Abstract

This study systematically investigates the influence of 3D printing parameters on the surface morphology and coating performance of polylactic acid (PLA) substrates finished with traditional Chinese lacquer. PLA specimens were fabricated using fused deposition modeling (FDM) with varying print speeds, layer heights, and infill densities, followed by natural lacquer coating and controlled curing. Surface roughness, gloss, adhesion, and wear resistance were evaluated through standardized tests, while microstructural analysis using SEM revealed the interfacial morphology and film uniformity. Results indicate that layer height is the most dominant factor, exerting significant effects on all surface and coating properties. Increasing layer height led to higher surface roughness, which in turn reduced gloss due to enhanced diffuse scattering but improved adhesion and wear resistance through stronger mechanical interlocking. Print speed showed a secondary influence on adhesion, attributed to its effect on interlayer bonding and surface porosity, while infill density exhibited minimal influence except on wear resistance. The application of Chinese lacquer significantly reduced surface irregularities owing to its excellent self-leveling and gap-filling capabilities, producing smooth, durable, and well-adhered coatings. Overall, the study demonstrates that integrating traditional lacquer with modern FDM technology provides a sustainable and high-performance finishing solution for 3D-printed PLA, bridging cultural craftsmanship with advanced additive manufacturing for potential applications in decorative, protective, and eco-friendly products.

1. Introduction

With the rapid development of additive manufacturing, fused deposition modeling (FDM) has become one of the most widely used 3D printing techniques due to its low cost, design flexibility, and material versatility [1,2,3]. Among the materials used, polylactic acid (PLA), a biodegradable thermoplastic derived from renewable resources, has attracted considerable attention for applications in consumer products, biomedical devices, and cultural heritage reproduction [4,5,6]. However, despite its sustainability and ease of processing, PLA suffers from inherent limitations such as poor surface finish, low gloss, weak wear resistance, and insufficient adhesion to coatings, which restrict its broader use in high-value products like decorative furniture and artware [7,8,9].

To address these deficiencies, surface finishing techniques are often applied to 3D-printed PLA. Conventional finishing methods include sanding, polishing, chemical vapor smoothing, and polymer coatings [10,11,12]. While these approaches can reduce roughness or improve appearance, they may involve high energy consumption, chemical hazards, or limited compatibility with eco-friendly applications [13]. Chinese lacquer, a traditional biomaterial derived from the sap of Toxicodendron vernicifluum, offers an environmentally sustainable alternative with exceptional mechanical durability, gloss, adhesion, and chemical resistance [14,15,16]. Renowned as the “king of coatings”, Chinese lacquer has been treasured in China for more than 8000 years. It exhibits naturally high gloss, outstanding corrosion resistance, and excellent adhesion, making it unparalleled among natural coatings. Historically, exquisite lacquerware required dozens or even hundreds of carefully applied layers, with the preparation of the lacquer substrate (胎体) being particularly critical and time-consuming. This highlights the significance of employing 3D-printed PLA as a modern substitute for traditional lacquer substrates, offering a controllable, efficient, and precise method for preparing lacquer bodies. Historically, Chinese lacquer has been employed in furniture, artworks, and cultural artifacts, demonstrating superior wear resistance, longevity, and aesthetic performance compared to synthetic coatings [17,18].

Recent research has begun to explore the integration of natural lacquer with modern materials. Studies have reported that lacquer films exhibit strong adhesion and toughness on wood, bamboo, and metals, and their unique curing mechanism under humid conditions provides self-leveling and gap-filling capabilities [19,20,21]. However, very limited attention has been given to the application of Chinese lacquer on 3D-printed polymers such as PLA. The interfacial compatibility between lacquer and PLA, particularly considering the characteristic layer lines and surface porosity of FDM products, remains poorly understood [22,23]. Moreover, the influence of printing parameters—including layer height, print speed, and infill density—on the performance of lacquer films has yet to be systematically investigated [24]. Moreover, while numerous 3D printing parameters exist—such as nozzle temperature, bed temperature, and extrusion flow rate—previous studies have shown that print speed, layer height, and infill density are the most direct and influential factors affecting surface morphology and coating adhesion in FDM parts [25,26,27]. Therefore, this study focuses on these three parameters.

At the same time, Chinese lacquer itself brings unique advantages to this research. As a natural, biodegradable, and VOC-free coating, it aligns well with sustainable manufacturing practices. Beyond its environmental benefits, lacquer provides high hardness, excellent wear and chemical resistance, and long-term stability, while also carrying significant cultural and artistic value [15,16,17,18,19]. These properties make it a promising candidate for enhancing the surface quality and durability of 3D-printed PLA components, particularly in decorative and functional applications.

Therefore, this study aims to bridge the gap between traditional lacquer technology and modern additive manufacturing. Specifically, we evaluate the effects of 3D printing parameters on the surface roughness, gloss, adhesion, and wear resistance of PLA substrates before and after coating with natural Chinese lacquer. In addition, microstructural analyses were conducted to elucidate the mechanisms of lacquer penetration, film formation, and interfacial bonding. By integrating experimental testing with statistical analysis, this work provides novel insights into the functional enhancement of 3D-printed PLA through natural lacquer coatings. The findings not only contribute to sustainable finishing strategies for polymer-based products but also promote innovative applications of traditional Chinese materials in modern manufacturing.

2. Materials and Methods

2.1. Materials and Equipment

Polylactic acid (PLA), a biodegradable thermoplastic polyester derived from renewable resources such as corn starch and sugarcane, was selected as the primary 3D printing material due to its widespread application in fused deposition modeling (FDM), good processability, and environmental friendliness. PLA filament (diameter 1.75 mm, MakerBot, Brooklyn, NY, USA) and polyvinyl alcohol (PVA) filament (diameter 1.75 mm, MakerBot, USA) were employed in this study. PVA was used as a water-soluble support material to facilitate the printing of complex geometries and was completely removed after fabrication.

Natural Chinese lacquer with a solid content of 71.97% was obtained from Shaanxi Longtou National Lacquer Cultural Industry Co., Ltd., Xi’an, China. The instruments and equipment used included a MakerBot Method 3D printer, an electronic balance (Shanghai Precision Scientific Instrument Co., Ltd., Shanghai, China), a surface roughness tester (Model SJ-210, Shanghai Taiming Optical Instrument Co., Ltd., Shanghai, China), a gloss meter (Shenzhen Sanenshi Technology Co., Ltd., Shenzhen, China), a contact angle goniometer (Krüss DSA100, Hamburg, Germany), a constant temperature and humidity chamber, an adhesion tester, and a 50 μm wire bar coater (Shanghai Chengyi Instrument Co., Ltd., Shanghai, China). Hitachi S-4800 scanning electron microscop (Hitachi, Tokyo, Japan).

Given the growing demand for sustainable materials and the unique cultural and functional value of traditional Chinese lacquer, the combination of PLA and lacquer provides an innovative approach for developing eco-friendly coatings and expanding the applications of bio-based polymers.

2.2. Three-Dimensional Printing Process

Specimens were fabricated using fused deposition modeling (FDM) technology. The mechanical properties and overall quality of FDM-printed specimens are influenced by multiple factors and are often difficult to predict prior to fabrication [28,29,30]. Among these, print speed, layer height, and infill density have been identified in previous studies as the most critical parameters. In this study, a full-factorial experimental design was employed, where three factors (print speed, layer height, and infill density) were each set at three levels (print speed: 60, 80, and 100 mm/s; layer height: 0.1, 0.2, and 0.3 mm; infill density: 10%, 40%, and 70%). This resulted in a total of 27 groups of specimens, with five replicates for each group, yielding 135 specimens in total.

All specimens were printed as rectangular blocks (50 × 50 × 5 mm3), providing flat surfaces suitable for lacquer coating and subsequent surface testing. The 3D models were created in 3ds Max, exported as STL files, and processed in MakerBot slicing software (Version 4.10.1.2056, MakerBot Industries, LLC, 2009–2025) for parameter setting and slicing. After printing, all support structures were removed.

2.3. Lacquering Process

The PLA specimens were coated with natural lacquer (solid content: 71.97%) using a 50 μm wire bar coater to form a uniform film and then placed in a constant temperature and humidity chamber (25 °C, relative humidity 80%) for curing. The drying time of the lacquer film was determined in accordance with GB/T 1728-2020 Paints and Putty Films—Determination of Drying Time. The tack-dry state was assessed by gently touching the film surface with a finger: if it felt tacky but no lacquer adhered to the finger, the film was considered surface-dry; complete dryness was defined as the absence of tackiness. Drying status was monitored at 10 min intervals, and all specimens reached dryness within 320–330 min. The fully dried specimens were then subjected to subsequent performance evaluations. It should be noted that the lacquer employed in this study was natural raw lacquer, in which the primary solvent components are water and inherent natural substances. No additional organic solvents were added, thus minimizing potential solvent–PLA interactions. Nevertheless, future work could further examine the interfacial chemical effects between lacquer components and PLA substrates.

2.4. Evaluation of PLA Surface Properties

2.4.1. Surface Roughness

Surface roughness before and after coating was measured in accordance with GB/T 1031-2009 Surface Roughness Parameters and Their Values. Ra (arithmetic mean deviation), Rq (root mean square deviation), and Rt (total height of the profile) were recorded.

2.4.2. Glossiness

Gloss measurements were conducted according to GB/T 9754-2007 Paints and Varnishes—Determination of Specular Gloss of Non-Metallic Paint Films at 20°, 60°, and 85°. A gloss meter (60° geometry) was used to measure four corners of each specimen, and the average value was reported.

2.4.3. Adhesion

Adhesion strength was determined following GB/T 5210-2006 Paints and Varnishes—Pull-off Test for Adhesion. After coating and drying, cylindrical studs were bonded to the lacquer surface using adhesive. Once cured, the assembly was subjected to a pull-off adhesion test using a tensile testing machine. The required tensile force to detach the coating from the substrate was recorded, with results expressed either as adhesive failure or cohesive failure.

2.4.4. Abrasion Resistance

Abrasion resistance was evaluated in accordance with GB/T 1768-2006 Paints and Varnishes—Determination of Resistance to Abrasion—Rotating Rubber Wheel Method. The dried films were abraded using a rubber wheel under specified conditions, and the mass loss after a defined number of abrasion cycles was used to quantify resistance.

2.4.5. Scanning Electron Microscopy (SEM)

Coated 3D-printed specimens were sectioned (4 mm × 2 mm × 1 mm cross-sectional samples with lacquer film) and mounted on specimen stubs. After sputter coating with gold, the samples were observed under a Hitachi S-4800 scanning electron microscope to investigate the microstructure of the lacquer layer and interface.

2.5. Statistical Analysis

All data were analyzed using three-way analysis of variance (ANOVA) with layer height, print speed, and infill density as independent factors. The effects of these parameters on surface roughness (Ra, Rq, Rt), gloss, and adhesion strength were assessed. Statistical analyses were conducted using SPSS software (Version 25.0, IBM Corp., Armonk, NY, USA), with a significance level of p < 0.05.

3. Results

3.1. Analysis of Surface Roughness of PLA Specimens

The surface roughness of PLA specimens, both before and after lacquer coating, was systematically analyzed using three-way ANOVA with print speed, layer height, and infill density as independent factors. The results are summarized in Table 1, where values represent the mean ± standard deviation of five replicates under each parameter condition. Error bars have been incorporated into all datasets to reflect variability and ensure statistical reliability.

Table 1.

Three-way ANOVA of surface roughness of specimens with and without Chinese lacquer coatings.

The results indicate that both print speed and layer height exerted highly significant effects (p < 0.001) on roughness parameters Ra, Rq, and Rt, regardless of whether specimens were coated or uncoated, while infill density showed no significant influence (p > 0.05). Specifically, Ra, Rq, and Rt increased with higher print speeds and larger layer heights. For example, without lacquer, Ra increased from 7.01 ± 0.89 μm at 0.1 mm layer height to 13.03 ± 1.25 μm at 0.3 mm. After coating, a similar trend was observed, with Ra rising from 1.01 ± 0.25 μm to 3.04 ± 0.38 μm as layer height increased. These results highlight the dominant role of layer height in governing surface roughness.

Infill density exhibited only minimal variations, with values fluctuating within 0.05 μm and no clear trend, which explains the lack of statistical significance. Although roughness values associated with print speed and infill density followed similar trends, only print speed reached significance. This is likely due to the overwhelming main effect of layer height, which masked the comparatively small influence of infill density.

Interaction effects were also tested. The interaction between print speed and layer height showed limited significance for Rt (p = 0.015 without lacquer; p = 0.024 with lacquer), suggesting that peak-to-valley height (Rt) is more sensitive to combined parameter variations than Ra or Rq. Other two-way and three-way interactions were not statistically significant (p > 0.05), indicating that the main effects of layer height and speed dominate. When comparing coated and uncoated specimens, the application of Chinese lacquer significantly reduced surface roughness across all parameter levels. For instance, Rt decreased from 39.04 ± 2.25 μm (uncoated, 0.3 mm layer height) to 15.04 ± 2.25 μm (coated, 0.3 mm). This reduction can be attributed to the self-leveling and pore-filling capabilities of lacquer, which smooth out the ridges formed during FDM printing.

3.2. Surface Gloss, Adhesion, and Wear Resistance of Chinese Lacquer on PLA Substrates

The surface gloss, adhesion, and wear resistance of PLA specimens coated with Chinese lacquer were evaluated, and the results of the three-way ANOVA are summarized in Table 2. The analysis revealed that layer height exerted the most significant influence on all three performance indicators (p < 0.001). In contrast, print speed showed no statistically significant effect on gloss or wear resistance, though it significantly influenced adhesion (p < 0.001). Infill density had no significant effect on gloss or adhesion, but strongly affected wear resistance (p < 0.001).

Table 2.

Three-way ANOVA of surface gloss, adhesion, and wear resistance of Chinese lacquer on PLA Substrates.

For gloss, the mean values decreased sharply with increasing layer height: specimens printed at 0.1 mm achieved the highest gloss (53.86 ± 0.26 GU), while those at 0.3 mm dropped to only 25.29 ± 0.17 GU. This confirms that gloss is highly sensitive to surface smoothness, with larger layer heights creating more pronounced step structures that enhance diffuse scattering and reduce specular reflection [31]. Print speed and infill density, however, had negligible effects on gloss, consistent with the lacquer’s self-leveling ability that compensates for micro-scale irregularities.

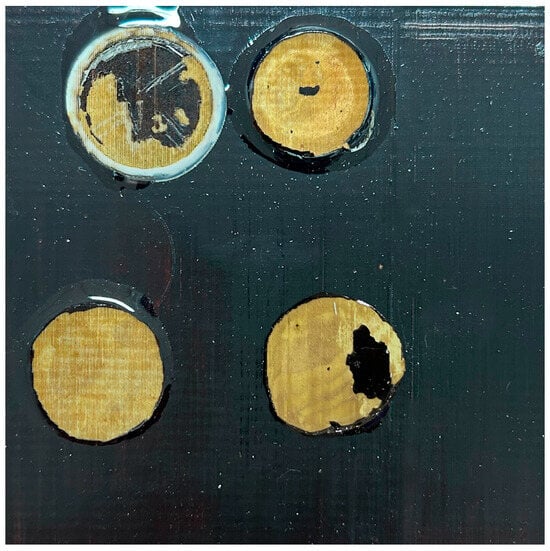

In terms of adhesion, the lacquer films showed an overall improvement with increasing layer height, rising from 7.23 ± 0.36 MPa at 0.1 mm to 8.65 ± 0.46 MPa at 0.3 mm. This enhancement can be attributed to deeper grooves and larger interfacial contact areas formed at higher layer heights, which facilitate lacquer infiltration and mechanical interlocking. A secondary effect of print speed was also observed: adhesion improved gradually with higher speeds (7.51 ± 0.56 MPa at 60 mm/s to 8.31 ± 0.62 MPa at 100 mm/s). The pull-off test images (Figure 1) demonstrated that the predominant failure mode was cohesive failure within the lacquer film, with occasional interfacial failures, further confirming strong bonding between PLA and lacquer.

Figure 1.

Pull-off adhesion test showing typical failure modes of Chinese lacquer coatings on 3D-printed PLA substrates.

With respect to wear resistance, mass loss decreased markedly as layer height increased, from 0.062 ± 0.011 g at 0.1 mm to 0.036 ± 0.007 g at 0.3 mm, indicating enhanced abrasion resistance at larger step sizes. This improvement is likely due to the local thickening of lacquer films within grooves, which act as protective “buffers” against abrasion. Infill density also had a significant effect: specimens with 70% infill showed superior resistance (0.039 ± 0.013 g) compared to those with 10% infill (0.059 ± 0.012 g), likely because denser substrates reduced deformation and better supported the lacquer film during abrasion. Representative worn surfaces are shown in Figure 2, highlighting the distinct groove-filling behavior of lacquer that helps preserve surface integrity under abrasion.

Figure 2.

Worn surface morphology of Chinese lacquer-coated PLA specimens after abrasion testing.

Overall, these findings demonstrate that layer height is the dominant parameter governing both optical and mechanical performance of lacquer-coated PLA, whereas print speed and infill density play secondary or negligible roles. Importantly, a trade-off exists: finer layer heights (0.1 mm) maximize gloss but weaken adhesion and wear resistance, while larger layer heights (0.3 mm) enhance mechanical robustness at the cost of surface appearance.

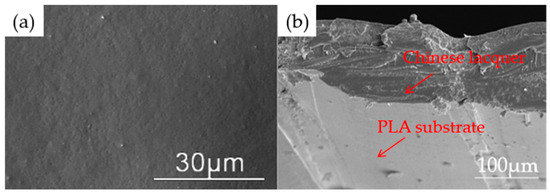

3.3. Microstructure of Chinese Lacquer on PLA Substrates

Figure 3 presents the microscopic morphology of the Chinese lacquer coating applied to 3D-printed PLA substrates. As shown in Figure 3a, the surface of the lacquer film exhibits a uniform and smooth appearance, with no visible cracks or defects, indicating good film formation and curing quality. In contrast, Figure 3b illustrates the cross-sectional interface between the lacquer and the PLA substrate, where the boundary is clearly distinguishable yet continuous, suggesting effective interfacial adhesion.

Figure 3.

Microstructure of Chinese lacquer coating on 3D-printed PLA: (a) surface morphology; (b) lacquer–PLA interface.

During the fused deposition modeling (FDM) process, PLA filaments are deposited layer by layer, creating distinct linear ridges and interfacial boundaries on the surface. These characteristic layer lines of FDM printing result in a textured surface that affects subsequent coating morphology. The lacquer film conforms to this stepped topography, displaying slight undulations corresponding to the underlying PLA structure. However, compared with the uncoated substrate, the lacquer-coated surface is markedly smoother, demonstrating that the lacquer effectively fills the grooves and levels the peaks formed during printing. This observation confirms that the inherent layered texture of the PLA substrate plays a decisive role in determining the final morphology of the lacquer film. The lacquer’s self-leveling and infiltrating behavior compensates for micro-defects and partially smooths the layer boundaries, thereby improving surface uniformity and enhancing the aesthetic and protective performance of the coating.

4. Discussion

The findings of this study demonstrate that the coating performance of Chinese lacquer on 3D-printed PLA substrates is predominantly determined by the surface morphology formed during the fused deposition modeling (FDM) process. Among the three process parameters investigated—print speed, layer height, and infill density—layer height exhibited the most pronounced and consistent influence across all evaluated properties, including surface roughness, gloss, adhesion, and wear resistance. This observation corroborates previous studies describing the “staircase effect” in FDM printing, where larger layer heights inherently generate more pronounced step edges and surface irregularities, resulting in elevated roughness even after coating application [32,33].

Although Chinese lacquer exhibited remarkable self-leveling and gap-filling capabilities, effectively mitigating minor variations caused by print speed and infill density, the macroscopic texture determined by layer height remained the dominant factor shaping the optical and mechanical performance of the coated surfaces. The significant reduction in gloss at higher layer heights can be attributed to the enhancement of diffuse light scattering, which reduces specular reflection—a well-documented phenomenon in coating science, where gloss is highly sensitive to nanoscale and microscale surface smoothness [34].

In contrast, the adhesion strength improved with increasing layer height, as deeper grooves enhanced lacquer infiltration and mechanical interlocking between the coating and the substrate. This micro-mechanical anchoring mechanism not only strengthened the interfacial bonding but also contributed to improved wear resistance, since the depressions created by larger layer heights allowed localized thickening of the lacquer film. These thicker regions acted as protective buffers against abrasive forces, thereby minimizing material loss during wear tests [35,36,37].

Consequently, a clear trade-off emerges between decorative and functional performance: finer layer heights yield smoother and glossier surfaces, while larger layer heights enhance adhesion and abrasion resistance. Such a balance between aesthetic and mechanical properties highlights the need for multi-objective optimization in future studies, potentially employing response surface methodology (RSM) or similar statistical tools to determine ideal processing conditions for specific applications.

Microscopic analysis further confirmed that Chinese lacquer not only smoothed the surface topography but also penetrated into voids and microdefects produced during the FDM process, thereby improving surface integrity and reducing the influence of inherent printing flaws such as porosity and weak interlayer bonding [38,39]. However, the presence of trapped air bubbles in the ridged regions occasionally led to localized coating defects, aligning with earlier reports on the difficulties of achieving uniform coating coverage on additively manufactured surfaces [40]. The results underscore the exceptional adaptability of Chinese lacquer as both a decorative and functional coating for 3D-printed PLA substrates. While layer height remains the primary parameter influencing coating behavior, the intrinsic self-leveling, infiltration, and toughening properties of natural lacquer effectively compensate for the surface imperfections typical of FDM printing. This synergy between traditional lacquer technology and modern additive manufacturing offers new opportunities for sustainable surface finishing, combining cultural craftsmanship with advanced material engineering to enhance both performance and aesthetics [41,42].

5. Conclusions

This study comprehensively examined how 3D printing parameters influence the surface morphology and coating performance of polylactic acid (PLA) specimens finished with traditional Chinese lacquer. The results reveal that layer height is the most critical parameter, exerting significant and consistent effects on surface roughness, gloss, adhesion, and wear resistance, while print speed and infill density contributed secondary or negligible influences.

As layer height increased, surface roughness also increased, leading to a decline in gloss due to enhanced diffuse light scattering. At the same time, the larger grooves and ridges formed at higher layer heights facilitated deeper lacquer penetration and stronger mechanical interlocking, thereby improving adhesion and wear resistance. Although the lacquer’s natural self-leveling and gap-filling properties effectively compensated for variations in print speed and infill density, the staircase effect inherent to FDM printing remained the dominant factor shaping the coated surface.

Chinese lacquer proved to be an exceptionally effective and sustainable coating material for 3D-printed PLA, enhancing both mechanical durability and visual quality. It significantly improved adhesion strength and wear resistance, while partially alleviating common FDM issues such as porosity, surface irregularity, and interlayer voids. However, a clear trade-off exists between aesthetic attributes (high gloss and smoothness) and functional performance (adhesion and abrasion resistance), emphasizing the importance of parameter optimization in balancing decorative appeal and protective performance. The integration of traditional Chinese lacquer with modern additive manufacturing offers a novel and eco-friendly approach to high-performance surface finishing. This synergy bridges ancient craftsmanship and advanced material science, enabling the development of sustainable, decorative, and mechanically robust coatings applicable to furniture manufacturing, cultural heritage restoration, and polymer-based engineering products.

Future research should focus on hybrid surface modification strategies—such as pre-treatment of PLA substrates, laser-assisted texturing, or the incorporation of nanomaterials into lacquer formulations—to further enhance coating uniformity, reduce bubble entrapment, and optimize interfacial bonding. Such efforts will broaden the application scope of Chinese lacquer in additive manufacturing and deepen the understanding of its behavior on polymeric substrates.

Author Contributions

Conceptualization, Y.X. and X.L.; methodology, Y.X., Y.F. and X.L.; software, Y.X.; validation, Y.X., Y.F. and X.L.; formal analysis, Y.X. and Y.F.; investigation, Y.X., Y.F. and Y.C.; resources, X.L. and A.O.; data curation, Y.X. and Y.C.; writing—original draft preparation, Y.X. and Y.F.; writing—review and editing, Y.X., Y.F., A.O., Y.C. and X.L.; visualization, Y.X.; supervision, X.L.; project administration, X.L.; funding acquisition, X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Scientific Research Contract (No. 11295) from Transilvania University of Brasov, dated 12 August 2025.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Yuemin Feng was employed by the company Tubao Decorative New Materials Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Bozkurt, Y.; Karayel, E. 3D printing technology; methods, biomedical applications, future opportunities and trends. J. Mater. Res. Technol. 2021, 14, 1430–1450. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-based 3D printing applications of PLA composites: A review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Taib, N.-A.A.B.; Rahman, M.R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bakri, M.K.B.; Julaihi, M.R.M.B. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Akhoundi, B.; Nabipour, M.; Kordi, O.; Hajami, F. Calculating printing speed in order to correctly print PLA/continuous glass fiber composites via fused filament fabrication 3D printer. J. Thermoplast. Compos. Mater. 2023, 36, 162–181. [Google Scholar] [CrossRef]

- Baran, E.H.; Erbil, H.Y. Surface modification of 3D printed PLA objects by fused deposition modeling: A review. Colloids Interfaces 2019, 3, 43. [Google Scholar] [CrossRef]

- Jordá-Vilaplana, A.; Fombuena, V.; García-García, D.; Samper, M.D.; Sánchez-Nácher, L. Surface modification of polylactic acid (PLA) by air atmospheric plasma treatment. Eur. Polym. J. 2014, 58, 23–33. [Google Scholar] [CrossRef]

- Li, J.; Lu, X.L.; Zheng, Y.F. Effect of surface modified hydroxyapatite on the tensile property improvement of HA/PLA composite. Appl. Surf. Sci. 2008, 255, 494–497. [Google Scholar] [CrossRef]

- Vicente, C.; Fernandes, J.; Deus, A.; Vaz, M.; Leite, M.; Reis, L. Effect of protective coatings on the water absorption and mechanical properties of 3D printed PLA. Frat. Integrità Strutt. 2019, 13, 748–756. [Google Scholar] [CrossRef]

- Aziz, R.; Haq, M.I.U.; Raina, A. Effect of surface texturing on friction behaviour of 3D printed polylactic acid (PLA). Polym. Test. 2020, 85, 106434. [Google Scholar] [CrossRef]

- Pušnik Črešnar, K.; Aulova, A.; Bikiaris, D.N.; Lambropoulou, D.; Kuzmič, K.; Fras Zemljič, L. Incorporation of metal-based nanoadditives into the PLA matrix: Effect of surface properties on antibacterial activity and mechanical performance of PLA nanoadditive films. Molecules 2021, 26, 4161. [Google Scholar] [CrossRef]

- Zhou, Y.; Long, C.; Huang, J.; Deng, Z.; Cao, T. Effect of surface treatments on properties of lacquer seed shell fiber-reinforced poly (lactic acid) composites. J. Reinf. Plast. Compos. 2013, 32, 1348–1358. [Google Scholar] [CrossRef]

- Lu, R.; Yoshida, T.; Miyakoshi, T. Oriental lacquer: A natural polymer. Polym. Rev. 2013, 53, 153–191. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, B.; Jiang, L.; Wu, J.; Sun, G. Natural lacquer was used as a coating and an adhesive 8000 years ago, by early humans at Kuahuqiao, determined by ELISA. J. Archaeol. Sci. 2018, 100, 80–87. [Google Scholar] [CrossRef]

- Kanehashi, S.; Oyagi, H.; Lu, R.; Miyakoshi, T. Development of bio-based hybrid resin, from natural lacquer. Prog. Org. Coat. 2014, 77, 24–29. [Google Scholar] [CrossRef]

- Li, D.; Li, K.; Fang, J. Research progress on modification and application of raw lacquer. ChemistrySelect 2022, 7, e202200943. [Google Scholar] [CrossRef]

- Song, X.; Yang, Y.; Yang, R.; Shafi, M. Keeping watch on intangible cultural heritage: Live transmission and sustainable development of Chinese lacquer art. Sustainability 2019, 11, 3868. [Google Scholar] [CrossRef]

- Lu, R.; Wan, Y.Y.; Honda, T.; Ishimura, T.; Kamiya, Y.; Miyakoshi, T. Design and characterization of modified urethane lacquer coating. Prog. Org. Coat. 2006, 57, 215–222. [Google Scholar] [CrossRef]

- Lu, R.; Harigaya, S.; Ishimura, T.; Nagase, K.; Miyakoshi, T. Development of a fast drying lacquer based on raw lacquer sap. Prog. Org. Coat. 2004, 51, 238–243. [Google Scholar]

- Li, Y.; Yuan, J.; Wang, H.; Li, S.; Liu, Z.; Lu, Y.; Zhang, J.; Yi, Y.; Shi, J.; Wu, H.; et al. Enhanced wood protection and sustainability via nano-modified raw lacquer coatings: Preparation, properties, and performance evaluation. Ind. Crops Prod. 2025, 233, 121417. [Google Scholar] [CrossRef]

- Wu, T.; Xu, W. Preparation of tung oil-modified raw lacquer films and application for mechanical carving technique. Coatings 2024, 14, 1264. [Google Scholar] [CrossRef]

- Kovan, V.; Tezel, T.; Topal, E.S.; Camurlu, H.E. Printing parameters effect on surface characteristics of 3D printed PLA materials. Mach. Technol. Mater. 2018, 12, 266–269. [Google Scholar]

- Arnold, C.; Monsees, D.; Hey, J.; Schweyen, R. Surface quality of 3D-printed models as a function of various printing parameters. Materials 2019, 12, 1970. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah; Arifin, Z. A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Almeida, J.H.S., Jr.; Jayaprakash, S.; Kolari, K.; Kuva, J.; Kukko, K.; Partanen, J. The role of printing parameters on the short beam strength of 3D-printed continuous carbon fibre reinforced epoxy-PETG composites. Compos. Struct. 2024, 337, 118034. [Google Scholar] [CrossRef]

- Wu, H.C.; Chen, T.C.T. Quality control issues in 3D-printing manufacturing: A review. Rapid Prototyp. J. 2018, 24, 607–614. [Google Scholar] [CrossRef]

- Pereira, T.; Potgieter, J.; Kennedy, J.V. A fundamental study of 3D printing testing methods for the development of new quality management strategies. In Proceedings of the 2017 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar]

- Santana, L.; Alves, J.L.; Netto, A.C.S. A study of parametric calibration for low cost 3D printing: Seeking improvement in dimensional quality. Mater. Des. 2017, 135, 159–172. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Improvement of surface finish by staircase machining in fused deposition modeling. J. Mater. Process. Technol. 2003, 132, 323–331. [Google Scholar] [CrossRef]

- Wenbin, H.; Yong, T.L.; Haiqing, G. A study of the staircase effect induced by material shrinkage in rapid prototyping. Rapid Prototyp. J. 2005, 11, 82–89. [Google Scholar] [CrossRef]

- Bonilla-Cruz, J.; Sy, J.A.C.; Lara-Ceniceros, T.E.; Gaxiola-López, J.C.; García, V.; Basilia, B.A.; Advincula, R.C. Superhydrophobic μ-pillars via simple and scalable SLA 3D-printing: The staircase effect and their wetting models. Soft Matter 2021, 17, 7524–7533. [Google Scholar]

- Järnström, J.; Ihalainen, P.; Backfolk, K.; Peltonen, J. Roughness of pigment coatings and its influence on gloss. Appl. Surf. Sci. 2008, 254, 5741–5749. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological behavior and dynamic mechanical properties for interpretation of layer adhesion in FDM 3D printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Günther, N.; Griese, M.; Stammen, E.; Dilger, K. Modeling of adhesive layers with temperature-dependent cohesive zone elements for predicting adhesive failure during the drying process of cathodic dip painting. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 485–494. [Google Scholar]

- Zhiani Hervan, S.; Altınkaynak, A.; Parlar, Z. Hardness, friction and wear characteristics of 3D-printed PLA polymer. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1590–1598. [Google Scholar]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of porosity and crystallinity on 3D printed PLA properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [PubMed]

- Von Windheim, N.; Collinson, D.W.; Lau, T.; Brinson, L.C.; Gall, K. The influence of porosity, crystallinity and interlayer adhesion on the tensile strength of 3D printed polylactic acid (PLA). Rapid Prototyp. J. 2021, 27, 1327–1336. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Z.; Wang, X.; Wang, F. Mathematical model for characterizing the full process of volatile organic compound emissions from paint film coating on porous substrates. Build. Environ. 2020, 182, 107062. [Google Scholar] [CrossRef]

- Hou, J.; Wang, Y.; Wang, T.; Xu, G.; Feng, X.; Liu, X. The Effects of Repeated Kurome Treatment on Chinese Lacquer and Its Film Propertie. Polymers 2025, 17, 1481. [Google Scholar] [CrossRef]

- Han, J.; Webb, M.; Hao, X.; Khanjian, H.; Schilling, M.R. Surface appearance and morphology changes of Asian lacquer due to artificial aging: Impacts of traditional additives. J. Cult. Herit. 2023, 63, 249–262. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).