Abstract

Sunflower stalks could be an alternative raw material for use in the particleboard industry since the requirements of P1 general purpose boards for use in dry conditions and P2 boards for interior fitment for use in dry conditions are easily satisfied. Acetylation of sunflower stalks is found to greatly improve the thickness swelling (TS) value, with acetylated boards showing 19.7% weight gain, meeting the TS requirements of P3 Non-Load-Bearing—Humid and P4 Load Bearing—Dry criteria; however, acetylation adversely affects the internal bond strength (IBS). It is suggested that combinations of industrial wood chips with sunflower raw material may be used for the overall improvement performance of the particleboards.

1. Introduction

Worldwide economic development has caused increased needs for converted wood products [1,2,3,4,5,6]. A big challenge in the composites industry is the availability of cheaper materials in order to minimize the production cost. The implementation of agricultural residues as an option is growing and has come to the minds of many researchers in laboratories worldwide [7,8,9,10,11]. The use of such materials may benefit both socioeconomic and environmental development since they are normally burnt in the field or ploughed into the soil.

Therefore, looking for potential replacements for slow-growing trees is of great importance, and available agricultural plants might be good alternatives [12,13]. A variety of plants have been studied for use in composites manufacturing, including vine stalks [14], topinambour stalks [12,15], cotton stalks [16,17], coconut chips [18], bamboo chips [19,20,21], flax chips [22], and banana chips [23]. Other agriculture residues also include rice and wheat straw [24,25], canola straws [26], reed stem [27], date palms [28], oil palms and poppy husks [29], and stalks from cotton [30].

Sunflower (Helianthus annuus L.), from the Asteraceae family, is another annual plant. It is an annual forb which is grown as a crop for its edible oil and edible fruits. Sunflower grows in biomass at 4 t/ha and is widely cultivated all over the world [31]. The harvested area in Europe is 368 × 106 ha, which represents the 16% of the harvested area worldwide [13].

Several research studies have been performed so far focusing on the utilization of sunflower stalks in particleboard manufacturing. Panels from sunflower stalks were successfully produced for the first time at the University of Minnesota [32,33]. Another study used sunflower stalks to reduce the cost of the final product [34]. Other researchers attempted to use sunflower stalks in combination with pine particles. They reported improved physico-mechanical properties; in addition, the boards met the requirements for general-grade particleboards [35]. The same conclusion was drawn in a study which used sunflower stalks in combination with poplar chips [36]. Other researchers suggested that sunflower stalk may be incorporated as a cheap raw material to produce particleboard with acceptable properties [37]. The feasibility of agricultural crop residues, such as cup plant, topinambour, and sunflower, used as an alternative raw material for particleboards was investigated [15]. The findings revealed that particleboards can be successfully produced from agricultural residues, especially when isocyanate is used as a binder. In all the abovementioned studies, particleboard composites met the British P2 general use and P3 interior fitment board criteria, as far as the thickness swelling value is concerned. However, the P4 load-bearing panel, which requires a thickness swelling value of 14%, has not been satisfied. A value of 16%, close to the critical 14%, was reported when 8% of titanium dioxide nanoparticles was incorporated during board production [37]. Therefore, reaching this value can be considered a challenge and may be achieved by applying the chemical modification technique [38].

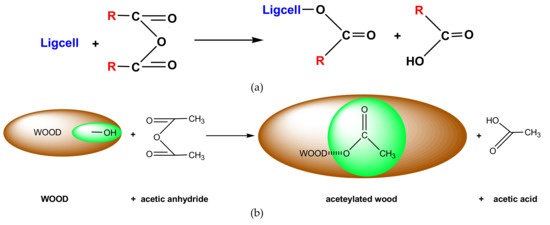

As a consequence, the objective of this communication was to investigate the technical feasibility of manufacturing particleboards from chemically modified sunflower stalks. The most studied type of chemical modification is the reaction with acetic anhydride, known as acetylation, which is depicted in Figure 1a [38] and schematically illustrated in Figure 1b. Acetic anhydride replaces the abundant hydrophilic hydroxyl groups which are present in the lignocellulosic material with hydrophobic acetyl groups. Thus, the material remains permanently in a swollen condition due to the bulking action of the hydrophobic acetyl groups.

Figure 1.

Reaction of anhydride with lignocellulosic material: (a) chemical illustration, (b) schematic illustration.

2. Materials and Methods

2.1. Raw Material

Sunflower furnish from stalks, supplied by Artvin Coruh Univesitesi, Turkey, was used in the present study. The furnish was first screened through a 3 mm aperture mesh to remove oversized particles, then through a 1 mm aperture mesh to remove undersized particles, and used as supplied (Figure 2). The particles were dried at 105 °C to 3% moisture content. Boards were manufactured from particles dried to this moisture content. Particles which were to be acetylated underwent a further 12 h drying in an oven to achieve a bone-dry condition.

Figure 2.

The raw material used in the study and the final board.

2.2. Acetylation

Particles were vacuum impregnated overnight with acetic anhydride and then reacted in a reaction vessel at 120 °C for 30 and 60 min time periods. At the end of the reaction, the vessel was removed from the oil bath and the still-hot reaction solution was decanted off. Ice-cold acetone was then added to quench the reaction. The particles were left to stand in acetone for an hour and prior to board manufacture, were dried overnight at 105 °C. Weight gains of 13.6% (Acetylated 1) and 19.7% (Acetylated 2) were achieved after 30 and 60 min reactions, respectively. Weight gain was based on the oven-dry weight of the raw material.

2.3. Board Manufacture

A PMDI (polymeric methylene diphenyl diisocyanate) isocyanate resin (type 1042, 100% solid, purchased from ICI Resins (Imperial Chemical Industries, London, UK)), 4% as a percentage of the oven-dry weight of the raw material, was applied to the furnish for board manufacture. Mattresses (50 × 50 cm) were hot pressed at 200 °C for 5 min. An extended reaction time was chosen to ensure heat transfer to the acetylated raw material. The target board density and target board thickness were 0.65 g·cm−3 and 12.5 mm, respectively. Three replicates were made for each board type (Figure 2). After manufacture, the boards were lightly sanded to remove loose fibres and conditioned at 20 °C and 65% relative humidity (RH). Values for internal bond strength (IBS) and thickness swelling (TS) after 24 h water immersion were then determined according to procedures defined in European Union standards EN 319 and EN 317. Humidity tests were performed for a total of three cycles of 30% to 90% RH.

2.4. Board Testing

2.4.1. Water Soak Test

The thickness swelling and water absorption tests after immersion in water were carried out according to EN 317. Pre-weighed and measured oven-dried specimens (four from each board) were immersed in water for 24 h (or 1 week) at 20 °C. After each soaking, the specimens were wiped of excess water, measured for thickness, and weighed. The thickness swelling (TS) was determined on the basis of initial oven-dry measurements.

2.4.2. Humidity Tests

Pre-weighed and measured oven-dried specimens (four from each board) were placed in a humidity room at 30% (RH) and 20 °C, and the thickness and weight were determined when they reached equilibrium. The specimens were then placed in humidity room at 90% RH and 20 °C and new measurements were taken when they reached equilibrium. This procedure was repeated for a total of three cycles of 30% to 90% RH. The specimens were then oven dried and their thickness was measured. Changes in thickness were calculated as a percentage of the original thickness of the oven-dry board.

2.4.3. Internal Bond Strength

Internal bond strength (IBS) tests were conducted on specimens (four from each board) to determine if the acetylation had any effect on resin bond strength. The tests were carried out according to EN 319.

3. Results and Discussion

The thickness swell values (TS) after 24 h immersion in water are summarised in Table 1. The results revealed that acetylation improved the dimensional stability. The TS values for Acetylated boards 1 and 2 were about 62.5 and 240% lower, respectively, than those of the controls. In a previous study concerning oriented strand board (Oriented Strand Board) from acetylated strands with 11.2% weight gain, a 147% improvement in TS value was reported [39].

Table 1.

Physical and mechanical properties for control and acetylated particleboards. Standard deviations in parentheses.

Table 1 also reveals that the equilibrium moisture content (EMC) was reduced due to acetylation. Figure 3 depicts the change in thickness at 30% and 90% relative humidity of the boards produced in this study. It is revealed that, at the end of the third cycle, control boards swelled over 27%, while the Acetylated 1 and 2 boards swelled approximately 14% and 6%, respectively. This is in good agreement with the reported results on acetylated OSB [39].

Figure 3.

Dimensional stability after climate ageing.

The IBS values are shown in Table 1. It is revealed that acetylation caused a significant decrease in IBS. The IBS values for the Acetylated 1 and 2 boards were about 13% and 39% lower than those for the controls. This reduction appears to be higher than values reported in the literature, since acetylation of strands to 20.4% weight gain previously resulted in a 30% decrease in IBS [39]. A similar observation was also made for chemically modified flakeboards and particleboards [40,41]. This seems to be attributed to the raw material used, since acetylation resulted in poor wetting of the raw material. Failure in control boards was observed in the raw material. On the other hand, in modified boards, failure was mainly due to the resin.

When the data were examined in the light of industry standards, we noted that control boards met the requirements of P1 general purpose boards for use in dry conditions and P2 boards for interior fitment for use in dry conditions. Acetylated 1 boards, on the other hand, did not meet the requirements of P2 criteria. Acetylated 2 boards conformed to the more stringent P3 Non-Load-Bearing—Humid and P4 Load Bearing—Dry criteria as far as the thickness swell value is concerned, since values lower than 17% and 16%, respectively, were achieved. However, the IBS value for Acetylated boards 2 was far below the standards and did not meet the more stringent requirements of P3 Non-Load-Bearing—Humid and P4 Load Bearing—Dry. An option to improve the IBS value is to increase the amount of resin; however, this will increase the production cost.

It is concluded, therefore, that sunflower stalks could be an alternative raw material for use in the particleboard industry since the requirements of P1 general purpose boards for use in dry conditions and P2 boards for interior fitment for use in dry conditions are easily satisfied. Acetylation of sunflower stalks greatly improves the TS value but adversely affects the IBS. It is suggested that combinations of industrial wood chips with sunflower raw material may be an avenue for the overall improvement of the performance of the particleboards.

Author Contributions

Methodology, A.N.P. and G.Z.K..; Validation, A.N.P. and G.Z.K..; Investigation, A.N.P.; Writing-Original Draft Preparation, A.N.P., G.Z.K. and A.C.M.; Writing-Review & Editing, A.N.P., G.Z.K. and A.C.M.; Visualization, X.X.; Supervision, A.N.P.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Youngquist, J.A.; English, B.E.; Spelter, H.; Chow, P. Agricultural fibers in composition panels. In Proceedings of the 27th International Particleboard/Composite Symposium, Washington State University, Pullman, WA, USA, 30 March–1 April 1993. [Google Scholar]

- Du, X.; Li, J.; Feng, H.; Chen, S. Image reconstruction of internal defects in wood based on segmented propagation rays of stress waves. Appl. Sci. 2018, 8, 1778. [Google Scholar] [CrossRef]

- Fortin-Smith, J.; Sherwood, J.; Drane, P.; Kretschmann, D. Characterization of maple and ash material properties for the finite element modeling of wood baseball bats. Appl. Sci. 2018, 8, 2256. [Google Scholar] [CrossRef]

- Mathis, D.; Blanchet, P.; Landry, V.; Lagière, P. Impregnation of wood with microencapsulated bio-based phase change materials for high thermal mass engineered wood flooring. Appl. Sci. 2018, 8, 2696. [Google Scholar] [CrossRef]

- Rinaldi, R.G.; Manin, L.; Moineau, S.; Havard, N. Table tennis ball impacting racket polymeric coatings: Experiments and modeling of key performance metrics. Appl. Sci. 2019, 9, 158. [Google Scholar] [CrossRef]

- Zheng, X.; Taverne, M.P.C.; Ho, Y.-L.D.; Rarity, J.G. Cavity Design in Woodpile Based 3D Photonic Crystals. Appl. Sci. 2018, 8, 1087. [Google Scholar] [CrossRef]

- Emdadi, Z.; Asim, N.; Amin, M.H.; Ambar Yarmo, M.; Maleki, A.; Azizi, M.; Sopian, K. Development of Green Geopolymer Using Agricultural and Industrial Waste Materials with High Water Absorbency. Appl. Sci. 2017, 7, 514. [Google Scholar] [CrossRef]

- Huang, X.; Liu, G.; Xu, D.; Xu, X.; Li, L.; Zheng, S.; Lin, H.; Gao, H. Novel Zeolitic Imidazolate Frameworks Based on Magnetic Multiwalled Carbon Nanotubes for Magnetic Solid-Phase Extraction of Organochlorine Pesticides from Agricultural Irrigation Water Samples. Appl. Sci. 2018, 8, 959. [Google Scholar] [CrossRef]

- Muradin, M.; Joachimiak-Lechman, K.; Foltynowicz, Z. Evaluation of eco-efficiency of two alternative agricultural biogas plants. Appl. Sci. 2018, 8, 2083. [Google Scholar] [CrossRef]

- Sieczka, A.; Koda, E. Kinetic and equilibrium studies of sorption of ammonium in the soil-water environment in agricultural areas of central poland. Appl. Sci. 2016, 6, 269. [Google Scholar] [CrossRef]

- Soltero, V.M.; Chacartegui, R.; Ortiz, C.; Lizana, J.; Quirosa, G. Biomass district heating systems based on agriculture residues. Appl. Sci. 2018, 8, 476. [Google Scholar] [CrossRef]

- Balducci, F.; Harper, C.; Meinlschimidt, P.; Dix, B.; Sanasi, A. Development of innovative particleboard panels. Drv. Ind. 2008, 59, 131–136. [Google Scholar]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crops Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Yeniocak, M.; Göktas¸, O.; Erdil, Y.Z.; Özen, E. Investigating the use of vine pruning stalks (Vitis Vinifera L. CV. Sultani) as raw material for particleboard manufacturing. Wood Res. 2014, 59, 167–176. [Google Scholar]

- Klimek, P.; Meinlschimidt, P.; Wimmer, R.; Plinke, B. Using sunflower (Helianthus annuus L.), topinambour (Helianthus tuberosus L.) and cup-plant (Silphium perfoliatum L.) stalks as alternative raw materials for particleboards. Ind. Crops Prod. 2016, 92, 157–164. [Google Scholar] [CrossRef]

- Gansberger, M.; Montgomery, L.F.R.; Liebhard, P. Botanical characteristics, crop management and potential of Silphium perfoliatum L. as a renewable resource for biogas production: A review. Ind. Crops Prod. 2015, 63, 362–372. [Google Scholar] [CrossRef]

- Nazerian, M.; Beyki, Z.; Gargari, R.; Kool, F. The effect of some technological production variables on mechanical and physical properties of particleboard manufactured from cotton stalks. Maderas Cienc. Technol. 2016, 18, 167–178. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Traboulay, E.; Hill, C.A.S. One layer Experimental Particleboard from Coconut Chips (Cocos nucifera L.). Holz Roh Werkst. 2002, 60, 394–396. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Hill, C.A.S.; Gkaraveli, A.; Ntalos, G.; Karastergiou, S. Bamboo chips (Bambusa vulgaris) as an alternative lignocellulosic raw material for particleboard manufacture. Holz Roh Werkst. 2004, 62, 36–39. [Google Scholar] [CrossRef]

- De Araujo, P.; Arruda, L.; Menezzi, C.; Texeira, D.; de Souza, M. Lignocellulosic composites from Brazilian giant bamboo. Part 2: Properties of cement and gypsum bonded particleboard. Maderas Cienc. Technol. 2011, 13, 297–306. [Google Scholar] [CrossRef]

- De Melo, R.; Stangerlin, D. Decay and termite resistanceof particleboard manufactured from wood, bamboo and rice husk. Maderas Cienc. Technol. 2011, 17, 55–62. [Google Scholar]

- Papadopoulos, A.N.; Hague, J.R.B. The potential use of Linum usitatissimun (flax) chips as a raw lignocellulosic material for particleboards. Ind. Crops Prod. 2003, 17, 143–147. [Google Scholar] [CrossRef]

- Papadopoulos, A.N. Banana chips (Musa acuminate) as an alternative lignocellulosic raw material for particleboard manufacture. Maderas Cienc. Technol. 2018, 20, 395–402. [Google Scholar]

- Li, X.; Cai, Z.; Winandy, J.; Basta, A. Selected properties of particleboard panels manufactured from rice straws of different geometries. Bioresour. Technol. 2010, 101, 4662–4666. [Google Scholar] [CrossRef] [PubMed]

- Mo, X.; Cheng, E.; Wang, D.; Sun, X. Physical properties of medium-density wheat straw particleboard using different adhesives. Ind. Crops Prod. 2003, 18, 47–53. [Google Scholar] [CrossRef]

- Kord, B.; Zare, H.; Hosseinzabeh, A. Evaluation of the mechanical and physical properties of particleboard manufactured from canola straws. Maderas Cienc. Technol. 2016, 18, 9–18. [Google Scholar] [CrossRef]

- Kord, B.; Roohani, M.; Kord, B. Characterisation and utilization of reed stems as a lignocellulosic residue for particleboard production. Maderas Cienc. Technol. 2015, 17, 517–524. [Google Scholar]

- Amirou, S.; Zerizer, A.; Pizzi, A.; Haddadou, I.; Zhou, X. Particleboards production from date palm biomass. Eur. J. Wood Wood Prod. 2013, 71, 717–723. [Google Scholar] [CrossRef]

- Küçüktüvek, M.; Kasal, A.; Kuşkun, T.; Erdil, Y. Utilizing poppy husk-based particleboards as an alternative material in case furniture construction. Bioresour. 2017, 12, 839–852. [Google Scholar]

- Guler, C.; Ozen, R. Some properties of particleboards made from cotton stalks (Gossypium hirsitum L.). Holz Roh Werkst. 2004, 62, 40–43. [Google Scholar] [CrossRef]

- Dix, B.; Meinlschmidt, P.; Van De Flierdt, A.; Thole, V. Leichte spanplatten für den Möbelbau aus Rückständen der landwirtschaftlichen produktion—TI.1: Verfügbarkeit der rohstoffe. Holztechnol 2009, 50, S–5. [Google Scholar]

- Gertjejansen, R.O.; Haygren, J.G.; French, D.W. Particleboard from Apsen Flaks and Sunflower Hulls. Technical Bulletin 290; Minnesota Agricultural Experiment Station, University of Minnesota: Minneapolis, MN, USA, 1977. [Google Scholar]

- Gertjejansen, R.O. Properties of Particleboard from Sunflower Stalks and Apsen Planer Shavings. Technical Bulletin 311; Minnesota Agricultural Experiment Station, University of Minnesota: Minneapolis, MN, USA, 1977. [Google Scholar]

- Khristova, P.; Yussifov, N.; Gabir, S.; Glavche, I.; Osman, Z. Particleboards from sunflower stalks and tannin modified UF resin. Cellul. Chem. Technol. 1998, 32, 327–337. [Google Scholar]

- Guler, C.; Bektas, I.; Kalaycioglu, H. (2006) The experimental particleboard manufacture from sunflower stalks (Helianthus annuus L.) and Calabrian pine (Pinus brutia). For. Prod. J. 2006, 56, 56–60. [Google Scholar]

- Bektas, I.; Guler, C.; Kalaycioglu, H. Manufacture of particleboards using sunflower stalks (Helianthus annuus L.) and poplar wood (Populus alba L.). J. Compos. Mater. 2005, 39, 39467–39473. [Google Scholar] [CrossRef]

- Ghofrani, M.; Haghdan, S.; Nickhah, V.; Ahmadi, K. Improvement of physical and mechanical properties of particleboard made of apple tree pruning and sunflower stalk using titanium oxide particles. Eur. J. Wood Wood Prod. 2015, 73, 661–666. [Google Scholar] [CrossRef]

- Rowell, R.M. Chemical modification of wood. For. Prod. Abstr. 1983, 6, 366–382. [Google Scholar]

- Papadopoulos, A.N.; Traboulay, E. Dimensional stability of OSB made from acetylated fir strands. Holz Roh Werkst. 2002, 60, 84–87. [Google Scholar] [CrossRef]

- Youngquist, A.J.; Krzysik, A.; Rowell, R.M. Dimensional stability of acetylated aspen flakeboard. Wood. Fiber Sci. 1986, 18, 90–98. [Google Scholar]

- Fuwape, J.A.; Oyagade, A.O. Strength and dimensional stability of acetylated Gmelina and Sitka spruce particleboard. J. Trop For. Prod. 2000, 6, 184–189. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).