Abstract

The aim of the study was to compare the physical and sensory properties of gluten-free bread with the addition of whole and ground flax seeds. The grinding process of flax seeds was carried out using a knife grinder and ball mill. After short-knife grinding (20 s) (GM-200, Retsch), the seeds were divided into whole (average particle size 0.634 mm), coarse (769 mm) and fine (0.328 mm) flour, and these flours were additionally ground with ball milling (60 s) (Pulverisette 6, Fritsh). The grinding energy of seeds was evaluated. Baking of gluten-free bread was performed with 10% addition of different forms of whole and ground flaxseeds. The colour, volume, texture and sensory parameters of bread were evaluated. In addition, the crumbling index of bread was developed and defined as the percentage share of crumbed pieces of the bread slice in relation to the mass of the entire crumb sample cut out together with crumbs. Specific grinding energy of flaxseeds during short (20 s) knife grinding was equal to 109.5 J·g−1, and additional ball milling (60 s) caused significantly (α = 0.05) more than 4 times higher energy consumption, but more reduced particles of whole (0.497 mm), coarse (0.621 mm) and fine flour (0.308 mm) were obtained. After adding ground seeds, it was necessary to add more water to the dough, which increased dough yield from 220% to 240% and even to 260% when ball milling of coarse flax flour was applied. The most significant increase in the volume of bread and the most reduced crumbling was observed for breads with addition of coarse fractions of flaxseeds ground with ball milling. In comparison with the control sample of gluten-free bread; significant improvement in bread volume, textureand sensory evaluation was observed after using both whole and ground flaxseeds. Furthermore, the crumbling index was related to an organoleptic evaluation and can be used in bread quality assessment as a complement to instrumental texture measurements.

1. Introduction

The demand for gluten-free bakery products is increasing due to the increasing percentage of people suffering from celiac disease or gluten allergy [1]. However, gluten-free diets may lead to possible nutrient imbalance, resulting in improper nutritional quality of diet [2]. In addition, gluten-free breads are often of unsatisfactory technological quality, which is why they are enriched with various additives, including hydrocolloids [3,4]. Korus et al. [5] confirmed that the replacement of some hydrocolloids with linseed mucilage (water extract) improved the sensory quality and texture of the bread.

Flaxseeds (LinumUsitatissimum L.) are increasingly used in the production of functional foods [6,7,8]. These seeds are abundant in many nutrients, such as polyunsaturated fatty acids, proteins, and lignans. Linseeds contain on an average 20% protein, 40% oil, 30% diet fibre, 4% ash, and 6% moisture [9]. Linseed oil contains high levels of linolenic acid (53.2%) followed by oleic acid (18.5%) and linoleic acid (17.2%), while the dominant saturated acids were palmitic (6.6%) and stearic (4.4%) [10].

Flaxseeds are a good source of alpha-linolenic acid, which is one of the essential fatty acids [11]. The results described by Kronberga and Karklina [12] show that the inclusion of flaxseeds in the daily diet could have an effect on body weight reduction, cholesterol, and glucose levels in the blood and also on reducing the risks of obesity andcoronary heart disease [13].

The addition of linseeds to bread formulation was found to beneficially decrease the content of saturated fatty acids and increase the content of unsaturated fatty acids [14]. Justo et al. [15] developed functional bread for women consisting of whole wheat flour, chia seeds, flaxseed flour, and folic acid. Nutritional analyses showed high nutritional value of this type of bread.

Flaxseeds, linseed flour, and other products from these seeds were used in different bread formulations and caused beneficial changes in rheological [16] and sensory evaluation [17,18,19,20,21]. For example, by-products from the flaxseed industrywere applied in wheat flour formulation of bread, and these results confirmed the usefulness of these residues in bakery production [22,23,24]. Other authors have also confirmed the possibility of using linseed fibre [17,19] or flaxseed flour addition [16,18,21]. Although flaxseeds and linseed products have been used in the production of bread, there are no clear guidelines for choosing grinders. Grinding of other non-cereal seeds is also not widely described in the available literature. In our previous studies, we compared the grinding of Plantago psyllium and Plantago ovata [3] or holy basil and chia seeds [4]. The grinding of plantago seedswas made using a hummer mill, and grinding trials were also carried out on a knife grinder, but no satisfactory results were obtained [3]. However, in the case of holy basil and chia seeds, a knife grinder was proposed. Knife grinding isnot usually used in grinding cereals, but in the case of non-cereal seeds, due to their specific properties, it is sometimes necessary [4]. Ball milling in crushing seeds has not been studied in detail and is usually used for wheat or rye bran or whole wheat grain [25,26]. The use of a ball mill causes a significant reduction of particles [26]. In addition, the use of different grinders can result in different particle sizes. Until now, only different sizes of rice flour have been tested in the gluten-free bread recipe [27].

The aim of the study was to compare the physical and sensory properties of gluten-free bread with the addition of whole and ground flax seeds. The grinding process of flax seeds using a knife grinder and ball mill was also studied.

2. Materials and Methods

2.1. Materials

Flaxseeds were the raw materials for research (MAKAR, Poland). Individual seeds had a length of 3.0 ± 0.12 mm, width equal to 1.5 ± 0.06 mm, and thickness equal to 0.1± 0.04 mm. Measurement of these physical characteristics was made by micrometric method using callipers. Bulk density of seeds was 700 ± 28 kg·m−3, and mass of 1000 seeds was equal to 1.4 ± 0.5 g.

The protein content in flaxseeds was determined by Kjeldahl method (Kjeltec 2300, Foss, ISO 20483:2006), the total fat content in the seeds was performed by Soxhlet method (Soxtec 2050, Foss, ISO 659:2009), the sugar content was estimated by Luff–Schoorl method [28], and total dietary fibreby Asp et al. [29] method.

The basic material for gluten-free bread baking was rice flour and corn flour. Rice flour (Melvit, Warsaw) was characterized by protein content of 7.1% ± 0.32% (ISO 20483:2006), ash content of 0.31% ± 0.02% (ISO 2171:2007),fat content of 0.8% ± 0.03% (ISO 659:2009), and carbohydrate content of 78.9% ± 4.0%. Total carbohydrates were calculated as the difference between the protein, fat, ash, and moisture contents in flour. Corn flour (Melvit, Warsaw) was characterized by protein content of 9.1% ± 0.42% (ISO 20483:2006), ash content of 0.43% ± 0.01% (ISO 2171:2007), fat content of 4.1% ± 0.28% (ISO 659:2009), and carbohydrate content of 70.2% ± 2.42%. Dried instant yeast was also used in bread formulation (Instaferm, Lallemand Iberia).

2.2. Measurement of Flaxseeds’ Physical Properties

The basic size characterization of flaxseeds was measured using a pair of callipers. The length, width, and thickness of these seeds were evaluated. A grain densimeter (Sadkiewicz Instruments, Bydgoszcz, Poland) (PN-ISO 7971-2) was used to measure the bulk density of the seeds. All physical measurements were done in three replications.

2.3. Grinding of Flaxseeds

The grinding of flaxseeds was carried out on a knife grinder (GRINDOMIX GM-200, Retsch, Germany; Haan, 1000 W, 3000 rpm). Preliminary trials were also done on a hammer mill (POLYMIX-Micro-Hammermill MFC, Kinematica, Switzerland; Luzern, 1000 W, 6000 rpm), but due to clogged sieves, the grinding process was not possible. The methodology proposed by Dziki et al. [30,31] was used for measurement and calculation of grinding energy. The mills were equipped with a computer system that allowed the recording and analysis of the grinding energy consumption. The amount of energy consumed during grinding was obtained using a digital multimeter (VC 870, VOLTCRAFT®, Germany, Wollerau) connected to a computer equipped with a special programme (VC870 Interface 4.2.6., VOLTCRAFT®, Germany, Wollerau) that recorded the data. Energy for grinding seeds is the difference between total energy (Et) and energy lost during idling (Ei).

Total energy was determined using total power consumed during grinding in grinding time from the following formula:

where Et—total energy, Pt—power consumed during grinding, and t—time of grinding.

Energy lost during idling was determined using power lost during idlingby the device:

where Ei—energy lost during idling, Pi—power lost during idling, and t—time of grinding.

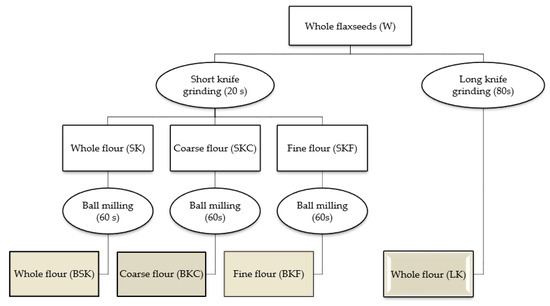

There is no literature available on the method of grinding whole linseeds; therefore, in the initial stage of testing, knife grinding was carried out at different times for 20 s, 40 s, 60 s, and 80 s. The assumption was to obtain low energy consumption, so at the beginning, we also analyzed shorter times, i.e., 10 s grinding time. After 10 s of grinding time, the degree of grinding was not sufficient (a large proportion of the material had not been fragmented)—only 20 s gave satisfactory results. After 80 s of grinding time, the degree of grinding was significantly greater and energy consumption was almost 3 times higher, so we decided to finish the process at this stage. After a knife-short grinding time (20 s), we decided to use an additional ball milling (Pulverisette 6, FRITSH, Germany; Idar-Oberstein, 1000 W, 650 rpm); the time was 60 s so that the total time was equal to 80 s as during long grinding. Ball milling in crushing linseeds has not been studied, but it was proven to be valuable for other cereals or fibres [25,26]. After grinding, the samples were screened, and their particle size distribution was analyzed on sieves (AS 200, Retsch, Germany, Haan) with hole sizes 0.2, 0.315, 0.4, 0.63, 0.8, and 1.0 mm. This arrangement of sieves is standard equipment of the screen. In the case of flax seeds rich in fat, sieves smaller than 0.2 mm clogged during sieving. After each grinding time, the fraction smaller than 0.2 mm was a trace—only sieving through a 0.4 mm sieve gave a larger percentage of the product. This product was defined as fine flour, while the product with particles larger than 0.4 mm was defined as coarse flour.The procedure for obtaining samples was shown in Figure 1. Briefly, all material ground for 20 s on a knife grinder was called short-knife grinding (SK), while material ground for 80 s was called long-knife grinding (LK). The fraction with dimensions larger than 0.4 mm was called coarse-short-knife grinding (CSK), while the fraction with dimensions smaller than 0.4 mm was called fine-short-knife grinding (FSK). Material ground briefly for 20 s on a knife grinder was additionally ground for 60 s on a ball miller.The whole fraction was called ball milling and short-knife grinding (BK), the fraction larger than 0.4 mm was called coarse ball milling and short-knife grinding (BKC), and the fraction smaller than 0.4 mm was called fine ball milling and short-knife grinding (BKF). Six replications of grinding energy measurements and seeds particle size distribution were made.

Figure 1.

Experimental design of obtaining samples.

2.4. Baking of Gluten-Free Bread with Flaxseeds

Gluten-free bread was made according to a single-phase laboratory baking method [3,4]. Rice and corn flours (50%:50%) were used for the control sample (C) of gluten-free bread. Whole or ground flaxseeds in the amount of 10% were used in the bread recipe [16,21]. The amount of flaxseed additive was also determined experimentally in preliminary tests based on an organoleptic evaluation. In preliminary tests, the proportions of the flaxseeds additive in the amounts of 5%, 10%, 15%, and 20% were tested, and it was found that the breads with a 10% share had a significantly better appearance, taste, aroma, and texture than the control bread; moreover, a 15% share caused a slightly noticeable bitterness of taste. The samples of gluten-free bread with different kinds of flaxseeds were named as follows: whole flaxseeds (W), whole ground fraction of flaxseeds obtained by short-knife grinding (SK), coarse particles of flaxseeds obtained by short-knife grinding (SKC), fine particles of flaxseeds obtained by short-knife grinding (SKF), mean particles of flaxseeds ground by short-knife and ball milling (BK), coarse particles ground by short-knife and ball milling (BKC), fine particles ground by short-knife and ball milling (BKF) and whole ground fraction obtained by long-knife grinding (LK). In addition to flaxseeds, dried instant yeast (1%) and salt (2%) were added to the gluten-free bread recipe.

Different levels of water (100%; 105%; 110%; 115%; 120%; 125%; 130%; 135%; 140%; 145%; 150%; 155; 160%) were tested in preliminary study for the evaluation of optimal dough consistency [1]. Dough yield expressed as a percentage was the sum of the flour weight (100 g) and water. In this study, only the optimal baking results were described. Optimal bread was characterized by the largest volume, and it had no sunken surface and was without holes in the crumb. When there is too little water, the bread is compacted and the volume is small; when there is too much water, the bread falls and holes are formed between the crust and the crumb as describedearlier [32]. All above-mentioned ingredients were mixed for 5 min (Kitchen Aid, St. Joseph, MI, USA, 80 rpm); then, the resulting dough (300 g) was put into a mould and left to rise in a fermentation cabined (30 °C, 75% RH, Sadkiewicz Instruments, Bydgoszcz, Poland) for 40 min and after that, was baked in a laboratory oven (230 °C, 45–50 min) (Sadkiewicz Instruments, Bydgoszcz, Poland). Three replications of the baking tests were done.

2.5. Measurement of Gluten-Free Bread Volume

The specific volume of the bread was calculated according to the Ziemichód et al. [3,4] method by dividing the loaf volume by their mass (cm3·g−1). The millet seeds replacement method was used to determine the loaf volume. Three replications were done for these measurements.

2.6. Evaluation of Bread Crumbling

During many tests of gluten-free bread [32,33], it was observed that this type of bread is characterized by a high degree of crumbling. The instrumental methods used so far did not allow for the determination of this indicator; therefore our own method of evaluation of crumbling was proposed. This parameter was determined when cutting out crumb samples (30 × 30 × 20 mm). The percentage share of crumbed pieces (mc) of the sample in relation to the mass of the entire crumb sample cut out together with crumbs (mw) was the degree of bread crumbling (Dc) and was calculated according to the formula:

where

- Dc—degree of bread crumbling,

- mc—mass of crumbed pieces of the sample,

- mw—mass of entire crumb sample with crumbs after cutting.

2.7. Assessment of the Color of a Bread Crumb

The colour (L*a*b*) of a bread crumb (middle slice with a thickness of 20 mm) was evaluated using a 4Wave colourimeter (CR30-16) as described by Ziemichód et al. [3,4].

2.8. Texture Measurement of Gluten-Free Bread Crumbs

Texture measurements of the bread crumb sample (30 × 30 × 20 mm) after 1 and 3 days from baking were done using a testing apparatus (ZWICK Z020/TN2S) as proposed by Różyło et al. [33,34]. The texture profile analysis was performed during double compression of crumb sample to a depth of 50% using apparatus (speed 1 mm∙s−1), and different parameters such as hardness, elasticity, and cohesiveness were calculated as described by Ziemichód et al. [3,4]. Hardness was calculated as maximum force during the first measurement, elasticity as second peak width, and cohesiveness as equal area under peak 2 divided by area under peak 1.

2.9. Sensory Evaluation of Gluten-Free Breads

The sensory analysis panel consisted of 68 (32 females and 36 males) untrained and habitual bread consumers who were between 23 and 50 years old. The taste, aroma, appearance, texture, and the overall acceptability of bread samples (quarter slice 1 cm thick) were evaluated according to a nine-point hedonic (1—dislike extremely, 5—neither like nor dislike, 9—extremely) scale as proposed by Lim et al. [35].

2.10. Statistical Analysis

Mean values and standard deviations were calculated. An analysis of variance and a Tukey test were performed using Statistica (Statistica 6.0 PL, Statsoft) at the significance level of α = 0.05. In addition, the Pearson correlation analysis was done.

3. Results and Discussion

3.1. Grinding Energy and Particle Size Distribution of Flaxseeds

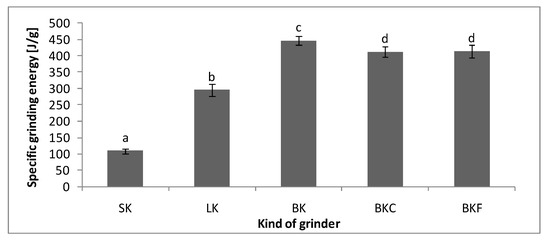

The basic chemical composition of flax seeds was as follows: moisture content of 7.2%, protein content of 24.5% ± 1.21%, fat content of 31.1% ± 1.63%, sugar content of 3.0% ± 0.12%, and fibre content of 27.3% ± 1.32%. It has been confirmed that these seeds have a high fat content, which is why the oil is pressed from them. In addition, flour is produced from by-products [22,23,24]. Flax flour available in the marketis usually skimmed flour, but considering the health benefits, we wanted to get whole-grain flour. During the tests, we tested various grinders andthe grinding of flaxseeds was possible only with a knife grinder as the sieves were sticking to each other during grinding in a hammer mill. However, in earlier works on grinding of psyllium seeds [3], a hammer mill was used to grind the hard seeds because it was impossible to grind them on a knife grinder. Specific grinding energy of flaxseeds (Figure 2) during short-knife grinding (20 s) (SK) was equal to 109.5 J·g−1 and was significantly (α = 0.05) lower than the energy consumption during long-knife grinding (80 s) (LK), which amounted to 295.6 J·g−1. After 20 s of grinding time (SK), the percentage of particles <0.4 mm was about 30% and of particles >0.4 mm was about 70%, while after long-knife grinding (LK), the percentage of particles <0.4 mm was about 61% and particles >0.4 mm about 39% (Table 1). Additional ball milling of products (60 s) obtained by short grinding (20 s) (BK, BKC, BKF) caused significantly (α = 0.05) higher total energy consumption in comparison with LK (80 s). Material ground using ball milling (BK) caused significant (α = 0.05) reduction in the size of particles in comparison with SK. The energy for grinding coarse or fine fractions using ball milling and knife grinding (BKC, BKF) was significantly lower than the mean product obtained by knife and ball milling together (BK). There were no significant differences between fine and coarse fractions using ball milling and knife grinding (BKC, BKF). So far, energy consumption testing of flaxseed crushing using knife grinding and ball milling has not been conducted in other studies. Todate, ball milling has only been used for wheat or rye bran or whole grains [25,26].

Figure 2.

Specific grinding energy of flaxseeds. SK—short-knife grinding (20 s), LK—long-knife grinding (80 s), BK—short-knife grinding (20 s) and ball milling (60 s), BKC—short-knife grinding (20 s) with ball milling (60 s) of coarse fraction, BKF—short-knife grinding (20 s) with ball milling (60 s) of fine fraction. a,b,…—means with different letters are significantly different (α < 0.05).

Table 1.

Particle size distribution of ground flax seeds.

3.2. Basic Baking Properties of Gluten-Free Bread with Ground Flaxseeds

The optimal addition of water to the control bread (C) allowed for a dough yield of 220%, and the addition of 10% of whole flax seeds increased the yield to 230%. On the other hand, the addition of whole ground seeds by short-knife grinding (SK) briefly resulted in an increase in the dough yield to 240%. The higher dough yield (250%) was obtained for bread baked with the coarse fraction of linseed flour obtained during short-knife grinding (SKC). The highest value of dough yield (260%) was obtained after using linseed coarse flour obtained by ball milling (BKC). Similar dough yield equal to 240% was obtained for SK, SKF, and BKF. Samples obtained by long-knife grinding (80 s) (LK) had dough yield at the level of 245%. The hydration properties of raw materials probably influenced the dough yield. These properties are related to starch damage, particle size, and also interactions between starch and non-starch components [36]. During grinding, the particle size is reduced, and this usually causes starch damage [37]. Furthermore, as observed during our studies, coarse flour obtained by short-knife grinding (SKC) and short-knife and mall milling (BKC) contained more bran than fine flour. It has often been confirmed that bran is rich in dietary fibre [38]. Fibre-rich fractions are characterized by high water-holding capacity and water absorption [39]; therefore, they increase the dough’s efficiency. For this reason, dietary fibresare often used in the production of gluten-free bread [3,4,40,41,42]. In our earlier research [3], it was found that the rich-in-fibreseeds of Plantago ovata and Plantago psyllium absorbed water very intensively. In other studies [26], the use of intensive ball milling of bran reduced their size to the nanoscale level, which resulted in almost complete disappearance of discernible tissue structures.In our study, BKC significantly increased the dough yield. As shown earlier, milling of bran increases its hydration rate and results in faster optimal dough development. Smaller bran particles cause faster dough development, probably due to increased proper contacts between flour particles [43]. It has been confirmed that the reduction of the particle size of various fibre-rich plant materials alters their structure, surface area, and functional properties [44].

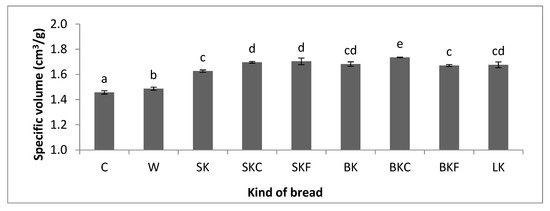

The addition of whole (W) and ground flaxseeds (SK, SKF, BK, BKC, BKF, and LK) resulted in a higher specific volume of bread in comparison with control bread (C) (Figure 3). Bread baked with the 10% share of short-knife ground (20 s) (SK) flaxseeds was characterized by a smaller volume than the one with coarse or fine flour ground by short-knife grinding (SKC, SKF). The highest specific volume was obtained for loaves baked with coarse flaxseed particles ground by shortknife with ball milling (BKC). A significantly lower volume (α = 0.05) similar to bread with whole flour ground by short-knife (SK) was obtained with fine flour ground with ball milling (BKF). Obtaining different volumes of bread with the addition of ground seeds is probably associated with different particle characteristics as shown in Table 1. Conventional bread contains gluten, which is a structuring agent. The lack of this ingredient in gluten-free bread forces the use of technological additives [3,4]. Flaxseeds contain water-extractable and muscilage-forming arabinoxylans, which slow down the rate of carbon dioxide diffusion from the dough, thus contributing to gas retention during fermentation. In addition, they are involved in creating a network forming the dough structure, contributing to increasing the volume of gluten-free bread [22]. Subsequently, the grinding of seeds can increase the integration of mucilage into the dough, resulting in a better development of its structure. Therefore, the dough was able to expand more during fermentation, and a larger volume of bread was obtained [45]. In other studies [27] where rice flour was fractionated in fine and coarse parts and used for making gluten-free bread, a higher specific volume of bread was obtained when a coarser fraction and great dough hydration were combined. With respect to the addition of flaxseeds flour, other studies also reported that the incorporation of these seed powders increased the specific loaf volume of gluten-free bread [23]. Previous studies have not been done for various fractions of ground flaxseed material. In our earlier study where ground psyllium seeds were used in gluten-free bread formulation, again, an increased volume of bread was obtained [3], although, in other studies, the addition of whole and ground basil and chia seeds reduced the specific volume of bread [3].

Figure 3.

Specific volume of gluten-free bread with ground flaxseeds. C—control gluten-free bread, W—gluten-free bread with whole flaxseeds, SK, SKC, SKF, BK, BKC, BKF, LK—gluten-free bread with ground flaxseeds obtained by the following: SK—whole fraction obtained by short-knife grinding (20 s), SKC—coarse fraction by short-knife grinding (20 s), SKF—fine fraction by short-knife grinding (20 s), BK—whole fraction by short-knife grinding (20 s) and ball milling (60 s), BKC—coarse fraction by short-knife grinding (20 s) and ball milling (60 s), BKF—fine fraction by short-knife grinding (20 s) and ball milling (60 s). LK—long-knife grinding (80 s). a, b,…—means with different lettersare significantly different (α < 0.05).

3.3. Color of Gluten-Free Bread with Ground Flaxseeds

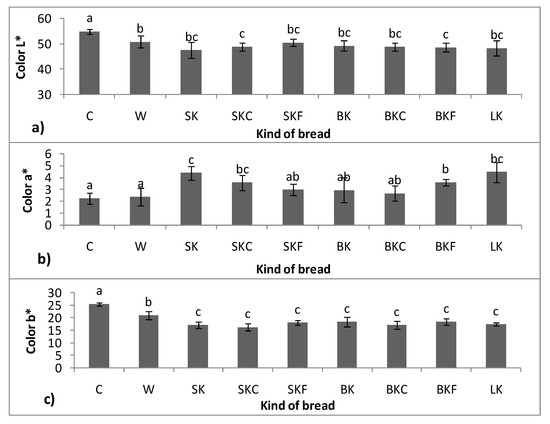

A significantly (α = 0.05) different colour of gluten-free bread (Figure 4a–c and Figure 5) was observed with the addition of whole and ground flaxseeds. The lightness (L*) of the bread crumbs with whole (W) and ground flaxseeds (SK, SKC, SKF, BK, BKC, BKF, and LK) was significantly lower than of the control sample of bread crumbs. The value of a* colour parameter didnot change after adding W but significantly (α = 0.05) increased in samples with the addition of ground flaxseeds (SK, SKC, BKF, LK). The b* colour value of bread crumbs decreased for each type of the additive. There were no significant differences between each sample of ground flaxseed flour (SK, SKC, SKF, BK, BKC, BKF, and LK). Flaxseeds have a much darker colour than the mixture of rice and corn flour from which the control sample of bread was prepared. Similarly, in a study presented by Pourabedin et al. [46] wheat bread colour L* parameter was reduced by adding flax flour. Other authors also obtained darker crumbs by using flaxseed meal in wheat bread recipe [47].

Figure 4.

Color parameters (L*a*b*) of gluten-free bread with ground flaxseeds, (a) ColourL* value; (b) Colour a* value; (c) Colour b* value.C—control gluten-free bread, W—gluten-free bread with whole flaxseeds. SK, SKC, SKF, BK, BKC, BKF, LK—gluten-free bread with ground flaxseeds obtained by the following: SK—whole fraction obtained by short-knife grinding (20 s), SKC—coarse fraction by short-knife grinding (20 s), SKF—fine fraction by short-knife grinding (20 s), BK—whole fraction by short-knife grinding (20 s) and ball milling (60 s), BKC—coarse fraction by short-knife grinding (20 s) and ball milling (60 s), BKF—fine fraction by short-knife grinding (20 s) and ball milling (60 s). LK—long-knife grinding (80 s). a, b,…—means with different letters are significantly different (α < 0.05).

Figure 5.

Appearance of gluten-free bread with whole and ground flax seeds. C—control gluten-free bread, W—gluten-free bread with whole flaxseeds, SK, SKC, SKF, BK, BKC, BKF, LK—gluten-free bread with ground flaxseeds obtained by the following: SK—whole fraction obtained by short-knife grinding (20 s), SKC—coarse fraction by short-knife grinding (20 s), SKF—fine fraction by short-knife grinding (20 s), BK—whole fraction by short-knife grinding (20 s) and ball milling (60 s), BKC—coarse fraction by short-knife grinding (20 s) and ball milling (60 s), BKF—fine fraction by short-knife grinding (20 s) and ball milling (60 s). LK—long-knife grinding (80 s).

3.4. Crumb Texture of Gluten-Free Bread with Ground Flaxseeds

Whole (W) and ground flaxseeds (SK, SKC, SKF, BK, BKC, BKF, and LK) beneficially affected the crumb texture of gluten-free bread (Table 2). The hardness of these bread crumbs was significantly (α = 0.05) reduced after adding both whole and ground seeds. Bread prepared with the addition of whole and course flaxseeds flour ground by short-knife with ball milling (BK, BKC) was characterized by significantly (α = 0.05) lower hardness than bread made with whole and course flaxseeds ground by short-knife grinding (20 s) (SK, SKC). In addition, the lowest hardness was obtained for bread with fine particles of flaxseeds. The mechanical properties of the bread crumb may depend on a combination of various factors including the swelling of starch granules or intermolecular contacts between them and also the leaching of amylose from starch granules [48]. Flaxseeds muscilage could loosen the bonds between the starch granules and thus soften the bread crumb. In addition, more intensively ground seeds can contribute to greater muscilage integration and greater loosening of the structure. Finer particles compared to larger ones are probably better built into the dough network. Whole flax seeds didnot improve the elasticity of gluten-free bread. This parameter was significantly (α = 0.05) higher for bread crumbs with each kind of ground flaxseeds (SK, SKC, SKF, BK, BKC, BKF, LK). Cohesiveness was significantly improved by the addition of whole flaxseeds, but ground flaxseeds caused considerable changes in this parameter of texture. Gluten-free bread is characterized by a high percentage of hardness, and therefore many technological additives are used to lower the hardness level of these loaves of bread [30,49]. Rapid hardening of gluten-free bread is caused by a high content of starch and its components—amylose and amylopectin—which retrograde easily [49]. In other studies, texture analysis of wheat bread with by-products of flaxseeds showed that the mean values of hardness, springiness, and chewiness were modified by these additives [20]. The incorporation of flaxseed powders significantly reduced the hardness level of gluten-free bread crumbs [23]. Bread enriched by cold-pressing residues of brownlinseed-enriched bread stayed significantly softer at the end of their shelf life than the marketed bread [19]. Cereal products enriched with flaxseed are characterized by a similar or improved shelf life compared to control products without these additives, suggesting that flaxseed may limit starch retrogradation and maintain moisture content [50]. As mentioned before, in these studies, flaxseeds caused significantly higher water absorption and optimal dough yield was much higher.

Table 2.

Texture parameters of gluten-free bread with ground flaxseeds.

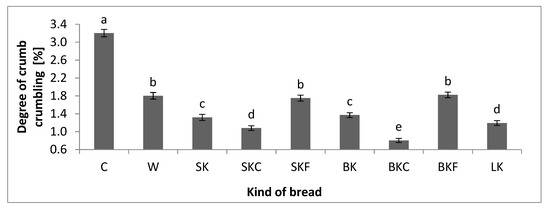

3.5. Crumbling of Gluten-Free Bread with Ground Flaxseeds

The degree of crumbling (Figure 6) was significantly (α = 0.05) different between measured samples of gluten-free bread. As we mentioned above in the methods section, this parameter was developed as a new texture assessment indicator. Our earlier studies on gluten-free bread have shown that often such bread crumbles during cutting, and by measuring the texture by compression, it is not possible to determine this parameter. During this research, we have obtained interesting results. C was characterized by the highest degree of crumb crumbling, equal to 3.2%, and addition of whole flax seeds significantly (α = 0.05) reduced this parameter to 1.8%; after grinding of flaxseeds, significantly lower crumbling was obtained. The lowest degree of crumbling (0.8%) was obtained by using BKC. In addition, it was interesting that fine flour, which caused the greatest reduction in bread crumb hardness, didnot reduce the crumbling of bread. The value of this parameter was similar to that of whole flaxseeds.

Figure 6.

Degree of crumb crumbling of gluten-free bread with ground flaxseeds, C—control gluten-free bread, W—gluten-free bread with whole flaxseeds, SK, SKC, SKF, BK, BKC, BKF, LK—gluten-free bread with ground flaxseeds obtained by the following: SK—whole fraction obtained by short-knife grinding (20 s), SKC—coarse fraction by short-knife grinding (20 s), SKF—fine fraction by short-knife grinding (20 s), BK—whole fraction by short-knife grinding (20 s) and ball milling (60 s), BKC—coarse fraction by short-knife grinding (20 s) and ball milling (60 s), BKF—fine fraction by short-knife grinding (20 s) and ball milling (60 s). LK—long-knife grinding (80 s), a, b,…—means with different letters in the same column are significantly different (α < 0.05).

3.6. Sensory Evaluation of Gluten-Free Bread with Ground Flaxseeds

Sensory evaluation of the obtained bread (Table 3) showed that control bread (C) was characterized by the lowest rating and that the addition of whole flax seeds caused a significant (α = 0.05) improvement in the quality of bread assessed by taste, aroma, appearance, texture, and overall experience of bread. Pearson correlation (Table 4) between the analytical and sensory evaluation of gluten-free bread showed that the assessment of the appearance of bread strongly depended on the colour values L* and b* (r = −0.93; −0.97) and also depended on the specific volume of bread (r = 0.85). Sensory texture was most strongly correlated with crumbling (r = −0.97) and less, but significantly, with mechanical texture measurements such as hardness, elasticity, and cohesiveness (r = −0.81; 0.81; 0.68) and also with colour L*, b* and volume of bread (r = −0.88; −0.93; 0.78). There werenot any significant (α = 0.05)differences between taste and aroma of gluten-free bread with whole (W) or ground flaxseeds (SK, SKC, SKF, BK, BKC, BKF, LK). Despite the fact that there was a noticeable difference in the graininess of different types of bread, concerning the particle size of the added flour, it did not have a significant impact on the taste score obtained. Wheat bread with flaxseed marc additive has excellent taste, as shown in other studies [51]. Flax addition gave the wheat bread high sensory acceptability [18]. Hrušková and Švec [16] reported that the addition of linseed fibre (2.5%, 5.0%) caused changes in the rheological properties of the dough. Furthermore, wheat bread and biscuits could be enriched by linseed fibrein the amount of 5%, but a larger addition could cause adverse sensory evaluation. In other studies [17,18], the sensory profiles of bread and other baking products with yellow and brown linseed fibrein the amounts of 2.5% and 5.0% were also acceptable. In another study, the sensory quality of wheat bread was improved up to a level of 10%–15% with flaxseed flour addition [19,20].

Table 3.

Sensory evaluation of gluten-free bread with ground flaxseeds.

Table 4.

Pearson correlation between the analytical and sensory evaluation of gluten-free bread.

Bread with whole grains (W) and with fine particles (SKF, BKF, and LK) received significantly worse texture scores compared to bread with other ground seeds (SK, SKC, BK, and BKC), but its assessment was still better than control bread. Bread with whole grains had significantly greater graininess, and this certainly affected its texture scoring, while in the case of fine flour bread, it was the opposite. Texture and overall punctuation in our study showed that bread with fine flour from flaxseeds (SKF and BKF) was significantly worse than bread with coarse flour (BKC and SKC). A worse assessment of the texture of bread with fine flour could be affected by the value of the crumbling indicator, which proves the usefulness of this indicator. The crumbling index was significantly correlated with taste, appearance and sensory texture of bread (r = −0.89; −0.91; −0.97). In view of the above, the crumbling index may be a proposal for a new future bread evaluation techniques.

4. Conclusions

Preliminary studies showed difficulties in grinding flaxseeds by a hammer mill. Therefore, we suggested the use of a knife grinder along with a ball miller. The specific grinding energy of these seeds was significantly (α < 0.05) higher when using a ball mill (447.2 J·g−1) rather than a long knife grinder (295.6 J·g−1) in the same time frame.

Despite the greater energy consumption of the ball milling process, we have noticed various benefits such as an increase in the dough yield (from 230% to 260%) and specific volume of bread (from 1.49 to 1.74 cm3·g−1) and a decrease in bread crumbling (from 1.8% to 0.8%) when coarse flaxseeds are ground and then used in the bread recipe in comparison with whole flaxseeds.

It has to be mentioned that there was a significant improvement in dough yield, bread colour, volume, texture, and sensory evaluation after using both whole and ground flaxseeds. In addition, these quality parameters were significantly better for gluten-free bread with ground flax flour in comparison with whole flaxseeds.

The crumbling index developed in these studies is closely related to the organoleptic assessment of the texture (r = −0.97), and therefore can be used in bread quality evaluation.

Author Contributions

Conceptualization, A.Z. and R.R.; methodology, A.Z. and R.R.; software, A.Z.; validation, A.Z., R.R., and D.D.; formal analysis, A.Z.; investigation, A.Z.; resources, A.Z.; data curation, A.Z.; writing—original draft preparation, A.Z.; writing—review and editing, R.R. and D.D..; visualization, A.Z.; supervision, D.D.; project administration, R.R.; funding acquisition, R.R and D.D. All authors have read and agreed to the published version of the manuscript

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hager, A.S.; Wolter, A.; Czerny, M.; Bez, J.; Zannini, E.; Arendt, E.K.; Czerny, M. Investigation of product quality, sensory profile and ultrastructure of breads made from a range of commercial gluten-free flours compared to their wheat counterparts. Eur. Food Res. Technol. 2012, 235, 333–344. [Google Scholar] [CrossRef]

- Vici, G.; Belli, L.; Biondi, M.; Polzonetti, V. Gluten free diet and nutrient deficiencies: A review. Clin. Nutr. 2016, 35, 1236–1241. [Google Scholar] [CrossRef] [PubMed]

- Ziemichód, A.; Wójcik, M.; Różyło, R. Seeds of Plantago psyllium and Plantago ovata: Mineral composition, grinding, and use for gluten-free bread as substitutes for hydrocolloids. J. Food Process Eng. 2019, 42, e12931. [Google Scholar] [CrossRef]

- Ziemichód, A.; Wójcik, M.; Różyło, R. Ocimumtenuiflorum seeds and Salvia hispanica seeds: Mineral and amino acid composition, physical properties, and use in gluten-free bread. CYTA J. Food. 2019, 17, 804–813. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, T.; Ziobro, R.; Juszczak, L. Linseed (Linumusitatissimum L.) mucilage as a novel structure forming agent in gluten-free bread. LWT Food Sci. Technol. 2015, 62, 257–264. [Google Scholar] [CrossRef]

- Susheelamma, N. Functional role of linseed (Linumusitatissimum L.) polysaccharide in steamed pudding (idli). J. Food Sci. Technol. 1989, 26, 16–20. [Google Scholar]

- Zhu, F.; Li, J. Physicochemical and sensory properties of fresh noodles fortified with ground linseed (Linumusitatissimum). LWT Food Sci. Technol. 2019, 101, 847–853. [Google Scholar] [CrossRef]

- Shafie, S.R.; Poudyal, H.; Panchal, S.K.; Brown, L. Linseed as a Functional Food for the Management of Obesity. In Omega-3 Fatty Acids: Keys to Nutritional Health; Springer International Publishing: Cham, Switzerland, 2016; pp. 173–187. [Google Scholar]

- Zhang, Z.S.; Wang, L.J.; Li, D.; Jiao, S.S.; Chen, X.D.; Mao, Z.H. Ultrasound-assisted extraction of oil from flaxseed. Sep. Purif. Technol. 2008, 62, 192–198. [Google Scholar] [CrossRef]

- Gruia, A.; Dumbravă, D.G.; Moldovan, C.; Bordean, D.M. Fatty acids composition and oil characteristics of linseed (LinumUsitatissimum, L.) from Romania. J. Agroaliment. Process. Technol. 2012, 18, 136–140. [Google Scholar]

- De Lorgeril, M.; Salen, P. Alpha-linolenic acid and coronary heart disease. Nutr. Metab. Cardiovasc. Dis. 2004, 14, 162–169. [Google Scholar] [CrossRef]

- Kronberga, M.; Karkliņa, D. Nutritional Supplements in Optimal Human Nutrition. Proc. Latv. Acad. Sci. Sect. B Natl. Exact Appl. Sci. 2013, 67, 367–372. [Google Scholar] [CrossRef]

- Simopoulos, A.P. The importance of the ratio of omega-6/omega-3 essential fatty acids. Biomed. Pharmacother. 2002, 56, 365–379. [Google Scholar] [CrossRef]

- Tańska, M.; Rotkiewicz, D. Quality of fat from oilseeds used to produce selected kinds of bread. Żywnosc Nauka Technol. Jakość 2011, 5, 62–74. (In Polish) [Google Scholar] [CrossRef]

- Bautista Justo, M.; Castro Alfaro, A.D.; Camarena Aguilar, E.; Wrobel, K.; Wrobel, K.; Alanis Guzman, G.; Gamino Sierra, Z.; Zanella, V.D. Integral bread development with soybean, chia, linseed, and folic acid as a functional food for woman. Arch. Latinoam. Nutr. 2007, 57, 78–84. [Google Scholar]

- Codină, G.G.; Istrate, A.M.; Gontariu, I.; Mironeasa, S. Rheological properties of wheat-flaxseed composite flours assessed by mixolab and their relation to quality features. Foods 2019, 8, 333. [Google Scholar] [CrossRef]

- Hrušková, M.; Švec, I. Rheological Characteristics of Composite Flour with Linseed Fibre—Relationship to Bread Quality. Czech J. Food Sci. 2017, 35, 424–431. [Google Scholar]

- Hrušková, M.; Švec, I. Flax—Evaluation of composite flour and using in cereal products. Potravinarstvo 2016, 10, 287–294. [Google Scholar]

- Švec, I.; Hrušková, M. Effect of golden and brown linseed fibre on wheat flour pasting, dough properties and bread quality. Cereal Res Commun. 2018, 46, 1–10. [Google Scholar] [CrossRef]

- Krishna Kumar, R.; Bejkar, M.; Du, S.; Serventi, L. Flax and wattle seed powders enhance volume and softness of gluten-free bread. Food Sci. Technol. Int. 2019, 25, 66–75. [Google Scholar] [CrossRef]

- Pejcz, E.; Mularczyk, A.; Gil, Z. Technological characteristics of wheat and non-cereal flour blends and their applicability in bread making. J. Food Nutr. Res. 2015, 54, 69–78. [Google Scholar]

- Tarek-Tilistyák, J.; Tarek, M.; Juhász-Román, M.; Jekő, J. Effect of oil-seed pressing residue on bread colour and texture. Acta. Univ. Sapientiae Aliment. 2015, 8, 118–124. [Google Scholar] [CrossRef]

- Wirkijowska, A.; Zarzycki, P.; Sobota, A.; Nawrocka, A.; Blicharz-Kania, A.; Andrejko, D. The possibility of using by-products from the flaxseed industry for functional bread production. LWT Food Sci. Technol. 2020, 118, 108860. [Google Scholar] [CrossRef]

- Tarek-Tilistyák, J.; Agócs, J.; Lukács, M.; Dobró-Tóth, M.; Juhász-Román, M.; Dinya, Z.; Jekő, J.; Máthé, E. Novel breads fortified through oilseed and nut cakes. Acta Aliment. 2014, 43, 444–451. [Google Scholar] [CrossRef]

- Thanatuksorn, P.; Kawai, K.; Kajiwara, K.; Suzuki, T. Effects of ball-milling on the glass transition of wheat flour constituents. J. Sci. Food Agric. 2009, 89, 430–435. [Google Scholar] [CrossRef]

- Van Craeyveld, V.; Holopainen, U.; Selinheimo, E.; Poutanen, K.; Delcour, J.A.; Courtin, C.M. Extensive dry ball milling of wheat and rye bran leads to in situ production of arabinoxylan oligosaccharides through nanoscale fragmentation. J. Agric. Food Chem. 2009, 57, 8467–8473. [Google Scholar] [CrossRef]

- De La Hera, E.; Rosell, C.M.; Gomez, M. Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem. 2014, 151, 526–531. [Google Scholar] [CrossRef]

- Egan, H.; Kirk, R.; Sawyer, R. The Luff Schoorl method. Sugars and Preserves. In Pearson’s Chemical Analysis of Foods, 8th ed.; Longman Scientific and Technical: Harlow, UK, 1981; pp. 152–153. [Google Scholar]

- Asp, N.G.; Johansson, C.G.; Hallmer, H.; Siljestróm, M. Rapid Enzymatic Assay of Insoluble and Soluble Dietary Fiber. J. Agric. Food Chem. 1983, 31, 476–482. [Google Scholar] [CrossRef]

- Dziki, D.; Laskowski, J. Study to analyze the influence of sprouting of the wheat grain on the grinding process. J. Food Eng. 2010, 96, 562–567. [Google Scholar] [CrossRef]

- Dziki, D. Effect of preliminary grinding of the wheat grain on the pulverizing process. J. Food Eng. 2011, 104, 585–591. [Google Scholar] [CrossRef]

- Różyło, R.; Dziki, D.; Gawlik-Dziki, U.; Cacak-Pietrzak, G.; Miś, A.; Rudy, S. Physical properties of gluten-free bread caused by water addition. Int. Agrophys. 2015, 29, 353–364. [Google Scholar] [CrossRef]

- Różyło, R.; Rudy, S.; Krzykowski, A.; Dziki, D.; Siastała, M.; Polak, R. Gluten-Free Bread Prepared with Fresh and Freeze-Dried Rice Sourdough-Texture and Sensory Evaluation. J. Texture Stud. 2016, 47, 443–453. [Google Scholar] [CrossRef]

- Różyło, R.; Dziki, D.; Laskowski, J.; Skonecki, S.; Łysiak, G.; Kulig, R.; Różyło, K. Texture and sensory evaluation of composite wheat-oat bread prepared with novel two-phase method using oat yeast-fermented leaven. J. Texture Stud. 2014, 45, 235–245. [Google Scholar] [CrossRef]

- Lim, H.S.; Park, S.H.; Ghafoor, K.; Hwang, S.Y.; Park, J. Quality and antioxidant property of bread containing turmeric. Curcuma longa L. cultivated in South Korea. Food Chem. 2011, 112, 1577–1582. [Google Scholar] [CrossRef]

- De La Hera, E.; Gomez, M.; Rosell, C.M. Particle size distribution of rice flour affecting the starch enzymatic hydrolysis and hydration properties. Carbohydr. Polym. 2013, 98, 421–427. [Google Scholar] [CrossRef]

- Lee, Y.T.; Shim, M.J.; Goh, H.K.; Mok, C.; Puligundla, P. Effect of jet milling on the physicochemical properties, pasting properties, and in vitro starch digestibility of germinated brown rice flour. Food Chem. 2019, 282, 164–168. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.; Cao, X.; Wang, J. Preparation and modification of high dietary fiber flour: A review. Food Res. Int. 2018, 113, 24–35. [Google Scholar] [CrossRef]

- Vázquez-Ovando, A.; Rosado-Rubio, G.; Chel-Guerrero, L.; Betancur-Ancona, D. Physicochemical properties of a fibrous fraction from chia (Salvia hispanica L.). LWT Food Sci. Technol. 2009, 42, 168–173. [Google Scholar]

- Mariotti, M.; Lucisano, M.; Pagani, M.A.; Ng, P.K. The role of corn starch, amaranth flour, pea isolate, and Psyllium flour on the rheological properties and the ultrastructure of gluten-free doughs. Food Res. Int. 2009, 42, 963–975. [Google Scholar] [CrossRef]

- Aprodu, I.; Banu, I. Influence of dietary fiber, water, and glucose oxidase on rheological and baking properties of maize based gluten-free bread. Food Sci. Biotechnol. 2015, 24, 1301–1307. [Google Scholar] [CrossRef]

- Cappa, C.; Lucisano, M.; Mariotti, M. Influence of Psyllium, sugar beet fibre and water on gluten-free dough properties and bread quality. Carbohydr. Polym. 2013, 98, 1657–1666. [Google Scholar] [CrossRef]

- Jacobs, P.J.; Bogaerts, S.; Hemdane, S.; Delcour, J.A.; Courtin, C.M. Impact of Wheat Bran Hydration Properties As Affected by Toasting and Degree of Milling on Optimal Dough Development in Bread Making. J. Agric. Food Chem. 2016, 64, 3636–3644. [Google Scholar] [CrossRef] [PubMed]

- Hemery, Y.; Holopainen, U.; Lampi, A.M.; Lehtinen, P.; Nurmi, T.; Piironen, V.; Rouau, X. Potential of dry fractionation of wheat bran for the development of food ingredients, part II: Electrostatic separation of particles. J. Cereal Sci. 2011, 53, 9–18. [Google Scholar] [CrossRef]

- Iglesias-Puig, E.; Haros, M. Evaluation of performance of dough and bread incorporating chia (Salvia hispanica L.). Eur. Food Res. Technol. 2013, 237, 865–874. [Google Scholar] [CrossRef]

- Pourabedin, M.; Aarabi, A.; Rahbaran, S. Effect of flaxseed flour on rheological properties, staling and total phenol of Iranian toast. J. Cereal Sci. 2017, 76, 173–178. [Google Scholar] [CrossRef]

- Conforti, F.D.; Davis, S.F. The effect of soya flour and flaxseed as a partial replacement for bread flour in yeast bread. Int. J. Food Sci. Technol. 2006, 41, 95–101. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Witczak, M.; Korus, J.; Ziobro, R.; Juszczak, L. Waxy starch as dough component and anti-staling agent in gluten-free bread. LWT Food Sci. Technol. 2019, 99, 476–482. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Moresoli, C.; Mondor, M.; Marcos, B.; Power, K.A. Flaxseed-enriched cereal-based products: A review of the impact of processing conditions. Comp. Rev.Food Sci. Food Saf. 2014, 13, 400–412. [Google Scholar] [CrossRef]

- Skudra, L.; Rakcejeva, T.; Rubene, S. Evaluation of Nutritive Value of Wheat Bread with Flax Seed Marc Additive. In Proceedings of the 4th International Congress on Flour Bread, 24–27 October 2007, Opatija, Croatia.

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).