Abstract

In this study, various wood material sources were used for the manufacture of wood-polymer composites (WPC). The materials were categorised as virgin wood particles (VWP), reprocessed WPC particles (RWP) and recycled thermoset composite particles (RCP) and derived from two virgin wood sources, three-layer particleboards, medium-density fibreboards (MDF) boards, or two different wood/polypropylene composites. All produced wood-polypropylene compounds contained 60% wood material and were manufactured using a co-rotating extruder. Malleated polypropylene was used as a coupling agent. Specimens were injection moulded and subsequently tested for their physico-mechanical properties. To characterize particles before and after processing, dynamic image analysis (DIA) measurement were performed. Additionally, X-ray micro-computed tomography (XµCT) was used to characterize the internal structure of the composites and to verify the obtained particle’s characteristics. It was found that length and aspect ratio of particles were remarkably different before and after processing (loss in length of 15–70% and aspect ratio of 10–40%). Moreover, there were notably differences between the particle sources (RCP retained the highest length and aspect ratio values, followed by VWP and RWP). The results suggest that increased aspect ratios can indeed significantly improve mechanical properties (up to 300% increase in impact bending strength and 75% increase in tensile strength, comparing WPC based either on virgin spruce or MDF material). This phenomenon is suggested to be partially superimposed by improved dispersion of particles, which is expected due to lower variance and increased mechanical properties of RWP composites. However, no notable alterations were observed for composite density. Reprocessed WPC and, particularly, RCP material have proved to be an appealing raw material substitute for the manufacturing of wood–polymer composites.

1. Introduction

In the last decades, wood-polymer composites (WPC) have emerged as one of the most promising class of hybrid composites. The broad segment of products ranges from building products, for example, deckings and claddings, to infrastructure and transportation. The performance of WPC is affected by wood content, applied process and additives [1,2]. The interfacing of both industries appeared to be beneficial and challenging as these industries have very different knowledge, expertise, manufacturing processes and perspectives [3]. In recent years, the market for WPC has steadily grown driven by the development of innovative and advanced concepts regarding product design, manufacturing technology, marketing strategies and the utilization of alternative raw materials [4]. For the manufacturing of WPC, by-products from the timber and timber-based industry are mostly used. These sources contain commonly softwood such as pine and spruce. With regard to changes in policy and concepts currently applied in silviculture in Germany, the availability of softwoods is decreasing [5]. For example, the support of sustainable biomass energy and new forestry concepts with focus on deciduous trees, lead to a raising demand on existing raw materials. In other words, these concepts lead to a further increase in pricing of these raw materials [6]. This trend will induce additional thoughts regarding the use of other materials (e.g., beech wood) available and cascade use in the near future.

One solution to encounter the up-coming scarcity of virgin softwoods it is suggested to be the utilization of recycled material sources, including both recycled polymers and wood for WPC manufacturing. Nonetheless, nationwide recycling systems are still missing, in-house reprocessing on side is already performed by several WPC producers. In case of in-house reprocessing, monitoring their own waste streams is easy, production costs can be reduced and a sustainable resource utilisation can be established. In regard to polymers, studies revealed that the performance of WPCs based on recycled polymers, particularly from isotactic polypropylene and high-density polyethylene, are only inferior to those of WPC based on virgin polymers [7]. As indicated by Winandy [8], many WPC companies in the United States use recycled polymers and also reprocess their own material. Apart from recycled polymers, recycled wood products and fibre material sources have shown that they also could be a valuable raw material source. Besides post-consumer wood pallets [9] and wooden poles [10], lignocellulosic fibres from newspapers, old corrugated containers [11,12,13] and thermomechanical pulp fibres [14] are considered to be valuable material sources for WPC. Other studies revealed the feasibility of particleboard [15] and fibreboard material [16] for wood-polypropylene composites. Especially the latter materials are of major interest as over 93 million m3 of particleboards and 97 million m3 of medium-density fibreboards (MDF) were produced around the world in 2016 [17]. The latter material is of major interest, particularly as the commercial MDF production just began in 1965 and 1973 in USA and Europe, respectively. Besides the well-studied recycling potential of particleboard materials, however, there is, to date, no commercially accepted method to recycle MDF [18]. Therefore, the material is burnt or stockpiled [19]. As estimated by Mitchell and Stevens [20] and Irle et al. [19] between 18% and 25% of the MDF board production volume is converted to waste in the form of off-cuts, machining errors, transport and storage losses only during the first year.

Teuber et al. [21] stated that under consideration of environmental issues and the scarcity of nationwide recycling systems, WPC can contribute to a sustainable use of raw materials and cascade utilisation. In this regard several studies indicated that environmental (e.g., by chemical modification, impact modifier etc. [22]), life cycles impacts (e.g., by the extrusion process, used additives etc. [20,23]) and, therefore social acceptability and health concerns [24] would also need to be addressed. In comparison to solid wood, WPC reveals environmental burdens as the carbon dioxide impact of processing WPC is higher than of the processing solid wood [25,26,27]. Nonetheless, WPC is indicated to be an eco-friendly alternative in comparison to neat polymers, particularly when recycling materials and biopolymers are used [26,27]. In case of biopolymers, their eco friendliness is still point of controversy discussions based on several life cycle assessment studies stating the effect on various impact categories or the lack of available data for new polymer materials [28,29]. For example, Yates and Barlow [28] indicated that the environmental impacts in several impact categories (e.g., intensive agricultural land use) are often higher for biopolymers in comparison to petrochemical plastics, although further improvements for the environmental profile of biopolymers can be expected.

From a material point of view, the reprocessing and reuse of recycled materials provide a great opportunity for producing new materials with comparatively enhanced properties. Nevertheless, several constraints have to be considered (e.g., thermal and oxidative degradation, polymer chain scission and decrease of molecular weight, wood particle/fibre degradation) towards using alternative material sources or exposing the material to several reprocessing cycles [30,31,32,33,34].

With regard to the wood materials utilized for the manufacture of WPC, the initial material can be classified as fibres or particles regarding their size and morphology. A number of studies demonstrated that the size and morphology strongly influence the physico-mechanical properties of WPC [35,36,37]. By using wood material with a decent aspect ratio, the properties are expected to improve [38]. However, length and aspect ratio of fibres or particles are often severely reduced during processing and thus no improved mechanical properties can be obtained [30,31,39,40,41,42,43]. In order to consider reprocessing WPC, other raw material sources, or a multiple material utilization, we need to gain further knowledge about particle characteristics and the structural properties of WPC. When it comes to the study of the internal structure of WPC, imaging techniques (e.g., light and electron microscopy) are usually used. These techniques have obstacles because they are restricted to 2D observations and are destructive in nature. To examine the actual and three-dimensional (3D) structure of WPC, X-ray micro-computed tomography (XµCT) revealed to be a valuable tool for structural examinations [44]. For the characterisation of extracted particles from WPC composites, 2D image analysis-based measurement like dynamic image analysis (DIA) are used.

In regard to alternative wood sources for the manufacture of WPC, the effect of different raw material sources on physico-mechanical properties of WPC is aimed in this study. Therefore, different raw material types (VWP: virgin wood particles; RWPs: reprocessed WPC particles; RCPs: recycled thermoset composite particles) were used. Apart from physico-mechanical properties, we examined the structural properties of these WPC. We assume that the physico-mechanical properties of WPC made of reprocessed materials improve due to structural homogenization. Furthermore, we hypothesize that the adhered resin residues of the recycled composite materials may increase the adherence to the polypropylene matrix. Apart from material properties, we assume that there are major differences in particle size between the material sources and due to processing. Therefore, we aim to contribute to refine the understanding of WPC and the utilization of alternative raw material sources by:

- Examining various raw material sources, such as virgin wood, reprocessed WPC, particleboard and MDF board material, for wood-polypropylene composites

- Quantifying the development of particle characteristics before and after processing through DIA and XµCT

- Visualising the internal composite microstructure and particle characteristics through XµCT imaging

- Identifying the effect of altered particle characteristics on physico-mechanical properties

2. Materials and Methods

For the production of WPC, isotactic polypropylene (PP) Sabic 575P (Sabic Europe, Sittard, The Netherlands) was used in this study. Licocene PP MA 7452 TP (MAPP; Clariant SE, Mutterz, Switzerland) was used as coupling agent. Three materials types were used as fillers: virgin wood particles (VWPs), reprocessed WPC particles (RWPs) and recycled thermoset composite particles (RCPs). As listed in Table 1, two different particle sources were selected for every particle type. As virgin wood particles (VWPs), we used either spruce (Picea abies (L.) Karst.) or beech wood (Fagus sylvatica L.). As reprocessed WPC particles (RWPs), we used the manufactured WPC materials, respectively. As recycled composite particles (RCPs), we used either material derived from particleboards or MDF boards.

Table 1.

Composition of WPC formulations. SID: sample identification; VWPs: virgin wood particles; RWPs: reprocessed WPC particles; RCPs: recycled composite particles.

As particleboard (PB) material, we used three-layer particleboards (n = 10) with a density of 650 kg m−3, a thickness of 15 mm and adhesive contents of 10% in the surface layer and 8.5% in the core layer based on oven dry weight of particles. All PBs were produced from mixtures of 60% beech and 40% spruce wood particles. Beech wood chips were used in the core and spruce particles in the surface layer with an amount of 60 and 40 weight percent, respectively. The urea–formaldehyde adhesive, Kaurit 350 (BASF, Ludwigshafen, Germany) was mixed with 3.5% (based on solid adhesive mass) ammonium sulphate as a hardener. The adhesive was applied in a rotary drum, using a spraying nozzle to assure homogeneous adhesive distribution. The rotary drum was operated at 30 rpm. The particles were hand spread into a mould (450 × 450 mm2) and subsequently cold pressed to enhance the rigidity of the mat. Thereafter, the mat was pressed at 200 °C and 200 bar for 15 s mm−1 in a hot-press (HP-200 Lab, Joos, Pfalzgrafenweiler, Germany) using stops to ensure a target thickness of 15 mm.

As MDF input material, we used MDF boards (n = 10) with a density of 800 kg m−3, a thickness of 16 mm and adhesive contents of 12% (UF, Kaurit 350). The MDF boards were supplied by the Fraunhofer Institute for Wood Research (WKI, Braunschweig, Germany). For the production of the MDF fibres, peeled beech logs with a high amount of multi-coloured heartwood were used. All PBs and MDF boards were conditioned at 20 °C and 65% RH for 28 days before further processing.

For the production of WPC, all particles were prepared in two steps using a hammer mill with a prior aperture size of 15 mm followed by an aperture size of 1 mm. Debarked panels of Norway spruce and European beech were used as virgin wood source, respectively.

2.1. WPC Manufacturing Process

The respective particle type (VWP, RWP, RCP), polymer and coupling agent were compounded to granulates at 170 °C mould temperature using a Leistritz MICRO27GL/GG40D co-rotating twin-screw extruder (TSE) (Leistritz Extrusionstechnik GmbH, Nürnberg, Germany) with two gravimetric feeders (Brabender GmbH&Co. KG, Duisburg, Germany) and a hot-cut pelletizer. A screw design with well distributed kneading elements (design A) was used [45]. The TSE is equipped with 10 heating barrels. The temperature profile ranged from 150 °C to 180 °C. The die temperature was 145 °C. The mass temperature at the 4-point die ranged between 140 °C and 145 °C. The screw rotating speed was adjusted to 80 rpm, resulting at a throughput of 3.5 kg h−1. For pelletization, a hot die-face system was applied with a rotating cutting knife at a velocity of 300 rpm. All compounded formulations were injection moulded in an Arburg Allrounder 320 C (Arburg GmbH + Co. KG, Loßburg, Germany). A 2 + 2 multi cavity tool was used for the production of specimens. Two bending specimens (80 × 10 × 4 mm3) and two tensile dog bone shaped tensile specimens (type 1A) were produced with each injection moulding cycle, respectively. In total, fifty specimens of each formulation were processed according to the requirements of testing. The injection moulded pressure ranged between 1400 bar and 1900 bar at a temperature of 185 °C.

2.2. Particle Separation

For particle characterisation via dynamic image analysis (DIA), particles were separated from the injection moulded polypropylene matrix via Soxhlet extraction in hot xylene for 10 h. The separated particles were dried for 48 h at 103 °C to remove excess solvent and moisture. Unprocessed particles underwent concurrently the same extraction process to exclude any effect of the extracting method on particle characteristics. Their length and aspect ratio were compared to the initial particle values.

2.3. Dynamic Image Analysis (DIA)

Particle length and aspect ratio were examined by using dynamic image analysis (DIA). The analyser (QICPIC, Sympatec GmbH, Clausthal-Zellerfeld, Germany) was connected to a vibrating chute (VIBRI) and a particle disperser (RODOS). The particles were dispersed in air and transported in a laminar air stream passing a laser light and an optical detector. The detector was able to collect a 2D-image of every particle between 5 µm and 5000 µm. Each particle was analysed using a skeletonization algorithm determining the shortest distance between the farthermost endings to calculate the particle length (LEFI). The projected area of the particle was divided by the total length of the skeleton sections, which coincides with the particle diameter (DIFI). All particles were classified into 50 length classes. Aspect ratios (AR) were calculated for each class by the division of mean LEFI and mean DIFI. Particle distribution was calculated by relative amount of each class and summarized cumulatively based on particle length (Q1).

2.4. X-ray Micro-Computed Tomography (XμCT)

Three samples of each composite were analysed using X-ray micro-computed tomography (XµCT) imaging. The lab-based XµCT device Nanotom® s (GE Sensing & Inspection Technologies GmbH, Wunsdorf, Germany) was used to image the samples at 70 kV and 180 µA and an isotropic voxel size of 5 µm. The actual three-dimensional (3D) datasets were reconstructed using Datos 2.0 software (GE Measurement & Control, Billerica, MA, USA) and further processed with Avizo Fire 9.2 software (Thermo Fisher Scientific, Hillsboro, OR, USA).Virtual slices were visualized close to the centre of the 3D reconstructed model to illustrate the internal structure of the following two regions:

- In-plane view or xz-plane view–virtual slice parallel to the melt flow.

- Orthogonal view or xy-plane view–virtual slice perpendicular to the melt flow.

In addition, a 3D volume of RWPs (blue) and RCPs (red) has been isolated for closer inspection to highlight the spatial organization of the woody components. Three region of interest (ROIs) were selected in every sample with a size of . Each ROI was analysed concerning the average grayscale values of X-ray attenuation. Based on the X-ray attenuation, different phases (air, polymer and wood) were extracted from the XμCT data by thresholding and a marker-controlled watershed algorithm using defined foreground and background regions [44]. The watershed algorithm generates a topographical map from the image gradient and therefore identifies catchment basins and watershed ridge lines. The obtained values of the selected ROIs per sample (n = 9) were averaged and treated as homogenous group. For particle characterization, the feret diameter was applied. The feret diameter represents the distance between parallel tangents on the opposite of the image of randomly oriented particles [46]. Particle length and width were determined using the maximum and minima of the feret diameter, respectively. The aspect ratio was calculated by dividing the FeretMax by FeretMin.

2.5. Physico-Mechanical Properties of WPC

Tensile strength and tensile modulus of elasticity (tMOE) were determined according to DIN EN ISO 527-1 (2012) [47] (n = 10), using a crosshead speed of 2 mm min−1. Flexural strength (MOR, modulus of rupture) and flexural modulus (fMOE) were tested according to EN ISO 178 (2010) [48] (n = 10). For these tests, a Zwick/Roell universal testing machine (ZwickRoell GmbH & Co. KG, Z010 Allround Line, Ulm, Germany) was used. Unnotched impact bending (Charpy) was performed according to EN ISO 179-1 (2010) [49] by using a Ceast, Resil Impactor (pendulum energy 1 J, n = 10). Density was determined according to EN ISO 1183-1 (2013) [50] (n = 5) using the immersion method. Prior to testing, all samples were conditioned in a climate chamber at 20 °C and 65% RH for 28 days.

A Kolmogorov-Smirnov normality test was carried out using Excel 2016 (Microsoft, Redmont, WA, USA) to confirm a normal distribution of the experimental results. For the normal distributed sample sets a two sample unequal variance (heteroscedastic) t-test was used to evaluate significant differences.

3. Results

3.1. Internal Structure and Particle Characterization

The results from the particle measurements are illustrated in Table 2, giving the particle length and aspect ratio of the examined samples. Each sample can be identified by their SID. The results are clustered by raw and extracted particle sources, whereby, the raw particle values have to be seen as initial values before processing. In addition, the samples are clustered by particle type. Particle length and aspect ratio are presented for the 10, 50 and 90 quantile (X10, X50, X90) of the length-based distribution.

Table 2.

Length and aspect ratio of particles for the X10, X50, X90 quantiles in dependence on used material source. The results are presented for the particles before (initial) and after processing (extracted). SID: sample identification. Particle type: VWPs (virgin wood particles), RWPs (reprocessed WPC particles), RCPs (recycled composite particles).

Between the various samples, particle length and aspect ratio were found to be noticeably different. Due to processing, altered particle characteristics are shown between raw and extracted particle sources. Length and aspect ratio reductions are clearly visible across all quantiles: mean length is reduced up to 60%. Reprocessing of WPC further reduces particle length and aspect ratio within all quantiles: mean length is reduced by up to 44%.

Comparing the different particle types, RCP particles exhibited higher aspect ratios compared to all other particle sources. Regarding the two RCP sources, MDF and particleboard particles differed notably. Depending on the quantile, considerably higher aspect ratio values are observed for MDF sources for both initial and extracted particles. By example, the mean values for extracted MDF and particleboard particles were 3.8 and 2.8, respectively.

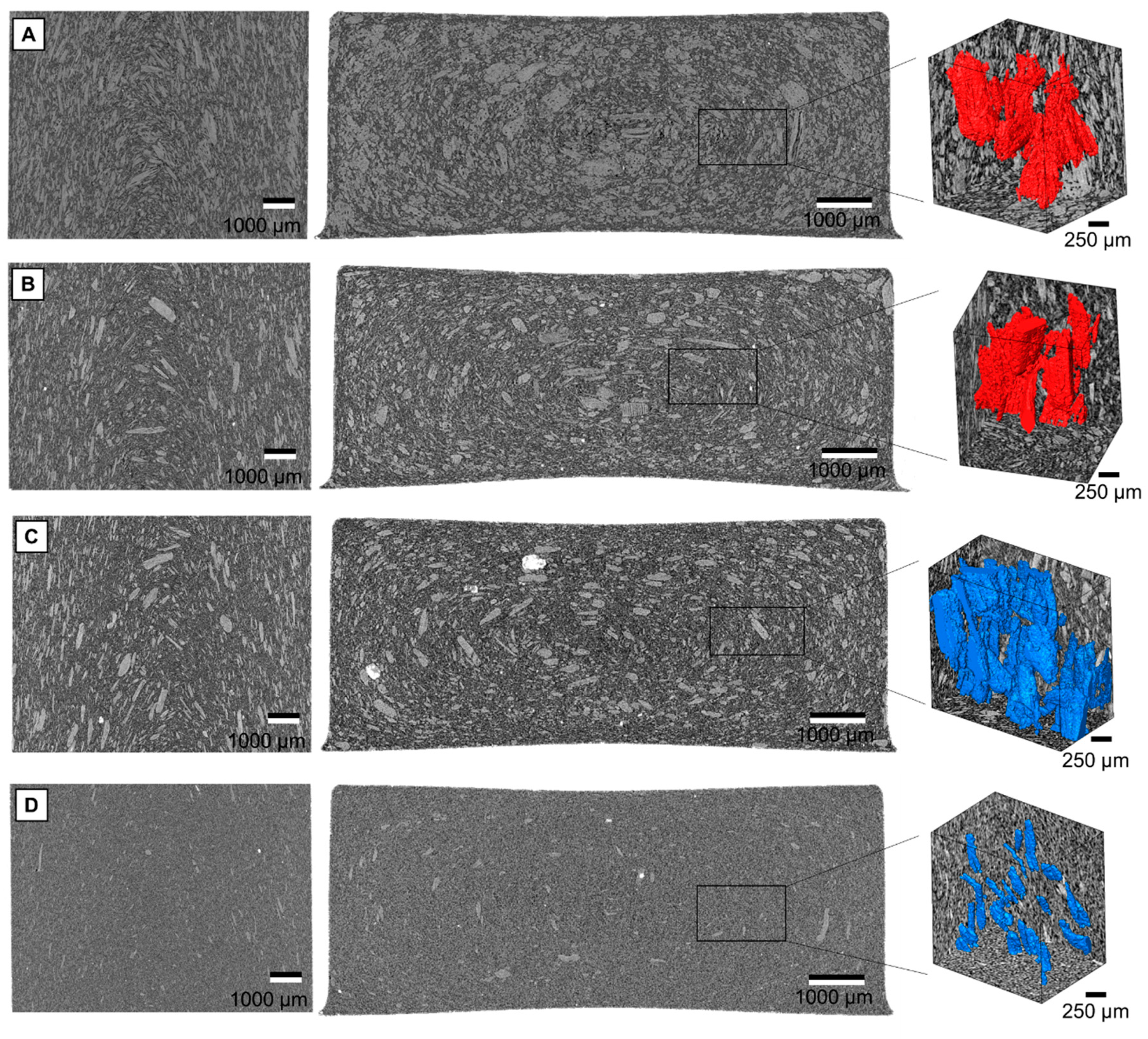

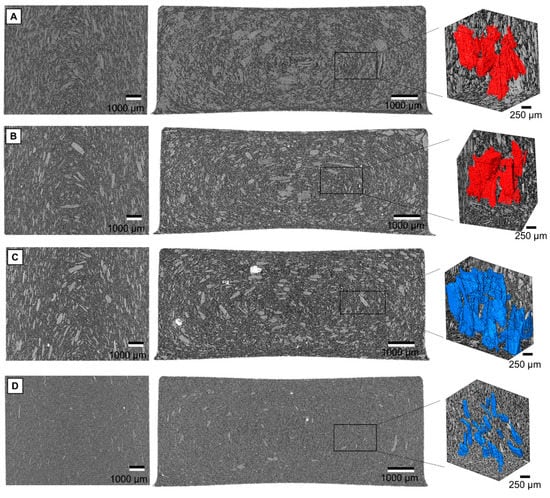

The XµCT images in Figure 1 visualizes the internal structure of the composites. Through XµCT, we were able to qualitatively and quantitatively analyse the particles/fibres in WPC, regarding their size, morphology and their spatial alignment. Regarding the images of the material composition, the air fraction is visualized in black, while wood particles and polypropylene matrix were marked in light grey and dark grey colour, respectively. High absorbing particles are highlighted in a bright white colour. In order to visualize the spatial structure of wooden components, the largest 10% of wood particle/fibres were highlighted within an isolated 3D volume in red (RWPs) and blue (RCPs), respectively.

Figure 1.

X-ray micro-computed tomography of four injection moulded WPC specimens based on RWPs [A: R-WPC (B); B: R-WPC (S)] and RCPs [C: WPC (PB), D: WPC (MDF)]. (Left) In-plane view of WPC samples showing wood particle/fibre length and alignment along the melt flow. Note the parallel aligned wood particles/fibres close to the surface layer, whereby within the inner core, the wood fibres/particles are aligned perpendicular to the melt flow. Wood particles/fibre are evenly distributed in all specimens but notably shorter and thinner within WPC (MDF). (Middle) Orthogonal view of specimens showing wood particle/fibre diameter and distribution. Note the high amount of thick wood fibre bundles within the reprocessed WPC ([A,B]). In addition to the wood particles bundles within the recycled WPC (PB) [C], high absorbing particulates (white) were observed. (Right) A 3D volume of wood tissue (blue) and wood fibre/particle agglomerations (red) has been isolated for closer inspection to highlight the spatial organization of the woody components. Scale bars = 1000 µm/250 µm.

XµCT imaging revealed that wood particles were present in all composites and particles/fibres were diverse in size, morphology and their spatial alignment (see Figure 1). We qualitatively observed that wood particles appeared to be dispersed homogeneously within all analysed composites. However, no model approach was applied for estimating and evaluating the quality of particle dispersion. An enriched layer of polymer was observed at the surface of all composites. Close to the surface, the particles were spatially aligned along the melt flow. Within the core layer, the particles were aligned perpendicular to the melt flow. The particle material were mostly wood fibre bundles and occurred frequently in all composites. In addition to the clearly depicted fibre bundles, we also observed single fibres, wood particle fragments and small particle agglomerations. Besides the wood particle characteristics, we observed the typical anatomical features within the fibre bundle structures. Vessel and tracheid elements were clearly observed in WPC and reprocessed WPC, respectively, whereas these structures appeared to be partially filled with polymer. In addition to the anatomical features, we noticed high absorbing particulates within the RCP composites. In contrast to all other composites, the MDF composites revealed a high amount of thin particles/fibres and fewer enlarged fibre bundles. Overall, it needs to be noted that particle structures below 20 µm were hard to separate from the surrounding matrix.

After phase separation and binarization, the composition and particle microstructure of the wood-polymer network were analysed. We quantified the phase fractions per volume (polymer, wood and void space) and length and aspect ratio of wood particles. For each composite, the results are listed in Table 3.

Table 3.

Results of the quantification of different phases (polymer, wood and void space) located in the manufactured wood-polypropylene composites. Values represent the mean with standard deviation in parenthesis of three-dimensionally labelled phase fractions and wood particles, respectively. The phase fractions were listed based on their tomographic (voxel) fractions [v%].

The accounted average length of particles were notably greater than the obtained length of particles after extraction. Through XµCT, the obtained mean length of particles were 362 to 410 µm. The total amount of particles were 1534 to 2025 per sample. The average aspect ratio were 2.6 to 7.5. It is evident that the obtained values for MDF WPCs are highest, while for all the other composites aspect ratio is nearly reduced by half. The average void fractions were between 0.16% and 0.62%. For most of the composites, void space were obtained both in the core layers surrounded by polymer and within larger particle/fibre bundles. The latter was primarily observed for the RWP composites. The average size of voids were 20 µm in size. The obtained average volume fraction of wood material ranged between 56.4% and 58.9% within the manufactured composites. Moreover, high absorbing particles were detected and partially present within both RCP composites. For the WPC (PB), the particles amounted up to 1.1% in volume and 500 µm in size, whereby for the WPC (MDF), the particles amounted up to 0.3% in volume and 100 µm in size.

3.2. Physico-Mechanical Properties

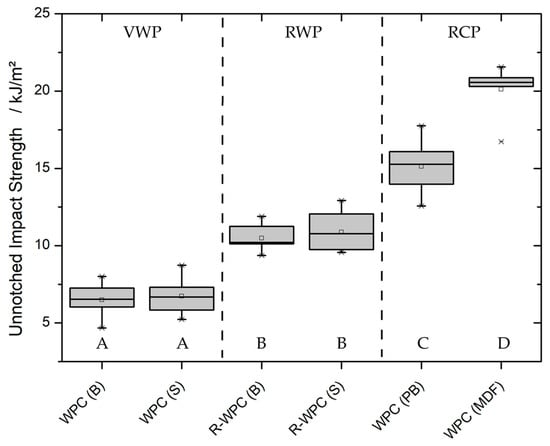

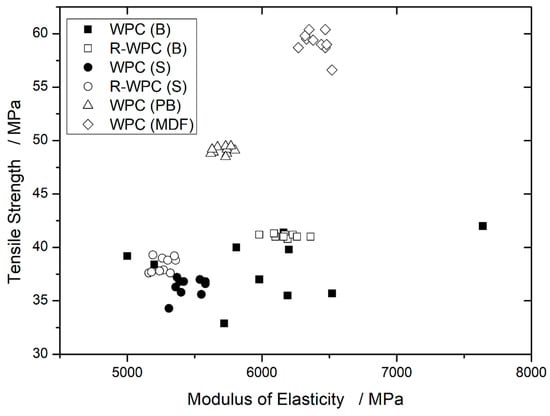

The results for all experiments investigating the physico-mechanical properties of the manufactured WPCs can be found in Table 4. For a simplified comparison, unnotched impact bending strength and tensile strength versus modulus of elasticity are illustrated in Figure 2 and Figure 3.

Table 4.

Physico-mechanical properties of injection moulded specimens of reinforced PP composites using various particle sources. Particle types: VWPs (virgin wood particles), RWPs (reprocessed WPC particles), RCPs (recycled composite particles).

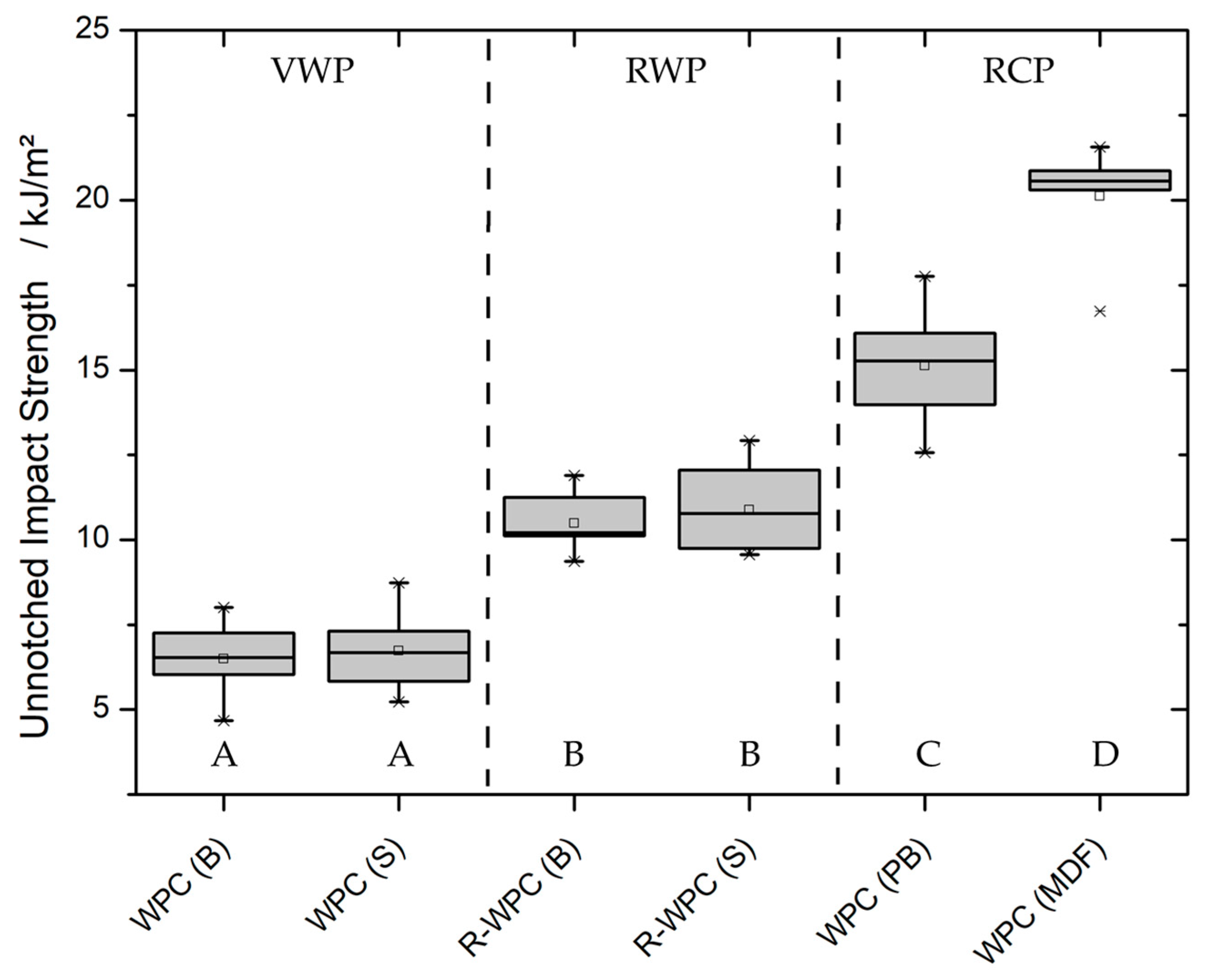

Figure 2.

Unnotched charpy impact bending strength of injection moulded wood-polypropylene composites based on various particle sources. Results of the statistical analyses are displayed, whereas values assigned with the same letter are not significantly different from each other at a significance level of α = 0.05.

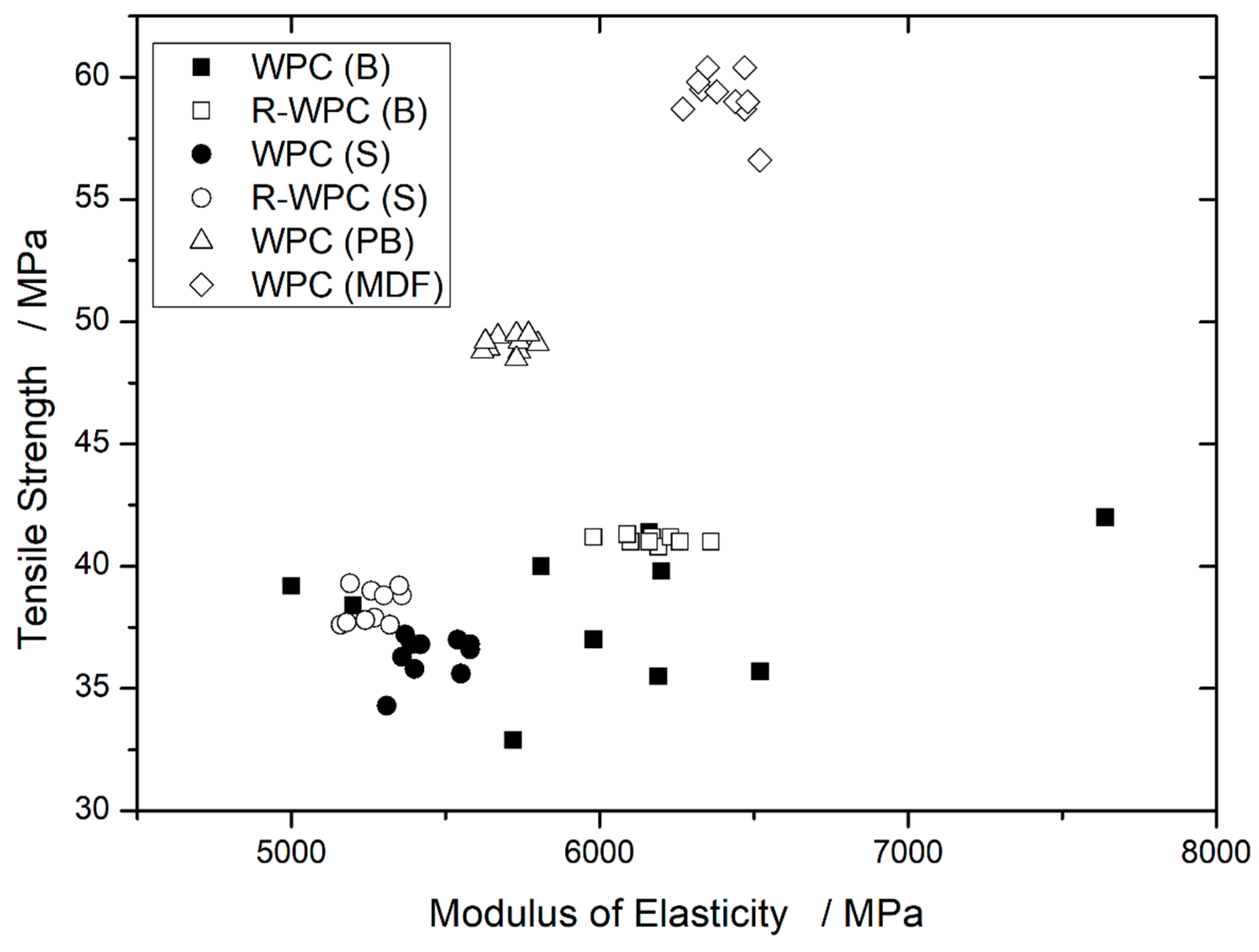

Figure 3.

Tensile strength and modulus of elasticity of injection moulded specimens of reinforced polypropylene composites using various particle sources. Tensile strength is plotted as a function of modulus of elasticity.

For all composites, there is a notable improvement in mechanical properties when WPC is reprocessed or RCP sources were used. In the case of composites based on MDF, the effect of improvements are far more pronounced than for all other composites. They provide higher tensile, flexural (MOR) and unnotched impact bending strength: compared to VWP composites, impact bending is tripled in case of WPC (MDF). The elasticity of composites is increased strongly upon the use of RCP, such as MDF, or beech wood particles. All composites exhibited comparable density values.

Figure 2 shows the results for unnotched charpy impact bending strength of the manufactured WPC specimens. The boxes are defined by the 25th and 75th percentile. The results reveal the pronounced effects of reprocessing and the utilization of RCP sources. With regard to reprocessing, significant differences between the VWP WPC and RWP WPC were observed: impact bending values increased up to 60% after reprocessing. In case of RCP materials, significant differences between PB and MDF based WPC were observed: impact bending values increased 33% when MDF were used.

Figure 3 shows the results for tensile strength and modulus of elasticity of the injection moulded specimens. Tensile strength is plotted as a function of the modulus of elasticity obtained from the same experiment.

It is evident that the obtained values for both VWP composite clusters are clearly varying. Reprocessing of composites resulted in notable lower variance and increased tensile strength values. The RCP composites revealed increased tensile strength and comparable clusters as the RWP composites.

4. Discussion

The following sections discuss the results and effects of various wood material types (VWP, RWP and RCPs) on particle characteristics, internal composite structure and physico-mechanical properties of WPC. One key focus was to examine and evaluate the altered particle characteristics due to processing. The aim of reusing wood material sources (i.e., thermoplastic or thermoset wood based composites) is to provide a multiple material utilisation of material sources and by-products from manufacturing processes.

4.1. Internal Structure and Particle Characterisation

Besides other factors (e.g., particle dispersion, orientation and matrix adhesion), particle length and aspect ratio are major factors effecting the reinforcing efficiency of fibrous lignocellulosic particles in the polymer matrix. In accord with previous studies on wood particle/fibre degradation due to processing [44,45,51,52], length and aspect ratio of particles are remarkably reduced by extrusion and injection moulding. In our study, however, we obtained retained particle length and aspect ratio values after extracting the particles from the polypropylene matrix. The mechanical results indicate that retained particle length and aspect ratio led to improved properties.

Along with the changed particle characteristics, we revealed notable alterations within the formed internal composite microstructure. As known from the literature, there is an alignment of wood particles within all composites [53,54]. Through XµCT imaging and in agreement with recent publications, we observed a parallel alignment of wood particles close to the surface (in-plane images) and perpendicular to the compression direction. Given the phenomena of particle/fibre alignment throughout injection moulding [53,54], we expected an altered spatial material distribution scaling between used raw material source and applied process. This assumption is supported by a previous work on TMP fibres and a novel compounding process [44]. In addition to the alignment, the occurrence and spatial distribution of void spaces might contributed to a reduced vulnerability and increased performance of polypropylene composites [[44]; Table 4 therein]. It is also possible that due to the partial-volume effect and a spatial resolution of 5 µm, smaller void structures were not detected. In terms of tomographic image analysis, we also observed a small amount of highly absorbing particulates within the composites based on RCP material. These particles are likely glue residues, penetrated the wood particles. However, other factors as coupling agent and particle/fibre agglomerations have to be considered. MAPP improves adhesion as the maleic moieties form bonds with the hydroxyl groups of the wood component [55], whereby the scarcity of noticed aggregates within the microstructure is in contrast to the improved mechanical properties after reprocessing. As indicated by Bledzki and Gassan [56], the tendency of wood to form aggregates, by means of a high intermolecular bonding among particles/fibres, is an important factor in processing wood–thermoplastic composites. According to them, the dispersion of particles in the polymer matrix is small and, therefore, the reinforcing ability of the particle is limited. For the extracted particles, however, we observed vast differences between VWP and RWP composites, respectively. However, we did not observe a difference within the XµCT images. Therefore, we hypothesise that the observed and analysed particles are already remarkably effected by shear stress and subsequently fractured by reprocessing. In other words, such fractures of wood particle bundles could not certainly be detected with imaging methods like XµCT. This needs to be noted because the internal composite structure is often only based on visual and qualitative assessment. Although, efforts have been made to develop quantification approaches and suitable tools for evaluating the material composition (e.g., [57,58,59,60]). Nonetheless, visual assessment is simple and rapid and often sufficient. It is however important to evaluate the spatial distribution of particles according to a scale indicating measurable units to keep the visual assessment as objective as possible. As our results illustrate, evaluations of particle structures should include evaluation of additional characteristics for example mean volume percentage and particle length. This can be challenging to objectively evaluate visually. Thus, supplementing visual assessment with threshold-based evaluations can be nonetheless valuable in order to obtain a better understanding of the structural characteristics. Thus, the microstructure of the wood-polymer network were visualized and separated phases (polymer, wood and, void space) were identified. Apart from quantification, the largest 10% of wood particle/fibres were highlighted within an isolated 3D volume to illustrate both the differences in particle size and morphology and the clusters within the wood-particle 3D network. In this case, thresholding and separation of especially small structures is challenging and, thereof, difficult to resolve features within a submicron range. Due to the mixed grey values of small particles and polypropylene, only larger particles or larger fibre bundles were easily distinguishable. In addition, we assumed that in some regions the depict layers of polypropylene were thinner than the achieved spatial resolution (5 µm). In this case, the polypropylene matrix was measured together with the wood particles. Hence, a detection of an interfacial failure within the polymer matrix could not be realized. Besides the obvious wood particles, small air pores/voids are displayed in the inner core layer of all composites. A direct association to the particle mixtures was not yet evident. A reduction of micro-sized voids were detected within the RCP composites and the WPC (MDF) in particular. Here, the tendency of less void space within the internal composite structure was also suggested by the slightly increased density value of the RCP composites. However, void space and its spatial distribution is not supposed to be totally prevented due to the given hydrophilic nature and hierarchical structure of the wood tissue, flow behaviour and relaxation of the polymer, methodical approach and settings of the process. For most of the composites, void space were obtained both in the core layers surrounded by polymer and within larger particle/fibre bundles. The latter was primarily observed for the WPC(B) and R-WPC(B). The average void were 20 µm in size.

4.2. Physico-Mechanical Properties

The mechanical properties were remarkably different, although, all raw material sources were affected by the same processing parameters, such as pre-milling, compounding and specimen consolidation. We suggest that both the altered particle characteristics and changed chemical interactions resulted in the observed different mechanical properties. Most of the obtained mechanical values accord with previous studies on lignocellulose reinforced WPC [42,61,62]. Apart from this, tensile and flexural strength properties of RCP composites and, particularly of WPC (MDF) were superior to other composites containing similar fibre contents. In this regard, a similar composition is important as the mechanical strength properties depend on various parameters. Thus, wood particle/fibre content is one of the main contributing factors on strength and elasticity [38,40]. In accordance to wood particle/fibre content, composite density is often ascribed as an important factor [2,40]. In this study, however, no remarkable differences between the composites were observed. Thus, strength properties have to be affected by other factors such as, increasing aspect ratio, fibre alignment and increased fibre-matrix interaction [63]. A high aspect ratio of MDF fibres before and after processing was observed and is supposed to notably contribute to the enhanced strength properties. We hypothesise that the retained fibre characteristics in combination with the fibre alignment resulted in the observed property increase. Fibre alignment has been stated to significantly affect the physico-mechanical properties of natural fibre-reinforced polypropylene composites [53,64,65]. A strong interphase between the wood-polypropylene matrix can only be suggested. Studies on polypropylene-glass fibre composites with varied MAPP concentrations have shown that transcrystalline layers can improve mechanical properties [55]. Nevertheless, further opposing effects like a sufficient dispersion of wood particles/fibres seems to be crucial to the performance of composites.

4.2.1. Recycled Thermoset Composite Materials

Solid wood sources are mostly free of contaminations while recycled materials from the production of derived wooden composites often contain additional components (e.g., adhesives, resins, coatings, abrasives particles), which possibly impact subsequent treatments or process adaptions before the introduction to WPC production [66]. Recycling residues from MDF production might also contain a high number of fine particles, whereas particle/surface area is increased, and more polymer is expected to bond the particles/fibres [54]. Concerning the increased mechanical properties of the composites based thermoset materials, we hypothesize that the retained particle/fibre length, which we observed here for the recycled MDF material, was the dominating effect for the reinforcement of the manufactured composites. Additionally, the thermoset resin residues are suggested to beneficially affect mechanical properties. Contributing to the latter, Slama [67] investigated sawn MDF residues containing cured urea-formaldehyde resin applied to reinforce polyethylene, which resulted in WPC with a higher hydrophobicity and dimensional stability than the control specimens made from virgin MDF fibres from the same producer. Migneault et al. [24] showed that the resin residues had beneficial effects on mechanical properties. In deviation from the results, the authors found in their study that the shorter fibre length of the residue material adversely affected mechanical properties [24]. Nevertheless, the statement of Migneault et al. [24] is difficult to compare, as alike many studies, only initial fibre length and, thereof much higher length and aspect ratio values were evaluated [16,68]. In comparison with studies considering the process induced particle changes, Mertens and Bütün [16,43] showed values for virgin and extracted fibres via Soxhlet extraction in hot xylene from wood fibre/polypropylene composites based on 60 w%. These values ranged between 1825 µm to 62 µm and 33.3 to 3.0 in mean length and aspect ratio for virgin and extracted fibres, respectively [43]. Compared to the composites based either on TMP (50 MPa) or recovered TMP fibres (49.0 MPa), tensile strength of WPC (MDF) (59.2 MPa) was remarkably increased [16,43]. Mertens et al. [43] recently discussed that a small amount of retentive fibres could be enough to reinforce the composite.

According to the strength values, this assumption seems to be valid as the adhesion is suggested to the remaining residues adhered to the particles/fibres. Surprisingly, the WPC (PB) based on beech and spruce particles with 60 and 40 weight per cent showed such improved performance. Deviating thereof, Grozdecki et al. [15] found no significant increase in strength values for wood-polypropylene composites based either on virgin softwood or industrial particleboard material. The influence on stiffness can be attributed to the type and morphology of particles. Hence, with the increase of beech or compressed beech fibre content the elasticity was also increased. Concerning impact bending strength, the RCP composites, namely WPC (MDF) and WPC (PB), revealed the highest values with 20.1 kJ m−2 and 15.1 kJ m−2, respectively. For the VWP composites, WPC (B) and WPC (S) revealed the lowest impact bending strength values with 6.5 kJ m−2 and 6.7 kJ m−2, respectively. The reprocessing of VWC brought a remarkable increase in impact bending values. Generally, impact strength indicates the ability of the composite to achieve a rapid transfer of stress into the bulk material. The avoiding of stress peaks can be attributed to stronger interfaces, as suggested above. Hence, compared to the VWP and RWP composites, RCPs revealed notably higher impact values. Compared to recent studies, the properties of the WPC (MDF) composites showed promisingly impact values [14,42].

4.2.2. Reprocessing of WPC

Even so that reprocessing or recyclability of WPC is still a minor subject in research [21], hitherto, several studies revealed that the issues has gained more interest in terms of scarcity of resources, mechanical and thermal degradation and particle degradation within lignocellulosic particle/fibre composites [32,33,69,70,71,72,73,74,75,76,77,78]. Repeated reprocessing usually results in reduced mechanical properties [32,70,71], several studies revealed initially increased mechanical properties after reprocessing wood/polypropylene composites [32,34,76,79]. For correlations between specific mechanical energy (SME) and particle degradation, the SME represents a direct measure for the energy imposed on the material [30]. Extruded wood flour polymer composites have revealed reduced flexural properties and minor changes in impact bending strength in polyvinyl chloride [33] but moderately steady tensile strength properties in polypropylene [34,76]. These findings accord with our results showing an initially increase in strength and stiffness after one reprocessing cycle (Table 4). The significant increase in impact bending strength is illustrated in Figure 2, where the RWP composites had and maintained, a remarkable advantage over the VWP composites. Increased mechanical values are generally attributed to improve interfacial bonding and enhanced dispersion of particles/fibres [69]. No obvious differences in particle dispersion were observed between VWP and RWP composites through XµCT. Regarding the increase in mechanical properties after one cycle, Dickson et al. [34], showed that decreasing properties can be expected for wood-polypropylene composites for more reprocessing cycles. A reduction in strength and elasticity values is stated upon more than two reprocessing cycles and attributed to incurred fibre damage [31,34,69]. The authors also revealed that compared to glass fibre composites, wood-polypropylene composites and, particularly MDF-polypropylene composites, may offer remarkable property retention up to several cycles of reprocessing [34].

4.2.3. Effect of Wood Species

The differences in mechanical properties of the WPC based on VWPs are likely affected by the wood particle source and the heterogenic and complex wood structure. As mentioned in several studies, the wood structure is featured by significant differences in mechanical properties, regarding the wood species and micro- and macroscopic structure [80,81]. The XµCT images displayed the anatomical structures of hardwoods, like the presence of vessels and tracheids as the principal element of softwoods [82]. Softening of lignin can influence the effect of temperature and moisture on the mechanical behaviour of wood [83], however, no higher compression of spruce particles were observed, resulting from an increased lignin content. Overall, besides the effect on composite structure and properties, open issues are still the effects of tree growth and harvesting conditions on composite properties [42].

5. Conclusions

The study has shown the feasible reuse of different material sources (virgin wood particles (VWPs), reprocessed WPC particles (RWPs), recycled thermoset composite particles (RCPs)) for manufacturing wood-polypropylene composites. Mechanical properties increased for WPC based on reprocessed or recycled materials. Apart from previous studies, the variation in composite properties could not be explained by density alone. Increasing aspect ratio of wood particles is suggested to have beneficial effects on all measured mechanical properties. Our observations are in agreement with previous studies that have examined particle length reduction or improvements in physico-mechanical properties due to reprocessing. Through X-ray micro-computed tomography (XµCT), the micro-structure of the wood-polymer network were visualized and separated phases (polymer, wood and void space) were identified. Regarding particle length measurements, DIA analysis and XµCT imaging revealed similar length values, except the notable differences for the reprocessed WPC. We suppose that the differences were attributed to factures and degradation of particles which were not evident through the depicted internal structure. In terms of the analysis of tomographic data, thresholding and separation of small structures is still challenging and it is difficult to resolve features sufficiently on a submicron range.

For further investigations, the following issues have to be considered to verify composite performance.

- Specific examination of the interfacial particle-matrix effect and particle surface interactions, that is, adherence of thermoset residues on stress transfer and water interaction.

- The scaling relationship of XµCT data and models to estimate quantitatively the dispersion of wood material sources.

- Effect of specific mechanical energy (SME) and process conditions on particle characteristics and the upscaling of the process to an industrial level.

In conclusion, WPC with beneficial mechanical performance can be produced using either RWP or RCP material sources as main input raw material. We believe that such approaches are necessary to encourage advanced recycling rates in the future. XµCT imaging has proven to be a valuable tool for examining the microstructure of wood-polymer networks. Imaging offers long-term perspectives to understand and develop composites with both a cascading material utilization and enhanced performance.

Author Contributions

Conceptualization, K.C.K. and A.K.; Formal analysis, K.C.K., P.S. and T.K.; Investigation, K.C.K. and T.K.; Methodology, P.S. and A.K.; Project administration, K.C.K.; Supervision, A.K.; Visualization, K.C.K., P.S. and T.K.; Writing–original draft, K.C.K.; Writing–review & editing, K.C.K., P.S., T.K. and A.K.

Funding

This research was funded by the Federal Ministry of Education and Research (BMBF), grant number 2210070. We acknowledge the Open Access Publication Funds of the Göttingen University.

Acknowledgments

We thank the Fraunhofer Institute for Wood Research (WKI) for providing MDF composites and the Department of Chemistry and Process Engineering of Composite Materials (University of Göttingen) for providing chipboards for our study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pothan, L.A.; Luyt, A.S.; Thomas, S. Polyolefin/Natural Fiber Composites. In Polyolefin Composites; Nwabunma, D., Kyu, T., Eds.; Wiley-Interscience: Hoboken, NJ, USA, 2008; pp. 44–86. [Google Scholar]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; p. 726. ISBN 978-0-470-16593-5. [Google Scholar]

- Clemons, C. Wood plastic composites in the United States: The interfacing of two industries. For. Prod. J. 2002, 52, 10–18. [Google Scholar]

- Carus, M.; Eder, A.; Dammer, L.; Korte, H.; Scholz, S.; Essel, R.; Breitmayer, E. Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC): European and Global Markets 2012 and Future Trends. Available online: http://www.bio-based.eu/markets (accessed on 6 June 2018).

- Dritte Bundeswaldinventur (BWi3)—Third National Forest Inventory. Available online: https://bwi.info (accessed on 7 June 2018).

- Mantau, U. Holzrohstoffbilanz Deutschland: Szenarien des Holzaufkommens und der Holzverwendung bis 2012. VTI Agric. For. Res. Sonderheft 2009, 327, 27–36. [Google Scholar]

- Kazemi Najafi, S. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef] [PubMed]

- Winandy, J.; Stark, N.; Clemons, C. Considerations in recycling of wood–plastic composites. In Proceedings of the 5th Global Wood and Natural Fiber Composites Symposium, Kassel, Germany, 27–28 April 2004; pp. 197–205. [Google Scholar]

- Stark, N.M. Wood fiber derived from scrap pallets used in polypropylene composites. For. Prod. J. 1999, 49, 39–46. [Google Scholar]

- Kamdem, D.P.; Jiang, H.; Cui, W.; Freed, J.; Matuana, L. Properties of wood plastic composites made of recycled HDPE and wood flour from CCA-treated wood removed from service. Compos. Part A Appl. Sci. Manuf. 2004, 35, 347–355. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Young, R.A.; Clemons, C.; Rowell, R.M. Recycled Newspaper Fibers as Reinforcing Fillers in Thermoplastics: Part I—Analysis of Tensile and Impact Properties in Polypropylene. J. Reinf. Plast. Compos. 1994, 13, 54–67. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Characteristics of wood–fiber plastic composites made of recycled materials. Waste Manag. 2009, 29, 1291–1295. [Google Scholar] [CrossRef] [PubMed]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling behavior. Bioresour. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef] [PubMed]

- Mertens, O.; Gurr, J.; Krause, A. The utilization of thermomechanical pulp fibers in WPC: A review. J. Appl. Polym. Sci. 2017, 134, 1–11. [Google Scholar] [CrossRef]

- Gozdecki, C.; Wilczyaski, A.; Kociszewski, M.; Zajchowski, S. Properties of wood-plastic composites made of milled particleboard and polypropylene. Eur. J. Wood Prod. 2015, 73, 87–95. [Google Scholar] [CrossRef]

- Bütün, F.Y.; Mayer, A.K.; Ostendorf, K.; Gröne, O.E.Z.; Krause, K.C.; Schöpper, C.; Mertens, O.; Krause, A.; Mai, C. Recovering fibres from fibreboards for wood polymer composites production. Int. Wood. Prod. J. 2018, 9, 42–49. [Google Scholar] [CrossRef]

- Faostat: Forestry Production and Trade. Available online: http://www.fao.org/faostat/en/#data/FO (accessed on 6 June 2018).

- Irle, M.; Barbu, M.C.; Reh, R.; Bergland, L.; Rowell, R.M. Wood composites. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 321–411. ISBN 978-0-9817876-1-9. [Google Scholar]

- Irle, M.; Privat, F.; Couret, L.; Belloncle, C.; Déroubaix, G.; Bonnin, E.; Cathala, B. Advanced recycling of post-consumer solid wood and MDF. Wood Mater. Sci. Eng. 2018, 1–5. [Google Scholar] [CrossRef]

- Mitchell, A.; Stevens, G. A life cycle assessment of closed loop MDF recycling using the microrelease process to produce recycled wood fibre from MDF waste. In Final Report of WRAP Project MDD005; WRAP: Banbury, UK, 2009; pp. 1–50. [Google Scholar]

- Teuber, L.; Osburg, V.S.; Toporowski, W.; Militz, H.; Krause, A. Wood polymer composites and their contribution to cascading utilisation. J. Clean. Prod. 2016, 110, 9–15. [Google Scholar] [CrossRef]

- Michaud, F.; Castéra, P.; Fernandez, C.; Ndiaye, A. Meta-heuristic Methods Applied to the Design of Wood—Plastic Composites, with Some Attention to Environmental Aspects. J. Compos. Mater. 2009, 43, 533–548. [Google Scholar] [CrossRef]

- Gu, F.; Guo, J.; Zhang, W.; Summers, P.; Hall, P. From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci. Total Environ. 2017, 601–602, 1192–1207. [Google Scholar] [CrossRef] [PubMed]

- Migneault, S.; Koubaa, A.; Perré, P. Effect of Fiber Origin, Proportion and Chemical Composition on the Mechanical and Physical Properties of Wood-Plastic Composites. J. Wood. Chem. Technol. 2014, 34, 241–261. [Google Scholar] [CrossRef]

- Kim, M.H.; Song, H.B. Analysis of the global warming potential for wood waste recycling systems. J. Clean. Prod. 2014, 69, 199–207. [Google Scholar] [CrossRef]

- Mahalle, L.; Alemdar, A.; Mihai, M.; Legros, N. A cradle-to-gate life cycle assessment of wood fibre-reinforced polylactic acid (PLA) and polylactic acid/thermoplastic starch (PLA/TPS) biocomposites. Int. J. Life Cycle Assess. 2014, 19, 1305–1315. [Google Scholar] [CrossRef]

- Bergman, R.; Sup-Han, H.; Oneil, E.; Eastin, I. Life-cycle Assessment of Redwood Decking in the United States with a Comparison to Three Other Decking Materials. In Proceedings of the CORRIM—The Consortium for Research on Renewable Industrial Materials, Seattle, WA, USA, 31 July 2013. [Google Scholar]

- Yates, M.R.; Barlow, C.Y. Life cycle assessments of biodegradable, commercial biopolymers—A critical review. Resour. Conserv. Recycl. 2013, 78, 54–66. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Sustainability assessments of bio-based polymers. Polym. Degrad. Stab. 2013, 98, 1898–1907. [Google Scholar] [CrossRef]

- Teuber, L. Evaluation of Particle and Fibre Degradation during Processing of Wood Plastic Composites (WPC) Using Dynamic Image Analysis. Ph.D. Thesis, Georg-August University of Goettingen, Göttingen, Germany, 2016. [Google Scholar]

- Dickson, A.R.; Sandquist, D. Mode of wood fibre breakage during thermoplastic melt processing. Compos. Part A-Appl. Sci. Manuf. 2018, 112, 496–503. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L. Reprocessing of wood fibre reinforced polypropylene composites. Part I: Effects on physical and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1091–1100. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S.; Sanetuntikul, J. Recycling of wood–plastic composites prepared from poly(vinyl chloride) and wood flour. Constr. Build. Mater. 2012, 28, 557–560. [Google Scholar] [CrossRef]

- Dickson, A.R.; Even, D.; Warnes, J.M.; Fernyhough, A. The effect of reprocessing on the mechanical properties of polypropylene reinforced with wood pulp, flax or glass fibre. Compos. Part A Appl. Sci. Manuf. 2014, 61, 258–267. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.; Krause, C. Effect of fiber length on processing and properties of extruded wood-fiber/HDPE composites. J. Appl. Polym. Sci. 2008, 110, 1085–1092. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M. Effects of processing method and fiber size on the structure and properties of wood–plastic composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Stark, N.M.; Berger, M.J. Effect of species and particle size on properties of wood-flour-filled polypropylene composites. In Proceedings of the Functional Fillers for Thermoplastic and Thermosets, San Diego, CA, USA, 8–10 December 1997; p. 16. [Google Scholar]

- Radovanovic, I. Verarbeitung und Optimierung der Rezeptur von Wood Plastic Composites (WPC). Ph.D. Thesis, University of Osnabrück, Osnabrück, Germany, 2007. [Google Scholar]

- Bouafif, H.; Koubaa, A.; Perre, P.; Cloutier, A. Effects of Composite Processing Methods on Wood Particle Development and Length Distribution: Consequences on Mechanical Properties of Wood-Thermoplastic Composites. Wood Fiber Sci. 2010, 42, 62–70. [Google Scholar]

- Schirp, A.; Stender, J. Properties of extruded wood-plastic composites based on refiner wood fibres (TMP fibres) and hemp fibres. Eur. J. Wood Prod. 2010, 68, 219–231. [Google Scholar] [CrossRef]

- Schirp, A.; Stender, J. Herstellung und Eigenschaften von extrudierten Wood-Plastic Composites mit Refinerfasern (Thermomechanical Pulp-Fasern). Chem. Ing. Tech. 2009, 81, 1773–1781. [Google Scholar] [CrossRef]

- Sobczak, L.; Lang, R.W.; Haider, A. Polypropylene composites with natural fibers and wood – General mechanical property profiles. Compos. Sci. Technol. 2012, 72, 550–557. [Google Scholar] [CrossRef]

- Mertens, O.; Krause, K.C.; Weber, M.; Krause, A. Performance of thermomechanical wood fibers in polypropylene composites. Wood Mater. Sci. Eng. 2018, 1–9. [Google Scholar] [CrossRef]

- Mertens, O.; Krause, K.C.; Krause, A. Evaluation of wood fiber composites based on a novel simultaneous defibration and compounding process. J. Appl. Polym. Sci. 2018, 135, 45859. [Google Scholar] [CrossRef]

- Teuber, L.; Militz, H.; Krause, A. Dynamic particle analysis for the evaluation of particle degradation during compounding of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 464–471. [Google Scholar] [CrossRef]

- Merkus, H.G. Particle Size Measurements: Fundamentals, Practice, Quality; Particle Technology Series; Springer: New York, NY, USA, 2009; p. 533. ISBN 978-1-4020-9015-8. [Google Scholar]

- European Committee for Standardization (CEN). Plastics—Determination of Tensile Properties—Part 1: General Principles; DIN EN ISO 527-1:2012; Beuth Verlag GmbH: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization (CEN). Plastics—Determination of Flexural Properties; DIN EN ISO 178:2010, German Version EN ISO 178:2010+A1:2013; Beuth Verlag GmbH: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization (CEN). Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test; ISO 179-1:2010; German version: DIN EN ISO 179-1:2010; Beuth Verlag GmbH: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization (CEN). Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pyknometer Method and Titration Method; EN ISO 1183-1:2013; German Version: DIN EN ISO 1183-1:2013; Beuth Verlag GmbH: Brussels, Belgium, 2013. [Google Scholar]

- Mertens, O.; Benthien, J.T.; Krause, A. Monitoring of fibre dimensions after a novel wood-plastic compounding approach. Eur. J. Wood Prod. 2018, 76, 801–804. [Google Scholar] [CrossRef]

- Teuber, L.; Militz, H.; Krause, A. Processing of wood plastic composites: The influence of feeding method and polymer melt flow rate on particle degradation. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef]

- Bourmaud, A.; Ausias, G.; Lebrun, G.; Baley, C.; Tachon, M.L. Observation of the structure of a composite polypropylene/flax and damage mechanisms under stress. Ind. Crops Prod. 2013, 43, 225–236. [Google Scholar] [CrossRef]

- Krause, A.; Krause, K.C. Relation between surface area and optimal concentration of coupling agent in WPC. In Proceedings of the 11th Pacific RIM Bio-Based Composites Symposium, Shizuoka, Japan, 27–30 November 2012; pp. 176–185. [Google Scholar]

- Brodowsky, H.; Mäder, E. Investigation of Transcrystalline Interphases in Polypropylene/Glass Fiber Composites Using Micromechanical Tests. Fibers 2018, 6, 16. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Thermoplastics reinforced with wood fillers: A literature review. Polym.-Plast. Technol. Eng. 1998, 37, 451–468. [Google Scholar] [CrossRef]

- Koddenberg, T.; Militz, H. Morphological imaging and quantification of axial xylem tissue in Fraxinus excelsior L. through X-ray micro-computed tomography. Micron 2018, 111, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Alhijjaj, M.; Yassin, S.; Reading, M.; Zeitler, J.A.; Belton, P.; Qi, S. Characterization of Heterogeneity and Spatial Distribution of Phases in Complex Solid Dispersions by Thermal Analysis by Structural Characterization and X-ray Micro Computed Tomography. Pharm. Res. 2017, 34, 971–989. [Google Scholar] [CrossRef] [PubMed]

- Rahn, H.; Alexiou, C.; Trahms, L.; Odenbach, S. 3-Dimensional quantitative detection of nanoparticle content in biological tissue samples after local cancer treatment. J. Magn. Magn. Mater. 2014, 360, 92–97. [Google Scholar] [CrossRef]

- Markl, D.; Wang, P.; Ridgway, C.; Karttunen, A.P.; Chakraborty, M.; Bawuah, P.; Pääkkönen, P.; Gane, P.; Ketolainen, J.; Peiponen, K.E.; et al. Characterization of the Pore Structure of Functionalized Calcium Carbonate Tablets by Terahertz Time-Domain Spectroscopy and X-ray Computed Microtomography. J. Pharm. Sci. 2017, 106, 1586–1595. [Google Scholar] [CrossRef] [PubMed]

- Ashori, A. Review Paper: Wood–plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Shubhra, Q.T.; Alam, A.; Quaiyyum, M. Mechanical properties of polypropylene composites: A review. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Sobczak, L.; Bruggemann, O.; Putz, R.F. Polyolefin composites with natural fibers and wood-modification of the fiber/filler-matrix interaction. J. Appl. Polym. Sci. 2012, 127, 1–17. [Google Scholar] [CrossRef]

- Aurich, T.; Mennig, G. Flow-induced fibre orientation in injection molded flax fibre reinforced polypropylene. Polym. Compos. 2011, 22, 680–689. [Google Scholar] [CrossRef]

- Joseph, P.V.; Joseph, K.; Thomas, S. Effect of processing variables on the mechanical properties of sisal-fibre-reinforced polypropylene composites. Compos. Sci. Technol. 1999, 59, 1625–1640. [Google Scholar] [CrossRef]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Slama, I. Characteristcis of physico-mechanicial properites of WPC based on MDF material sources: Benefits and limitations for recyling. Original title: “Caractéristiques physico-mécaniques des composites bois-plastiques provenant de la valorisation des résidus des panneaux MDF: Étude des possibilités de recyclage.”. Diploma Thesis, Université du Québec en Abitibi-Témiscamingue, Québec City, QC, Canada, 2009. [Google Scholar]

- Schirp, A.; Mannheim, M.; Plinke, B. Influence of refiner fibre quality and fibre modification treatments on properties of injection-moulded beech wood–plastic composites. Compos. Part A Appl. Sci. Manuf. 2014, 61, 245–257. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L. Reprocessing of wood fibre reinforced polypropylene composites. Part II: Hygrothermal ageing and its effects. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1565–1571. [Google Scholar] [CrossRef]

- Lopez, J.P.; Girones, J.; Mendez, J.A.; Puig, J.; Pelach, M.A. Recycling Ability of Biodegradable Matrices and Their Cellulose-Reinforced Composites in a Plastic Recycling Stream. J. Polym. Environ. 2012, 20, 96–103. [Google Scholar] [CrossRef]

- Le Duigou, A.; Pillin, I.; Bourmaud, A.; Davies, P.; Baley, C. Effect of recycling on mechanical behaviour of biocompostable flax/poly(l-lactide) composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1471–1478. [Google Scholar] [CrossRef]

- Bakkal, M.; Bodur, M.S.; Berkalp, O.B.; Yilmaz, S. The effect of reprocessing on the mechanical properties of the waste fabric reinforced composites. J. Mater. Process. Technol. 2012, 212, 2541–2548. [Google Scholar] [CrossRef]

- Ausias, G.; Bourmaud, A.; Coroller, G.; Baley, C. Study of the fibre morphology stability in polypropylene-flax composites. Polym. Degrad. Stab. 2013, 98, 1216–1224. [Google Scholar] [CrossRef]

- Sarabi, M.T.; Behravesh, A.H.; Shahi, P.; Soury, E. Reprocessing of Extruded Wood-Plastic Composites; Mechanical Properties. J. Biobased Mater. Bioenergy 2012, 6, 221–229. [Google Scholar] [CrossRef]

- Kraiem, D.; Pimbert, S.; Ayadi, A.; Bradai, C. Effect of low content reed (Phragmite australis) fibers on the mechanical properties of recycled HDPE composites. Compos. Part B Eng. 2013, 44, 368–374. [Google Scholar] [CrossRef]

- Morán, J.; Alvarez, V.; Petrucci, R.; Kenny, J.; Vazquez, A. Mechanical properties of polypropylene composites based on natural fibers subjected to multiple extrusion cycles. J. Appl. Polym. Sci. 2007, 103, 228–237. [Google Scholar] [CrossRef]

- Kaci, M.; Hamma, A.; Pillin, I.; Grohens, Y. Effect of Reprocessing Cycles on the Morphology and Properties of Poly(propylene)/Wood Flour Composites Compatibilized with EBAGMA Terpolymer. Macromol. Mater. Eng. 2009, 294, 532–540. [Google Scholar] [CrossRef]

- Kumar Sinha, M. A review of processing technology for the utilisation of agro-waste fibres. Agric. Wastes 1982, 4, 461–475. [Google Scholar] [CrossRef]

- Soccalingame, L.; Bourmaud, A.; Perrin, D.; Bénézet, J.C.; Bergeret, A. Reprocessing of wood flour reinforced polypropylene composites: Impact of particle size and coupling agent on composite and particle properties. Polym. Degrad. Stab. 2015, 113, 72–85. [Google Scholar] [CrossRef]

- Eder, M.; Burgert, I.; Terziev, N.; Daniel, G. The effect of (induced) dislocations on the tensile properties of individual Norway spruce fibres. Holzforschung 2008, 62, 77–81. [Google Scholar] [CrossRef]

- Niemz, P. Physik des Holzes und der Holzwerkstoffe./Physics of Wood and Wood-Based Materials; ETH—Eidgenössische Technische Hochschule: Zürich, Switzerland, 2005; p. 159. ISBN 3-87191-324-9. [Google Scholar]

- Standfest, G.; Kutnar, A.; Plank, B.; Petutschnigg, A.; Kamke, F.A.; Dunky, M. Microstructure of viscoelastic thermal compressed (VTC) wood using computed microtomography. Wood Sci. Technol. 2012, 47, 121–139. [Google Scholar] [CrossRef]

- Kärenlampi, P.P.; Tynjälä, P.; Ström, P. Effect of temperature and compression on the mechanical behavior of steam-treated wood. J. Wood. Sci. 2003, 49, 298–304. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).