Abstract

Innovative approaches for preparing flame retardant cotton fabrics were employed by utilizing a microwave-assisted technique with a minimum amount of co-solvent. Our attempts at flame retardant cotton fabrics treated with low cost inorganic formulations, such as urea and diammonium phosphate, were done successfully. The evidence of flame retardant chemical penetrations or surface modification of cotton fabrics was confirmed by scanning electron microscope (SEM) and the treated cotton fabrics were evaluated by flammability tests, such as 45° angle (clothing textiles test), vertical flame (clothing textile test) and limiting oxygen index (LOI). For formulations with urea only, LOI values of treated fabrics were 21.0–22.0% after add-on values for the formulation were 5.16–18.22%. For formulations comprising urea with diammonium phosphate, LOI values were greater than 29.0% after add-on values for the formulation were 1.85–7.73%. With the formulation comprising urea and diammonium phosphate, all treated fabrics passed the vertical flame test for add-on values 5.34–7.73%. Their char lengths were less than half the length of the original fabric and after-flame and after-glow times were less than 3.2 s. Additional thermal properties of desired products will be discussed using thermogravimetric analysis (TGA) and microscale combustion calorimeter (MCC).

1. Introduction

Due to its environmentally friendly properties, microwave assisted technique is deemed in green chemistry to be a substitute for organic solvents in chemical reactions. Microwave energy is becoming a very attractive technique in all areas of organic [1], inorganic [2] and nanoparticle syntheses [3,4]. During the last 10 years, the research of microwave-assisted reactions of cellulose, such as decomposition, derivation, heating and dissolution, has received increasing attention [5,6,7]. Furthermore, the use of microwave in chemical modification, such as esterification, acetylation and graft copolymerization provided shorter reaction times compared with conventional techniques [8,9,10]. To our knowledge, there are no reported methods for creating flame retardant cotton fabrics using the microwave technique. Herein, the use of microwave to graft flame retardant onto cotton fabric is studied.

Cotton use is popular in a variety of consumer markets because cotton is abundant, low-priced, attractive to customers and an adaptable starting material in the development of new products. However, cotton is easily damaged by flame, microorganisms and bugs and needs to be chemically modified for resiliency. In the following paper, improving flame resistance of cotton fabrics will be emphasized.

Phosphorus compounds are widely used in the textile industry to make flame resistant cotton textiles [11]. When phosphorus flame retardant compounds react chemically with cotton, an ether cross linker between the cellulosic material and the phosphorus compound is created in the products. During condense phase, a protective char is formed when thermal decomposition converts the phosphorus functional groups to phosphoric acid. Intumescence and char formation impart low flammability to cotton textiles [12,13]. Some studies on organophosphorus flame retardants (FRs) report assessments of the mechanism of phosphorus substances [14,15]. Inhibition of fire, reduction in heat, formation of char and alteration of the surface by phosphoric acid containing compounds are chemical or physical actions of phosphorus-based FRs in both the condense phase and in the flame [16,17,18,19,20]. Scientific evidence shows that the main material is protected against heat and flame because phosphorus largely remains in the char [21,22]. It has also been shown that materials comprising other flame retardant elements enhance the efficiency of phosphorus.

Multiple advantages are found when nitrogen flame retardants are combined with phosphorus compounds, including: (1) high effectiveness when measured by cone calorimeter, (2) low toxicity during combustion and (3) subdued smoke development in fire accidents [23]. Some nitrogen compounds such as melamine, urea and dicyandiamide, will create a phosphorus-nitrogen intermediate accelerating phosphorylation of cellulose and synergizing the flame retardant action of phosphorus [24,25].

In earlier research, phosphorus-nitrogen synergism containing urea-derivative compounds created better flame retardant properties. Diammonium phosphate (DAP) is often used as a flame retardant chemical to yield semi-durable finishes on cotton [26,27]. It causes a drop in the temperature of combustion of the material, decreases the highest rates of weight loss and gives higher char yields. In an effort to make flame retardant cotton fabrics, urea and DAP were used for phosphorus and nitrogen components because they are economic and environmentally friendly compounds. As a non-durable or semi-durable flame retardant, DAP is broadly used on infrequently washed or disposable products [28]. Literature states that DAP is the most effective within non-durable and durable flame retardants in delivering flame retardant properties to cellulosic materials and in yielding char [29].

In this paper, thermal degradation of untreated control and treated fabric samples were studied by thermogravimetric analysis (TGA) in a nitrogen atmosphere to determine char content at 600 °C. ASTM D2863-09 procedure [30] was used to establish the limiting oxygen index (LOI) values of untreated and treated samples to determine how much oxygen in nitrogen was needed to burn them. Finally, the flammability of fabric samples was assessed by 45° angle (clothing textiles test, ASTM D1230-01; 16 CFR 1610) [31] and vertical flame tests (ASTM D6413-11; 16 CFR 1615, 1616) [32] to determine that effective flame resistance can be provided by urea/DAP treatment on cotton fabrics by using microwave assisted technology.

2. Materials and Methods

2.1. Materials

Urea and diammonium phosphate were obtained from Adrich and used without further purification. Bleached and mercerized Twill fabric, 258 g/m2 (Style 423) was purchased from TestFabrics Inc. (West Pittston, PA, USA).

2.2. Microwave Assisted Fabric Treatment

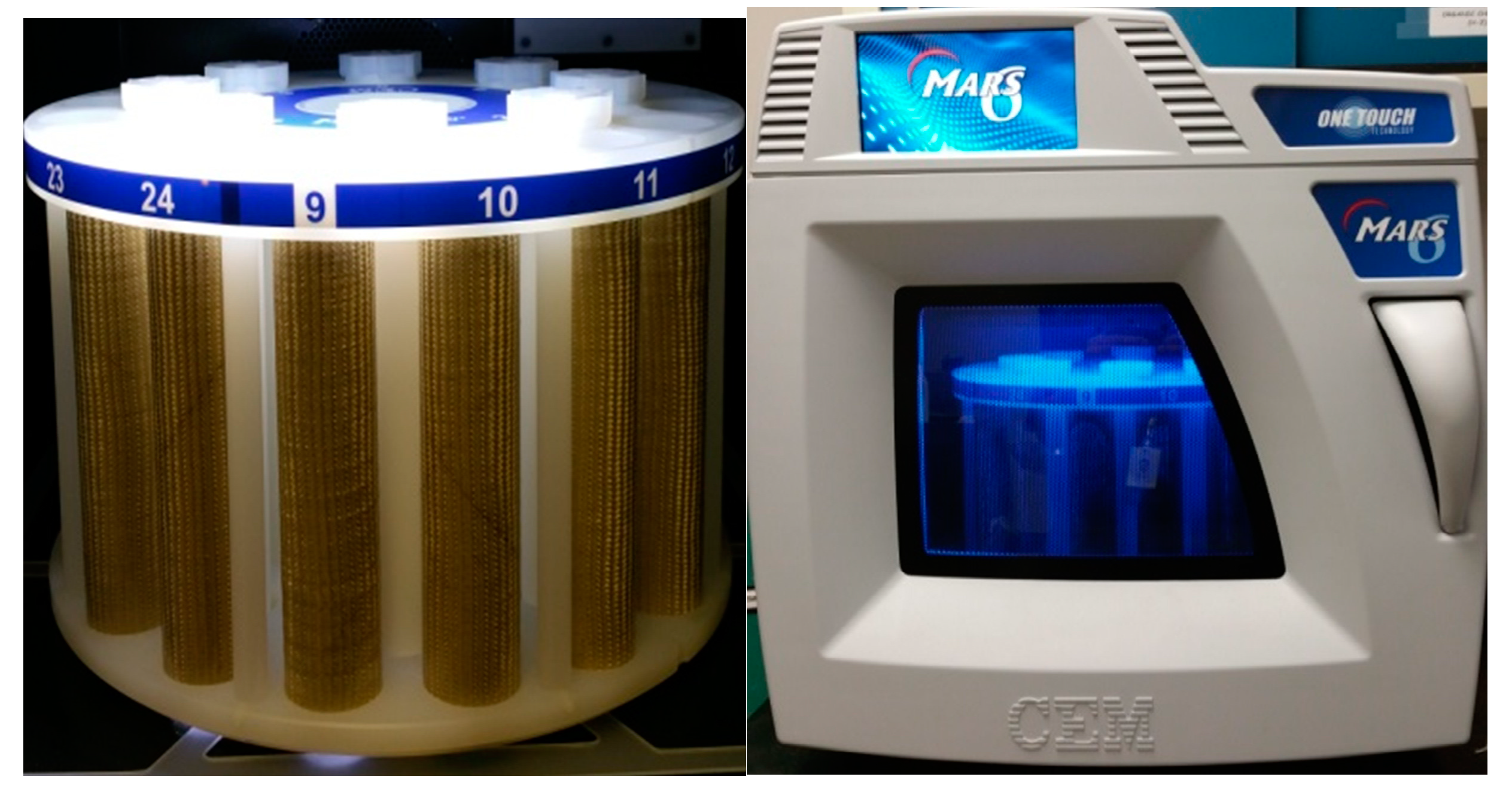

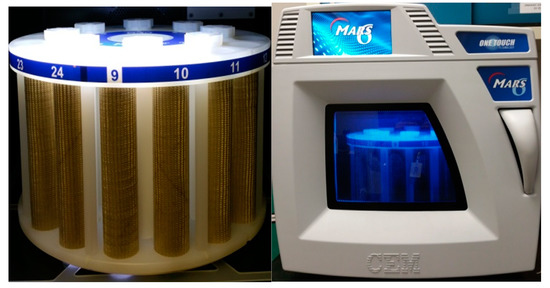

Microwave assisted treatments were performed using a MARS 6 (CEM Corporation, Matthews, NC, USA) microwave oven with a multi-mode like that of a household microwave oven. It is capable of providing continuous power up to a maximum of 1800 W at a frequency of 2.45 GHz. The reaction vessel used in the MARS6 was a 100 mL (maximum pressure and temperature: 500 psi and 210 °C) MARSXpress plus Teflon digestion vessel supplied by CEM Corporation (Figure 1). Urea solutions were made by dissolving urea in deionized water to make 5%, 10%, 15% and 20% weight by volume solutions. Urea/DAP solutions were prepared as follows: UD1 (4 g Urea and 8.8 g DAP dissolved in 288 mL deionized water), UD2 (12 g Urea and 26.4 g DAP dissolved in 400 mL deionized water), UD3 (12 g Urea and 26.4 g DAP dissolved in 361 mL deionized water) and UD4 (15 g Urea and 33 g DAP dissolved in 352 mL of deionized water). For each set, approximately 50 mL of solution was added to each CEM vessel with a fabric sample (2.5′′ × 6′′). All fabric samples were dried in the lab oven at 100 °C for 5 min and immediately weighed after removal from oven to record initial weight. Fabric was presoaked in urea and urea/DAP solutions solution for 1 h and treated in MARS6 microwave in MARSXpress plus vessels. The CEM method used was a classic ramp to temperature method with power = 1100 W, ramp time = 10 min, hold time = 10 min and temperature = 90 °C.

Figure 1.

Pictures for Microwave assisted system (MARS 6 Microwave reaction system and MARSXpress plus 100 mL digestion vessels in vessel carousel, CEM Corporation).

2.3. Fabric Treatment Add-On (wt%)

Treated fabric was dried in a lab oven (model LTF 146491, Mathis U.S.A. Inc, Concord, NC, USA) at 100 °C for 5 min and cured in another lab oven (model LTE 18795, Mathis U.S.A. Inc.) at 140 °C for 3 min. Immediately after removal from the lab oven, fabric was placed in a desiccator, where it was allowed to cool to room temperature before weighing. The weights from before and after the treatment were recorded and the values were fit into the equation below to obtain add-on (wt%).

Add-on (%) = [(weightafter drying − weightbefore treatment)/weightbefore treatment] × 100

2.4. Thermogravimetric Analysis (TGA)

Untreated control and treated fabric samples with urea and urea/DAP were tested by thermogravimetric analysis (TGA) for thermal stability (TA Instrument, Q500, New Castle, DE, USA) Under a continuous nitrogen atmosphere, samples (5–7 mg) were analyzed at a heating rate of 10 °C/min starting at room temperature and ending at 600 °C.

2.5. Flammability Testing (Limiting Oxygen Index (LOI), 45° Angle and Vertical Flammability Tests)

Untreated control and treated fabric samples were subjected to limiting oxygen index (LOI) test (Dynisco, Franklin, MA, USA), 45° angle flame test (SGS Govmark Organization Inc., Farmingdale, NY, USA), and vertical flame test (SGS Govmark Organization Inc.). In 45° angle flame test (ASTM D1230-01, 16 CFR 1610, clothing textiles test) [31], a fabric strip was placed in a u-shaped frame and held at a 45° angle by a special device. A standardized flame was lowered to the fabric strip near the lower end for 10 s. The time it took for the flame to burn the length of the fabric and break the string stopping the timer was noted. In the vertical flame test (ASTM D6413-11, 16 CFR 1615, 1616) [32], a piece of fabric in a frame was suspended vertically above a controlled flame and exposed for 12 s. After-flame and afterglow time were recorded. The length of char was measured and other fabric behavior was noted. In the LOI test (ASTM D2863-09) [30], a strip of fabric was vertically held in a u-shaped support while a mixture of oxygen and nitrogen travelled upwards through a transparent funnel that surrounded the sample. A flame was passed over the upper end of the sample for 5 s until it ignited and the burning behavior was noted as the sample continued to burn to a specified length.

2.6. Microscale Combustion Calorimeter (MCC)

The MCC (SGS Govmark Oranization Inc., MCC-2, Farmingdale, NY, USA) consists of a sample mounting post, which contains a thermocouple in the post with its tip at the top directly below the sample holder to monitor temperature. A small fabric sample is inserted in a ceramic cup and placed on the sample holder. This assembly is then inserted into a furnace so that everything is inside the furnace. The heat release combustion (HRC) correlates directly to flow rates of the gases involved in the combustion process and to the oxygen concentrations. HRC uses oxygen reduction as a determining factor.

2.7. Scanning Electron Microscope (SEM)

Scanning electron microscope (SEM) images were taken using a FEI Quanta 3D FEG FIB/SEM system with a magnification of 1500×. Samples consisted of a thin layer of cotton fiber spread onto double-sided carbon tape on the SEM stub and sputter-coated with a thin layer of Platinum.

3. Results and Discussions

3.1. Fabric Treatment

Table 1 shows formulations (urea:DAP:deionized water) for flame resistant treatments and add-ons (wt%) values. After being dried and cured, the treated fabrics appeared white in color. Formulations of urea only treatment; U1, U2, U3 and U4 showed 5.16 ± 0.50, 7.36 ± 0.95, 13.08 ± 1.41 and 18.22 ± 0.19 add-ons (wt%) and formulations of urea with DAP treatment; UD1, UD2, UD3 and UD4 showed 1.85 ± 0.16, 5.34 ± 0.27, 5.74 ± 0.69 and 7.73 ± 0.71 add-ons (wt%) for twill cotton fabrics, respectively.

Table 1.

Fabric treatment data.

3.2. Thermal Properties

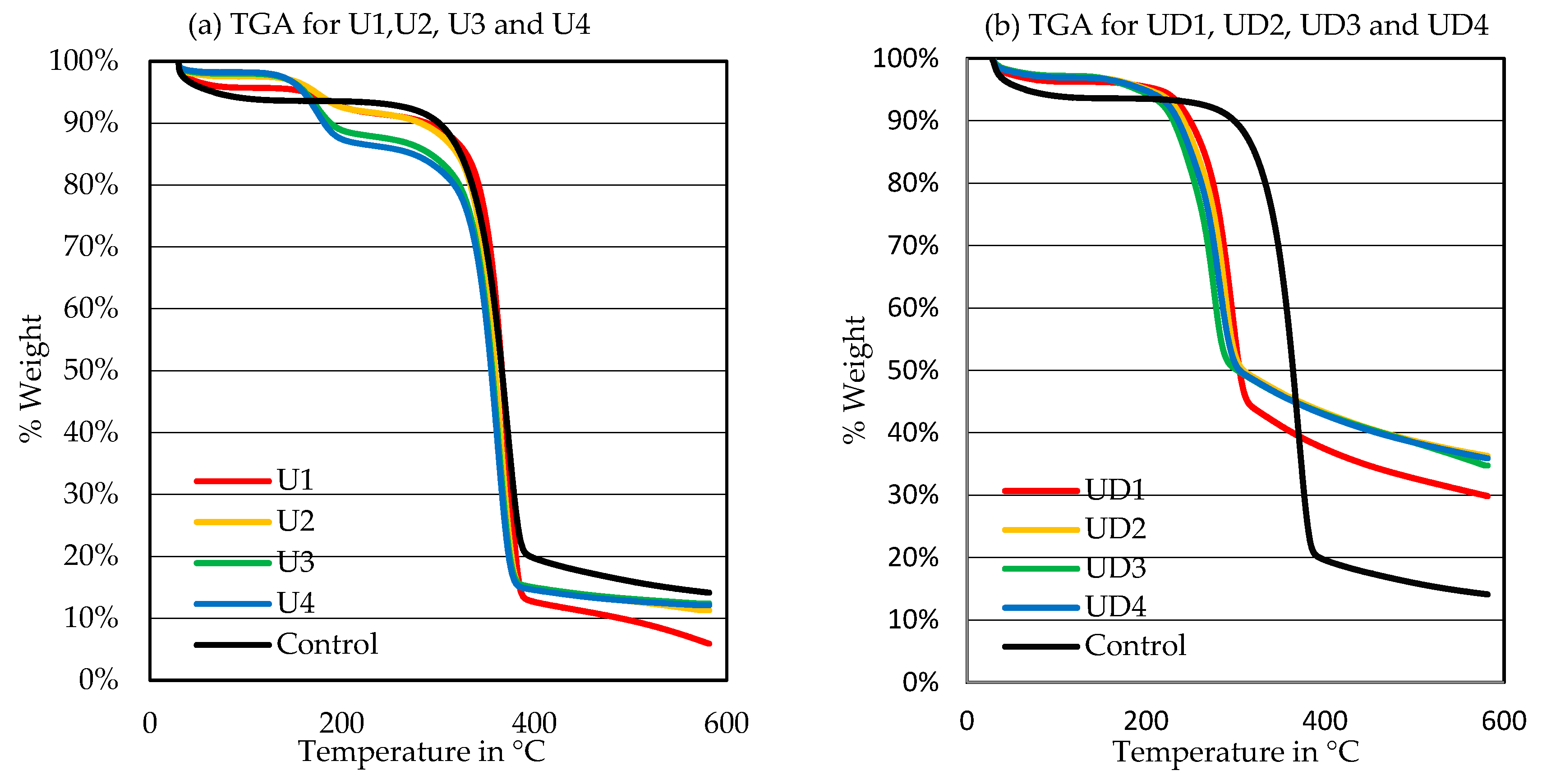

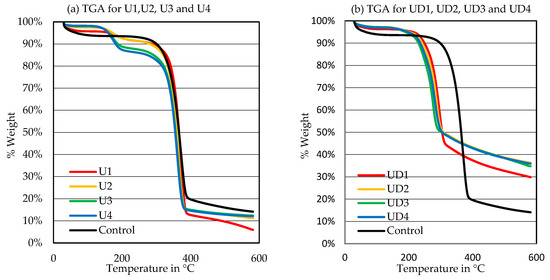

Thermogravimetric analysis (TGA) examines the reduction in mass with respect to the temperature. It also gives the onset temperature, which is the temperature when weight loss begins. A nitrogen atmosphere was used for all tests. Degradation of various add-ons (wt%) of urea only treated samples, U1–U4 and urea/DAP treated samples, UD1–UD4, along with untreated control twill, are presented graphically in Figure 2. Additionally, Table 2 shows detailed values for add-on (wt%), degradation onset (°C) and char content (% at 600 °C) for untreated, U1–U4 and UD1–UD4 fabric samples. Untreated twill fabric showed an onset of degradation temperature at 331.05 °C and char residue of 12.75% of the original weight at 600 °C. For urea treated, U1–U4 fabric, the decomposition of urea appears between 161.45–165.05 °C and the char yields are less than that of the untreated fabric.

Figure 2.

Degradation thermograms of treated samples of urea only (a) and urea/diammonium phosphate (b) at various add-ons (wt%) by TGA in nitrogen atmosphere.

Table 2.

Thermal degradation and char content determination of different add-ons (wt%) of urea only and urea/diammonium phosphate treated samples by TGA at 600 °C in nitrogen atmosphere. (Three observations for each sample).

DAP provides a significantly lower decomposition temperature for cellulose. The onset of degradation temperature for urea/DAP treated, UD1–UD4, fabrics are ranged between 252.14–264.17 °C, which is 78.91–66.88 °C lower than untreated fabrics. The cause of this may be the acceleration of fabric degradation because of the in situ formation of phosphonic acid derivatives. The onset of degradation temperature range between 252.14–264.17 °C results from the liberation of water and ammonia by the phosphorylation chemical reaction [33]. The prevention of the 1, 6 anhydro ring from closing, due to the phosphorylation arising on the C-6 hydroxyl of dehydroglucose, triggers the depolymerization of cellulose and prevents the formation of flammable levoglucosan [34]. The pyrolysis system is also quenched as cellulose dehydration is catalyzed by the byproduct of phosphoric acid. At the lower temperature, the decomposition reactions become slow and produce more stable char. Overall, UD1–UD4 treated samples yield high char during the thermal degradation process. Fabric offers 31.68% of char at a very low add-on, 1.85 wt% (UD1). While, 5.34, 5.74 and 7.73 wt% offer 36.13%, 36.05% and 33.52% of char, respectively. The char amount at 600 °C for UD1–UD4 treated fabric was 31.68–36.13%, almost triple of that of untreated fabric. Chars shield against heat and flame spread because they generate thermally stable cohesive phases. These phases have decomposition temperatures that exceed the temperatures of the oxidizing zones of flames. In addition, chars are intumescing so they foam and release gases that decrease flammability, which makes it crucial to create flame-retardants that promote intumescing and char formation.

3.3. Flame Retardant Performance

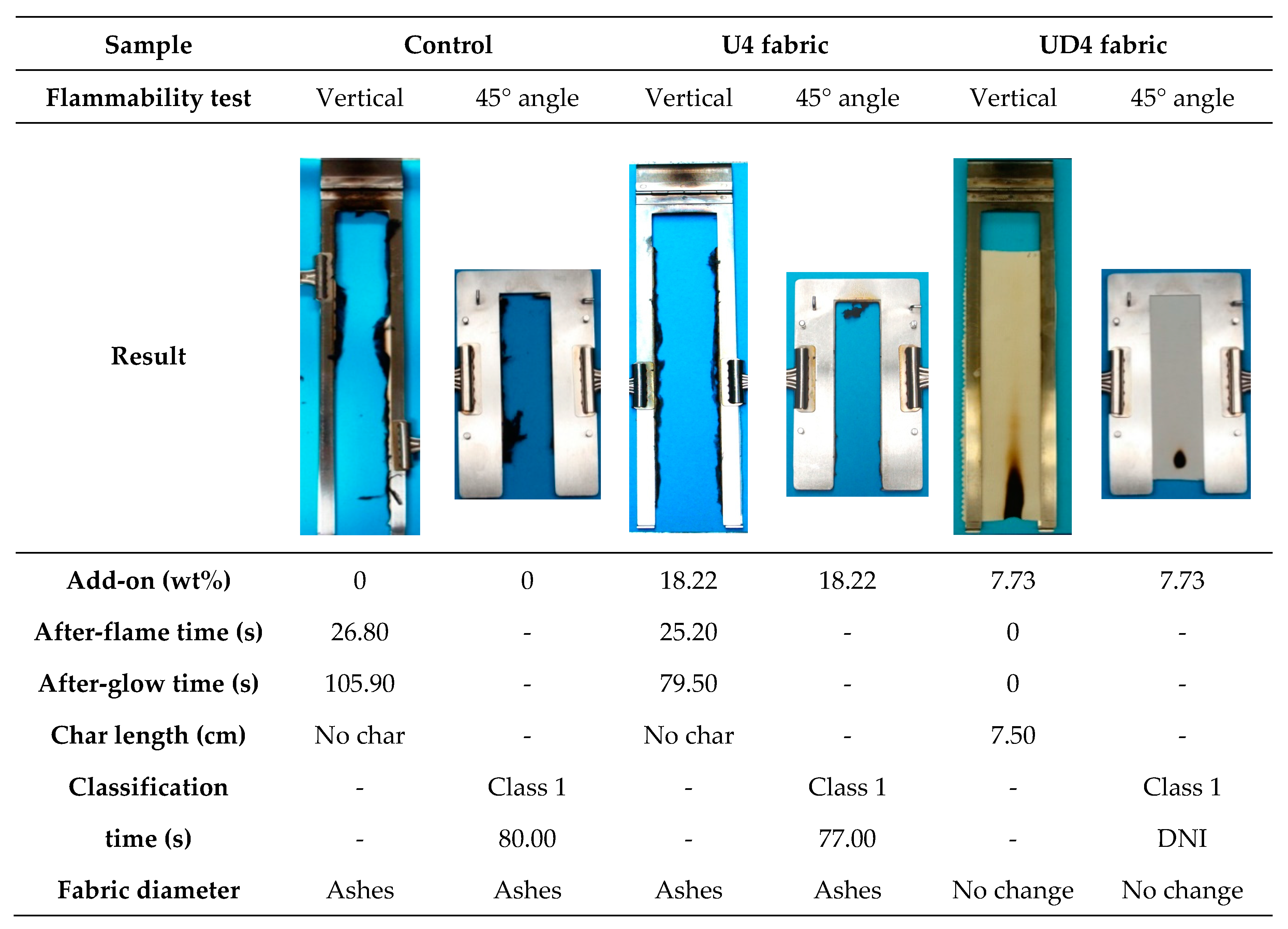

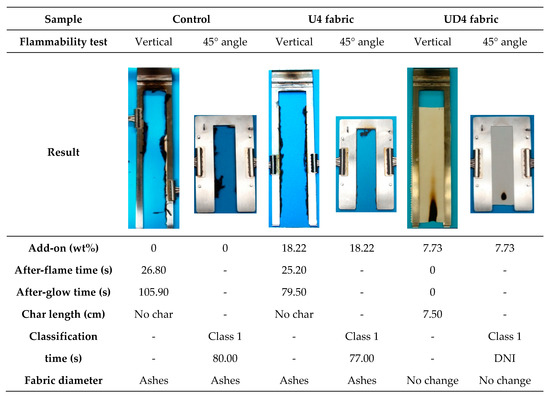

To appraise the ignition sensitivity and combustibility of fabrics treated with urea only (U1–U4) and urea/DAP (UD1–UD4), limiting oxygen index (LOI), 45° angle and vertical flammability tests were carried out. Table 3 and Figure 3 summarize the results of the flame retardant tests on untreated control, U1–U4 and UD1–UD4 fabrics.

Table 3.

Vertical flammability (ASTM D-6413-11), 45° angle flammability (ASTM D-1230-01) and LOI (ASTM D-2863-09) tests for different add-ons (wt%) of treated fabrics. All values for vertical and 45° angle tests are averages from two observations.

Figure 3.

Vertical and 45° angle flammability test results of control and highest add-ons (wt%) for urea only (U4) and urea/DAP (UD4) treated sample.

Limiting oxygen index (LOI) values represent the minimum amount of oxygen, in an atmosphere of oxygen and nitrogen, needed to support a candle like flame during burning for 2 inches or 3 min, whichever comes first. The ease of ignition is defined as the capacity with which ignition of a material occurs under given conditions of oxygen concentration. A flammable textile has an LOI value below 21% and a flame–retardant textile has an LOI value of 26% or higher. The first row of Table 3 gives the LOI value of untreated fabrics, 20.9% (average) oxygen in nitrogen. U1, U2, U3 and U4 provided LOI values of 21.5, 21.5, 22.0 and 21.0%, when add-on values were 5.16, 7.36, 13.08 and 18.22 wt%, respectively. With the urea/DAP mixture formulation (UD1–UD4), LOI values greater than 29.0% were realized for all add on percentages (wt%) even 1.85%.

45° angle and vertical flammability tests are significant in the assessment of the flame retardant properties for treated fabrics. The after-flame and after-glow time are noted and char length is measured upon completion of the vertical flammability test. Both untreated and urea only treated fabrics (U1–U4) burned completely during the vertical test. Urea did not protect the fabric from flames but altered the combustion behavior of cotton. Compared to untreated fabric, U1–U4 significantly decreased the after-glow time from 105.9 s to 78.0–90.1 s. This shows that urea induced more flame combustion and blocked the incomplete combustion of cotton fabric. During the vertical testing, there was no presence of afterglow burning once the flame was removed, as well as no melting or dripping for all UD1–UD4 fabric samples. Following the 12-s exposure to flame, it is obvious that all UD fabrics have shorter char lengths and after-flame and after-glow times, when compared with the control and U1–U4 samples. All UD1–UD4 fabrics pass the vertical flame test with small char lengths and char widths, though the rest of the samples fail the test with their higher values.

Flammability requirements for all clothing textiles, before sale or introduction into trade, are instituted in the 45° angle flammability test. The Standard offers a consistent method to test textiles and divides textile products used for clothing into three classes of flammability performance, thus limiting the use of any risky flammable clothing textiles. During the test procedure, a 16 mm (5/8 in) flame is positioned to touch the bottom of a specimen fixed at a 45° angle for 10 s. The fabric sample burns its full length or until the thread that stops the timer is broken, a distance of 127 mm (5 in). Class I or II specimens meet the requirements of the Standard. Class III, rapid and intense burning, does not meet the requirements of the Standard. Table 3 shows that U1–U4 with 5.16–18.12 add ons (wt%) were completely burned and were totally consumed during the test. The test also shows the effectiveness of UD1–UD4 at 1.87–7.73 add ons (wt%). UD2-UD4 do not ignite once exposed to the flame and only the area of contact turns brown, while UD1 burned for 1.2 s before extinguishing. All ignitable samples show a time of flame spread greater than 3.5 and 7 s. Therefore, based on the classifications for textile products, all treated fabric samples are class 1 and are suitable for clothing due to slow burning or no combustibility.

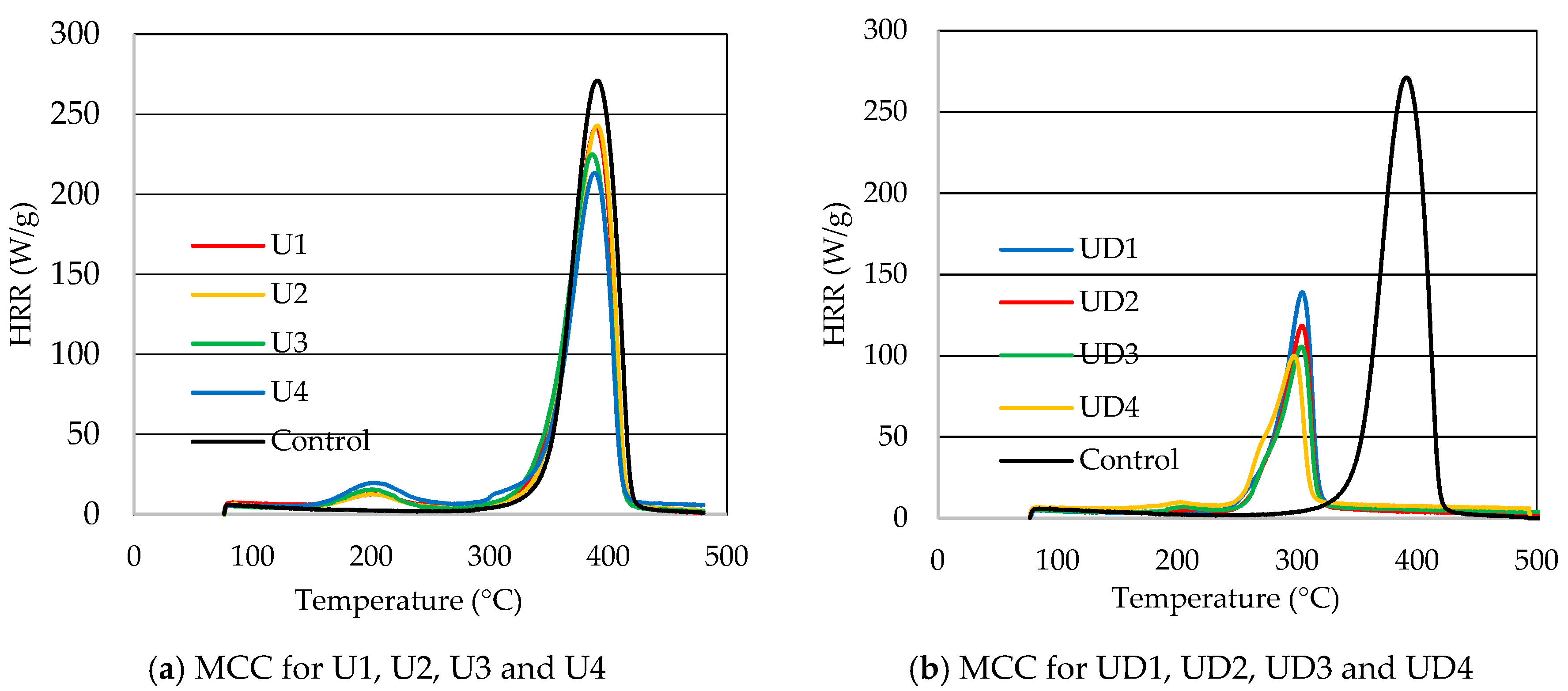

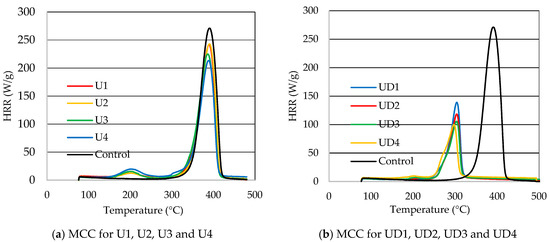

3.4. Microscale Combustion Calorimeter (MCC)

HRR (heat release rate) versus temperature of the control cotton fabric and flame retardant treated fabrics are shown in Figure 4. The flammability parameters, total heat release (THR), heat release combustion (HRC) and temperature of maximum of heat release combustion (Tmax), were computed and are presented in Table 4. The thermal decomposition of the untreated control sample starts at less than 300 °C. The thermal decomposition as indicated by rising HRC strengthens as the temperature increases. Then, it attains a maximum point at 390.88 °C and ends around 425 °C with an approximate value of 12.00 kJ/g in THR. When treated with the flame retardants, cotton fabric shows a substantial reduction in THR, HRC and Tmax values. In Table 4, Tmax values are lower in all UD1–UD4 samples when compared with U1–U4 samples. Upon closer review of 7.36:7.73 wt% MCC curves of U2 : UD4 fabrics, lower Tmax values with higher HRC values are found. In addition, as the concentrations of U1–U4 and UD1–UD4 increase, the initial decomposition temperature, THR and HRC values all continuously decrease. All treated fabrics have lower THR, HRC and Tmax values than the control and at comparable add-on levels, all UD1–UD4 samples are lower than U1–U4 samples. In urea only treated MCC curves (a), the shoulder between 160–240 °C is due mainly to the process of decomposition and dehydration of urea to form a shielding char. The protective layer then prevents the cotton fabrics from igniting and reduces the normal thermal degradation of cotton fabrics and structural disintegration of the char to release volatiles and gases. As seen in MCC curves for urea/DAP treated fabric (b), once urea has burned, the main material starts to burn and gives rise to the second peaks at around 260–310 °C. These peaks on the same shoulder decrease with increasing add-on values.

Figure 4.

Microscale combustion calorimeter (MCC) graphs of heat release combustion curves for control, (a) urea only treated samples, U1–U4 and (b) urea/DAP treated sample, UD1–UD4 fabrics.

Table 4.

Microscale combustion calorimetry (MCC) data of control and treated fabrics (reported value is the average from three observations).

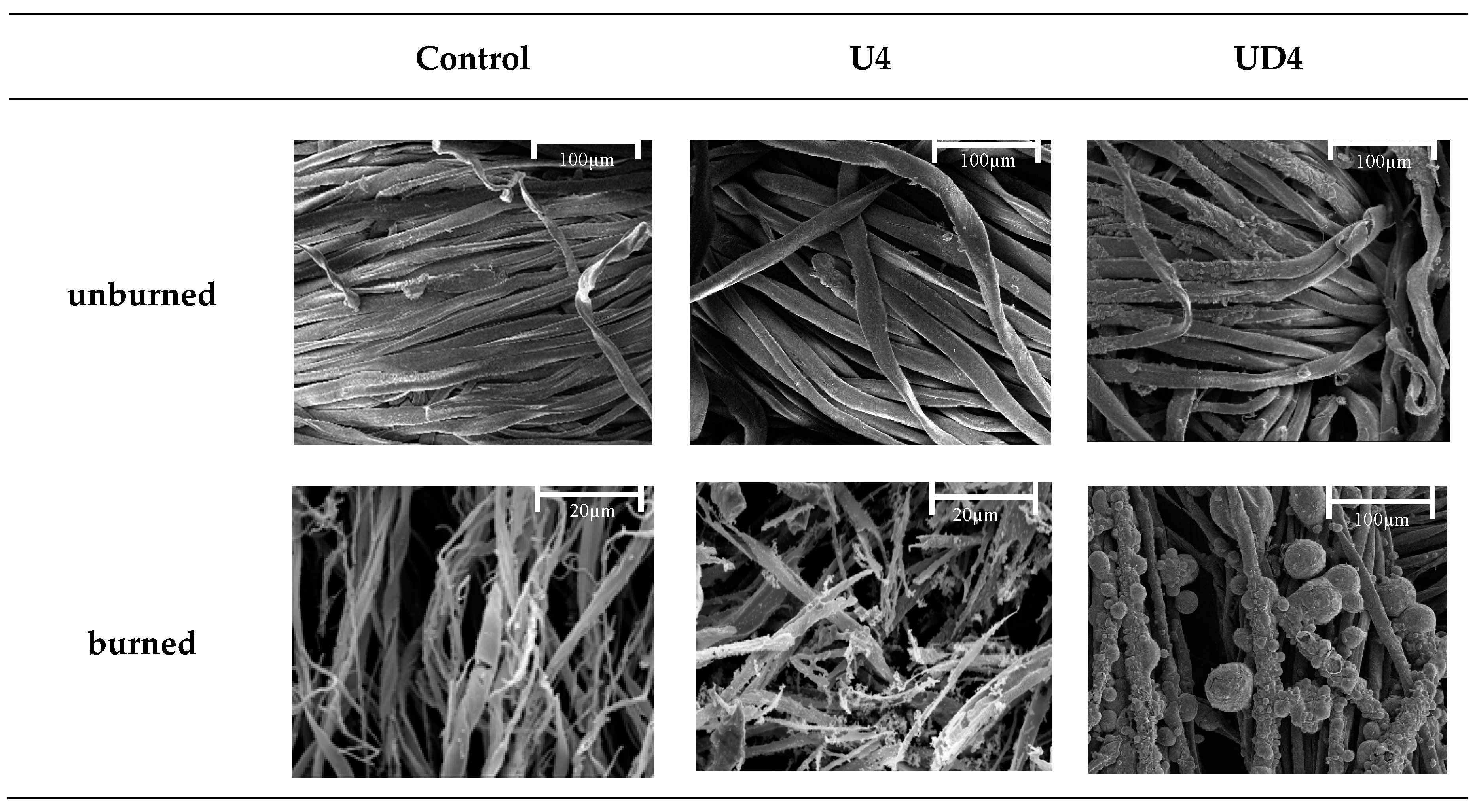

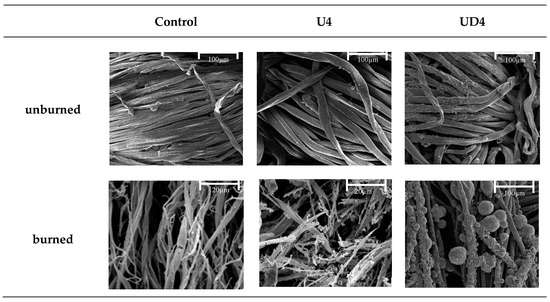

3.5. Scanning Electron Microscope (SEM) Study

Scanning electron microscopic images of unburned and burned control, U4 and UD4 (highest add ons wt%) are presented in Figure 5. When unburned, sample U4’s surface morphology looks very similar to the control, with the fibers still unbroken and appearing as twisted ribbons or collapsed and twisted tubes. The burned samples were taken from the area where the flame touched the fabrics turning the fabrics to char. Fibers that were untreated or from urea only treatment (U4) were severely damaged and disintegrated. While most charred fibers of U4 appear to be twisted and deformed, the charred fibers of the untreated control fabric have a hollow construction. For urea/DAP treated fabric, UD4, the morphology of the charred fibers remained intact but changed in the surface characteristics. These results confirm that when being burned, the chemicals form a protective layer over each fiber to support the resistance of heat transfer. These chemicals also retard the breakdown of underlying materials, so that combustion could not be self-sustained. This layer may be due to gas formation during decomposition through a burning mechanism of the chemicals in the flame retardants. It appears that one of the nodules has burst and a few are larger than the rest. This phenomenon may occur because of gas build up inside the nodules, which causes expansion and bursting of the nodules. This release of gases and the chemicals decomposing into gases may also help to dilute the flame and hinder the degradation of underlying materials. Similar protective coatings on burned, treated fabrics, polymeric materials and epoxy acrylate resins were seen in other studies where the burned surface morphology was connected to the flame retardant ability of the phosphorus, nitrogen encompassing FRs [35,36].

Figure 5.

SEM micrographs of 1500× of the before burned (top) and after burned (bottom) for control, U4 and UD4.

4. Conclusions

Economic inorganic flame retardant finishing treatments based on urea and diammonium phosphate have been applied to cotton fabrics using microwave-assisted technology. All the urea/DAP treated fabrics showed a substantial resistance to flame application during limiting oxygen index (LOI), 45° angle and vertical flammability tests. Urea/DAP treated samples passed all tests at the levels of 5.34–7.73 add-ons (wt%) and all samples are regarded as class I fabrics after 45° angle testing. Furthermore, the flame retardant formulation acted as char-promoters for the surface of cotton fabrics, as assessed by thermogravimetric analysis (TGA) and microscale combustion calorimeter (MCC). Tests performed on TGA revealed that the char yields for urea/DAP fabrics were 31.68–36.13%. In the MCC experiments, a better reduction in heat of combustion was shown through the smaller values found for THR, HRC and Tmax for all urea/DAP samples. The flame retardant formulation was very effective at lower add-ons (wt%), such as 1.85–7.73 wt% of urea/DAP, providing the fabric with high fire performance. For the SEM study, urea/DAP samples contained a layer encasing the cotton fibers to shield them from being demolished by heat and flame. The superior action of urea/DAP could be attributed to its degradation into more gas products resulting from the nitrogen atom bonded to the phosphorus in phosphorus moiety. An efficient method has been developed, which has the advantages of shorter reaction time, simple procedure and no environmental pollution compared to the conventional method. The results reveal that most of the flame retardant treated fabrics showed better anti-flammable activity than the control fabric

Author Contributions

Conceptualization, S.C. and B.C.; Formal Analysis, J.S.; Investigation, S.C.; Writing-Original Draft Preparation, S.C.; Writing-Review & Editing, B.C. and S.C.

Funding

This research received no external funding.

Acknowledgments

The authors want to thank Dongmei Cao for the FEI Quanta 3D FEG FIB/SEM observations.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Polshettiwar, V.; Nadagouda, M.N.; Varma, R.S. Microwave-Assisted Chemistry: A Rapid and Sustainable Route to Synthesis of Organic and Nanomaterials. Aust. J. Chem. 2009, 62, 16–26. [Google Scholar] [CrossRef]

- Gonzalez-Arellano, C.; Balu, A.M.; Luque, R.; Macquarrie, D.J. Catalytically active self-assembled silica-based nanostructures containing supported nanoparticles. Green Chem. 2010, 12, 1995–2002. [Google Scholar] [CrossRef]

- Chen, S.Q.; Wang, Y. Microwave-assisted syethesis of a Co3O4—Graphene sheet-on-sheet nanocomposite as a superior anode material for Li-ion batteries. J. Mater. Chem. 2010, 20, 9735–9739. [Google Scholar] [CrossRef]

- Gonzalez-Arellano, C.; Luque, R.; Macquarrie, D.J. Nanotubular self-assembly of n-dodecylamine-TEOS-water-acetonitrile mixtures. Chem. Commun. 2009, 30, 4581–4583. [Google Scholar] [CrossRef] [PubMed]

- Dogan, H.; Hilmioglu, N.D. Dissolution of cellulose with NMMO by microwave heating. Carbohydr. Polym. 2009, 75, 90–94. [Google Scholar] [CrossRef]

- Semsarilar, M.; Perrier, S. Solubilization and functionalization of cellulose assisted by microwave irradiation. Aust. J. Chem. 2009, 62, 223–226. [Google Scholar] [CrossRef]

- Hou, A.; Wang, X.; Wu, L. Effect of microwave irradiation on the physical properties and morphological structure of cotton cellulose. Carbohydr. Polym. 2008, 74, 934–937. [Google Scholar] [CrossRef]

- Li, J.; Zhang, L.; Peng, F.; Bian, J.; Yuan, T.; Xu, F.; Sun, R. Microwave-assisted solvent-free acetylation of cellulose with acetic anhydride in the presence of iodine as a catalyst. Molecules 2009, 14, 3551–3566. [Google Scholar] [CrossRef] [PubMed]

- Possidonio, S.; Fidale, L.C.; Seoud, O.A.E. Microwave assisted derivatization of cellulose in an ionic liquid: An efficient, expedient synthesis of simple and mixed carboxylic esters. J. Polym. Sci. Part A Polym. Chem. 2009, 48, 134–143. [Google Scholar] [CrossRef]

- Gospodinova, N.; Grelard, A.; Jeannin, M.; Chitanu, G.C.; Carpov, A.; Thiery, V.; Besson, T. Efficient solvent-free microwave phosphorylation of microcrystalline cellulose. Green Chem. 2002, 4, 220–222. [Google Scholar] [CrossRef]

- Salmeia, K.A.; Gaan, S.; Malucelli, G. Recent Advances for Flame Retardancy of Textiles Based on Phosphorus Chemistry. Polymers 2016, 8, 319. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Kandola, B.K.; Davies, P.J.; Zhang, S.; Padbury, S.A. Developments in flame retardant textiles—A review. Polym. Degrad. Stab. 2005, 88, 3–12. [Google Scholar] [CrossRef]

- Lu, Y.; Jia, Y.; Zhou, Y.; Zou, J.; Zhang, G.; Zhang, F. Straightforward one-step solvent-free synthesis of the flame retardant for cotton with excellent efficiency and durability. Carb. Polym. 2018, 201, 438–445. [Google Scholar] [CrossRef] [PubMed]

- Lewin, M.; Weil, E.D. Mechanisms and Modes of Action in Flame Retardancy of Polymers, 1st ed.; Woodhead Publishing Ltd.: Cambridge, UK; CRC Press LLC: Boca Raton, FL, USA, 2001. [Google Scholar]

- Schartel, B. Phosphorus-based Flame Retardancy Mechanisms—Old Hat or a Starting Point for Future Development? Materials 2010, 3, 4710–4745. [Google Scholar] [CrossRef] [PubMed]

- Basch, A.; Lewin, M. Low Add-on Levels of Chemicals on Cotton and Flame Retardancy. Text. Res. J. 1973, 43, 689–691. [Google Scholar] [CrossRef]

- Braun, U.; Bahr, H.; Sturm, H.; Schartel, B. Flame retardancy mechanisms of metal phosphinates and metal phosphinates in combination with melamine cyanurate in glass-fiber reinforced poly(1,4-butylene terephthalate): The influence of metal cation. Polym. Adv. Technol. 2008, 19, 680–692. [Google Scholar] [CrossRef]

- Braun, U.; Schartel, B. Flame Retardancy Mechanisms of Aluminium Phosphinate in Combination with Melamine Cyanurate in Glass-Fibre-Reinforced Poly(1,4-butylene terephthalate). Macromol. Mater. Eng. 2008, 293, 206–217. [Google Scholar] [CrossRef]

- Levchik, S.V.; Wilkie, C.A. Char formation. In Fire Retardancy of Polymeric Materials; Grand, A.F., Wilkie, C.A., Eds.; CRC Press: Boca Raton, FL, USA, 2000; pp. 171–215. [Google Scholar]

- Lewin, M. Physical and chemical mechanisms of flame retarding of polymers. In Fire Retardancy of Polymers: The Use of Intumescence; Le Bras, M., Camino, G., Bourbigot, S., Delobel, R., Eds.; Royal Society of Chemistry Information Services: London, UK, 1998; pp. 3–32. [Google Scholar]

- Camino, G.; Costa, L.; Trossarelli, L.; Costanzi, F.; Pagliari, A. Study of the mechanism of intumescence in fire retardant polymers: Part VI—Mechanism of ester formation in ammonium polyphosphate-pentaerythritol mixtures. Polym. Degrad. Stab. 1985, 12, 213–228. [Google Scholar] [CrossRef]

- Peng, H.Q.; Wang, D.Y.; Zhou, Q.; Wang, Y.Z. An S- and P-containing Flame Retardant for Polyprolylene. Chin. J. Polym. Sci. 2008, 26, 299–309. [Google Scholar]

- Horacek, H.; Grabner, R. Advantages of flame retardants based on nitrogen compounds. Polym. Degrad. Stab. 1996, 54, 205–215. [Google Scholar] [CrossRef]

- Levchik, S.V. Introduction to flame retardancy and polymer flammability. In Flame Retardant Polymer Nanocomposites; Morgan, A.B., Wilkie, C.A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 1–19. [Google Scholar]

- Weil, E.D. Synergists, adjuvants and antagonists in flame retardant systems. In Fire Retardancy of Polymeric Materials; Grand, A.F., Wilkie, C.A., Eds.; CRC Press: Boca Raton, FL, USA, 1999; pp. 115–145. [Google Scholar]

- Parikh, D.V.; Calamari, T.A.; Peterson, D.B. FR/Resilient perpendicular-laid nonwovens containing cotton. AATCC Rev. 2002, 2, 33–37. [Google Scholar]

- Reeves, W.A.; Perkins, R.M.; Piccolo, B. Some chemical and physical factors influencing flame retardancy. Text. Res. J. 1970, 40, 223–231. [Google Scholar] [CrossRef]

- Weil, E.D.; Levchik, S.V. Flame retardants in commercial use or development for textiles. J. Fire Sci. 2008, 26, 243–281. [Google Scholar] [CrossRef]

- Gaan, S.; Sun, G. Effect of phosphorus flame retardants on thermo-oxidative decomposition of cotton. Polym. Degrad. Stab. 2007, 92, 968–974. [Google Scholar] [CrossRef]

- Minimum Oxygen Concentration to Support Candle-Like Combustion; ASTM D-2863-09; American Society for Standards and Testing: West Conshohocken, PA, USA, 2009.

- Standard Test Method for Flame Resistance of Textiles; ASTM D-1230-01; American Society for Standards and Testing: West Conshohocken, PA, USA, 2001.

- Standard Test Method for Flame Resistance of Textiles (Vertical Test); ASTM D-6413-11; American Society for Standards and Testing: West Conshohocken, PA, USA, 2011.

- Hendrix, J.E.; Bostic, J.E., Jr.; Olson, E.S.; Barker, R.H. Pyrolysis and combustion of cellulose. I. Effects of triphenyl phosphate in the presence of nitrogenous bases. J. Appl. Polym. Sci. 1970, 14, 1701–1723. [Google Scholar] [CrossRef]

- Pacsu, E.; Schwenker, R.F. The effect of chemical modification on the flame and glow resistance of cotton cellulose. Text. Res. J. 1957, 27, 173–175. [Google Scholar] [CrossRef]

- Liu, S.M.; Yang, Y.; Jiang, Z.J.; Zhou, Y.H.; Zuo, J.; Zhao, J.Q. Synergistic flame retardant effect of poly(ether sulfones) and polysiloxane on polycarbonate. J. Appl. Polym. Sci. 2012, 124, 4502–4511. [Google Scholar] [CrossRef]

- Varga, K.; Noisternig, M.F.; Griesser, U.J.; Alja, L.; Koch, T. Thermal and Sorption study of Flame-Resistant Fibers. Lenzinger Ber. 2011, 89, 50–59. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).