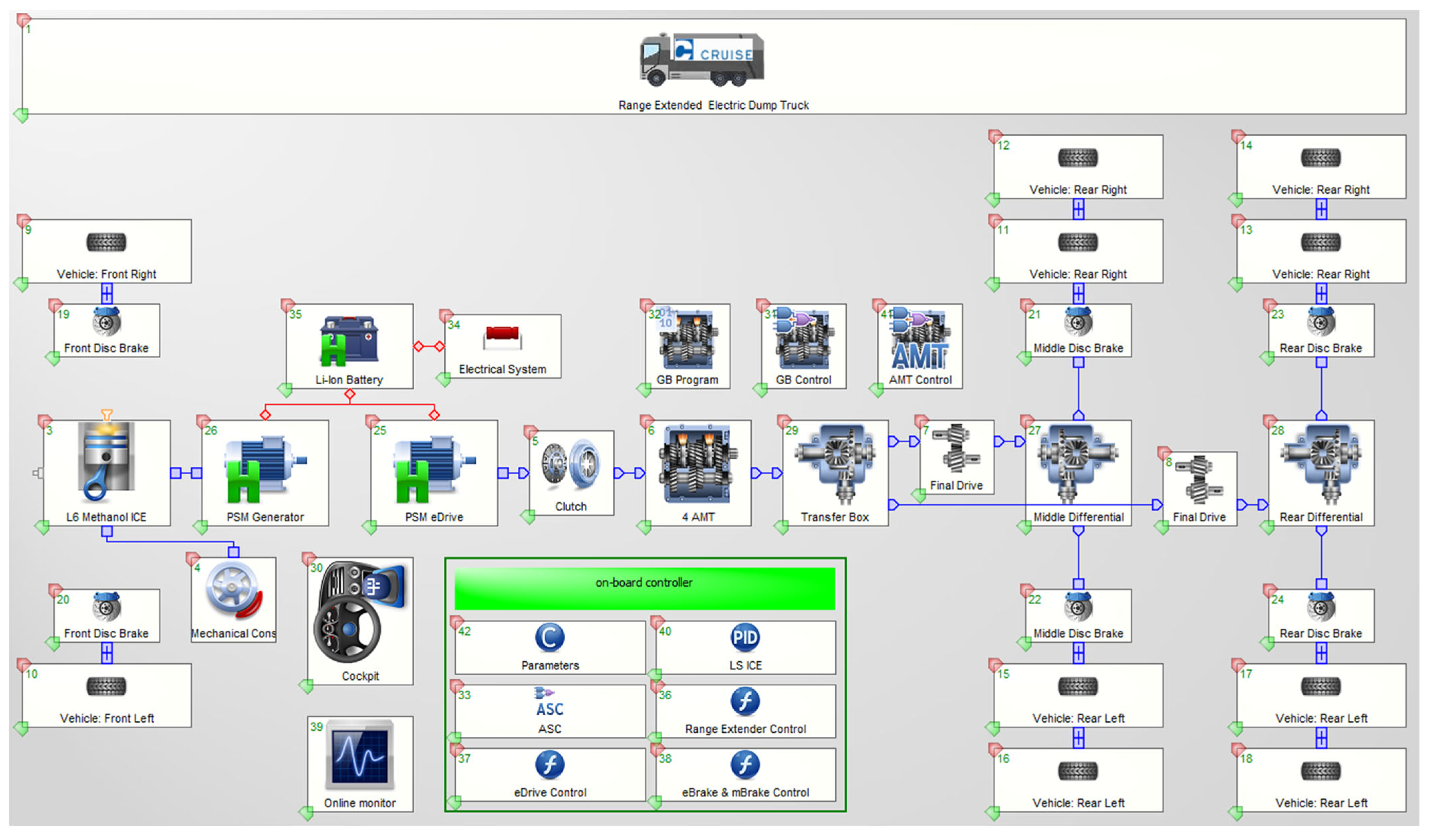

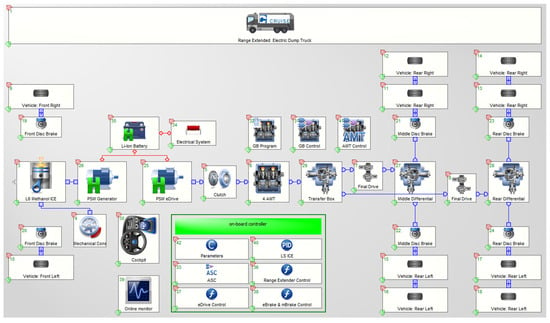

A simulation model of the extended-range electric dump truck is built under the hybrid vehicle module in AVL Cruise, and the model is shown in Figure 7.

Figure 7.

AVL Cruise vehicle simulation model.

3. Design of Control Strategies for Range-Extended Electric Dump Trucks

Rule-based control strategies are currently the mainstream control method for extended-range electric vehicles, especially in the commercial vehicle sector. The extended-range electric dump truck studied in this paper adopts a rule-based control strategy to achieve a balance among the vehicle’s fuel economy, cost, and reliability. Based on determining the design principles and logic of the vehicle control strategy, this section presents the constant power control strategy, power-following control strategy, constant speed and variable torque control strategy, as well as the braking energy recovery strategy.

3.1. Design Principles of Vehicle Control Strategies

The design of the rule-based control strategies for vehicles follows the following principles:

(1) Priority to pure electric driving mode. When the dump truck is in pure electric driving, the electric energy utilization rate can reach up to 85%, which is the mode with the best economic performance of the whole vehicle. On the premise of meeting the power demand, the pure electric driving mode shall be used first.

(2) Priority to the thermal efficiency of the range extender. The maximum thermal efficiency of a certain M100 methanol range extender measured through bench tests is 38.22%. The operating point of the range extender is selected within the high-efficiency range, thereby effectively reducing the methanol consumption rate of the entire vehicle.

(3) Priority to energy recovery during deceleration. On the premise of ensuring braking safety, the braking forces of mechanical braking and electric motor braking are reasonably distributed, and braking is prioritized through energy recovery to maximize the recovery of braking energy.

(4) Protect the lifespan of the battery. By reasonably setting the charge and discharge SOC thresholds of the dump truck’s traction battery and the output power of the range extender, the battery lifespan can be improved to a certain extent [26].

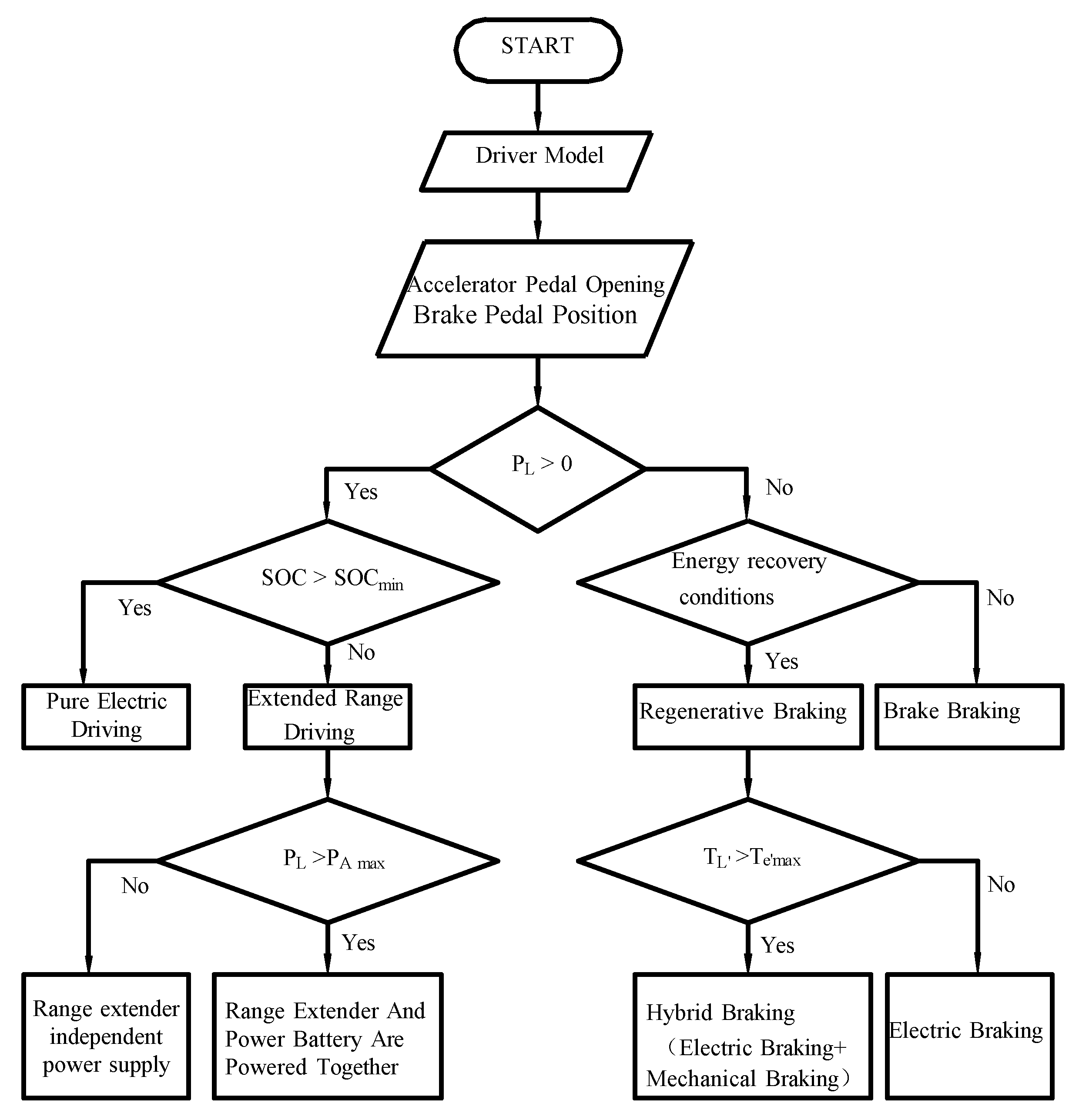

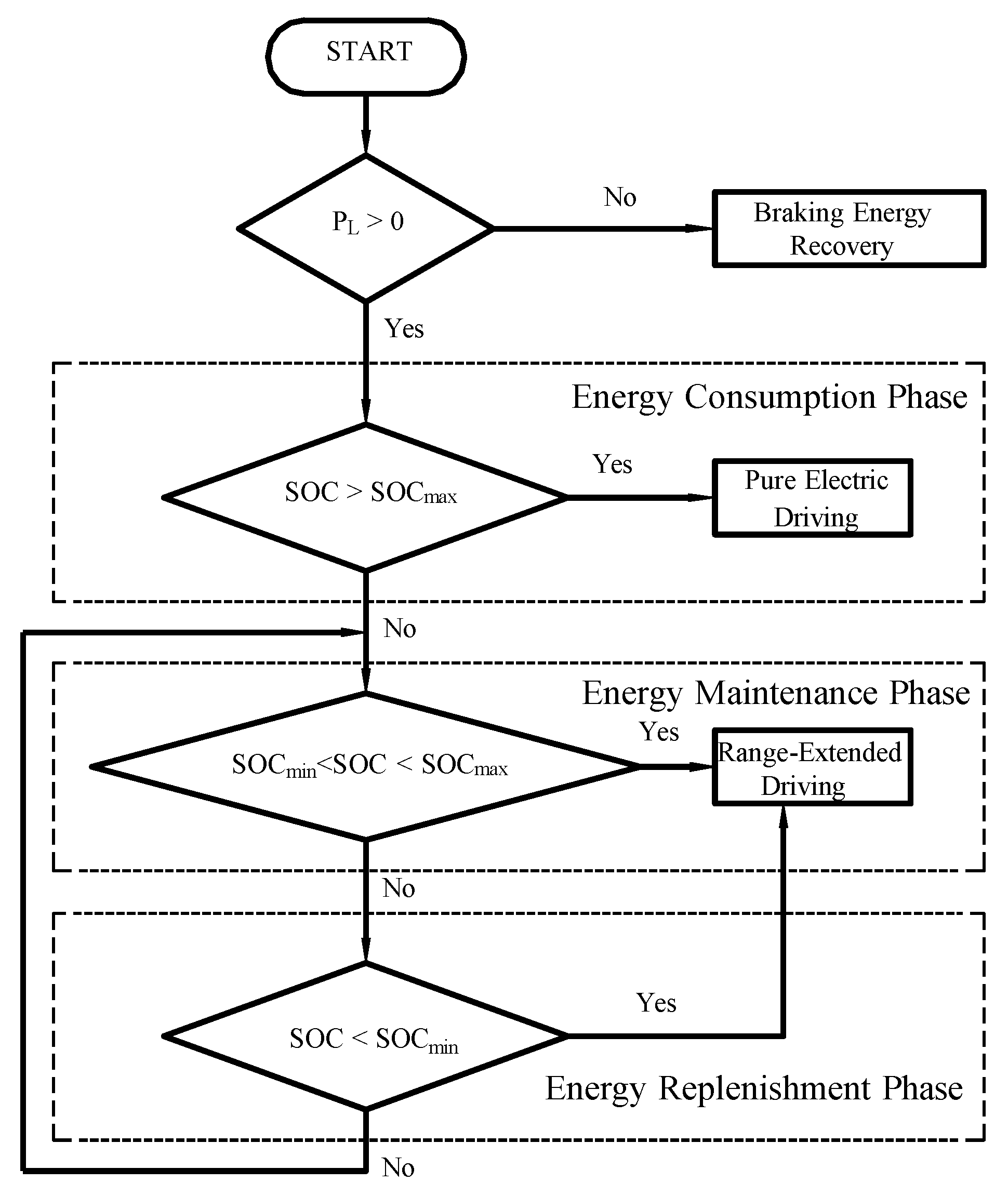

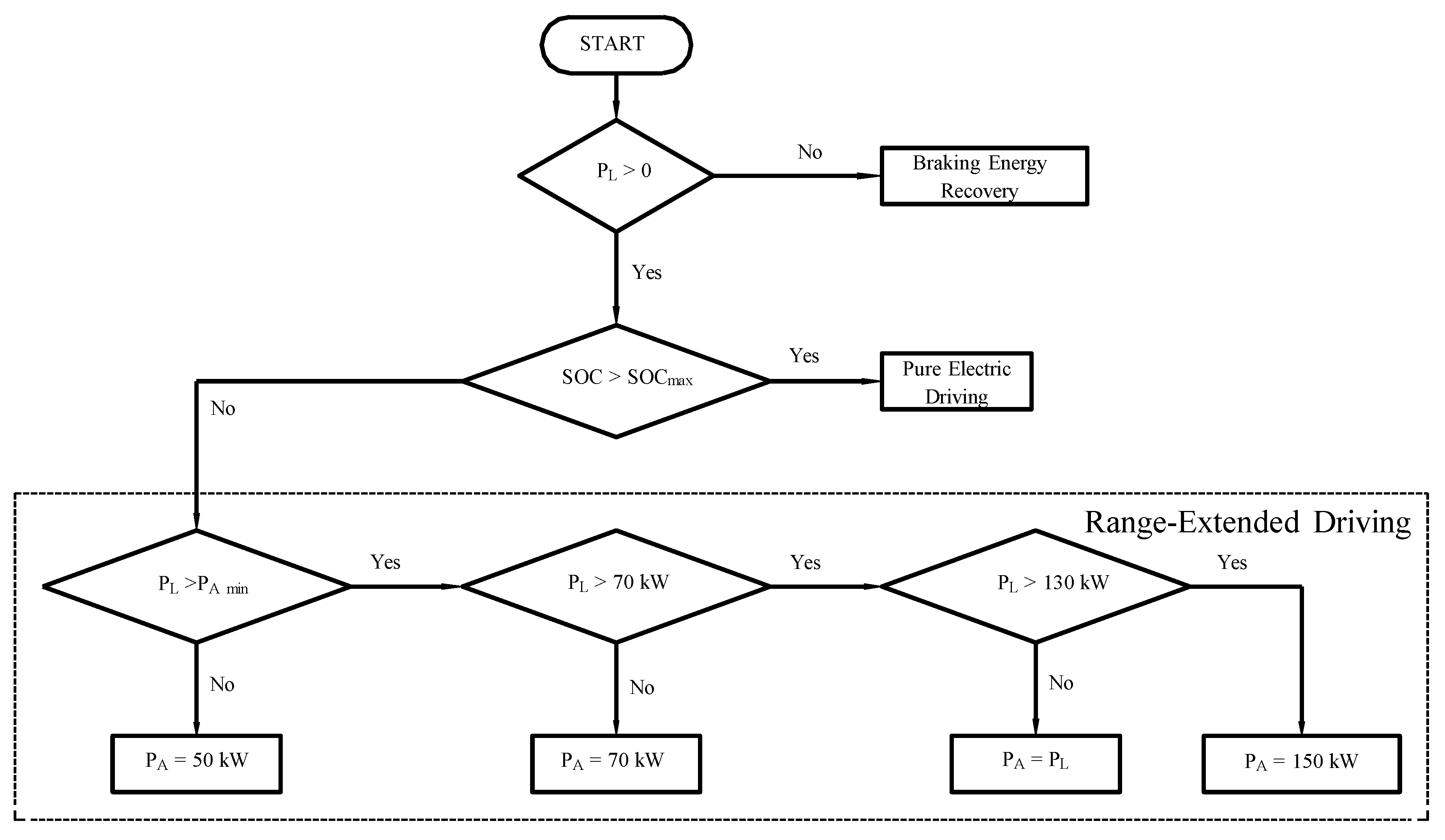

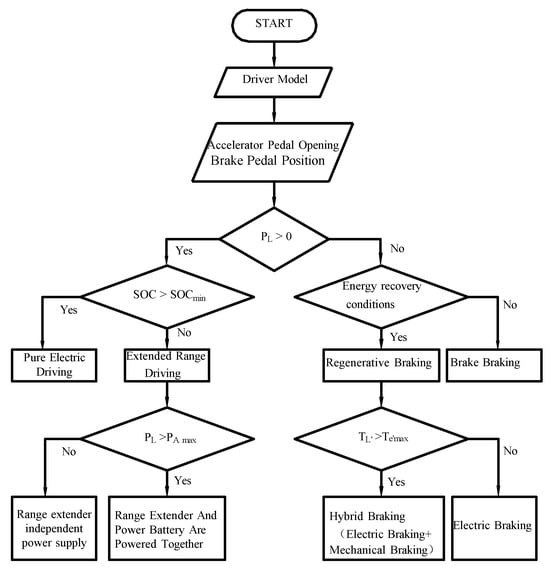

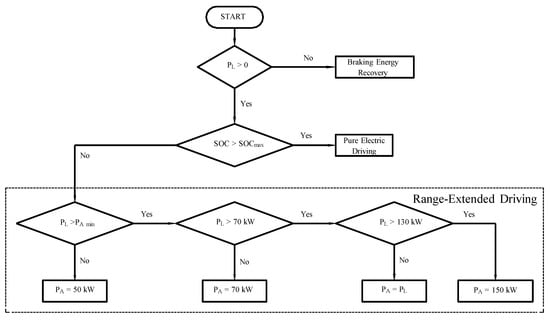

3.2. Core Logic of Vehicle Control Strategies

Based on the design principles of the aforementioned vehicle control strategies, the core logic of the dump truck’s control strategy has been designed, which is shown in Figure 8. The driver model outputs control signals for the accelerator and brake pedals. When the accelerator pedal opening is greater than 0, the drive motor starts to propel the dump truck; when the brake pedal is pressed or the accelerator opening is 0, the dump truck decelerates. The vehicle’s required power PL is determined by the accelerator pedal opening, and the driving state of the dump truck is judged according to the positive or negative value of PL. Whether to enter the extended-range driving mode is determined according to the current SOC value of the traction battery. The power supply mode is determined by comparing the magnitude of PL with the maximum output power PAmax of the range extender.

Figure 8.

Basic Logic of Dump Truck Control Strategy.

3.3. Constant Power Control Strategy

The constant power control strategy regulates the operation of the range extender at a fixed power. Whether the range extender operates is determined according to the threshold value of the traction battery’s SOC. The constant power operating point of the range extender is selected at the high-efficiency point corresponding to the power required for the dump truck’s driving. However, when the dump truck is decelerating, the power demand of its drive motor is zero. The electrical energy generated by the range extender and the braking energy recovery system will be stored in the traction battery. If the charging power is too high at this time, it will cause the traction battery to generate a large amount of heat, posing significant safety hazards and affecting the lifespan of the traction battery. Therefore, the output power of the range extender operating at a fixed point must not exceed 135 kW, which is the maximum allowable charging power for the traction battery during stationary charging.

The constant power control strategy for dump trucks takes the optimal fuel economy of the range extender as the primary design principle. After the range extender is started, it raises its rotational speed to 1300 r/min and operates at a fixed output power of 100 kW. When the SOC of the traction battery is lower than the minimum value of 30%, the range extender will start and supply power to the drive motor at a constant power of 100 kW. If the vehicle’s required power P_L is less than the output power of the range extender, the range extender will charge the traction battery until the battery’s SOC reaches the maximum value of 80%. If the vehicle’s required power P_L is greater than the output power of the range extender, the range extender will supply power to the drive motor together with the traction battery, and at this time, the maximum discharge power of the traction battery is 120 kW.

Figure 9 shows the constant power point of the range extender, where the area exceeding the calibrated power of the range extender (150 kW) is indicated by gray shading. In Figure 9, the solid lines represent the constant methanol consumption rate lines, and the dashed lines represent the constant power lines. The performance output data for the constant point is shown in Table 6.

Figure 9.

Constant Power Point of the Range Extender.

Table 6.

Performance Data at Constant Power Points.

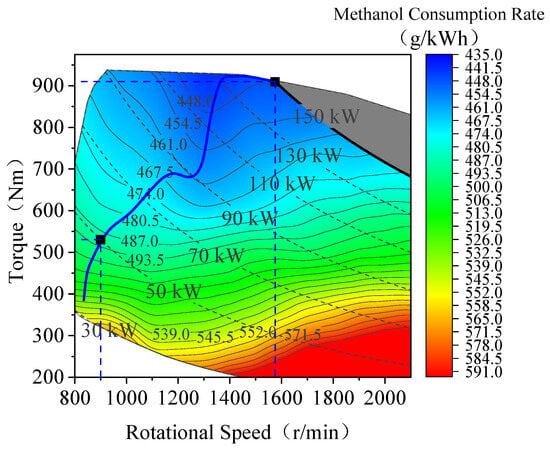

3.4. Power-Following Control Strategy

While maintaining the State of Charge (SOC) of the traction battery, the power-following control strategy enhances the judgment of the vehicle’s required power. The range extender operates along the optimal methanol consumption curve and supplies power to the drive motor based on the vehicle’s instantaneous power demand. This reduces the electrical energy flowing to the traction battery, lowers the frequency, depth, and charging power of the battery’s charge–discharge cycles, and thereby extends the battery’s lifespan [26].

The optimal fuel consumption curve of the range extender is shown in Figure 10. In the low-speed range, the range extender often has a high methanol consumption rate due to insufficient combustion. To avoid this problem, the minimum operating speed of the range extender is increased to 900 r/min. To reduce the methanol consumption rate of the range extender in the high-speed range, the maximum output power of the range extender at 1575 r/min is set to 150 kW. The performance output data of the range extender under the power-following control strategy are shown in Table 7.

Figure 10.

Optimal Methanol Consumption Curve for the Range Extender.

Table 7.

Performance Data of the Power Follow Control Strategy Range Extender.

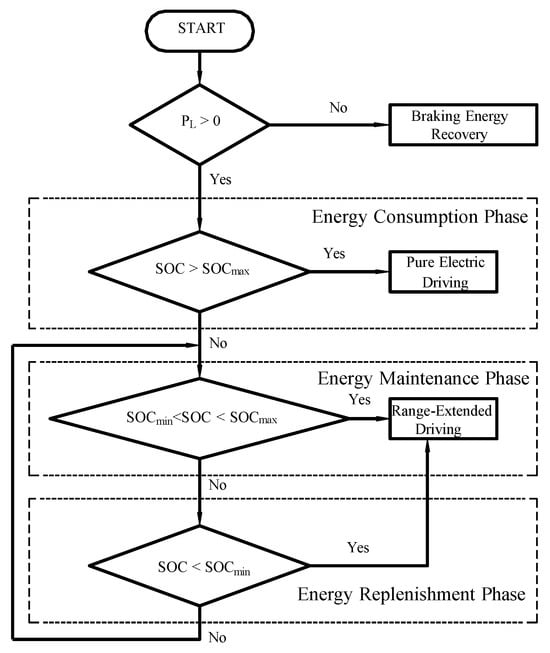

The control rules for the power-following control strategy are shown in Figure 11. Based on the established optimal methanol consumption curve for the range extender, the minimum output power of the range extender is set to 50 kW, and the maximum output power is set to 150 kW. The minimum state of charge (SOC) of the power battery is set at 55%, and the maximum at 60%. The actual operating modes of the range extender are as follows:

Figure 11.

Power-following Control Strategy Control Rules.

(1) When the SOC of the power battery is greater than a certain value, the dumper truck is in the energy consumption phase. The power battery can independently provide the required electrical energy to the drive motor, and the range extender does not start.

(2) When the current SOC of the power battery is between two specified values, the dumper truck enters the energy maintenance phase. The range extender maintains its previous on/off state; that is, during the SOC rising phase, the range extender operates along the optimal methanol consumption curve, while during the SOC falling phase, the range extender is turned off.

(3) When the current SOC of the power battery is less than a certain value, the dumper truck enters the energy replenishment phase, and the range extender is activated. If the SOC is less than a specified value, the actual output power of the range extender is equal to 50 kW; if it is between two specified values, the range extender operates along the optimal methanol consumption curve, at which point the output power is equal to a certain value; if it is greater than a specified value, the actual output power of the range extender is equal to 150 kW.

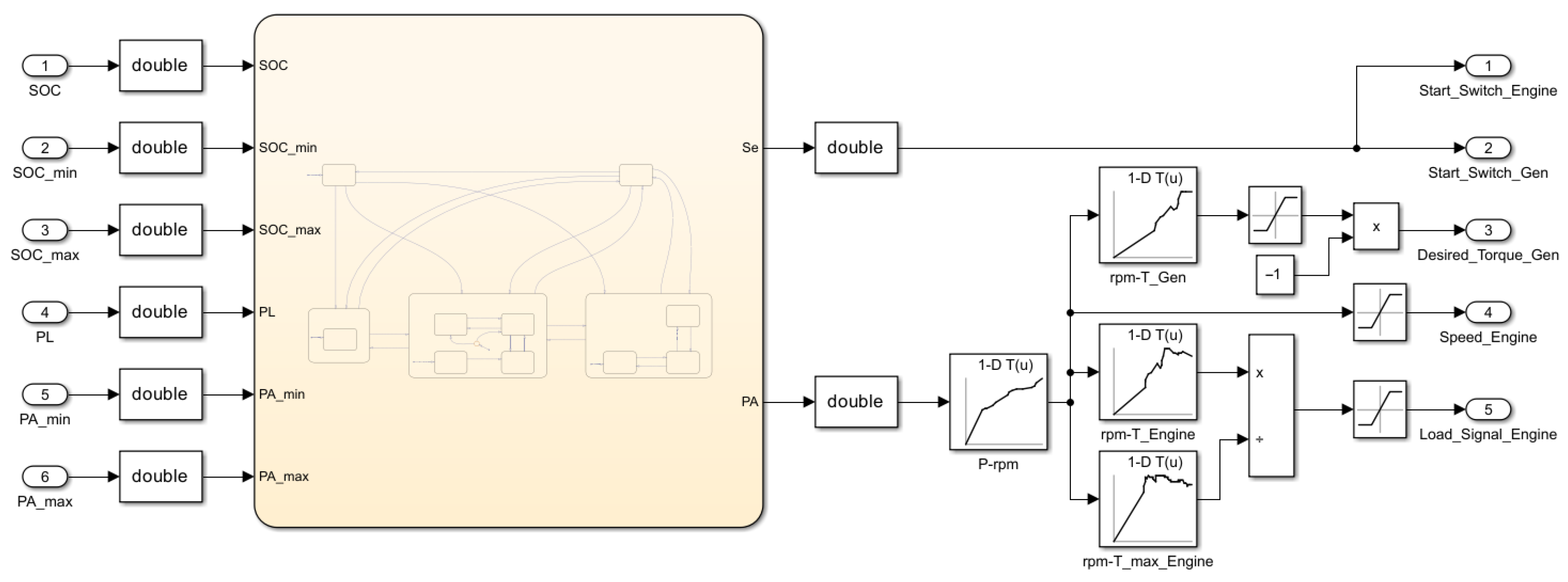

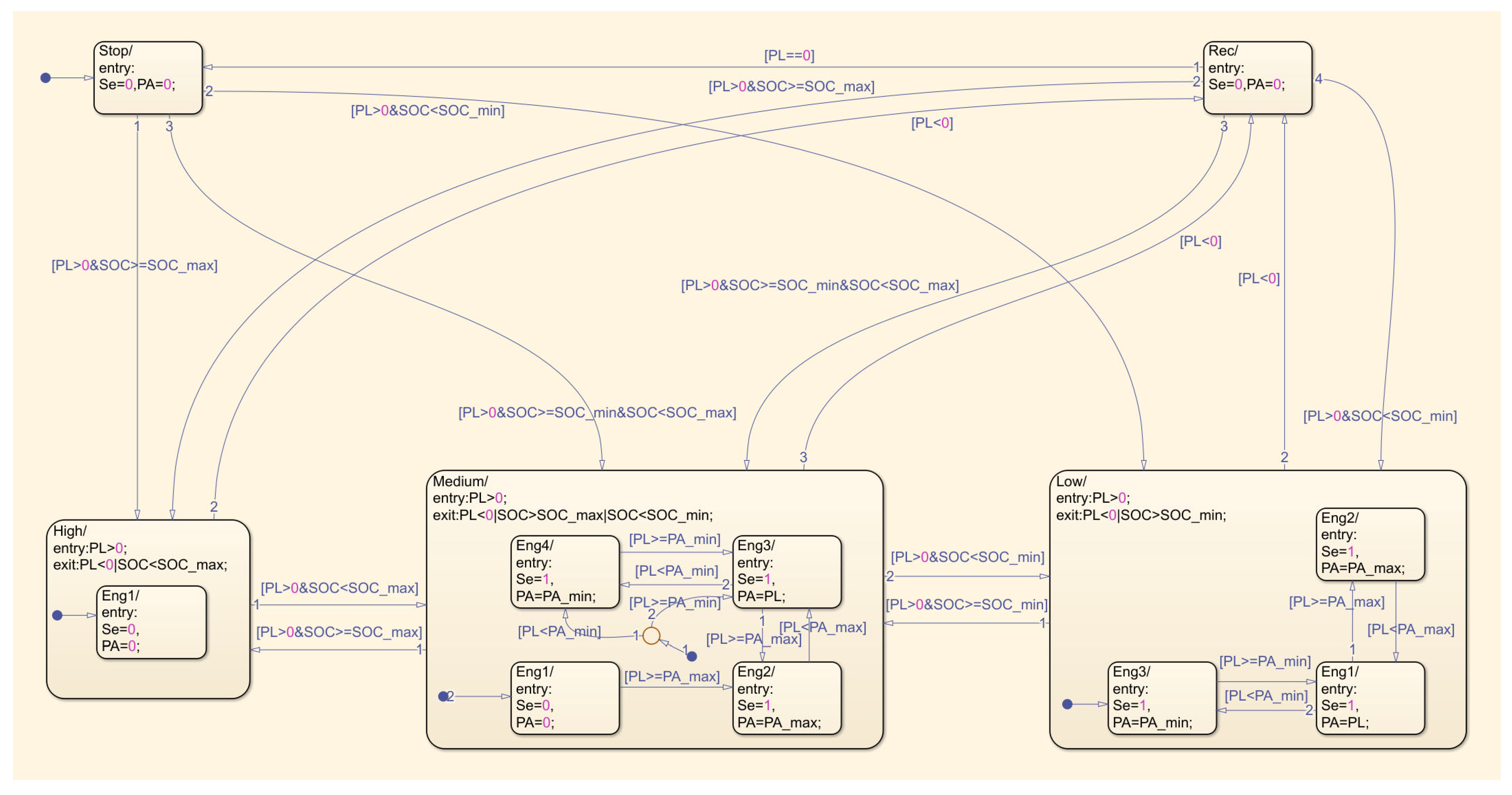

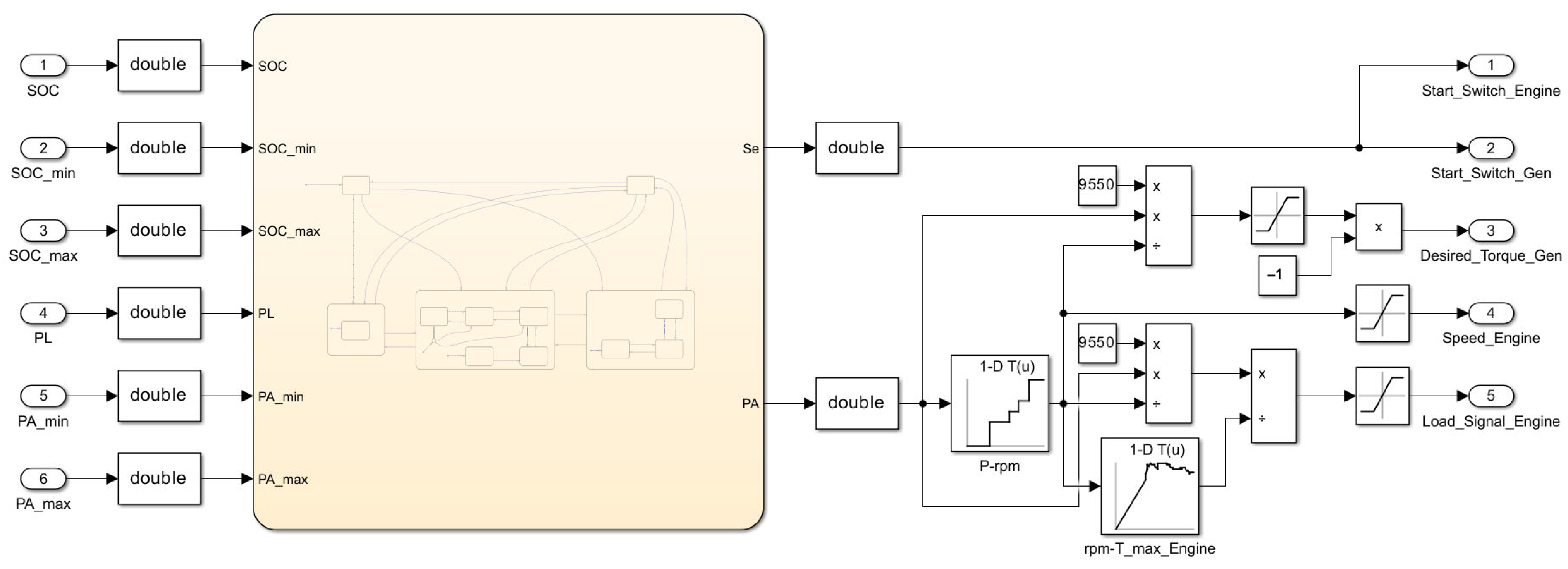

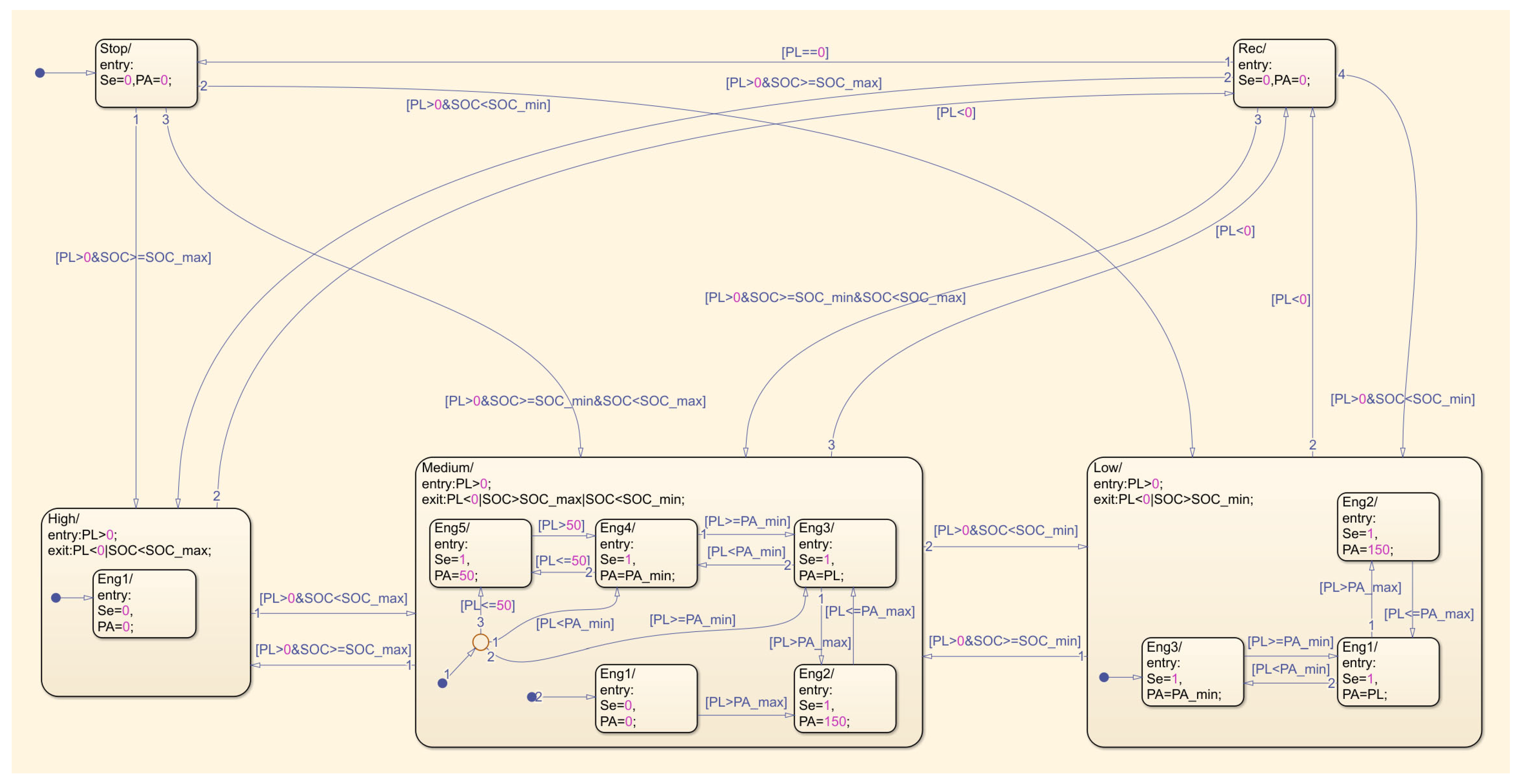

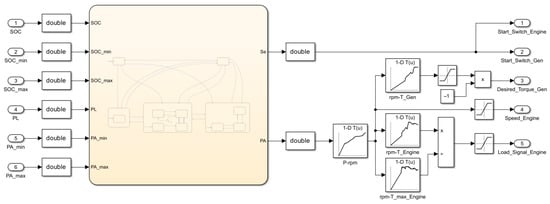

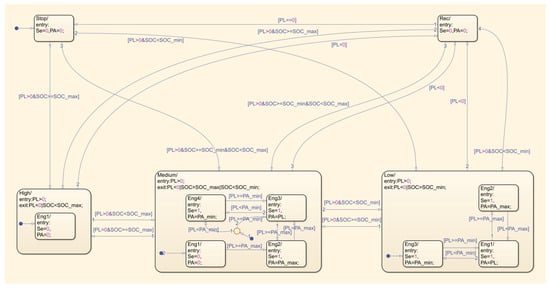

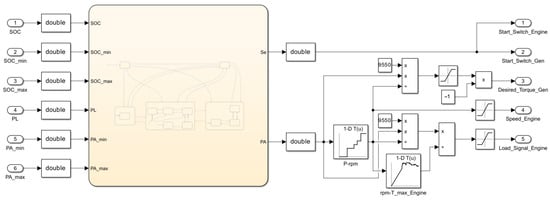

The power-following control strategy model built in MATLAB R2022b/Simulink is shown in Figure 12. The opening/closing and working state judgment of the range extender is realized through the Stateflow module (as shown in Figure 13). In Figure 13, the arrows represent the path directions of the control strategy, the contents enclosed in square brackets are the judgment conditions, and the contents in the boxes are the output quantities of the control strategy. The closed-loop control of the range extender’s operating point in AVL Cruise is achieved through the engine load output by the power-following control strategy model and the required torque of the generator.

Figure 12.

Power Tracking Control Strategy Model.

Figure 13.

Power-following Control Strategy for Range Extender Operating State Switching.

3.5. Constant-Speed and Variable-Torque Control Strategy

The constant power control strategy selects the power point in the range where the range extender’s output power is relatively high. Therefore, even when the power required by the entire vehicle is low, it still generates relatively high charging power. Meanwhile, the selected power point must ensure that the range extender achieves optimal fuel economy. Hence, after the range extender is started, it will increase its rotational speed to the set speed and operate stably with a constant output power, which undoubtedly increases the charge–discharge depth of the power battery. All the aforementioned issues will have an impact on the service life of the power battery.

The power-following control strategy requires the range extender to frequently adjust its rotational speed within the range of 900–1575 r/min. The high-frequency fluctuations in rotational speed cause the moving components of the engine, such as the crankshaft, connecting rods, and pistons, to bear frequent alternating loads, thereby affecting the stability and service life of the range extender. Based on the power-following control strategy, a constant-speed and variable-torque control strategy suitable for the M100 methanol range extender is designed to reduce the charge–discharge depth of the power battery and the frequency of rotational speed switching.

On the premise of ensuring that the range extender operates in the economic and efficient zone (methanol consumption < 462 g/kWh), the constant-speed and variable-torque control strategy enables the range extender to have a wide operating power range and low rotational speed fluctuation, with its power range set to 70–130 kW. This strategy for the range extender divides its output power into three intervals: low, medium, and high. The output power of the low-power interval is 70–90 kW, that of the medium-power interval is 90–110 kW, and that of the high-power interval is 110–130 kW. Based on the universal characteristic test data of the range extender and the optimal methanol consumption curve, three operating speeds (1150 r/min, 1250 r/min, and 1350 r/min) with relatively low methanol consumption rates of the range extender are determined. The operating points of the constant-speed and variable-torque control strategy are shown in Figure 14, where the area exceeding the calibrated power of the range extender (150 kW) is indicated by gray shading. In Figure 14, the solid lines represent the constant methanol consumption rate lines, and the dashed lines represent the constant power lines. The black vertical lines represent the power range intervals of the range extender, and the square markers indicate the operating power points of the range extender. The arrows indicate the jumps between adjacent power intervals. The range extender can realize power-following control within the range of 70–130 kW, as well as constant power control with a minimum output power of 50 kW and a maximum output power of 150 kW. The performance output data of the range extender are shown in Table 8.

Figure 14.

Working Point of the Constant-Speed and Variable-Torque Control Strategy.

Table 8.

Performance Data of the Range Extender with Constant-Speed and Variable-Torque Control Strategy.

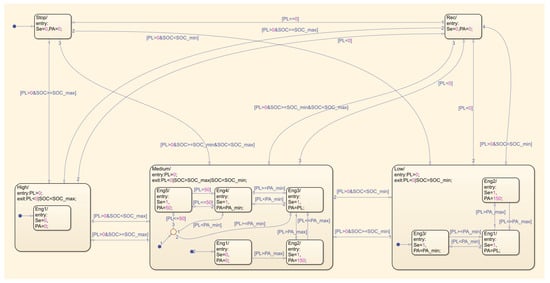

In the constant-speed and variable-torque control strategy, the minimum and maximum output powers of the range extender, as well as the minimum and maximum values of the traction battery’s SOC, remain consistent with those described earlier for the power-following control strategy. The control rules of the constant-speed and variable-torque control strategy are shown in Figure 15. When the SOC of the traction battery is less than SOCmax, the dump truck enters the range-extended driving mode. The constant-speed and variable-torque control strategy sets the output power in the high methanol consumption range of 50–70 kW and the external characteristic range of 130–150 kW to 70 kW and 150 kW, respectively, corresponding to the range extender speeds of 1150 r/min and 1575 r/min. Other rules are the same as those of the power-following control strategy.

Figure 15.

Control Rules for Constant-Speed and Variable-Torque Control Strategy.

The constant-speed and variable-torque control strategy model built in MATLAB R2022b/Simulink is shown in Figure 16. The opening/closing and working state judgment of the range extender is realized through the State flow module (as shown in Figure 17). In Figure 17, the arrows represent the path directions of the control strategy, the con-tents enclosed in square brackets are the judgment conditions, and the contents in the boxes are the output quantities of the control strategy. The closed-loop control of the range extender’s operating point in AVL Cruise is achieved through the engine load output by the power-following control strategy model and the required torque of the generator. When the SOC of the traction battery is less than the minimum value, SOCmin, to achieve rapid charging of the traction battery, the range extender skips the minimum output power of 50 kW and directly operates within the range of 70–150 kW.

Figure 16.

Model of Constant-Speed and Variable-Torque Control Strategy.

Figure 17.

Switching of the Working State of the Range Extender under the Constant-Speed and Variable-Torque Control Strategy.

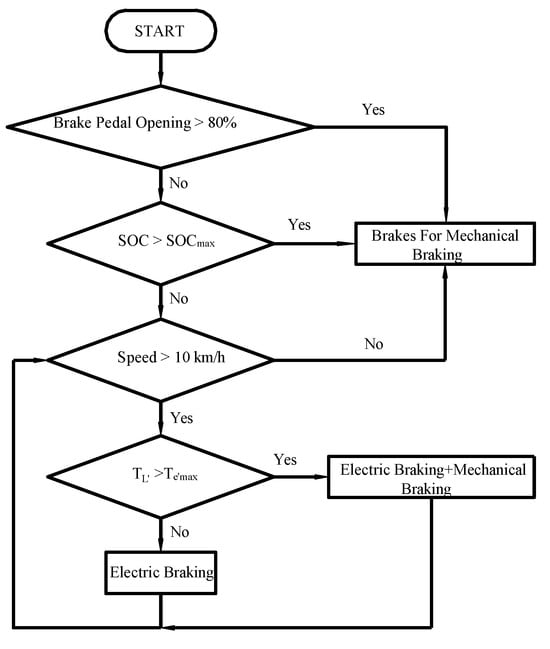

3.6. Braking Energy Recovery Strategy

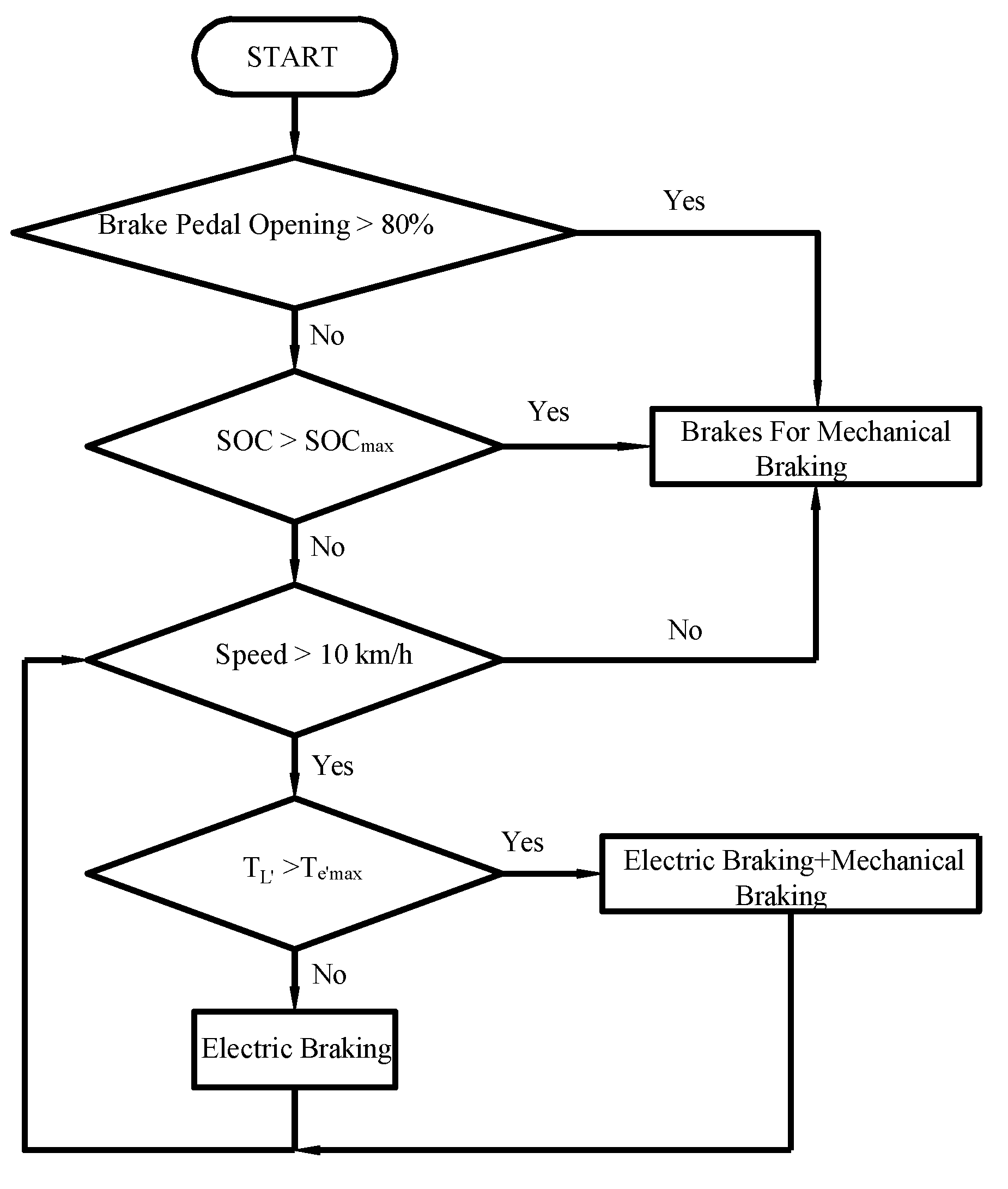

The extended-range electric dump truck described in this paper adopts a combination of mechanical braking and electric braking during braking. Among them, the brakes for each axle of the mechanical braking system are all ventilated disk brakes, and the braking force distribution among the front, middle, and rear axles is 4:3:3. Figure 18 illustrates the control rules for the braking energy recovery strategy, which are primarily set as follows:

Figure 18.

Control Rules for Brake Energy Recovery Strategy.

(1) When the total vehicle power demand is less than 0, and the brake pedal opening is 0, the dump truck enters a coasting phase and begins to recover braking energy.

(2) When the brake pedal opening exceeds 80%, the dump truck enters an emergency braking mode. To ensure a safe braking distance, the clutch automatically disconnects the power transmission path from the drive motor, relying solely on the brakes for mechanical braking.

(3) When the state of charge (SOC) of the power battery exceeds 80%, in order to reduce the impact of overcharging on the battery’s lifespan, mechanical braking is again performed solely through the brakes.

(4) When the dump truck recovers energy through electric braking, the involvement of mechanical braking is determined by the magnitude of the total vehicle demand braking torque.

4. Simulation Analysis of Control Strategies for Range-Extended Electric Dump Trucks

4.1. Vehicle Power Performance Simulation

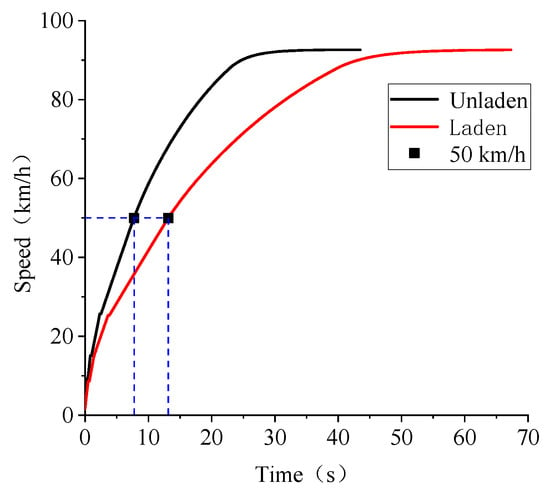

The evaluation indicators for the power performance of dump trucks mainly include the 0–50 km/h acceleration time, maximum speed, and maximum gradient. In AVL Cruise, the power performance of the dump truck is simulated and analyzed under two conditions: acceleration and climbing, while also verifying the correctness of the design parameters for the vehicle’s power system.

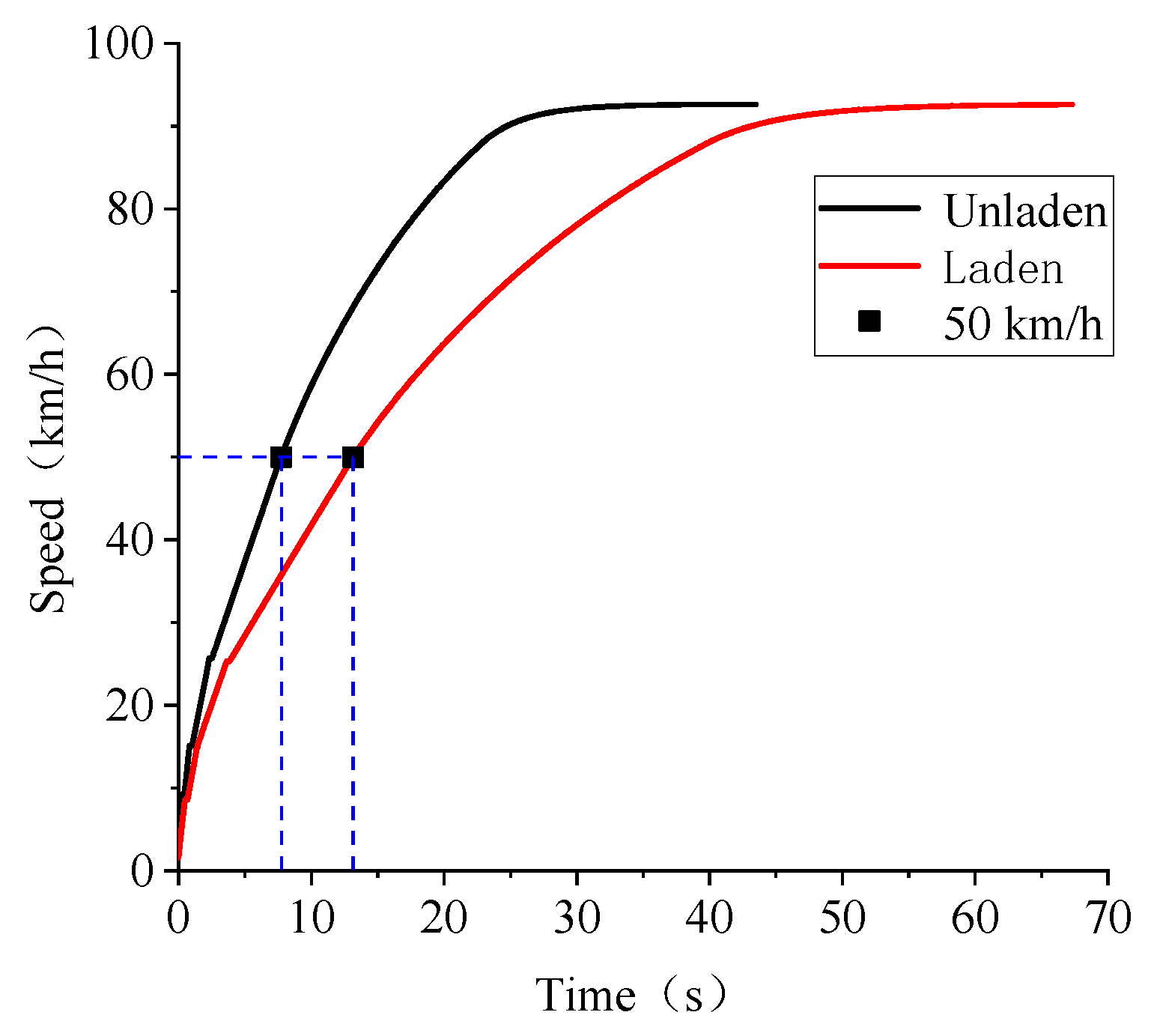

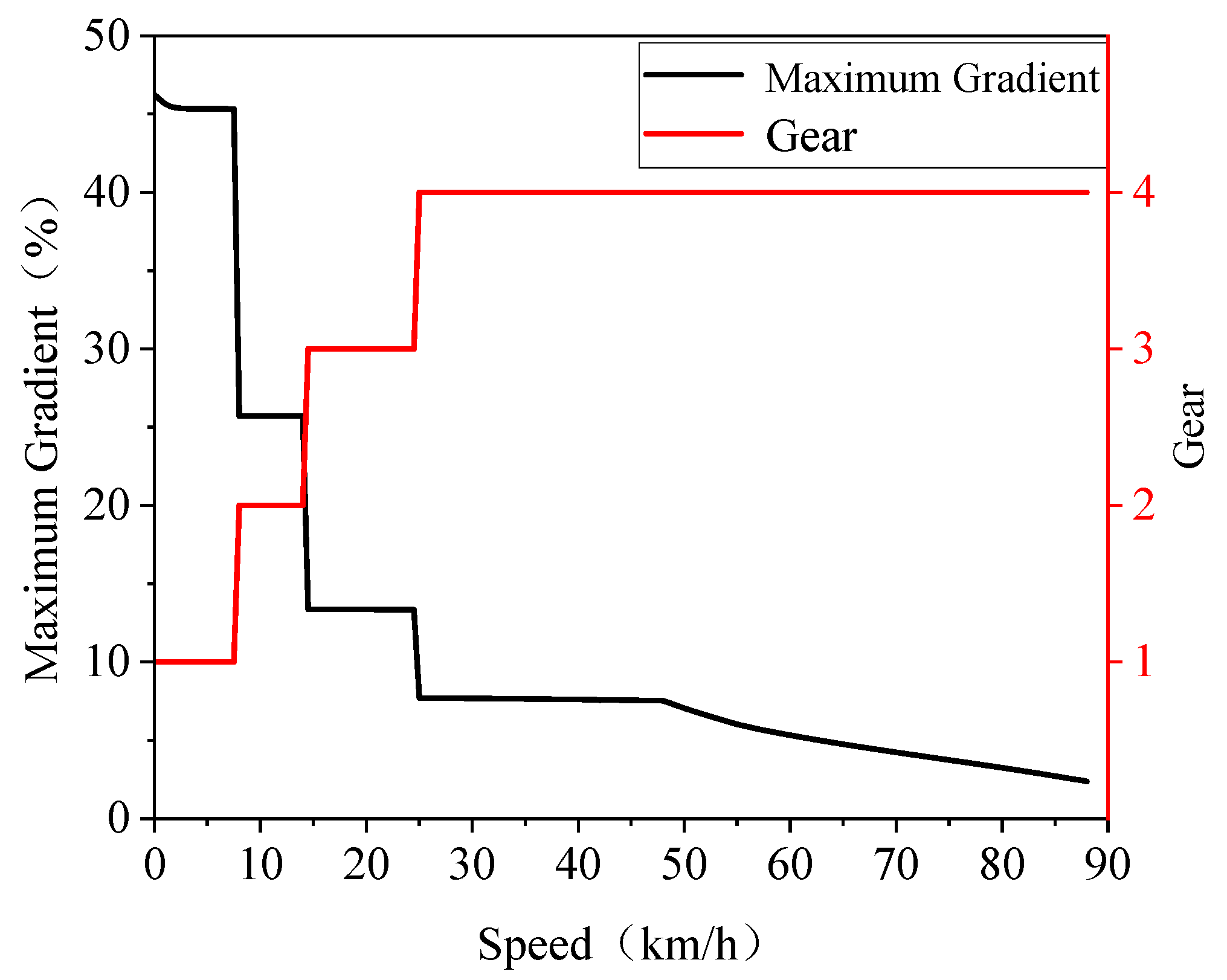

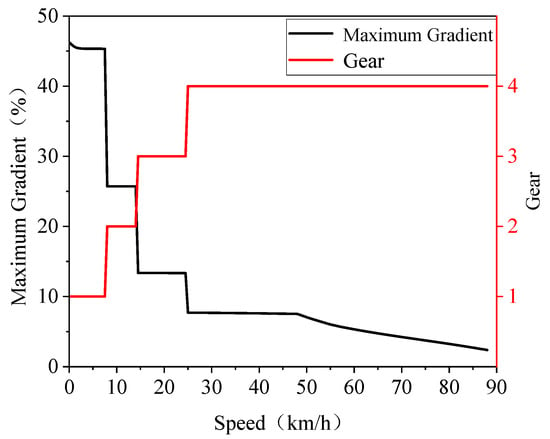

Simulations were conducted for the range-extended electric dump truck at 100% throttle for both unladen and laden acceleration times. The results are shown in Figure 19. The maximum speed of the dump truck when unladen is 92.63 km/h, with a 0–50 km/h acceleration time of 7.73 s, meeting the performance design requirements of a maximum speed of 90 km/h and a 0–50 km/h acceleration time of 8.0 s. When laden, the maximum speed of the dump truck is 92.59 km/h, with a 0–50 km/h acceleration time of 13.17 s. The simulation results for the maximum gradient when laden are shown in Figure 20, where the maximum gradient in first gear is 45.92%, meeting the performance design requirement of a maximum gradient of 45%.

Figure 19.

Maximum Speed of Dump Trucks.

Figure 20.

Maximum Gradient for Dump Trucks.

In the simulation results of the dumper’s performance, the errors between the maximum speed, 0–50 km/h acceleration time, and maximum gradient and the design specifications are 2.92%, 3.38%, and 2.04%, respectively, all within 5%. This indicates that the parameters of the dumper’s power system are reasonably matched, and the constructed vehicle simulation model meets the engineering design requirements.

4.2. Operating Conditions

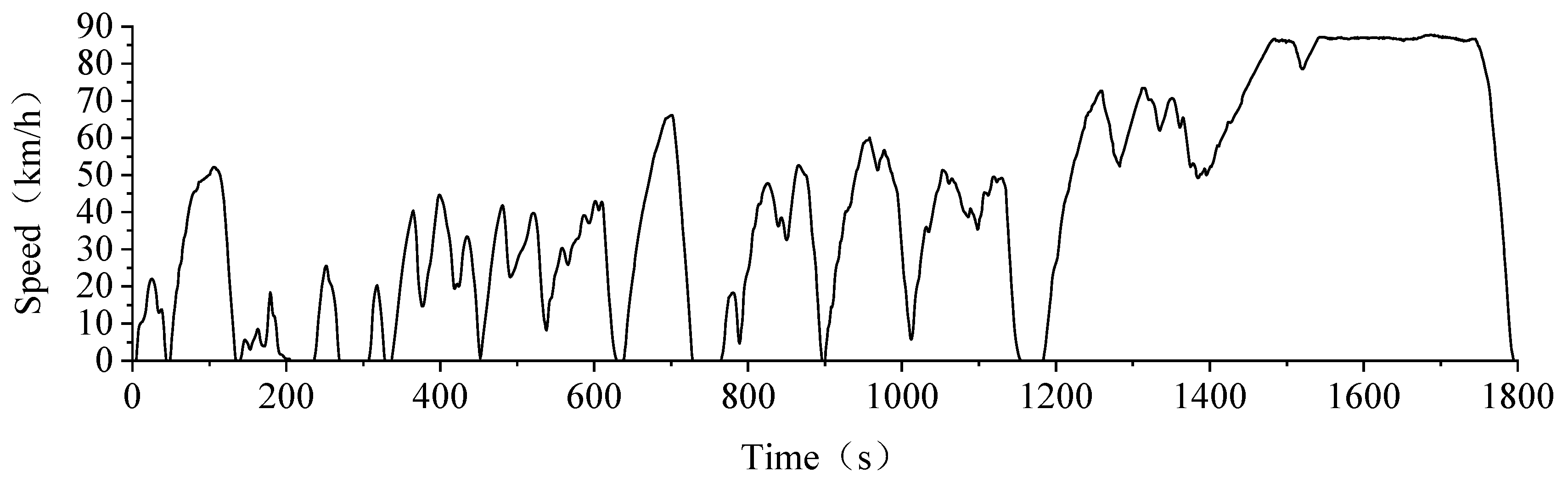

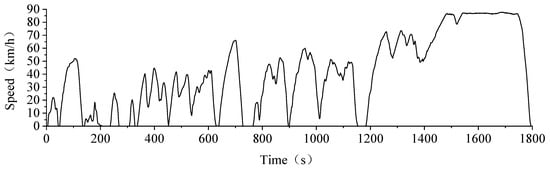

In accordance with the currently universally adopted commercial vehicle fuel economy testing methods worldwide and the national standard GB/T 38146.2–2019 [27], the fuel economy of the 25 t extended-range electric dump truck under three control strategies is evaluated through the CHTC-D cycle conditions. CHTC-D is currently China’s latest dump truck cycle condition, applicable to dump trucks with a designed maximum total mass exceeding 3.5 t. As shown in Figure 21, the simulation duration of the CHTC-D cycle condition is 1300 s, with an operating mileage of 8.37 km, a maximum speed of 71.4 km/h, and an average speed of 23.19 km/h. The CHTC-D cycle condition is divided into two parts: low-speed and high-speed. The low-speed condition lasts 540 s with a total distance of 0.97 km, while the high-speed condition lasts 760 s with a total distance of 7.4 km.

Figure 21.

CHTC-D Cycle Condition Road Spectrum.

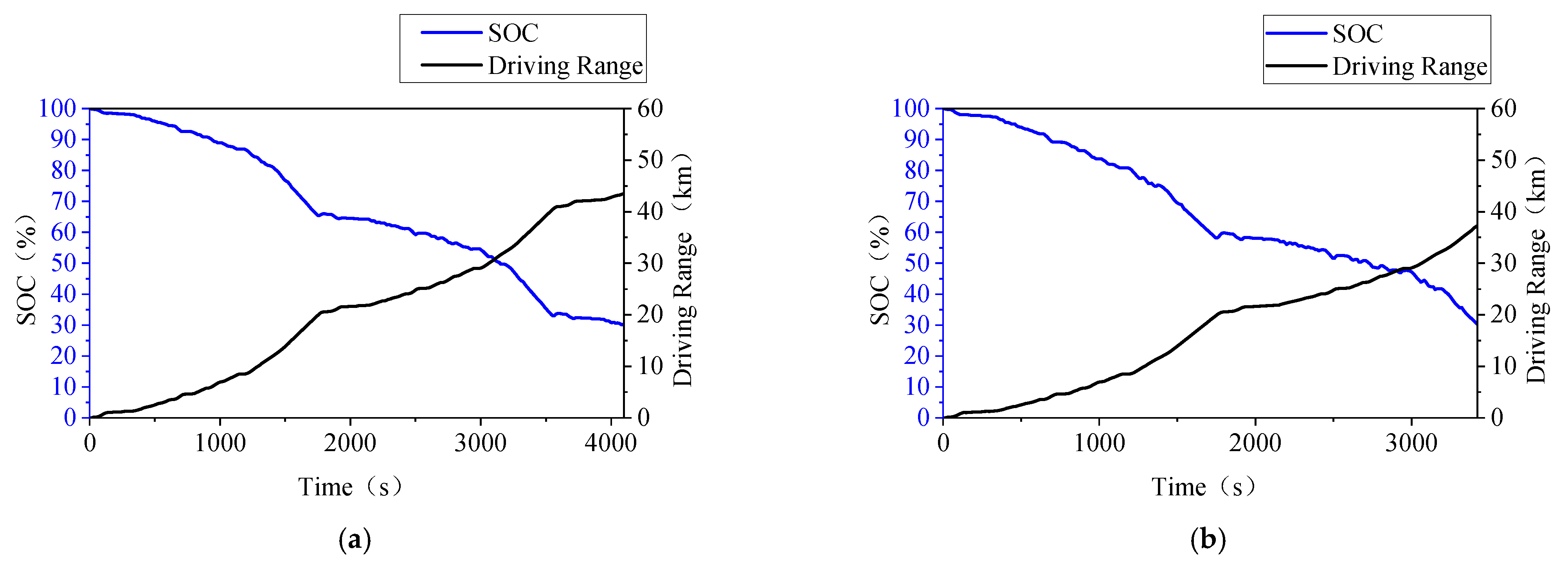

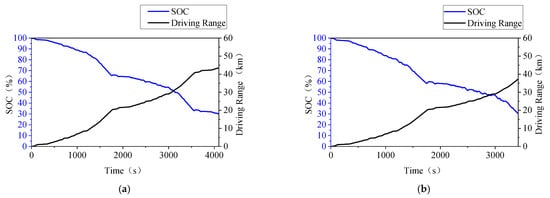

As shown in Figure 22a, under the CHTC-D operating conditions, the unloaded pure electric driving range of the dumper is 51.6 km, with an energy consumption of 0.96 kWh/km, which falls within the range of 1.2 kWh/km, meeting the performance design requirements for the dumper. As shown in Figure 22b, the loaded pure electric driving range of the dumper is 44.4 km, with an energy consumption of 1.09 kWh/km.

Figure 22.

Pure electric driving range of the CHTC-D dump truck. (a) Unloaded pure electric driving range of the CHTC-D dump truck; (b) Full-load pure electric driving range of the CHTC-D dump truck.

4.3. Simulation Analysis of Constant Power Control Strategy

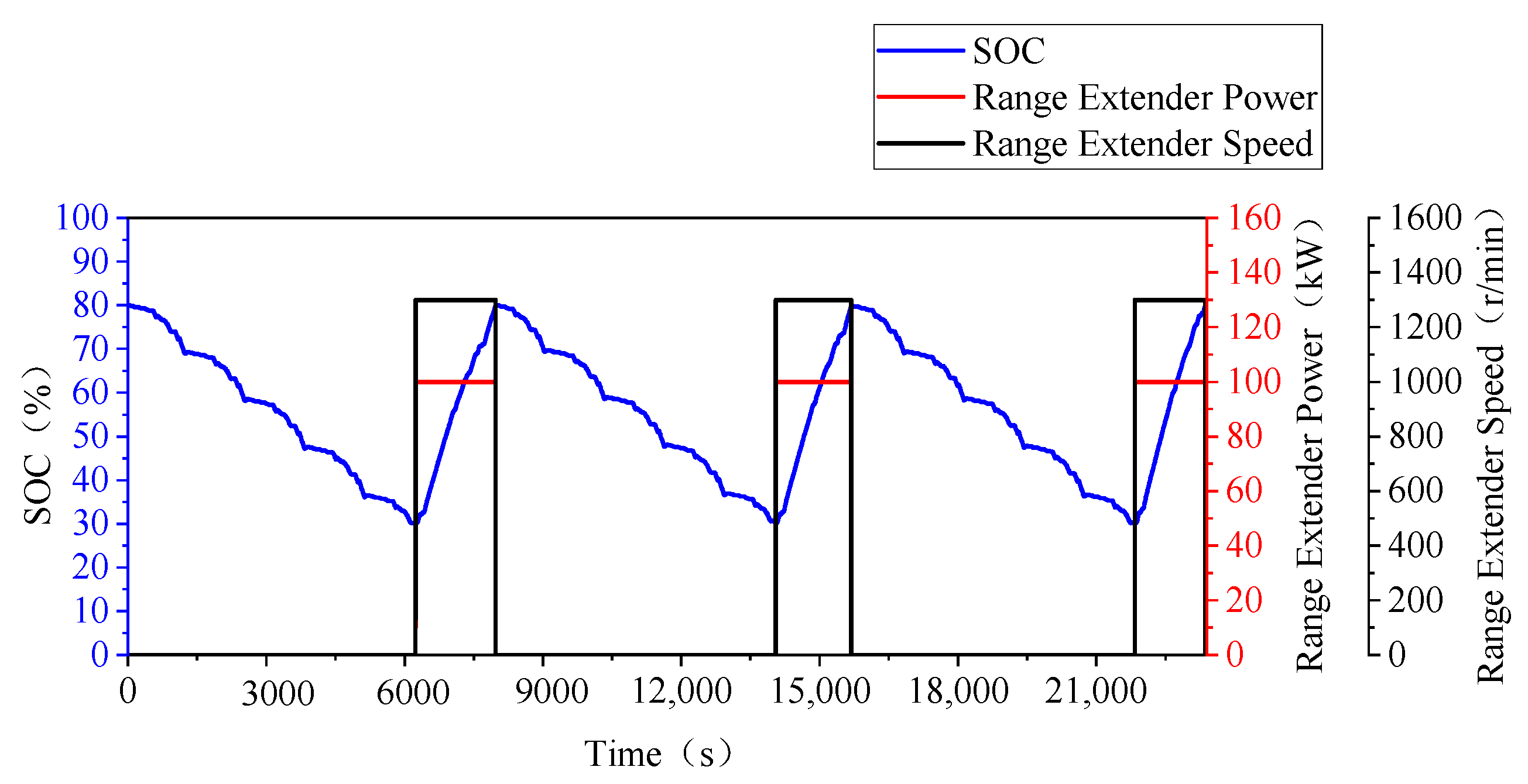

The constant power control strategy for the dumper truck is simulated under full load conditions. The simulation duration is set to 18 cycles of CHTC-D, covering a driving distance of 150.66 km. The initial SOC of the traction battery is 80%.

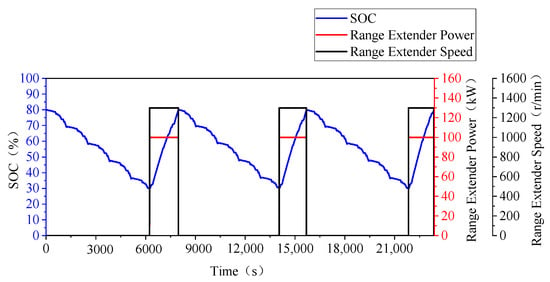

Figure 23 presents the simulation results for the dumper truck under the CHTC-D cycle conditions. It can be observed from the figure that when the SOC of the power battery falls below 30%, the range extender activates, supplying power to the drive motor at a constant power of 100 kW and a speed of 1300 r/min, while simultaneously storing the remaining electrical energy in the power battery. Once the SOC of the power battery exceeds 80%, the range extender ceases operation. The range extender was activated a total of three times, and its output power was sufficient to meet the power demands of the drive motor, while maintaining the SOC of the power battery within the range of 30% to 80%. At the end of the simulation, the SOC of the power battery was 80%, with a total consumption of 93.81 L of methanol.

Figure 23.

Simulation results of the constant power control strategy CHTC-D under cyclic operating conditions.

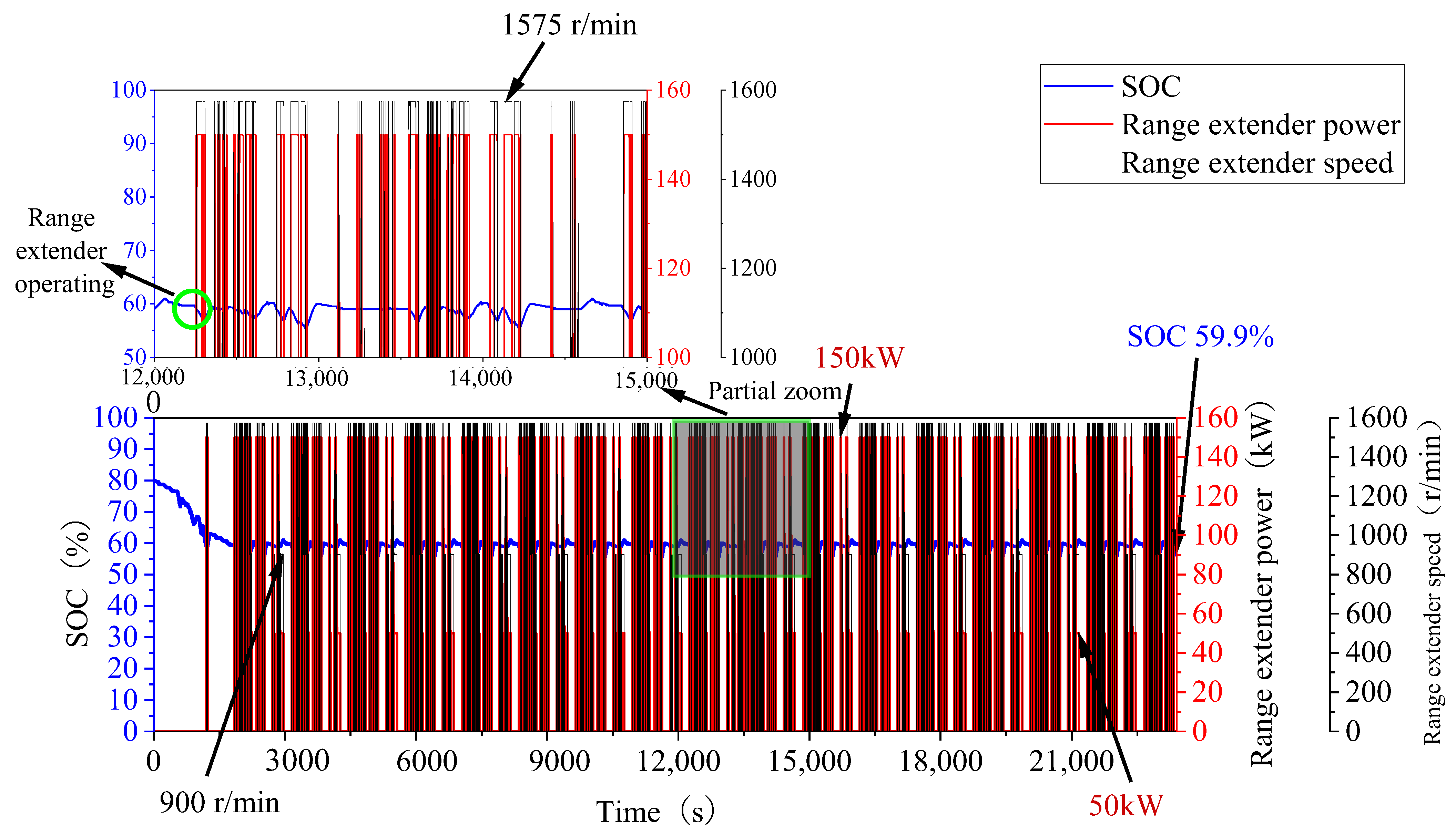

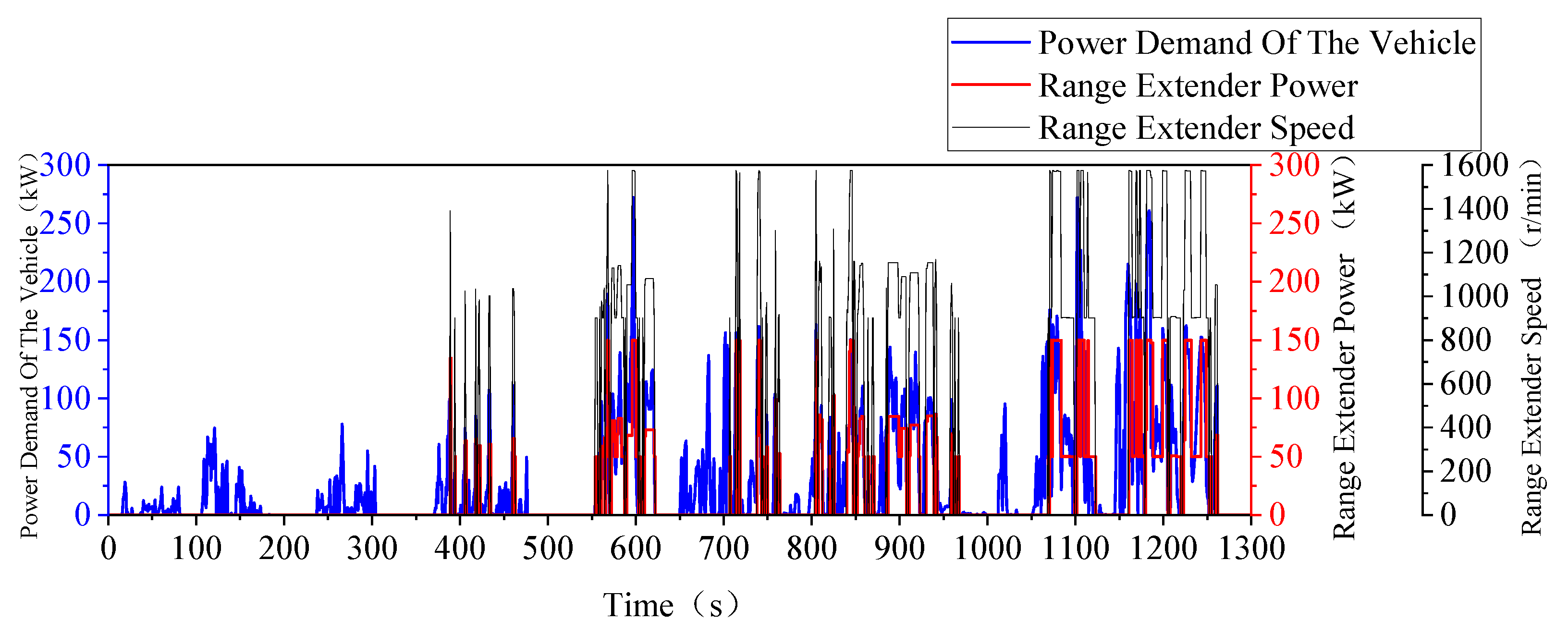

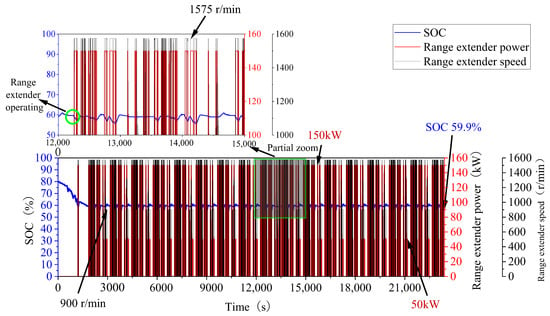

4.4. Simulation Analysis of Power Follow Control Strategy

The power-following control strategy for the dumper truck is simulated under full load conditions. The simulation duration is set to 18 cycles of CHTC-D, covering a driving distance of 150.66 km. The initial SOC of the traction battery is 80%.

Figure 24 shows the simulation results of the dumper under the CHTC-D cycle conditions. It can be seen from the figure that when the state of charge (SOC) of the power battery is below 60%, the range extender starts operating along the optimal methanol consumption curve. Depending on the power demand of the entire vehicle, the actual output power of the range extender is between 50 and 150 kW, with the actual operating speed varying between 900 and 1575 r/min. The overall simulation results conform to the rules established by the power follow control strategy. After the range extender starts, the SOC of the power battery in the dumper under the CHTC-D cycle conditions is maintained within the range of 55.4–61.1%. At the end of the simulation, the SOC of the power battery is 59.9%, and the range extender has consumed a total of 95.22 L of methanol.

Figure 24.

Simulation results of the power-following control strategy CHTC-D cycle conditions.

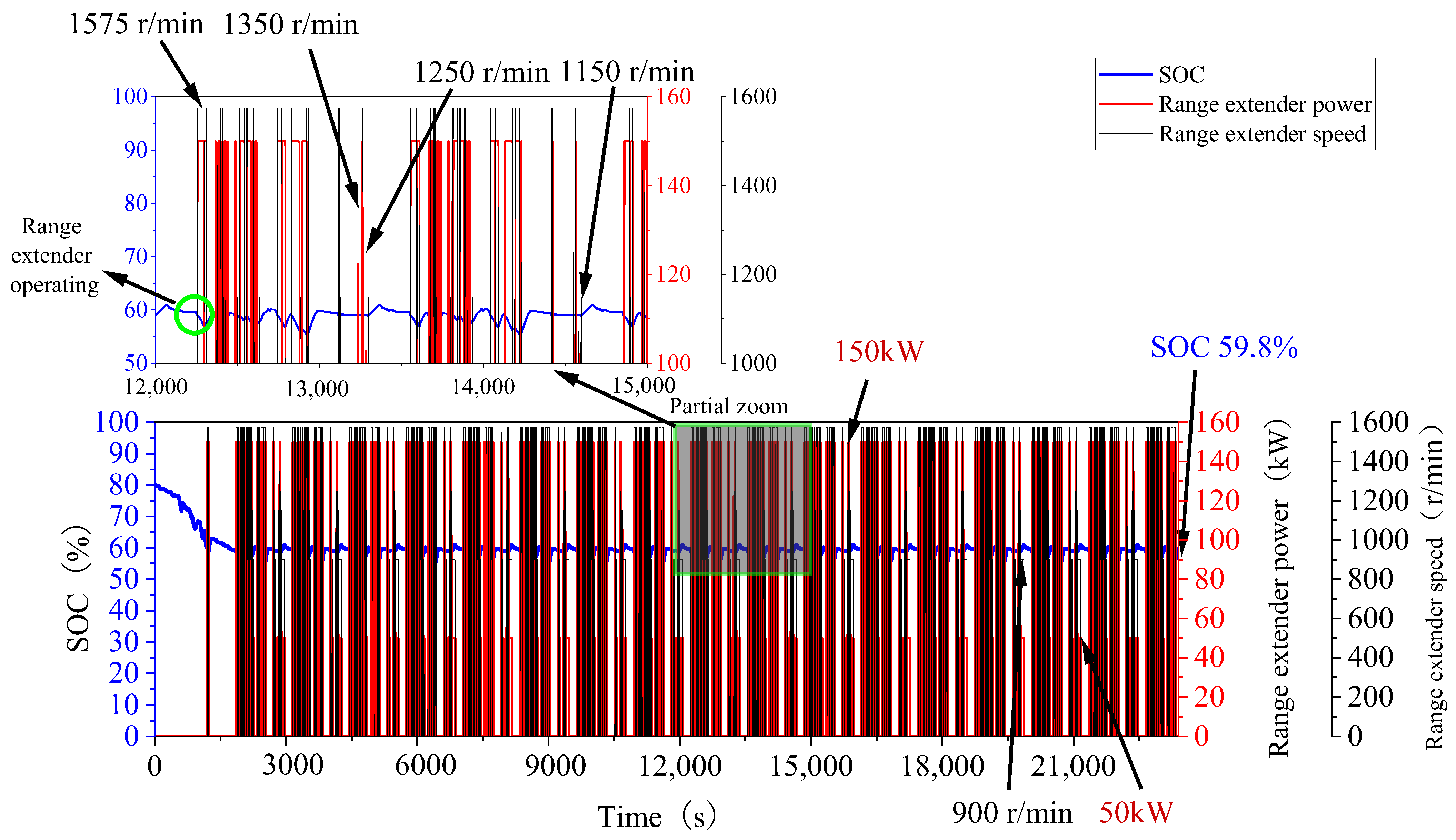

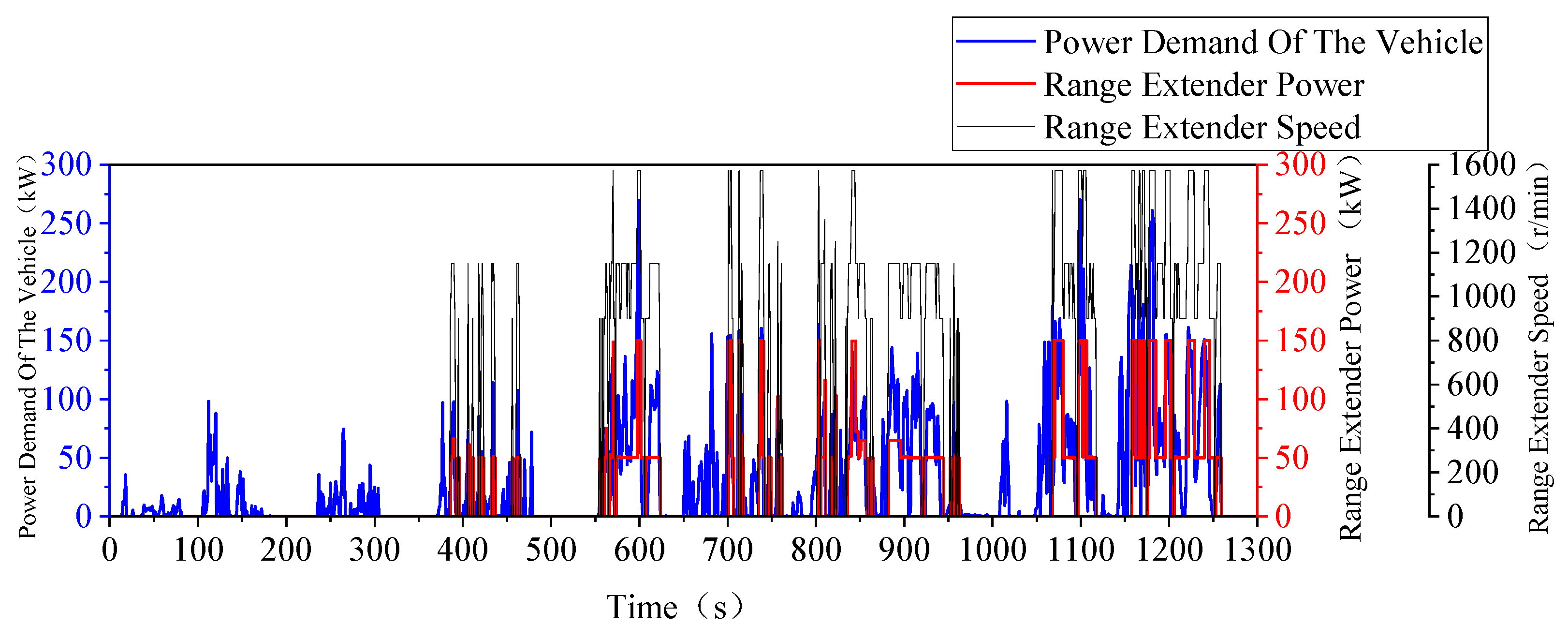

4.5. Simulation Analysis of Constant Speed and Variable Torque Control Strategy

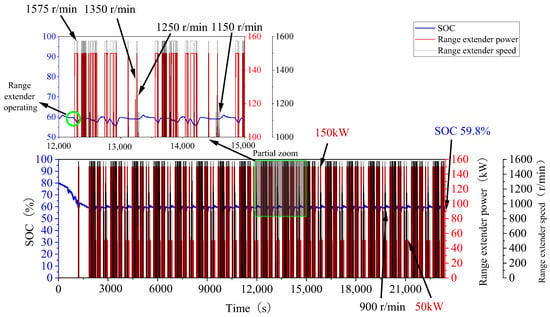

The constant speed and variable torque control strategy for the dumper truck is simulated under full load conditions. The simulation duration is set to 18 cycles of CHTC-D, covering a driving distance of 150.66 km. The initial SOC of the traction battery is 80%.

Figure 25 shows the simulation results of the dumper under the CHTC-D cycle conditions. It can be seen from the figure that, due to the fact that the SOC threshold of the fixed torque control strategy is the same as that of the power-following control strategy, the range extender starts when the power battery’s SOC falls below 60%. Depending on the power demand of the vehicle, the actual output power of the range extender is between 50 and 150 kW, with the range of 70–130 kW achieved by varying the torque output at different speeds to follow the power demand. The fixed points of 50 kW and 150 kW operate at actual speeds of 900 r/min, 1150 r/min, 1250 r/min, 1350 r/min, and 1575 r/min. The overall simulation results conform to the rules established by the fixed torque control strategy. After the range extender is activated, the SOC of the power battery in the dumper under the CHTC-D cycle conditions is maintained within the range of 55.5–60.1%, and at the end of the simulation, the SOC of the power battery is 59.8%, with the range extender consuming a total of 92.32 L of methanol.

Figure 25.

Simulation results of the constant-speed torque control strategy CHTC-D under cyclic operating conditions.

4.6. Comparative Analysis of Control Strategies

Based on the above discussion, the summary of the control strategy settings is shown in Table 9.

Table 9.

The Summary of the Control Strategy Settings.

According to the recommended calculation method for fuel consumption and driving range of hybrid commercial vehicles outlined in the national standard GB/T 19754-2021 [28], the electric energy consumed by the dump truck is converted into equivalent methanol consumption, so as to calculate the driving range of the dump truck. The energy conversion relationship is shown in the following:

In the formula, FCm represents the equivalent methanol consumption, measured in L/100 km; qm denotes the calorific value of methanol, taken as 21,570 kJ/kg; ρm indicates the density of methanol at 20 °C, taken as 0.79 kg/L; S is the driving distance of the dumper, measured in km; Eb0 refers to the electrical energy consumed by the dumper during pure electric driving before the range extender is activated, measured in kWh; Eb1 represents the electrical energy consumed by the dumper after the range extender is first activated, measured in kWh; ηA indicates the average thermal efficiency of the range extender. Within the range of 50–150 kW on the range extender’s optimal fuel consumption curve (as shown in Figure 10), data points were collected at intervals of 25 r/min, and the average value of all collected data points is calculated, resulting in an average thermal efficiency of ηA = 36%.

Since there are no clear regulations on the fuel consumption limits for vehicle-mounted M100 methanol range extenders at this stage, the methanol consumption level of dump trucks will be evaluated in accordance with the relevant provisions on the fuel consumption limits for dump trucks in the national standard GB/T 30510-2018 [29].

The equivalent diesel consumption corresponding to the methanol consumption of the dump truck, with the conversion relationship being as follows:

In the formula, FCm represents the equivalent diesel consumption, measured in L/100 km; qm is the calorific value of diesel, taken as 42,652 kJ/kg; ρm is the density of diesel at 20 °C, taken as 0.84 kg/L; and ηd is the average thermal efficiency of a straight-six diesel engine of the same displacement, taken as 44%.

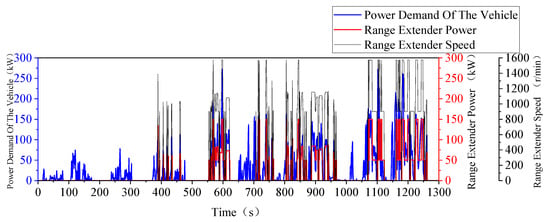

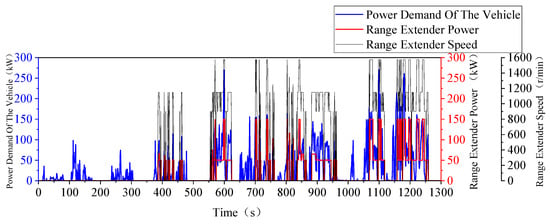

Figure 26 and Figure 27 show the simulation results of a dumper truck using a power-following control strategy and a constant-speed and variable-torque control strategy during a single CHTC-D cycle in extended range driving mode.

Figure 26.

Simulation results of a single CHTC-D cycle under the power-following control strategy.

Figure 27.

Simulation results of a single CHTC-D cycle under the constant-speed and variable-torque control strategy.

In a single CHTC-D cycle condition for the dump truck, the average vehicle speed is 23.19 km/h, the maximum required power of the entire vehicle is 260.23 kW, and the average required power is 28.16 kW. The maximum output power of the range extender is 150 kW. Under the power-following control strategy, the average output power is 24.71 kW, and under the constant-speed and variable-torque control strategy, the average output power is 24.52 kW.

The simulation results of fuel economy under three control strategies for dump trucks are shown in Table 10.

Table 10.

Statistical Results of Fuel Economy Simulation for Three Control Strategies of Dump Trucks.

Under the CHTC-D cycle condition, the dump truck exhibits superior fuel economy when adopting the constant-speed and variable-torque control strategy: compared with the constant-power control strategy, methanol consumption is reduced by 0.57%; and compared with the power-following control strategy, methanol consumption is decreased by 3.04%.

For the design of dump trucks with a total mass of 20–25 tons, the national standard GB/T 30510-2018 [29] specifies a diesel consumption limit of 37.5 L/100 km. The extended-range electric dump truck studied in this paper, under the three control strategies in the CHTC-D cycle condition, has equivalent diesel consumption that meets all the national standard requirements, accounting for only 64.88–66.93% of the national standard limit.

In addition, based on the current market prices in the Shanxi region, China, the price of M100 methanol fuel is ¥2100 yuan/ton, and the price of 0# diesel is ¥7.09 yuan/L. The fuel cost of methanol range-extended electric dump trucks is approximately 60% of that of diesel range-extended electric dump trucks. Therefore, M100 methanol range-extended electric dump trucks have obvious advantages in terms of fuel costs.

5. Summary

Combining the operating characteristics of dump trucks during extended-range driving under low battery conditions and the universal characteristics of the self-developed M100 methanol range extender, this study presents a rule-based constant power control strategy, a power-following control strategy, and an energy recovery strategy. A constant-speed and variable-torque control strategy based on the rule-based control strategy for the range extender is further proposed, which optimizes the operating speed range of the range extender.

A complete vehicle powertrain simulation model for the dump truck was established using AVL Cruise and MATLAB R2022b/Simulink. The simulation results of the overall vehicle dynamic performance of the dump truck show that the errors between the maximum speed, 0–50 km/h acceleration time, maximum climbing gradient of the dump truck, and the design indicators are all within 5%. This indicates that the parameter matching in the dump truck’s power system is reasonable, and the overall vehicle simulation model meets the requirements of engineering design.

Based on the vehicle simulation model, the simulation results of the dump truck under the China Heavy-duty Commercial Vehicle Test Cycle-Dynamic (CHTC-D) show that the constant-speed and variable-torque control strategy saves 0.57% and 3.04% of methanol, respectively, compared with the constant power control strategy and the power-following control strategy, exhibiting better fuel economy. Meanwhile, on the premise of meeting the vehicle’s required power, the constant-speed and variable-torque control strategy maintains the state of charge (SOC) of the power battery within the range of 55–60%. This not only reduces the charge–discharge depth of the power battery under the constant power control strategy, but also decreases the frequent switching of the range extender’s rotational speed under the power-following control strategy, thus possessing certain engineering application value. The fuel cost of the methanol extended-range electric dump truck is approximately 60% of that of the diesel extended-range electric dump truck. It can be seen from this that the M100 methanol extended-range electric dump truck has significant advantages in terms of fuel cost.

For the constant-speed and variable-torque control strategy proposed in this paper, future research will take the methanol consumption of the range extender as the optimization objective, set both the power interval values and the three fixed rotational speeds as design variables, and conduct optimization design and sensitivity analysis. Based on this, the start-stop test and variable-power test of the range extender will be carried out to further verify the response performance of the control strategy, laying a solid foundation for subsequent real-vehicle tests.

Author Contributions

Data curation, Y.D.; writing—original draft preparation, J.Z. and W.Z.; writing—review and editing, X.Z.; funding acquisition, Y.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Science and Technology Innovation Plan of Colleges and Universities of Shanxi Province of China (CN) (Grant No. 2024L232), and the Excellent Doctoral Award Fund for Working in Shanxi (Grant No. 20242037), and the Doctoral Startup Foundation of Taiyuan University of Science and Technology (Grant No. 20232113), Billion-Yuan Project for Higher Education in Shanxi Province (Grant No. 20242083) and Shanxi Engineering Research Center of Internal Combustion Engine Power Technology, and Advanced Technology Innovation Center of Zero Carbon Power Special Vehicle.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Author Yanbo Dai was employed by CNPC Jichai Power Company Limited. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Liu, Y.; Qiao, J.; Xu, H.; Liu, J.; Chen, Y. Optimal Vehicle Size and Driving Condition for Extend-ed-Range Electric Vehicles in China: A Life Cycle Perspective. PLoS ONE 2020, 15, 0241967. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Zhu, J.; Hu, Z.; Meng, Y.; Zhao, Y. Multi-objective Optimization of Performance for High-power Methanol Engine. J. Chongqing Univ. Technol. (Nat. Sci.) 2023, 37, 56–63. [Google Scholar]

- Wang, Q.; You, S.; Li, L.; Yang, C. Survey on Energy Management Strategy for Plug-in Hybrid Electric Vehicles. Jixie Gongcheng Xuebao/J. Mech. Eng. 2017, 53, 1–19. [Google Scholar] [CrossRef]

- Larsson, V.; Johannesson, L.; Egardt, B. Analytic Solutions to the Dynamic Programming Sub-problem in Hybrid Vehicle Energy Management. IEEE Trans. Veh. Technol. 2015, 64, 1458–1467. [Google Scholar] [CrossRef]

- Shi, L. Research on Power System Parameter Matching and Vehicle Control Strategy of Extended-Range Electric Vehicles. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2022. [Google Scholar]

- Hu, Y.J.; Song, K.; Zhang, T. Energy Management Strategy for a Fuel Cell E-REV Based on Minimum Power Loss Algorithm. Adv. Mater. Res. 2012, 1775, 603–608. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Chen, J.; Zhang, X. Study on Energy Management Strategy and Dynamic Modeling for Auxiliary Power Units in Range-Extended Electric Vehicles. Appl. Energy 2016, 194, 363–375. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, J.; Yang, T.; Zhang, B. Research on Control Strategy Matching of Vehicle M100 Methanol Range Extender. Mach. Des. Manuf. 2025, 3, 372–377. [Google Scholar]

- Liu, H.; Lei, Y.; Yin, X.; Fu, Y.; Li, X. Multi-point control strategy optimization for auxiliary power unit of range-extended electric vehicle. J. Jilin Univ. (Eng. Technol. Ed.) 2022, 52, 1741–1750. [Google Scholar]

- Yang, Y.; Xu, Y.; Zhang, H.; Yang, F.; Ren, J.; Wang, X.; Jin, P.; Huang, D. Research on the Energy Management Strategy of Extended Range Electric Vehicles Based on a Hybrid Energy Storage System. Energy Rep. 2022, 8, 6602–6623. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Song, Z. Control Strategy and Performance Simulation Study on Extended Range Electric Vehicle. E3S Web Conf. 2019, 79, 03006. [Google Scholar] [CrossRef]

- Liu, H.; Lei, Y.; Fu, Y.; Li, X. A Novel Hybrid-Point-Line Energy Management Strategy Based on Multi-Objective Optimization for Range-Extended Electric Vehicle. Energy 2022, 247, 123357. [Google Scholar] [CrossRef]

- Altun, E.Y.; Kutlar, A.O. Energy Management Systems’ Modeling and Optimization in Hybrid Electric Vehicles. Energies 2024, 17, 1696. [Google Scholar] [CrossRef]

- Zhong, Y.; Qiu, H.; Li, F.; Fan, Z.; Yi, S. Energy Management Control of Range-Extended Electric Vehicle Based on Fuzzy Control. Veh. Engine 2024, 02, 68–74+82. [Google Scholar]

- Nie, J.; Chen, C.; Wei, C.; Wang, A.; Liu, Y. Adaptive fuzzy energy management strategy for range-extended electric vehicles integrated with deep learning. Energy Sci. Eng. 2024, 12, 2164–2179. [Google Scholar] [CrossRef]

- Gu, Y. Study on Adaptive Energymanagement Strategy Forextended-Range Electric Vehiclebased on Micro-Trips Identification. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2020. [Google Scholar]

- Song, P. Research on Driving Cycle Prediction and Intelligent Energy Management Strategy for Plug-in Hybrid Electric Buses. Ph.D. Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

- Zhang, F.; Wang, L.; Coskun, S.; Pang, H.; Cui, Y.; Xi, J. Energy Management Strategies for Hybrid Electric Vehicles: Review, Classification, Comparison, and Outlook. Energies 2020, 13, 3352. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, X.; Liu, Q.; Li, S.; Xu, Y. Review Article: A Comprehensive Review of Energy Management Strategies for Hybrid Electric Vehicles. Mech. Sci. 2022, 13, 147–188. [Google Scholar] [CrossRef]

- Villani, M.; Shiledar, A.; D’Arpino, M.; Rizzoni, G. Battery Selection and Optimal Energy Management for a Range-Extended Electric Delivery Truck. SAE Int. J. Adv. Curr. Pract. Mobil. 2022, 5, 1282–1291. [Google Scholar] [CrossRef]

- Niu, L.; Zhang, Q.; Zhu, F.; Zong, F.; Zheng, F. Fuzzy Control Strategy for Range-extended Electric Vehicles Based on Global Optimization Algorithm. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2022, 41, 137–145. [Google Scholar]

- Gao, F.; Gao, X.; Zhang, H.; Yang, K.; Song, Z. Energy Management Strategy for Fuel Cell Tram with Both Optimal Global and Instantaneous Characteristics. Trans. China Electrotech. Soc. 2023, 38, 5923–5938. [Google Scholar]

- Yang, Y.; Zhang, Y.; Tian, J.; Li, T. Adaptive Real-Time Optimal Energy Management Strategy for Extender Range Electric Vehicle. Energy 2020, 197, 117237. [Google Scholar] [CrossRef]

- Wang, Y.; Lou, D.; Xu, N.; Fang, L.; Tan, P. Energy Management and Emission Control for Range Extended Electric Vehicles. Energy 2021, 236, 121370. [Google Scholar] [CrossRef]

- Yao, M.; Zhu, B.; Zhang, N. Adaptive Real-Time Optimal Control for Energy Management Strategy of Extended Range Electric Vehicle. Energy Convers. Manag. 2021, 234, 113874. [Google Scholar] [CrossRef]

- Madani, S.S.; Shabeer, Y.; Allard, F.; Fowler, M.; Ziebert, C.; Wang, Z.; Panchal, S.; Chaoui, H.; Mekhilef, S.; Dou, S.X.; et al. A Comprehensive Review on Lithium-Ion Battery Lifetime Prediction and Aging Mechanism Analysis. Batteries 2025, 11, 127. [Google Scholar] [CrossRef]

- GB/T 38146.2-2019; China Automotive Test Cycle—Part 2: Heavy—Duty Commercial Vehicles. Standardization Administration of the PRC: Beijing, China, 2019.

- GB/T 19754-2021; Test Methods for Energy Consumption of Heavy-Duty Hybrid Electric Vehicles. Standardization Administration of the PRC: Beijing, China, 2021.

- GB/T 30510-2018; Fuel Consumption Limits for Heavy-Duty Commercial Vehicles. Standardization Administration of the PRC: Beijing, China, 2018.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).