Reliability Modeling and Assessment of a Dual-Span Rotor System with Misalignment Fault and Shared Load

Abstract

1. Introduction

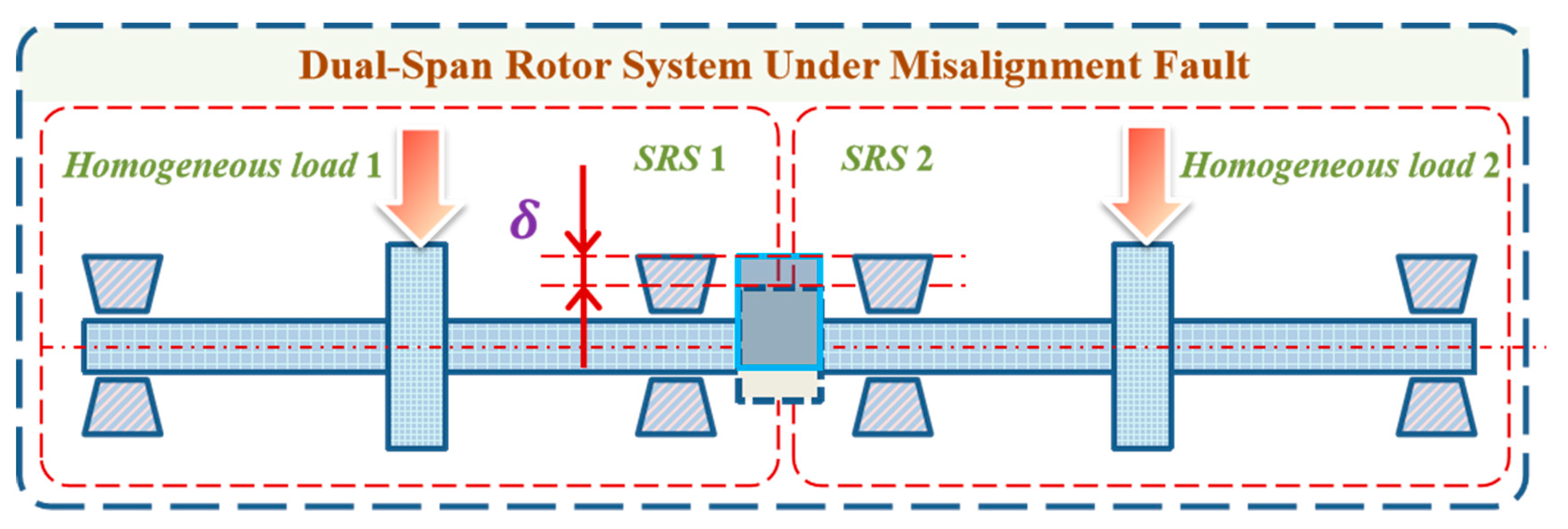

2. Dynamics Analysis of Double-Span Rotor System

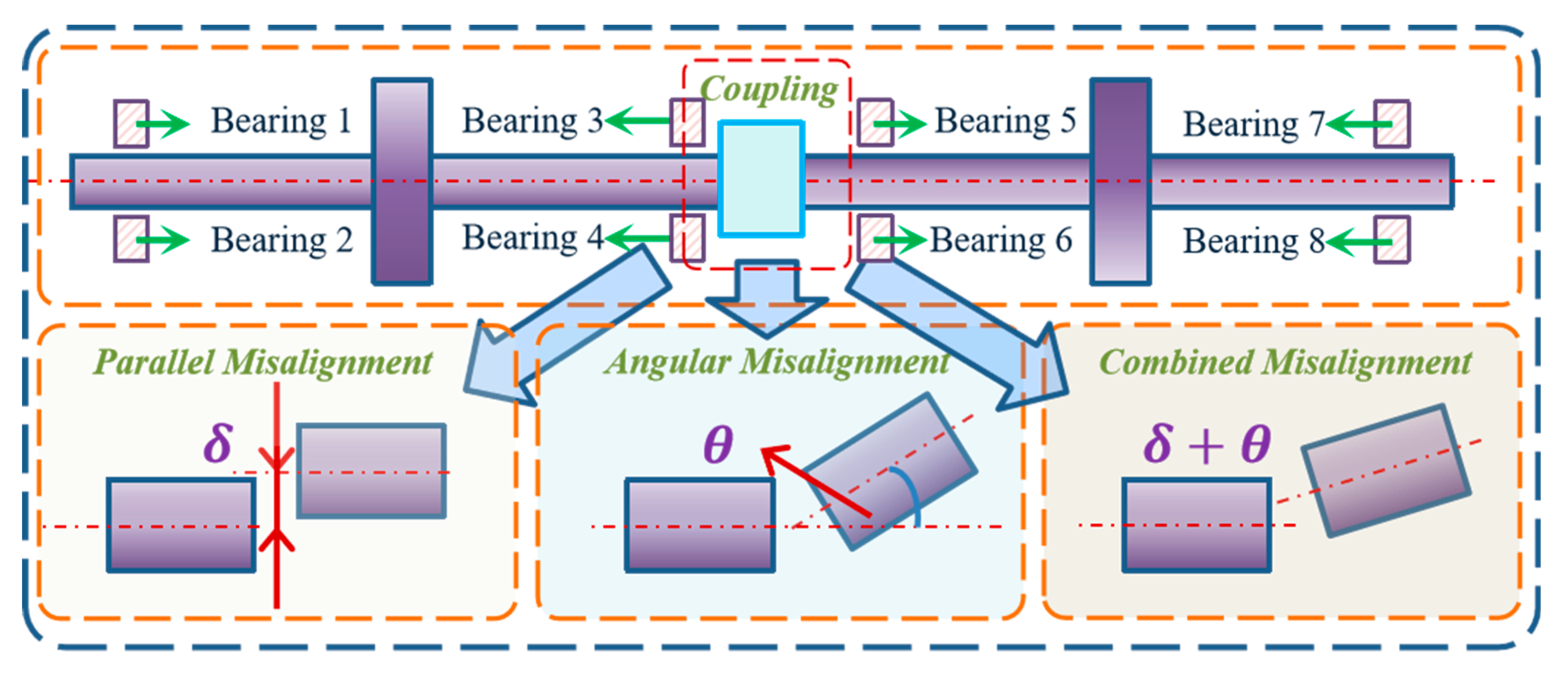

2.1. Misalignment Fault Analysis

2.2. System Dynamics Modeling

2.3. Dynamic Stress and Neural Network

3. Reliability Analysis

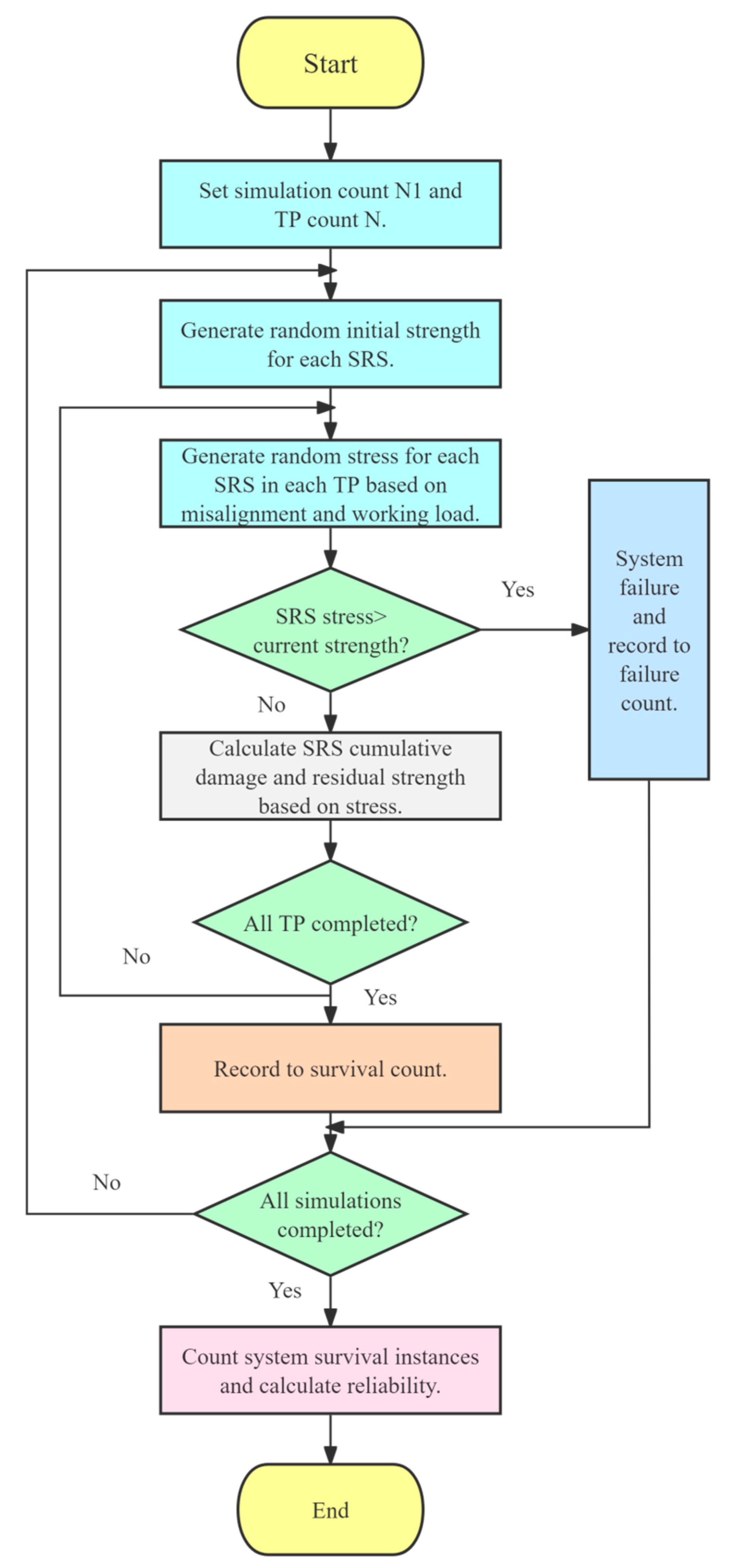

3.1. System Reliability Modeling

3.2. Reliability Validation

4. Numerical Examples

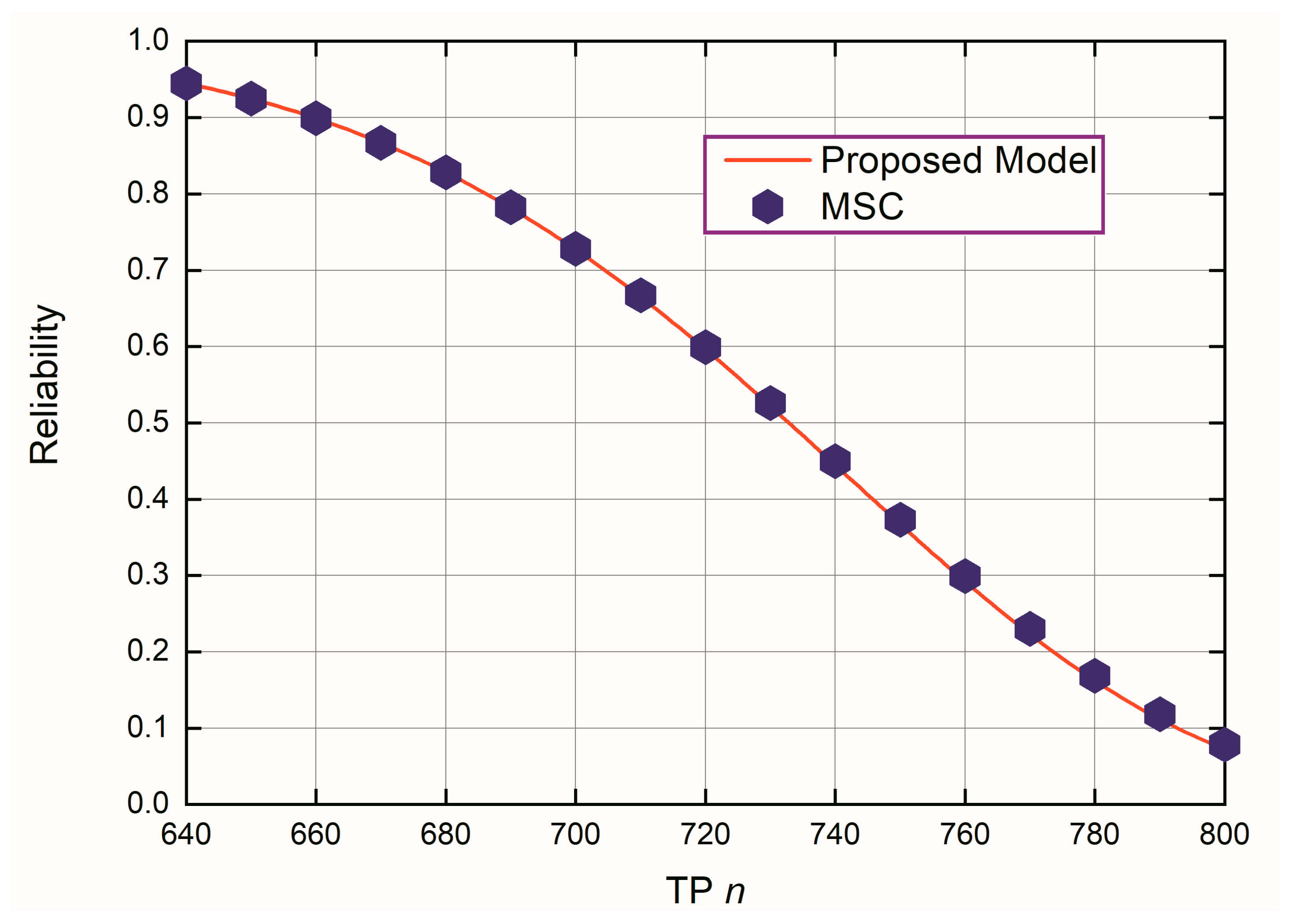

4.1. Model Validation

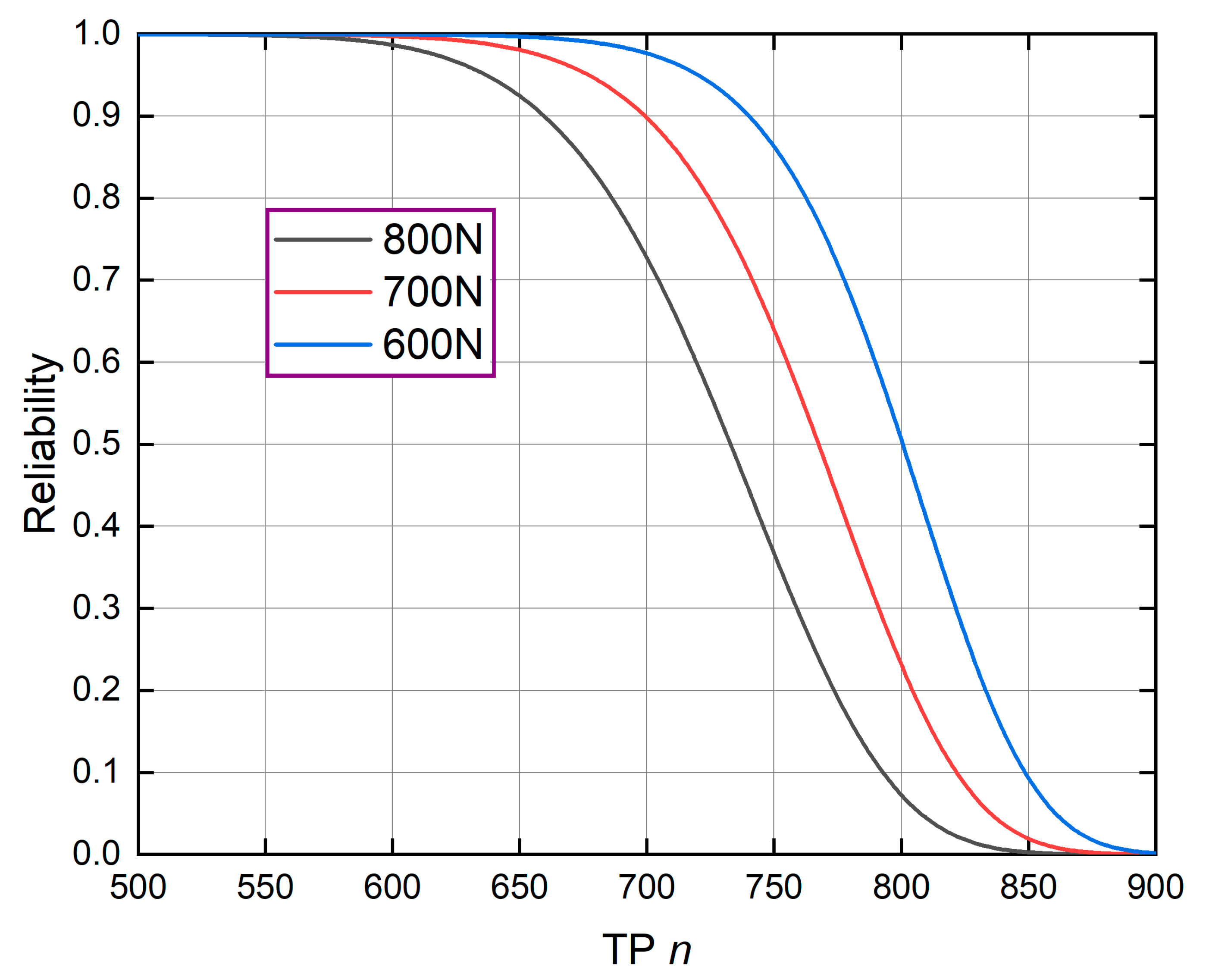

4.2. Influence of Different Working Load Statistical Characteristics

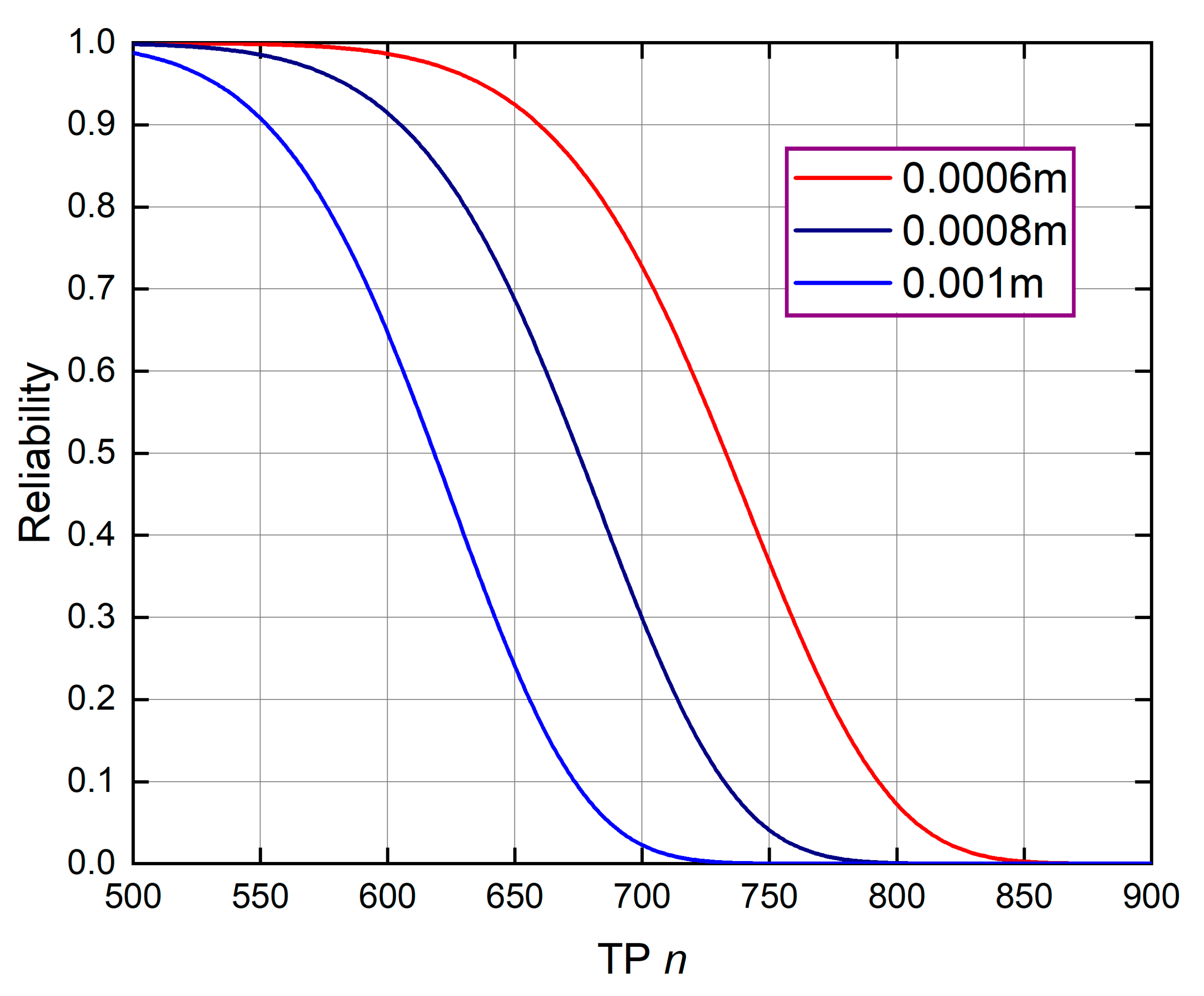

4.3. Influence of Different Misalignment Amounts on System Reliability

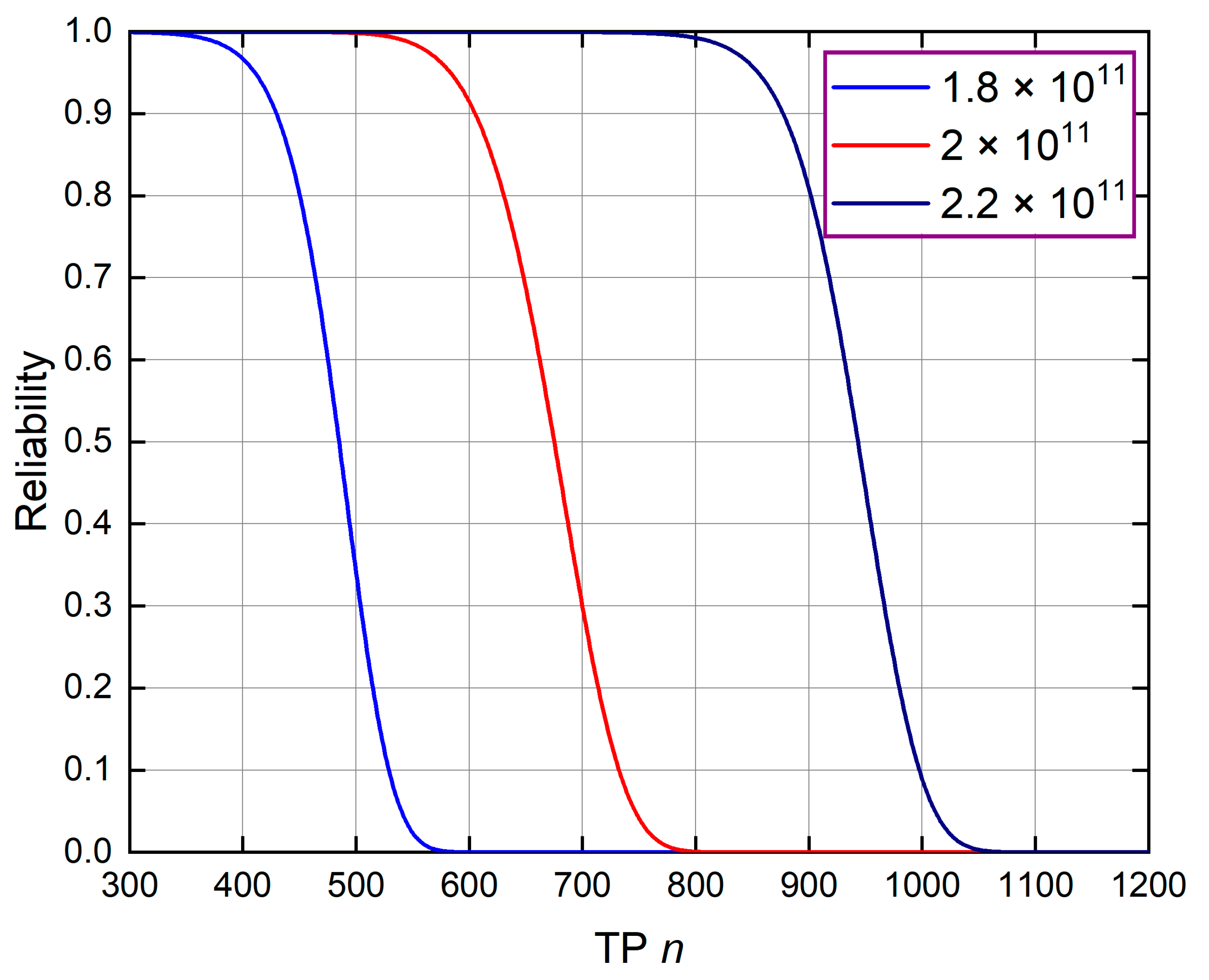

4.4. Influence of Different Elastic Moduli on System Reliability

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, Q.; Chu, F. Parametric instability of a rotor-bearing system with two breathing transverse cracks. Eur. J. Mech.-A/Solids 2012, 36, 180–190. [Google Scholar] [CrossRef]

- Zhao, B.; Xie, L.; Li, H.; Zhang, S.; Wang, B.; Li, C. Reliability Analysis of Aero-Engine Compressor Rotor System Considering Cruise Characteristics. IEEE Trans. Reliab. 2019, 69, 245–259. [Google Scholar] [CrossRef]

- Tian, B.; Yu, Z.; Xie, L.; Zhang, Y. Dynamic analysis of the dual-rotor system considering the defect size uncertainty of the inter-shaft bearin. J. Mech. Sci. Technol. 2022, 36, 575–592. [Google Scholar] [CrossRef]

- Riquelme, D.; Madariaga, C.; Jara, W.; Bramerdorfer, G.; Tapia, J.A.; Riedemann, J. Study on Stator-Rotor Misalignment in Modular Permanent Magnet Synchronous Machines with Different Slot/Pole Combinations. Appl. Sci. 2023, 13, 2777. [Google Scholar] [CrossRef]

- Wang, P.; Xu, H.; Yang, Y.; Ma, H.; He, D.; Zhao, X. Dynamic characteristics of ball bearing-coupling-rotor system with angular misalignment fault. Nonlinear Dyn. 2022, 108, 3391–3415. [Google Scholar] [CrossRef]

- Li, M.; He, L. The dynamics of a parallel-misaligned and unbalanced rotor system under the action of non-linear oil film forces. J. Mech. Eng. Sci. 2010, 224, 1875–1889. [Google Scholar] [CrossRef]

- Chandra, S.R.M.; Sekhar, A.S. Detection and monitoring of coupling misalignment in rotors using torque measurements. Measurement 2015, 61, 111–122. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Li, J.; Lu, H.; Ma, H. Feature extraction method based on NOFRFs and its application in faulty rotor system with slight misalignment. Nonlinear Dyn. 2020, 99, 1763–1777. [Google Scholar] [CrossRef]

- da Silva Tuckmantel, F.W.; Cavalca, K.L. Vibration signatures of a rotor-coupling-bearing system under angular misalignment. Mech. Mach. Theory 2019, 133, 559–583. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, J.; Tian, Z. Stochastic dynamics of a nonlinear misaligned rotor system subject to random fluid-induced forces. J. Comput. Nonlinear Dyn. 2017, 12, 011004. [Google Scholar] [CrossRef]

- Fu, C.; Lu, K.; Yang, Y.; Xie, Z.; Ming, A. Nonlinear vibrations of an uncertain dual-rotor rolling bearings system with coupling misalignment. J. Nonlinear Math. Phys. 2022, 29, 388–402. [Google Scholar] [CrossRef]

- Zigang, L.; Jun, J.; Zhui, T. Non-linear vibration of an angular-misaligned rotor system with uncertain parameters. J. Vib. Control 2016, 22, 129–144. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Huang, S.C. Transfer matrix for rotor coupler with parallel misalignment. J. Mech. Sci. Technol. 2009, 23, 1383–1395. [Google Scholar] [CrossRef]

- Patel, T.H.; Zuo, M.J.; Darpe, A.K. Vibration response of coupled rotor systems with crack and misalignment. J. Mech. Eng. Sci. 2011, 225, 700–713. [Google Scholar] [CrossRef]

- Al-Hussain, K.M. Dynamic stability of two rigid rotors connected by a flexible coupling with angular misalignment. J. Sound Vib. 2003, 266, 217–234. [Google Scholar] [CrossRef]

- Arifovic, J.; Gençay, R. Using genetic algorithms to select architecture of a feedforward artificial neural network. Phys. A Stat. Mech. Its Appl. 2001, 289, 574–594. [Google Scholar] [CrossRef]

- Shaheed, M.H. Feedforward neural network based non-linear dynamic modelling of a TRMS using RPROP algorithm. Aircr. Eng. Aerosp. Technol. 2005, 77, 13–22. [Google Scholar] [CrossRef]

- Aroui, T.; Koubaa, Y.; Toumi, A. Application of Feedforward Neural Network for Induction Machine Rotor Faults Diagnostics using Stator Current. J. Electr. Syst. 2007, 3, 213–226. [Google Scholar]

- Xie, L.; Zhou, J.; Wang, X. Data mapping and the prediction of common cause failure probability. IEEE Trans. Reliab. 2005, 54, 291–296. [Google Scholar] [CrossRef]

- Gao, T.; Gao, P.; Wang, L. Investigation on Vibration Characteristics of Double-disc Rotor System with Crack. J. Liaoning Petrochem. Univ. 2022, 42, 71–79. [Google Scholar]

- Gao, P.; Xie, L. Availability models of series mechanical systems considering failure and maintenance dependencies. Trans. Can. Soc. Mech. Eng. 2018, 42, 222–232. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Modulus of elasticity E | Pa | |

| Mean value of working load | 12,000 | N |

| Standard deviation of working load | 800 | N |

| Magnitude of misalignment | 0.0006 | m |

| Initial strength deviation | 2 | MPa |

| Mean value of initial strength | 60 | MPa |

| 2 | m | |

| 0.06 | m | |

| Density | 7800 | kg/m3 |

| Angular velocity | 62.83 | Rad/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, P. Reliability Modeling and Assessment of a Dual-Span Rotor System with Misalignment Fault and Shared Load. Appl. Sci. 2025, 15, 11477. https://doi.org/10.3390/app152111477

Gao P. Reliability Modeling and Assessment of a Dual-Span Rotor System with Misalignment Fault and Shared Load. Applied Sciences. 2025; 15(21):11477. https://doi.org/10.3390/app152111477

Chicago/Turabian StyleGao, Peng. 2025. "Reliability Modeling and Assessment of a Dual-Span Rotor System with Misalignment Fault and Shared Load" Applied Sciences 15, no. 21: 11477. https://doi.org/10.3390/app152111477

APA StyleGao, P. (2025). Reliability Modeling and Assessment of a Dual-Span Rotor System with Misalignment Fault and Shared Load. Applied Sciences, 15(21), 11477. https://doi.org/10.3390/app152111477