Development of Alloyed Pipe Steel Composition for Oil and Gas Production in the Arctic Region

Abstract

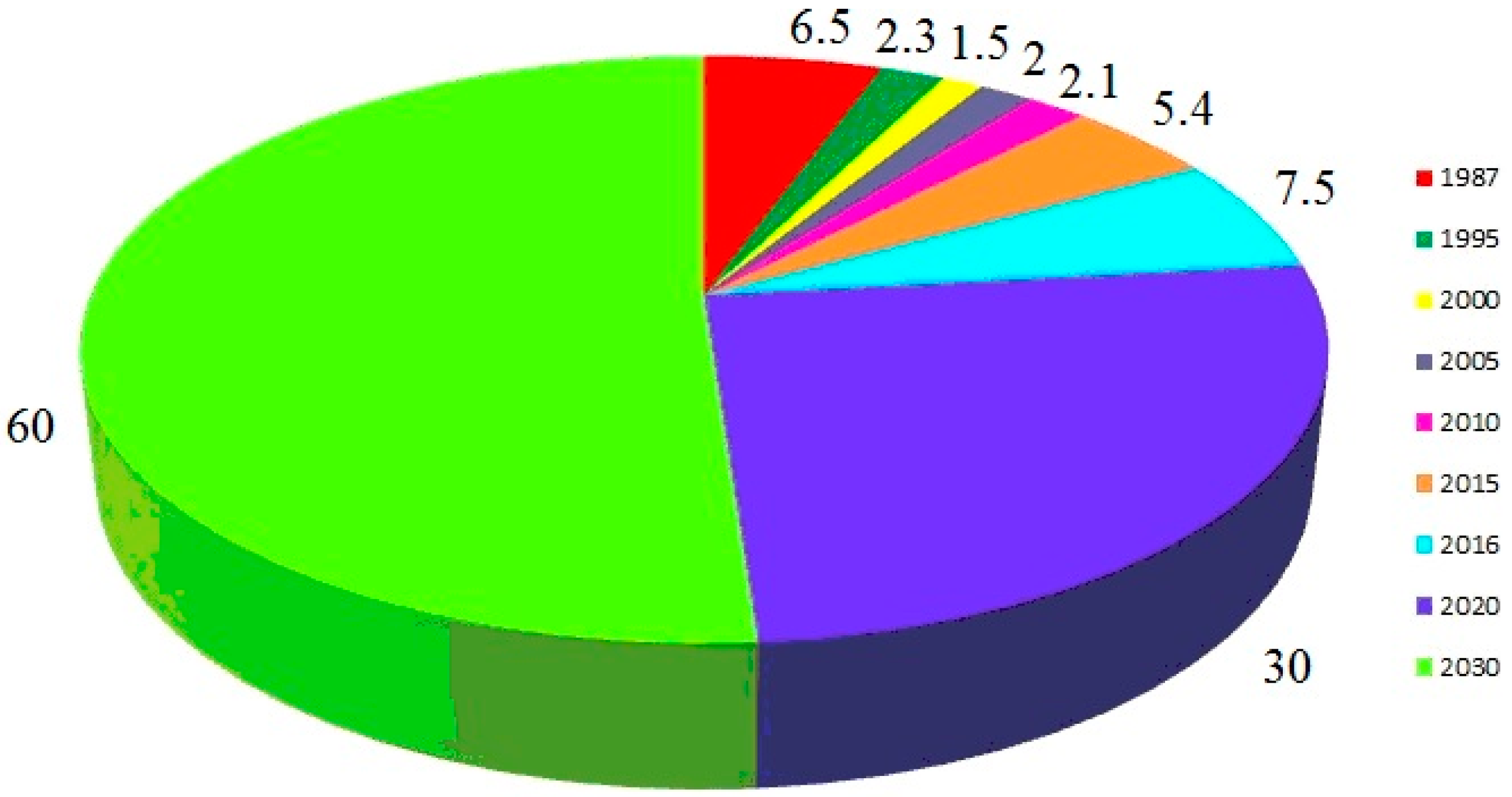

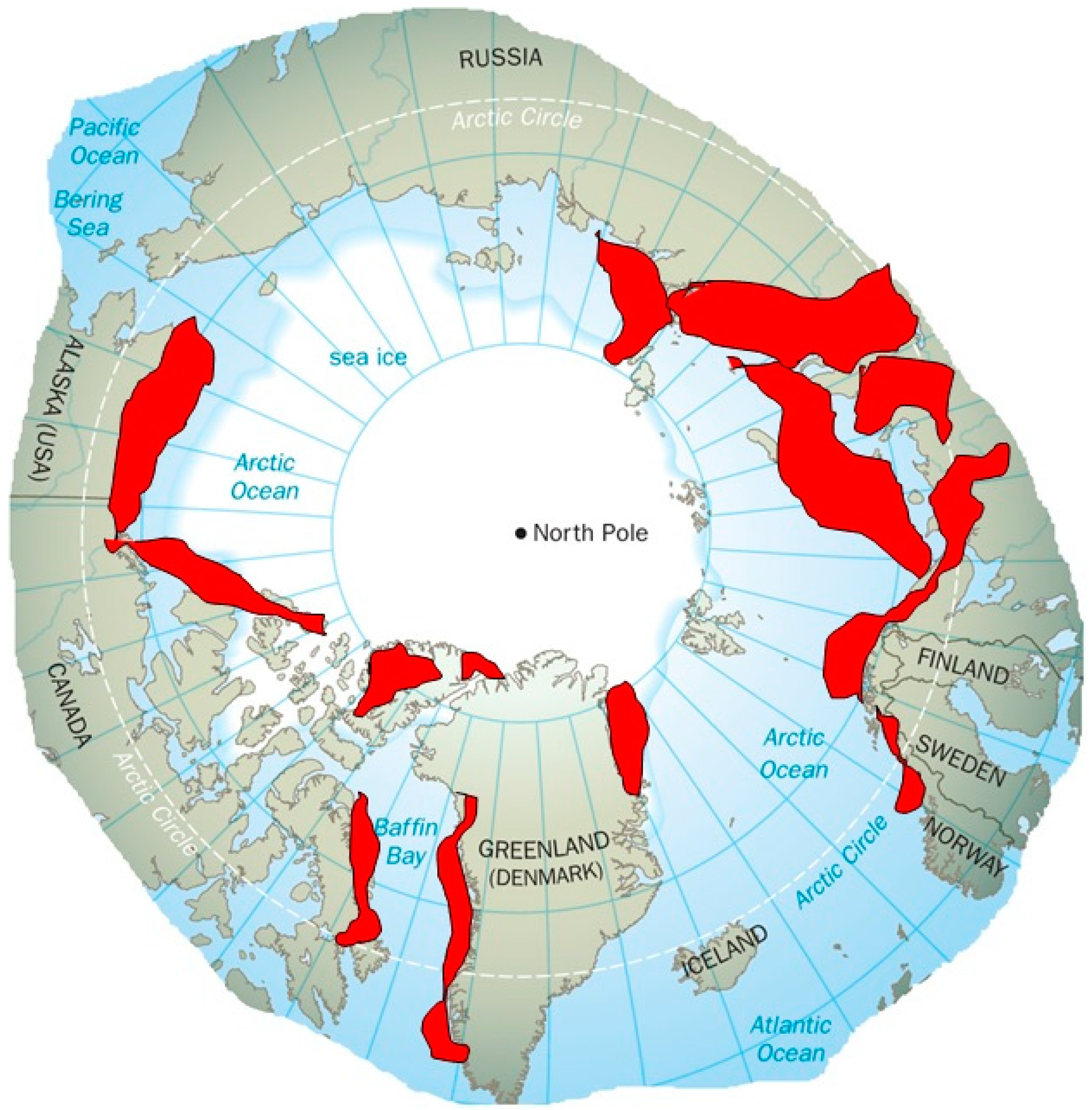

:1. Introduction

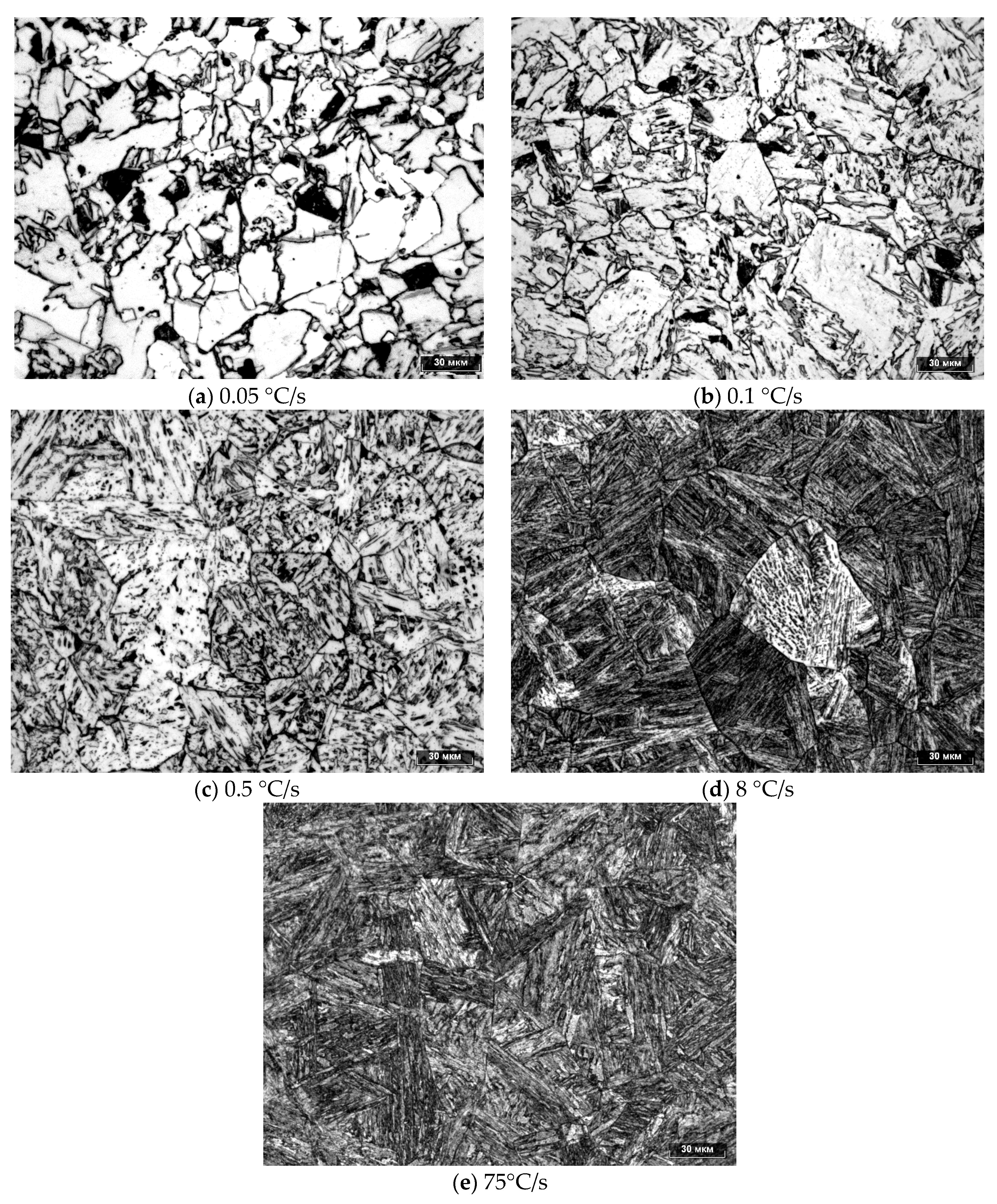

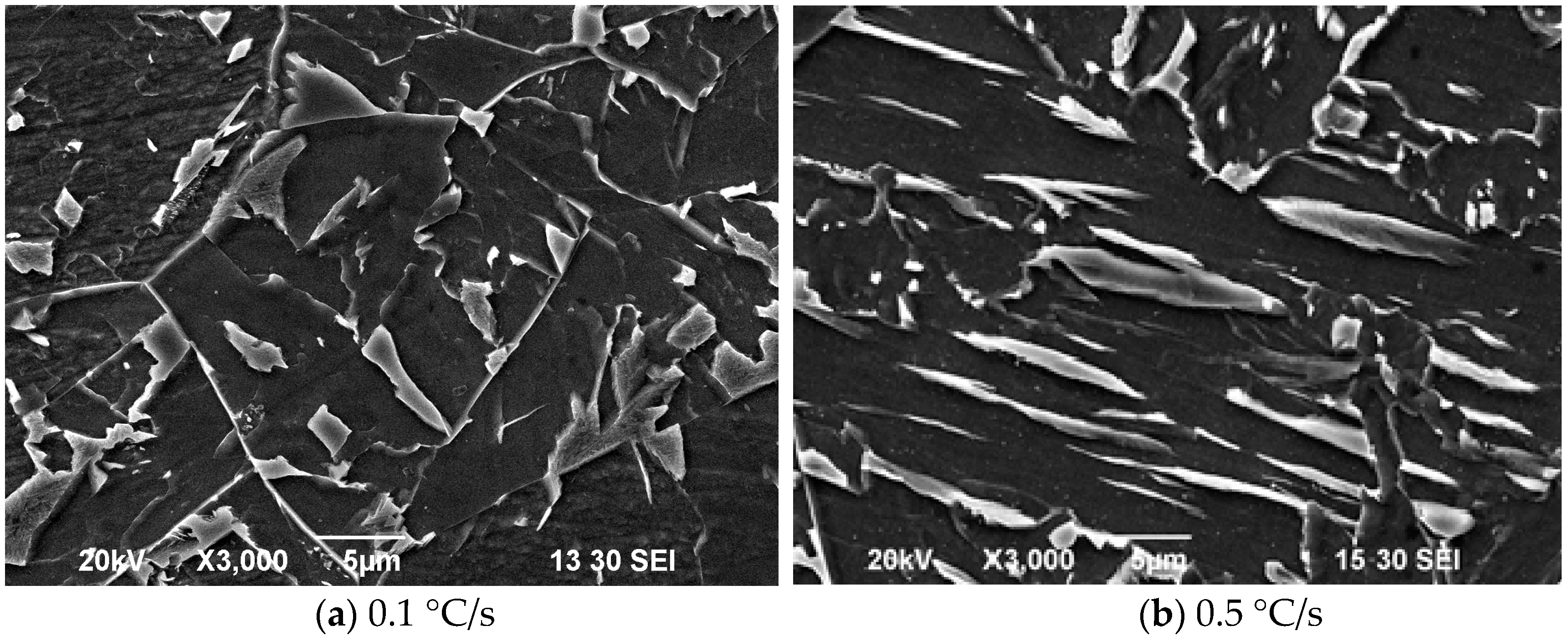

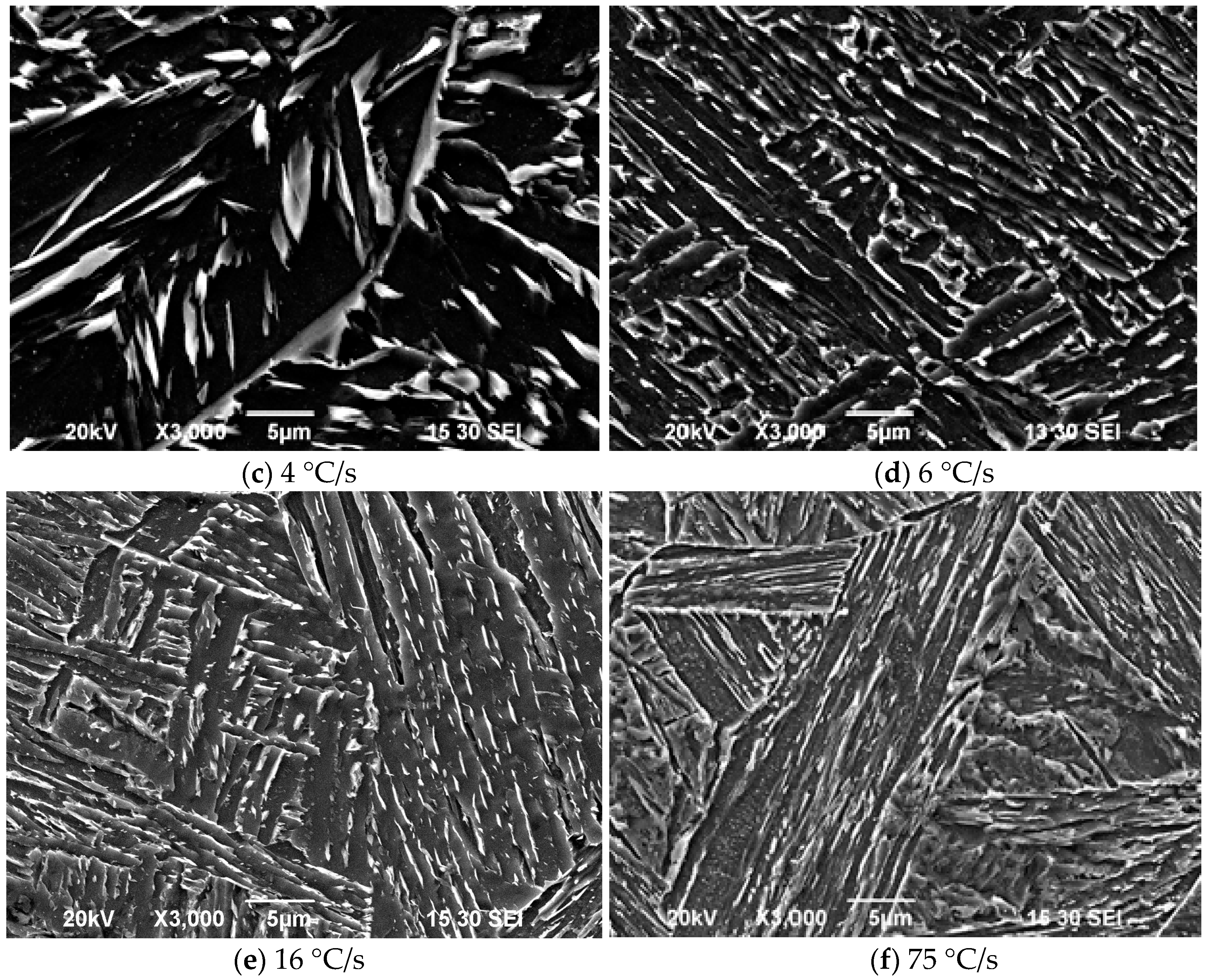

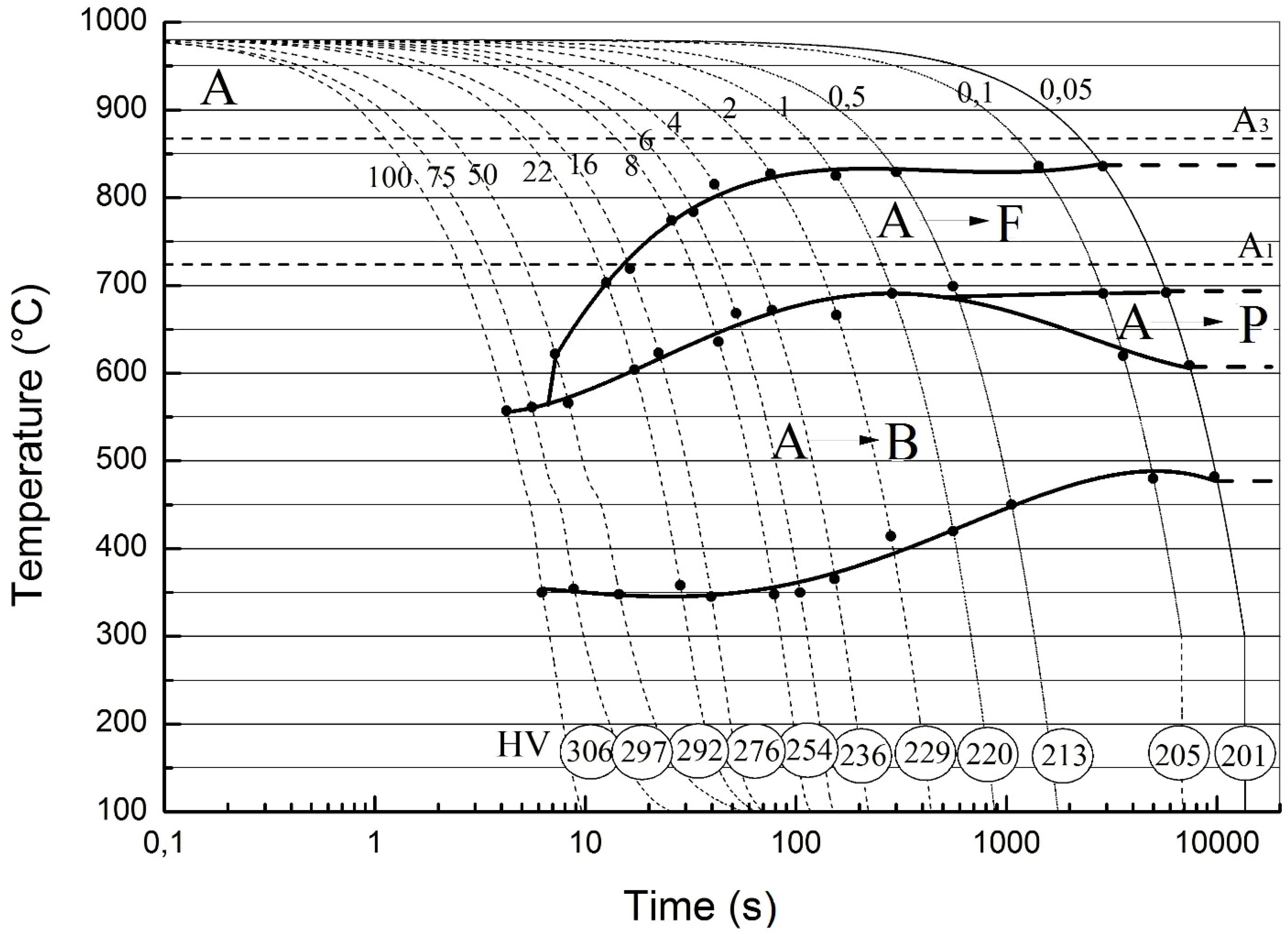

2. Materials and Methods

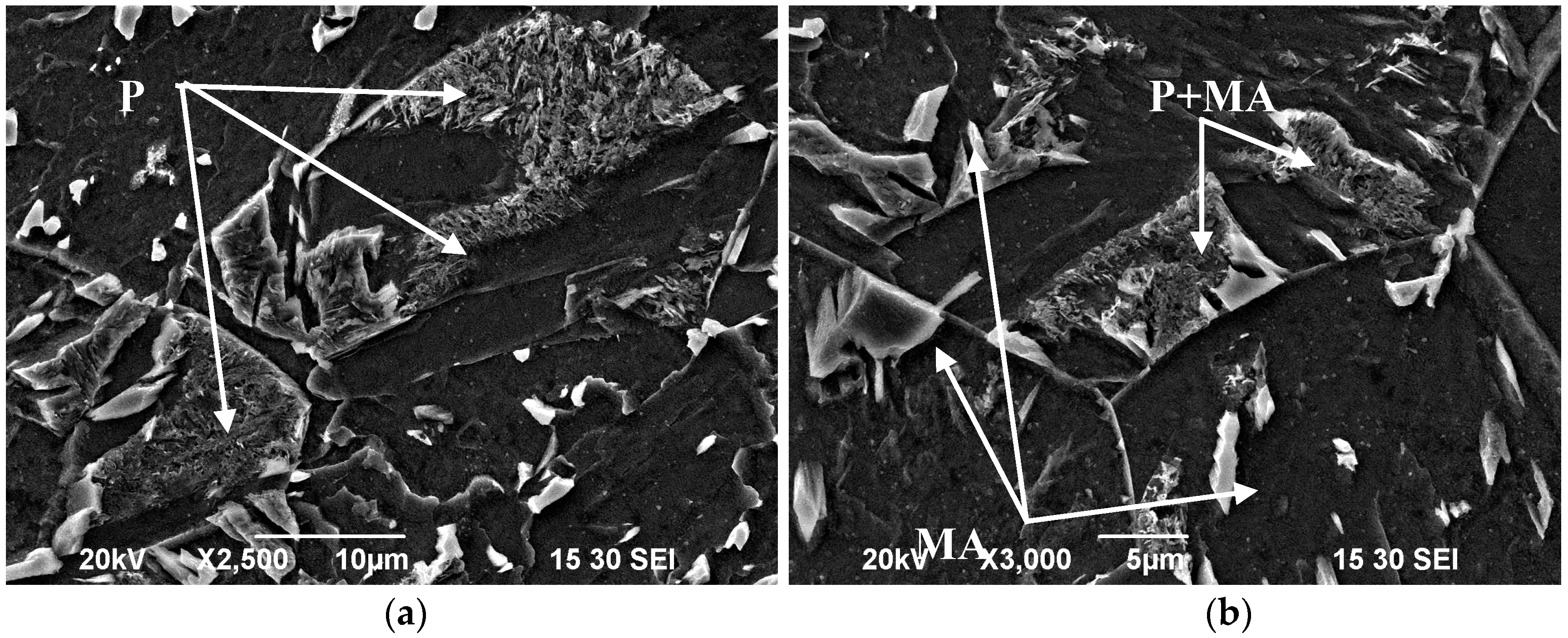

3. Results

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gorynin, I.V. Structural materials for Arctic shelf development. Her. Acad. Sci. 1999, 69, 8–15. (In Russian) [Google Scholar]

- Didenko, N.I.; Klochkov, Y.S.; Skripnuk, D.F. Ecological Criteria for Comparing Linear and Circular Economies. Resources 2018, 7, 48. [Google Scholar] [CrossRef]

- Didenko, N.I.; Skripnuk, D.F.; Kikkas, K.N. The analysis of convergence—Divergence in the development of innovative and technological processes in the countries of the Arctic council. In Proceedings of the 2018 International Conference on Information Networking, Chiang Mai, Thailand, 10–12 January 2018; pp. 626–631. [Google Scholar] [CrossRef]

- Gudkov, A.V.; Dadonov, D.N.; Krotkov, E.A.; Shchepinin, V.E.; Didenko, N.I. Thermal wear of cable lines isolation research owing to current flow of the high harmonics at oil extraction electrical generating systems. In Proceedings of the 2017 6th International Conference on Reliability, Infocom Technologies and Optimization: Trends and Future Directions, ICRITO 2017, Noida, India, 20–22 September 2017; pp. 182–187. [Google Scholar] [CrossRef]

- Blueprint of Resolution of the Government of the Russian Federation “Strategy for the Development of Arctic Zone of the Russian Federation and Ensuring the National Safety for the Period till 2020 Year” (Ratified by the President of the Russian Federation 18.09.2008 N Пр-1969). Available online: http://legalacts.ru/doc/strategija-razvitija-arkticheskoi-zony-rossiiskoi-federatsii-i/ (accessed on 15 March 2019). (In Russian).

- Blueprint of Resolution of the Government of the Russian Federation “Basics of the State Policy of the Russian Federation in Arctic Zone for the Period till 2020 Year and Further Perspectives” (Ratified by the President of the Russian Federation 18.09.2008 N Пр-1969). Available online: http://government.ru/info/18359/ (accessed on 15 March 2019). (In Russian).

- Ruksha, V.V.; Belkin, M.S.; Smirnov, A.A.; Arutunyan, V.G. Structure and dynamics in trucking industry along the North see path: History, the present, and perspectives. Arct. Ecol. Econ. 2015, 4, 104–110. (In Russian) [Google Scholar]

- Nord Stream 2. Programme for the Assessment of the Affect on the Environment. Available online: http://www.greenpeace.org/russia/Global/russia/image/2017/NordStream2-GreenpeaceRussiacomments.pdf (accessed on 15 March 2019). (In Russian).

- Skripnuk, D.; Ulitin, V.V. Technical and economic substantiation of permafrost thermal stabilization technology under global warming conditions. Mater. Phys. Mech. 2016, 26, 85–88. [Google Scholar]

- Pogodaeva, T.V.; Zhaparova, D.V.; Rudenko, D.Y.; Skripnuk, D.F. Innovations and socio-economic development: Problems of the natural resources intensive use regions. Mediterr. J. Soc. Sci. 2015, 6, 129–135. [Google Scholar] [CrossRef]

- Nikolaev, A.B. Several problems of the Arctic shelf hydrocarbon resources development. North Mark. Form. Econ. Order 2016, 4, 171–178. (In Russian) [Google Scholar]

- King, H.M. Oil and Natural Gas Resources of the Arctic—[Electronic Resort]. Available online: https://geology.com/articles/arcticoil-and-gas/ (accessed on 23 August 2018).

- Circum-Arctic Resource Appraisal: Estimates of Undiscovered Oil and Gas North of the Arctic Circle [Electronic resort]. Available online: https://pubs.usgs.gov/fs/2008/3049/fs2008–3049.pdf (accessed on 23 August 2018).

- Forecast for Social and Economic Development of Russia till 2024 Year [Electronic Resort]. Available online: https://acta.tatar/2018/10/07/prognoz-socialno-yekonomicheskogo-ra/ (accessed on 23 August 2018).

- Afanasyeva, O.V. Analysis of the Investment Programmes of key Enterprises in Thermal and Energetic Complex for Medium-Term Perspective. Armature Eng. 2016, 1, 36–45. (In Russian) [Google Scholar]

- Pumpyanskii, D.A.; Pyshmintsev, I.Y.; Farber, V.M. Strengthening pipe steel. Steel Transl. 2005, 35, 47–56. [Google Scholar]

- Thompson, S.W.; Colvin, D.J.; Krauss, G. Continuous cooling transformations and microstructure in a low-carbon high-strength low-alloy plate steel. Met. Transl. 1990, 21A, 1493–1507. [Google Scholar] [CrossRef]

- Bramfitt, B.L.; Speer, J.G. A Perspective on the morphology of bainite. Met. Transl. 1990, 21A, 817–829. [Google Scholar] [CrossRef]

- Chukin, M.V.; Poletskov, P.P.; Nikitenko, O.A.; Nabatchikov, D.G. Study of microstructure of rolled heavy plates made of low-alloyed pipe steel with increased strength and cold resistance. CIS Iron Steel Rev. 2017, 13, 25–31. [Google Scholar] [CrossRef]

- Efron, L.I.; Il’inskii, V.I.; Golovanov, A.V.; Morozov, Y.D. Production of cold-resistant tube steels by controlled high-temperature rolling. Steel Transl. 2003, 33, 60–65. [Google Scholar]

- DeArdo, A.J. Modern Thermomechanical Processing of Microalloyed Steel: A Physical Metallurgy Perspective. In Proceedings of the International Conference, Microalloying ’95, Pittsburgh, PA, USA, 11–14 June 1995; pp. 15–33. [Google Scholar]

- Bernshtein, M.L.; Zaimovskiy, V.A.; Kaputkina, L.M. Thermomechanical Processing of Steel; Metallurgy: Moscow, Russia, 1983. (In Russian) [Google Scholar]

- Efron, L.I. Formation of structures and mechanical properties of constructional steels during thermomechanical treatment in flow of the rolling mill. Steel Transl. 1995, 8, 57–64. [Google Scholar]

- Kodzhaspirov, G.; Rudskoi, A. Thermomechanical processing of steels & alloys as an advanced resource saving technique. In Proceedings of the METAL 2016—25th Anniversary International Conference on Metallurgy and Materials, Hotel Voronez IBrno, Czech Republic, 25–27 May 2016; pp. 248–254. [Google Scholar]

- Li, J.-D.; Jiang, Z.-H.; Li, S.-P. Continuous Cooling Transformation Behaviors and Mechanical Properties of High Strength Microalloyed Pipeline Steel. In Proceedings of the International Seminar on Application of High Strength Line Pipe, Xi’an, China, 28–29 June 2010; pp. 126–133. [Google Scholar]

- Smirnov, M.A.; Pyshmintsev, I.Y.; Boryakova, A.N. Influence of cooling rate on properties of low-carbon pipe steel. Bull. South Ural State Univ. Metall. 2007, 21, 15–18. (In Russian) [Google Scholar]

- Krauss, G.; Thompson, S.W. Ferritic microstructures in continuosly cooled low- and ultralow carbon steels. ISIJ Int. 1995, 35, 937–945. [Google Scholar] [CrossRef]

- Koptseva, N.V.; Chukin, D.M.; Efimova, Yu.Yu.; Nikitenko, O.A.; Ishimov, A.S. Influence of cooling rate on structure forming of rolled wire from 80P steel grade intended for high-tensile reinforcement production. Ferrous Metals 2014, 2, 23–31. (In Russian) [Google Scholar]

- Chukin, M.V.; Poletskov, P.P.; Koptseva, N.V.; Baryshnikov, M.P.; Efimova, Y.Y.; Nikitenko, O.A.; Ishimov, A.S.; Gushchina, M.S.; Bereshnaya, G.A. Structural and phase transformations during continuous cooling of high-strength medium carbon complex alloyed low-tempered steels. Theory Tech. Process Metall. Prod. 2016, 1, 57–62. (In Russian) [Google Scholar]

- Chukin, M.V.; Salganik, V.M.; Poletskov, P.P.; Denisov, S.V.; Kuznetsova, A.S.; Berezhnaya, G.A.; Gushchina, M.S. Main types and application fields of strategic high-strength flat products. Vestn. Nosov Magnitogorsk State Tech. Univ. 2014, 4, 41–44. (In Russian) [Google Scholar]

- Rudskoy, A.I.; Kodzhaspirov, G.E.; Kliber, J.; Apostolopoulos, C. Advanced metallic materials and processes. Mater. Phys. Mech. 2016, 25, 1–8. [Google Scholar]

- Kim, Y.M.; Kim, S.K.; Lim, Y.J.; Kim, N.J. Effect of Microstructure on Yield Ratio and Low-Temperature Toughness of Linepipe Steels. ISIJ Int. 2002, 42, 1571–1577. [Google Scholar] [CrossRef]

- Gräf, M.; Schröder, J.; Schwinn, V.; Hulka, K. Production of Large Diameter Pipes Grade X70 with High Toughness Using Acicular Ferrite Microstructures. In Proceedings of the International Conference on Application and Evaluation of High Grade Linepipes in Hostile Environments, Yokohama, Japan, 8–9 Novermber 2002; pp. 1–14. [Google Scholar]

- Schastlivtsev, V.M.; Koptseva, N.V.; Artemova, T.V. Electron microscopic investigation of martensitic structure in low carbon alloys of iron. Phys. Met. Phys. Metall. 1976, 41, 1251–1260. (In Russian) [Google Scholar]

- Sadovskiy, V.D.; Fokina, E.A.; Schastlivtsev, V.M. Retained Austenite in Hardened Steel; Science: Moscow, Russia, 1986. (In Russian) [Google Scholar]

- Rodionov, D.P.; Schastlivtsev, V.M.; Stepanova, N.N.; Smirnov, L.V. Shape of martensite crystals in packet (lath) martensite. Phys. Met. Phys. Metall. 1986, 61, 115–120. (In Russian) [Google Scholar]

- Smirnov, M.A.; Pyshmintsev, I.Y.; Boryakova, A.N. Classification of low-carbon pipe steel microstructures. Metallurgist 2010, 54, 444–454. [Google Scholar] [CrossRef]

- Efron, L.I.; Il’inskii, V.I.; Morozov, Y.D.; Golovanov, A.V. Tube steel of increased strength and low-temperature stability with predominantly bainite structure. Steel Transl. 2003, 33, 66–72. [Google Scholar]

- Matrosov, Y.I. Development of Principles of Microalloying and Modes of Controlled Rolling of Pearlite-Reduced Steels for Pipes of Gas Transmission Pipelines. Ph.D. Thesis, Bardin Central Research Institute for Ferrous Metallurgy, Moscow, Russia, 1982. [Google Scholar]

- Rudskoi, A.I.; Kodzhaspirov, G.; Kliber, J.; Apostolopoulos, C. Thermomechanical processing of steels and alloys physical foundations, resource saving technique and modelling. Mater. Phys. Mech. 2018, 38, 16–25. [Google Scholar] [CrossRef]

- Rudskoi, A.I.; Bogatov, A.A.; Nukhov, D.S.; Tolkushkin, A.O. Mater. Phys. Mech. 2018, 38, 76–81. [CrossRef]

- Rudskoy, A.I.; Bogatov, A.A.; Nukhov, D.S.; Tolkushkin, A.O. New method of severe plastic deformation of metals. Met. Sci. Heat Treat. 2018, 60, 3–6. [Google Scholar] [CrossRef]

- Kodzhaspirov, G.; Rudskoi, A. Simulation of dynamic recrystallization of steels and alloys during rolling and forging through the use of FEM and experimental planning methods. In Proceedings of the METAL 2017—26th International Conference on Metallurgy and Materials, IBrno, Czech Republic, 24–26 May 2017; pp. 320–325. [Google Scholar]

- Matveev, M.A.; Kolbasnikov, N.G.; Kononov, A.A. Refinement of the structure of microalloyed steels under plastic deformation near the temperatures of polymorphic transformation. Met. Sci. Heat Treat. 2017, 59, 197–202. [Google Scholar] [CrossRef]

- Davydov, V.V.; Kruzhalov, S.V.; Grebenikova, N.M.; Smirnov, K.Y. Method for determining defects on the inner walls of tubing from the velocity distribution of the flowing fluid. Meas. Tech. 2018, 61, 365–372. [Google Scholar] [CrossRef]

- Bobrynina, E.V.; Larionova, T.V.; Koltsova, T.S.; Ginzburg, S.A.; Michailov, V.G. Effect of alumina addition on weld deposits microstructure at the welding of carbon steel. Mater. Phys. Mech. 2018, 38, 26–32. [Google Scholar] [CrossRef]

- Ziniakov, V.Y.; Gorodetskiy, A.E.; Tarasova, I.L. Control of vitality and reliability analysis. Stud. Syst. Decis. Control 2016, 49, 193–204. [Google Scholar] [CrossRef]

- Kamyshev, A.V.; Makarov, S.V.; Pasmanik, L.A.; Smirnov, V.A.; Modestov, V.S.; Pivkov, A.V. Generalized coefficients for measuring mechanical stresses in carbon and low-alloyed steels by the acoustoelasticity method. Russ. J. Nondestruct. Test. 2017, 53. [Google Scholar] [CrossRef]

- Borovkov, A.I.; Mamchits, D.V.; Nemov, A.S.; Novokshenov, A.D. Problems of modeling and optimization of variable-hardness panels and structures made of layered composites. Mech. Solids 2018, 53, 93–100. [Google Scholar] [CrossRef]

- Koptseva, N.V.; Chukin, M.V.; Nikitenko, O.A. Use of the Thixomet pro software for quantitative analysis of the ultrafine-grain structure of low-and medium-carbon steels subjected to equal channel angular pressing. Met. Sci. Heat Treat. 2012, 54, 387–392. [Google Scholar] [CrossRef]

- Mirzaev, D.A.; Okishev, K.Y.; Schastlivtsev, V.M.; Yakovleva, I.L. The kinetics of formation of bainite and packet martensite. I. Allowance for packet structure. Fiz. Met. Metalloved. 2000, 90, 55–65. [Google Scholar]

- Svishchenko, V.V.; Cheprasov, D.P.; Ivanovskiy, A.A.; Filatov, Yu.A. Phase composition of products of intermediate transformation in 24Х2НА steel grade. Polzunov Bull. 2005, 2, 95–97. (In Russian) [Google Scholar]

- Vander Voort, G.F. Metallography and Microstructures: ASM Handbook; ASM Int.: Novelty, OH, USA, 2004; p. 9. [Google Scholar]

- Bhadeshia, H.K. Bainite in Steels, 2nd ed.; Ins. of Materials: London, UK, 2001. [Google Scholar]

Nord Stream;

Nord Stream;  Nord Stream 2 (planned).

Nord Stream 2 (planned).

| C | Mn | Mo | Cr | Ni | S | P | Other Elements (Al, Cu, V, Nb, Ti) |

|---|---|---|---|---|---|---|---|

| 0.062 | 1.80 | 0.120 | 0.032 | 0.90 | till 0.002 | till 0.015 | 0.53 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poletskov, P.; Gushchina, M.; Polyakova, M.; Alekseev, D.; Nikitenko, O.; Chukin, D.; Vasil’ev, Y. Development of Alloyed Pipe Steel Composition for Oil and Gas Production in the Arctic Region. Resources 2019, 8, 67. https://doi.org/10.3390/resources8020067

Poletskov P, Gushchina M, Polyakova M, Alekseev D, Nikitenko O, Chukin D, Vasil’ev Y. Development of Alloyed Pipe Steel Composition for Oil and Gas Production in the Arctic Region. Resources. 2019; 8(2):67. https://doi.org/10.3390/resources8020067

Chicago/Turabian StylePoletskov, Pavel, Marina Gushchina, Marina Polyakova, Daniil Alekseev, Olga Nikitenko, Dmitrii Chukin, and Yuri Vasil’ev. 2019. "Development of Alloyed Pipe Steel Composition for Oil and Gas Production in the Arctic Region" Resources 8, no. 2: 67. https://doi.org/10.3390/resources8020067

APA StylePoletskov, P., Gushchina, M., Polyakova, M., Alekseev, D., Nikitenko, O., Chukin, D., & Vasil’ev, Y. (2019). Development of Alloyed Pipe Steel Composition for Oil and Gas Production in the Arctic Region. Resources, 8(2), 67. https://doi.org/10.3390/resources8020067