Abstract

This article presents experimental research focused on the implementation and evaluation of new wireless communication technologies to enhance the quality and stability of motion control in autonomous mobile robots. The reason for this research arises from the fact that autonomous mobile robots are increasingly used in industrial applications, where reliable real-time operation is required, which depends on low latency and the stability of wireless communication. The theoretical part deals with the possibilities of using local 5G technology in industrial mobile robotics and with the parameters of this technology. The experimental part includes measurements in which the robot was simultaneously connected to both the private 5G SA network and the Wi-Fi 6E network during its operation, where a custom Python script was used to record connection quality parameters (latency, jitter, packet loss, RSSI) together with the robot’s position in space and a timestamp. The collected data were processed and visualized in the form of graphs and heatmaps, enabling an analysis of network dynamics in relation to the robot’s movement in space. The results show that Wi-Fi 6E is more sensitive to environmental conditions, and during dynamic robot movement it often exhibits unstable latency, increased jitter, and packet loss. In contrast, the private 5G SA network demonstrates higher stability and resilience to outages, making it more suitable for industrial environments. This research highlights the importance of implementing new communication technologies to improve the quality and stability of autonomous mobile robot control.

1. Introduction

Industry 4.0 represents a new standard for automated, flexible, and interconnected production. Industry 4.0 and the concept of smart factories place high demands on reliable low-latency wireless communication. Autonomous Mobile Robots (AMR) are increasingly used in logistics and manufacturing environments, where their efficient operation requires stable networks capable of handling the transmission of control signals in real time. Reliable low-latency wireless communication is therefore crucial for their effective coordination and safe movement of robots [].

Traditional industrial Wireless Fidelity (Wi-Fi) networks are widely adopted due to their low cost and ease of deployment; however, in industrial environments they frequently experience unstable latency and service interruptions, which may undermine the reliability and safety of automated systems [].

Wi-Fi 6 (IEEE 802.11ax) introduces a set of technological improvements aimed at increasing spectral efficiency and reducing interference in environments with multiple clients. It divides communication channels into smaller sub-channels, enables bidirectional parallel data transmission, and mitigates congestion in overlapping networks. According to Bartolín-Arnau et al. Wi-Fi 6 and 6E demonstrate excellent performance under low-interference conditions, particularly in the 6 GHz band, yet their stability in industrial environments remains strongly influenced by interference []. Jacobsen et al. demonstrated that Wi-Fi 6 can achieve ultra-low latency (<1 ms) and high throughput under conducive conditions; however, its performance deteriorates with an increasing number of clients and higher interference levels [].

Although Wi-Fi 6 introduces several mechanisms to improve efficiency, its performance remains sensitive to interference and varying network loads. Therefore, for applications that demand consistent low latency and high reliability, such as autonomous robot control, the 5G network represents a promising alternative communication technology. A recent study highlighted that 5G networks provide significantly lower latency and greater transmission stability compared to Wi-Fi, which is crucial for the remote control of robotic systems [].

The 5G standard, developed by the 3rd Generation Partnership Project (3GPP) consortium, was designed as a universal communication framework capable of supporting a wide spectrum of use cases []. In the industrial sector, 5G technology enables three key application scenarios that fundamentally enhance production capabilities and technological processes. The first is enhanced Mobile Broadband (eMBB), which delivers ultra-high data rates and supports high-quality image and video transmission. The second is massive Machine-Type Communication (mMTC), enabling reliable connectivity for a vast number of low-power devices, making it ideal for large-scale sensor networks. The third is Ultra-Reliable Low-Latency Communication (URLLC), which provides near-instantaneous response and high reliability, essential for applications such as automated production lines and robotic systems [].

In recent years, 5G technology has become a key driving force of the industrial revolution, enabling high-speed communication, reliable ultra-low latency communication and massive connectivity, thereby significantly supporting the digitalization of manufacturing—from remote operations and robotics to real-time data collection and processing. Nevertheless, the integration of 5G into manufacturing processes remains at an exploratory stage [].

The 3GPP technical specification [] defines latency requirements ranging from 0.5 to 500 ms depending on the scenario, with experimentally achieved values as low as 0.625 ms [,]. 5G supports up to one million connected devices per square kilometre and targets reliability levels exceeding 99.999%, as demonstrated by simulations achieving 99.9996% for low-latency applications [,]. Other defining features include network slicing, which enables multiple virtual networks on shared infrastructure tailored to specific Quality of Service (QoS) needs, and Mobile Edge Computing (MEC), which brings computational resources closer to end devices to minimize delay [,]. The peak data rate can reach up to 20 Gbps [].

5G networks are deployed as public or private systems. Public networks cover wide areas under mobile carriers, while private (campus) networks serve restricted environments such as factories or campuses, offering higher security and configurability. Standalone (SA) networks operate on a dedicated 5G core, providing greater reliability and control compared to Non-Standalone (NSA) versions relying on 4G infrastructure [,].

5G networks operate in two Frequency Ranges—FR1 (sub-6 GHz) and FR2 (mmWave). FR1 supports broad coverage and better obstacle penetration (e.g., 600 MHz–3.8 GHz), whereas FR2 offers extremely high data rates in 24–52 GHz bands but limited range and penetration [,].

2. Related Works

5G technologies bring new opportunities for efficient communication and control in industrial applications, which explains the growing interest in experimental measurements and analyses of these networks that examine their behaviour under real-world conditions and validate their ability to meet the demanding requirements of modern industry.

Lackner et al. conducted a comparison of data rates and Round-Trip Time (RTT) across five end devices in a licenced 5G Standalone Non-Public Network (NPN) at Reutlingen University. They found that the Huawei P40 Pro+ achieved the most stable RTT (averaging 7.2–8.7 ms, with a maximum of 11.4–15.6 ms), while the performance of other devices was limited by the absence of software updates []. A similar study was carried out by Sachinkumar Bavikatti Mallikarjun et al. in the campus network of TU Kaiserslautern, showing that throughput and RTT varied depending on location and device: indoors, peak Downlink (DL) throughput reached 813 Mbit/s and Uplink (UL) 232 Mbit/s, whereas outdoors the values were 870 Mbit/s (DL) and 126 Mbit/s (UL) [].

Merwaday et al. presented an advanced simulation experiment in the field of 5G IIoT, where they tested a communication-control design for robotic manipulation. Their system dynamically adjusted the Quality of Service (QoS) according to the current state of robotic control, resulting in a doubling of network capacity (31 control loops with 100% success rate) and a significant reduction in latency, which demonstrates the high efficiency and reliability of this approach [].

Similarly, Hamidovic et al. analyzed how QoS priorities and channel configurations affect Key Performance Indicators (KPIs) in a 5G SA campus network. Their results confirmed that with eMBB priorities, downlink throughput remained stable at up to 450 Mbps and uplink at 120 Mbps, whereas URLLC configurations reduced latency to 3.9–4.6 ms. They also identified the influence of user location and interference, highlighting the need for optimization of QoS and channel settings in industrial applications [].

Kamtam et al. conducted a systematic review of teleoperation of connected and autonomous vehicles, focusing on the impact of network latency and mitigation methods. They found that variable latency significantly degrades control, with teleoperation remaining acceptable up to ~300 ms, while values above 700 ms render it practically uncontrollable [].

Important insights were also provided by Polak et al., who measured the Reference Signal Received Power (RSRP), Reference Signal Received Quality (RSRQ), Signal-to-Interference-plus-Noise Ratio (SINR), and data rates in an industrial environment using a portable measurement setup with 4 × 4 Multiple-Input Multiple-Output (MIMO) antennas. They discovered that metallic structures and interference caused variations of up to 20 dB and fluctuations in coverage between day and night. Nevertheless, the 5G network demonstrated stability and automatic fallback to 4G, with average latency recorded at 40 ms and data rates ranging from 30 to 60 Mbps [].

A significant case study was carried out by J. Cañete-Martín et al., who demonstrated that an integrated digital model of a 5G network and a digital model of an industrial factory with Automated Guided Vehicles (AGV) enabled effective collision avoidance. In the event of communication failure, AGVs stopped, confirming the critical role of a reliable 5G network. Optimization of 5G base station placement reduced undetected communications from 20.62% to 9.84% and decreased packet loss from 5.9% to 2.1% [].

Recent research also explores future extensions of 5G communication through reconfigurable intelligent surfaces, which can dynamically shape the propagation environment to improve signal reliability in complex industrial conditions []. Furthermore, the integration of terrestrial and satellite communication systems is considered a key step toward next-generation networks, ensuring continuous and reliable connectivity even beyond the reach of current private 5G deployments [].

3. Performance Metrics and Signal Quality Indicators in Mobile Networks

KPI form the basis for a comprehensive understanding and effective optimization of wireless networks operations. In the theory of wireless networks systems, KPI represent metric indicators that quantify various aspects of network performance and Quality of Service (QoS). Understanding the significance, units, and threshold values of individual indicators enables accurate assessment of network conditions and helps identify potential issues in mobile communication.

3.1. Radio Frequency Signal Quality Indicators

They are used to evaluate the physical layer of the wireless link between the User Equipment (UE) and the base station.

- RSSI represents the total signal power received at the device antennas, not dependent on the specific signal source. It is measured in dBm and includes the total received power from neighbouring base stations, internal and external interference, as well as ambient noise. A higher RSSI value indicates a stronger signal [,].

RSSI = serving signal + interference + noise

- RSRP quantifies the strength of the reference signal received from the serving base station in a mobile network. It is measured in dBm, and its value is independent of channel bandwidth and does not include interference or noise. A lower RSRP value indicates a weaker signal [,].

- RSRQ is a quantitative indicator of reference signal quality defined by the 3GPP consortium. It is calculated from RSSI and RSRP values and reflects the quality of the signal from the serving base station. A higher RSRQ value (in dB) corresponds to better signal quality [,].

- SINR is the ratio between the strength of the received signal and the sum of interference and noise in a mobile network. This parameter is crucial for determining signal quality and is measured in dB. A higher SINR value indicates better signal quality [,].

- Channel Quality Indicator (CQI) is a dimensionless numerical value that the user equipment reports to the base station as an indicator of channel quality. CQI is used for adaptive modulation and coding, with values ranging from 0 to 15, where 0 indicates that no data transmission is possible, and values from 1 (poor quality) to 15 (excellent quality) [,].

Table 1 presents the threshold values of the key KPI parameters that describe signal quality in the Radio Frequency (RF) channel. The values are grouped into four categories and provide a concise reference for evaluating mobile connectivity conditions in wireless networks.

Table 1.

Assessing RF Channel Status by KPI [].

3.2. Network Performance Metrics

Focused on user experience, i.e., how well the network performs in terms of data transmission and communication.

Latency refers to the time elapsed from when a data packet is sent from the source device until a response is received from the destination device. It is most measured using the Round-Trip Time (RTT) metric, which represents the total time for a packet to travel ‘there and back.’ RTT is measured in milliseconds (ms) and is among the key performance indicators of network performance. Latency is critical to the responsiveness of real-time applications and is particularly important in scenarios such as robotic control, video conferencing, online gaming, or automated industrial processes [].

Latency can be easily measured using the ping tool, which sends a packet to a target IP address and records the time it takes for the response to return [].

Jitter describes the variability in packet delay, representing how consistently packets arrive over time. High jitter can cause communication instability, audio or video interruptions, and control irregularities in robotics [,]. The average jitter is calculated according to the following formula:

where J is the average jitter, N is the total number of measured packets, is the delay of i-th packet and represents the average delay.

Packet-to-packet jitter is a network performance metric that quantifies the variation in delay between consecutive data packets. It reflects how consistently packets arrive at their destination in time. In stable networks, this variation is minimal, while in unstable conditions the delay between packets fluctuates significantly. Measuring packet-to-packet jitter is essential for evaluating the temporal stability of a communication channel—especially in real-time systems such as robotic control, video streaming, or voice transmission—where irregular packet timing can cause visible delays, motion irregularities, or data loss. Packet-to-packet jitter can be expressed by the following formula:

where Ji is the packet-to-packet jitter, is the delay of the i-th packet, and is the delay of the previous (i − 1) packet.

Connection reliability is an indicator that expresses the ability of a specific connection to remain stable and uninterrupted without outages or failures. Connection reliability is measured as the ratio of successfully delivered data packets to the total number of transmitted packets within a defined time interval and is expressed as a percentage (%) [].

Reliability = (Nreceived/Nsent) × 100%

4. Technologies and Methods

The aim of this study is to experimentally investigate the implementation of modern wireless communication technologies, specifically Wi-Fi 6E and 5G Standalone (SA), in the motion control of autonomous mobile robots. The research focuses on how network performance parameters (such as latency, jitter, RSSI) influence the real-world motion behaviour, control accuracy, and communication stability of the autonomous mobile robot operating under dynamic industrial conditions.

Special emphasis is placed on comparing the stability and quality of transmission during robot movement in changing environments and on assessing the suitability of Wi-Fi 6E and 5G SA for the needs of industrial robotics. The results are expected to contribute to a better understanding of the possibilities and limitations of these technologies in ensuring reliable and low-latency data transmission, which is essential for the safe and efficient control of AMR.

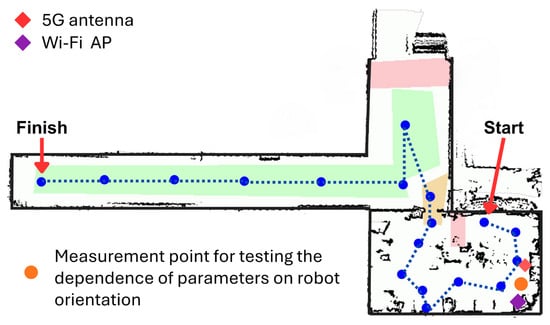

The experiments were conducted using the SmartTechLab laboratory infrastructure, located at the Faculty of Manufacturing Technologies with seat in Prešov []. SmartTechLab is a research and education facility dedicated to industrial automation and digitalisation []. The laboratory is equipped with a private 5G SA network provided by the operator Telekom, as well as a dedicated Wi-Fi 6E Access Point (AP). For the experimental measurements, an autonomous mobile robot MiR100 was used, moving along predefined trajectories within the SmartTechLab industrial laboratory and in another university facilities. The layout of the laboratory and the main measurement trajectory are shown in Figure 1. The figure illustrates the measurement points and the placement of the access points for both communication technologies within the experimental area. The orange circle marks the specific location where the dependence of network parameters on the robot’s rotation was measured.

Figure 1.

Map of the experimental area with robot trajectory and measurement points.

The measurement process started from the start position, from which the robot followed a predefined trajectory. At each measurement point, the robot made a short stop, while network indicators were continuously recorded—both during movement between the points and during stops at the individual points. After reaching the end point, the robot turned around and returned along the same trajectory back to the starting position. Measurements were carried out in the same way during the return path, meaning that each measurement point was recorded twice—in both directions. This procedure enabled not only the verification of result consistency but also the identification of possible asymmetries in network behaviour depending on the robot’s direction of movement.

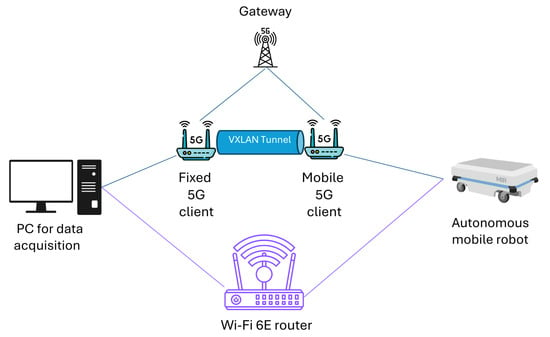

Throughout the entire experiment, the robot was connected in parallel to two independent networks—Wi-Fi 6E and the private 5G Standalone network—which made it possible to continuously monitor the parameters of both technologies under identical conditions. Figure 2 shows the architecture of the experimental setup, illustrating how the robot is connected to both networks—Wi-Fi 6E and the private 5G Standalone network.

Figure 2.

Schematic architecture of the experimental setup.

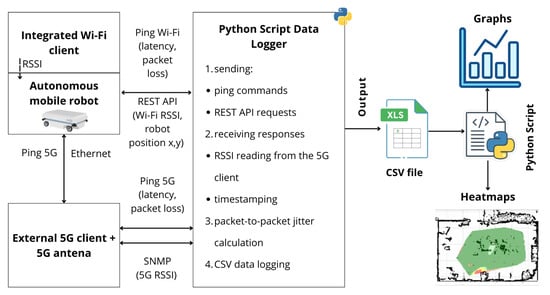

During the experiment, key connectivity quality indicators—namely latency, jitter, packet loss, and RSSI—were recorded in real time in parallel with the robot’s coordinates on the map. This approach enabled the subsequent creation of heatmaps that visualized the distribution of the measured parameters as a function of the robot’s location and movement. Data collection was carried out using a custom Python (v3.10) script that integrated multiple communication mechanisms. The entire data acquisition process is illustrated in Figure 3.

Figure 3.

Methodology of data collection from both wireless technologies (Wi-Fi and 5G).

Latency and packet loss values were obtained using the ping command, while jitter was calculated from the recorded latency value. Robot position data and Wi-Fi RSSI were obtained via the REST API (version v2.0.0) a web interface that enables applications to communicate over the Internet using standard HTTP requests [], during communication with the robot, whereas 5G RSSI values were collected through the SNMP protocol (Simple Network Management Protocol—a simple protocol for managing network devices []) from the mobile client device SCALANCE MUM853-1 (Siemens AG, Munich, Germany).

All collected data were stored in CSV files with assigned timestamps, which enabled subsequent processing, statistical analysis, and visualization in the form of graphs and map-based outputs.

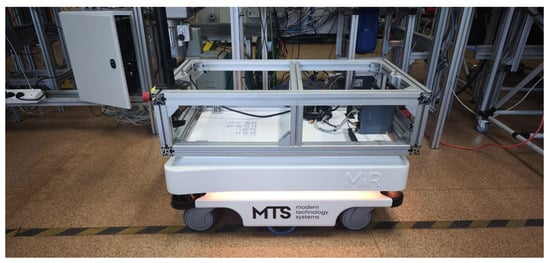

To conduct these experiments, the autonomous mobile robot MiR100, shown in Figure 4, was used as the mobile platform. The MiR100 (Mobile Industrial Robots, Odense, Denmark) is an autonomous mobile vehicle designed for intralogistics and automated material transport []. Its key technical parameters used in the experiments are summarized in Table 2. In the experiment, it served both as a network end-user and as a source of signal quality measurements during movement.

Figure 4.

AMR MiR100 used as a mobile platform for real-time measurement.

Table 2.

Parameters of the MiR100 Mobile Robot used in network measurements [].

The MiR100 mobile robot operated within the SmartTechLab industrial laboratory, which is equipped with both a private 5G Standalone (SA) network and a Wi-Fi 6E access point. These networks provided the communication infrastructure for testing the connectivity quality and stability of the autonomous robot during dynamic motion. A detailed description and technical configuration of both networks, together with the associated hardware, are presented in the following subsection.

Design and Configuration of Campus Wi-Fi 6E and 5G SA Network in SmartTechLab

Both networks were designed to ensure reliable and stable data connectivity in a dynamic environment. The specific technical parameters of both solutions are presented in the following tables, describing the fundamental properties, frequency bands, channel bandwidth, and other operational characteristics of the applied technologies. The configuration of the Wi-Fi 6E network used in the experiment is summarized in Table 3.

Table 3.

Configuration of the Wi-Fi 6E network used in the experiment.

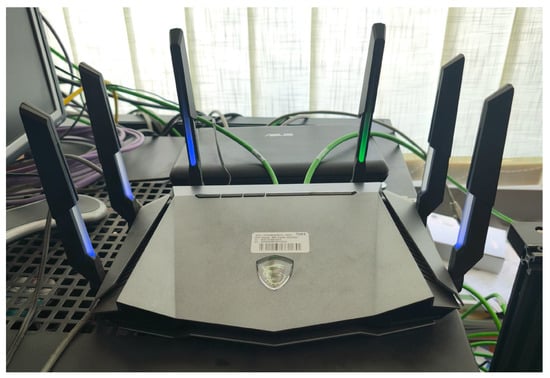

To ensure Wi-Fi connectivity during the experiment, a high-performance MSI RadiX AX6600 Wi-Fi 6 Tri-Band Gaming Router (Micro-Star International Co., Ltd., New Taipei City, Taiwan) was used, belonging to the category of modern Wi-Fi 6 devices. This router is designed for environments with high demands on throughput, low latency, and connection stability, which also makes it suitable for research applications in the field of mobile robotics. The device is equipped with six high-gain external antennas, providing strong and uniform coverage in the laboratory and adjacent areas. The router supports three frequency bands (2.4 GHz, 5 GHz, and 6 GHz), enabling efficient network distribution and minimization of interference []. A visual representation of the device is provided in Figure 5.

Figure 5.

Wi-Fi 6E router.

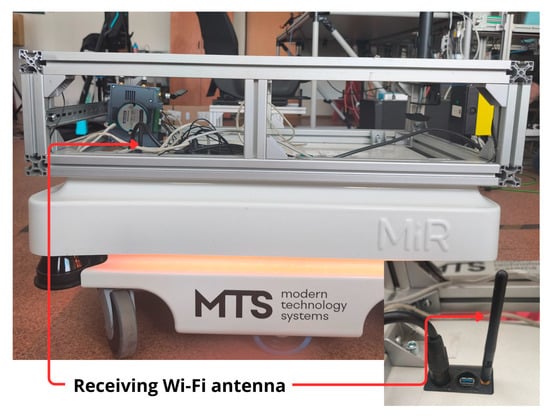

In the experiment, the router was configured to operate in the 2.4 GHz band, which provides better penetration through walls and obstacles compared to higher frequency bands. It was connected to the laboratory’s fixed Ethernet infrastructure and supplied wireless connectivity for the autonomous mobile robot MiR100. The placement of the receiving Wi-Fi antenna system on the robot is shown in Figure 6.

Figure 6.

Placement of the receiving Wi-Fi antenna system on the autonomous mobile robot.

At the front of the robot, a receiving antenna was integrated, continuously monitoring the RSSI (Received Signal Strength Indicator) values during the experiment. These values were transmitted via the REST API together with the robot’s position data. The configuration of the 5G network used in the experiment is summarized in Table 4.

Table 4.

Configuration of the 5G network used in the experiment.

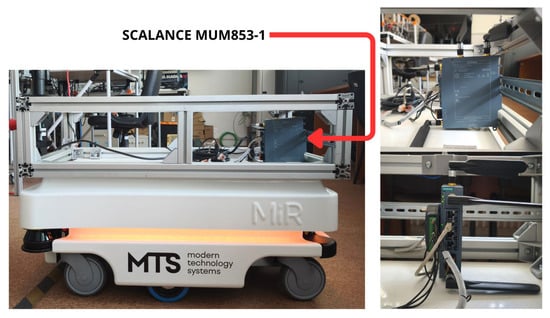

The proposed 5G network employs a combination of stationary and mobile 5G clients to ensure reliable and high-speed data connectivity in the dynamically changing environment of the laboratory. The network consists of such components as SCALANCE MUM853-1 (Siemens AG, Munich, Germany) a mobile 5G client, SCALANCE MUM856-1 (Siemens AG, Munich, Germany) a stationary client which are connected to the 5G gateway.

The SCALANCE MUM853-1 is a mobile 5G client developed by Siemens (Germany), designed for industrial applications and the integration of mobile devices into 5G networks. It supports licenced 5G frequency bands and provides the low latency and high throughput required for reliable communication [].

In our case, this 5G client is mounted directly on the mobile robot MiR100, as shown in Figure 7.

Figure 7.

Placement of the mobile client on the robot.

It serves as a wireless mobile client, enabling the robot to dynamically connect to the 5G network during movement and to communicate with the stationary client.

The stationary 5G client SCALANCE MUM856-1 (Siemens, Germany) is permanently connected to a computer in the laboratory. It ensures stable and high-speed data connectivity with the 5G network, enabling the real-time collection and evaluation of data from the AMR robot and other devices. Figure 8 shows the stationary client SCALANCE MUM856-1.

Figure 8.

The stationary client SCALANCE MUM856-1.

The stationary client is connected to the fixed LAN infrastructure of the network and serves as a gateway between the 5G system and the internal enterprise network. The technical parameters of SCALANCE 5G clients used in the experiment are summarized in Table 5.

Table 5.

Technical Parameters of SCALANCE 5G Clients [].

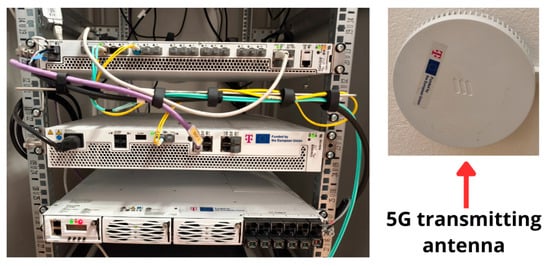

Mobile and stationary clients are connected to the private 5G SA network managed by a 5G gateway. This gateway establishes a private and isolated network infrastructure for industrial applications, minimizing interference and enabling a controlled environment. The private 5G network was implemented using the system shown in Figure 9—the Ericsson Radio Dot System (Telefonaktiebolaget LM Ericsson, Stockholm, Sweden) which combines ceiling-mounted radio units (Radio Dots) with a centralized Indoor Radio Unit (IRU).

Figure 9.

5G Ericsson Radio Dot System.

The radio units provide wireless coverage of the area, while the IRU processes the radio signals and communicates with the network core []. This architecture enables high throughput, low latency, and stable indoor connectivity.

The mobile 5G client (MUM853-1) transmits and receives data from the stationary client (MUM856-1) via a VXLAN tunnel. For network monitoring, tools such as the SNMP protocol, Telegraf (an agent for metric data collection), and the InfluxDB database are used, where these metrics are stored and analyzed [].

5. Analysis and Results

This chapter presents the results of experimental measurements focused on evaluating the quality of wireless communication during the dynamic movement of an autonomous mobile robot. The measurements were carried out in the SmartTechLab environment, with the robot being connected in parallel to both the Wi-Fi network and the private 5G SA network.

The main objective was to analyze how the robot’s movement and changing environmental conditions are reflected in key communication parameters—latency, jitter, packet loss, and RSSI. These indicators have a direct impact on the stability and reliability of data transmission, and consequently on the safety and efficiency of real-time robot motion control. A summary of the basic statistical parameters obtained from both networks is presented in Table 6.

Table 6.

Basic statistical parameters of measured networks.

Average values were calculated as arithmetic means from all measurement samples collected during the experiment.

5.1. RSSI

RSSI represents the power of the received signal and directly affects the quality of wireless communication used for real-time robot control. Different technologies tolerate different RSSI levels. A lower RSSI generally increases latency, jitter, and packet loss, which may lead to delayed or unstable robot responses.

The average signal strength was higher for Wi-Fi (−55.95 dBm), which is attributed to the different frequency band and network topology. In the case of 5G, the average value was −72 dBm, which did not result in degraded transmission quality, as 5G was able to maintain stable communication without packet loss even at weaker signal levels.

The receiving antennas for both technologies were placed next to each other and mounted at the front of the robot, ensuring comparable measurement conditions. The difference between the technologies was evident in the behaviour of RSSI: while a Wi-Fi value around −81 dBm caused a connection outage, 5G was able to sustain communication even at levels close to −111 dBm.

For the visualization of RSSI measurement points, the same colour scale was applied for both technologies. However, this does not imply that identical RSSI values represent the same connection quality for the two technologies. The identical scale was chosen solely for the purpose of visualizing the measured data and comparing how the two technologies behave under different RSSI levels.

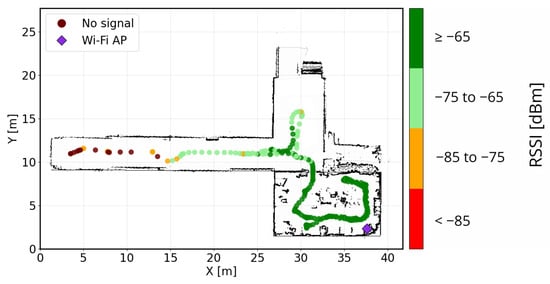

During the experiments, the Wi-Fi signal strength was recorded while the mobile robot followed a predefined trajectory. Figure 10 and Figure 11 show the measured values in the forward and return directions. The measurement points are colour-coded according to the RSSI level, with the purple symbol indicating the position of the Access Point (AP).

Figure 10.

Wi-Fi RSSI distribution along the robot trajectory—forward direction.

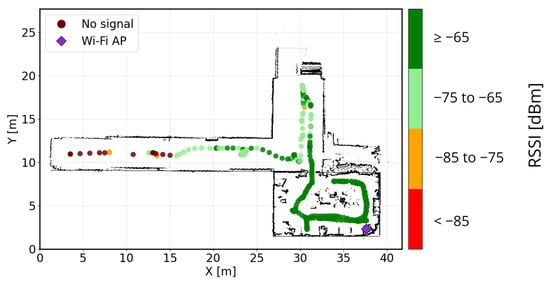

Figure 11.

Wi-Fi RSSI distribution along the robot trajectory—backward direction.

In the direction from the laboratory towards the end of the corridor at Figure 10, a stable signal with RSSI values better than −65 dBm was recorded in the vicinity of the AP, which corresponds to very good signal quality. As the distance from the signal source increased, the signal level gradually deteriorated, and at the end of the corridor it became unstable and, in some sections, completely dropped out, resulting in a loss of communication with the robot.

On the return path towards the laboratory Figure 11, the restoration of the connection was not immediate. Although the robot followed the same trajectory, the no signal zone persisted longer than during the forward movement. For most of the corridor and in the vicinity of the laboratory, however, the signal quality was good.

Both measurements demonstrate differences in RSSI values at certain points depending on the robot’s direction of movement, which may be attributed to the orientation of the receiving antenna relative to the source and other external factors.

While the Wi-Fi measurements clearly revealed the limitations of this technology in the university environment, where RSSI values around −81 dBm led to connection dropouts and interrupted communication with the robot, measurements conducted along the same trajectory, at the same time, and with identical methodology for the 5G network revealed a markedly different behaviour.

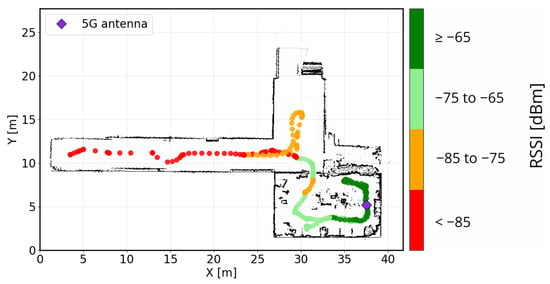

Although the same RSSI colour scale was applied for the visualization of both technologies, the interpretation itself differs. While Wi-Fi lost connectivity when the signal decreased, 5G was able to maintain a stable connection even at levels around −111 dBm. This difference underscores the higher robustness and resilience of the 5G network against attenuation and interference, which is crucial for autonomous mobile robot applications where communication continuity is key property. The results of the 5G RSSI measurement along the forward trajectory are shown in Figure 12.

Figure 12.

5G RSSI distribution along the robot trajectory—forward direction.

At the antenna, the signal strength reached values better than −65 dBm. As the distance increased, it gradually dropped below −85 dBm, yet the connection was maintained throughout the entire experiment, even when the RSSI value fell below −111 dBm. No complete signal loss occurred, indicating higher coverage stability compared to Wi-Fi. In addition, latency values remained stable during all measurements, and no packet loss was observed.

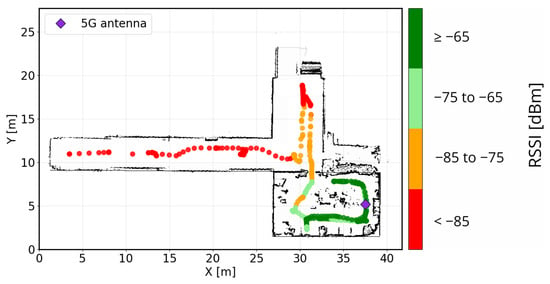

The RSSI behaviour during the return trajectory for the 5G network is presented in Figure 13. Even on the return path, communication was maintained, with RSSI values oscillating between −65 and −90 dBm depending on the robot’s distance and position. In contrast to Wi-Fi, no sections with complete signal loss were observed, indicating that the 5G network maintained a stable connection throughout the same environment. Furthermore, distance and RSSI had only a minimal impact on latency, jitter, and packet loss.

Figure 13.

5G RSSI distribution along the robot trajectory—backward direction.

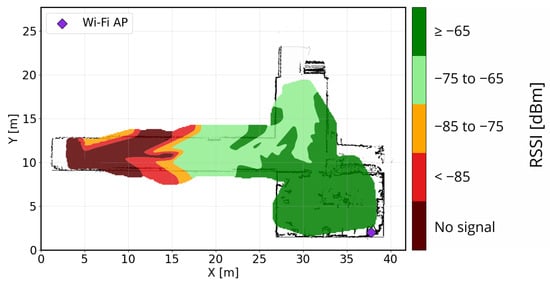

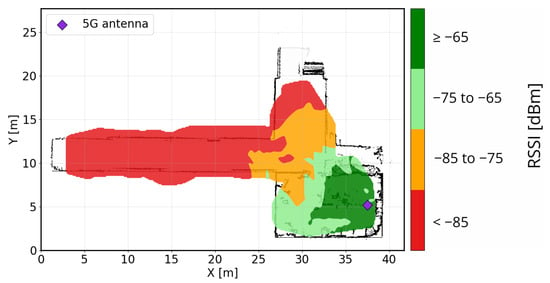

In evaluating communication technologies, it is not sufficient to observe only instantaneous RSSI values; it is also important to consider their spatial distribution. Coverage zones create ‘network stability maps,’ which indicate where the robot can rely on a stable connection and where it enters to the risk-zone area. The spatial distribution of RSSI for both technologies is illustrated in Figure 14 and Figure 15, which present the Wi-Fi and 5G coverage zones along the robot’s trajectory.

Figure 14.

Wi-Fi RSSI coverage zones.

Figure 15.

5G RSSI coverage zones.

The analysis of the spatial distribution of RSSI for Wi-Fi showed that communication quality was strongly dependent on the signal strength and the robot’s distance from the access point. In the green and light-green zones, the network behaved stably, with latency and jitter values still acceptable for data transmission. However, once the robot entered the orange and red areas, the connection parameters began to deteriorate sharply—in these sections, latency and jitter reached extreme values of up to 3000 ms, and communication was accompanied by packet loss. The most critical situation occurred in the dark red zones, where a complete loss of connection was observed.

The analysis of the spatial distribution of RSSI for 5G revealed a different network behaviour compared to Wi-Fi. In the green and light-green zones, communication was highly stable, with latency and jitter remaining at low levels and showing only minimal fluctuations. In the orange and red areas, RSSI values gradually decreased; however, the connection quality was maintained without any interruptions. Unlike Wi-Fi, no sharp dropout zones appeared—even at very weak signal levels, the 5G network was able to sustain connectivity.

Throughout the entire experiment, latency remained within a narrow range of 16 ms to 32 ms, with an average value of 19.38 ms, representing significantly more stable results compared to Wi-Fi. Jitter remained minimal, and not a single data packet was lost, even in zones where RSSI dropped below −111 dBm.

These results confirm that 5G provides smooth coverage over longer distances in corridor environments with signal attenuation, without sharp boundaries between functional and non-functional zones. For autonomous mobile robots, this translates into reliable communication even at weak signal levels, ensuring continuity of motion control and enhancing overall operational safety.

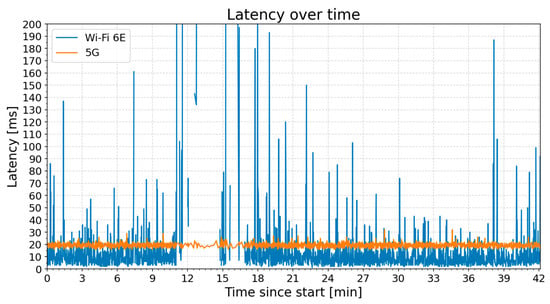

5.2. Latency

Network latency represents the most critical network parameter for AMR, as low and predictable latency directly dictates the stability and real-time responsiveness of the motion control loop.

In the Wi-Fi network, the average latency measured was 16.54 ms, but with extreme values reaching up to 3120 ms. indicating high variability and the occurrence of short-term outages. In contrast, the 5G network exhibited more stable behaviour, with an average of 19.37 ms and a maximum value of only 32 ms. Although the average latency of Wi-Fi was slightly lower, its instability represents a significant risk for applications requiring consistent connectivity. On the other hand, under the given parameters, the 5G network demonstrated latency stability, making it predictable and reliable for real-time communication applications, despite the slightly higher average latency compared to Wi-Fi.

A statistical comparison confirmed that the difference between both technologies was significant (Mann–Whitney rank test, p < 0.001), with Wi-Fi showing a lower median latency (8 ms) but substantially higher variability (standard deviation = 11.8 ms) compared to 5G (median = 19 ms, standard deviation = 1.6 ms). The Brown–Forsythe test (p < 10−100) further confirmed that 5G provided significantly more stable latency with lower dispersion. This stability is critical for continuous robot control, where consistent transmission delays ensure predictable system response.

As shown in Figure 16, latency in the 5G network remained stable even though the robot moved during the measurements in an environment that included various wireless networks, metal structures, walls, and other devices that could have caused signal interference. The robot also moved at different speeds and changed its yaw orientation, which had no significant impact on the consistency of the 5G connection.

Figure 16.

Graph of latency in the Wi-Fi 6E and 5G networks over time.

In contrast, Wi-Fi 6E exhibited regular oscillations already during operation within the laboratory, and once outside its premises, the connection quality decreased significantly. In the critical interval between the 12th and 15th minute of the experiment, the Wi-Fi network even completely stopped transmitting data, which demonstrates its limited reliability for industrial applications. This interruption correlates with a noticeable drop in the RSSI values observed during the same time interval.

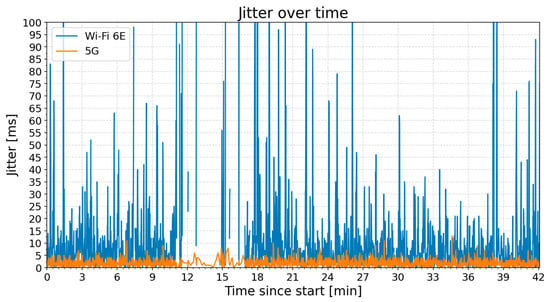

5.3. Jitter

Transmission time variability is among the critical factors affecting the quality of autonomous mobile robot control. High jitter negatively affects real-time robot control by causing irregular command and feedback delays, which lead to unstable motion and poor synchronization. Even with low average latency, unpredictable jitter can disrupt control loops more severely than constant delay. In our experiment, it was shown that Wi-Fi 6E could not maintain transmission stability—the measured jitter values reached extremes of up to 3088 ms, with an average of 12.71 ms. Such behaviour indicates frequent irregularities in communication, which can lead to delayed execution of commands or staggered robot movement.

In contrast, the 5G SA network demonstrated high consistency. The maximum jitter value was only 13 ms, with an average of 1.94 ms, representing significantly more stable parameters suitable for tasks requiring a predictable data flow.

Statistical testing confirmed these observations, showing a highly significant difference between the two technologies (Mann–Whitney rank test, p < 10−229). Wi-Fi exhibited large fluctuations (mean = 9.13 ms, interquartile range = 8 ms), while 5G maintained nearly constant values (mean = 1.85 ms, interquartile range = 2 ms). The Brown–Forsythe test (p < 10−100) confirmed a strong disparity in variability, supporting that 5G provides stable and predictable transmission timing.

Figure 17 clearly shows that while Wi-Fi 6E suffers from frequent fluctuations, 5G maintains low and nearly constant values throughout the entire robot trajectory. The jitter profile of Wi-Fi 6E is characterized by frequent and irregular peaks, at times reaching hundreds to thousands of milliseconds. These spikes are distributed along the entire robot path and highlight the network’s sensitivity to environmental changes—particularly when passing through corridors or areas with metallic obstacles.

Figure 17.

Graph of packet-to-packet jitter in the Wi-Fi 6E and 5G networks over time.

The average jitter value was 12.71 ms; however, the extreme maximum reached as high as 3088 ms, indicating short-term outages or channel overload. Such behaviour is highly risky for robot control, as it may lead to staggered reactions or delayed execution of motion commands.

In contrast, the 5G SA network exhibited significantly more stable behaviour throughout the experiment. The curve in the graph is relatively flat, with only minimal deviations, where the maximum jitter value measured was just 13 ms and the average was 1.94 ms. This pattern confirms consistent data transmission, independent of the robot’s position or speed, which is a crucial advantage for applications requiring real-time control.

These results confirm that the deployment of the new 5G technology can eliminate the problem of transmission variability typical of traditional Wi-Fi networks, thereby significantly contributing to the reliability and stability of autonomous mobile robot control in real industrial conditions.

5.4. Packet Loss

Packet loss in real-time robot control causes missing commands or feedback data, leading to jerky motion, delayed reactions, or even safety risks. Unlike jitter, packet loss cannot be compensated and directly reduces the reliability and precision of robot communication.

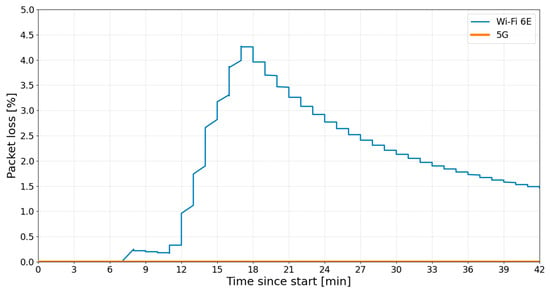

As shown in Figure 18, during the experiment packet loss occurred only in the case of the Wi-Fi 6E network. The highest values were recorded between the 12th and 15th minute of the experiment, when the robot was located at the finish point of the measurement, where a temporary connection dropout occurred. After the robot returned closer to the access point, the signal stabilized and packet loss gradually decreased. The average packet loss value for Wi-Fi 6E was 1.71%, representing a significant limitation for tasks requiring reliable and uninterrupted data transmission.

Figure 18.

Graph of cumulative packet-to-packet jitter in the Wi-Fi 6E and 5G networks over time.

In contrast, the 5G SA network did not exhibit any packet loss (0%) throughout the entire experiment, thereby confirming its ability to maintain stable data communication even during the robot’s dynamic movement and in an environment with potential electromagnetic interference. This result underscores the higher resilience and predictability of the 5G network compared to Wi-Fi 6E and highlights its suitability for applications requiring real-time control.

5.5. Analysis of Communication Quality Under Dynamic Motion Conditions

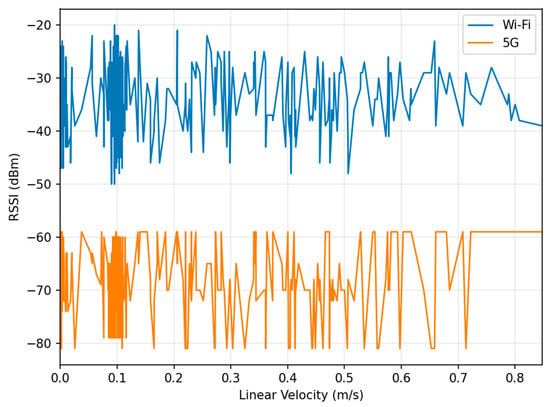

Graph on Figure 19 illustrates the variations in RSSI during the robot’s movement with different linear velocity. The following analysis focuses on evaluating the communication quality of Wi-Fi and 5G networks under dynamic motion conditions of the mobile robot.

Figure 19.

Variation in signal strength under dynamic linear velocity change.

Wi-Fi maintains a relatively high signal intensity of −20 to −50 dBm. In comparison, 5G shows a signal level of −60 to −80 dBm, which represents a good quality level for this technology, with a significantly smoother profile. This indicates that even at lower signal levels, 5G can preserve transmission quality. While Wi-Fi demonstrates stronger signal strength, its instability leads to connection dropouts, whereas 5G provides a consistent channel—which is crucial for controlling the mobile robot during operation.

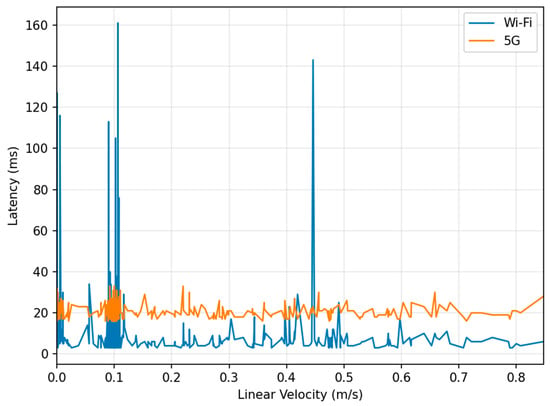

The graph Figure 20 shows the latency profile as the robot’s linear speed increases.

Figure 20.

Impact of linear velocity on latency in Wi-Fi and 5G networks.

Wi-Fi exhibits significant fluctuations with sharp peaks exceeding 150 ms, which is attributed to the configuration of the technology in our laboratory. In contrast, 5G maintains latency mostly within the range of 18–30 ms, with very little variability even at higher speeds (up to 0.8 m/s). This indicates stable behaviour of the networks. The short-term latency peaks observed in the Wi-Fi network can be attributed to multipath propagation and Doppler spread effects caused by the robot’s motion and reflections from surrounding metallic structures.

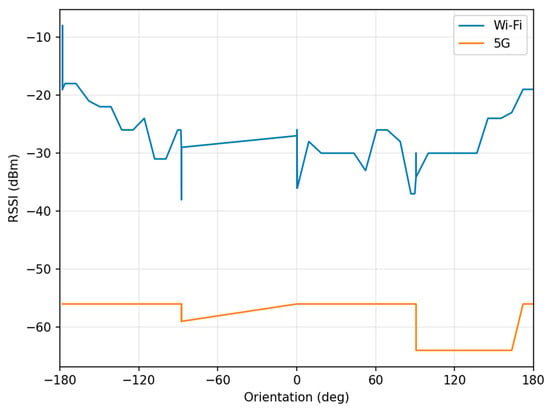

Figure 21 shows the variation in RSSI depending on the robot’s orientation.

Figure 21.

Dependence of signal strength on robot orientation in Wi-Fi and 5G networks.

The Wi-Fi RSSI varies in the range of −20 to −40 dBm, with instabilities clearly associated with changes in the robot’s orientation. Significant decreases occur when the robot loses the optimal alignment of the antenna with respect to the source. In contrast, the 5G RSSI remains relatively stable between −55 and −65 dBm, with only minor variations during orientation changes.

The stability of the 5G signal indicates lower dependence on the robot’s direction and orientation, which makes communication with mobile robots more reliable. Connectivity remains consistent even during rotations, which is critical when the robot operates at greater distances from the signal source.

5.6. Analysis of Robot Reaction Time Characteristics Under Wi-Fi 6E and 5G Communication Technologies

To assess the influence of wireless communication technologies on control responsiveness, the robot’s reaction time was experimentally tested under Wi-Fi 6E and 5G SA networks. Measuring this parameter is essential for evaluating how network latency and stability affect the execution speed of commands in real-time robotic applications.

The robot’s response time was measured under two different network configurations—Wi-Fi 6E and 5G SA. A custom Python 3.10 script was used to send motion commands to the robot via its REST API over both network. For each command, the script recorded the time between sending the request and receiving the response from the robot. This interval represents the end-to-end reaction time, including communication delay and processing time on the robot side. The experiment was repeated multiple times to obtain minimum, average, and maximum values for each technology.

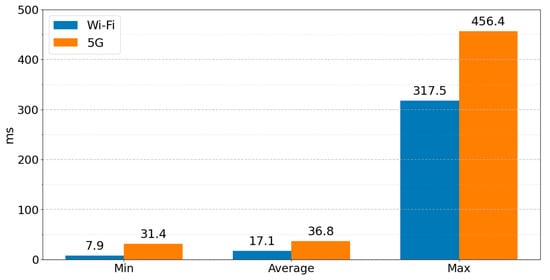

Figure 22 illustrates the comparison of robot reaction times measured over Wi-Fi 6E and 5G SA networks.

Figure 22.

Reaction time statistics.

While Wi-Fi achieved lower values, it exhibited higher variability. In contrast, 5G showed higher average values, but these were concentrated within a narrower range, confirming its stability. The maximum values indicate that extreme delays may occur in both cases—Wi-Fi reached a maximum of 317.5 ms, while 5G recorded as much as 456.4 ms.

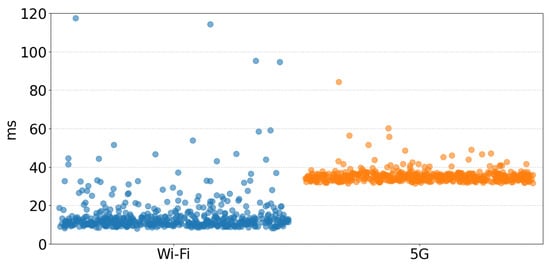

Figure 23 presents individual response time measurements in milliseconds for Wi-Fi 6E and 5G SA technologies, with each point representing a single measurement.

Figure 23.

Distribution of reaction times.

The results show that Wi-Fi achieved lower average response times (around 10–20 ms), but with high variability and the occurrence of extreme values, indicating connection instability. In contrast, 5G response times were concentrated within a narrower interval (approximately 33–37 ms), with very few outliers. The variance of the measured response times was 605.88 ms2 for Wi-Fi 6E and 514.44 ms2 for 5G SA. The standard deviation reached 24.62 ms for Wi-Fi 6E and 22.68 ms for 5G SA, indicating higher fluctuation and lower stability of latency in the Wi-Fi network.

6. Discussion and Conclusions

This work focuses on connecting mobile robot with modern wireless communication systems. Comparative experiments between Wi-Fi 6E and the private 5G SA network revealed substantial differences in performance under dynamic motion conditions.

Although Wi-Fi 6E achieved a lower average latency (16.54 ms), it suffered from extreme peaks reaching up to 3120 ms, packet loss, and high sensitivity to robot orientation and distance from the access point. Such instability poses a risk for applications requiring consistent and predictable delays. In contrast, the 5G SA network maintained high consistency with an average latency of 19.38 ms and a maximum of 32 ms, confirming its suitability for real-time control.

The jitter of Wi-Fi 6E reached extreme values of up to 3088 ms, while 5G remained highly stable, with an average jitter of 1.94 ms and a maximum of 13 ms, independent of the robot’s position or orientation. Packet loss for Wi-Fi (1.71%) indicated limited reliability under changing conditions, whereas 5G recorded 0% loss throughout the entire experiment—even in areas with high attenuation and reflections. Similarly, the RSSI analysis showed that 5G maintained a stable connection even at −111 dBm without degradation in latency or jitter, while Wi-Fi lost connectivity at around −81 dBm. A key finding of this study is that the quality and stability of autonomous robot control depend not only on the RSSI but primarily on the temporal variability of network parameters—namely latency, jitter, and packet loss. The experiments revealed that even with weaker signal levels, 5G was able to maintain a stable data flow with consistent reaction times, fundamentally changing how network performance should be assessed in industrial applications.

From a practical perspective, the 5G Standalone network proved to be a more suitable communication technology for autonomous mobile robots operating in real industrial environments where high reliability, low latency, and predictable network behaviour are essential. This finding paves the way for future integration of 5G into intelligent manufacturing systems and the development of digital twins that can use real-time data from mobile robots for adaptive control and multiagent systems.

5G technology represents a significant advancement in wireless communication for industrial applications and mobile robotics. It offers stable latency and low jitter, making it a predictable and suitable network for mobile robot control. This stability ensures smooth robot operation by the operator without jerky motion during movement. 5G provides reliability in transmitting commands, data, and visualizing robot operation in the control environment.

Future research may focus on integrating additional mobile robots into 5G communication, all connected within a single network. The aim is to analyze the potential of implementing 5G as a communication technology for multi-agent systems. Moreover, connecting more robots to the network opens the possibility of studying inter-robot communication via 5G and their real-time interaction. Such an approach enables testing of coordinated tasks such as joint material transport, dynamic task allocation, or collaborative navigation in shared spaces.

Another development direction involves using 5G as the primary communication technology for creating a digital twin of a manufacturing laboratory on the NVIDIA Isaac Sim platform, integrating multiple mobile and stationary robotic systems. Creating a digital twin of a manufacturing lab with several mobile and stationary robots allows monitoring and analyzing entire production processes in real time. A digital twin supported by 5G communication can thus serve as a platform for multi-agent system research, enabling testing of cooperation between multiple robots and communication over a 5G network. At the same time, it provides the possibility to collect and visualize data from physical robots in real time, opening opportunities for remote monitoring, control, and diagnostics.

Author Contributions

Conceptualization, N.N.; methodology, N.N.; software, N.N.; validation, N.N.; formal analysis, V.R.; investigation, N.N.; resources, K.Ž. and J.P.; data curation, V.R.; writing—original draft preparation, N.N. and V.R.; writing—review and editing, N.N.; visualization, V.R.; supervision, K.Ž. and J.P.; project administration, K.Ž. and J.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the EU NextGenerationEU through the Recovery and Resilience Plan for Slovakia under the projects No. 09I03-03-V03-00075 and 09I05-03-V02-00042 and supported by the projects VEGA 1/0061/23 and KEGA 014TUKE-4/2023 granted by the Ministry of Education, Research, Development and Youth of the Slovak Republic.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed at the corresponding.

Acknowledgments

This research was supported by the project TUKE 5G Infrastructure for Smart Communities (5GSC) with funding received from the European Union’s Connecting Europe Facility (CEF) programme under Grant Agreement ID: 101133546.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 3GPP | 3rd Generation Partnership Project |

| AGV | Automated Guided Vehicle |

| AMR | Autonomous Mobile Robot |

| AP | Access Point |

| CQI | Channel Quality Indicator |

| DL | Downlink |

| eMBB | Enhanced Mobile Broadband |

| FR | Frequency Range |

| IoT | Internet of Things |

| KPI | Key Performance Indicators |

| MEC | Mobile Edge Computing |

| MIMO | Multiple Input Multiple Output |

| mMTC | massive Machine-Type Communication |

| mmWave | millimetres Wave |

| NPN | Non-Public Network |

| NSA | Non-Standalone |

| QoS | Quality of Service |

| RF | Radio Frequency |

| RSRP | Reference Signal Received Power |

| RSRQ | Reference Signal Received Quality |

| RSSI | Received Signal Strength Indicator |

| RTT | Round-Trip Time |

| SA | Standalone |

| SINR | Signal-to-Interference plus Noise Ratio |

| UL | Uplink |

| URLLC | Ultra-Reliable Low-Latency Communication |

| Wi-Fi | Wireless Fidelity |

References

- Voigtländer, F.; Ramadan, A.; Eichinger, J.; Grotepass, J.; Ganesan, K.; Diez Canseco, F.; Pensky, D.; Knoll, A. 5G for the Factory of the Future: Wireless Communication in an Industrial Environment. In Proceedings of the International Conference on Cloud and Robotics (ICCR 2018), Munich, Germany, 12–14 November 2018. [Google Scholar] [CrossRef]

- Bartolín-Arnau, L.M.; Orozco-Santos, F.; Sempere-Payá, V.; Silvestre-Blanes, J.; Albero-Albero, T.; Llacer-Garcia, D. Exploring the Potential of Wi-Fi in Industrial Environments: A Comparative Performance Analysis of IEEE 802.11 Standards. Telecom 2025, 6, 40. [Google Scholar] [CrossRef]

- Maldonado, R.; Aguilar, R.; Vargas, C.; Rodríguez, J.; Skarmeta, A. Comparing Wi-Fi 6 and 5G Downlink Performance for Industrial IoT. IEEE Access 2021, 9, 86928–86937. [Google Scholar] [CrossRef]

- Krejčí, J.; Babiuch, M.; Suder, J.; Krys, V.; Bobovský, Z. Latency-Sensitive Wireless Communication in Dynamically Moving Robots for Urban Mobility Applications. Smart Cities 2025, 8, 105. [Google Scholar] [CrossRef]

- Am, S.; Nget, T.; Nov, L.; Math, S.; Thap, T. A Study of Quality of Service (QoS) in Private 5G Networks for Smart Factori 4.0. In Proceedings of the Third International Conference on Information Systems in Higher Education (ISHE 2024), Phnom Penh, Cambodia, 1–2 March 2024. [Google Scholar] [CrossRef]

- Cheng, J.; Yang, Y.; Zou, X.; Zuo, Y. 5G in manufacturing: A literature review and future research. Int. J. Adv. Manuf. Technol. 2024, 131, 5637–5659. [Google Scholar] [CrossRef]

- 3GPP. Service Requirements for Cyberphysical Control Applications in Vertical Domains. TS 22.104 v17.2.0, 3rd Generation Partnership Project. 2019. Available online: http://www.3gpp.org/ftp//Specs/archive/22_series/22.104/22104-h20.zip (accessed on 25 November 2025).

- Varga, P.; Peto, J.; Franko, A.; Balla, D.; Haja, D.; Janky, F.; Soos, G.; Ficzere, D.; Maliosz, M.; Toka, L. 5G support for Industrial IoT Applications—Challenges, Solutions, and Research gaps. Sensors 2020, 20, 828. [Google Scholar] [CrossRef] [PubMed]

- Belguidoum, A.B.; Tounsi, M.L.; Mekaoui, S. Optimization of 5G Throughput and Latency in Non-Standalone and Standalone Mode. Telecommun. Syst. 2025, 88, 30. [Google Scholar] [CrossRef]

- Kumar, S.; Rathi, M. 5G and Its Impact on IoT. In Proceedings of the National Conference on Emerging Trends in Computer Science (NCETCS 2025), Coimbatore, India, 19 April 2025. [Google Scholar]

- Muzaffar, R.; Ahmed, M.; Sisinni, E.; Sauter, T.; Bernhard, H.-P. 5G Deployment Models and Configuration Choices for Industrial Cyber-Physical Systems—A State of Art Overview. IEEE Trans. Ind. Cyber-Phys. Syst. 2023, 1, 236–256. [Google Scholar] [CrossRef]

- Eswaran, S.; Honnavalli, P. Private 5G Networks: A Survey on Enabling Technologies, Deployment Models, Use Cases and Research Directions. Telecommun. Syst. 2023, 82, 3–26. [Google Scholar] [CrossRef] [PubMed]

- Homayouni, S.; Paier, M.; Stangelmayer, G.; Kaipl, C.; Sulz, C.; Schweeger, T.; Rehak, J. Design and Development of Private 5G Standalone Network for Vertical Industries. In Proceedings of the 2023 International Wireless Communications and Mobile Computing Conference (IWCMC), Marrakesh, Morocco, 19–23 June 2023. [Google Scholar] [CrossRef]

- Lackner, T.; Hermann, J.; Dietrich, F.; Kuhn, C.; Angos, M.; Jooste, J.L.; Palm, D. Measurement and Comparison of Data Rate and Time Delay of End-Devices in Licensed Sub-6 GHz 5G Standalone Non-Public Networks. Procedia CIRP 2022, 107, 1132–1137. [Google Scholar] [CrossRef]

- Mallikarjun, S.B.; Schellenberger, C.; Hobelsberger, C.; Schotten, H.D. Performance Analysis of a Private 5G SA Campus Network. In Proceedings of the 26th ITG-Symposium—Mobile Communication: Technologies and Applications, Osnabrück, Germany, 18–19 May 2022. [Google Scholar]

- Merwaday, A.; Vannithamby, R.; Eisen, M.; Sudhakaran, S.; Cavalcanti, D.A.; Frascolla, V. Communication-Control Co-design for Robotic Manipulation in 5G Industrial IoT. In Proceedings of the 2023 IEEE 21st International Conference on Industrial Informatics (INDIN), Lemgo, Germany, 18–20 July 2023. [Google Scholar] [CrossRef]

- Hamidovic, D.; Hadziaganovic, A.; Muzaffar, R.; Bernhard, H.-P. 5G Campus Network Factory Floor Measurements with Varying Channel and QoS Flow Priorities. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023. [Google Scholar] [CrossRef]

- Kamtam, S.B.; Lu, Q.; Bouali, F.; Haas, O.C.L.; Birrell, S. Network Latency in Teleoperation of Connected and Autonomous Vehicles: A Review of Trends, Challenges, and Mitigation Strategies. Sensors 2024, 24, 3957. [Google Scholar] [CrossRef] [PubMed]

- Polak, L.; Kufa, J.; Sotner, R.; Fryza, T. Measurement and Analysis of 4G/5G Mobile Signal Coverage in a Heavy Industry Environment. Sensors 2024, 24, 2538. [Google Scholar] [CrossRef] [PubMed]

- Cañete-Martin, J.; Gómez-Jerez, J.; Lucas-Estañ, M.C.; Gozalvez, J.; Ubis, F. Integration of 5G and Industrial Digital Models: A Case Study with AGVs. In Proceedings of the 2024 IEEE 29th International Conference on Emerging Technologies and Factory Automation (ETFA), Padova, Italy, 10–13 September 2024. [Google Scholar] [CrossRef]

- Jiang, H.; Luo, J.; Zhang, R. Large-Scale RIS-Enabled Air-Ground Channels: Near-Field Modeling and Analysis. IEEE Trans. Wirel. Commun. 2025, 24, 1074–1088. [Google Scholar] [CrossRef]

- Chen, S.; Sun, S.; Kang, S. System Integration of Terrestrial Mobile Communication and Satellite Communication—The Trends, Challenges and Key Technologies in B5G and 6G. China Commun. 2020, 17, 156–167. Available online: https://www.scribd.com/document/883007005/System-Integration-of-Terrestrial-Mobile-Communication-and-Satellite-Communication-the-Trends-Challenges-and-Key-Technologies-in-B5G-and-6G (accessed on 25 November 2025). [CrossRef]

- Zhu, S.; Zhou, S.; Wang, L.; Zang, C.; Liu, Y.; Liu, Q. Performance Analysis and Prediction of 5G Round-Trip Time Based on the VMD-LSTM Method. Sensors 2024, 24, 6542. [Google Scholar] [CrossRef] [PubMed]

- How to Measure Jitter & Keep Your Network Jitterbug Free. Available online: https://obkio.com/blog/how-to-measure-jitter/ (accessed on 2 August 2025).

- Rashid, M.M.; Lucas-Estañ, M.C.; Sepulcre, M.; Gozalvez, J. 5G RAN Slicing to Support Reliability in Industrial Applications. In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Germany, 6–9 September 2022. [Google Scholar] [CrossRef]

- Demčák, J.; Lishchenko, N.; Pavlenko, I.; Pitel’, J.; Žídek, K. The Experimental SMART Manufacturing System in SmartTechLab. In Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2022; pp. 228–238. [Google Scholar] [CrossRef]

- Žídek, K.; Duhančík, M.; Hrehová, S. Real-Time Material Flow Monitoring in SMART Automated Lines Using a 3D Digital Shadow with the Industry 4.0 Concept. In Proceedings of the 25th International Carpathian Control Conference, Krynica-Zdrój, Poland, 22–24 May 2024. [Google Scholar] [CrossRef]

- Karlsson, S.; Jongeling, R.; Čaušević, A.; Sundmark, D. Exploring behaviours of RESTful APIs in an industrial setting. Softw. Qual. J. 2024, 32, 1287–1324. [Google Scholar] [CrossRef]

- Gautam, R.; Suyog, P.; Nagaraja, G.S. Analysis of SNMP Based Protocols in IoT and Real-World Scenarios. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 1867–1871. [Google Scholar] [CrossRef]

- Mobile Industrial Robots Explore our robots. Available online: https://mobile-industrial-robots.com/products/robots (accessed on 10 August 2025).

- RadiX AX6600 WiFi 6 Tri-Band Gaming Router. Available online: https://www.msi.com/Networking/RadiX-AX6600-WiFi-6-Tri-Band-Gaming-Router (accessed on 17 August 2025).

- SIEMENS SCALANCE M industrial routers. Available online: https://www.siemens.com/global/en/products/automation/industrial-communication/industrial-remote-communication/remote-networks/scalance-m-industrial-routers-ip-based-networks.html (accessed on 17 August 2025).

- Ericsson Enterprise Wireless Solutions Ericsson Radio Dot System. Available online: https://cradlepoint.com/product/radios/ericsson-radio-dot-system/ (accessed on 17 August 2025).

- InfluxData Inc. Telegraf. Available online: https://www.influxdata.com/time-series-platform/telegraf/ (accessed on 17 August 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).