Abstract

Semi-flexible pavement (SFP) relies primarily on the properties of cementitious grouting material (CGM), which plays a crucial role in providing durability and crack resistance. This paper investigates the performance of CGMs containing recycled waste glass (RWG) as a replacement to fine granite aggregate (FGA) and their effect on SFP mixtures. Two high-fluidity glass-cementitious grouts (Glcement grouts) were developed and tested at five RWG replacement levels (0%, 30%, 50%, 70%, and 100%). The results indicated that CGM with 70% RWG provided the most balanced performance, with a flowability of 11.8 s, low drying shrinkage (0.04%), and water absorption not exceeding 1.9%. The mechanical properties were significantly enhanced, achieving a high compressive strength of 121.9 MPa and a high flexural strength of 13.9 MPa. Microstructural analysis confirmed a refined interfacial transition zone with low porosity (5.36%), contributing to superior durability. Furthermore, the SFP mixture injected with Glcement exhibited high mechanical performance, attributed to improved interlocking within voids. In conclusion, replacing FGA with RWG in CGM optimizes both mechanical and durability properties, promoting sustainable and low-carbon pavement construction.

1. Introduction

The rapid increase in traffic loads and the prevalence of harsh environmental conditions have imposed significant stress on conventional asphalt pavements. Over time, these pavements frequently undergo various forms of deterioration, including rutting, fatigue cracking, corrugation, and raveling [1,2]. Such defects can severely undermine pavement durability and performance, ultimately resulting in reduced service life [3]. Although conventional asphalt pavement construction is generally economical and provides satisfactory performance, the frequent need for maintenance and rehabilitation poses major challenges. These include traffic disruptions and the high costs associated with repairing deteriorated pavement surfaces, underscoring the need for more durable and sustainable pavement solutions [4]. In response, there is a growing need for advanced materials and construction methods that can enhance the durability of road infrastructure. One notable advancement is the innovation of SFP. This innovative approach seeks to improve the sustainability of pavement construction by addressing the limitations of conventional asphalt, offering an alternative that can endure modern traffic demands and harsh environmental conditions. SFP demonstrates a progressive method for road infrastructure design by emphasizing enhanced durability, reduced maintenance expenses, and minimized environmental impacts. SFP is a composite pavement made by pouring an appropriate CGM onto an open-graded asphalt skeleton layer (OAS) with a 20%–35% void rate [5,6]. SFP exhibits favorable properties, including jointless construction, excellent fatigue resistance, high-temperature resistance, high strength, impermeability, fuel oil spillage resistance, and overall cost-effectiveness. Moreover, the sustainability of SFP can be further improved by incorporating recycled materials, such as RWG, to reduce reliance on FGA and minimize environmental impacts.

By adding synthetic admixtures and solid wastes as additives, researchers can explore CGMs with enhanced performance properties, such as high flowability, high strength, enhanced pozzolanic reaction, and controlled micro-expansion. Additives can partially replace cement in CGM. This, in turn, reduces initial construction costs and greenhouse gas emissions, and provides high strength. Waste glass is one of the most widely utilized waste materials in civil engineering projects. Its unique composition and beneficial properties, including amorphous nature, high silica content, pozzolanic reaction, ease of recycling, very low impact resistance, low energy consumption, low absorption smooth surface capacity, and transformative potential [7,8,9,10], make RWG a promising alternative for sustainable recycling applications. In other words, the enormous quantities of waste glass can be transformed into a valuable, low-cost potential alternative material through processes that require relatively low energy consumption. Due to its abundance, brittleness and very low impact resistance, waste glass can be easily crushed into desirable sizes, making it an ideal and unique material for dry recycling. Furthermore, its chemical stability allows for repeated recycling without significant compositional changes, enabling sustainable applications in engineering and construction. Thus, RWG offers an energy-efficient and environmentally friendly option for sustainable material design.

Annually, 18 million tons of waste glass are produced worldwide, and this number is increasing sharply. As a non-biodegradable material, waste glass occupies a significant landfill space and suffers from low recycling rates, contributing to serious environmental issue worldwide. Its production and disposal also involve high energy consumption and emit also large amounts of CO2 and other pollutants, thereby hindering sustainable urban development [11]. However, adding RWG as a potential alternative material in CGM for road projects is a sustainably and environmentally feasible solution to promote energy saving, improve the flowability and durability of grouts, reduce landfill waste, and decrease the demand for natural stone resources.

The performance of SFP mainly depends on the quality of the CGM [12], as it is in direct contact with the OAS and acts as the main crack-resistant material under traffic loading. CGM is a complex mixture of cement, fine aggregate, water, and supplementary materials, and it is widely exploited to fill defects and cracks in large-scale road projects. The two most important considerations relating to the effectiveness of CGM after hardening are its compressive strength and porosity. Porosity, in particular, has a significant effect on the strength, durability, moisture transport, diffusion behavior, and interaction of the grout with surrounding materials. These interrelated properties play critical roles in determining the quality and long-term performance of the following SFP. Many studies have addressed the porosity of CGM. Zhang et al. [13] reported that increasing the proportion of superfine cement in cementitious mortar reduces porosity and enhances strength properties. Al-Nawasir et al. [14] showed that porosity has a crucial role in adhesion at the asphalt–grout interface. Kamali and Ghahremaninezhad [15] studied the microstructure and hydration of cementitious mortar containing RWG, and concluded that RWG exhibits pozzolanic activity and can improve the flowability of cementitious mortar and hydration. Meena and Singh [16] studied using RWG powder as a pozzolanic material in concrete and concluded that RWG significantly enhances the durability of concrete, as its interaction with limestone during the early hydration stage promotes the formation of additional calcium silicate hydrate (CSH) gel, resulting in a denser cementitious matrix. Spiesz et al. [17] reported that glass concrete mixtures exhibit satisfactory mechanical performance, high translucency, high durability, and good air purification capabilities. Research by Mirzahosseini and Riding [18] demonstrated that the curing temperature, color, and composition of RWG particles significantly influence the properties and pozzolanic reaction of concrete. Furthermore, the study conducted by Yin et al. [19] revealed that adding up to 15% RWG replacement level by weight of cement significantly improves mechanical properties of cementitious mortars.

Referring to Mohammadinia et al. [20], the strength test results of concrete showed that incorporating 30% coarse aggregate from RWG with a size of 8 mm in footpath concrete construction provided good strength properties. Limbachiya [21] indicated that applying RWG as an aggregate replacement in concrete mixture leads to a gradual reduction in workability and strength due to the lack of fine proportion and the low compression resistance of RWG. Moreover, the effect of various sizes of RWG on the mechanical properties of self-compacting concrete was evaluated by Ling and Poon [22] and Małek et al. [23]. Meanwhile, Yousefi et al. [24] investigated the effect of RWG particle size on the compressive strength of cementitious mortar. According to Bostanci et al. [25], the compressive strength of cementitious mortar containing 15% RWG with a maximum grain size of 5 mm decreased by 8.1%. On the other hand, a study by Limbachiya et al. [26] indicated that the concrete mixtures containing RWG up to15% as an aggregate replacement exhibited comparable mechanical properties to the control mixture. In addition, several studies have examined the thermal behavior of glass-cement mortars. For instance, Sikora et al. [27] revealed a significant reduction in thermal conductivity and sorptivity coefficient of CGM when RWG replaced a high FGA content. Further, Liu et al. [28] showed that the mechanical performance and microstructure of cementitious mortar improved under high curing temperatures, attributed to the promotion of cement hydration and the pozzolanic reaction.

The formulation of CGM plays a significant role in determining the quality of SFP. The major requirement of CGM is its ability to penetrate the OAS rapidly and, once cured, form a composite with high crack resistance [29]. Similarly, the performance and quality of CGM are influenced by numerous factors, including type of cement and content [7], aggregate type and size [30], water-to-cement (W/C) ratio [31], type and concentration of superplasticizer [32], and other supplementary materials [33]. Selecting the optimal constituents for CGM is essential for constructing a mechanically robust and sustainable SFP. However, researchers have differing opinions on optimal grout constituent selection, as this depends on targeted specifications. The compatibility between different types of constituents is a key factor in achieving such balance.

Based on the results of the literature review, there is a clear scarcity of systematic studies on the effect of RWG on the performance of high-fluidity cementitious grout used for SFP, and further investigation is needed. Additionally, no studies are available in the literature addressing the performance of SFP mixture injected with high-fluidity glass–cementitious grout (Glcement-based SFP mixture).

The primary aim of this study was to investigate the effect of RWG as an FGA replacement on the performance properties of CGMs, and to study the mechanical performance of Glcement-based SFP mixture. To accomplish this aim, the following specific objectives were established:

- (a)

- To show the advantages of Glcement grouts in terms of performance and engineering properties.

- (b)

- To highlight the benefits of Glcement-based SFP mixture in terms of durability and mechanical properties.

- (c)

- To demonstrate that the CGM can be designed for enhanced durability and economy by incorporating RWG.

In the present study, two different types of high-fluidity Glcement grouts were tested for flowability, compressive strength, dry density, drying shrinkage, and water absorption. The optimized Glcement grout was then identified and further investigated in terms of wet density, flexural strength, and porosity. Field emission scanning electron microscopy (FESEM) was also introduced to analyze the microstructural surface morphology of the optimal grout. Furthermore, a detailed experimental investigation was carried out on the Glcement-based SFP mixture, including indirect tensile strength (ITS), Cantabro abrasion, degree of grouting saturation, compressive strength, and Marshall stability.

2. Materials and Methods

2.1. Ordinary Portland Cement

Ordinary Portland cement (OPC), in conformity with the requirements of JKR MS-Part1 2003 [34], was selected for the design of all CGMs due to its quick setting and high strength. The OPC material was purchased from a local manufacturer in Klang. The X-ray fluorescence technique (XRF) was employed to characterize the chemical components of OPC and RWG. The physical properties and chemical composition of OPC are given in Table 1 and Table 2, respectively.

Table 1.

Physical properties of OPC.

Table 2.

Chemical components of OPC and RWG.

2.2. Recycled Waste Glass

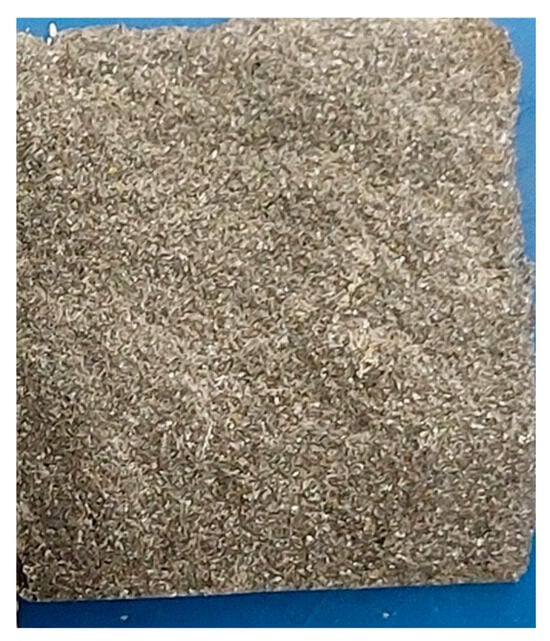

Waste glass was obtained from a local supplier in Kuala Lumpur. RWG was originally produced from waste glass bottles, as illustrated Figure 1. First, all ferrous and non-ferrous metals, plastics, and papers were completely removed. The glass bottles were then mechanically ground and sieved at room temperature to produce fine aggregate sizes. Finally, the RWG materials retained on each sieve were transferred to containers and labeled according to the sizes (see Figure 1). The chemical composition of RWG is listed in Table 2, while the physical properties of RWG, together with those of FGA and coarse aggregates, are presented in Table 3.

Figure 1.

Mechanical grinding process of waste glass bottles.

Table 3.

Physical properties of RWG and granite aggregates.

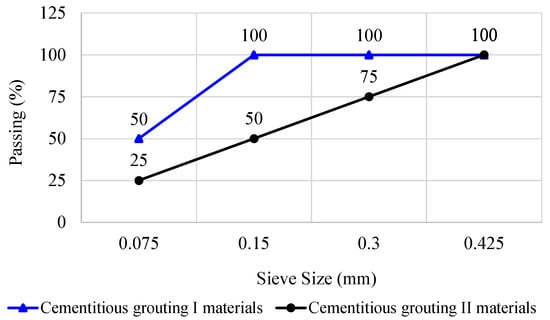

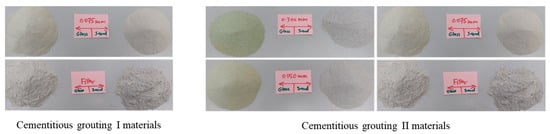

The fine aggregate gradations of RWG used for the formulation of Glcement grouts are attached in Table 4 and presented graphically in Figure 2. In this study, RWG was introduced as a replacement to FGA in the CGMs. RWG with a maximum grain size of 0.075 mm was utilized in the Glcement I grout mix design, while a larger size of 0.30 mm was applied in the Glcement II grout, as shown in Figure 3 and Table 4.

Table 4.

Fine aggregate sizes of RWG and FGA used for the design of glass-cementitious grouts.

Figure 2.

The grading curves of cementitious grouting materials.

Figure 3.

Photographic presentation of the fine aggregate sizes of cementitious grouting materials.

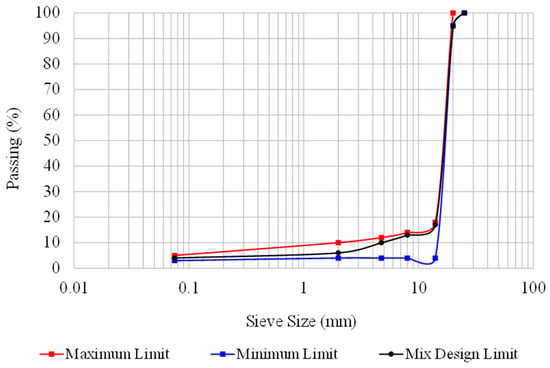

2.3. Granite Aggregates

Granite aggregates were used as both coarse and fine aggregates in the SFP mix design. The aggregates were sourced from a rock quarry located in Kajang, and their properties, as listed in Table 3, met the requirements of the Malaysian standard JKR S4-FP 2008 [44]. The sizes of the FGA used in the Glcement grout mix design are similar to those of the RWG, as presented in Table 4 and Figure 3. As stipulated in the Malaysian SFP specifications (REAM SP3-2007) [45], open-graded aggregate fractions with a maximum nominal particle size of 25 mm are only adopted for the design of SFP mixtures. The gradation curve for the SFP mix design is illustrated in Figure 4.

Figure 4.

Aggregate gradation of the semi-flexible pavement mix design.

2.4. MasterEase 3003 Superplasticizer

MasterEase 3003 superplasticizer (MES03) was selected for its superior ability to improve the dispersion of cement particles in CGM mixture. This enhancement promotes better hydration and allows for a reduction in the required water content, thereby contributing to sustainability by improving strength properties of the grout upon curing. Furthermore, MES03 exhibited the most significant improvement in flowability and strength compared to the other superplasticizers tested in the laboratory. The physical and chemical properties of MES03, as provided by a supplier in Klang, Malaysia, are tabulated in Table 5.

Table 5.

Physical and chemical properties of MasterEase 3003 superplasticizer.

2.5. Bitumen Binder

PEN (60/70) bitumen grade was used for the design of the Glcement-based SFP mixture. The binder was purchased from a refinery in Klang, Malaysia. As displayed in Table 6, the properties of bitumen binder satisfied the Malaysian SFP specifications (JKR S4-FP 2008) [44].

Table 6.

Basic properties of bitumen binder.

2.6. Design and Performance Test Methods of Glass-Cementitious Grouting Materials

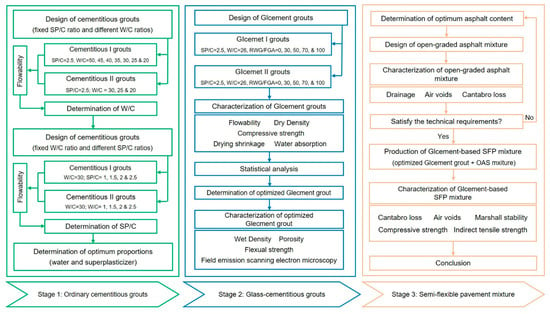

2.6.1. Design of Glcement Grouts

The experimental program methodology is illustrated in Figure 5. The design of CGMs plays a key role in determining the rigidity and strength of SFP and differs significantly from that of conventional concrete. In this study, “Glass-Cementitious Grouting Material” or “Glcement Grout” is herein defined as a high-fluidity cementitious grouting material incorporating fine recycled waste glass aggregate, specifically developed for use in SFP applications. In contrast, “Base Grout” or “Ordinary Grout” is defined as a comparable high-fluidity cementitious grouting material that does not contain recycled waste glass aggregate, see Table 7. Ordinary grouts consisted of OPC, FGA, tap water, and MES03. Moreover, RWG was incorporated as a sustainable material to produce two Glcement grouts, as presented in Figure 6. The optimum proportions of water and MES03 were precisely determined by conducting a fluidity test for ordinary grouts, as they have a significant effect in determining the quality of grouts. A high W/C ratio results in low strength but good flowability, in the meantime, an overdose of MES03 can cause segregation and drainage. In this study, the optimum proportions were found to be 26% water and 2.5% MES03, as detailed later in Section 3.1 and Section 3.2.

Figure 5.

The methodology of the experimental program.

Table 7.

Contents and proportions of cementitious grouting materials.

Figure 6.

Photographic presentation of the formulation, casting, curing, and testing of Glcement grouts.

Ten grouts with varying RWG concentrations and particle sizes were prepared for this study (see Table 7). Based on the RWG size, the grouts were divided into two equal groups: five Glcement I grouts and five Glcement II grouts. The first grout in each group was prepared without RWG to serve as the bBse grout, as presented in Table 7. The remaining eight Glcement grouts incorporated RWG as a replacement for FGA. The RWG replacement levels were approximately 0%, 30%, 50%, 70%, and 100% by mass of FGA. In all grout mixtures, the combined sand (FGA and RWG) to cement (S/C) ratio was maintained at 30%. This ratio has been reported to yield high strength properties [30,33]. In addition, the increase in sand content will increase the porosity of CGM. Table 7 shows in detail the trial constituent proportions used to prepare Glcement grouts in accordance with the hand-mixing procedures stipulated in Malaysian standard REAM SP3-2007 [45].

The Glcement grouts were designed according to ASTM C305 [49]. First, all dry materials (FGA, OPC, and RWG) were mixed using a mechanical mixer at a slow mixing rate of 90 rpm for 3 min to produce a homogeneous mixture. About 2/3 of the MES03 was poured into the dry mix, followed by 2/3 of the required mixing water, and the mixture was then stirred homogeneously for 5 min. The remaining MES03 and water were subsequently poured, and the mixture was re-mixed at a high mixing rate of 350 rpm for further 7 min. To ensure uniform consistency, materials adhering to the bottom and side of the mixing bowl were manually scraped and remixed for an additional minute, and then, it could proceed with the flowability test or other tests. This method was adopted to reduce the absorption of MES03 by OPC and improve the hydration and fluid workability of the grouts.

2.6.2. Flowability Test

The first important consideration to be determined for fresh CGM is its flowability (i.e., pourable consistency). The flowability of all grouts was determined according to the ASTM C939 standard [50], which involves measuring the time required for wet grout to pass through a standard flow cone. As per the REAM SP3-2007 [45], the acceptable flowability is indicated by a flow time of 11 to 16 s.

2.6.3. Compressive Strength Test

The compressive strength of Glcement grouts was investigated using 50 mm cubes that cured for 1, 3, 7, and 28 days, in accordance with the requirements stipulated in ASTM C109 [38]. This test is essential, as it reflects the overall quality and durability of the CGM under heavy traffic loading. The compressive strength was calculated after testing according to Equation (1).

where

: compressive strength (MPa);

maximum applied load (kN); and

surface area of sample (m).

2.6.4. Dry Density Test

The density of hardened grouts was measured using 50 × 50 × 300 mm standard cesam, following the method adopted by Koting [31], which conforms to ASTM C642 [51]. Density is directly associated the strength and durability of a grout; a higher density indicates a more compact and robust structure.

2.6.5. Drying Shrinkage Test

The drying shrinkage test determines the volumetric contraction in hardened grout caused by factors other than temperature changes or externally applied forces, primarily due to moisture loss and evaporation. The test is conducted on laboratory-prepared specimens exposed to controlled moisture and temperature conditions. The 28-day drying shrinkage was measured as the evaluation index, in accordance with ASTM C596 [52] and the relevant literature [53,54].

2.6.6. Water Absorption Test

The effect of RWG on the water absorption in Glcement grouts was investigated following the ASTM C642 standard method [51]. Understanding water absorption helps predict how CGM will perform under various environmental conditions, which is crucial for assessing the suitability of Glcement grouts for SFP applications. The high absorption capacity of CGM adversely affects the durability and service life of SFP by influencing its mechanical and physical properties.

2.7. Performance Test Methods of the Optimized Glass-Cementitious Grouting Material

2.7.1. Wet Density Test

The density of fresh optimized grout was measured by using a vessel with a stopper, according to ASTM C948 [55]. First, the weight of vessel filled with fresh grout was recorded. Then, the weight of the grout alone was measured and recorded. The wet density was calculated by dividing the weight of the grout by its volume.

2.7.2. Flexural Strength Test

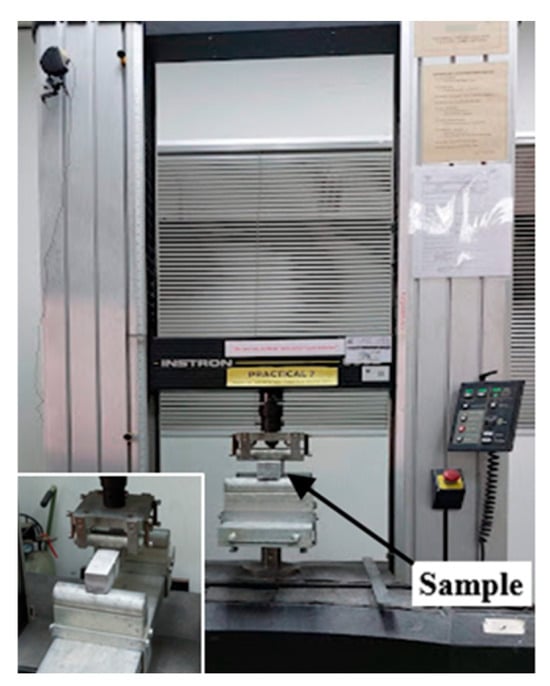

The 28-day flexural strength was determined using prismatic samples with dimensions of 50 × 50 × 300 mm, conforming to ASTM C348 [56]. An Intron testing machine with a 100 kN load capacity was utilized. The test involved placing the Glcement beam sample on two supports, after which a two-point load was applied until the sample broke, as illustrated in Figure 7.

Figure 7.

Flexural strength test setup.

2.7.3. Porosity Test

The porosity test was conducted according to the RILEM CPC-11.3 method [57]. In this test, the dry weight of cube samples was measured and recorded as W1. Then, the weight of samples while submerged in water was determined and recorded as W2. The samples were subsequently immersed in a water bath for 24 h at room temperature to allow for the pores to be fully saturated. After immersion, the samples were taken out, wiped, weighed as WSSD. The effective porosity (ϕe) was calculated as a percentage of the bulk volume based on Equation (2).

2.7.4. Microstructure Analysis

Raw materials and the structure of the CGM are the essential parameters that can cause technical problems and directly affect the quality and performance of the following SFP. Therefore, the microstructural images, depicting the relationships among the OPC, FGA, and RWG, provide a comprehensive understanding of the macroscopic properties of Glcement grouts. Indeed, microstructure analysis is the most commonly used experimental method to illustrate the micromorphology and bonding properties of the materials, which ultimately govern behavior of SFP.

FESEM can capture high-quality microstructure images that intuitively and effectively reveal the relationships between different raw materials and their components. With a spatial resolution down to approximately 1.5 nm, 3 to 6 times higher than that of conventional SEM, FESEM offers exceptional imaging capabilities and a virtually unlimited depth of field. Hence, the FESEM analysis was employed in this study to characterize the topographic and elemental features of the optimized Glcement grout surface, taking advantage of its virtually unlimited depth of field. Additionally, the surfaces and edges of RWG particles were also analyzed to demonstrate the angularity of the RWG in the CGM matrix.

2.8. Design and Performance Test Methods of the Glcement-Based SFP Mixture

2.8.1. Design of of the Glcement-Based SFP Mixture

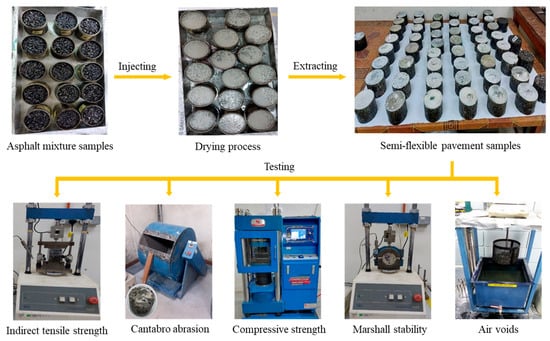

To investigate the feasibility of Glcement grouts as CGMs, the Glcement-based SFP mixture was designed and tested. In this study, “Glcement-Based SFP Mixture” is herein defined as the semi-flexible pavement mixture injected with the optimized glass-cementitious grouting material (Glcement II-70), as shown in Figure 8, while “OAS Mixture” refers to an open-graded asphalt skeleton mixture designed as a surfacing layer in SFP.

Figure 8.

Photographic presentation of the production and testing of SFP mixture.

The Marshall mix design method [58] was applied for the design of OAS mixture, mainly due to its effectiveness. The asphalt content was found to be 3.5%. As stipulated in the REAM SP3-2007 specifications [45], three parameters of OAS mixture were adopted for SFP applications and are listed in Table 8. The test results showed all technical properties of the mixture met the specifications.

Table 8.

Main parameters of open-graded asphalt mixture for semi-flexible pavement.

The SFP mixtures were designed in accordance with the REAM SP3-2007 specifications [45]. First, the aggregate fractions were preheated to 160 °C for 60 min. Simultaneously, the asphalt was heated to 150 °C for 60 min as well. Once ready, the asphalt was combined with the aggregate fractions, and mixed thoroughly for approximately 10 min at 150 °C. The mixture was then placed in a Marshal mold and automatically compacted 50 blows for each face at 145 °C. The prepared samples were left in the molds to cool at ambient temperature. After 24 h, the OAS samples were moved to a flat surface and injected with the optimized CGM (see Figure 8). Due to the sufficient fluidity of the CGM, there was no need for external vibrations during the injection. The SFP samples were left at room temperature and extracted from the molds after a 48 h injection. This process involved the production of SFP samples in the form of cylinders, as illustrated in Figure 8.

The performance of the Glcement-based SFP mixture was tested for mechanical properties, including degree of grouting saturation, ITS, Cantabro abrasion, compressive strength, and Marshall stability, as portrayed in Figure 8.

2.8.2. Degree of Saturation Test

The degree of grouting saturation is an important parameter for characterizing the effectiveness of the SFP mixture, as it reflects how well the OAS is injected, as given in Equation (3). After injection, the remaining air content should fall within the range of 3%–6% [33,62,63]. A higher air content (e.g., >6%) reflects inadequate injection of the SFP mattress, thereby compromising its structural integrity. Under heavy traffic loading, stress concentrations develop over localized areas, which accelerates the initiation of cracks at the interface between the OAS and the CGM, ultimately leading to premature pavement deterioration [33].

where SD: degree of grouting saturation; Wi and Wf: weight of OAS sample before and after injection in g, respectively; V: volume of OAS sample in cm3; Dg: density of fresh CGM in g/cm3; and Pc: the connected porosity in OAS sample.

2.8.3. Indirect Tensile Strength Test

The ITS test evaluates the durability of pavement mixtures based on the bonding properties [64]. As per the AASHTO T283 test standard [65], the ITS test is conducted using a Marshall apparatus with a consistent deformation rate but different grips. Samples are immersed in a water bath for 30 min at a temperature of 60 °C. The maximum load at failure is recorded for each sample and then used to estimate the ITS according to Equation (4). Figure 8 presents the ITS testing apparatus setup.

where ITS: indirect tensile strength (kPa); Ppeak: peak load (kN); Ds: diameter of sample (m); and Ts: thickness of sample (m).

2.8.4. Compressive Strength Test

The serviceability of SFP mattress is a function of crack resistance. Crack resistance is characterized by the compressive strength, which serves as a reliable indicator of the quality of the SFP mixture under different traffic loading conditions. The test was carried out according ASTM D1074 standard [66]. During the test, the load was applied at a constant rate of 0.50 kN per second using a universal machine until the sample fails. The strength was calculated as defined by Equation (1).

2.8.5. Cantabro Abrasion Loss Test

As stipulated in the EN 12697-17 standard [60], the Cantabro abrasion test is curial for demonstrating the production quality of surface courses by assessing the resistance to degradation, disintegration, and crushing. In this test, the initial SFP samples were weighed and recorded as Wi. The samples were then subjected to abrasion in a LA machine drum, without steel balls, at a rotating speed of 30–33 rpm. After 300 revelations, the samples were carefully taken out and weighed as Wf. The Cantabro abrasion loss (CAL) was calculated as a percentage using Equation (5).

2.8.6. Marshall Stability Test

The maximum applied load that a Marshall specimen can bear before failure is called as Marshall stability. Marshall test specimens are conditioned in a temperature-controlled water bath (60 °C) for 30 min before testing, as per ASTM D6927 [67]. During testing, the deformation rate was 50 mm per minute. The maximum stability was noted and recorded.

3. Results and Analysis

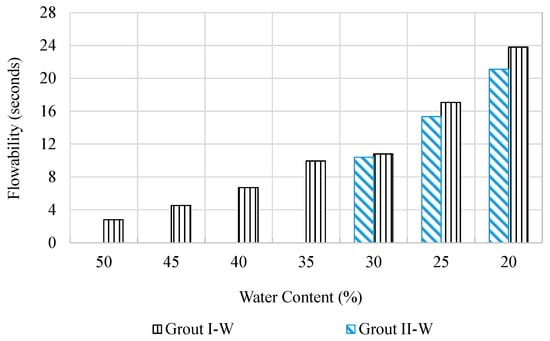

3.1. Optimum Water Content

The effect of water content on the flowability of Base I-W is shown in Figure 9. The water content ranged from 50% (highest) to 25% (lowest), with a 5% decrement by the total weight of OPC. The MES03 content was fixed at 2.5% that is the maximum value reported in the literature. As plotted in Figure 9, the flowability of Base I-W increases with increasing water content. The flowability was 2.8 s at 50% water content, while at 25% water, the flowability increased significantly to 17.1 s.

Figure 9.

Effect of water content on the flowability of cementitious grouting material.

The optimum water content for Glcement II grouts was also determined. Based on the results of Base I-W shown in Figure 9, only three different water contents (30%, 25%, and 20%) were applied for Base II-W. The flowability of Base II-W was also drawn in Figure 9. A similar trend to that of Base I-W was observed, where the flowability values of Base II-W increased dramatically as water content decreased. According to REAM SP3-2007 [45], the flow time to pass one liter of wet grout through the test funnel should be between 11 and 16 s. The flowability results for both Base I-W and Base II-W indicate that the water content complying with the REAM requirements lies between 25% and 30%.

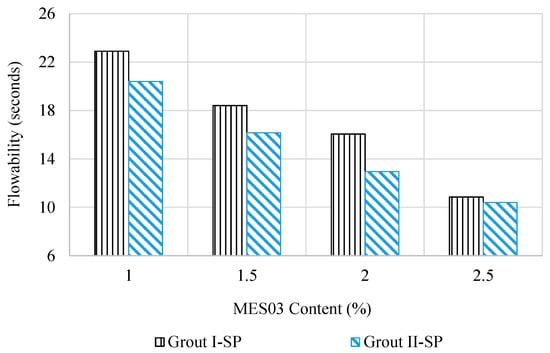

3.2. Optimum Superplasticizer Content

The flowability results of Base I-SP and Base II-SP are shown in Figure 10. In these grouts, the MES03 contents varied from 1% to 2.5% with a 0.5% increment by the total weight of OPC, while the water content was fixed at 30% due to the obtained results in Section 3.1.

Figure 10.

Effect of superplasticizer content on the flowability of cementitious grouting material.

As can be observed in Figure 10, the flowability of CGMs exhibited a linear decline with increasing MES03 dosage. This reduction is primarily attributed to the dispersive and decomposing actions of MES03 on OPC-forming compounds, thereby reducing flowability. Based on Figure 10, the targeted flowability was achieved with MES03 content ranging between 2.0% and 2.5%. Owing to its effectiveness in improving both workability and the strength of CGM at high content, an MES03 dosage of 2.5% was selected for the design of all Glcement grouts.

Due to the acceptable flowability of both Base I-W and Base II-W achieved at a water content of 25% to 30%, with 2.5% MES03, the principle of trial and error was applied to determine the lowest feasible water content within this range that meets the targeted flowability (11–16 s). The first trail for each Glcement grout was conducted at 26% water and 2.5% MES03. The results of these trails, tabulated in Table 9, showed that the flowability values of the Base grouts are within the acceptable limit. The rationale for selecting the lowest water content that met the targeted flow is that higher water content leads to increased evaporation rate, reduced compressive strength, and a greater likelihood of shrinkage cracks. Therefore, the water content of 26% and MES03 of 2.5% were adopted for the design of all RWG-replaced grouts. At these optimum proportions, the flowability results are 14.28 s for the Base I grout and 12.24 s for the Base II grout.

Table 9.

Engineering properties and normalized indices of Glcement grouts.

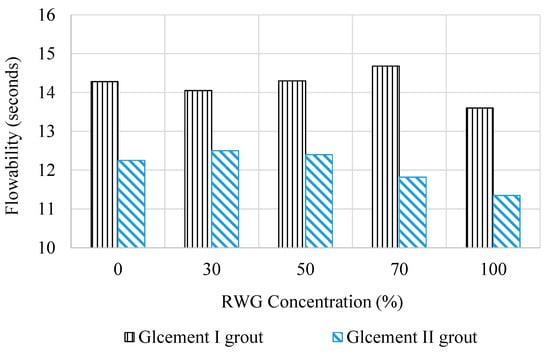

3.3. Flowability

The flowability results of Glcement grouts are shown graphically in Figure 11. The effect of RWG concentration showed slight variation for each grout type, showing an overall inconsistent trend. At lower concentrations, the angular yet smooth glass particles may enhance flowability by promoting better dispersion and reducing both internal and interparticle friction. In contrast, higher concentrations tend to increase viscosity and induce particle agglomeration, which restricts flowability. This competing interaction between improved dispersion and increased viscosity accounts for the irregular trend observed.

Figure 11.

Effect of glass content on the flowability of cementitious grouting material.

The results also indicated that Glcement II grouts had lower flow time compared to Glcement I grouts. This reduction could be due to the coarser RWG particles requiring less pore water, resulting in increased fluidity. Based on the normalized flowability index displayed in Table 9, the Glcement-100 grouts had the lowest flowability values, in comparison with the bBse grouts. This can be attributed to the smoother surface capacity and lower absorption of the higher RWG concentration, which hindered water absorption compared to FGA particles. A recent study conducted by AL-Qudah, Koting, Ibrahim, and Alibrahim [33] showed that RWG reduces affinity but increases workability and draindown. However, all RWG-replaced grouts fulfilled the requirement [45].

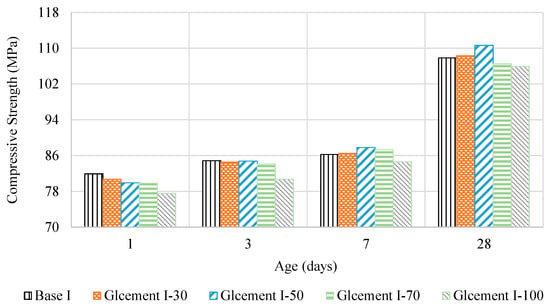

3.4. Compressive Strength

The compressive strength of Glcement I grouts and Glcement II grouts at different curing periods is shown in Figure 12 and Figure 13, respectively. All grouts with varying RWG concentrations had values higher than the minimum allowable limit of 105 MPa at 28 days. Figure 12 shows that the compressive strength of Glcement I-50 was highest after 28 days. Overall, the grouting I materials containing RWG had comparable strength values. This is attributed to the sand-like particle size of RWG, which imparts properties similar to those of natural stone materials. In addition, RWG is free of clay and other contaminants and possesses most of the properties of high-quality natural silica sand [68]. As attached in Table 9, all Glcement I grouts had lower compressive strength values than Base I grout after 1 day of curing. However, after 28 days of curing, the Glcement I-50 recorded a strength value that was 1.026 times higher, compared to the Base I.

Figure 12.

Effect of glass content on the compressive strength of cementitious grouting I material.

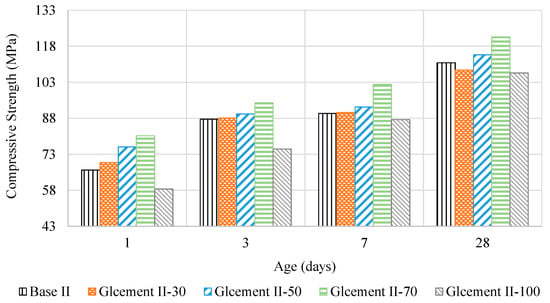

Figure 13.

Effect of glass content on the compressive strength of cementitious grouting II material.

Figure 13 portrays the compressive strength of Glcement II grouts. A significant variance was observed between the Base II grout and the other II grouts. The compressive strength values increased until reached a maximum value of 9.6% for Glcement II-70, after which the strength values declined. This stems from the covalent silica bonds (SiO2) abundantly present in the RWG. The SiO2 reacts with Ca(OH)2 in the OPC to form CSH. The CSH, as the main product of the hydration of OPC, is primarily responsible for the strength development of grout. Previous studies have demonstrated that SiO2 enhances concrete mixtures by reacting with Ca(OH)2 [69,70], thereby improving the overall quality of the mixtures.

However, inclusion of more SiO2 bonds reduces the convenient adherence between the grout constituents, ultimately leading to a deterioration in strength. As tabulated in the normalized index table (Table 9), Glcement II-70 exhibited the best performance in terms of shear and tensile strength resistance, with an increase of 1.096 times, compared to Base II. Table 9 also shows that all Glcement II grouts satisfied the stipulated requirements. Similar findings have been reported in previous studies indicating that the incorporation of RWG into concrete can lead to significant improvements in compressive strength due to its pozzolanic properties, which enhances the microstructure of concrete and reduce porosity [17,71,72].

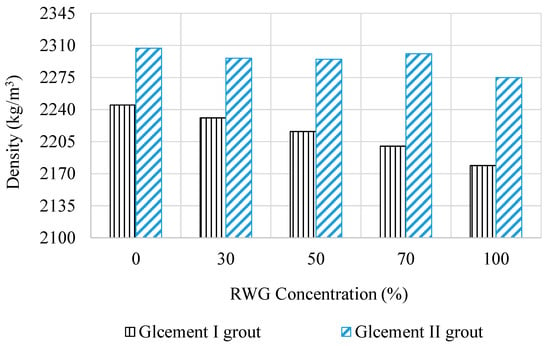

3.5. Dry Density

The dry density of Glcement grouts are graphically plotted in Figure 14 and tabulated in Table 9. With increasing RWG concentration, the density of hardened grouts decreased linearly. This reduction is attributed to the fact that the specific gravity of RWG is lower than that of FGA. However, the effect of adding RWG was minimal, especially when the maximum RWG particle size was 0.075 mm. As depicted in Table 9, the density of Glcement I-100 and Glcement II-100 decreased by 2.94% and 1.13%, respectively, compared to the Base grouts. The density of all RWG-replaced grouts was above the minimum requirement (2200 kg/m3), except for Glcement I-100, which recorded the lowest value. Małek, Łasica, Jackowski, and Kadela [23] asserted that density decreases with increasing RWG concentration. Glcement II grouts are denser than Glcement I grouts. A denser grout provides higher strength, and lower permeability due to the reduced voids and porosity. Specifically, replacing OPC with RWG can increase compressive strength while slightly reducing density. This dual benefit aligns with modern building trends that favor lighter materials for enhanced efficiency and sustainability.

Figure 14.

Effect of glass content on the density of cementitious grouting material.

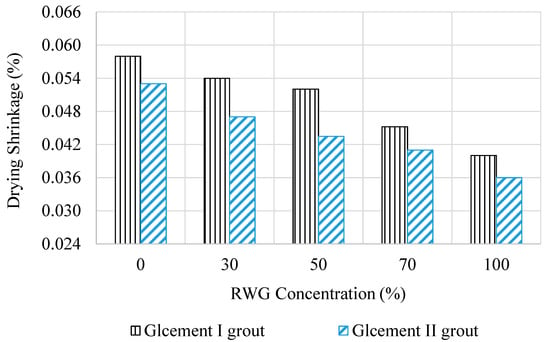

3.6. Drying Shrinkage

The effect of using RWG on the 28-day drying shrinkage of CGMs is presented in Table 9 and Figure 15. As observed in Figure 15, RWG is effective in reducing drying shrinkage. As such, the Base grouts exhibited the highest shrinkage values. The results show that the dry shrinkage of Glcement I-100 and Glcement II-100 are 0.040 and 0.036, respectively, which are 31% and 32.1% lower than those of Base I and Base II. A similar trend was reported by Ning et al. [73], who revealed that adding slag waste, particularly from steel and silicon–manganese production, decreased the drying shrinkage of concrete mixture under the same conditions. The improvement in engineering properties, particularly the reduction in shrinkage, can be attributed to the expansion characteristics of the waste materials, which can compensate for the contraction caused by drying.

Figure 15.

Effect of glass content on the drying shrinkage of cementitious grouting material.

Drying shrinkage is any reduction occurring in the volumetric properties of hardened grouts following the loss of capillary water via evaporation. This water loss is mainly responsible for drying shrinkage and can ultimately lead to cracking of the grouts. The reduction in drying shrinkage of Glcement grouts could be related to two reasons: (i) RWG particles have a smooth and surface low water absorption capacity, reducing water demand for the grouts; (ii) the pozzolanic reaction of RWG with Ca(OH)2 improved the pore structure by forming CSH gel. This in turn enhanced the adhesion of RWG to OPC, thereby limiting drying-induced shrinkage.

Comparing with Glcement I grouts, Glcement II grouts exhibited less drying shrinkage. This is because the RWG used in Glcement II grouts is coarser, exhibiting negligible surface water retention compared to the RWG used in Glcement I, and contributes to an improved microstructure. Previous studies conducted by Mallum et al. [74] and Hamada et al. [75] revealed the similar point, as concrete mixtures containing RWG have a denser and less porous microstructure than conventional mixtures, attributed to strong bonding. Drying shrinkage decreases with increasing RWG concentration, indicating improved performance against shrinkage cracking. Although higher cement content contributes to increased strain values, the presence of RWG helps control this effect, which is beneficial for SFP applications.

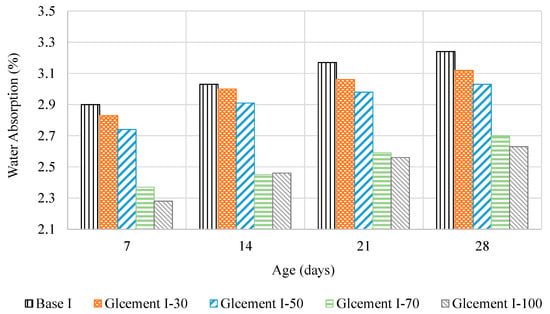

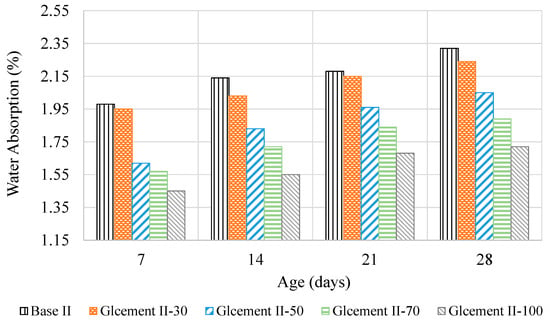

3.7. Water Absorption

The water absorption results of Glcement I grouts and Glcement II grouts, respectively, cured at 7, 14, 21, and 28 days are graphically plotted in Figure 16 and Figure 17. The results revealed that, as the concentration of RWG increases, the water absorption of Glcement grouts at various RWG replacement levels tends to decrease. This reduction in water absorption can be attributed to the smooth surface and negligible surface water retention capacity of RWG, in comparison with FGA, as well as its ability to improve the microstructure. The chemical composition of RWG also influences hydration rates and water absorption. Soda–lime glass typically exhibits lower water absorption, which can improve the overall performance of CGM. Furthermore, the pozzolanic reactions between RWG and Ca(OH)2 forms CSH gel, leading to a refined interfacial transition zone and a less porous material.

Figure 16.

Effect of glass content on the water absorption of cementitious grouting I material.

Figure 17.

Effect of glass content on the water absorption of cementitious grouting II material.

The results are agreement with Subba et al.’s [76] findings, which indicated that the adding waste material reduces the water absorption of cementitious mortar. However, as listed in Table 9, the water absorption of CGMs incorporating 100% RWG (Glcement I-100 and Glcement II-100) was 1.232 and 1.349 times lower, respectively, when compared with those of the CGMs containing 0% RWG (Base I and Base II). The water absorption of Glcement I grouts was significantly higher than that of Glcement II grouts, mainly due to differences in the surface area and texture of RWG. The surface area of a particle increases as its size decreases [7]. Therefore, the finer RWG particles used in Glcement I grout have a greater number of individual grains per unit volume compared to the coarser RWG particles used in Glcement II grout. Additionally, RWG ground into sand-like particles also exhibits properties that closely resemble those of natural-stone sand materials. Consequently, Glcement I grout absorbed more water.

A major portion of the absorbed water can be lost due to the drying of hydrated grout. This loss in absorbed water is primarily responsible for drying shrinkage, which ultimately leads to cracking in the SFP. Accordingly, the lower water absorption of Glcement grouts contributes significantly to enhancing the performance of the following SFP mattress.

3.8. Performance of Optimized Glass-Cementitious Grout

3.8.1. Performance Ranking

The experimental investigations of Glcement grouts listed in Table 9 revealed that the performance of Glcement II grouts is superior to the performance of Glcement I grouts. Based on this, the performance of five Glcement II grouts was ranked on a five-point scale to identify the optimal formulation. The grout with the best performance was ranked as 1, while the grout with the worst performance was ranked as 5, as presented in Table 10.

Table 10.

Performance ranking of cementitious grouting II materials.

The relative importance index showed the CGM with an additional 70% RWG (Glcement II-70) exhibited the best strength and performance properties. Therefore, the engineering properties of Glcement II-70, including wet density, flexural strength, and porosity, were further evaluated.

3.8.2. Engineering Properties

The engineering properties of Glcement II-70 grout are listed in Table 11. The results show that the density met the requirement. Moreover, the Glcement II-70 beam samples tested in the transverse strength direction exhibited behavior similar to that observed in the compressive strength test. The 28-day flexural strength of the grout also satisfied the relevant standard requirements.

Table 11.

Engineering properties of the optimized glass-cementitious grout (Glcement II-70).

The porosity value of the Glcement II-70 grout was 5.36% according to the RILEM CPC 11.3 method [57]. This value indicates Glcement II-70 grout has a low porosity level. The low porosity of the grout is primarily attributed to its very low W/C ratio (26%), meaning that almost all the mixing water was consumed during hydration, leaving minimal capillary porosity. Due to its density, Glcement II-70 grout is classified as Category A, signifying a low-porosity material [7,77].

The results confirms that the application of Glcement II-70 grout as a grouting material provides high crack resistance and durability. Hence, the RWG can be successfully used as an FGA replacement in the production of CGMs for SFPs. Similar results have been reported in previous studies on cementitious mortars, where porosity values were found to be below 15% [77,78].

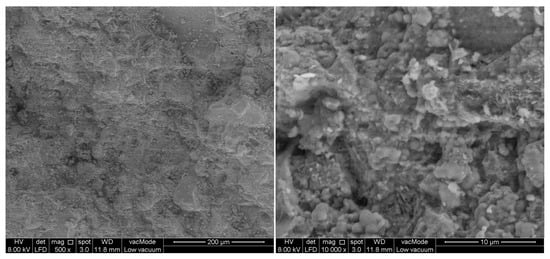

3.8.3. Microstructure

Microstructural characterization is an essential analytical method in experimental approach used to reveal the interfacial bonding characteristics and micromorphology of constituent materials, which directly influence the durability and mechanical strength of the final mixture. FESEM provides excellent spatial resolution and depth of field, allowing for detailed imaging of both surface and subsurface structures. In this study, FESEM was utilized to examine the elemental distribution and interfacial morphology within the Glcement grout, offering a detailed understanding of the microstructural integration of FGA, RWG, and OPC, as portrayed in Figure 18.

Figure 18.

Microstructure image of the optimized glass-cementitious grout (Glcement 70-II).

Figure 18 displays the FESEM micrographs of the optimized Glcement grout, illustrating its internal morphology and micromechanical features. The images demonstrate the propagation of sand particles (RWG and FGA) with OPC within the CGM matrix. The sand particles appear prominently along the interface with the CGM, signifying a strong bond throughout the entire depth of the grout structure. This reflects the successful integration of grout constituents, as presented in Figure 19.

Figure 19.

Internal interface image of the optimized glass-cementitious grout (Glcement 70-II).

The microstructural analysis also shows the advantageous macro-scale properties of the Glcement grout, such as adequate interfacial adhesion, low porosity, high density, and appropriate surface roughness, which are main requirements contributing to its suitability for SFPs. These combined properties enhance crack resistance and compressive strength and reduce water absorption. Moreover, the incorporation of RWG as a replacement to FGA in the CGM promotes matrix densification by forming amorphous and semi-crystalline CSH [16], resulting in a stronger grout structure. Under microscopic view, the Glcement II-70 grout demonstrates a durable, well-optimized composition that enhances the overall mechanical performance and structural integrity of SFPs.

The microstructural interface images of RWG fractions revealed a variety of particle shapes and surface textures depending on the type of glass and preparation method. High-resolution images showed smooth surfaces along with particles exhibiting diverse angularity and forms, including rounded, angular, flaky, needle-shaped, and elongated morphologies. The microstructural features of RWG are affected by particle size, processing techniques, and the inherent nature of the glass material, influencing properties such as bonding, deformation behavior, and mechanical performance. Notably, coarse RWG fractions exhibited a higher proportion of rounded, angular, needle-shaped, flaky, and elongated particles compared to fine RWG fractions.

3.9. Mechanical Performance of Glcement-Based SFP Mixture

The SFP mixtures were evaluated 28 days after grout injection. The 28-day curing period is the standard duration for assessing the mechanical properties and performance of SFP mixtures [33,45]. For each mechanical performance test, the average value of three duplicate samples was calculated and recorded. The mechanical performance test results of the Glcement-based SFP mixture can be found in Table 12.

Table 12.

Mechanical performance properties of SFP mixture injected with glass-based grout.

The mechanical performance results show that the mixture met all REAM SP3-2007 requirements [45] and demonstrate that the Glcement-based SFP mixture possesses good mechanical properties. This is attributed to enhanced interlocking between the SFP components (OAS mixture and Glcement grout) and indicates the potential for adding RWG as a replacement to FGA in CGMs for SFPs. By confirming a balance of environmental, economic, and technical benefits linked to SFPs, this approach represents an excellent step towards a more sustainable future for pavement materials. The results are in agreement with Khan et al.’s [79] findings, which concluded that the SFP mixture injected with waste PET grout exhibited satisfactory mechanical properties. In short, the coherence of results with those in the literature confirms the viability of integrating RWG material in SFPs, both improving mechanical interlocking and contributing to sustainability goals in pavement technology.

4. Conclusions

This paper addressed the performance of CGM containing RWG as an FGA and its effect on the performance of SFP mixture. Based on the analysis and results, the following conclusions are drawn:

- The flowability values of CGMs decreased slightly with increasing RWG concentration as an FGA replacement. Additionally, the flowability decreased as the RWG particle size increased. In contract, the compressive strength of CGMs significantly improved with increasing RWG concentration and particle size, attributed to enhanced pozzolanic reactivity and CSH formation.

- As the RWG concentration increased, the density of CGMs decreased due to the lower bulk density of RWG. Similarly, the drying shrinkage and water absorption of CGMs containing RWG were lower than those of the Base grouts. This behavior is attributed to the smooth surface and negligible surface water retention of RWG particles compared to FGA, as well as the improved microstructure of the CGM. Moreover, both water absorption and drying shrinkage decreased further with increasing RWG particle size.

- Compared to RWG concentration, RWG particle size had a larger effect on the overall engineering properties of CGMs. Consequently, Glcement II grout proved more suitable as a CGM than Glcement I grout. Among all CGMs, Glcement II-70 grout exhibited optimal performance, demonstrating superior void-filling capacity, fluidity, and mechanical properties. Furthermore, the SFP mixture injected with Glcement II-70 met all performance requirements, showing excellent mechanical behavior due to enhanced interlocking within the voids.

- Comparing environmental pollution indicators of CGMs with and without RWG, the optimized and rational application of 70% RWG significantly reduces adverse effects on the ecological environment. This approach is a feasible, eco-friendly technology for disposing of waste glass and promotes the socioeconomic sustainable development of cities.

Author Contributions

Conceptualization, A.H.A.-Q. and M.R.I.; methodology, A.H.A.-Q., S.K. and M.R.I.; investigation, A.H.A.-Q.; writing—original draft, A.H.A.-Q.; resources, A.H.A.-Q., S.K. and M.M.A.; supervision, S.K. and M.R.I.; funding acquisition, S.K. and A.I.A.-M.; writing—review and editing, M.R.I., M.M.A. and A.I.A.-M.; formal analysis, M.M.A.; visualization, M.M.A. and A.I.A.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Faculty of Engineering (grant no. GPF048A-2020), Universiti Malaya, Malaysia, and the Ongoing Research Funding Program (ORF-2025-424), King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to acknowledge the support of the Universiti Malaya, Research University-Faculty Grant (GPF048A-2020), Malaysia, and the Ongoing Research Funding program (ORF-2025-424), King Saud University, Riyadh, Saudi Arabia. All authors have approved the manuscript and agreed with the submission to Coatings.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| SFP | Semi-flexible pavement |

| CGM | Cementitious grouting material |

| RWG | Recycled waste glass |

| FGA | Fine granite aggregate |

| Glcement | Glass-cementitious |

| OAS | Open-graded asphalt skeleton |

| OPC | Ordinary Portland cement |

| CSH | Calcium silicate hydrate |

| W/C | Water-to-cement ratio |

| FESEM | Field emission scanning electron microscopy |

| ITS | Indirect tensile strength |

| MES03 | Master ease 3003 superplasticizer |

| REAM | Road Engineering Association of Malaysia |

| S/C | Sand-to-cement ratio |

| MES03/C | MasterEase 3003 superplasticizer-to-cement ratio |

References

- Nciri, N.; Kim, N.; Cho, N. From street to road: An innovative approach to explore discarded chewing gum as a performance-enhancing modifier for road pavement applications. Polymers 2021, 13, 1963. [Google Scholar] [CrossRef]

- Joumblat, R.; Al Basiouni Al Masri, Z.; Al Khateeb, G.; Elkordi, A.; El Tallis, A.R.; Absi, J. State-of-the-art review on permanent deformation characterization of asphalt concrete pavements. Sustainability 2023, 15, 1166. [Google Scholar] [CrossRef]

- Xia, L.; Cao, D.; Zhang, H.; Zhang, M.; Shan, L.; Zhang, H.; Wang, T. Surface modification of recycled polyester fiber and performance evaluation of its asphalt mastic and mixture. Sustainability 2023, 16, 278. [Google Scholar] [CrossRef]

- AL-Qudah, A.H.; Koting, S.; Ibrahim, M.R.; Alibrahim, M.M.; Jegatheesan, N. Resistance of Rubberized Asphalt Mixture to Aging and Moisture Damage. IIUM Eng. J. 2024, 25, 130–147. [Google Scholar] [CrossRef]

- Pratelli, C.; Betti, G.; Giuffrè, T.; Marradi, A. Preliminary in-situ evaluation of an innovative, semi-flexible pavement wearing course mixture using fast falling weight deflectometer. Materials 2018, 11, 611. [Google Scholar] [CrossRef]

- Anderton, R.C.; Ahlrich, G.L. Evaluation of Resin-Modified Paving Process; Transportation Research Board: Paris, France, 1991. [Google Scholar]

- AL-Qudah, A.H. Mechanical Properties of Asphaltic Concrete Mixture with Crumb Rubber and Aged Binder. Master’s Thesis, Universiti Malaysia Perlis, Perlis, Malaysia, 2018. [Google Scholar]

- Jain, J.A.; Neithalath, N. Chloride transport in fly ash and glass powder modified concretes–influence of test methods on microstructure. Cem. Concr. Compos. 2010, 32, 148–156. [Google Scholar] [CrossRef]

- Çınar, M.; Çelik, F.; Çanakcı, H.; Nassani, D.E. Fresh properties of cementitious grout with rice husk powder. Arab. J. Sci. Eng. 2017, 42, 3819–3827. [Google Scholar] [CrossRef]

- Celik, F.; Akcuru, O. Rheological and workability effects of bottom ash usage as a mineral additive on the cement based permeation grouting method. Constr. Build. Mater. 2020, 263, 120186. [Google Scholar] [CrossRef]

- Paul, S.C.; Šavija, B.; Babafemi, A.J. A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. J. Clean. Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Cheng, P.; Ma, G.; Li, Y. Preparation and performance improvement mechanism investigation of high-performance cementitious grout material for semi-flexible pavement. Polymers 2023, 15, 2631. [Google Scholar] [CrossRef]

- Zhang, D.; Ma, Z.; Zou, Y.; Xie, H.; Guan, R. Study on the strength and micro characteristics of grouted specimens with different superfine cement contents. Materials 2021, 14, 6709. [Google Scholar] [CrossRef]

- Al-Nawasir, R.; Al-Humeidawi, B.; Shubbar, A. Influence of sustainable grout material on the moisture damage of semi-flexible pavement. Period. Polytech. Civ. Eng. 2024, 68, 961–973. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. An investigation into the hydration and microstructure of cement pastes modified with glass powders. Constr. Build. Mater. 2016, 112, 915–924. [Google Scholar] [CrossRef]

- Meena, A.; Singh, R. Comparative Study of Waste Glass Powder as Pozzolanic Material in Concrete. Bachelor’s Thesis, National Institute of Technology, Rourkela, India, 2012. [Google Scholar]

- Spiesz, P.; Rouvas, S.; Brouwers, H. Utilization of waste glass in translucent and photocatalytic concrete. Constr. Build. Mater. 2016, 128, 436–448. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A. Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cem. Concr. Res. 2014, 58, 103–111. [Google Scholar] [CrossRef]

- Yin, W.; Li, X.; Sun, T.; Chen, Y.; Xu, F.; Yan, G.; Xu, M.; Tian, K. Utilization of waste glass powder as partial replacement of cement for the cementitious grouts with superplasticizer and viscosity modifying agent binary mixtures: Rheological and mechanical performances. Constr. Build. Mater. 2021, 286, 122953. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Wong, Y.C.; Arulrajah, A.; Horpibulsuk, S. Strength evaluation of utilizing recycled plastic waste and recycled crushed glass in concrete footpaths. Constr. Build. Mater. 2019, 197, 489–496. [Google Scholar] [CrossRef]

- Limbachiya, M.C. Bulk engineering and durability properties of washed glass sand concrete. Constr. Build. Mater. 2009, 23, 1078–1083. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Properties of architectural mortar prepared with recycled glass with different particle sizes. Mater. Desig. 2011, 32, 2675–2684. [Google Scholar] [CrossRef]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of waste glass addition as a replacement for fine aggregate on properties of mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, A.; Tang, W.; Khavarian, M.; Fang, C.; Wang, S. Thermal and mechanical properties of cement mortar composite containing recycled expanded glass aggregate and nano titanium dioxide. Appl. Sci. 2020, 10, 2246. [Google Scholar] [CrossRef]

- Bostanci, S.C.; Limbachiya, M.C.; Kew, H. Portland-composite and composite cement concretes made with coarse recycled and recycled glass sand aggregates: Engineering and durability properties. Constr. Build. Mater. 2016, 128, 324–340. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Meddah, M.S.; Fotiadou, S. Performance of granulated foam glass concrete. Constr. Build. Mater. 2012, 28, 759–768. [Google Scholar] [CrossRef]

- Sikora, P.; Horszczaruk, E.; Skoczylas, K.; Rucinska, T. Thermal properties of cement mortars containing waste glass aggregate and nanosilica. Proced. Eng. 2017, 196, 159–166. [Google Scholar] [CrossRef]

- Liu, S.; Xie, G.; Wang, S. Effect of curing temperature on hydration properties of waste glass powder in cement-based materials. J. Therm. Analy. Calorimet. 2015, 119, 47–55. [Google Scholar] [CrossRef]

- Li, G.; Xiong, H.; Ren, Q.; Zheng, X.; Wu, L. Experimental study and performance characterization of semi-flexible pavements. Coatings 2022, 12, 241. [Google Scholar] [CrossRef]

- Saboo, N.; Khalpada, V.; Sahu, P.K.; Radhakrishnan, R.; Gupta, A. Optimal proportioning of grout constituents using mathematical programming for semi flexible pavement. Internat. J. Pave. Res. Techn. 2019, 12, 297–306. [Google Scholar] [CrossRef]

- Koting, S.; Karim, M.R.; Mahmud, H.B.; Hamid, N.A.A. Mechanical properties of cement-bitumen composites for semi-flexible pavement surfacing. Balt. J. Road Bridge Eng. 2014, 9, 191–199. [Google Scholar] [CrossRef]

- Bang, J.W.; Lee, B.J.; Kim, Y.Y. Development of a semirigid pavement incorporating ultrarapid hardening cement and chemical admixtures for cement grouts. Advan. Mater. Sci. Eng. 2017, 2017, 4628690. [Google Scholar] [CrossRef]

- AL-Qudah, A.H.; Koting, S.; Ibrahim, M.R.; Alibrahim, M.M. Investigation of the Performance and Fuel Oil Corrosion Resistance of Semi-Flexible Pavement with the Incorporation of Recycled GlassWaste. Materials 2025, 18, 3442. [Google Scholar] [CrossRef]

- JKR MS-Part1 2003; Portland Cement (Ordinary and Rapid-Hardening): Part 1. Specifications (Second Revision). Department of Standards Malaysia: Kuala Lumpur, Malaysia, 2003.

- ASTM C187-11; Annual Book of ASTM Standards, Standard Test Method for Amount of Water Required for Normal Consistency of Hydraulic Cement Paste. ASTM: West Conshohocken, PA, USA, 2011.

- ASTM C191-21; Annual Book of ASTM Standards, Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM C188-17; Annual Book of ASTM Standards, Standard Test Method for Density of Hydraulic Cement. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM C109-20; Annual Book of ASTM Standards, Standard Test Methods for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C88-13; Annual Book of ASTM Standards, Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. ASTM: West Conshohocken, PA, USA, 2013.

- ASTM C125-20; Annual Book of ASTM Standards, Standard Terminology Relating to Concrete and Concrete Aggregates. ASTM: West Conshohocken, PA, USA, 2020.

- BS 812-Part 107; Annual Book of BS Standards, Standard Test Method for Mechanical and Physical Properties of Aggregates. Determination of Particle Density and Water Absorption. BS: London, UK, 1995.

- ASTM C131-14; Annual Book of ASTM Standards, Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM: West Conshohocken, PA, USA, 2014.

- BS 812-Part 112; Annual Book of BS Standards, Standard Test Method for Determination of Aggregate Impact Value. BS: London, UK, 1990.

- JKR-08; Standard Specification for Road Works, Section 4, Flexible Pavement. JKR: Kuala Lumpur, Malaysia, 2008.

- REAM SP3-07; Standard Specification for Semi Rigid Wearing Course. Section 3, Semi-Flexible Pavement. REAM: Kuala Lumpur, Malaysia, 2007.

- ASTM D5-06; Annual Book of ASTM Standards, Standard Test Method for Penetration of Bituminous Materials. ASTM: West Conshohocken, PA, USA, 2006.

- ASTM D36-09; Annual Book of ASTM Standards, Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM: West Conshohocken, PA, USA, 2009.

- ASTM D4402-15; Annual Book of ASTM Standards, Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM C305-14; Annual Book of ASTM Standards, Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM C939-16; Annual Book of ASTM Standards, Standard Test Method for Flow of Grout for Preplaced-Aggregate Concrete (Flow Cone Method). ASTM: West Conshohocken, PA, USA, 2016.

- ASTM C642-15; Annual Book of ASTM Standards, Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM C596-18; Annual Book of ASTM Standards, Standard Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement. ASTM: West Conshohocken, PA, USA, 2018.

- Jamshidi, A.; Kurumisawa, K.; Nawa, T.; Igarashi, T. Performance of pavements incorporating waste glass: The current state of the art. Renew. Sustain. Energ. Revi. 2016, 64, 211–236. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, J.; Pei, J.; Li, R.; Chen, X. Formulation and performance comparison of grouting materials for semi-flexible pavement. Constr. Build. Mater. 2016, 115, 582–592. [Google Scholar] [CrossRef]

- ASTM C948-23; Annual Book of ASTM Standards, Standard Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM C348-21; Annual Book of ASTM Standards, Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM: West Conshohocken, PA, USA, 2021.

- Rilem, T.C. CPC 11.3 Absorption of water by concrete by immersion under vacuum. In RILEM Recommendation for the Testing and Use of Constructions Materials; E & FN SPON: London, UK, 1994; pp. 36–37. [Google Scholar]

- ASTM D6926-04; Annual Book of ASTM Standards, Standard Test Method for Preparation of Bituminous Mixtures Using Marshall Apparatus. ASTM: West Conshohocken, PA, USA, 2004.

- ASTM D6390-11; Annual Book of ASTM Standards, Standard Test Method for Determination of Draindown Characteristics in Uncompacted Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2011.

- EN 12697-17; Annual Book of EN Standards, Standard Test Method for Particle Loss of Porous Asphalt Specimens, Bituminous Mixtures. BS: London, UK, 2017.

- ASTM D3203-2005; Annual Book of ASTM Standards, Standard Test Method for Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixtures. ASTM: West Conshohocken, PA, USA, 2005.

- Hassani, A.; Taghipoor, M.; Karimi, M.M. A state of the art of semi-flexible pavements: Introduction, design, and performance. Constr. Build. Mater. 2020, 253, 119196. [Google Scholar] [CrossRef]

- An, S.; Ai, C.; Ren, D.; Rahman, A.; Qiu, Y. Laboratory and field evaluation of a novel cement grout asphalt composite. J. Mater. Civ. Eng. 2018, 30, 04018179. [Google Scholar] [CrossRef]

- AL-Qudah, A.; Rahim, M.A.; Ghazaly, Z.M.; Mashaan, N.S.; Koting, S.; Napiah, M.; Omar, W.M.; Issa, Y. Effect of aged crumb rubber bitumen on performance dense graded mix in Malaysia. Int. J. Civ. Eng. Technol. 2018, 9, 1356–1369. [Google Scholar] [CrossRef]

- AASHTO T283-07; Annual Book of AASHTO Standards, Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. AASHTO: Washington, DC, USA, 2007.

- ASTM D1074-17; Annual Book of ASTM Standards, Standard Test Method for Compressive Strength of Asphalt Mixtures. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D6927-05; Annual Book of ASTM Standards, Standard Test Method for Marshall Stability and Flow of Bituminous Mixtures. ASTM: West Conshohocken, PA, USA, 2005.

- Leite, B.J.; Young, D.D. Use of waste glass as aggregate for pavement material. In Proceedings of the Ohio Highway Engineering Conference Proceedings, Columbus, OH, USA, 24–28 September 1972. [Google Scholar]

- Hamzani; Munirwansyah; Hasan, M.; Sugiarto, S. Determining the properties of semi-flexible pavement using waste tire rubber powder and natural zeolite. Constr. Build. Mater. 2021, 266, 121199. [Google Scholar] [CrossRef]

- Rahma, A.; El Naber, N.; Issa Ismail, S. Effect of glass powder on the compression strength and the workability of concrete. Cogent Eng. 2017, 4, 1373415. [Google Scholar] [CrossRef]

- Jurczak, R.; Szmatuła, F.; Rudnicki, T.; Korentz, J. Effect of ground waste glass addition on the strength and durability of low strength concrete mixes. Materials 2021, 14, 190. [Google Scholar] [CrossRef]

- Lu, P.; Gong, M. Toughness Reinforcement Design of Grouting Materials for Semi-Flexible Pavements Through Water-Based Epoxy Resin and Emulsified Asphalt. Coatings 2025, 15, 493. [Google Scholar] [CrossRef]

- Ning, S.; Jiang, X.; Li, B.; Shan, L.; Li, H. Research on Mechanical and Shrinkage Characteristics of a Resource-Based Cement Solid-Waste Concrete. Materials 2023, 17, 177. [Google Scholar] [CrossRef]

- Mallum, I.; Mohd Sam, A.R.; Lim, N.H.A.S.; Omolayo, N. Sustainable utilization of waste glass in concrete: A review. Silicon 2022, 14, 3199–3214. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Thomas, B. Effect of recycled waste glass on the properties of high-performance concrete: A critical review. Case Stud. Constr. Mater. 2022, 17, e01149. [Google Scholar] [CrossRef]

- Subba, R.; Kumar, C.; Sharma, D. Utilizing Crushed Waste Glass as A Sustainable Replacement for Fine Aggregate in Concrete. Internat. J. Multidiscipl. Res. 2023, 5, 1–13. [Google Scholar]

- Odler, I.; Rößler, M. Investigations on the relationship between porosity, structure and strength of hydrated Portland cement pastes. II. Effect of pore structure and of degree of hydration. Cem. Concr. Res. 1985, 15, 401–410. [Google Scholar] [CrossRef]

- Jantasuto, O.; Wiwattanachang, N.; Youngsukasem, N. Relationship between Porosity & Compressive Strength of Concrete with Variable W/C Ratio. UTK Res J. 2021, 15, 74–82. [Google Scholar]

- Khan, M.I.; Sutanto, M.H.; Khahro, S.H.; Zoorob, S.E.; Al-Sabaeei, A.M.; Javed, Y. Fatigue Prediction Model and Stiffness Modulus for Semi-Flexible Pavement Surfacing Using Irradiated Waste Polyethylene Terephthalate-Based Cement Grouts. Coatings 2023, 13, 76. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).