Combustion Air Humidifier for a Biomass Boiler with Flue Gas Condensation

Abstract

1. Introduction

2. Materials and Methods

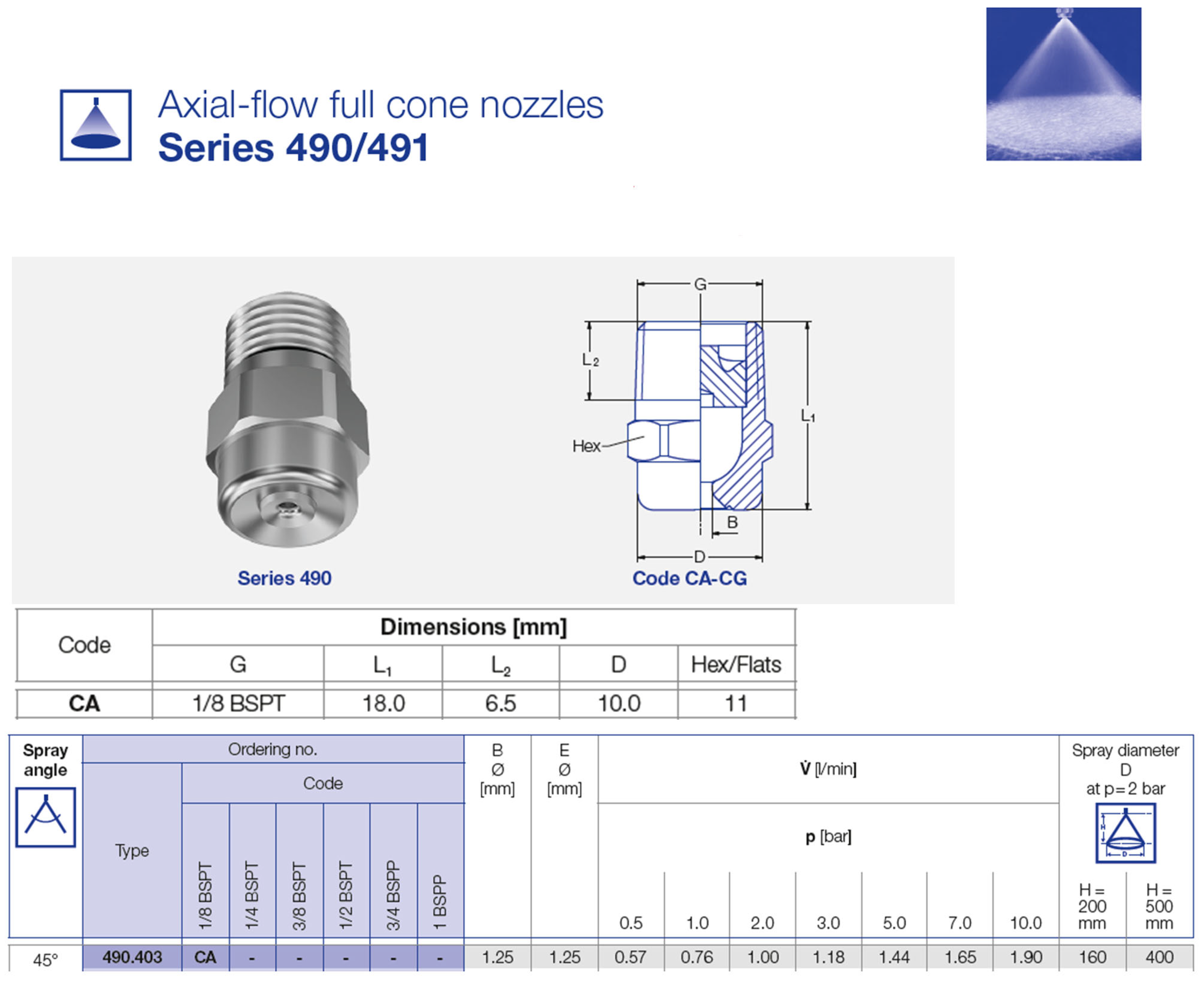

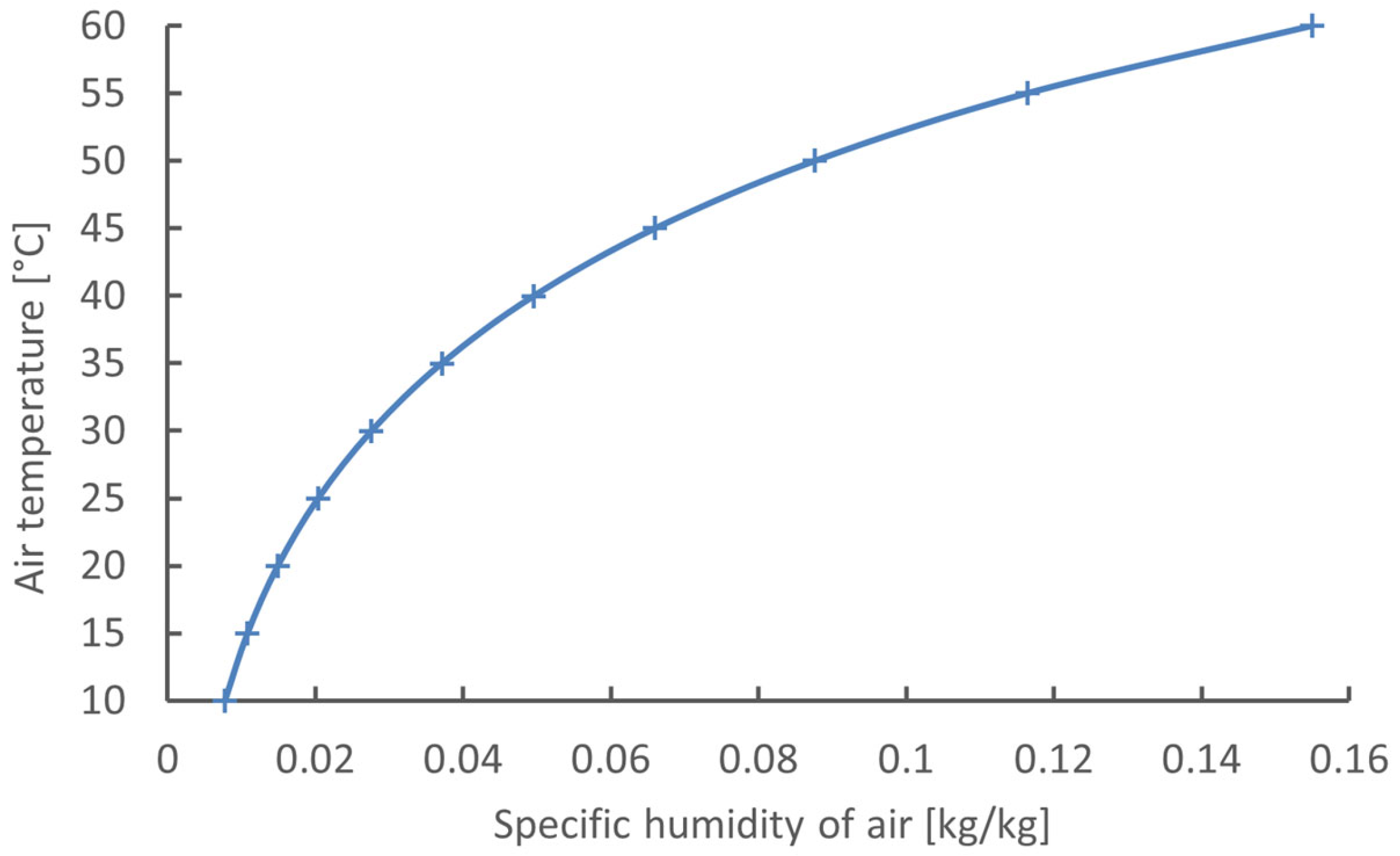

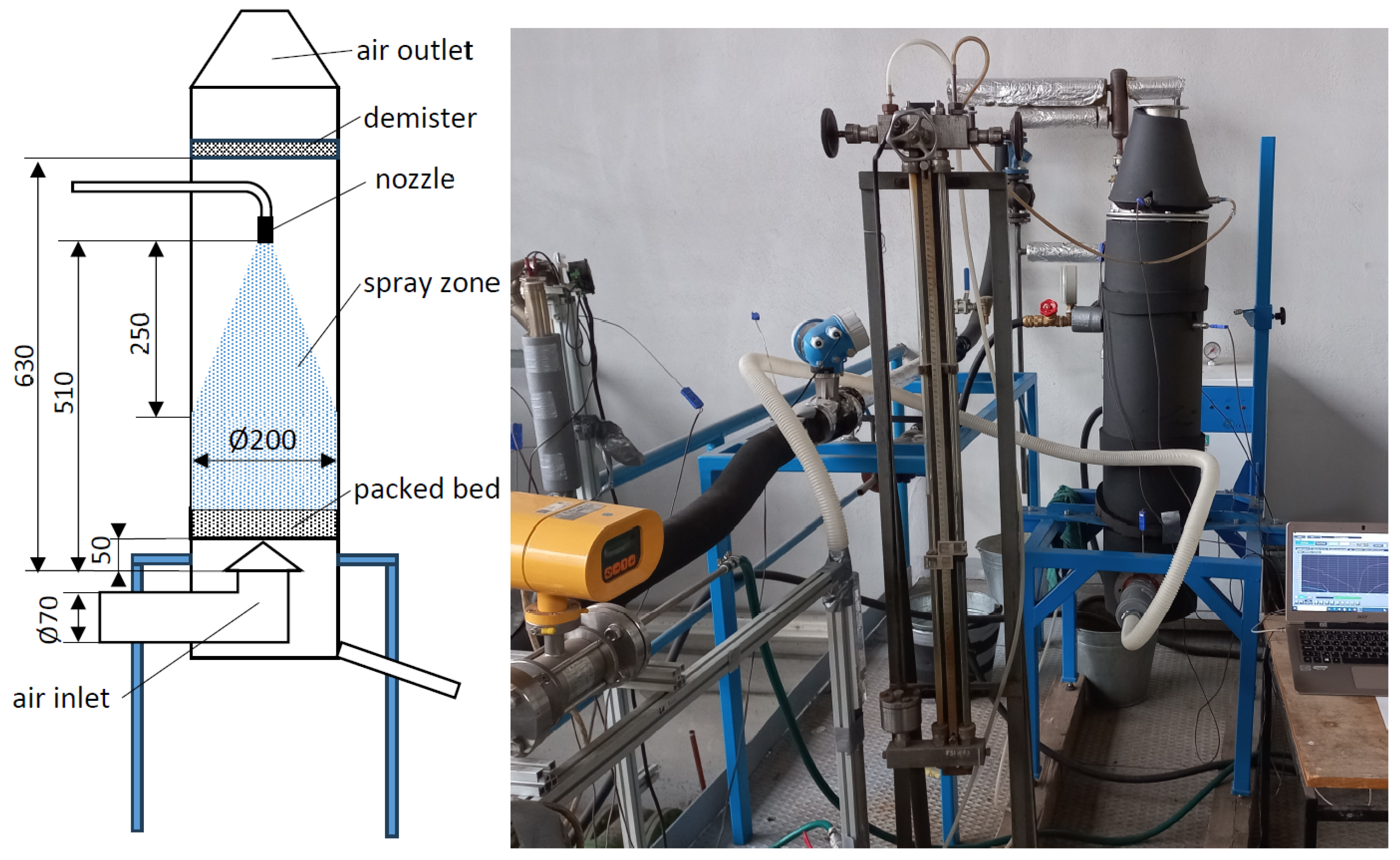

2.1. Combustion Air Humidifier

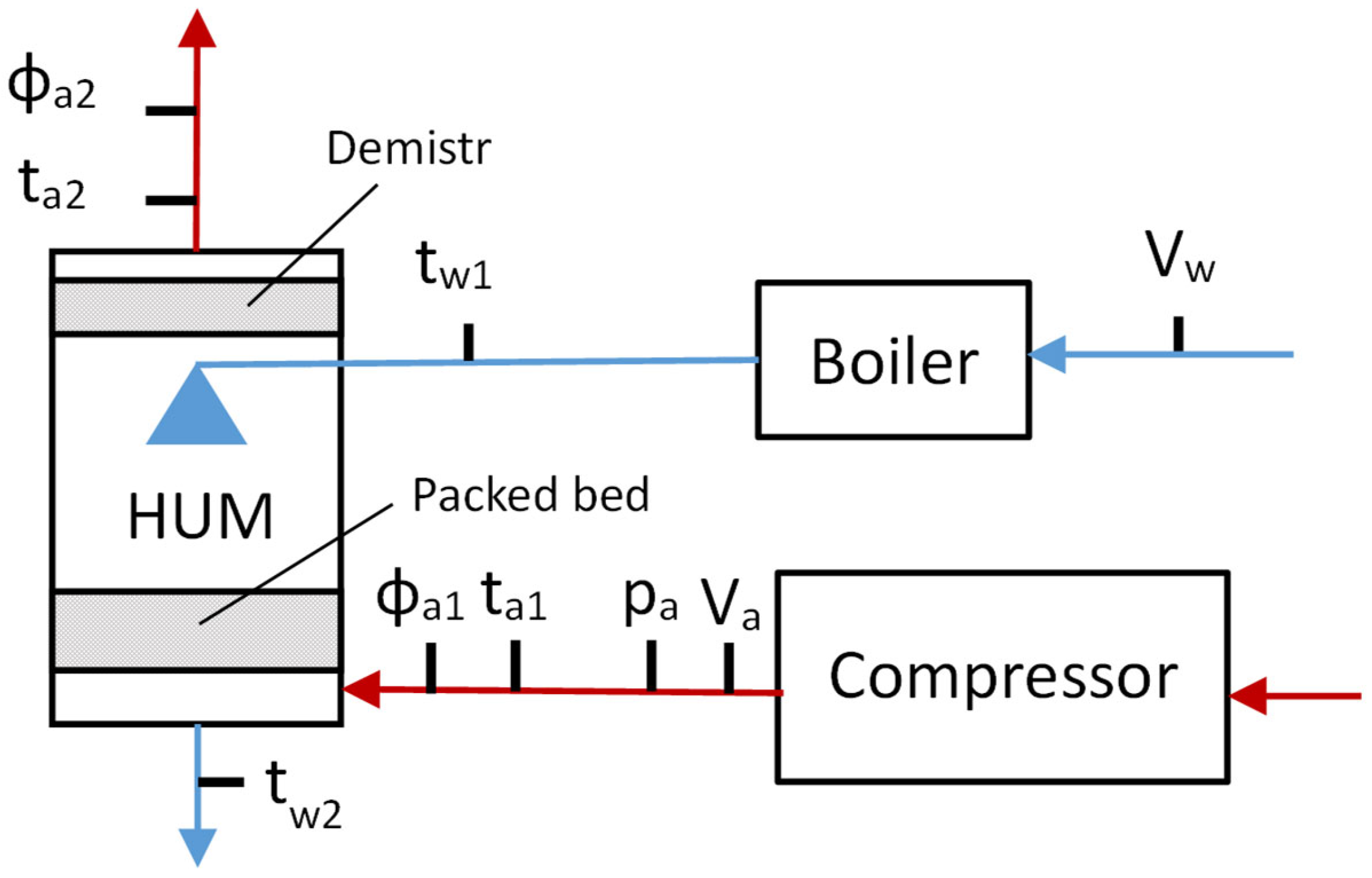

2.2. Experimental Setup

2.3. Evaluation of Experiments

2.4. Uncertainty Analysis

3. Results and Discussion

- (1)

- Without packed bed (without).

- (2)

- With packed bed of Raschig rings with a volume of 300 mL ≈ a layer of cca 1 cm (RR300).

- (3)

- With packed bed of Raschig rings with a volume of 1400 mL ≈ a layer of cca 5 cm (RR1400).

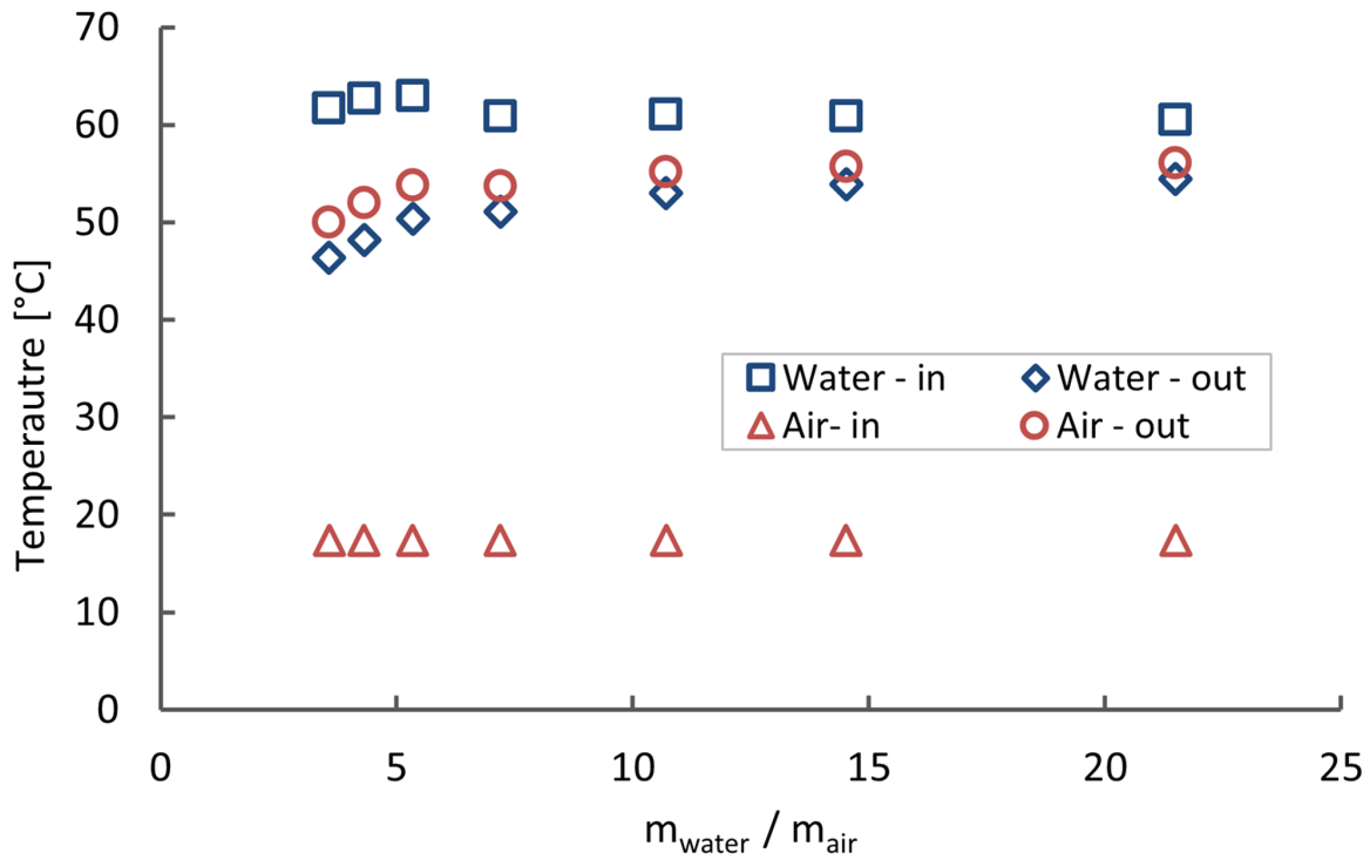

An Analysis of the Effect of Spray Water Temperature and Air Velocity on Heat and Mass Transfer in the Humidifier

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | specific surface, m2/m3 |

| cp | specific heat capacity, J/kgK |

| D | diffusion coefficient, m2/s |

| DH | district heating |

| d | diameter, m |

| h | specific enthalpy, kJ/kg |

| HTC | heat transfer coefficient |

| Lef | Lewis factor |

| m | mass flow rate, kg/s |

| Nu | Nusselt number |

| p | pressure, Pa |

| Pr | Prandtl number |

| n | molar flux, kmol/m2s |

| Q | heat transfer rate, W |

| Re | Reynolds number |

| RR | Raschig rings |

| S | surface, m2 |

| St | Stanton number |

| Stm | mass Stanton number |

| t | temperature, °C |

| x | specific humidity, kg/kg |

| V | volume, m3 |

| volume flow rate, m3/s | |

| y | molar fraction, mol.% |

| w | velocity, m/s |

| α | heat transfer coefficient, W/m2K |

| αV | volumetric heat transfer coefficient, kW/m3K |

| β | mass transfer coefficient, m/s |

| ϕ | relative humidity,% |

| λ | thermal conductivity, W/mK |

| μ | dynamic viscosity, Pas |

| ν | kinematic viscosity, m2/s |

| ρ | density, kg/m3 |

| ΔT | temperature difference, °C |

| Subscripts | |

| a | air |

| amb | ambient |

| dr | droplet |

| da | dry air |

| G | gas |

| L | liquid |

| o | outer |

| pb | packed bed |

| sat | saturated |

| w | water |

| wv | water vapour |

| ∆W | evaporated water |

| 1 | inlet |

| 2 | outlet |

Appendix A

Appendix B

| State | Packed | Va | ϕa1 | Tϕ1 | xa1 | Vw | Tw1 | Tw2 | Ta1 | Ta2 | ϕa2 | xa2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | Bed | Nm3/h | % | °C | kg/kg | L/min | °C | °C | °C | °C | % | kg/kg |

| 1 | RR 1400 | 2.7 | 44% | 17.3 | 0.005 | 0.921 | 61.7 | 54.6 | 17.5 | 59.9 | 100% | 0.154 |

| 2 | RR 1400 | 3.4 | 44% | 17.3 | 0.005 | 0.934 | 61.6 | 53.4 | 17.5 | 59.3 | 100% | 0.149 |

| 3 | RR 1400 | 4 | 44% | 17.3 | 0.005 | 0.931 | 61.6 | 51.8 | 17.5 | 58.5 | 100% | 0.142 |

| 4 | RR 1400 | 6 | 44% | 17.3 | 0.005 | 0.934 | 62.2 | 49.9 | 17.5 | 57.6 | 100% | 0.135 |

| 5 | RR 1400 | 8 | 44% | 17.3 | 0.005 | 0.919 | 62.8 | 47.7 | 17.5 | 56.4 | 100% | 0.126 |

| 6 | RR 1400 | 10 | 44% | 17.3 | 0.005 | 0.918 | 63.3 | 45.8 | 17.5 | 55.1 | 100% | 0.117 |

| 7 | RR 1400 | 12 | 44% | 17.3 | 0.005 | 0.927 | 63.6 | 44.3 | 17.5 | 54.0 | 100% | 0.110 |

| 8 | RR 300 | 2.7 | 44% | 17.3 | 0.005 | 0.929 | 63.0 | 56.2 | 17.5 | 59.5 | 100% | 0.151 |

| 9 | RR 300 | 3.4 | 44% | 17.3 | 0.005 | 0.947 | 61.9 | 54.3 | 17.5 | 57.9 | 100% | 0.138 |

| 10 | RR 300 | 4 | 44% | 17.3 | 0.005 | 0.936 | 62.0 | 53.3 | 17.5 | 57.5 | 100% | 0.134 |

| 11 | RR 300 | 6 | 44% | 17.3 | 0.005 | 0.925 | 62.1 | 50.5 | 17.5 | 55.7 | 100% | 0.121 |

| 12 | RR 300 | 8 | 44% | 17.3 | 0.005 | 0.927 | 62.5 | 48.6 | 17.5 | 54.4 | 100% | 0.113 |

| 13 | RR 300 | 10 | 44% | 17.3 | 0.005 | 0.930 | 62.8 | 47.0 | 17.5 | 53.2 | 100% | 0.105 |

| 14 | RR 300 | 12 | 44% | 17.3 | 0.005 | 0.925 | 63.3 | 45.6 | 17.5 | 52.1 | 100% | 0.099 |

| 15 | - | 2.7 | 44% | 17.3 | 0.005 | 0.924 | 60.5 | 54.5 | 17.4 | 56.1 | 100% | 0.124 |

| 16 | - | 3.4 | 44% | 17.3 | 0.005 | 0.936 | 60.9 | 53.9 | 17.4 | 55.7 | 100% | 0.121 |

| 17 | - | 4 | 44% | 17.3 | 0.005 | 0.921 | 61.1 | 53.0 | 17.4 | 55.2 | 100% | 0.117 |

| 18 | - | 6 | 44% | 17.3 | 0.005 | 0.928 | 60.9 | 51.1 | 17.4 | 53.8 | 100% | 0.108 |

| 19 | - | 8 | 44% | 17.3 | 0.005 | 0.918 | 63.0 | 50.4 | 17.4 | 53.8 | 100% | 0.109 |

| 20 | - | 10 | 44% | 17.3 | 0.005 | 0.926 | 62.7 | 48.2 | 17.4 | 52.0 | 100% | 0.098 |

| 21 | - | 12 | 44% | 17.3 | 0.005 | 0.922 | 61.7 | 46.4 | 17.4 | 50.0 | 100% | 0.088 |

| 22 | RR 1400 | 2.7 | 31% | 13.6 | 0.003 | 0.940 | 42.0 | 39.4 | 13.9 | 41.7 | 100% | 0.055 |

| 23 | RR 1400 | 4 | 31% | 13.6 | 0.003 | 0.940 | 42.3 | 38.5 | 13.9 | 41.6 | 100% | 0.054 |

| 24 | RR 1400 | 6 | 31% | 13.6 | 0.003 | 0.940 | 43.2 | 37.9 | 13.9 | 41.7 | 100% | 0.055 |

| 25 | RR 1400 | 8 | 31% | 13.6 | 0.003 | 0.933 | 44.0 | 37.1 | 13.9 | 41.5 | 100% | 0.054 |

| 26 | RR 1400 | 10 | 31% | 13.6 | 0.003 | 0.924 | 44.7 | 36.3 | 13.9 | 41.3 | 100% | 0.053 |

| 27 | RR 1400 | 12 | 31% | 13.6 | 0.003 | 0.948 | 45.3 | 35.6 | 13.9 | 40.8 | 100% | 0.052 |

| 28 | RR 300 | 2.7 | 31% | 13.6 | 0.003 | 0.933 | 42.7 | 40.2 | 13.7 | 41.6 | 100% | 0.054 |

| 29 | RR 300 | 4 | 31% | 13.6 | 0.003 | 0.921 | 42.9 | 39.0 | 13.7 | 41.0 | 100% | 0.053 |

| 30 | RR 300 | 6 | 31% | 13.6 | 0.003 | 0.932 | 43.3 | 38.0 | 13.7 | 40.6 | 100% | 0.051 |

| 31 | RR 300 | 8 | 31% | 13.6 | 0.003 | 0.923 | 43.5 | 37.2 | 13.7 | 39.9 | 100% | 0.049 |

| 32 | RR 300 | 10 | 31% | 13.6 | 0.003 | 0.930 | 43.6 | 36.0 | 13.7 | 39.1 | 100% | 0.047 |

| 33 | RR 300 | 12 | 31% | 13.6 | 0.003 | 0.954 | 43.7 | 35.3 | 13.7 | 38.5 | 100% | 0.045 |

| 34 | - | 2.7 | 31% | 13.6 | 0.003 | 0.936 | 43.0 | 40.5 | 13.7 | 41.1 | 100% | 0.053 |

| 35 | - | 4 | 31% | 13.6 | 0.003 | 0.932 | 43.0 | 39.4 | 13.7 | 40.2 | 100% | 0.050 |

| 36 | - | 6 | 31% | 13.6 | 0.003 | 0.926 | 43.0 | 38.2 | 13.7 | 39.3 | 100% | 0.048 |

| 37 | - | 8 | 31% | 13.6 | 0.003 | 0.939 | 43.1 | 37.3 | 13.7 | 38.5 | 100% | 0.046 |

| 38 | - | 10 | 31% | 13.6 | 0.003 | 0.931 | 43.1 | 36.3 | 13.7 | 37.7 | 100% | 0.043 |

| 39 | - | 12 | 31% | 13.6 | 0.003 | 0.922 | 42.9 | 35.2 | 13.7 | 36.7 | 100% | 0.041 |

Appendix C

| State | Qin = Qw | Qa | Qloss | Qout 1 | diffr. 2 | mw1 | mda | mwv1 | mw2 | mwv2 |

|---|---|---|---|---|---|---|---|---|---|---|

| No. | kW | kW | kW | kW | % | kg/h | kg/h | kg/h | kg/h | kg/h |

| 1 | 0.48 | 0.42 | 0.02 | 0.44 | 9.7 | 54.4 | 3.46 | 0.02 | 53.9 | 0.53 |

| 2 | 0.57 | 0.50 | 0.02 | 0.52 | 7.5 | 55.1 | 4.36 | 0.02 | 54.5 | 0.65 |

| 3 | 0.67 | 0.57 | 0.02 | 0.59 | 12.8 | 55.0 | 5.13 | 0.03 | 54.3 | 0.73 |

| 4 | 0.85 | 0.81 | 0.02 | 0.83 | 3.0 | 55.2 | 7.70 | 0.04 | 54.2 | 1.04 |

| 5 | 1.03 | 1.01 | 0.02 | 1.03 | −0.3 | 54.3 | 10.3 | 0.06 | 53.1 | 1.30 |

| 6 | 1.18 | 1.17 | 0.02 | 1.19 | −0.6 | 54.3 | 12.8 | 0.07 | 52.9 | 1.51 |

| 7 | 1.32 | 1.32 | 0.02 | 1.34 | −1.6 | 54.9 | 15.4 | 0.08 | 53.3 | 1.69 |

| 8 | 0.47 | 0.41 | 0.02 | 0.43 | 9.5 | 54.8 | 3.46 | 0.02 | 54.3 | 0.52 |

| 9 | 0.53 | 0.47 | 0.02 | 0.49 | 8.9 | 55.9 | 4.36 | 0.02 | 55.3 | 0.60 |

| 10 | 0.61 | 0.54 | 0.02 | 0.56 | 8.3 | 55.3 | 5.13 | 0.03 | 54.6 | 0.69 |

| 11 | 0.79 | 0.73 | 0.02 | 0.74 | 6.0 | 54.7 | 7.70 | 0.04 | 53.8 | 0.93 |

| 12 | 0.95 | 0.90 | 0.02 | 0.92 | 3.1 | 54.8 | 10.3 | 0.06 | 53.7 | 1.16 |

| 13 | 1.09 | 1.05 | 0.02 | 1.07 | 1.7 | 55.0 | 12.8 | 0.07 | 53.7 | 1.35 |

| 14 | 1.20 | 1.18 | 0.02 | 1.20 | 0.2 | 54.7 | 15.4 | 0.08 | 53.3 | 1.52 |

| 15 | 0.41 | 0.33 | 0.02 | 0.35 | 14.1 | 54.6 | 3.46 | 0.02 | 54.2 | 0.43 |

| 16 | 0.48 | 0.41 | 0.02 | 0.43 | 11.0 | 55.3 | 4.36 | 0.02 | 54.8 | 0.53 |

| 17 | 0.55 | 0.47 | 0.02 | 0.49 | 11.0 | 54.4 | 5.13 | 0.03 | 53.8 | 0.60 |

| 18 | 0.68 | 0.65 | 0.02 | 0.67 | 1.1 | 54.9 | 7.70 | 0.04 | 54.1 | 0.83 |

| 19 | 0.86 | 0.87 | 0.02 | 0.89 | −2.9 | 54.3 | 10.3 | 0.06 | 53.2 | 1.12 |

| 20 | 0.99 | 0.99 | 0.02 | 1.00 | −0.8 | 54.8 | 12.8 | 0.07 | 53.6 | 1.26 |

| 21 | 1.04 | 1.05 | 0.02 | 1.07 | −2.2 | 54.5 | 15.4 | 0.08 | 53.3 | 1.35 |

| 22 | 0.18 | 0.15 | 0.01 | 0.17 | 5.0 | 56.0 | 3.47 | 0.01 | 55.8 | 0.19 |

| 23 | 0.26 | 0.23 | 0.01 | 0.24 | 7.2 | 56.0 | 5.14 | 0.02 | 55.7 | 0.28 |

| 24 | 0.36 | 0.34 | 0.01 | 0.36 | 1.5 | 56.0 | 7.72 | 0.02 | 55.6 | 0.42 |

| 25 | 0.47 | 0.45 | 0.01 | 0.47 | 0.0 | 55.5 | 10.3 | 0.03 | 55.0 | 0.56 |

| 26 | 0.57 | 0.56 | 0.01 | 0.57 | −1.1 | 55.0 | 12.9 | 0.04 | 54.4 | 0.69 |

| 27 | 0.67 | 0.66 | 0.01 | 0.67 | −0.8 | 56.4 | 15.4 | 0.05 | 55.7 | 0.80 |

| 28 | 0.17 | 0.15 | 0.01 | 0.17 | −0.1 | 55.5 | 3.47 | 0.01 | 55.3 | 0.19 |

| 29 | 0.26 | 0.22 | 0.01 | 0.23 | 10.6 | 54.8 | 5.14 | 0.02 | 54.6 | 0.27 |

| 30 | 0.35 | 0.32 | 0.01 | 0.34 | 4.8 | 55.5 | 7.72 | 0.02 | 55.1 | 0.40 |

| 31 | 0.42 | 0.42 | 0.01 | 0.43 | −0.9 | 54.9 | 10.3 | 0.03 | 54.5 | 0.51 |

| 32 | 0.51 | 0.50 | 0.01 | 0.51 | −0.3 | 55.4 | 12.9 | 0.04 | 54.8 | 0.61 |

| 33 | 0.58 | 0.57 | 0.01 | 0.59 | −1.0 | 56.8 | 15.4 | 0.05 | 56.2 | 0.70 |

| 34 | 0.17 | 0.15 | 0.01 | 0.16 | 3.1 | 55.7 | 3.47 | 0.01 | 55.5 | 0.18 |

| 35 | 0.24 | 0.21 | 0.01 | 0.22 | 7.0 | 55.4 | 5.14 | 0.02 | 55.2 | 0.26 |

| 36 | 0.32 | 0.30 | 0.01 | 0.31 | 1.4 | 55.1 | 7.72 | 0.02 | 54.8 | 0.37 |

| 37 | 0.40 | 0.38 | 0.01 | 0.39 | 0.8 | 55.9 | 10.3 | 0.03 | 55.4 | 0.47 |

| 38 | 0.46 | 0.46 | 0.01 | 0.47 | −1.2 | 55.4 | 12.9 | 0.04 | 54.9 | 0.56 |

| 39 | 0.51 | 0.52 | 0.01 | 0.53 | −2.3 | 54.9 | 15.4 | 0.05 | 54.3 | 0.63 |

References

- Scheuch, Maxixum Energy Gain from Flue Gas. Available online: https://www.scheuch.sk/wp-content/uploads/2023/03/Scheuch_Folder_ERCS_E_Web.pdf (accessed on 27 March 2025).

- LAB, Combustion Air Humidification. Available online: https://www.lab.fr/en/combustion-air-humidification-0# (accessed on 27 March 2025).

- Dlouhý, T.; Havlík, J. Effect of combustion air humidification on the operation of a biomass boiler—Theoretical analysis. Heliyon 2025, 11, e42299. [Google Scholar] [CrossRef] [PubMed]

- Hewitt, G.F.; Shires, G.L.; Bott, T.R. Process Heat Transfer; Begell House: New York, NY, USA, 1994. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, C.; Zhang, Z.; Du, J.; Tu, Y.; Ren, Z. Process Intensification of Gas–Liquid Separations Using Packed Beds: A Review. Separations 2024, 11, 284. [Google Scholar] [CrossRef]

- Garg, K.; Das, S.K.; Tyagi, H. Thermal design of a humidification-dehumidification desalination cycle consisting of packed-bed humidifier and finned-tube dehumidifier. Int. J. Heat Mass Transf. 2022, 183, 122153. [Google Scholar] [CrossRef]

- VDI-GVC. (Ed.) VDI Heat Atlas; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Morales, A.A.; Carvajal, D.S. Heat and mass transfer in a direct contact humidifier of a humidification-dehumidification desalination system. In Proceedings of the 2017 IEEE 6th International Conference on Renewable Energy Research and Applications (ICRERA), San Diego, CA, USA, 5–8 November 2017; pp. 273–278. [Google Scholar] [CrossRef]

- Chen, Q.; Thu, K.; Bui, T.D.; Li, Y.; Ng, K.C.; Chua, K.J. Development of a model for spray evaporation based on droplet analysis. Desalination 2016, 399, 69–77. [Google Scholar] [CrossRef]

- Hijjaji, K.; Gabsi, S.; Frikha, N. Determination of heat and mass transfer coefficients in a spray humidifier of a humidification–dehumidification desalination system. Desalination Water Treat. 2021, 225, 392–401. [Google Scholar] [CrossRef]

- Toman, F.; Kracík, P.; Pospíšil, J. Heat transfer during condensation of water vapour in the presence of non-condensable gas in vertical tube of small diameter. Case Stud. Therm. Eng. 2022, 40, 102519. [Google Scholar] [CrossRef]

- Garg, K.; Beniwal, R.; Das, S.K.; Tyagi, H. Experimental investigation of a low-cost humidification-dehumidification desalination cycle using packed-bed humidifier and finned-tube heat exchanger. Therm. Sci. Eng. Prog. 2023, 41, 101858. [Google Scholar] [CrossRef]

- Flagiello, D.; Parisi, A.; Lancia, A.; Di Natale, F. A Review on Gas-Liquid Mass Transfer Coefficients in Packed-Bed Columns. ChemEngineering 2021, 5, 43. [Google Scholar] [CrossRef]

- Zhu, Q.; Wu, W.; Ren, Y.; Wang, F.; Han, Y. Study on the Heat and Mass Transfer Characteristics of Humidifiers in Humidification–Dehumidification Desalination Systems. Energies 2023, 16, 8006. [Google Scholar] [CrossRef]

- Huang, X.; Chen, H.; Ling, X.; Liu, L.; Huhe, T. Investigation of heat and mass transfer and gas–liquid thermodynamic process paths in a humidifier. Energy 2022, 261, 125156. [Google Scholar] [CrossRef]

- Chen, J.; Han, D.; He, W.; Liu, Y.; Gu, J. Theoretical and experimental analysis of the thermodynamic and economic performance for a packed bed humidifier. Energy Convers. Manag. 2020, 206, 112497. [Google Scholar] [CrossRef]

- Onda, K.; Takeuchi, H.; Okumoto, Y. Mass transfer coefficients between gas and liquid phases in packed columns. J. Chem. Eng. Jpn. 1968, 1, 56–62. [Google Scholar] [CrossRef]

- Klimanek, A. Numerical Modelling of Natural Draft Wet-Cooling Towers. Arch. Comput. Methods Eng. 2016, 20, 61–109. [Google Scholar] [CrossRef]

- Sezen, K.; Gungor, A. Water droplet evaporation in atmospheric air stream. Phys. Fluids 2023, 35, 017122. [Google Scholar] [CrossRef]

- Chen, J.; Han, D.; He, W.; Ji, C.; Si, Z.; Zheng, M.; Gu, J.; Song, Y. Characteristic analysis of heat and mass transfer process within structured packing humidifier. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 361. [Google Scholar] [CrossRef]

- Joint Committee for Guides in Metrology (JCGM). Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement; Bureau International des Poids et Mesures: Sèvres, France, 2008; Available online: https://www.bipm.org/documents/20126/2071204/JCGM_100_2008_E.pdf/cb0ef43f-baa5-11cf-3f85-4dcd86f77bd6 (accessed on 27 March 2025).

- Farrance, I.; Frenkel, R. Uncertainty of measurement: A review of the rules for calculating Uncertainty components through functional relationships. Clin. Biochem. Rev. 2012, 33, 49–75. [Google Scholar] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Havlík, J.; Dlouhý, T. Combustion Air Humidifier for a Biomass Boiler with Flue Gas Condensation. ChemEngineering 2025, 9, 68. https://doi.org/10.3390/chemengineering9040068

Havlík J, Dlouhý T. Combustion Air Humidifier for a Biomass Boiler with Flue Gas Condensation. ChemEngineering. 2025; 9(4):68. https://doi.org/10.3390/chemengineering9040068

Chicago/Turabian StyleHavlík, Jan, and Tomáš Dlouhý. 2025. "Combustion Air Humidifier for a Biomass Boiler with Flue Gas Condensation" ChemEngineering 9, no. 4: 68. https://doi.org/10.3390/chemengineering9040068

APA StyleHavlík, J., & Dlouhý, T. (2025). Combustion Air Humidifier for a Biomass Boiler with Flue Gas Condensation. ChemEngineering, 9(4), 68. https://doi.org/10.3390/chemengineering9040068