Abstract

Process simulation plays a crucial role in modern manufacturing, enhancing efficiency, decision making, and system optimization. However, its adoption varies across industries and regions, influenced by factors such as technological readiness, organizational culture, and workforce expertise. This study explores the application of process simulation in the Saudi manufacturing industry, investigating the extent of its use, key success stories, documented benefits, and barriers to adoption. Using a qualitative approach, semi-structured interviews were conducted with industry leaders and engineers to capture real-world insights into how simulation is implemented and perceived. Findings reveal that while simulation has led to measurable improvements in productivity, cost efficiency, and operational decision making, challenges such as technical constraints, resistance to change, and a shortage of skilled professionals hinder wider adoption. These insights not only reflect the current state of simulation in Saudi manufacturing but also suggest broader implications for industries in other regions facing similar challenges. Understanding the key drivers and barriers to simulation adoption can help shape policies, training programs, and investment strategies to maximize benefits of simulation in manufacturing globally.

1. Introduction

Simulation has emerged as an effective tool for optimizing processes and decision making in manufacturing organizations [1,2]. It enables decision makers to model complex systems, test various scenarios, and identify the most efficient strategies without interrupting actual operations [1,2,3,4,5]. Simulation is widely used in manufacturing systems, supply chains, and logistics. It plays a key role in linking strategic and operational levels through the construction of viable tools and models. In Saudi Arabia, where manufacturing plays a critical role in economic diversification, understanding the application and impact of simulation is vital [6].

Simulation refers to the creation of a virtual representation of a real-world system to analyze and predict behavior [1,7]. In manufacturing, simulation has been shown to be effective for the optimization of production planning, resource allocation, supply chain management, and quality control [1,6,8,9,10,11]. Common types of simulation include discrete event simulation (DES), which focuses on system performance over time; system dynamics, which examines interaction among components; and agent-based modeling, which models the behavior of individual entities [4,6,9]. These tools have proven invaluable for addressing complex problems in modern manufacturing [1,2,3].

The integration of simulation with multi-objective optimization is pivotal for advanced manufacturing decision support. Contemporary studies, such as those employing fuzzy AHP-based MCDM for laser cutting parameter optimization [12] and RSM for nano-additized biodiesel combustion enhancement [13], demonstrate powerful frameworks for resolving complex trade-offs. These methodologies represent a logical extension for simulation applications, moving from descriptive analysis towards prescriptive optimization in industrial contexts.

Globally, simulation has revolutionized manufacturing by enabling cost reduction, improving productivity, and enhancing operational efficiency [14,15]. For example, it has been shown that simulation optimizes assembly lines, reduces inventory costs, and improves workforce planning [1]. Challenges such as high implementation costs, data availability issues, and resistance to change continue to persist [1,3,7,9]. However, despite barriers, the use of simulation continues to increase, driven by advancements in computing power and integration with Industry 4.0 technologies, such as the Internet of Things (IoT), digital twins, and artificial intelligence [2,4,16,17].

In Saudi Arabia, simulation has gained traction as a means to address manufacturing challenges, such as resource optimization and production bottlenecks. A number of studies in the petrochemical and industrial goods sectors have highlighted its effectiveness in reducing lead times, minimizing waste, and improving overall efficiency. For instance, Alquraish [8] provides a comprehensive review of simulation tools in manufacturing, emphasizing their role in enhancing productivity, quality, and system efficiency, particularly in complex, dynamic production environments undergoing digital transformation. Similarly, Aldurgam et al. [11] demonstrated through a real-world case study in an air conditioner assembly plant that integrating discrete-event simulation with multi-objective optimization enabled the evaluation of time–cost tradeoffs, leading to measurable improvements in bottleneck management and operational decision making. Furthermore, Aljuaid et al. [18] illustrate how the integration of Industry 4.0 technologies with localized manufacturing models in Saudi Arabia’s automotive sector has improved customization, agility, and customer satisfaction outcomes that are enabled by simulation-driven planning and control. Ahmed and Robinson [19] offer critical insights into the practices of expert modelers, revealing that successful simulation deployment is highly context-dependent and often hinges on iterative model development, stakeholder engagement, and alignment with strategic objectives. Together, these studies underscore the tangible value of simulation in optimizing industrial operations, particularly when integrated into broader improvement frameworks and tailored to organizational context.

Jeddah serves as a critical industrial and logistical hub in Saudi Arabia, hosting three major industrial cities and two key seaports, Jeddah Islamic Port and King Abdullah Port. The city plays a central role in the Kingdom’s trade infrastructure, handling 46% of total imports and 39% of total exports via its seaports [18]. This strategic position, combined with a growing manufacturing base and a vibrant investment climate, makes Jeddah a microcosm of Saudi Arabia’s broader industrial transformation.

The manufacturing sector in Jeddah has evolved steadily, contributing significantly to economic diversification. Key sub-sectors include industrial goods (e.g., steel, plastics, construction materials), food and beverage, and energy-related manufacturing. Despite this growth, many facilities continue to face operational inefficiencies such as production bottlenecks, supply chain delays, and suboptimal resource utilization, challenges that advanced tools like process simulation could help address [7,12,15]. However, adoption remains uneven, particularly among small and medium enterprises. By focusing on Jeddah, this study captures a representative snapshot of the current state of simulation adoption in a high-impact industrial region.

2. Related Work

Simulation has emerged as a cornerstone technology for analyzing, optimizing, and improving complex systems, gaining significant traction across manufacturing, industrial engineering, and decision-making domains. Its centrality has only intensified with the advent of Industry 4.0, where it plays a vital role in enhancing operational processes, optimizing resource allocation, and boosting overall system performance [8,20,21,22,23].

The value of simulation within manufacturing has been well-established through research and practice. Studies also highlight its critical role in tackling the inherent complexity of production systems. It serves as a powerful tool for optimizing these systems, improving productivity and quality, reducing costs, and facilitating better decision making [8,20,21,23]. Comprehensive reviews by Alquraish [8] and Jahangirian et al. [21] underscore this broad impact, detailing tools, challenges, future prospects, and diverse applications ranging from production planning to supply chain management. Similarly, Hosseinpour and Hajihosseini [23] reinforce the importance of simulation for cost reduction and system optimization. Surveys such as Hlupic et al. [20] confirm the availability, adoption, and effectiveness of simulation software in achieving these benefits within manufacturing environments.

This utility naturally extends to specific manufacturing functions like production planning and control (PPC). Jeon and Kim [6] survey simulation modeling techniques specifically applied to PPC, demonstrating its effectiveness in evaluating schedules, minimizing lead times, and optimizing resource allocation.

A key recurring theme is the utility of simulation as a decision support tool. It allows decision makers to rigorously assess alternatives, evaluate potential outcomes within various scenarios, and reduce uncertainty [16,19,21]. Ahmed and Robinson [19] look into the practices of expert modelers, highlighting how simulation directly contributes to developing robust decision support systems (DSS) and enhancing decision-making processes in industrial engineering. Robinson [16] further emphasizes its value in improving decision quality and risk assessment. Indeed, this capability is particularly crucial in areas like supply chain risk management, where Hoad et al. [24] illustrate how simulation-based risk assessment identifies disruptions, evaluates impacts, and assists contingency plan development.

Furthermore, simulation is useful for manufacturing system design and operation. Studies by Negahban and Smith [4], Polenghi et al. [2], and Smith [25], among others [3,26], consistently report on its effectiveness in this realm. Simulation enables the evaluation of different system configurations, identifies bottlenecks, optimizes resource allocation, and supports capacity planning and performance evaluation. These capabilities directly translate to improved system efficiency, cost reduction, and enhanced operational performance [2,3,4,22,25,26]. Melão and Pidd [22] explore these applications within industrial engineering, reinforcing the role of simulation in optimization processes and resource allocation.

Recent industrial applications demonstrate the transformative potential of advanced simulation technologies. For instance, Kim, Kim, and Noh [27] developed a digital twin (DT)-based system for dynamic supply chain management in an automobile body manufacturing plant in South Korea. Their framework integrated real-time simulation with a tabu search optimization algorithm to dynamically allocate production and logistics resources. In the event of a production disruption, such as equipment failure at a Tier-2 manufacturer, the system automatically identified alternative production sites and recalculated optimal logistics routes, ensuring on-time delivery. This proactive response capability led to an 8.82% reduction in total supply chain costs, primarily through inventory optimization and improved routing efficiency. This case exemplifies how simulation, particularly in the form of digital twins, is evolving from a static analysis tool into a dynamic, decision support system for real-time operational control.

In essence, the industrial engineering and manufacturing research literature collectively establish that simulation is a versatile and effective modeling tool. It underpins improvements across the manufacturing and industrial engineering landscape—from core production optimization and PPC to strategic decision support, risk mitigation, and the fundamental design and operation of complex systems.

3. Methodology

This study employed a semi-structured interview technique to investigate the application of simulation in Saudi production operations. The methodology was elected to explore the following research objectives: uncover adoption patterns, document implementation lessons, and identify potential barriers to simulation use. The interview technique is a structured yet flexible approach, ensuring rigorous and comprehensive data collection and analysis, as shown in Figure 1.

Figure 1.

The research methodology framework.

3.1. Interview Guide Development

The interview guide was designed to address the research objectives while permitting flexibility to explore emergent themes. It was divided into three sections, as follows: General Questions (A): focused on contextualizing the participant’s role, facility, and existing operational improvement tools (e.g., mathematical models, quality frameworks); Simulation Experience (B): for participants with prior simulation exposure, the questions probed project details (objectives, scope, KPIs, software, stakeholders), tangible benefits, challenges, and future intentions; Awareness and Potential (C): for non-users, it explored barriers to adoption (e.g., budget, expertise) alongside perceptions of utility of simulation and interest in academic partnerships

3.2. Participant Selection

Participants were selected via purposive sampling to target managerial roles in production facilities within Jeddah, Saudi Arabia’s second-largest industrial city. Jeddah is a key industrial hub in Saudi Arabia, hosting three major industrial cities and handling 46% of the Kingdom’s imports and 39% of its exports [28]. The study’s sample—52.35% industrial production, 16.78% food and beverage, and 15.44% energy—closely reflects Jeddah’s actual industrial composition, supporting the representativeness and transferability of the findings within the Saudi context. While the focus on Jeddah provides valuable depth, future research should expand to other industrial centers such as Riyadh and the Eastern Province to validate broader applicability. Eligible roles of participants included production managers, operations directors, and quality improvement leaders, while non-managerial staff were excluded. Facilities ranged from large-scale manufacturers to small-sized factories, ensuring diversity in operational complexity.

3.3. Interviewer Training

A training session was conducted to standardize procedures, emphasizing adherence to the guide while maintaining conversational flexibility to probe deeper insights. Interviewers were given mock sessions to refine questioning techniques and ensure consistency in data collection.

3.4. Data Collection

Interviews were conducted in person, lasting ≤ 15 min to minimize participant contribution. Responses were recorded, transcribed verbatim, and anonymized to protect confidentiality. Field notes captured contextual nuances, such as participant hesitations or unstructured observations.

3.5. Data Analysis

Thematic analysis was applied to identify patterns related to simulation adoption, benefits, and barriers. Findings were compared with existing literature to validate insights. A thematic analysis was conducted. Two researchers independently coded the transcripts and compared results, resolving discrepancies through discussion and refining the codebook iteratively. The final themes were reviewed against the data to ensure consistency and credibility.

The methodology ensured a systematic exploration of simulation in Saudi production operations, balancing structured inquiry with open-ended dialogue to yield actionable insights.

Data was collected through semi-structured interviews with 149 professionals across 126 manufacturing facilities in Jeddah, Saudi Arabia. Participants were selected via purposive sampling to ensure representation across organizational size (small, medium, large), industrial sub-sector (industrial production, food and beverage, energy), and managerial level (production managers, quality leads, top management, engineers). Interviews lasted no more than 15 min, were conducted in person with consent, and anonymized to protect confidentiality.

4. Results and Discussion

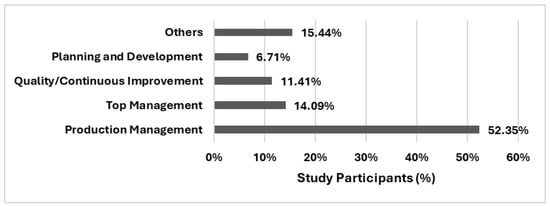

The findings of this study, derived from semi-structured interviews, provide a detailed overview of simulation adoption in the Jeddah manufacturing sector. Figure 2 illustrates that the majority of participants were individuals representing the intended target audience, including production managers, owners/CEOs of industrial facilities, quality improvement services, and planning and development departments. Engineers from various departments such as production, supply chain, mechanical, extrusion, operation manufacturing, and technical support also took part in the interviews. The participant distribution captured frontline and strategic perspectives on simulation across a large range of Saudi Arabian manufacturing institutions. The high engagement of production managers and engineers highlights simulation’s perceived value in solving immediate operational challenges, while the participation of top management personnel might signal awareness of its strategic benefits.

Figure 2.

Positions of manufacturing professionals who participated in the study (N = 149).

The distribution of participants across roles—52.35% in production management, 14.09% in top management, and 11.41% in quality/continuous improvement—reveals a frontline-centric engagement with operational improvement tools. This aligns with findings by Hlupic et al. [20], who observed that simulation adoption is often driven by mid-level engineers and production managers rather than strategic leadership. The relatively low representation of top management (14.09%) may explain the perception gap regarding simulation’s value, as senior decision makers are less exposed to its technical benefits. This disconnect between operational insight and strategic investment is a known barrier in emerging economies [10] and suggests a need for executive education programs to bridge the knowledge gap and align simulation with long-term business goals.

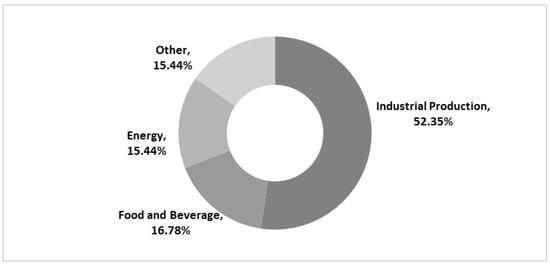

The study participants were employed in a variety of organizations, as shown in Figure 3. Approximately half of organizations belong to the industrial production sector, which includes industries involved in steel, aluminum, construction, plastic, paper, and wooden products. The remaining participants were distributed between the food industry and the energy industry. This diversity ensures that the study captures a broad range of industrial contexts, highlighting the versatility of simulation applications across sectors. However, the concentration in the industrial production sector is approximately similar to the distribution of all other sectors in Saudi Arabia.

Figure 3.

Industrial organizations participation by sector (N = 149).

The dominance of the industrial production sector (52.35%), followed by food and beverage (16.78%) and energy (15.44%), reflects Jeddah’s economic structure and its role as a hub for manufacturing and logistics. This distribution is consistent with data from the Jeddah Chamber of Commerce [28], which highlights the city’s concentration in steel, plastics, and construction materials. The underrepresentation of high-tech businesses and SMEs suggests that simulation adoption is currently concentrated in large, capital-intensive firms, a pattern also observed in South Africa [20]. This reinforces the idea that simulation is perceived as a tool for complex, large-scale systems rather than agile, small-scale improvements—limiting its diffusion across the broader industrial ecosystem.

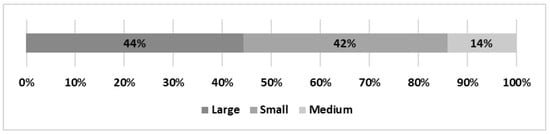

Based on the employee count within the facilities, approximately 44% of organizations can be classified as large, with >200 employees. Around 14% of organizations fall into the medium-sized category, with employee counts ranging from 100 to 199. The remaining organizations are categorized as small, with a capacity of <100 employees (see Figure 4). This distribution indicates that the study encompasses a mix of large-scale manufacturers and smaller facilities, ensuring a representative sample of the manufacturing landscape in Saudi Arabia. Larger organizations may have greater resources and infrastructure to implement advanced simulation tools, whereas smaller organizations might face constraints in terms of budget and expertise. Understanding these size-based variances is crucial for tailoring simulation strategies to meet the needs and capabilities of organizations. This aligns with global trends where SMEs lag in digital tool adoption due to capacity constraints [1]. Future initiatives should focus on modular, cloud-based simulation platforms and government-supported pilot programs to lower entry barriers for SMEs.

Figure 4.

Participating manufacturing organizations by size (N = 149).

4.1. Status of Performance Improvement in Manufacturing Organizations

Managers in manufacturing organizations are committed to consistently monitoring and enhancing their performance. This section provides insights into the key operational performance indicators that hold significance for managers and the methodologies they employ to drive performance improvement.

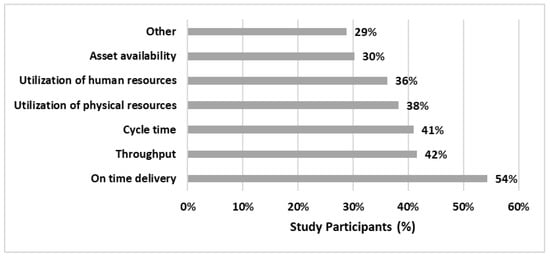

On-time delivery emerged as the most frequently mentioned key performance indicator (KPI) within the manufacturing facility, as shown in Figure 5. Many managers expressed that it can pose significant challenges and has a direct impact on customer satisfaction. These KPIs collectively provide a holistic view of manufacturing performance, enabling organizations to identify bottlenecks, improve efficiency, and drive sustainable growth.

Figure 5.

Operational key performance indicators (KPIs) in industrial organizations.

On-time delivery is a critical KPI for manufacturing industries due to its impact on customer satisfaction, competitive advantage, supply chain efficiency, reputation, and operational efficiency. By prioritizing on-time delivery, manufacturers can enhance their performance, maintain customer loyalty, and drive sustainable success. The prominence of on-time delivery as a top priority suggests that simulation tools could play a pivotal role in predicting and mitigating delays, thereby enhancing overall operational excellence.

Given the nature of manufacturing industries, production is consistently evaluated based on sequential measurements such as production throughput, cycle time, utilization of physical resources, utilization of human resources, and asset availability. These KPIs are vital for manufacturing industries, as they provide insights into operational efficiency, resource utilization, productivity, and the organization’s ability to meet customer expectations. By monitoring and improving these KPIs, manufacturers can optimize their processes, enhance performance, and drive sustainable growth.

Certain participants identified aspects such as the number of defects, sales performance, product quality, material losses, material deviations, incidents causing loss of time, equipment efficiency, reliability of suppliers, and inventory availability. These areas are typically evaluated using one or multiple key performance indicators (KPIs).

These metrics are central to maintaining customer satisfaction and supply chain reliability, as delays or bottlenecks directly impact delivery performance and resource utilization. This emphasis aligns with global manufacturing trends where real-time visibility into production dynamics is critical for competitiveness [27]. The prominence of time- and capacity-related KPIs suggests that Saudi firms are particularly sensitive to production continuity and throughput optimization—areas where simulation can deliver significant value. For instance, Kim et al. [27] demonstrated that a digital twin-based system reduced total supply chain costs by 8.82% through dynamic logistics and production planning, directly addressing similar operational priorities.

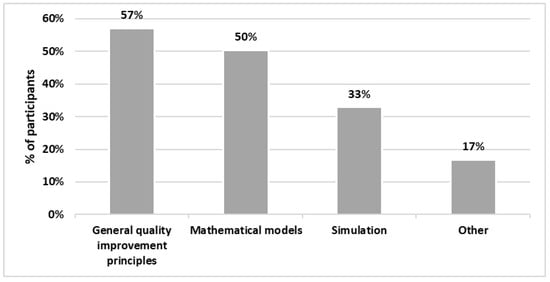

Figure 6 shows that the most widely adopted methodologies for enhancing operational performance were general quality improvement principles and mathematical models. These stood out significantly against the methodologies utilized.

Figure 6.

Tools or methodologies used to improve operations in industrial organizations.

General quality improvement principles are the most widely adopted operational enhancement tools, utilized by 57% of surveyed organizations. Frameworks such as Lean Manufacturing, Six Sigma, Total Quality Management (TQM), and Kaizen emphasize systematic process optimization, waste reduction, and defect minimization. Their popularity stems from their adaptability, ease of implementation, and alignment with efficiency and customer satisfaction goals. However, while effective for incremental improvements in well-defined processes, they lack the analytical depth to model complex, dynamic systems or long-term uncertainties.

Mathematical models, employed by 50% of the organizations examined, are a rigorous, quantitative approach to decision making. Techniques like linear programming, queuing theory, and statistical process control are useful for deterministic problems such as resource allocation, scheduling, and capacity planning. However, their reliance on assumptions (e.g., linearity, stationarity) limits their applicability in highly stochastic or nonlinear environments, limiting effectiveness in complex operational scenarios.

Simulation, despite its theoretical advantages, was only used by 33% of organizations in the study. Discrete event simulation (DES), system dynamics, and agent-based modeling enable “what-if” analyses and evaluation of variability in dynamic systems.

Various other tools and informal methods, including heuristic decision making and managerial intuition, were found to be prevalent, particularly in resource-constrained settings. While useful for rapid adjustments, these approaches lack reproducibility and scalability, often leading to suboptimal outcomes. Their persistence highlights gaps in technological maturity and evidence-based decision making, pointing to broader challenges in organizational culture and digital literacy. As Negahban and Smith [4] note, traditional tools excel in stable environments but are ill-suited for complex, variable systems where simulation can provide critical insights.

This pattern aligns with findings in transitional economies, where organizations first institutionalize familiar, low-complexity methodologies before advancing to sophisticated analytics [1]. The fact that Saudi firms already have robust frameworks like Lean in place suggests they are not resistant to innovation but rather have not yet integrated simulation as a complementary tool. Global best practices demonstrate that these approaches are not mutually exclusive but synergistic. The opportunity lies in embedding simulation within existing improvement cultures, using it to enhance, rather than replace, current practices. Collectively, these findings reveal a preference for pragmatic, incremental improvement methods over advanced analytical tools, underscoring the need for greater education and investment in sophisticated modeling techniques to bridge the gap between theoretical potential and practical implementation.

4.2. Simulation Applications and Experience

Simulation implementation in industrial organizations appears to be quite limited within the sector, as evidenced by the finding that a significant majority of respondents (67.11%) had not implemented the simulation as a tool, compared to only 32.89% who were active users. This aligns with findings from previous studies which highlight that simulation adoption remains concentrated in specific regions and industries, and with limited uptake elsewhere.

The case studies presented below were selected through a purposive sampling strategy to ensure they collectively represent the diversity of simulation applications within the Saudi manufacturing sector. Selection was based on two key criteria to maximize illustrative range and conceptual transferability, as follows: 1-Sectoral and Application Diversity: Cases were chosen from distinct industrial sectors—including petrochemicals (Yokogawa control panel training), logistics (Arena-based warehouse optimization), and general manufacturing (Simio for process planning)—to demonstrate the adaptable value of simulation across different operational environments. 2-Variety of Impact: The selected cases highlight different primary objectives, spanning operational efficiency (e.g., throughput, cycle time), human capital development (e.g., operator training), and strategic planning (e.g., project-based logistics). The cases demonstrate the impactful application of simulation across various industrial domains, including warehouse logistics, control system training, manufacturing process optimization, and project-based planning.

In the context of a warehouse logistics improvement initiative, arena simulation was employed to redesign outbound loading operations with the goal of reducing what is termed Gate-to-Gate time—the duration from truck arrival to departure. Implemented over one month and involving all warehouse personnel, the simulation achieved a 14% reduction in handling time, enabling the facility to receive more trucks and improve throughput. The case highlighted the importance of stakeholder involvement, accurate data, and patience in sustaining improvements, reinforcing the role of discrete event simulation in aligning operational changes with KPIs such as capacity and productivity.

In another case, an eight-hour dynamic simulation of a control panel operation was conducted using Yokogawa software to enhance operator readiness and system reliability. The simulation provided a realistic virtual environment for operators to practice troubleshooting in a context where conditions were unfavorable, thereby improving their confidence, awareness, and response times. Conducted collaboratively by operations, training, engineering, and consulting teams, the exercise ensured system functionality and operational safety before real-world deployment. This case emphasizes the critical role of simulation in human performance development and operational risk mitigation, particularly in high-consequence industrial environments where control room decisions directly impact safety and efficiency.

Two additional cases involved the use of Simio, a 3D-based discrete event simulation platform. The first case applied Simio in the development of a shipment delivery plan using car carriers in the initial phase of a time-sensitive project. By modeling the stochastic nature of the logistics system, Simio helped planners visualize operational dynamics, reduce planning time, and improve data clarity. However, users acknowledged its limitations, noting that “Simio is not for all operations,” and emphasized the need for context-specific tool selection. In a second application, Simio was used in a trial-and-error mode to reduce manufacturing errors and losses. The team learned that experience is crucial for building credible models and that simulation improves processes—not product quality—reinforcing the moral that realistic expectations are required.

Collectively, these cases illustrate that simulation is a powerful enabler of operational excellence, offering benefits in planning, training, quality, and efficiency. They also reveal common challenges, such as data quality, model validity, and organizational resistance, while emphasizing the importance of user expertise, stakeholder engagement, and alignment with strategic objectives. The experiences suggest that while simulation tools are increasingly recognized for their value, their successful implementation depends on a flexible, systematic, and learning-oriented approach to industrial problem solving.

The findings are consistent with some previous studies, suggesting that simulation adoption is more prevalent in regions such as Europe and North America, where it is integrated into operational planning and optimization. In contrast, the limited adoption in Saudi Arabia highlights potential challenges, such as a lack of awareness, expertise, or access to the necessary resources and tools. Addressing these barriers could play a key role in encouraging wider adoption of simulation technologies in industrial organizations.

The findings are consistent with some previous studies, indicating that simulation adoption is significantly more advanced in mature industrial economies such as those in Europe and North America [1,20], where it is systematically integrated into operational planning, decision making, and continuous improvement frameworks. In contrast, the limited adoption in Saudi Arabia highlights potential challenges, such as a lack of awareness, expertise, or access to the necessary resources and tools. Relying on the comparative analysis by Usiagu et al. [1], this study highlights that while the USA benefits from robust industry–academia collaboration, embedded simulation curricula, and widespread technological readiness, countries like Saudi Arabia and several African nations face similar constraints in data availability, technical capacity, and organizational readiness. Despite these barriers, there is a growing recognition across both contexts of simulation’s potential to enhance resource allocation, reduce inefficiencies, and support strategic decision making. This convergence in challenges and aspirations underscores the importance of shared solutions, particularly knowledge transfer, collaborative research, and capacity-building initiatives through university–industry partnerships.

4.3. Simulation Barriers and Potential

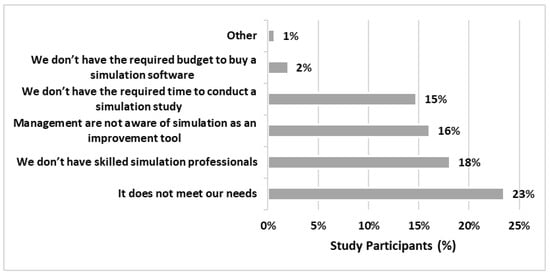

This section discusses the factors contributing to the low adoption rate of simulation in industrial organizations and the reluctance of managers to apply simulation for operational improvement. Figure 7 presents the main barriers to simulation implementation. The most frequently reported barrier was that simulation does not meet organizational needs, as cited by 23% of respondents. This perception is likely rooted in a lack of awareness or prior negative experiences with simulation initiatives. This finding resonates with Ahmed and Robinson [19], who observed that simulation is often misapplied or poorly communicated to decision makers, leading to skepticism and reduced confidence in its value.

Figure 7.

Main barriers to simulation adoption in industrial organizations.

The most frequently cited barrier was “It does not meet our needs” (23%), followed by “We don’t have skilled professionals” (18%). This order is critical; the primary obstacle is not technical capacity but perceived relevance and trust. As Hlupic and Paul [20] found in South Africa, this perception often stems from poor model communication, misaligned objectives, or past negative experiences.

The second most common barrier, reported by 18% of respondents, was the lack of skilled simulation professionals. This reflects the general shortage of expertise in simulation in industrial organizations of Saudi Arabia. As simulation requires specialized knowledge and experience, managers may feel that their teams are not adequately equipped to develop and implement simulation models effectively. Consequently, they might tend to rely on more familiar and accessible tools, such as quality improvement principles and mathematical models.

Another significant barrier, identified by 16% of respondents, was management’s lack of awareness of simulation as an improvement tool. Some managers indicated that they were unfamiliar with simulation and its potential applications. This lack of awareness limits its consideration as a viable option for addressing operational inefficiencies, suggesting a need for increased education and advocacy to highlight the benefits of simulation.

Time constraints were also highlighted, with 15% of respondents reporting insufficient time to conduct simulation studies. Managers often face pressure to manage daily operations and meet short-term goals, leaving little room for time-intensive methods such as simulation. The perception that simulation requires substantial time and resources may deter adoption, even when long-term benefits outweigh initial investment. The low citation of cost (2%), as well as just 1% indicating other barriers, suggests that financial constraints are not the main obstacle; rather, the challenge is cognitive and cultural lack of understanding of simulation’s value. This reinforces the importance of academic–industry partnerships to build credibility through low-risk, high-visibility pilot studies that demonstrate tangible benefits.

Yet, barriers such as perceived complexity, software costs, and the need for technical expertise might have hindered broader adoption in the present cohort. This gap suggests a need for greater awareness and training to demonstrate the strategic value of simulation in industrial decision making.

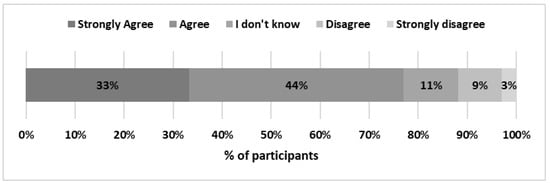

In general, participants perceived simulation positively, as reflected in the results shown in Figure 8. A significant majority, 77%, selected either “strongly agree” or “agree,” indicating that they believed simulation holds substantial potential for improving operations within their organizations. Many participants viewed simulation as a modern and innovative approach compared to traditional methods, expressing interest in exploring its capabilities to enhance decision-making processes.

Figure 8.

Perspective of participants on the potential of simulation.

Several participants appreciated the ability of simulation to analyze and evaluate potential solutions more efficiently than existing practices. Some also noted that simulation could significantly impact how decisions are made and communicated within teams, fostering a more collaborative and informed approach to operational challenges.

However, 11% of respondents were uncertain about the potential of simulation, selecting “I don’t know.” This may reflect a lack of familiarity or experience with the tool, underscoring the importance of simulation initiatives to demonstrate its benefits. A smaller proportion expressed skepticism, with 9% disagreeing and 3% strongly disagreeing, suggesting that some managers may have concerns about the applicability or practicality of simulation in their specific contexts.

Further underscoring this positive perception, a significant majority of participants (76%) expressed willingness to conduct simulation studies in their organizations, revealing a robust latent interest in leveraging simulation for operational improvement despite current low adoption rates. Many participants viewed this as an opportunity to modernize their processes and leverage advanced technologies to address existing challenges.

On the other hand, 24% of respondents were hesitant about adopting simulation studies. This reluctance might stem from a lack of familiarity, concerns about resource requirements, or skepticism about its applicability to their own specific contexts. Addressing these concerns through targeted awareness campaigns and pilot studies could help demonstrate the practical benefits of simulation and encourage broader adoption in industrial organizations.

Several participants expressed interest in gaining hands-on experience with simulation, viewing it as a chance to better understand its applications and benefits. Others indicated that partnering with external experts or institutions, such as universities, could provide a low-cost way to develop simulation models tailored to their operational needs. This collaborative approach was seen by some as a potential way to minimize resource constraints, while maximizing learning and improvement opportunities. Alternatively, some participants believed that simulation might only be beneficial in addressing large-scale or critical issues, such as resolving significant bottlenecks or operational inefficiencies. This perspective implies that simulation is seen as a tool best suited for tackling high-impact challenges, rather than low-level improvements. These insights underline the importance of clarifying the broader applications and adaptability of simulation to encourage wider adoption across diverse operational scenarios.

This empirical study has examined the adoption landscape of simulation technology within Saudi Arabia’s manufacturing sector, centered in the industrial hub of Jeddah. Using semi-structured interview technique involving 149 professionals across 126 facilities, the study provides critical insights into current adoption levels, implementation barriers, and future prospects. The findings revealed that simulation remains underutilized in manufacturing, with only 34% of surveyed organizations employing simulation for operational improvement. This limited use stands in stark contrast to the widespread incorporation of traditional methodologies such as general quality improvement principles (57%) and mathematical models (50%), which are perceived as more accessible and less resource-intensive alternatives.

Key barriers to wider simulation adoption include a notable lack of skilled professionals (reported by 18% of respondents) and insufficient management awareness of simulation’s capabilities (16%). Furthermore, 23% of participants perceived simulation as misaligned with their organizational needs, suggesting a gap in understanding how this technology can address specific operational challenges. Time constraints also emerged as a significant obstacle, with 15% citing insufficient capacity to conduct simulation studies in the context of day-to-day operational demands. Despite these barriers, the study uncovered strong latent interest in the potential of simulation. A substantial majority of respondents (77%) expressed belief in its value for operational improvement, and 76% indicated willingness to implement simulation studies within their organizations.

5. Conclusions

These findings carry important implications for Saudi Arabia’s industrial development. The capacity for simulation to optimize processes, reduce waste, and enhance efficiency aligns directly with national goals for economic diversification and global competitiveness.

The expressed interest in academic partnerships, particularly collaborations with universities, presents a practical pathway to overcome resource constraints while building local expertise. To accelerate adoption, targeted awareness initiatives demonstrating sector-specific applications are required, alongside expanded training programs to develop expertise within the industrial workforce.

While this study provides valuable insights into the Jeddah region, future research should expand geographically to other industrial centers in Saudi Arabia and examine sector-specific adoption patterns more specifically. Longitudinal studies tracking the impact of simulation implementation might further validate its benefits within the Saudi context. In conclusion, though simulation adoption in Saudi manufacturing remains nascent, its power to improve manufacturing and potential to contribute to a strategic alignment with national objectives position it as a key enabler in the Kingdom’s industrial transformation. Addressing knowledge, skill, and perception barriers will be essential to unlocking its full contribution in the evolving manufacturing landscape.

Author Contributions

Conceptualization, A.A. and A.T.; methodology, A.A.; formal analysis, A.T.; data curation, A.A.; writing—original draft preparation, A.T.; writing—review and editing, A.A.; visualization, A.T.; supervision, A.A.; funding acquisition, AAT. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the University of Jeddah, Jeddah, Saudi Arabia, under grant no. (UJ-24-DR-858-1). Therefore, the authors thank the University of Jeddah for its technical and financial support.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and the protocol was approved by the Ethics Committee of Jeddah International College (S3) on 17 March 2025.

Data Availability Statement

The data is available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Usiagu, G.S.; Adefemi, A.; Okoli, C.E.; Dauda, C.D.; Olu-Lawal, K.A. Simulation Techniques in Industrial Engineering: A USA and African Perspective Review. Magna Sci. Adv. Res. Rev. 2024, 10, 265–272. [Google Scholar] [CrossRef]

- Polenghi, A.; Fumagalli, L.; Roda, I. Role of Simulation in Industrial Engineering: Focus on Manufacturing Systems. IFAC-PapersOnLine 2018, 51, 496–501. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Bernidaki, D. Simulation in Manufacturing: Review and Challenges. Procedia CIRP 2014, 25, 213–229. [Google Scholar] [CrossRef]

- Negahban, A.; Smith, J.S. Simulation for Manufacturing System Design and Operation: Literature Review and Analysis. J. Manuf. Syst. 2014, 33, 241–261. [Google Scholar] [CrossRef]

- Alrabghi, A.; Tameem, A. Empowering Healthcare Agility: A Strategic Framework for Pandemic-Responsive Operational Planning. J. Multidiscip. Healthc. 2025, 18, 3321–3330. [Google Scholar] [CrossRef]

- Jeon, S.M.; Kim, G. A Survey of Simulation Modeling Techniques in Production Planning and Control (PPC). Prod. Plan. Control. 2016, 27, 360–377. [Google Scholar] [CrossRef]

- Alrabghi, A. Simulation in Saudi Healthcare: An Empirical Study Revealing the Current Status and Future Prospects. South. Afr. J. Ind. Eng. 2020, 31, 28–39. [Google Scholar] [CrossRef]

- Alquraish, M. Modeling and Simulation of Manufacturing Processes and Systems: Overview of Tools, Challenges, and Future Opportunities. Eng. Technol. Appl. Sci. Res. 2022, 12, 9779–9786. [Google Scholar] [CrossRef]

- Greasley, A. The Usage of Simulation. In Enabling a Simulation Capability in the Organisation; Springer: London, UK, 2008; pp. 7–20. ISBN 978-1-84800-169-5. [Google Scholar]

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Aldurgam, M.M.; Alghadeer, M.Y.; Abdel-Aal, M.A.M.; Selim, S.Z. Productivity Improvement Through Multi-Objective Simulation Optimization—A Case Study. IEEE Access 2019, 7, 40230–40239. [Google Scholar] [CrossRef]

- Basar, G.; Der, O. Multi-Objective Optimization of Process Parameters for Laser Cutting Polyethylene Using Fuzzy AHP-Based MCDM Methods. Proc. Inst. Mech. Eng. Part. E J. Process Mech. Eng. 2025. [Google Scholar] [CrossRef]

- Savaş, A.; Şener, R.; Uslu, S.; Der, O. Experimental Study on Performance and Emission Optimization of MgO Nanoparticle-Enriched 2nd Generation Biodiesel: A Method for Employing Nanoparticles to Improve Cleaner Diesel Combustion. J. Energy Inst. 2025, 120, 102024. [Google Scholar] [CrossRef]

- de Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in Industry 4.0: A State-of-the-Art Review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Alsaadi, N. Modeling and Analysis of Industry 4.0 Adoption Challenges in the Manufacturing Industry. Processes 2022, 10, 2150. [Google Scholar] [CrossRef]

- Robinson, S. Discrete-Event Simulation: From the Pioneers to the Present, What Next? J. Oper. Res. Soc. 2005, 56, 619–629. [Google Scholar] [CrossRef]

- Alrabghi, A. A Modelling Approach for Asset Degradation: Advancing Digital Twin in Maintenance. Int. J. Simul. Model. 2025, 24, 76–86. [Google Scholar] [CrossRef]

- Aljuaid, A.A.; Masood, S.A.; Tipu, J.A. Integrating Industry 4.0 for Sustainable Localized Manufacturing to Support Saudi Vision 2030: An Assessment of the Saudi Arabian Automotive Industry Model. Sustainability 2024, 16, 5096. [Google Scholar] [CrossRef]

- Ahmed, R.; Robinson, S. Modelling and Simulation in Business and Industry: Insights into the Processes and Practices of Expert Modellers. J. Oper. Res. Soc. 2014, 65, 660–672. [Google Scholar] [CrossRef]

- Hlupic, V.; J Paul, R. Simulation Software in Manufacturing Environments: A Users’ Survey. J. Comput. Inf. Technol. 1993, 1, 205–212. [Google Scholar]

- Jahangirian, M.; Eldabi, T.; Naseer, A.; Stergioulas, L.K.; Young, T. Simulation in Manufacturing and Business: A Review. Eur. J. Oper. Res. 2010, 203, 1–13. [Google Scholar] [CrossRef]

- Melão, N.; Pidd, M. Use of Business Process Simulation: A Survey of Practitioners. J. Oper. Res. Soc. 2003, 54, 2–10. [Google Scholar] [CrossRef]

- Hosseinpour, F.; Hajihosseini, H. Importance of Simulation in Manufacturing. Int. J. Econ. Manag. Eng. 2009, 3, 229–232. [Google Scholar] [CrossRef]

- Hoad, K.; Monks, T.; O’Brien, F. The Use of Search Experimentation in Discrete-Event Simulation Practice. J. Oper. Res. Soc. 2015, 66, 1155–1168. [Google Scholar] [CrossRef]

- Smith, J.S. Survey on the Use of Simulation for Manufacturing System Design and Operation. J. Manuf. Syst. 2003, 22, 157–171. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the Design and Operation of Manufacturing Systems: State of the Art and New Trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, G.Y.; Noh, S. Do Digital Twin-Based Prediction and Optimization for Dynamic Supply Chain Management. Machines 2025, 13, 109. [Google Scholar] [CrossRef]

- Jeddah Chamber of Commerce Jeddah City Economic Components. Available online: https://www.jcci.org.sa/en/%D8%A5%EF%BB%97%EF%BA%98%EF%BA%BC%EF%BA%8E%D8%AF-%EF%BB%A3%EF%BA%AA%EF%BB%B3%EF%BB%A8%EF%BA%94-%EF%BA%9F%EF%BA%AA%D8%A9 (accessed on 20 August 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).