Abstract

The basis of the construction industry is building materials with high-quality indicators in terms of physical, mechanical, and thermophysical characteristics, however, there are a number of issues affecting the quality of manufactured products. The development of the construction industry provides new opportunities for designing efficient construction facilities. To obtain enhanced design capabilities, it is very important to relieve the load on the structure, and this can be achieved by reducing the mass of materials without losing strength. This study investigates the enhancement of foam concrete through the combined incorporation of mineral fibers recycled from basalt insulation waste and complex polymer modifiers. The aim was to improve the material’s mechanical performance, durability, and pore structure stability while promoting sustainable use of industrial by-products. The experimental program included tests on density, compressive strength, water absorption, and thermal conductivity for mixtures of different densities (400–1100 kg/m3). Results demonstrated that the inclusion of mineral fibers and polymer modifiers significantly enhanced structural uniformity and pore wall integrity. Compressive strength increased by up to 35%, water absorption decreased by 25%, and thermal conductivity was reduced by 18% compared with the control mixture.

1. Introduction

The continuous advancement of the construction sector creates new possibilities for developing more efficient and sustainable building systems [1]. Enhancing structural performance for aerated concrete requires minimizing the applied loads, which is commonly accomplished by reducing material density without compromising mechanical strength [2,3]. Foam concrete is a modern cellular building material, which, due to its unique properties, occupies an important place in the construction industry. Obtained by introducing foaming or gas-forming additives into a cement–sand mixture, foam concrete is characterized by a porous structure, which provides it with a number of valuable performance qualities [4,5]. Lightness, low thermal conductivity, high sound and heat insulation, fire resistance, biostability, and resistance to external factors make this material in demand when solving many construction problems [6,7,8].

Foam concrete and related lightweight cementitious composites have evolved from being considered mainly as non-structural thermal insulating fillers to being engineered for structural and semi-structural applications, including load-bearing wall elements, lightweight panels, void filling in transportation infrastructure, and foundation load reduction in low- to mid-rise construction. Current state-of-the-art research in lightweight and foam concretes is strongly driven by sustainability and circularity objectives. A growing body of work has demonstrated that waste-derived constituents—including expanded polystyrene beads, crumb rubber, recycled plastics, waste glass powders, industrial by-products such as fly ash, and other polymer-based residues—can be successfully incorporated to reduce density, improve thermal insulation, and divert solid waste from landfills while lowering the embodied carbon of construction materials [9]. These approaches highlight that lightweight concretes are no longer viewed purely as insulation materials but as multifunctional sustainable composites aimed at both performance and resource efficiency [10].

Recent studies have demonstrated the improvement of foam concrete performance when mineral additives are introduced, significantly enhancing strength and durability [11,12]. One of the key advantages of foam concrete is its versatility. It is used in both low-rise and industrial construction, in the construction of load-bearing and enclosing structures, and in thermal insulation of walls, floors, and ceilings [13,14]. Due to the ability to reduce the load on the foundation and increase the energy efficiency of buildings, foam concrete is especially relevant in the context of modern requirements for environmental friendliness and energy saving [15,16]. In addition, its use in road construction contributes to the durability of road surfaces [17]. An important role in the quality and performance characteristics of foam concrete is played by such factors as the composition of the mixture, the type and amount of foaming agent, the water–cement ratio, as well as the technological parameters of production [18,19]. Modern research is aimed at finding optimal solutions to increase the strength and durability of foam concrete, reduce its shrinkage, and ensure uniform distribution of pores [20,21]. Recent advances in lightweight concrete have increasingly focused on incorporating waste-derived materials to enhance both performance and sustainability. Numerous studies have investigated the use of polystyrene beads, crumb rubber, waste glass powder, fly ash, silica fume, and recycled polymer plastics to reduce density, improve thermal performance, and lower the environmental footprint of concrete production [22,23]. These approaches have been shown to enhance certain properties—such as insulation and durability—while simultaneously supporting waste recycling and carbon reduction in the construction industry [24,25].

The findings of recent research [26] confirmed that optimized activator chemistry enhances bubble stability and pore uniformity, which complements the present study’s physical stabilization approach using fiber and polymer systems. Some research has investigated PLA fibers of different geometries (straight, hook-shaped, corrugated) and shown that they increase strength, fracture energy, and crack resistance [27,28]. It has been demonstrated that EPS-based lightweight concrete incorporating fly ash and silica fume can achieve structural-grade compressive strength while reducing density and improving durability [29]. Hybrid lightweight aggregate concretes using recycled EPS beads have been examined and substantial gains in thermal insulation and reductions in waste stream volume have been found [30]. A scientific review synthesized empirical findings on lightweight concrete incorporating diverse waste materials including fly ash, recycled plastics, expanded polystyrene, and silica fume, highlighting the dual benefit of performance improvement and waste mitigation [31].

This article discusses the features of foam concrete production and analyzes the main physical and mechanical characteristics of the material and the factors affecting its quality [32,33]. Also discussed are the prospects for the use of foam concrete in the construction industry, taking into account modern standards and requirements for energy efficiency, sustainability, and environmental friendliness of building materials. Particular attention is paid to the possibility of improving operational technologies and the use of various additives, which opens up new horizons for its application.

Nevertheless, limited attention has been paid to the synergistic use of mineral waste fibers and polymer-based modifiers in foam concrete. The majority of existing research treats polymer fibers or mineral fillers as independent additives. Yet, the interaction between the polymer matrix and mineral fibers may offer a combined benefit: The polymer film could encapsulate pores and fill microcracks, while mineral fibers may reinforce the cell walls and improve load distribution during the hydration process. Such a hybrid system could enhance both mechanical integrity and pore stability, leading to stronger and more durable lightweight concrete.

The aim of this article is to study the structure of modified foam concrete based on complex modifiers and mineral fiber from industrial waste. Recent studies highlight the necessity of developing comprehensive evaluation frameworks that integrate mechanical, environmental, and economic indicators to assess the overall benefits of recycled materials [34,35].

The tasks of the study:

- -

- To develop and optimize the composition of modified foam concrete using mineral fiber and complex modifiers to determine its setting time and water–cement ratio;

- -

- To investigate the structure formation of modified foam concrete using mineral fiber and complex modifiers to determine its structural and phase composition;

- -

- To determine the physico-mechanical and construction–technical properties of foam concrete using mineral fiber and complex modifiers.

2. Materials and Methods

2.1. Materials

The main problem faced by foam concrete production is the uneven distribution of the material’s pore structure, leading to reduced and uneven density, strength, water absorption, and thermal conductivity. The main reason for this is the setting time of the cement binder, as the uniformity of pore distribution and, as a result, uniform density depend on the setting time. Therefore, the complex modifier used should first be tested for its effect on the setting time.

The use of mineral fiber from basalt insulation waste reduces the load on the foam and thus ensures the stability of the foam for a longer period of time. Since the fiber that holds the cell structure is mineral in nature, namely Si, during the hydration process, the fibers become an integral part of the material structure, forming a monolith.

The following materials were used in the production of modified foam concrete: Cement: Portland cement type CEM I 42.5 N, normal hardening, conforming to Interstate Standard (GOST) 31108-2020. Sand: Natural quartz sand in accordance with Interstate Standard (GOST) 8735-88 (ST SEV 5446-85), with a bulk density of 1500 kg/m3, particle density of 2.59 g/cm3, and a void ratio of 42.8%. Mineral fiber: Recycled basalt insulation waste, non-uniform in structure and density (30–220 kg/m3), composed mainly of silicon oxide (SiO2). The fibrous morphology ensures microreinforcement of pore walls during hydration. Polymer modifier: PB 2000 (Technical Specifications TU 2481-185-05744685-01), a brown synthetic foam concentrate, was used as both a foaming agent and a polymer-based complex modifier. It is chemically neutral, chloride-free, and environmentally friendly, ensuring stable foam generation and improved workability. Water: Potable tap water meeting the requirements of Interstate Standard (GOST) 23732-2011.

2.2. Methods

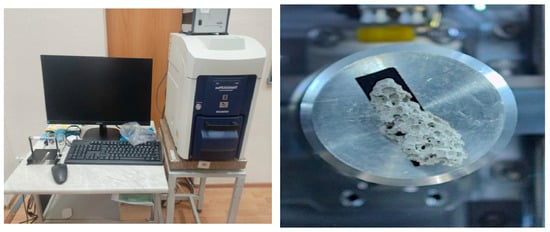

Studies of the chemical composition and structure of foam concrete are carried out using a Hitachi scanning electron microscope (SEM) and a Bruker energy dispersive X-ray spectroscope (EDS) in Figure 1.

Figure 1.

Bruker Scanning Electron Microscope (SEM) and Energy dispersive X-ray Spectroscope (EDS) instruments.

SEM is used to observe the distribution and bonding of mineral fibers within the cement matrix, as well as the integrity of pore walls formed under the influence of polymer modifiers. It is also used to analyze the pore morphology, wall thickness, and fiber–matrix interface in the foam concrete samples. This allowed observation of the uniform polymer film formation and the anchoring effect of mineral fibers within the cement matrix, which explains the improved strength and reduced water absorption. EDS analysis provided information on the elemental composition of the modified zones and confirmed the uniform distribution of silicon- and carbon-containing phases associated with the fibers and polymer films. It is also employed to confirm the elemental composition of the modified regions—identifying silicon- and calcium-rich phases from the cement hydration products and carbon peaks associated with the polymer modifier. These findings verified the chemical interaction and integration of the polymer and mineral components within the composite structure.

The determination of the physical and mechanical properties of foamed concrete is carried out according to standard procedures. Density determination is performed on four samples for each composition. Compressive strength determination is carried out using six samples for each composition. Water absorption determination is conducted on six samples for each composition. Thermal conductivity determination is performed on three samples for each composition. All tests were conducted under standard laboratory conditions to ensure the reliability and reproducibility of the results.

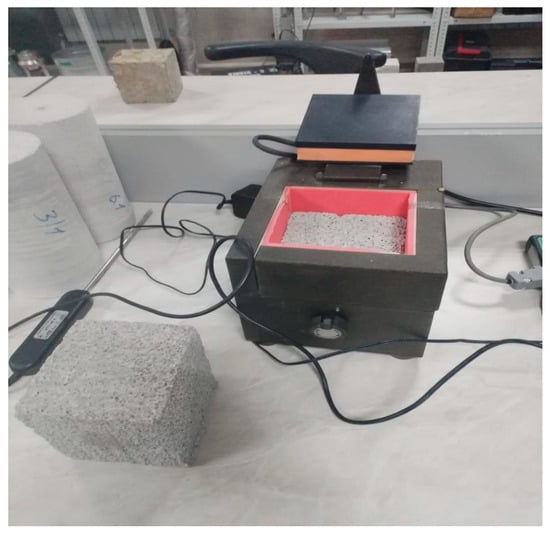

The density of foam concrete was determined according to the Interstate Standard GOST 12730.1. in Figure 2.

Figure 2.

Determination of the density of foam concrete samples.

A caliper, a drying cabinet, and laboratory scales were used to determine the density. Regular shaped samples with dimensions of 100 × 100 × 100 mm were used for testing. The volume of the samples of the correct shape is calculated by their geometric dimensions. The sizes of the samples were determined with a caliper with an error of no more than 1%. The mass of the samples was determined by weighing with an error of no more than 0.1%. The samples were dried to a constant mass.

The strength of foam concrete was determined according to the Interstate Standard GOST 10180-2012 in Figure 3. Samples of regular shape with dimensions of 100 × 100 × 100 mm were tested at the age of 28 days.

Figure 3.

Determination of strength of foam concrete specimens.

The Figure 4 shows the procedure used to evaluate the water absorption capacity of foam concrete specimens.

Figure 4.

Determination of water absorption of foam concrete samples.

The Figure 5 shows the procedure used to evaluate the thermal conductivity of foam concrete specimens.

Figure 5.

Determination of thermal conductivity of foam concrete samples.

In the development of modified foam concrete using mineral fiber and complex modifiers, its setting time was determined.

The properties of sand were determined using methods in accordance with Interstate Standard (GOST) 8735-88 (ST SEV 5446-85) and ST SEV 6317-88 ‘Sand for construction works. Test methods’ (with amendments) in Table 1.

Table 1.

Properties of sand.

Portland cement of type CEM I 42.5 N (normal hardening) conforming to Interstate Standard (GOST) 31108-2020 was used as the binder in the production of foamed concrete.

A foam concentrate, PB 2000 (TU 2481-185-05744685-01), a brown synthetic foam concentrate, is used as the foaming agent for producing cellular concrete. The foam concentrate used is an environmentally friendly, chemically neutral product that does not contain chlorides and ensures high-quality foaming.

As a fibrous filler, mineral fiber obtained from waste basalt insulation was used. The material is characterized by non-uniform density and structure, with a density range of 30 to 220 kg/m3.

The main problem faced by foam concrete production is the uneven distribution of the material’s pore structure, leading to reduced and uneven density, strength, water absorption, and thermal conductivity. The main reason for this is the setting time of the cement binder, as the uniformity of pore distribution and, as a result, uniform density depend on the setting time. In this regard, the complex modifier used should first be tested for its effect on setting times.

In order to adopt the optimal composition of the complex modifier, the setting time of the cement binder was taken as the main indicator in Table 2.

Table 2.

Setting time.

Thus, one of the main parameters in the production of foam concrete is the setting time, since the stratification and shrinkage of the mixture and, as a result, unstable density depend on this indicator. The optimal amount of the additive is 1.5%.

Four types of aerated concrete of various compositions were considered in the work in Table 3.

Table 3.

Types of samples depending on content.

Mixtures of foam concrete of different densities were used to determine the optimal compositions of the mineral fiber which are D 400, D 800, D 1100. The optimization is presented in Table 4.

Table 4.

Mineral fiber content depending on foam concrete density.

The selection of the optimal M1 composition was carried out by determining the properties of cement for the duration of setting and hardening, as well as determining the strength of density, water absorption, frost resistance, and thermal conductivity. To select the optimal M2 composition, density, thermal conductivity, strength, and frost resistance were determined. M3 is compiled based on the optimal conditions of selected M1 and M2 formulations. The compositions of investigated foam concrete are presemted in Table 5.

Table 5.

Optimal compositions of the studied foam concretes D 400, D 800, and D 1100.

According to the results of composition optimization, studies were conducted on the physico-mechanical properties of foam concrete using a complex modifier and mineral fiber at different densities of foam concrete.

3. Results and Discussion

3.1. Chemical Composition and Microstructure

The structure formation of modified foam concrete using mineral fiber and complex modifiers was investigated to determine its structural and phase composition. In the process of studying the quality of foam concrete using mineral fiber and complex modifiers, the results of an energy dispersive X-ray spectroscope were obtained. These studies are necessary to ensure the stability and quality of foam concrete, taking into account the structural features of foam concrete and its changes during structure formation, which eliminate all possible risks in the technological process of manufacturing the material.

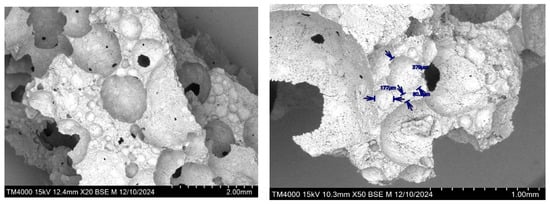

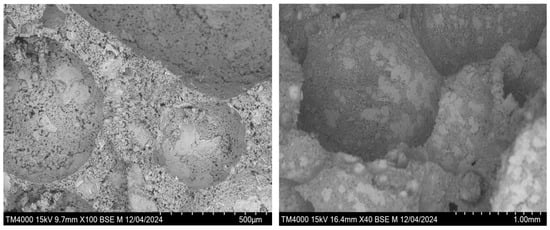

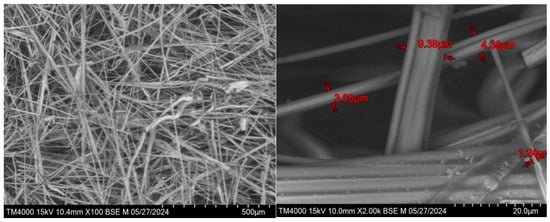

The results of the scanning electron microscope allowed us to determine the structure of the cell skeleton and its integrity and quality.

To study the structure of foam concrete, a sample with a density of 400 kg/m3 was taken. In Figure 6, we see an uneven pore structure of foam concrete, as well as defects and cracks in larger cells that violate the integrity of the pores.

Figure 6.

Control sample of foam concrete D 400.

These results of the scanning microscope show that, during the preparation of the foam concrete solution:

- -

- firstly, the foam is unstable and its delamination leads to the formation of uneven pores, and an increase in pores leads to an increase in the surface area of the pore walls, and as a result, the foam is unable to maintain its structure since the solution has a high load on the foam due to the large area;

- -

- secondly, the internal stress of concrete is created after the beginning of setting and hardening, and the reason is large pores, a large area, and a thin structure of the pore wall contributing to the formation of microcracks.

Thus, in order to obtain low-density thermal insulation foam concrete, it is necessary to use polymer components to reduce internal stress. The polymer component creates a film on the crack areas and thereby ensures the integrity of the pore structure. One of the important factors is the stability of the foam, and it is difficult to achieve its stability because, as the foam bubble increases, its area increases and the solution affects it, thereby forming defects in the pore or destroying the pores. To reduce the pore structure and density of foam concrete, a reinforcing component is needed, since the created frame will reduce the load on the foam despite its multiplicity, thereby allowing the solution to take shape and harden.

The obtained results of modified foam concrete showed that the presence of a polymer reduces the internal stress of concrete due to an additional polymer shell on the walls and in the open spaces of the pore structure. However, the use of a polymer provides only a reduction in high internal stress of foam concrete.

Figure 7 shows a Type 4 sample using mineral fiber and a complex modifier. According to the results of the scanning electron microscope, a cell skeleton was obtained, which had a structure without microcracks and chips, and there are no large fibers in the image that violate the integrity of the cell. This study confirms that, during the mixing process, the mineral fiber is destroyed but into smaller fibers that allow the cell walls to be structured, reinforcing only them and not creating their own frame, thereby allowing the surface of the finished product to be polished after laying, eliminating the release of fibers on the surface that violate the aesthetics of the surface. Given the thickness and length of the fibers, it can be concluded that the fibers are destroyed by mixing the mixture, but during the formation of the structure, the destroyed fibers, although small, reinforce the cell structure.

Figure 7.

Type 4 cell structure, foam concrete sample D 400.

Figure 8 shows mineral fibers and their dimensions. The maximum fiber size is 9.38 µm per minute.

Figure 8.

Microstructure of mineral fiber.

Thus, the results obtained confirm that mineral fiber can significantly strengthen the walls of cells, creating the effect of their microreinforcement, and when using a complex modifier based on polymer components, a protective film is formed that ensures the formation of cracks and chips on the surface of the cell, thereby allowing high-quality material to be obtained.

Having studied the changes in the chemical processes of hydration, we see that there are no significant changes in the quantitative parameters of the active oxides involved in the hydration process. These studies show reinforcement of the cellular concrete wall structure with mineral fiber, as well as a complex modifier consisting of polymer components.

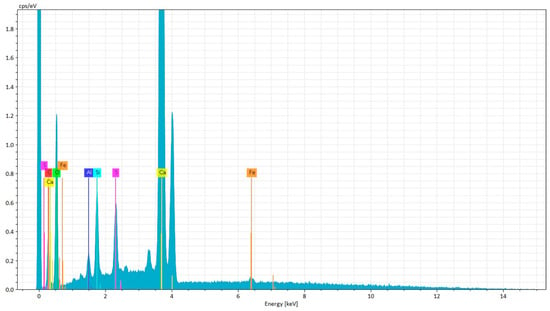

The presented studies show an increase in the activity of portlandite, as well as an increase in silicon in the composition of foam concrete with mineral fiber, as well as with a complex modifier.

Figure 9 shows a control sample where we observe a large amount of portlandite. According to chemical analysis, the composition of calcium oxide was 93.64%, which indicates a high activity of the cement binder. However, there is also a negative side to the high activity of cement, which is the risk of high alkalinity and, as a result of corrosion of the material (peeling and cracks and chips), peeling occurs due to the migration of free lime, which promotes the movement of salts through the structure of the material, creating locations for its maximum accumulation, thereby causing corrosion processes.

Figure 9.

Studies of the chemical composition of a control sample of foam concrete.

The chemical and mineralogical composition of the control foam concrete specimen was determined through EDS analysis, and the results are presented in Table 6.

Table 6.

Results of the chemical and mineralogical composition of the control sample of foam concrete.

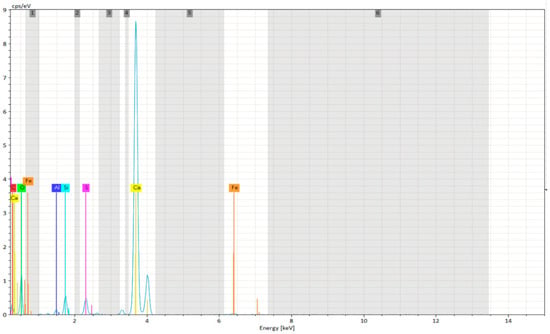

To further analyze the elemental composition of the foam concrete samples containing mineral fiber and a complex modifier, an EDS spectrum was obtained, as shown in Figure 10.

Figure 10.

Studies of the chemical composition of a control sample of foam concrete with mineral fiber, as well as with a complex modifier.

The elemental and oxide composition of the foam concrete containing mineral fiber and a complex modifier was determined using EDS analysis. The corresponding results are presented in Table 7.

Table 7.

Results of the chemical and mineralogical composition of a sample of foam concrete with mineral fiber, as well as with a complex modifier.

Mineral fibers from basalt insulation waste consist of silicon oxide minerals, which means that, during the hydration process, the entire mixture, from cement to inert materials, is coated with polymer, and the interaction during the hydration of cement and mineral powder is identical to that of inert materials such as sand, with the difference being the thread-like shape. These components structure the form of foam concrete according to chemical analysis, increasing the silicon content compared to the control sample, which indicates that the mineralogy of the cell structure is changing and it can be concluded that the mineral fiber subsequently reacts with the cement binder, not enveloping it but forming a single mineral. The polymer component creates a shell in the cell wall structures, eliminating its micropores and thus ensuring the monolithicity of the pore walls.

The conducted studies showed the effectiveness of the applied additives, taking into account the microstructure images, and the chemical and mineralogical composition can be concluded based on the improvement of the structure of foam concrete. The research of physical–mechanical and construction–technical properties of foam concrete with the use of mineral fiber and complex modifiers in comparison with the control sample showed a significant difference in the improvement of foam concrete with additives and mineral fiber.

3.2. Compressive Strength and Density

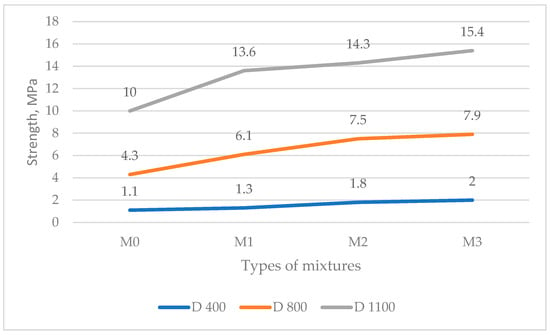

To analyze the combined effect of polymer components and mineral fibers, three grades of foam concrete were investigated: D 400 (thermal insulating), D 800 (structural thermal insulating), and D 1100 (structural).

Based on the results of qualitative indicators of strength we can conclude that the greatest strength effect is achieved when using M3. This is due to the fact that the composition of M3 contains both polymeric component and mineral fiber strengthening the structure of foam concrete, which provides a framework at the time of setting and hardening of foam concrete, and the polymeric component having in its composition surfactant provides effective wetting and plasticity of the mixture and, as a result, quality cell walls of foam concrete. As a result of the obtained data we see an increase in the strength of foam concrete from the control sample of M0 by 82%. M2 showed an increase in strength by 64% while M1 showed an increase in strength by 19%. The results are explained by the fact that because of the instability of the frame during setting and curing caused by the presence of surfactants M1 has not gained high strength and no stable density, presented in Figure 11. High density indicates the uneven distribution of density in the structure of foam concrete as there was shrinkage of the material. We seea similar result in the M0 control sample.

Figure 11.

Compressive strength data.

Studies of physical–mechanical and construction–technical properties of heat insulating constructive foam concrete D 800 with the use of mineral fiber and complex modifiers in comparison with the control sample showed the following results: M3 showed the highest quality indicators; Table 8 shows an increase in the strength of M3 by 85%, while M2 showed 74%, and M1 showed an increase in strength by 42%. The obtained results of thermal insulating and structural foam concrete in terms of percentage ratio are higher than the results of thermal insulating foam concrete. This fact is explained by the fact that the density is higher and in the process of setting and curing, by reducing the size of the cells, the internal stress on the walls of the cells is reduced, thereby allowing effective hydration.

Table 8.

Compressive strength and density data.

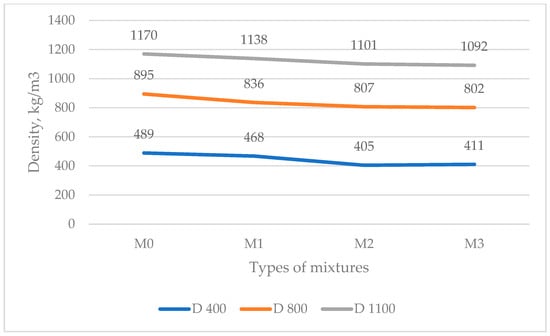

To analyze the effect of the modifier and mineral fiber on the density of foam concrete, the density values for all mixtures were determined. The results are shown in Figure 12.

Figure 12.

Density data.

The study of structural foam concrete D 1100 as well as heat insulating and heat insulating constructive showed similar results of physical and mechanical properties. Maximum strength was achieved in the sample M3 compared to M0 (control) (64%), and strength of the sample M2 was 43% and that of M1 was 36% but not significantly different compared to the control sample. This fact is because high-density cells in foam concrete are much smaller and their walls are much thicker in contrast to the foam concrete with low density.

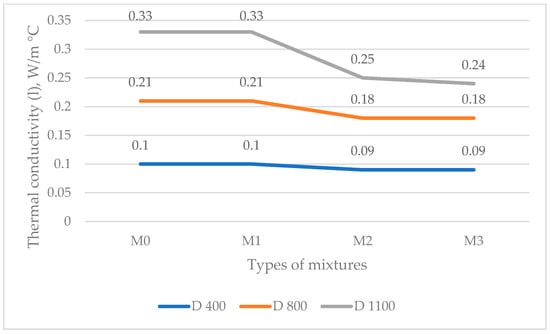

3.3. Thermal Conductivity

Low thermal conductivity for D 400 is obtained in the samples of M2 and M3. This result was obtained due to the stable density of the material as the main indicator of thermal conductivity. Over the entire tested surface, according to the results of the study, a decrease in thermal conductivity in the samples of M2 and M3 by 10% can be seen in Table 9.

Table 9.

Thermal conductivity data.

Thermal conductivity for D 800 also showed improvement in M2 and M3 samples. The reduction of thermal conductivity from the control sample of M0 in relation to M2 and M3 was 14% while the thermal conductivity of M1 showed the same results as M0 in Figure 13. Also, according to the results of the study, it can be concluded that the compliance of the actual density with the design density provides high quality of all physical and mechanical characteristics.

Figure 13.

Thermal conductivity data.

Thermal conductivity of the studied structural foam concrete D 1100 showed the highest results in the sample of M3, which amounted to a decrease in thermal conductivity by 27%. Also, the thermal conductivity reduction in the sample of M2 was 24%. The sample of M1 showed the same results as M0.

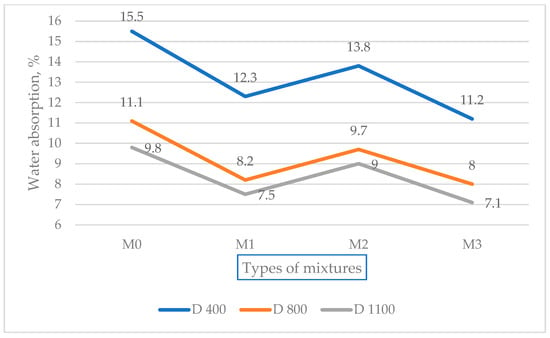

3.4. Water Absorption

Low water absorption of foam concrete was also shown by the sample of M3, 28% lower than that of the control sample. This effect is explained by the fact that the integrity of the closed cell walls and the polymeric component contained in the additive provides a protective framework of the cell. The results are shown in Table 10.

Table 10.

Water absorption data.

Water absorption of insulating and structural foam concrete showed the following results: M1 showed a 29% reduction in water absorption, sample M2 showed a result of 14%, and M3 showed a 28% reduction in water absorption.

Water absorption of foam concrete with density 1100 (M1) with the use of complex modifiers significantly decreased, because the composition contains a polymer component, and amounted to 23.5%. M3 showed the lowest water absorption of 27.6% as the composition contained not only complex modifiers but also mineral fiber, which improved the structure of foam concrete. M2 showed a decrease in water absorption of only 8.2%, which is explained by the lack of complex modifiers. The results are presented graphically in the Figure 14.

Figure 14.

Water absorption data.

An analysis of existing technologies for producing high-quality foam concrete materials has been shown [16,36], and the use of polymer fiber improves the structure of foam concrete [28]. However, given that the fiber is a polymer and has low adhesion due to low internal stress, it subsequently loses strength and resistance to aggressive environments [37,38].

Based on compressive strength results, the mixes were classified according to standard thresholds for lightweight and cellular concretes. The D 400 series (1.1–2.0 MPa; ≈400–500 kg/m3) corresponds to non-structural, thermal insulating concretes used for void filling and roof insulation. The D 800 series (4.3–7.9 MPa; ≈800–900 kg/m3) represents semi-structural concretes suitable for self-supporting or enclosure elements. The D 1100 series (10.0–15.4 MPa; ≈1100 kg/m3) approaches the lower limit of load-bearing lightweight concrete. Although below the ≈17 MPa structural threshold defined in ACI 213R, these results indicate potential for limited structural applications in low-rise construction.

Regarding to the results of the study, it can be concluded that the use of a complex of modified additives based on a polymer component and mineral fiber allows the highest quality to be achieved: The polymer strengthens the skeleton structure by polymerizing all components of the cement binder, aggregate, and mineral fiber, and the mineral fiber reinforces the cell walls, removing the load from the upper part of the mixture and ensuring uniform density in the early stages of foam concrete structure formation.

- During the research, the composition of modified foam concrete using mineral fiber and complex modifiers was optimized, and the work carried out made it possible to establish the effective ratios of all components of modified foam concrete.

- The work carried out to study the structure formation of modified foam concrete using mineral fiber and complex modifiers showed that mineral fibers come into contact during the hydration process and not only improve the structure of foam concrete in the early stages of hardening but also form a single stone in the pore walls, increasing the physical–mechanical properties of foam concrete, while the presence of a modifier enveloping all mineral components creates both an integral structure and the hydrophobicity of the material. This process is confirmed by a twofold increase in silicon in the foam concrete composition compared to the control sample. This is because mineral fibers consist of more than 50% silicon.

- Tests conducted on the physical, mechanical, and structural properties of foam concrete of various densities using mineral fiber and complex modifiers confirmed the effectiveness of mineral fiber and complex modifiers for all types of foam concrete, from thermal insulation to structural. The results obtained for the optimal compositions showed stability in production and high-quality indicators, as reflected in the article.

4. Conclusions

Based on the results of the research, it can be concluded that the use of a complex of modified additives based on a polymer component and mineral fiber achieves the highest quality, since the polymer component strengthens the structure of the skeleton by polymerizing, and the mineral fiber reinforces the cell structure by taking the load of the upper part of the mixture, ensuring uniform density, thereby creating a high-quality material.

Studies of foam concrete with the use of mineral fiber and complex modifiers conducted on an energy dispersive X-ray spectroscope and scanning electron microscope showed the following results: The integrity of the cell structure of foam concrete, the correctness of the cell shape, as well as uniformity of cell wall thickness, while the control sample had a large number of defects. The integrity of the cell wall structure was broken, and the pore structure did not have uniform wall thickness.

Chemical analysis showed a change in the mineralogical composition after the use of mineral fiber and complex modifiers, and the results show that, in the process of hydration, there is a change in the phase composition that provides a decrease in the amount of portlandite in foam concrete by 11.7%.

Studies to determine the physical–mechanical and construction–technical properties of foam concrete with the use of mineral fiber and complex modifiers showed that the main factor affecting the properties of foam concrete are the features of the applied additives. According to the research, the complex application of mineral fiber and complex modifiers allows obtaining foam concrete of high quality.

According to the results of the study of compressive strength from the complex application of mineral fiber and complex modifiers in relation to the control sample of thermal insulating foam concrete D 400, it was increased by 82%. Water absorption from the complex application of mineral fiber and complex modifier in relation to the control sample of heat insulating foam concrete D 400 was increased by 82%.

Thermal conductivity of the material with mineral fiber and complex modifier, as well as just mineral fiber, showed the same reduction in thermal conductivity by 10%. Thus, according to the results of the research the following results were obtained: Complex application of mineral fiber and complex modifier positively affects the strength and water absorption, but the thermal conductivity is affected only by mineral fiber in the manufacture of insulating foam concrete D 400.

When studying the compressive strength of thermal insulation and structural foam concrete D 800 in relation to the control sample, the highest quality indicators were for the sample with the combined use of mineral fiber and an integrated modifier, which showed an increase of 85%, and water absorption decreased by 29%, however, thermal conductivity for the sample of thermal insulation foam concrete D 400 showed the same results. With the combined use of mineral fiber and a complex modifier, as well as simply with mineral fiber, a 14% decrease in thermal conductivity was obtained.

The study of structural foam concrete D 1100 on physical–mechanical and construction–technical properties showed an increase in strength in relation to the control sample (64%), water absorption decreased by 27.6%, and thermal conductivity decreased by 27%. Thus, the main factor affecting the properties of foam concrete is the quality of its structure according to the physical–mechanical and construction–technical properties.

Author Contributions

Conceptualization, R.L. and D.D.; writing—original draft preparation, Z.S.; formal analysis, A.A.; resources, A.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (grant no. BR21882278 “Establishment of a construction and technical engineering centre to provide a full cycle of accredited services to the construction, road-building sector of the Republic of Kazakhstan”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the findings of this study were generated in-house through laboratory experiments. The datasets are not publicly available due to internal research storage policy, but they are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to express gratitude to the research and production center “ENU-Lab” of L.N. Gumilyov Eurasian National University for providing a base for the experimental section.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Awwad, T.; Shakhmov, Z.A.; Lukpanov, R.E.; Yenkebayev, S.B. Experimental Study on the Behavior of Pile and Soil at the Frost Condition. In International Congress and Exhibition “Sustainable Civil Infrastructures”: Innovative Infrastructure Geotechnology; Springer Science and Business Media B.V.: Dordrecht, The Netherlands, 2019; pp. 69–76. [Google Scholar]

- Lukpanov, R.; Dyussembinov, D.; Altynbekova, A.; Yenkebayev, S.; Zhumagulova, A. Investigation of Effect of Proposed Two-Stage Foam Injection Method and Modified Additive on Workability of Foam Concrete. Materials 2024, 17, 2024. [Google Scholar] [CrossRef]

- Rudenko, O.; Beisekenov, N.; Sadenova, M.; Galkina, D.; Kulenova, N.; Begentayev, M. Physical–Mechanical and Microstructural Properties of Non-Autoclaved Aerated Concrete with Ash-and-Slag Additives. Sustainability 2025, 17, 73. [Google Scholar] [CrossRef]

- Bartenjeva, E. The Effect of Mineral Additives on Foam Concrete Porosity. IOP Conf. Ser. Mater. Sci. Eng. 2020, 962, 022023. [Google Scholar] [CrossRef]

- Ma, X.; Li, H.; Wang, D.; Li, C.; Wei, Y. Simulation and Experimental Substantiation of the Thermal Properties of Non-Autoclaved Aerated Concrete with Recycled Concrete Powder. Materials 2022, 15, 8341. [Google Scholar] [CrossRef] [PubMed]

- Baranova, A.; Shustov, P.; Yazina, O. Structural and Heat-Insulating Foam Concrete of Non-Autoclaved Hardening Based on Microsilica. In MATEC Web of Conferences; EDP Sciences: London, UK, 2018; Volume 212. [Google Scholar]

- Vishtorsky, E.; Bogomolov, S.; Smirnov, A.; Mutalibova, G. Use of Industrial Waste in the Production of Non-Autoclaved Foam Concrete. In E3S Web of Conferences; EDP Sciences: London, UK, 2024; Volume 549. [Google Scholar]

- Vishtorsky, E.; Bogomolov, S.; Smirnov, A.; Mutalibova, G. Water Demand Management in the Production of Non-Autoclaved Foam Concrete. In E3S Web of Conferences; EDP Sciences: London, UK, 2023; Volume 458. [Google Scholar]

- Kytinou, V.K.; Metaxa, Z.S.; Zapris, A.G.; Kosheleva, R.I.; Prokopiou, V.D.; Alexopoulos, N.D. Exploitation of Extruded Polystyrene (XPS) Waste for Lightweight, Thermal Insulation and Rehabilitation Building Applications. Dev. Built Environ. 2024, 20, 100580. [Google Scholar] [CrossRef]

- Leão, L.S.; Spini, G.P.; de França, M.S.; Costa, E.B.C. Recycled Expanded Polystyrene (EPS) as an Eco-Friendly Alternative for Sand in Rendering Mortars. Constr. Build. Mater. 2024, 414, 135018. [Google Scholar] [CrossRef]

- Utepov, Y.; Bazarbayev, D.; Tsygulyov, D.; Yenkebayev, S.; Shakhmov, Z.; Lukpanov, R.; Dyussembinov, D. Homogeneous Pore Distribution in Foam Concrete by Two-Stage Foaming. Mag. Civ. Eng. 2021, 103, 10313. [Google Scholar] [CrossRef]

- Mohamad, A.; Khadraoui, F.; Chateigner, D.; Boutouil, M. Influence of Porous Structure of Non-Autoclaved Bio-Based Foamed Concrete on Mechanical Strength. Buildings 2023, 13, 2261. [Google Scholar] [CrossRef]

- Dyussembinov, D.S.; Awwad, T.; Sabitov, Y.Y.; Zhumagulova, A.A.; Shakhmov, Z.A.; Kaliyeva, Z.; Bazarbayev, D.O. Self-Compacting Concrete with Finely Dispersed Additives and Superplasticizer. Mag. Civ. Eng. 2023, 123, 71–83. [Google Scholar] [CrossRef]

- Shon, C.-S.; Mukangali, I.; Zhang, D.; Ulykbanov, A.; Kim, J. Evaluation of Non-Autoclaved Aerated Concrete for Energy Behaviors of a Residential House in Nur-Sultan, Kazakhstan. Buildings 2021, 11, 610. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, L.; Yuan, L.; Wu, G.; Zheng, R.; Mu, Y. Research on Flexural Performance of Basalt Fiber-Reinforced Steel–Expanded Polystyrene Foam Concrete Composite Wall Panels. Buildings 2025, 15, 285. [Google Scholar] [CrossRef]

- Markin, S.; Sahmenko, G.; Korjakins, A.; Mechtcherine, V. The Impact of Production Techniques on Pore Size Distribution in High-Strength Foam Concrete. Infrastructures 2025, 10, 14. [Google Scholar] [CrossRef]

- Miura, S.; Ishikawa, T.; Yoshida, N.; Hisari, Y.; Abe, N. Challenges for Transportation Geotechnics in Extreme Climates of Kazakhstan and Korea. In Advances in Transportation Geotechnics 2; CRC Press: Boca Raton, FL, USA, 2012; pp. 655–660. ISBN 978-0-415-62135-9. [Google Scholar]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Dotsenko, N.; Kotenko, M. Influence of Recipe Factors on the Structure and Properties of Non-Autoclaved Aerated Concrete of Increased Strength. Appl. Sci. 2022, 12, 6984. [Google Scholar] [CrossRef]

- Jierula, A.; Li, H.; Chen, Y.; Wu, C.; Wu, X.; Yin, H. Study on the Influence of Density and Water–Cement Ratio on the Cement Utilization, Fluidity, Mechanical Properties, and Water Absorption of Foam Concrete. Buildings 2024, 14, 3550. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Shuyskiy, A.; Beskopylny, N.; Dotsenko, N. Mathematical Modeling and Experimental Substantiation of the Gas Release Process in the Production of Non-Autoclaved Aerated Concrete. Materials 2022, 15, 2642. [Google Scholar] [CrossRef]

- Li, L.; Sun, W.; Ayti, A.; Chen, W.; Liu, Z.; Gómez-Zamorano, L.Y. Machine Learning Modeling of Foam Concrete Performance: Predicting Mechanical Strength and Thermal Conductivity from Material Compositions. Appl. Sci. 2025, 15, 7125. [Google Scholar] [CrossRef]

- Rodriguez, C.; Gómez, P.; Martí, F.; Srivastava, S.; Sanchez, M.; Fernandez, F.; Beleña, I.; Hernández, M. Development of Low-Carbon Autoclaved Aerated Concrete Using an Alkali-Activated Ground Granulated Blast Furnace Slag and Calcium Carbide Slag. Appl. Sci. 2025, 15, 9946. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, C.; Hu, Z.; Wang, L.; Yue, G.; Zheng, S.; Li, Q.; Wang, P. Study on the Performance of Foam Concrete Prepared from Decarburized Fly Ash. Appl. Sci. 2022, 12, 12708. [Google Scholar] [CrossRef]

- Lermen, R.T.; Favaretto, P.; Silva, R.D.A.; Hidalgo, G.E.N.; Tubino, R.M.C.; Tiecher, F. Effect of Additives, Cement Type, and Foam Amount on the Properties of Foamed Concrete Developed with Civil Construction Waste. Appl. Sci. 2019, 9, 2998. [Google Scholar] [CrossRef]

- Pedro, R.; Tubino, R.M.C.; Anversa, J.; De Col, D.; Lermen, R.T.; Silva, R.D.A. Production of Aerated Foamed Concrete with Industrial Waste from the Gems and Jewels Sector of Rio Grande Do Sul-Brazil. Appl. Sci. 2017, 7, 985. [Google Scholar] [CrossRef]

- Xiong, Y.; Wang, S.; Ma, L.; Wang, T.; Zhou, M.; Hu, Z.; Wang, Z. Unveiling the Influence of Activators on Stability and Pore Features of Foamed Concrete. Materials 2025, 18, 3320. [Google Scholar] [CrossRef]

- Yildizel, S.A.; Acik, M.; Kaplan, G.; Bayraktar, O.Y. Enhancing Foam Concrete: A Comparative Analysis of PLA+ Fiber Reinforcements with Plain, Hooked, and Corrugated Fibers. Constr. Build. Mater. 2024, 443, 137807. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Öksüzer, N.; Kamiloğlu, H.A.; Eyüboğlu, M.; Yılmaz, F. The Toughness of Polypropylene Fiber-Reinforced Foam Concrete under Various Uni- and Tri-Axial Compression Loads. KSCE J. Civ. Eng. 2023, 27, 2982–2992. [Google Scholar] [CrossRef]

- Rosca, B. Eco-Friendly Lightweight Aggregate Concrete of Structural Grade Made with Recycled Brick Aggregate Containing Expanded Polystyrene Beads. Sustainability 2025, 17, 3050. [Google Scholar] [CrossRef]

- González-Betancur, D.; Hoyos-Montilla, A.A.; Tobón, J.I. Sustainable Hybrid Lightweight Aggregate Concrete Using Recycled Expanded Polystyrene. Materials 2024, 17, 2368. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.K.; Kumar, M.U. The Empirical Investigation of Lightweight Concrete via the Utilization of Varied Waste Materials: A Review. Int. Res. J. Eng. Technol. 2024, 11, 1504–1511. [Google Scholar]

- Zhang, T.; Li, T.; Xu, H.; Wang, M.; Lu, L. Preparation and Performance Study of Novel Foam Vegetation Concrete. Materials 2024, 17, 6295. [Google Scholar] [CrossRef] [PubMed]

- Mohtadi, A.; Ghomeishi, M.; Dehghanbanadaki, A. Towards Sustainable Construction: Evaluating Thermal Conductivity in Advanced Foam Concrete Mixtures. Buildings 2024, 14, 3636. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Wang, X.; Tu, S.; Song, Y.; Shi, T.; Wang, L.; Zhou, H. A Comprehensive Benefit Evaluation of Recycled Carbon Fiber Reinforced Cement Mortar Based on Combined Weighting. Constr. Build. Mater. 2025, 489, 142196. [Google Scholar] [CrossRef]

- Jiang, Z.; He, G.; Jiang, Y.; Zhao, H.; Duan, Y.; Yuan, G.; Fu, H. Synergistic Preparation and Properties of Ceramic Foams from Wolframite Tailings and High-Borosilicate Waste Glass. Constr. Build. Mater. 2024, 457, 139367. [Google Scholar] [CrossRef]

- Lv, X.-S.; Cao, W.-X.; Yio, M.; Ji, W.-Y.; Lu, J.-X.; She, W.; Poon, C.S. High-Performance Lightweight Foam Concrete Enabled by Compositing Ultra-Stable Hydrophobic Aqueous Foam. Cem. Concr. Compos. 2024, 152, 105675. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Huei Lee, Y.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-Reinforced Foamed Concretes: A Review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Li, P.; Guo, W.; Wang, R.; Zhang, D.; Gao, M.; Peng, C. Experimental Investigation of the Dynamic Mechanical Properties of Polypropylene-Fiber-Reinforced Foamed Concrete at High Temperatures. Polymers 2023, 15, 2544. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).